Waste dimethyl sulfoxide recovery and treatment method

A dimethyl sulfoxide, recycling and processing technology, applied in chemical instruments and methods, preparation of alkali metal nitrates, organic compounds, etc. The effect of low energy consumption, high extraction efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

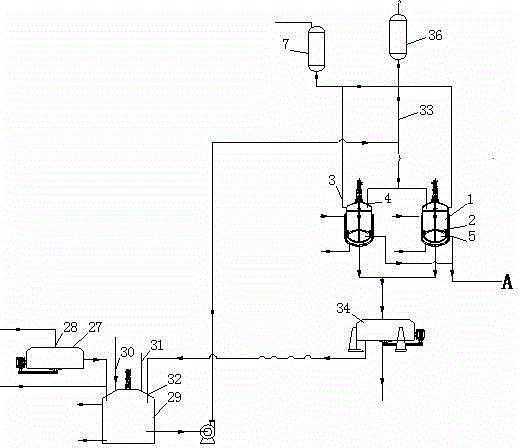

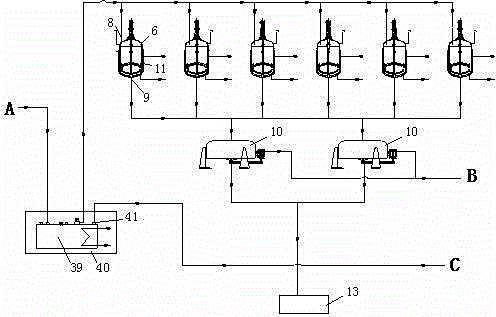

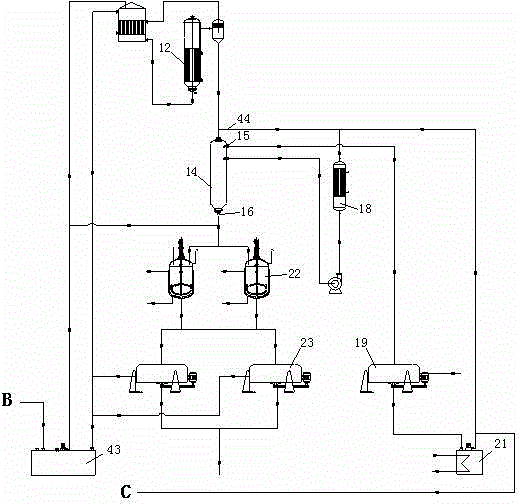

[0037] During specific implementation: a kind of recovery processing method of dimethyl sulfoxide waste salt, comprises the following steps

[0038]a. After adding water to dimethyl sulfoxide waste salt to make a solution, add nitric acid to react, so that nitric acid and sodium nitrite undergo oxidation reaction and sodium hydroxide to produce neutralization reaction to generate sodium nitrate; at the same time, nitric acid and dimethyl The oxidation reaction of sulfoxide produces dimethyl sulfone;

[0039] b. cooling the solution obtained in step a to the crystallization temperature of dimethyl sulfone, and separating and proposing the dimethyl sulfone crystals and mother liquor;

[0040] c. Evaporating and concentrating the remaining mother liquor after separating dimethyl sulfone in step b, then cooling and crystallizing, generating solid sodium nitrate in a precipitated state and solid sodium methanesulfonate in a suspended state, and removing the solid sodium nitrate in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com