Oscillatory water current type water washing machine

A water washing machine and water flow technology, which is applied to textile processing machine accessories, textiles and papermaking, liquid/gas/steam textile material treatment, etc., can solve the problems of low washing efficiency, cleanliness gap, and complex structure, etc., and achieve improvement Decontamination ability, less water consumption, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

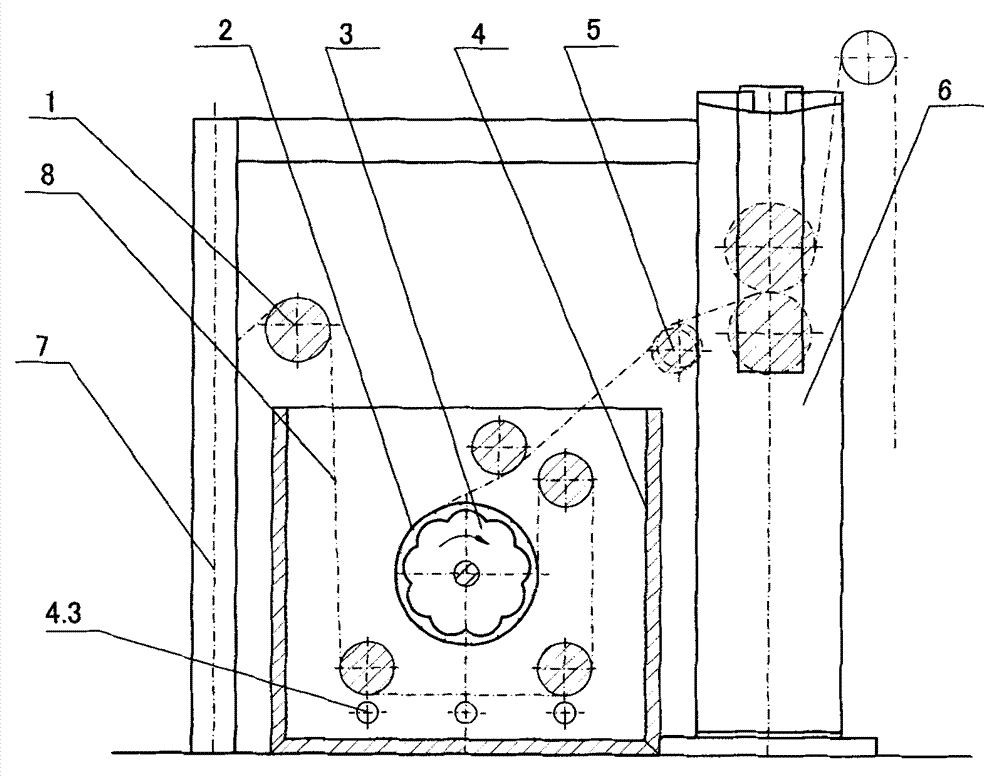

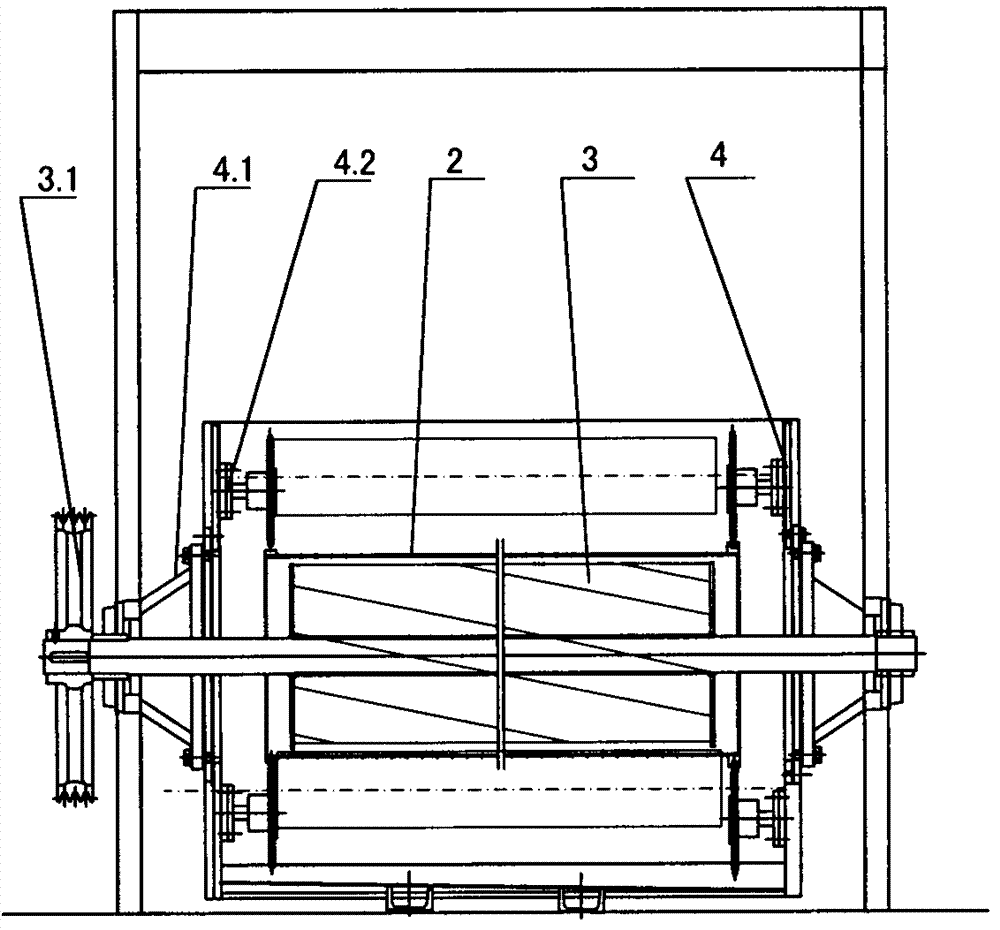

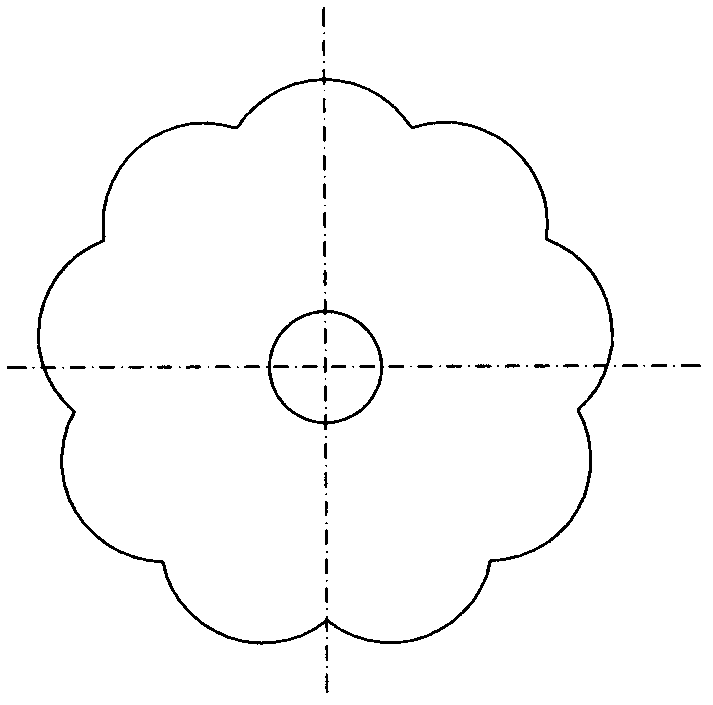

[0022] figure 1 The shown oscillating water flow washing machine includes a cloth guide roller 1, an outer cylinder 2, an inner shaft cylinder 3, a water tank 4, a tension roller 5, a paddle car 6 and a frame 7. The frame 7 is connected with the rolling car 6 on one side to form a rectangular frame. Such as figure 2 The shown water tank 4 is a reclining rectangular open container directly installed in the frame 7, and the two outer end faces of the water tank 4 are respectively coaxially connected with the shaft seat 4.1, and the water tank 4 is provided with a heating pipe 4.3. The water washing process has requirements on the water temperature, and the heat source is introduced into the water tank 4 through the heating pipe 4.3 to increase the water temperature. The outer cylinder 2 is a thin-walled cylindrical cylinder with throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com