Washing machine automatic deceleration clutch

A deceleration clutch, fully automatic washing machine technology, applied in the field of washing machines, to achieve the effect of reducing noise, eliminating impact, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

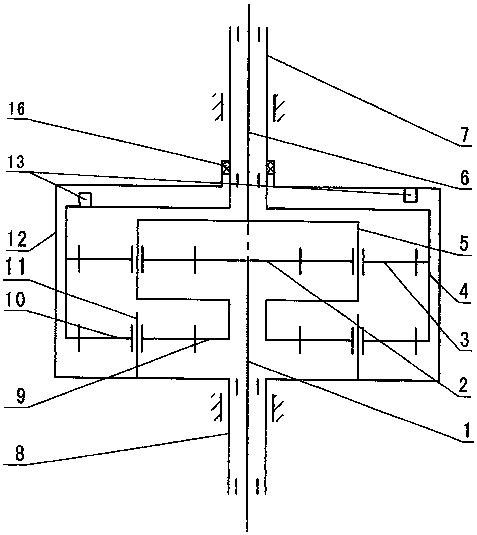

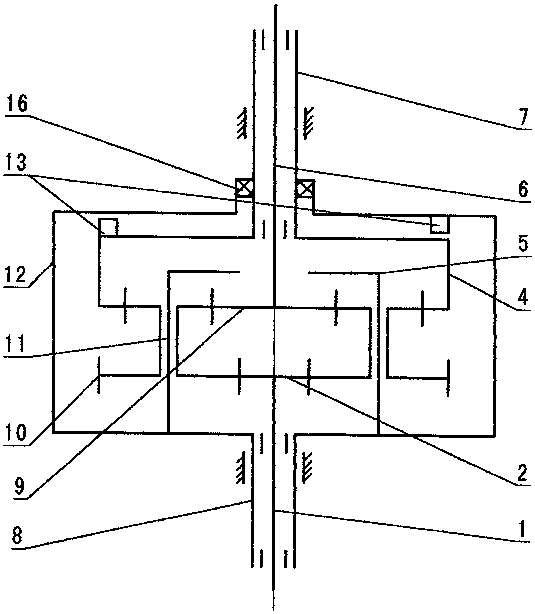

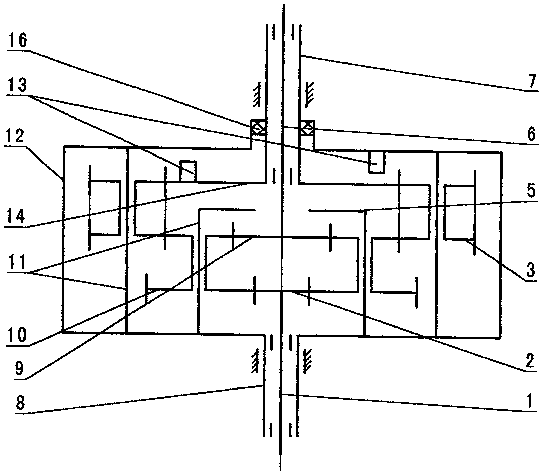

[0031] 1. Combine figure 1 The fully automatic deceleration clutch of the washing machine is composed of an input shaft 1, an output shaft 6, an output shaft sleeve 7, an input shaft sleeve 8, a brake wheel 12 and a double drive gear mechanism 15 installed inside the brake wheel 12, and the input shaft 1 is installed on In the input shaft sleeve 8, the output shaft 6 is installed in the output shaft sleeve 7, the input shaft sleeve 8 is fixed on the lower end of the brake wheel 12, the planetary shaft is fixed on the input shaft sleeve 8, the input shaft 1, the output shaft sleeve 7 And the output shaft 6 is connected with the double driving gear mechanism 15 respectively, and the clutch device 13 is housed between the brake wheel 12 and the output shaft sleeve 7. A sealing ring 16 is installed between the upper opening of the brake wheel 12 and the output shaft sleeve 7 to prevent the outside world from polluting the double drive gear mechanism 15, and also to prevent the dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com