Combination floating body type multifunctional hydrant

A multi-functional, water supply plug technology, applied in the field of farmland irrigation, can solve the problems of poor water flow, lax automatic closing, uneven quality, etc., to eliminate the conditions of vacuum negative pressure formation, solve the operation vibration, and reduce the opening force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

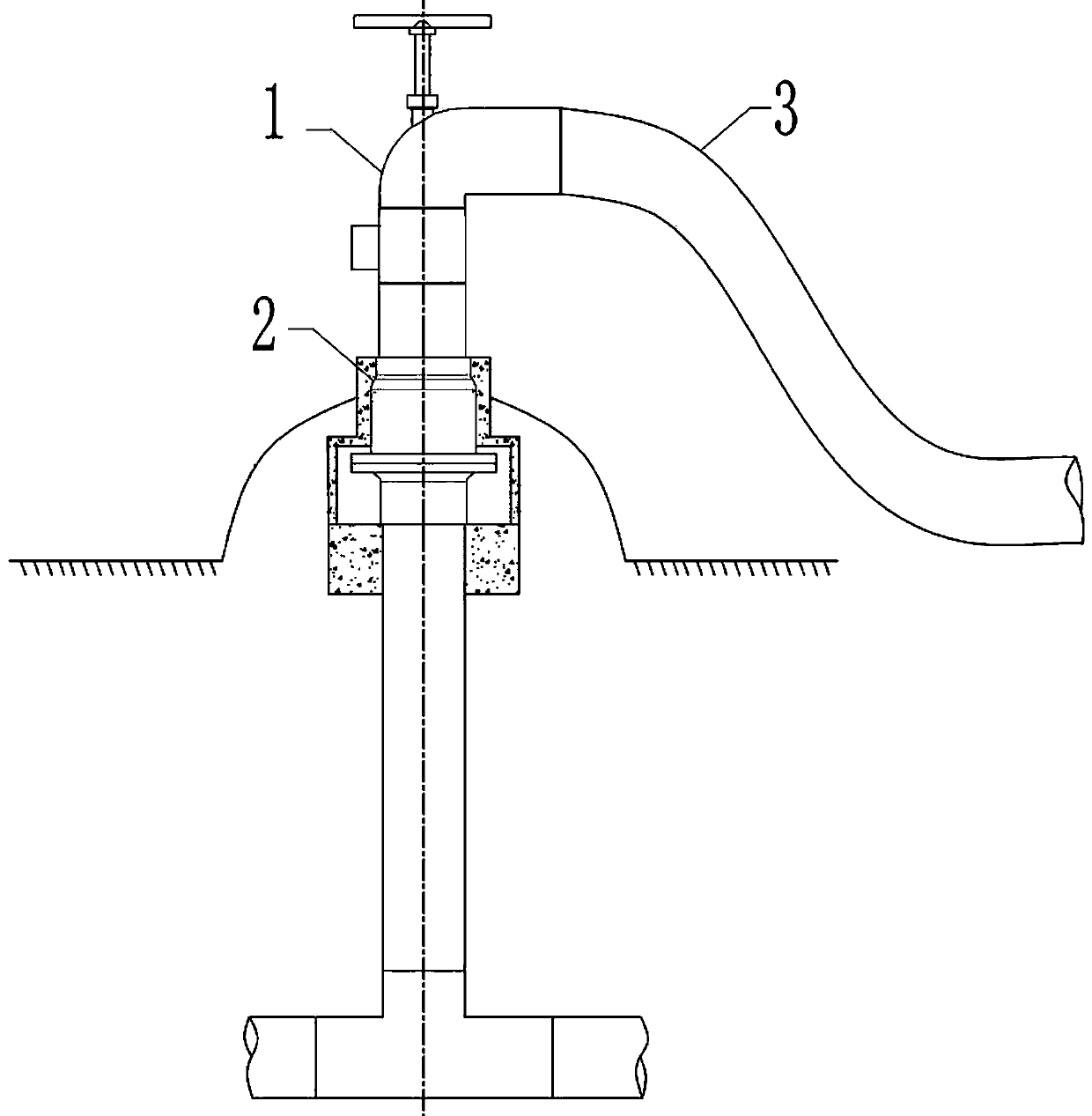

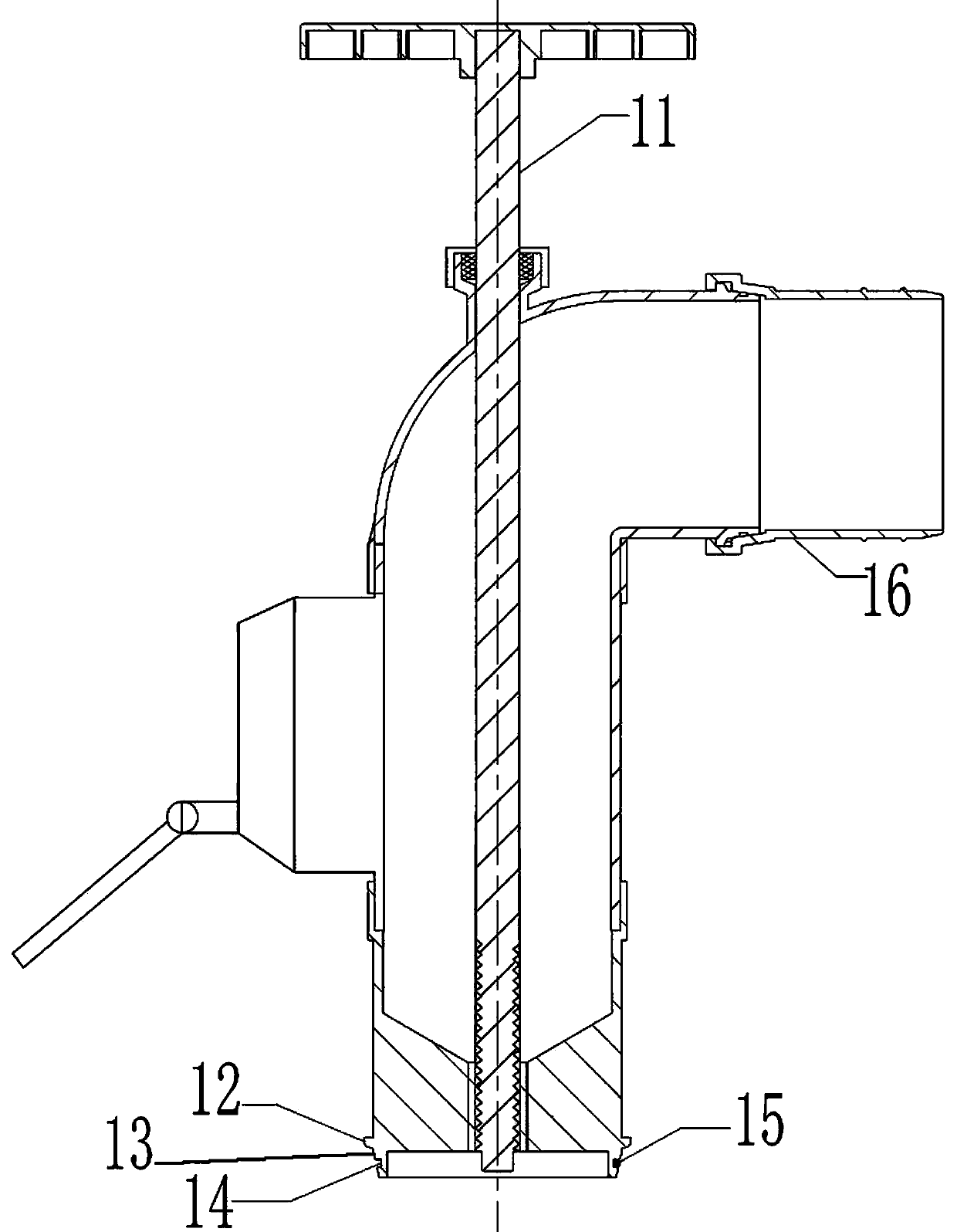

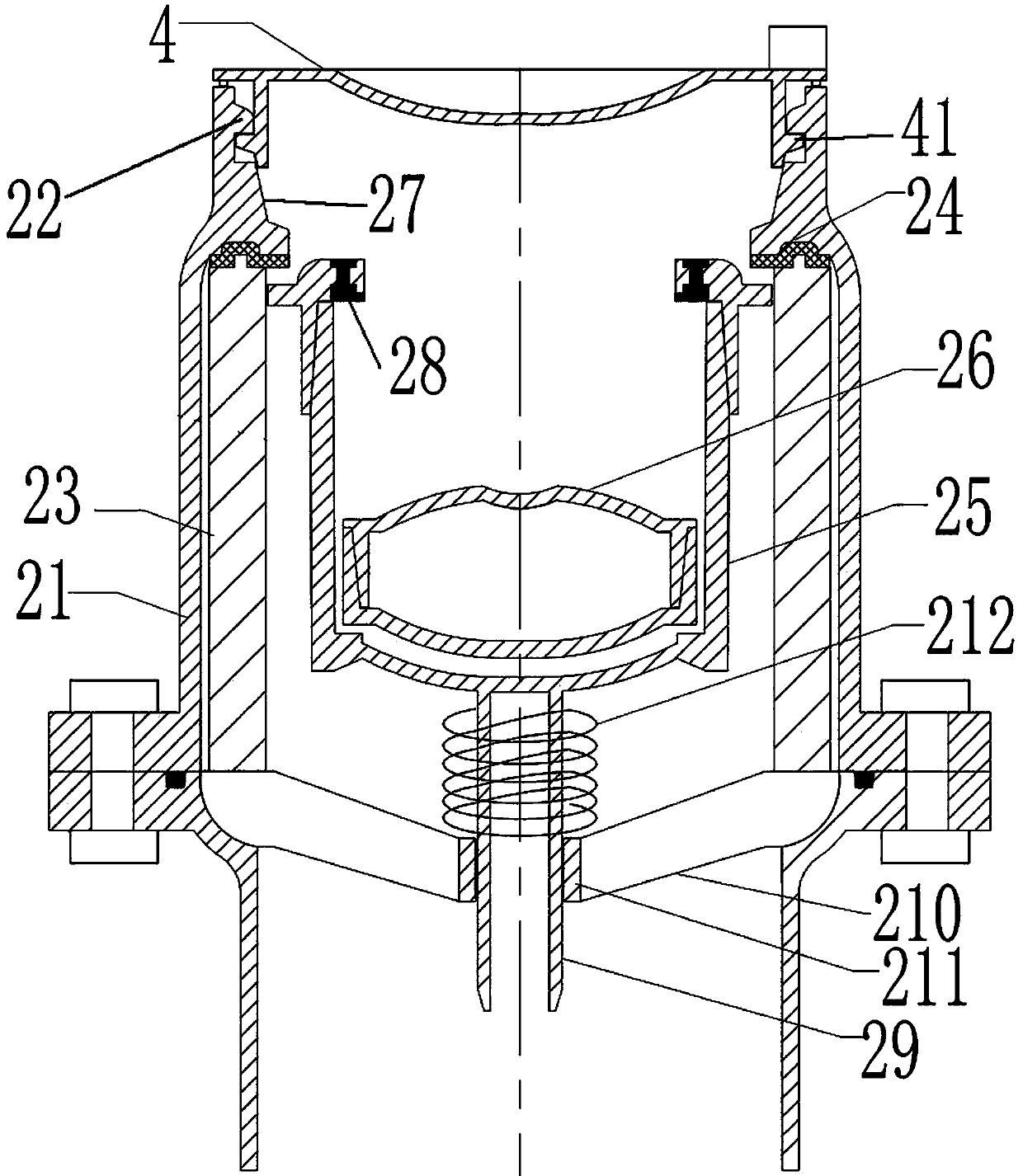

[0046] Attached below figure 1 to attach Figure 9 The present invention will be further described.

[0047] as attached figure 1 , attached figure 2 And attached image 3 As shown, a combined floating body multifunctional water supply cock includes an upper bolt body 1 and a lower bolt body 2, the lower end of the lower bolt body 2 is connected with the underground pipeline tee standpipe, and the upper bolt body 1 is vertically screwed with a screw Ⅰ 11. The lower bolt body 2 includes: a valve housing 21, which is airtight all around, and its lower end is provided with a water inlet, and its upper end is provided with a water outlet connected to the quick connector 12 of the upper bolt body 1; the large floating body 25 is cylindrical structure, which is installed in the valve housing 21 by sliding in the axial direction of the valve housing 21, N water holes 214 are arranged at intervals on the outer wall of the large floating body 25, and N is a natural number greater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com