A connecting method for a valve core and a floating pipe

A connection method and spool technology, applied to valve devices, climate change adaptation, engine components, etc., can solve the problems of typhoon passing through without any damage, and achieve the effect of solving spool leakage, easy popularization and application, and good firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

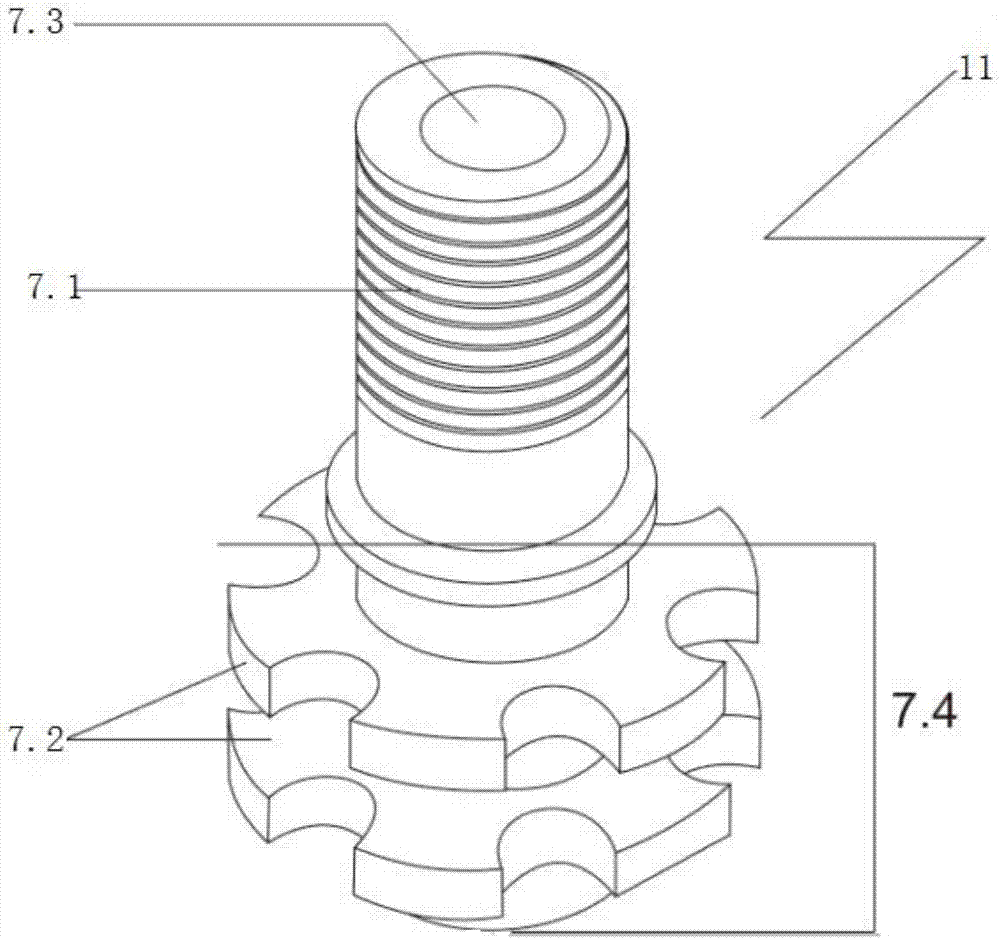

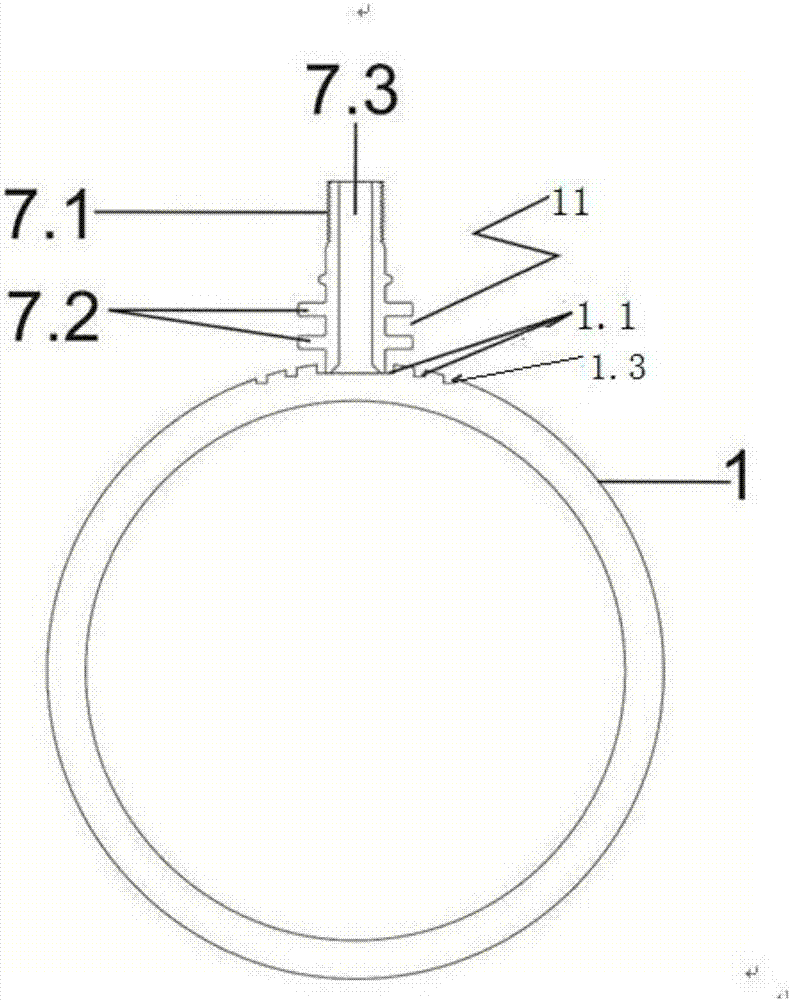

[0021] Embodiment 1: see figure 1 , a spool 11, the spool 11 includes a spool body and a spool base 7.2 arranged at the bottom of the spool body, the spool body is provided with a spool thread 7.1, and the upper end is provided with a spool port 7.3, The base of the valve core is set as a multi-layer skirt, wherein each layer of skirt is provided with a groove, which is convenient for better welding. The overall structural design of the spool structure is ingenious and compact, and the spool base can better realize the hot-melt connection with the floating pipe.

Embodiment 2

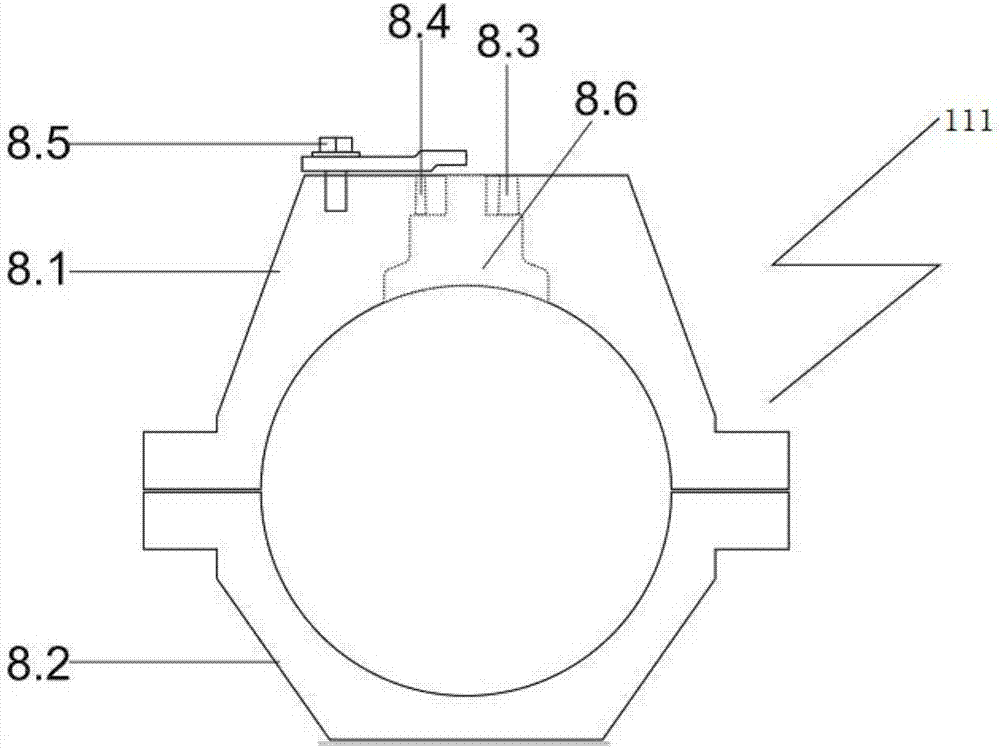

[0022] Example 2: see Figures 2A-2G , a method for connecting a spool and a floating pipe, the method for connecting comprises the following steps:

[0023] 1) A valve mold 111 is installed on the outside of the floating tube, wherein the valve core mold includes the upper half part 8.1 of the mold and the lower half part 8.2 of the mold, the valve core is placed in the valve core fixing groove on the surface of the floating tube, and the valve core fixing bar 8.5 to fix, the position where the valve core is installed on the plastic floating pipe is provided with a valve core fixing groove 1.1, and the periphery of the valve core fixing groove is provided with a welding groove 1.3;

[0024] 2) Put the valve core in the middle of the valve core fixing groove 1.1, and install the valve mold;

[0025] 3) Place the support member 8a under the valve core inside the floating tube for support;

[0026] 4) Inject the liquid plastic from the plastic injection port 8.3 until it overf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com