Patents

Literature

125results about How to "Small opening force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

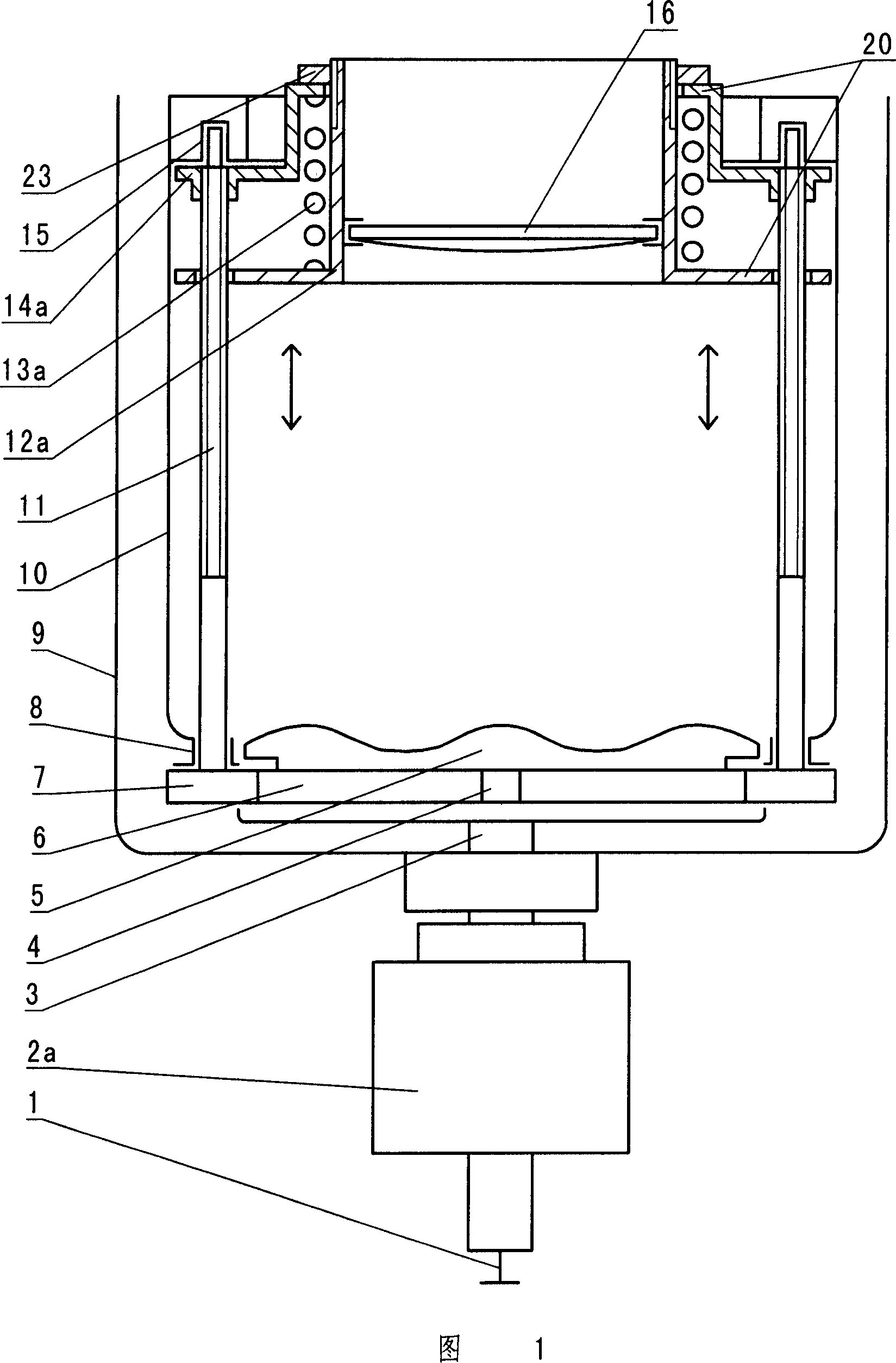

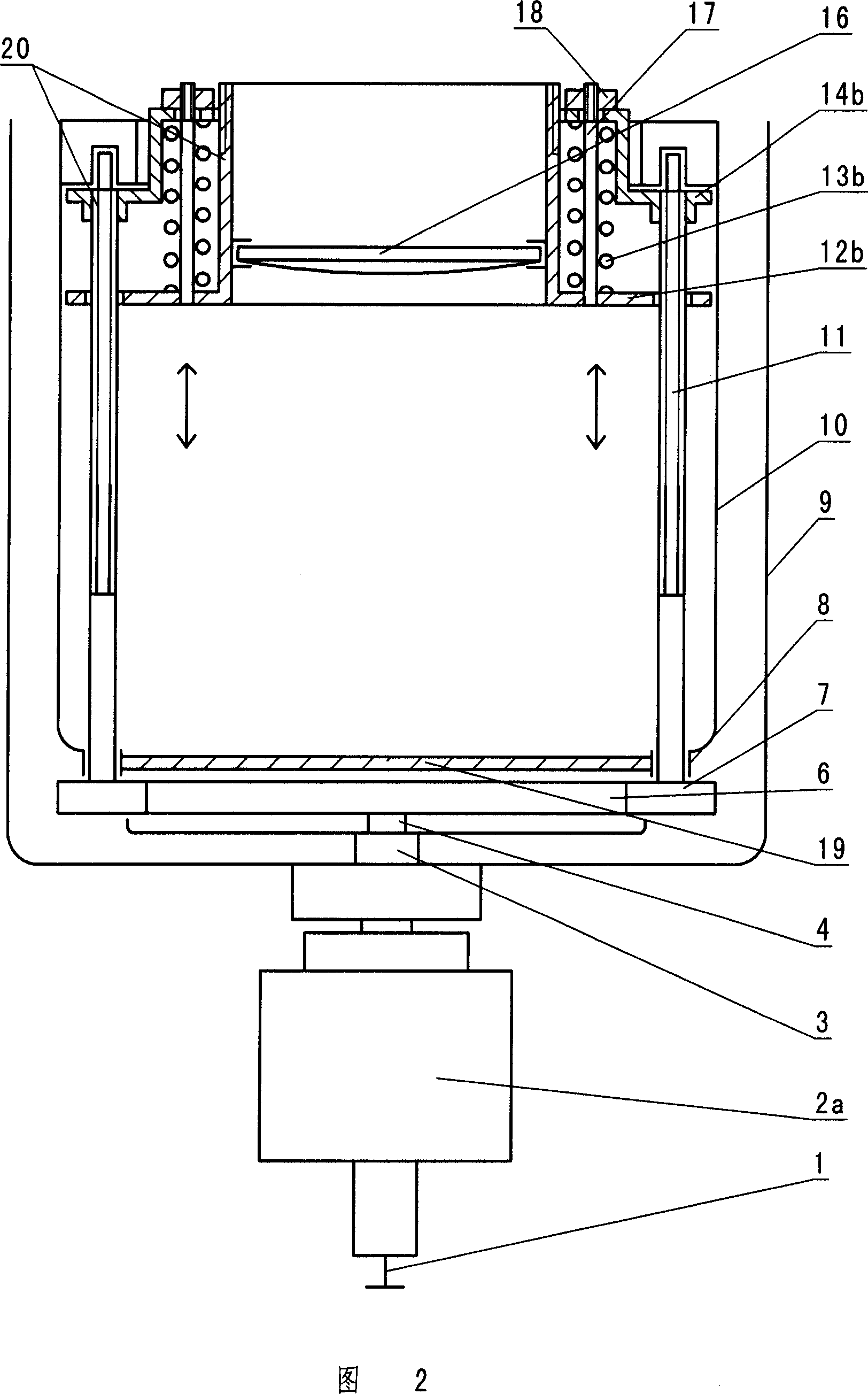

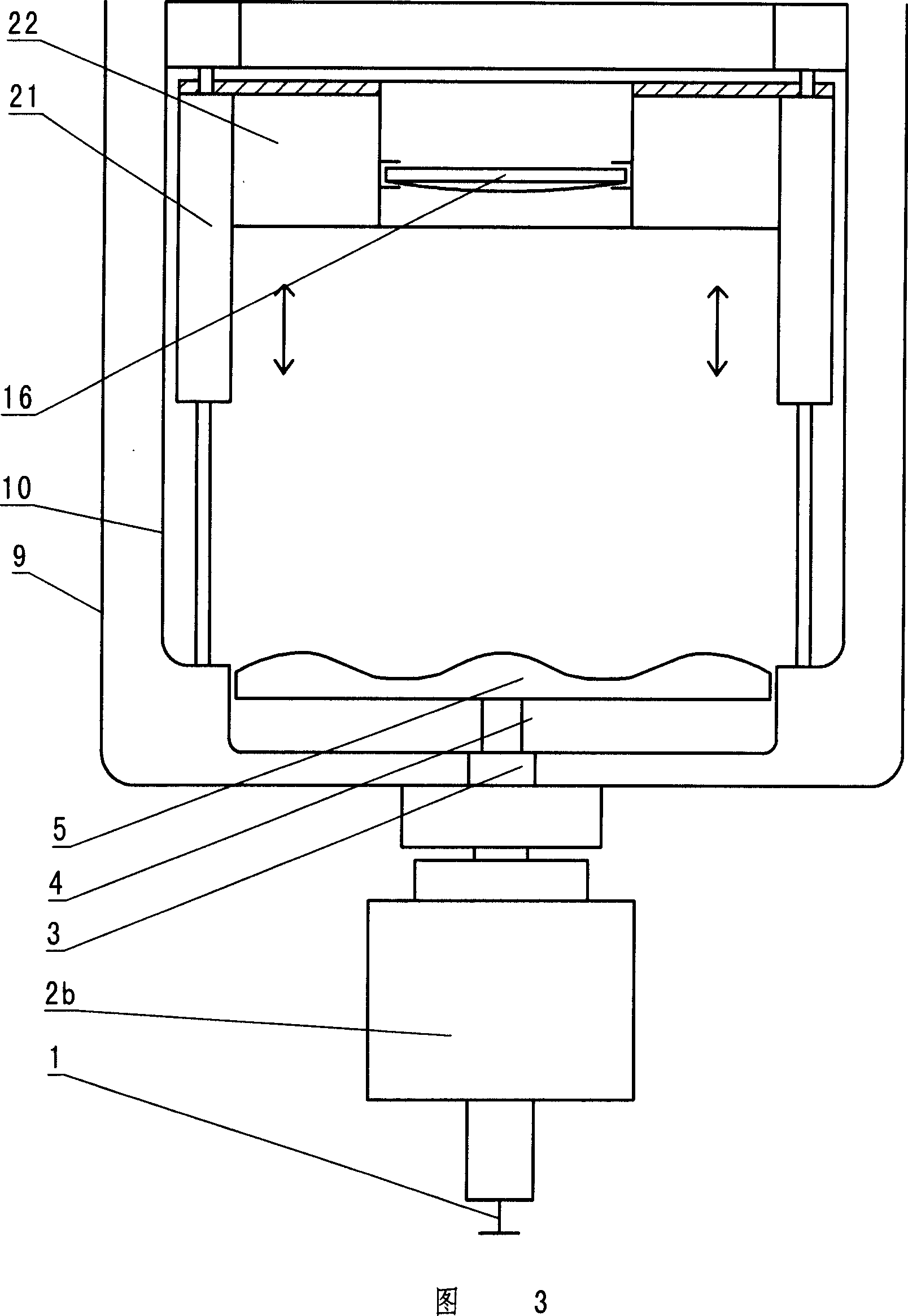

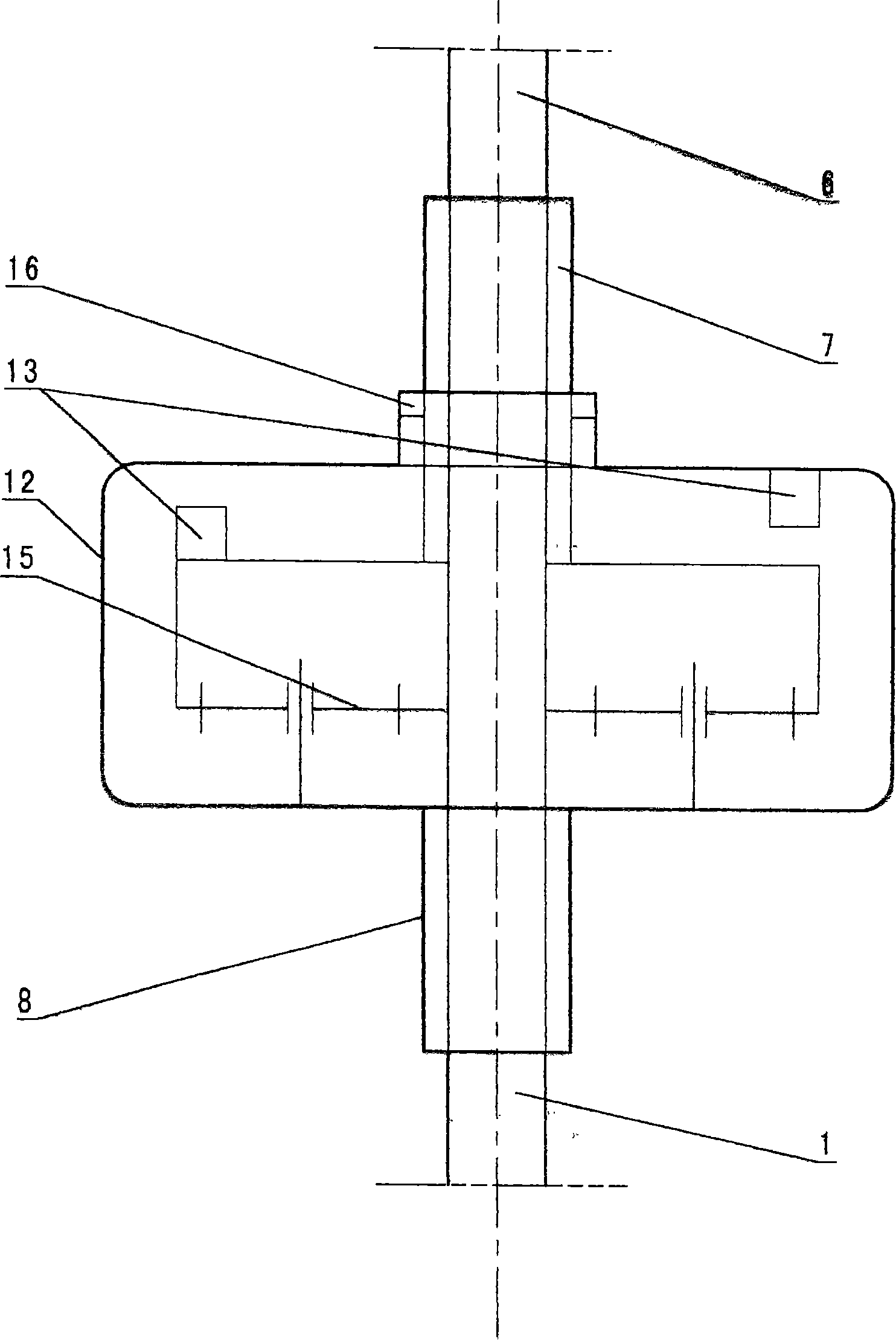

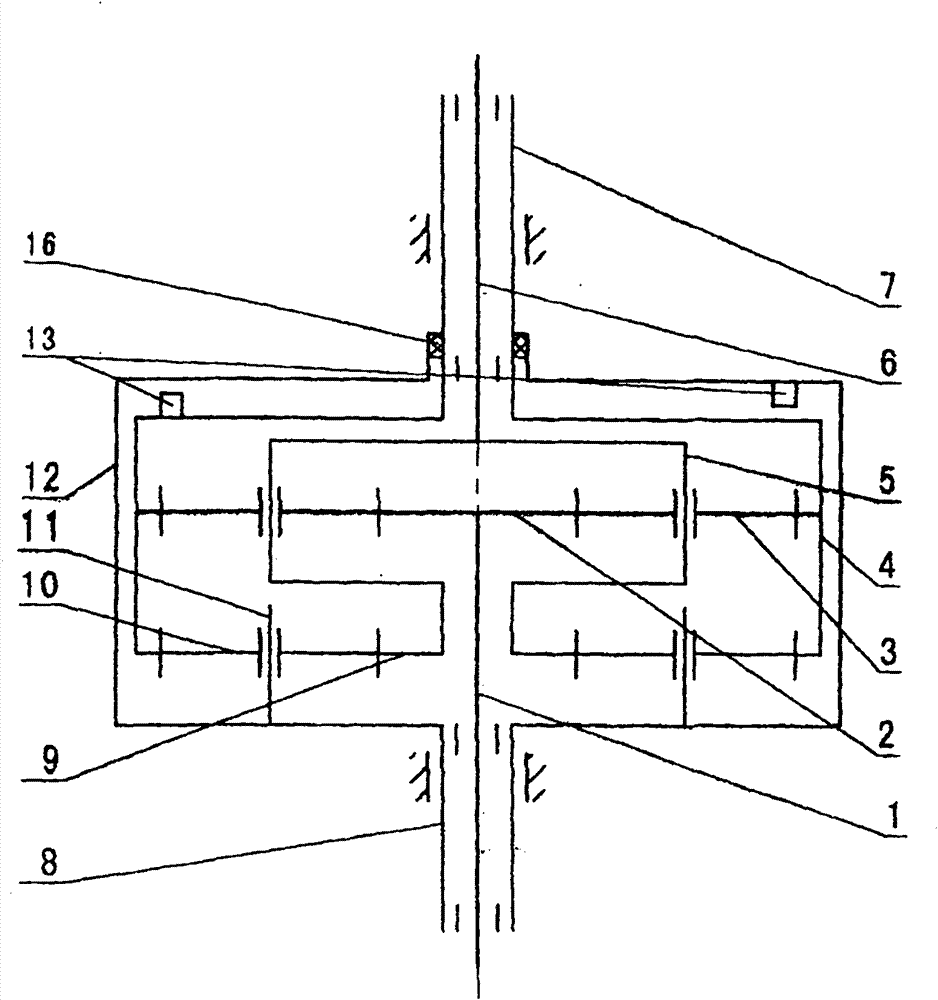

Washing mode of washing machine and fully automatic washing machine

InactiveCN1986942ASignificant comprehensive benefitsImprove washing qualityWashing machine with receptaclesTextiles and paperReduction driveReciprocating motion

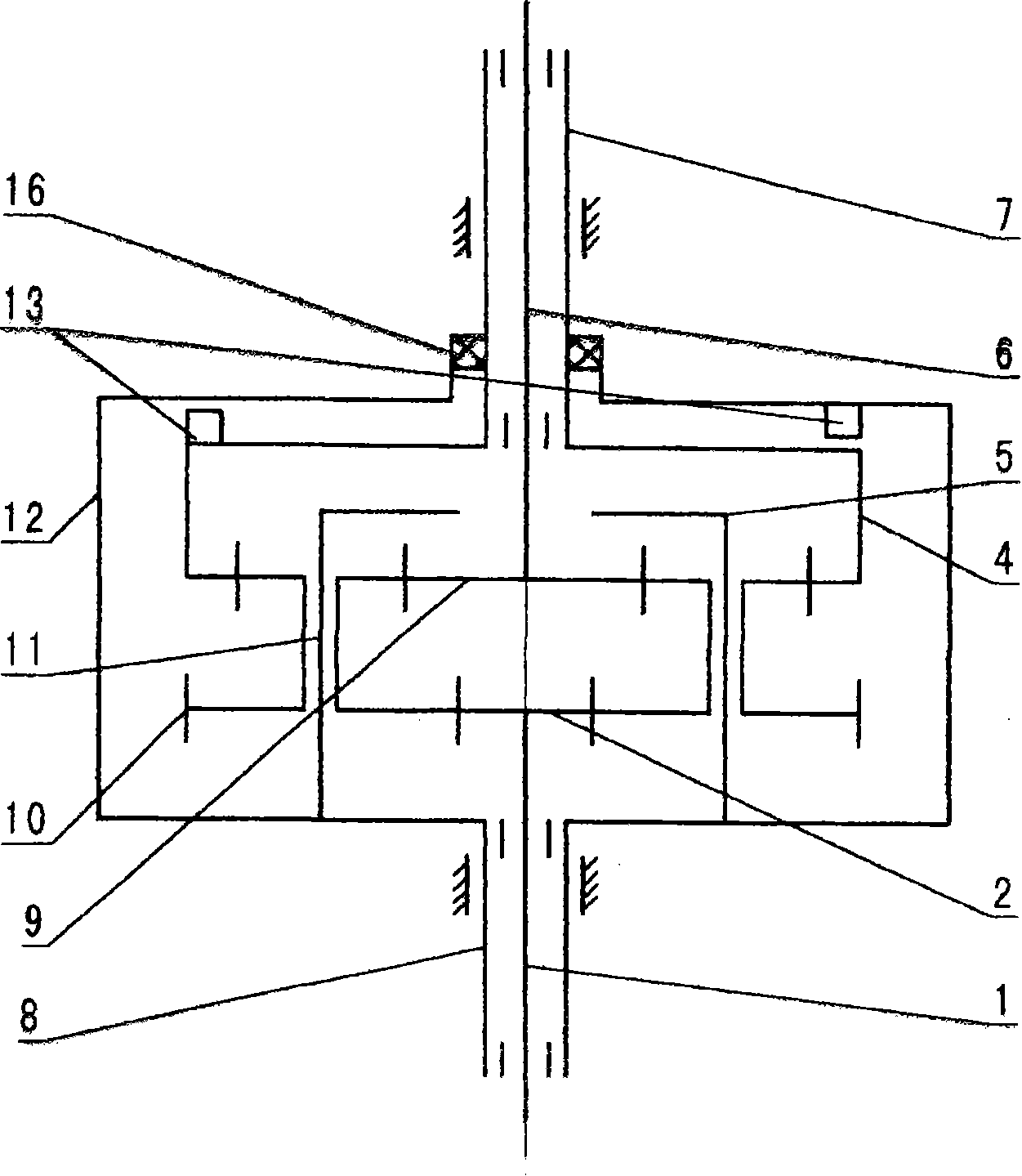

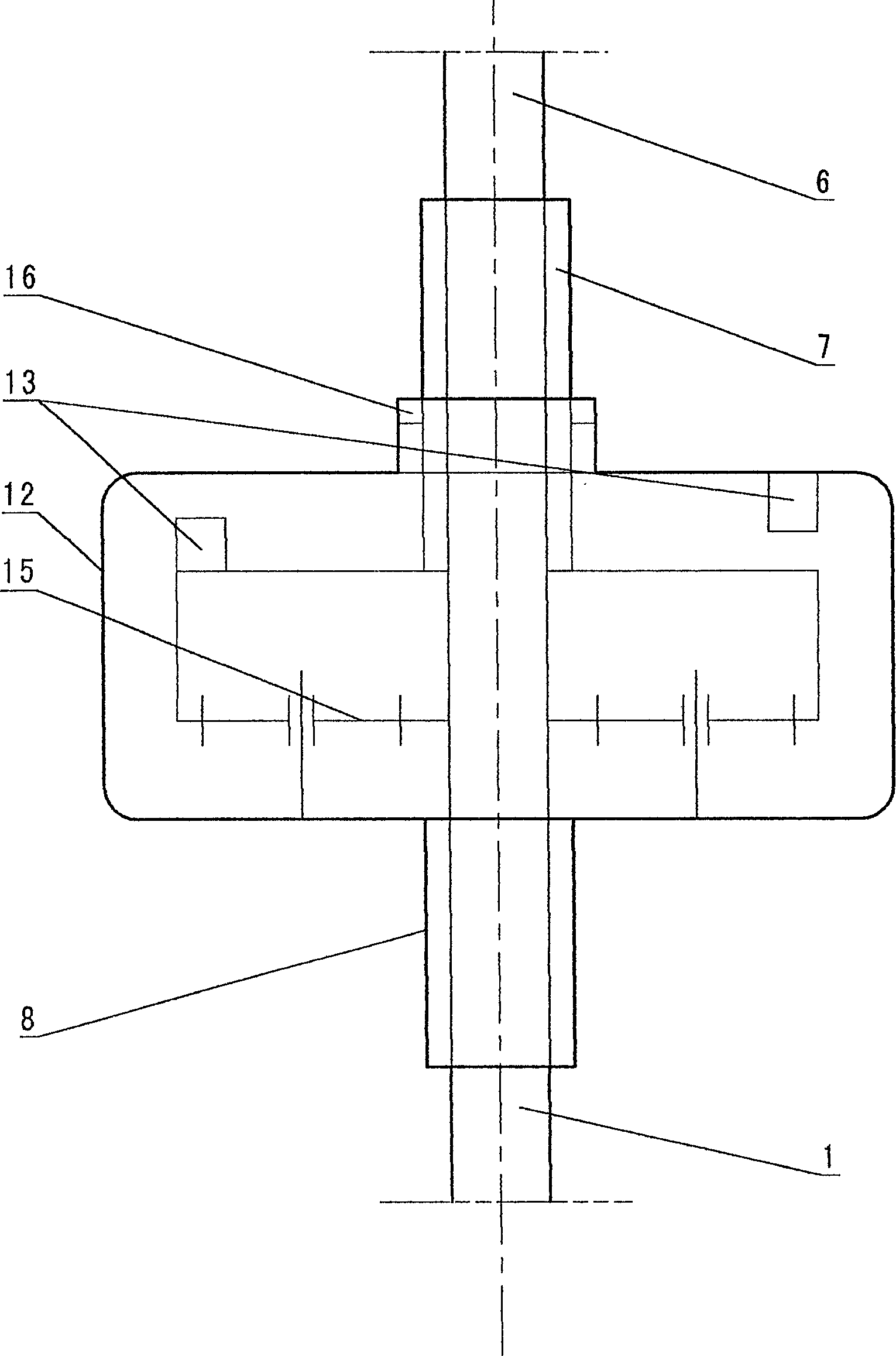

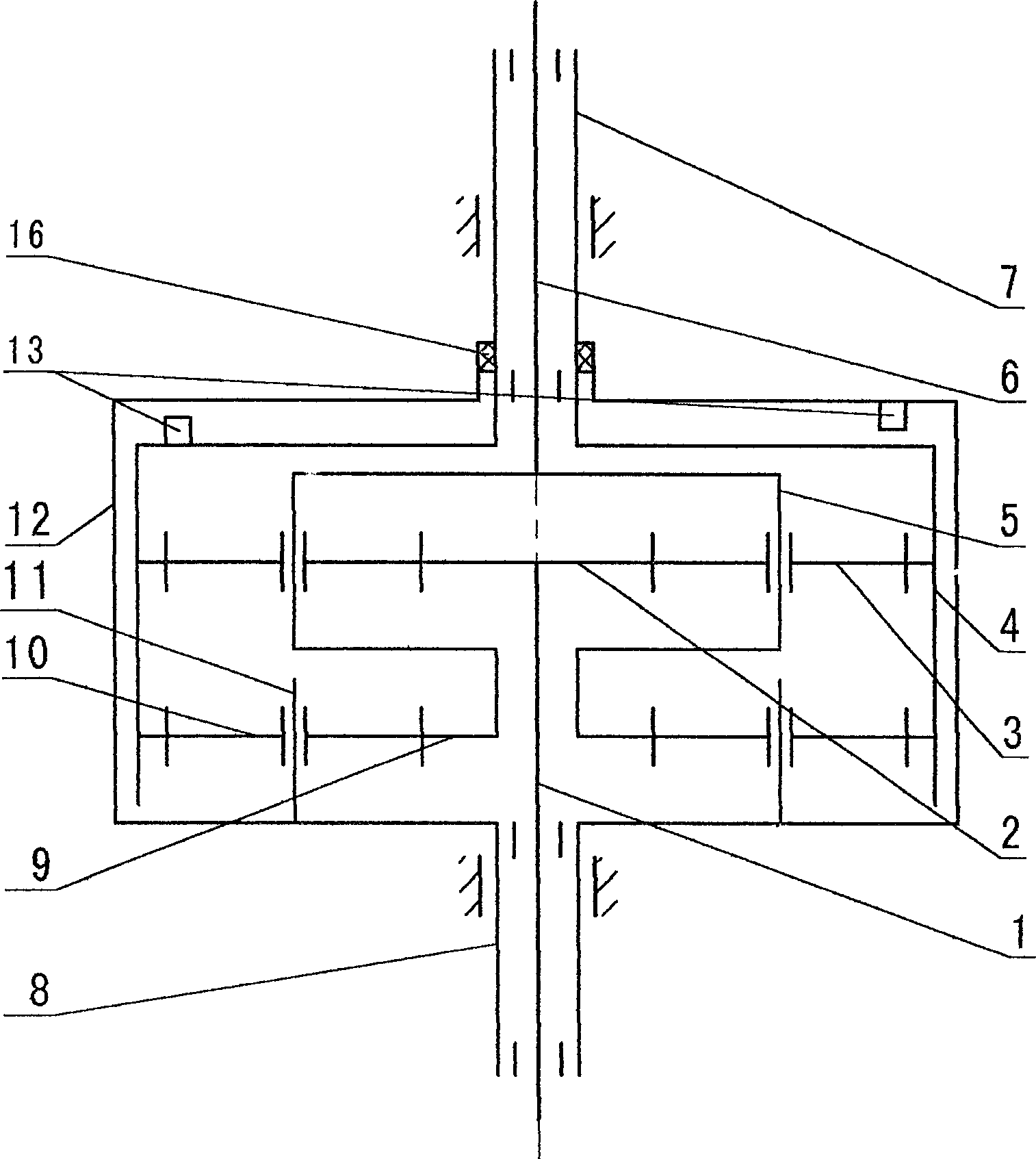

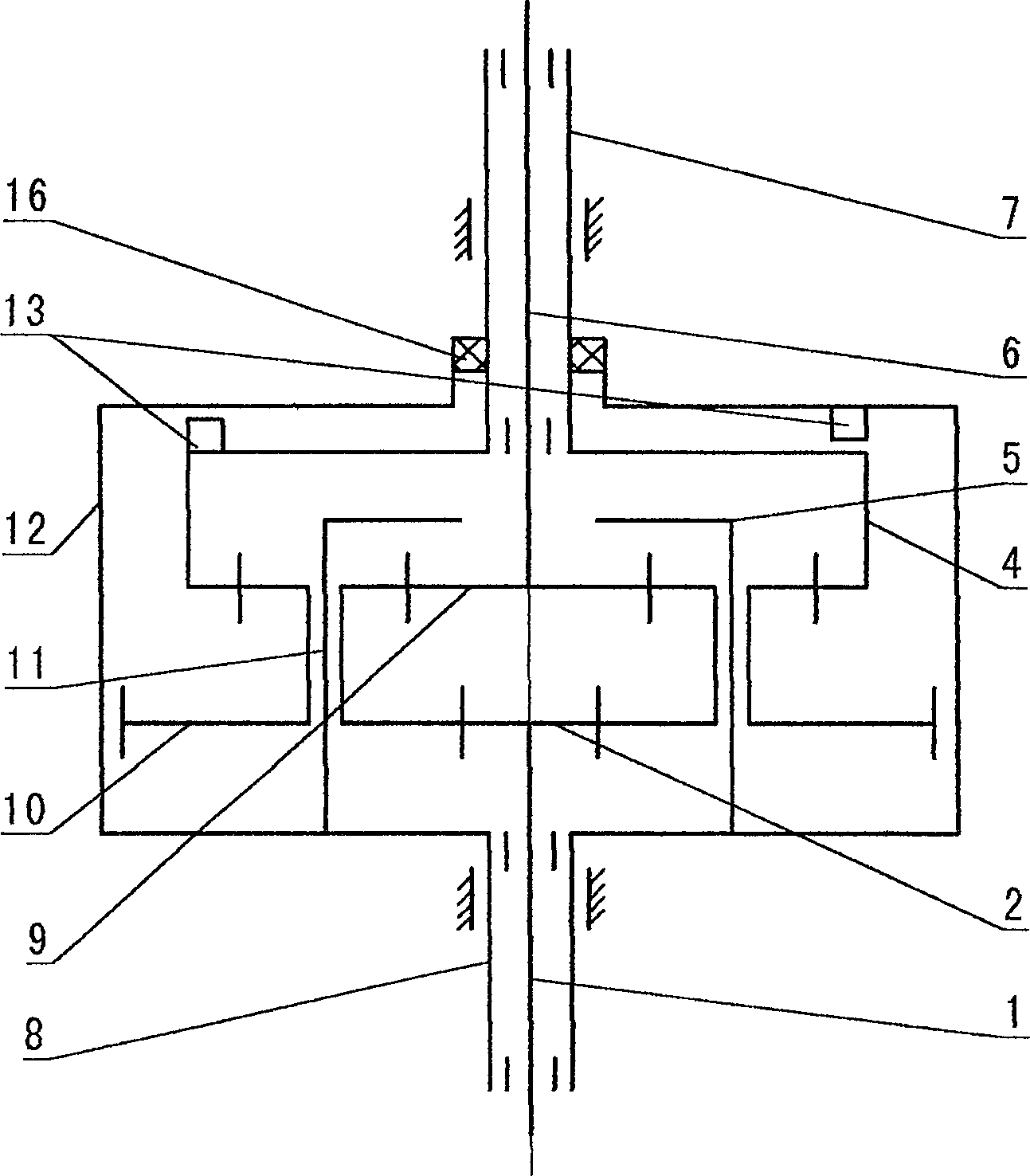

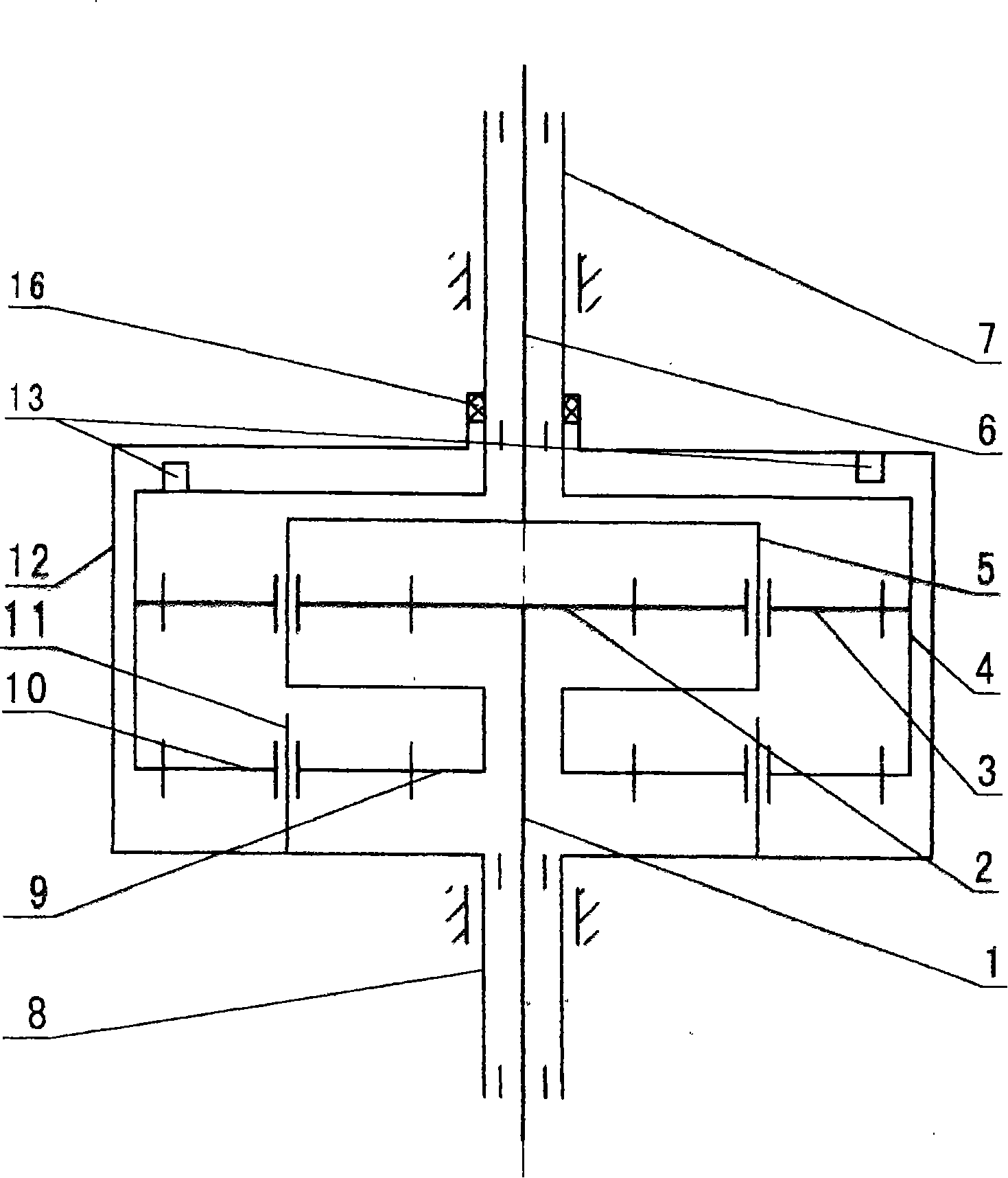

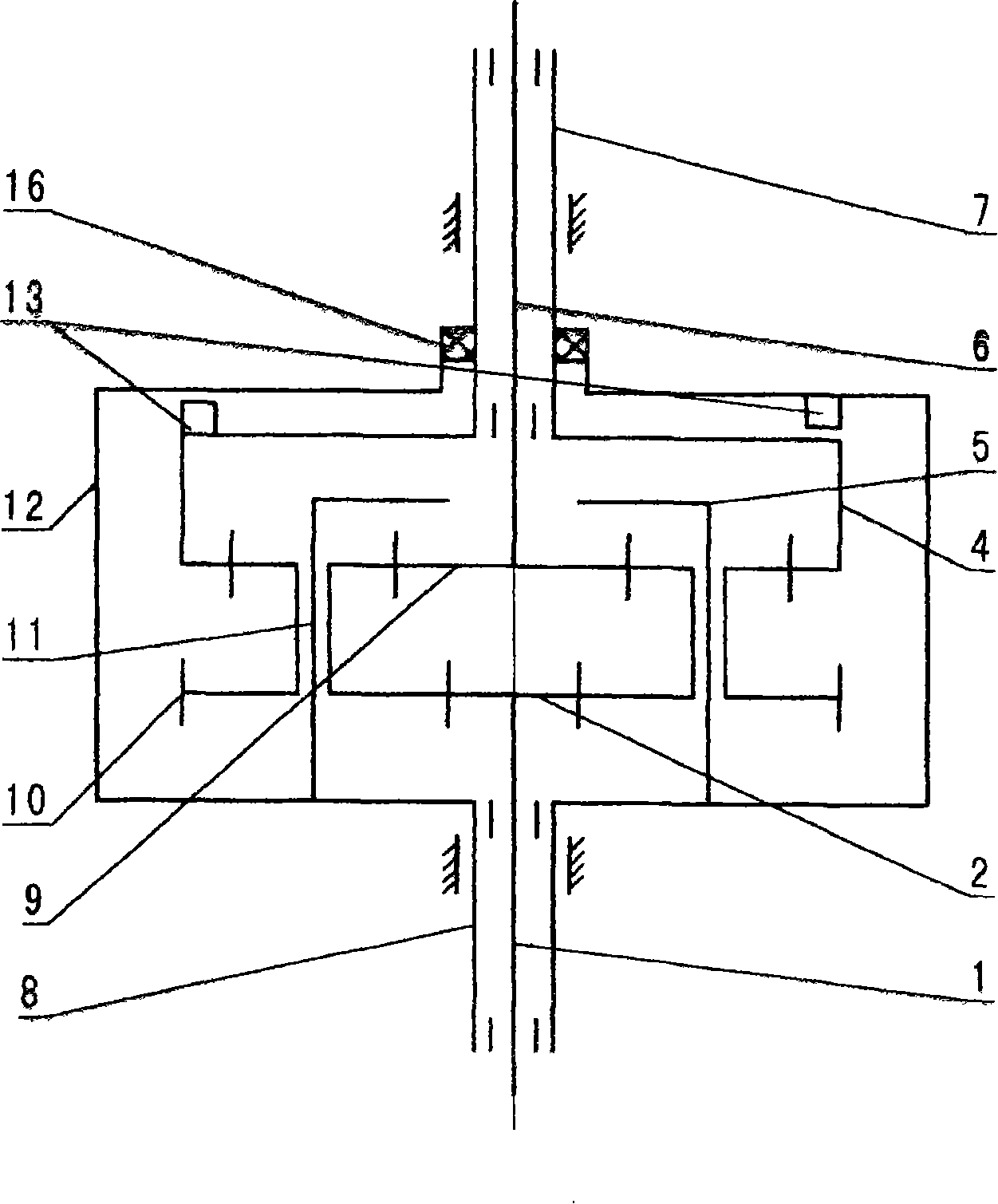

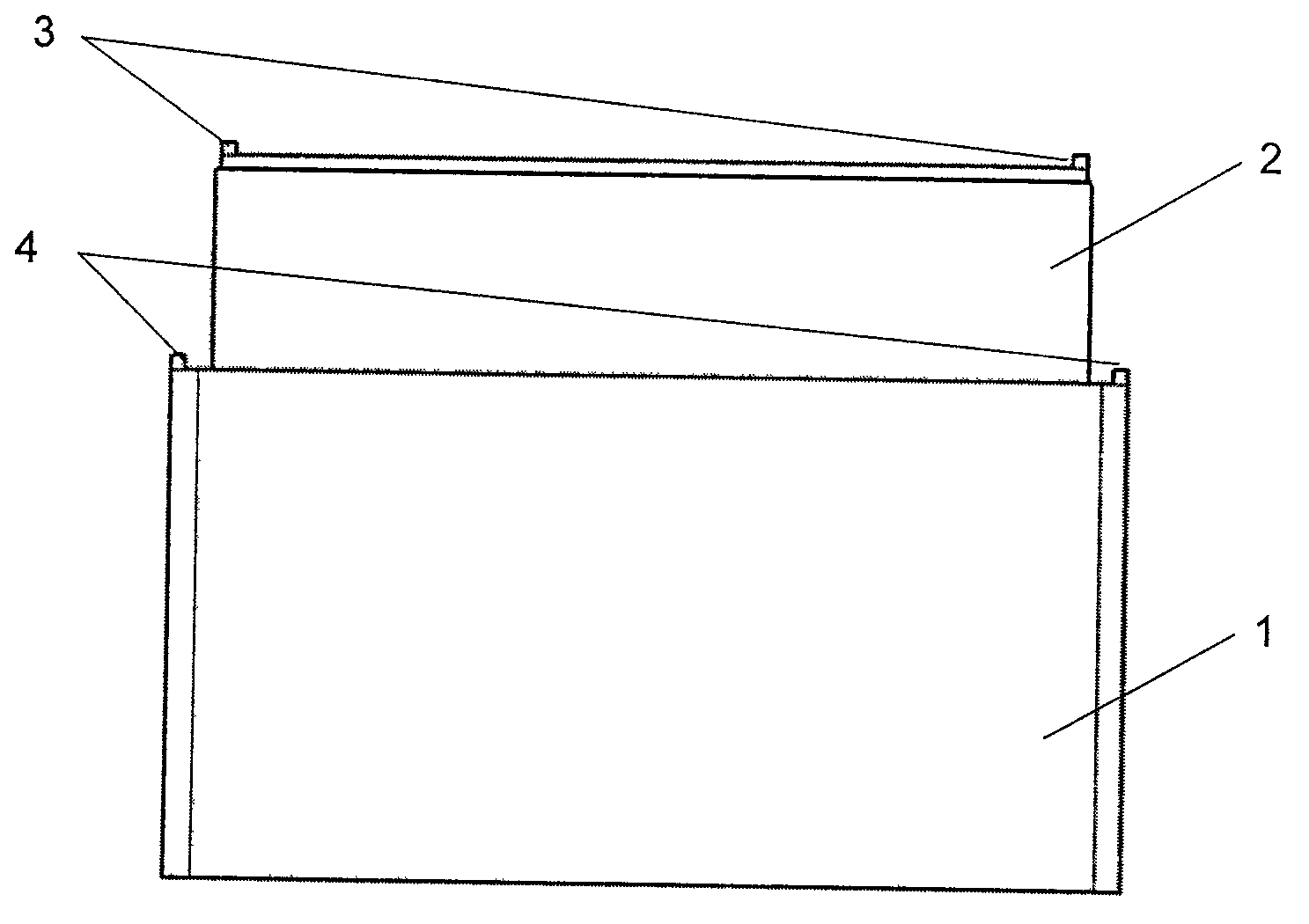

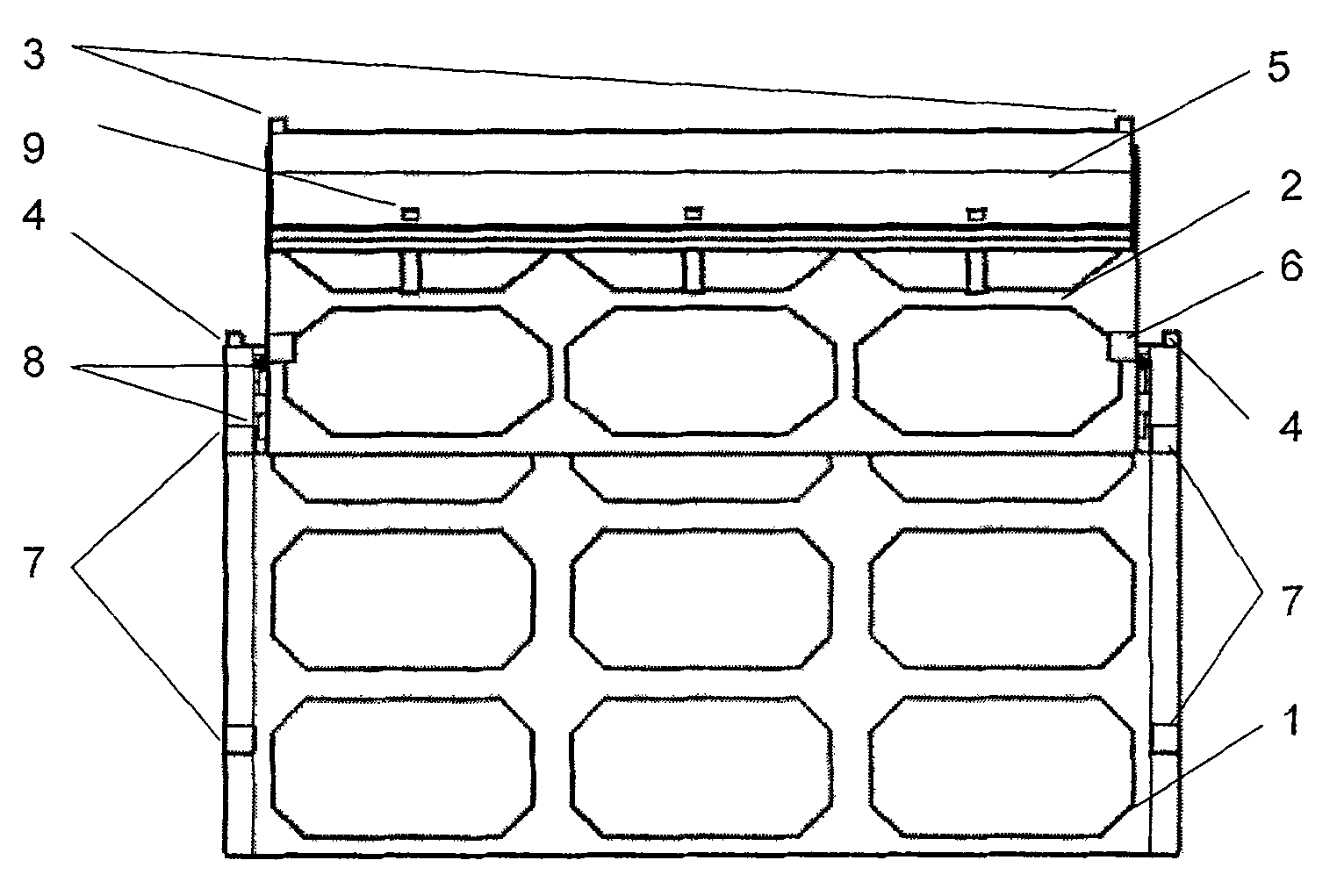

A washing mode of washer is characterized by that an axially reciprocating pressure disc is arranged in a washing drum for generating both bidirectionally rotary water stream and axially reciprocating pressure water stream to flush, beat and press the object to be washed. A full-automatic washer with said washing mode is composed of an external drum, an internal drum, a speed reducer or speed-reducing clutch with output axle and axle sleeve, a waving wheel or bottom plate, and an axially reciprocating pressure disc unit in said internal drum.

Owner:ANHUI JULONG TRANSMISSION TECH

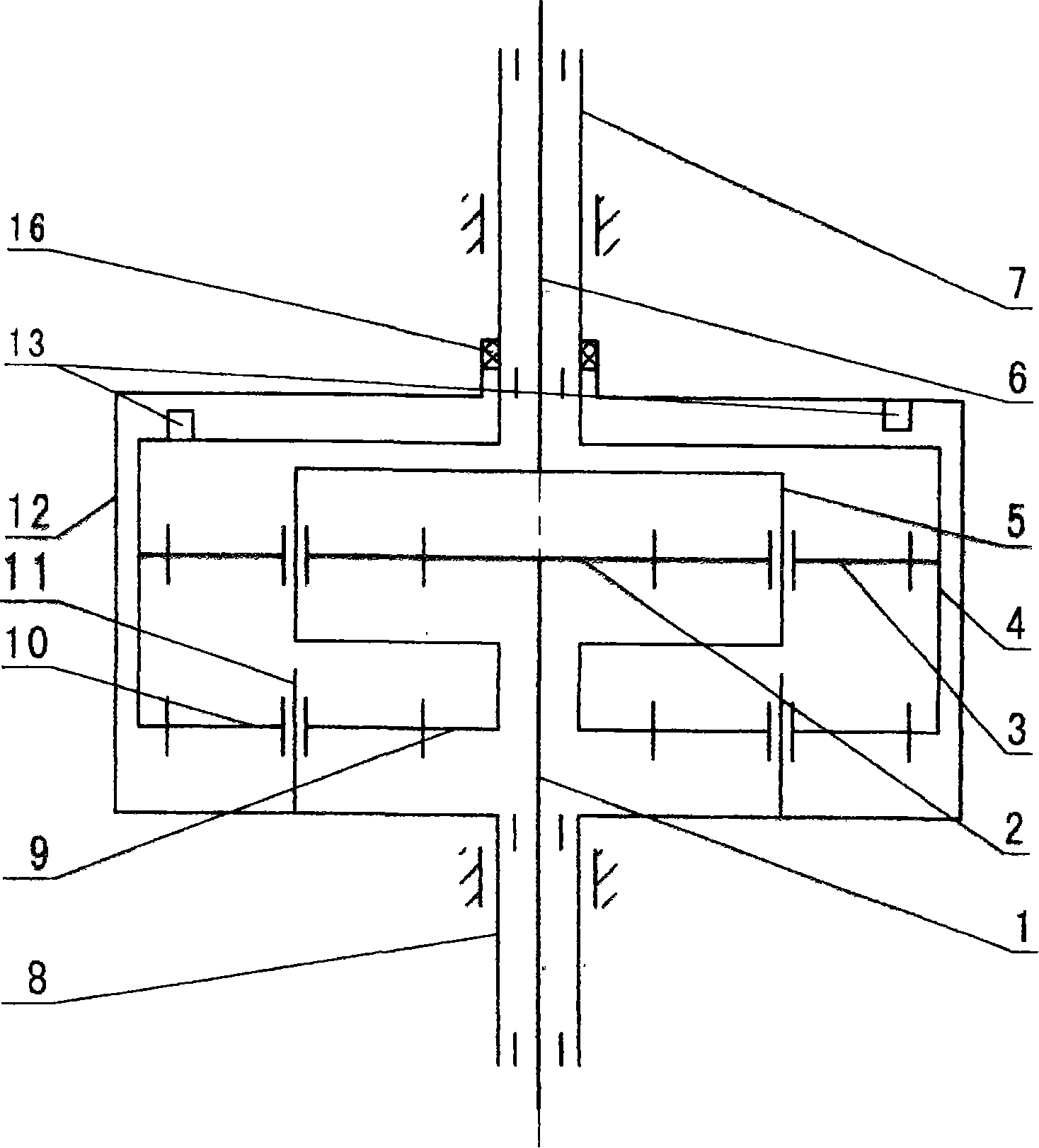

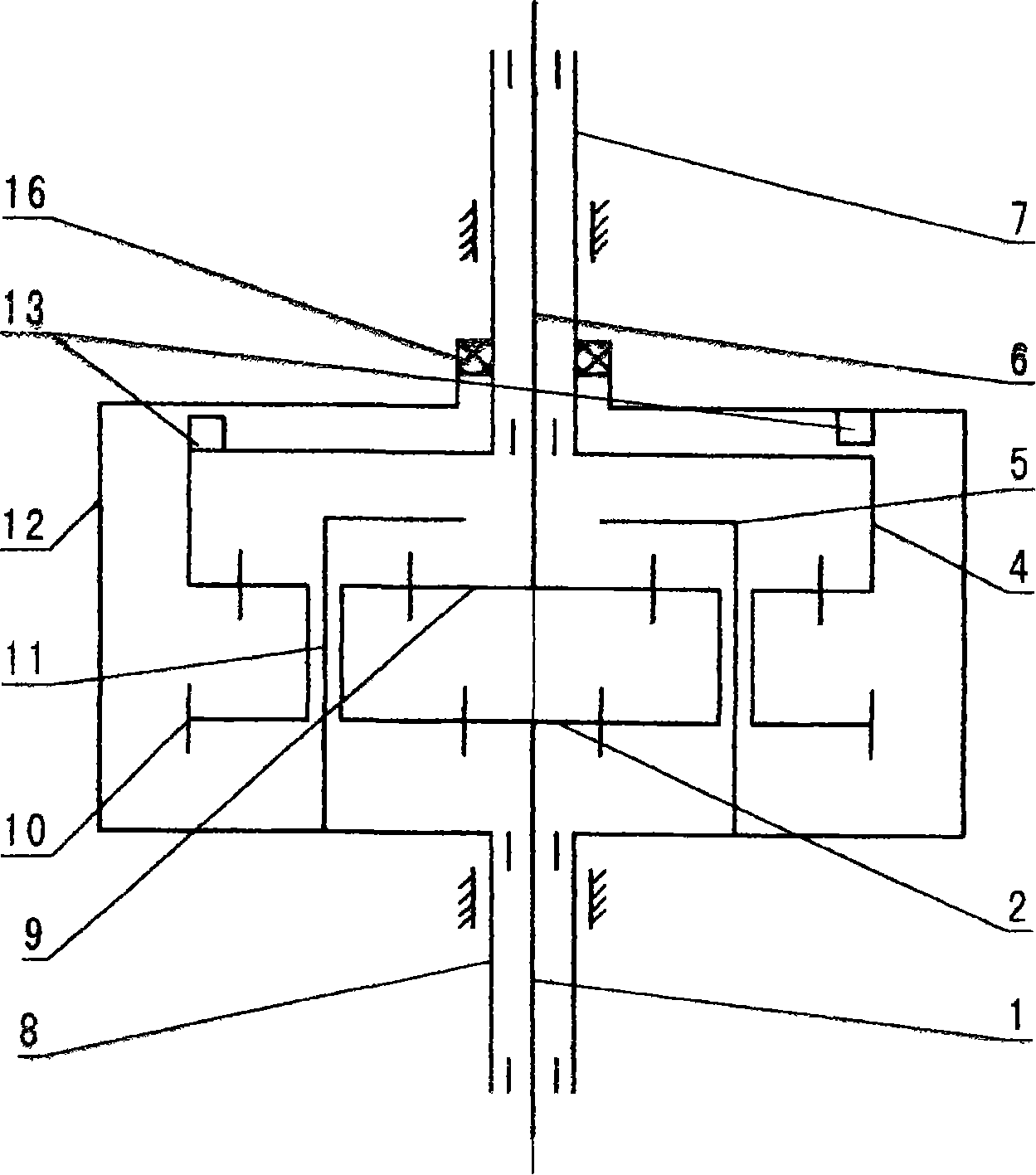

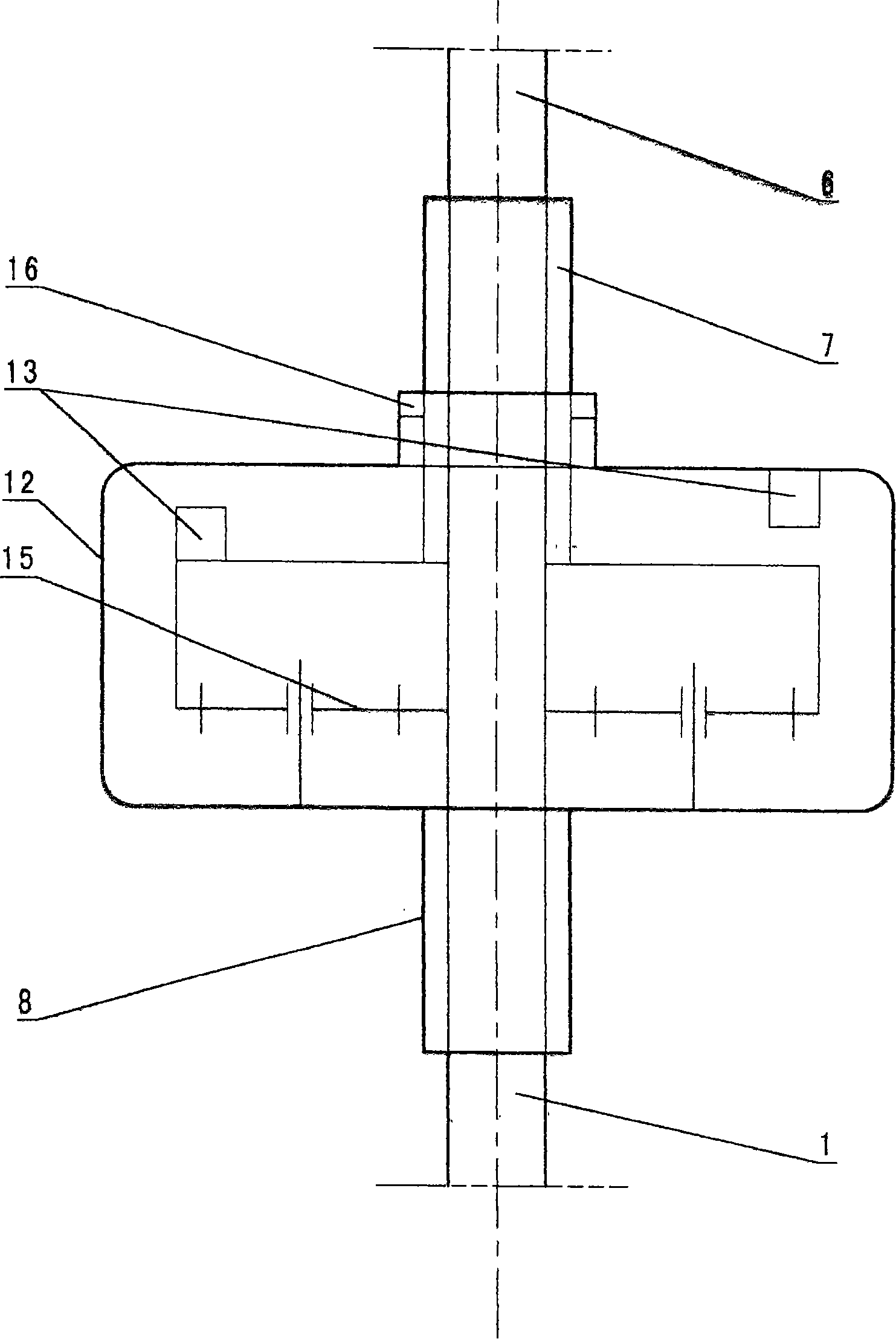

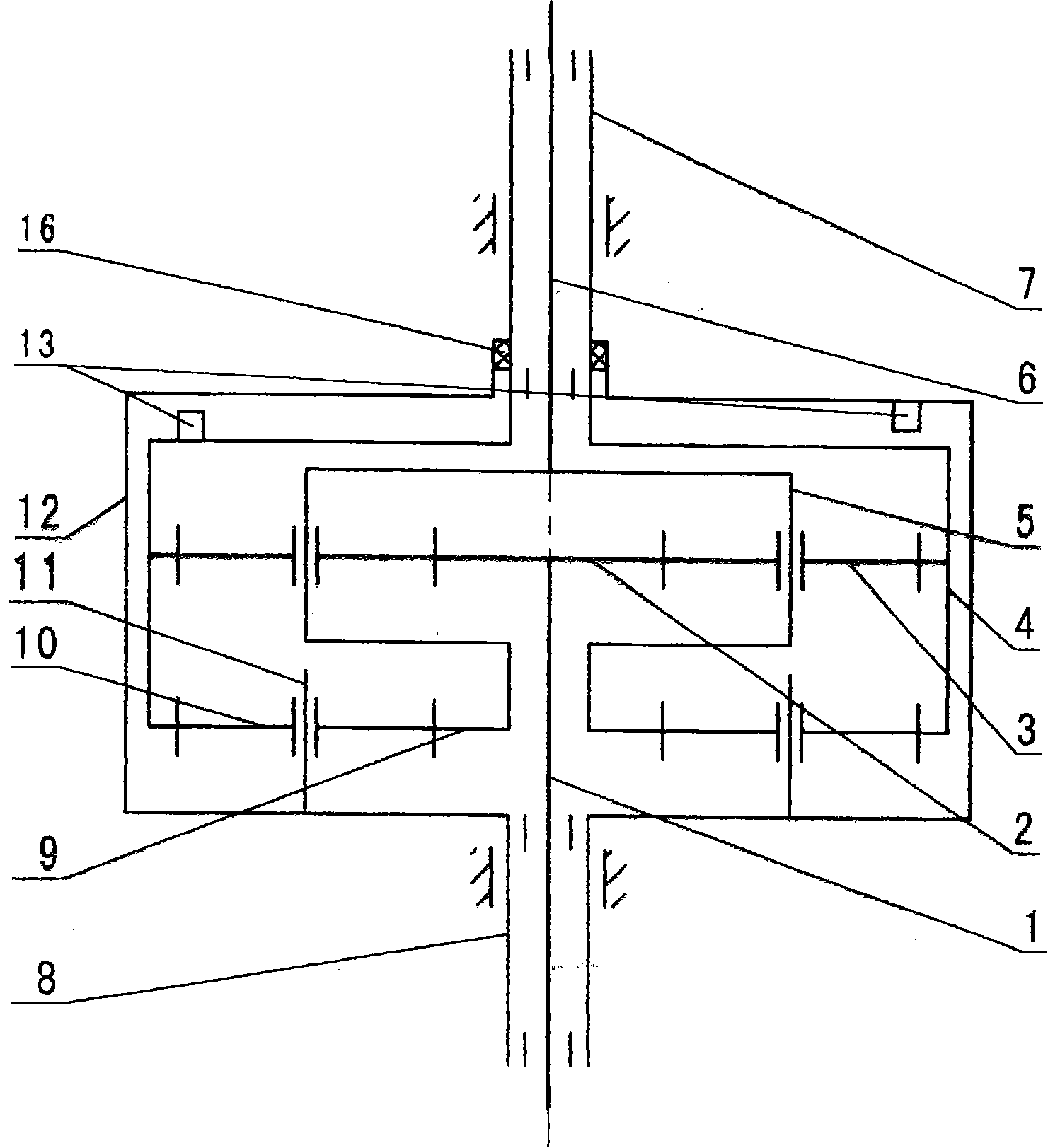

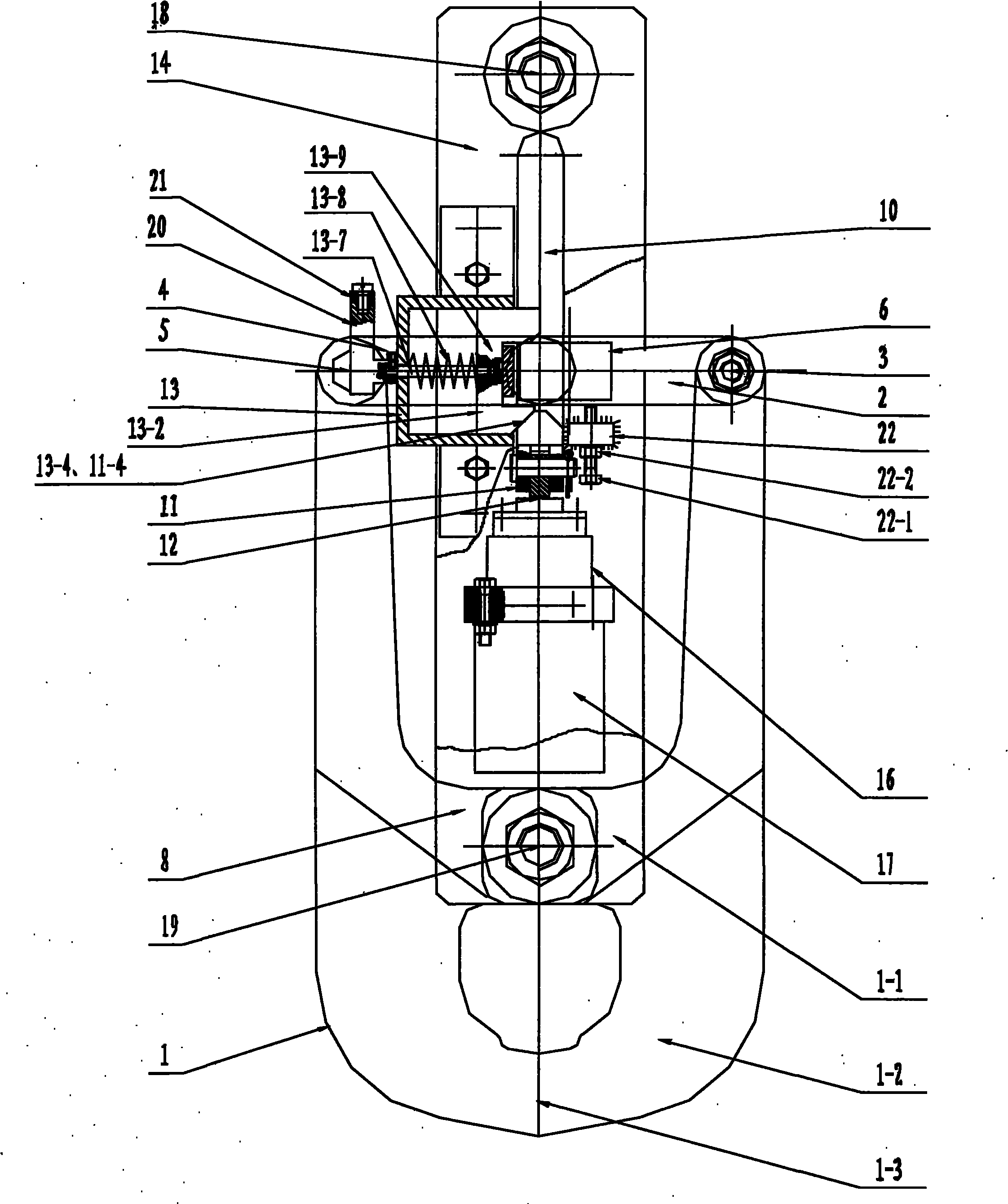

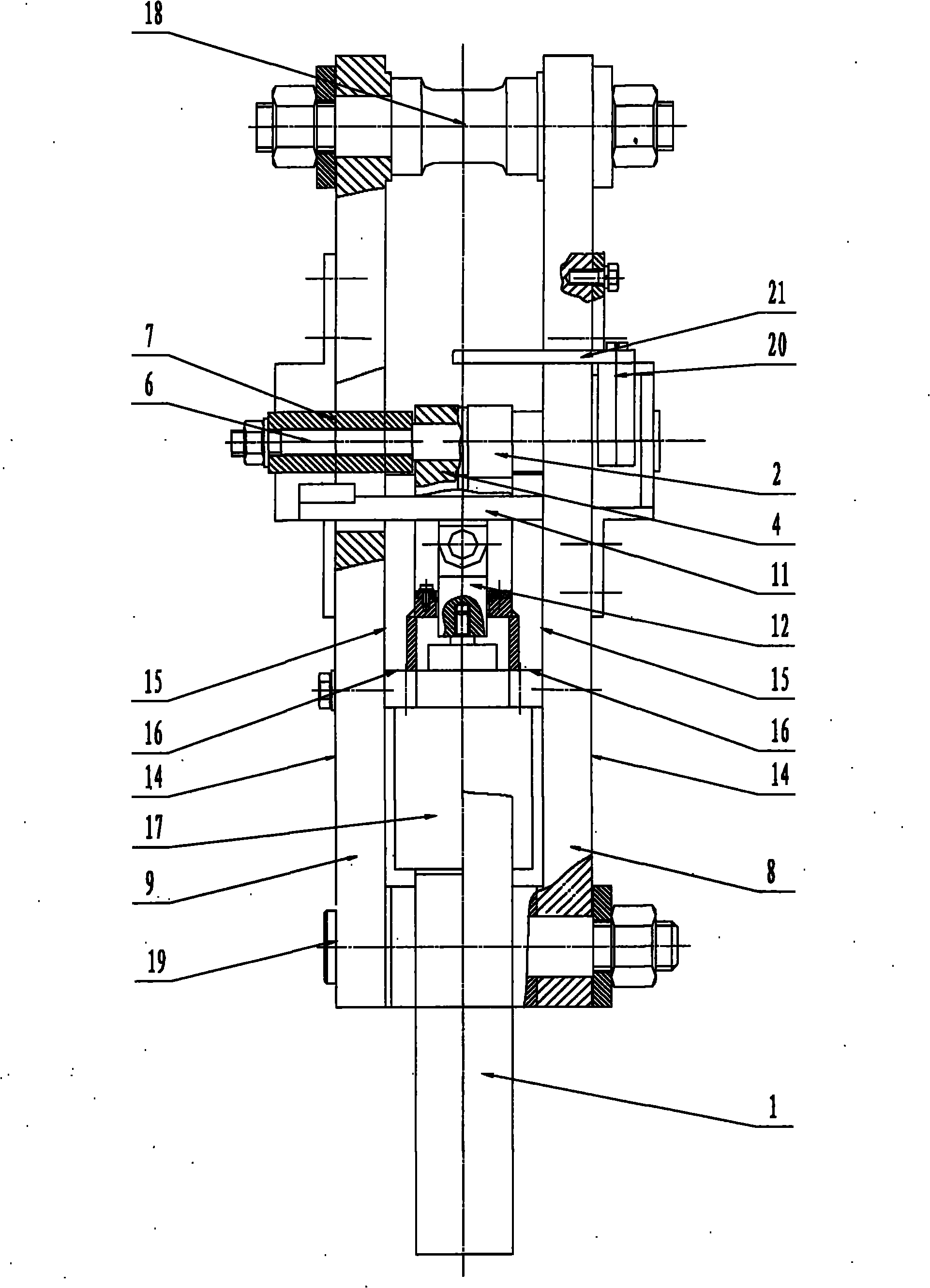

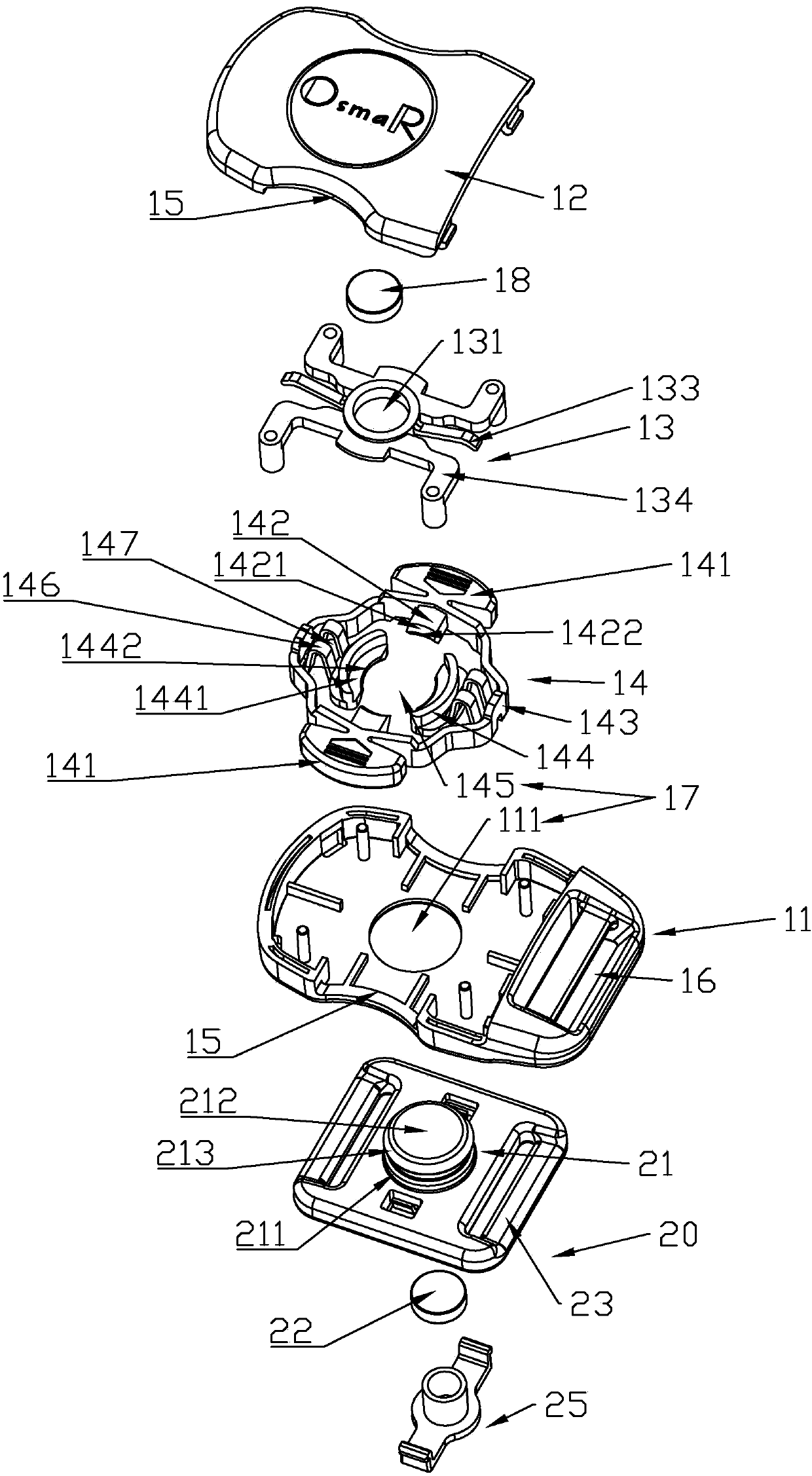

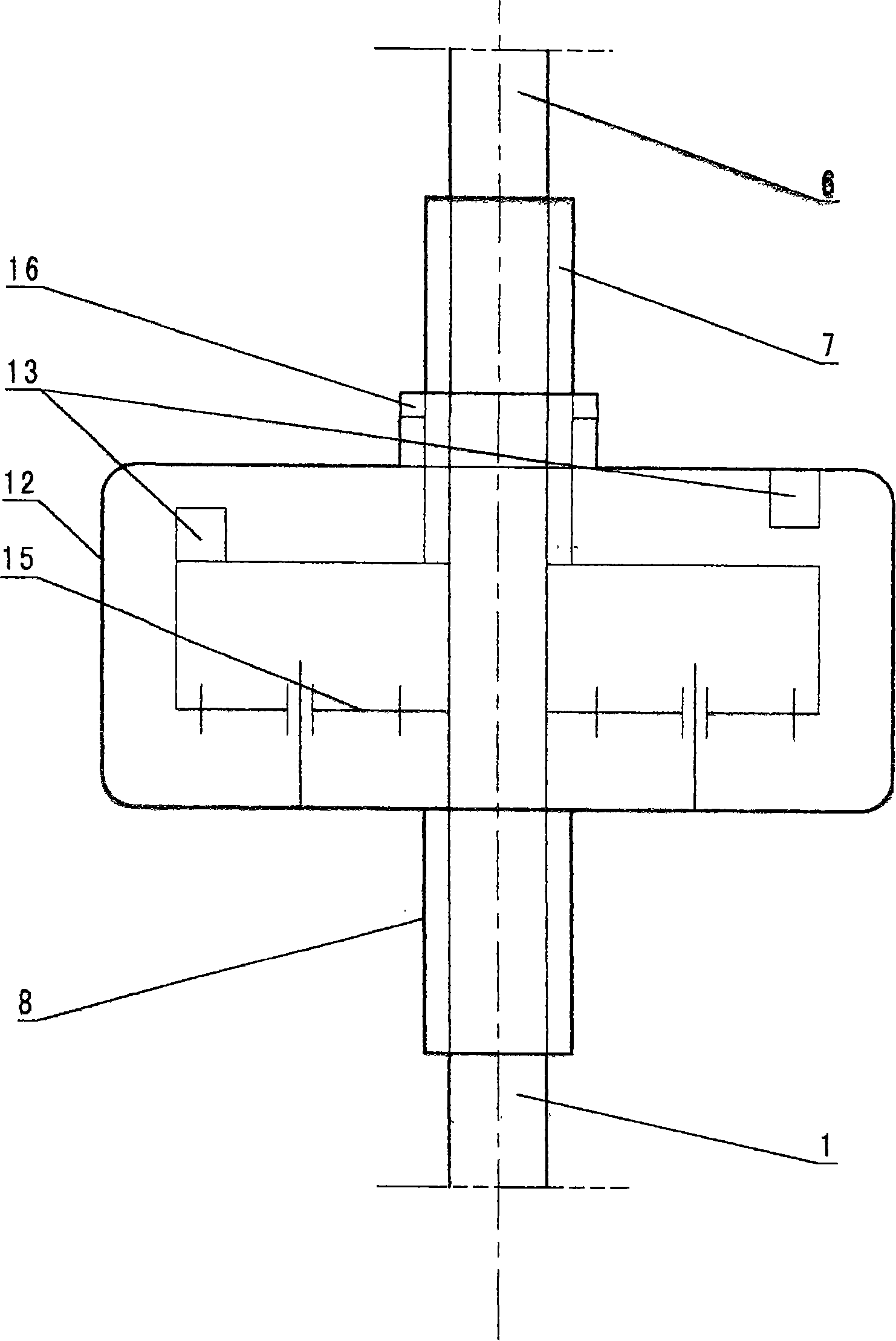

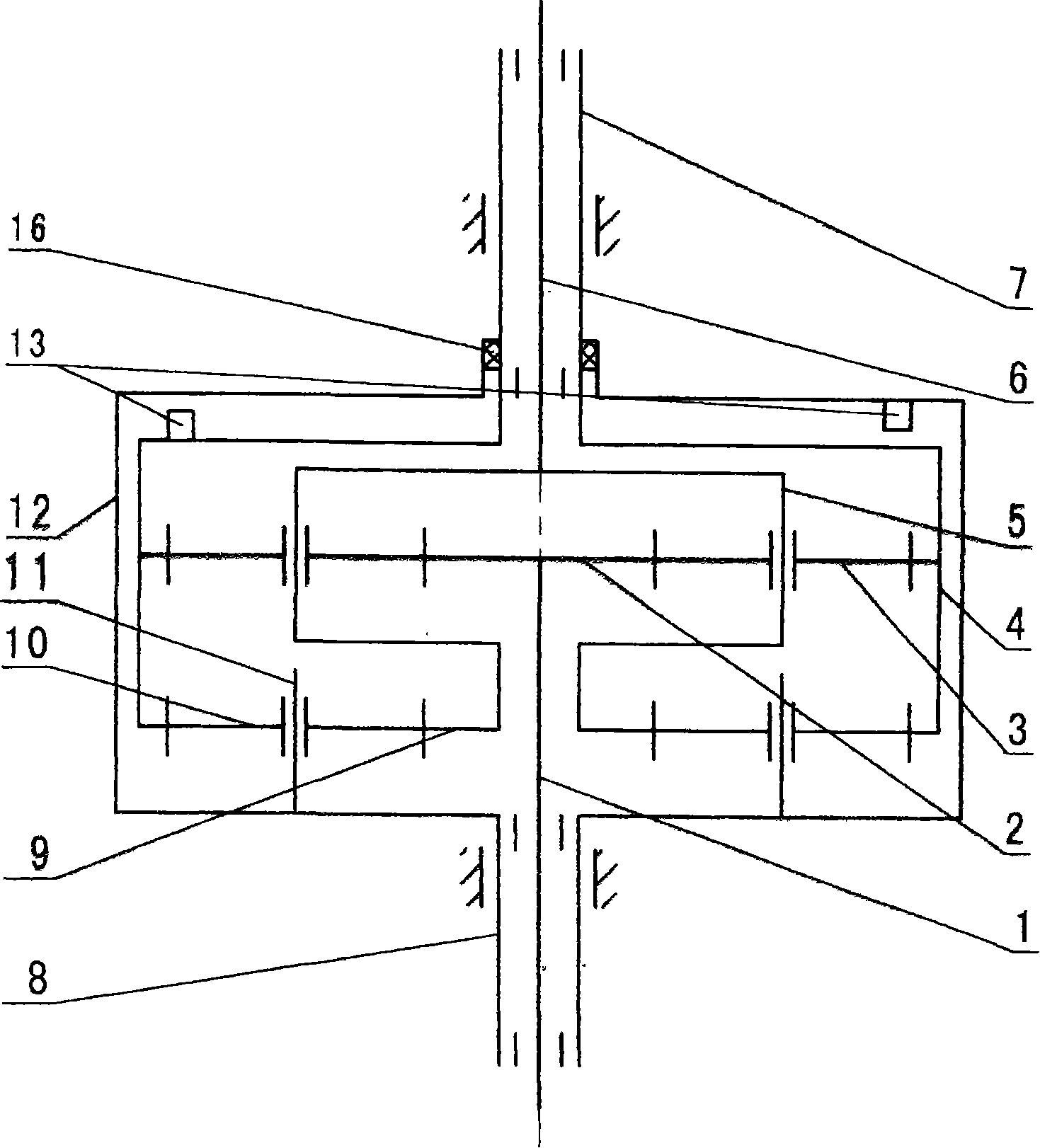

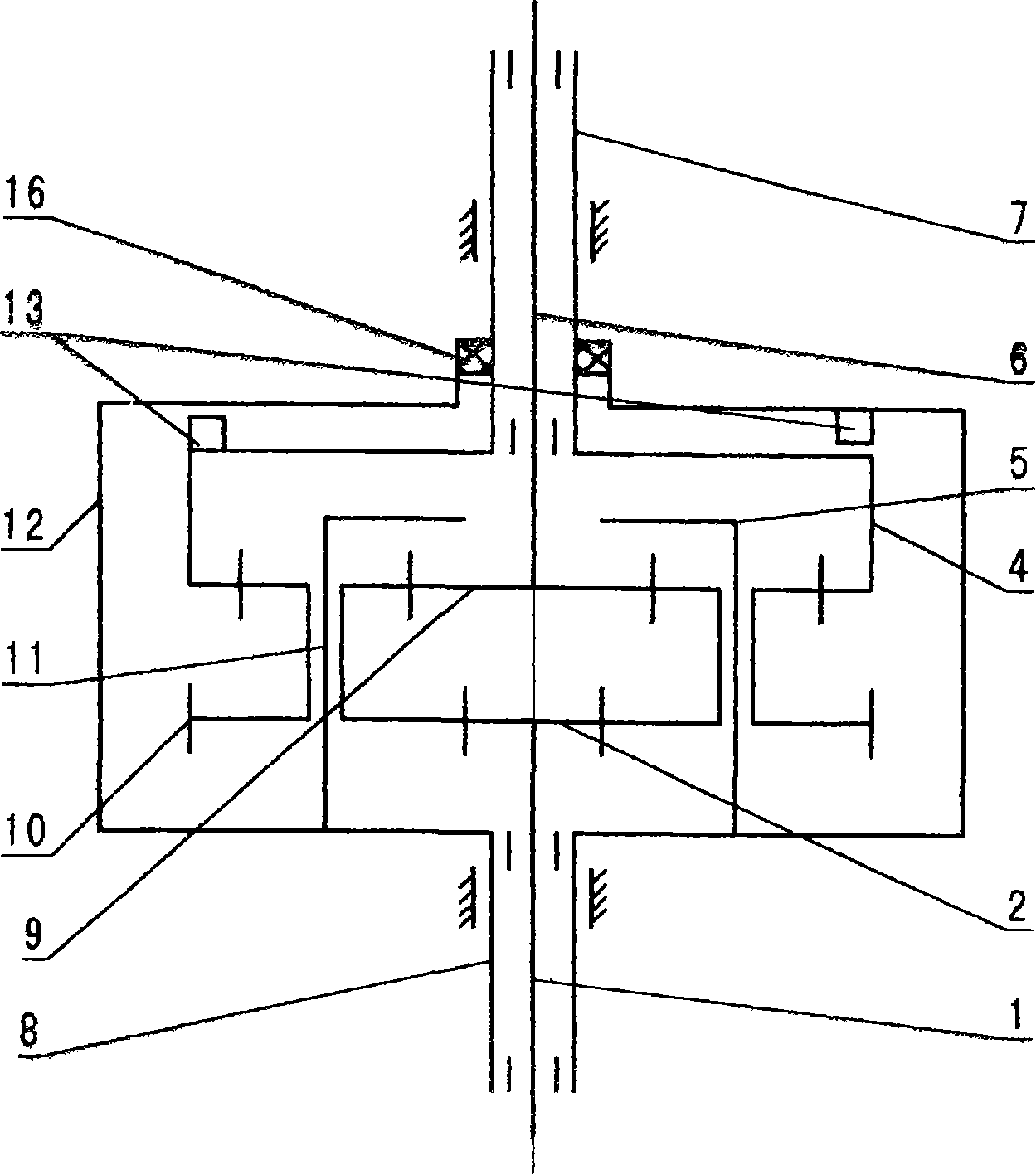

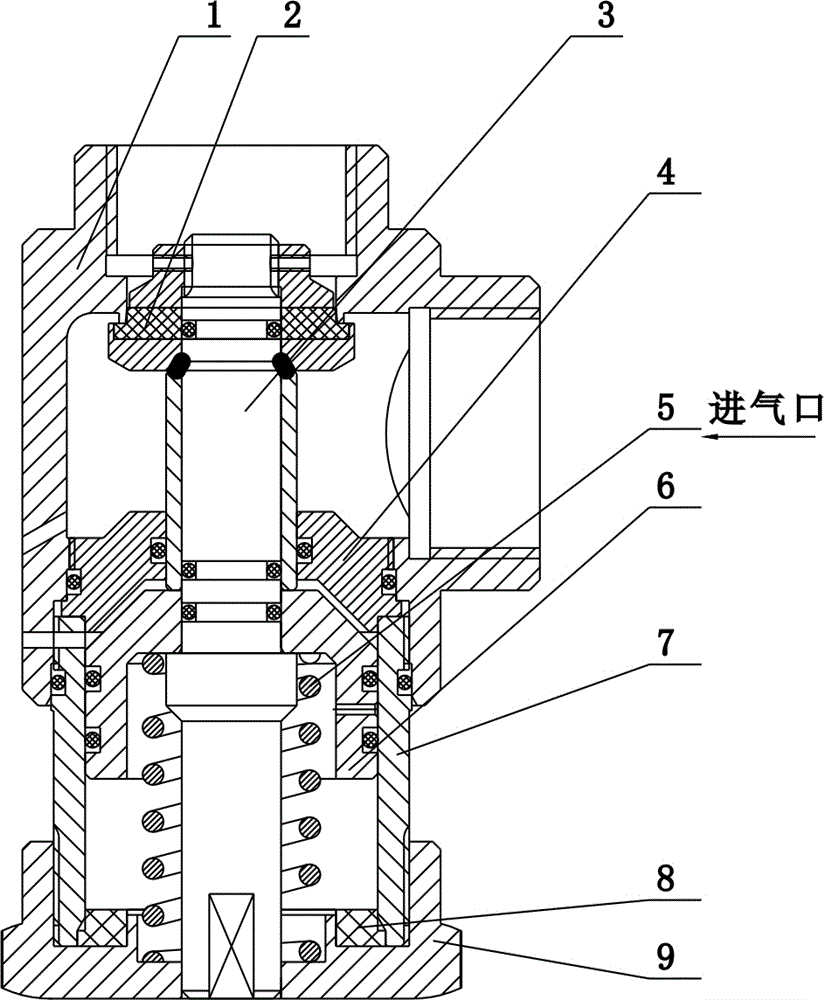

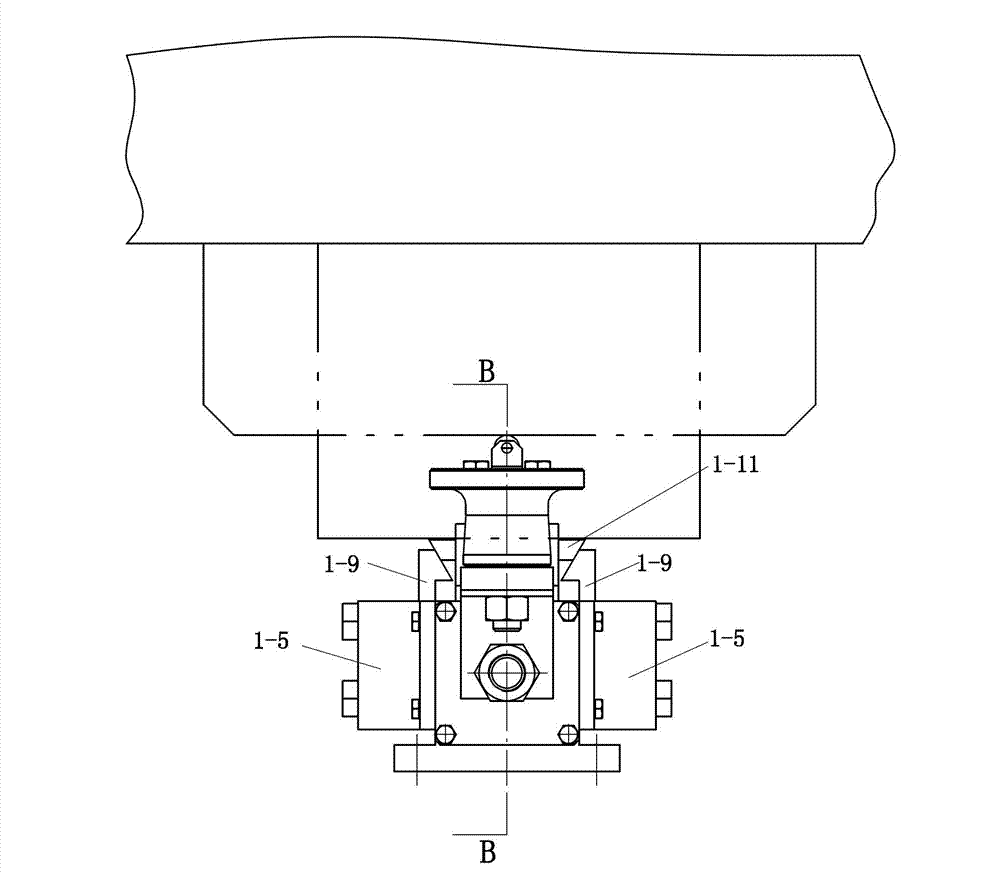

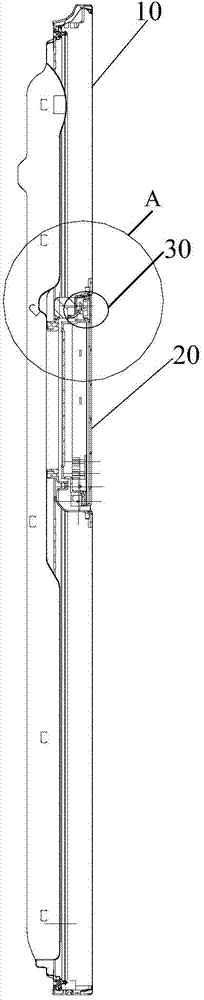

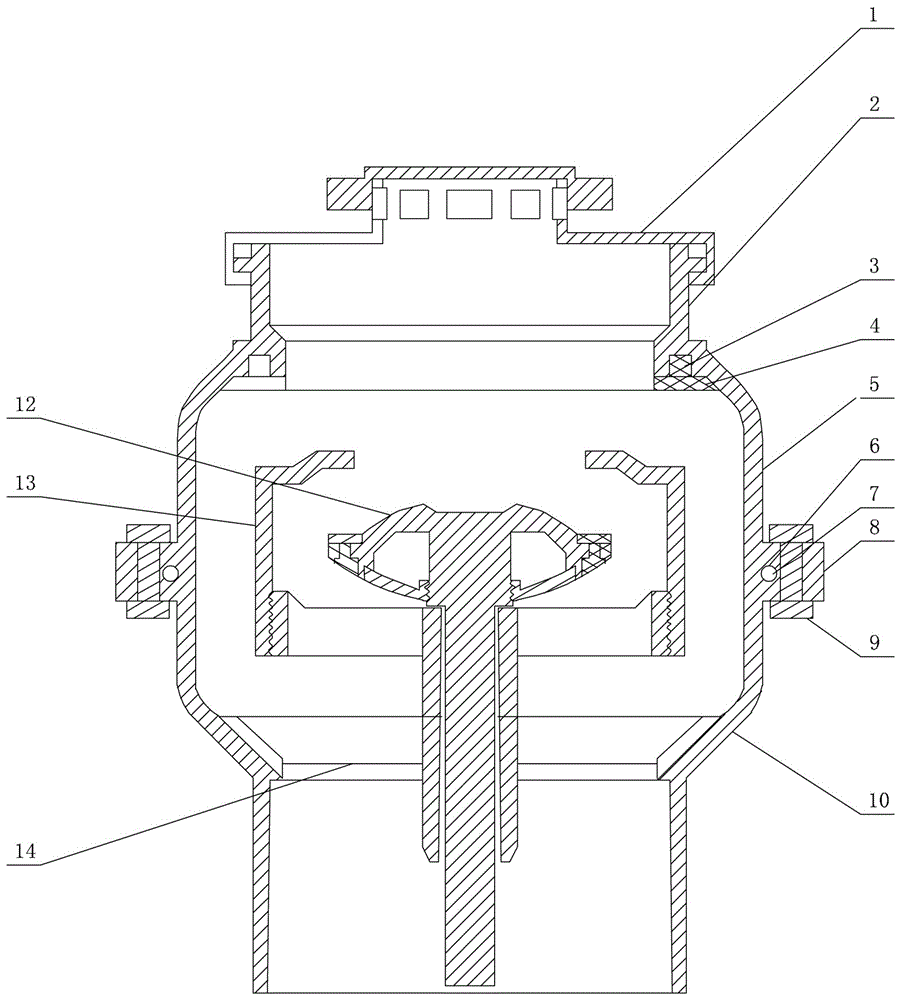

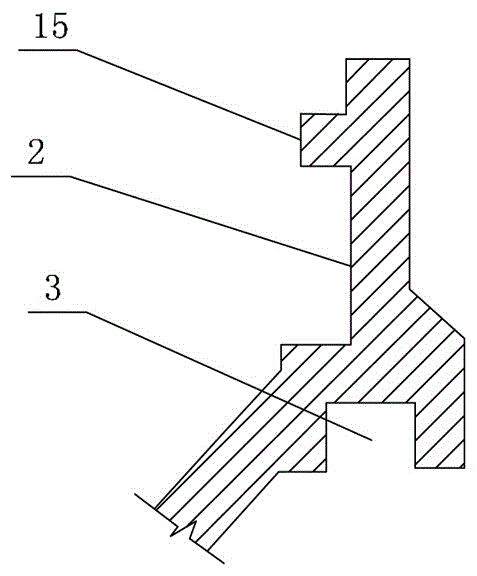

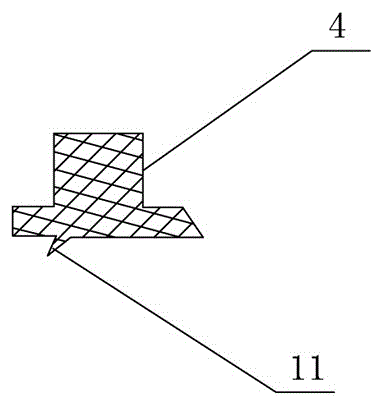

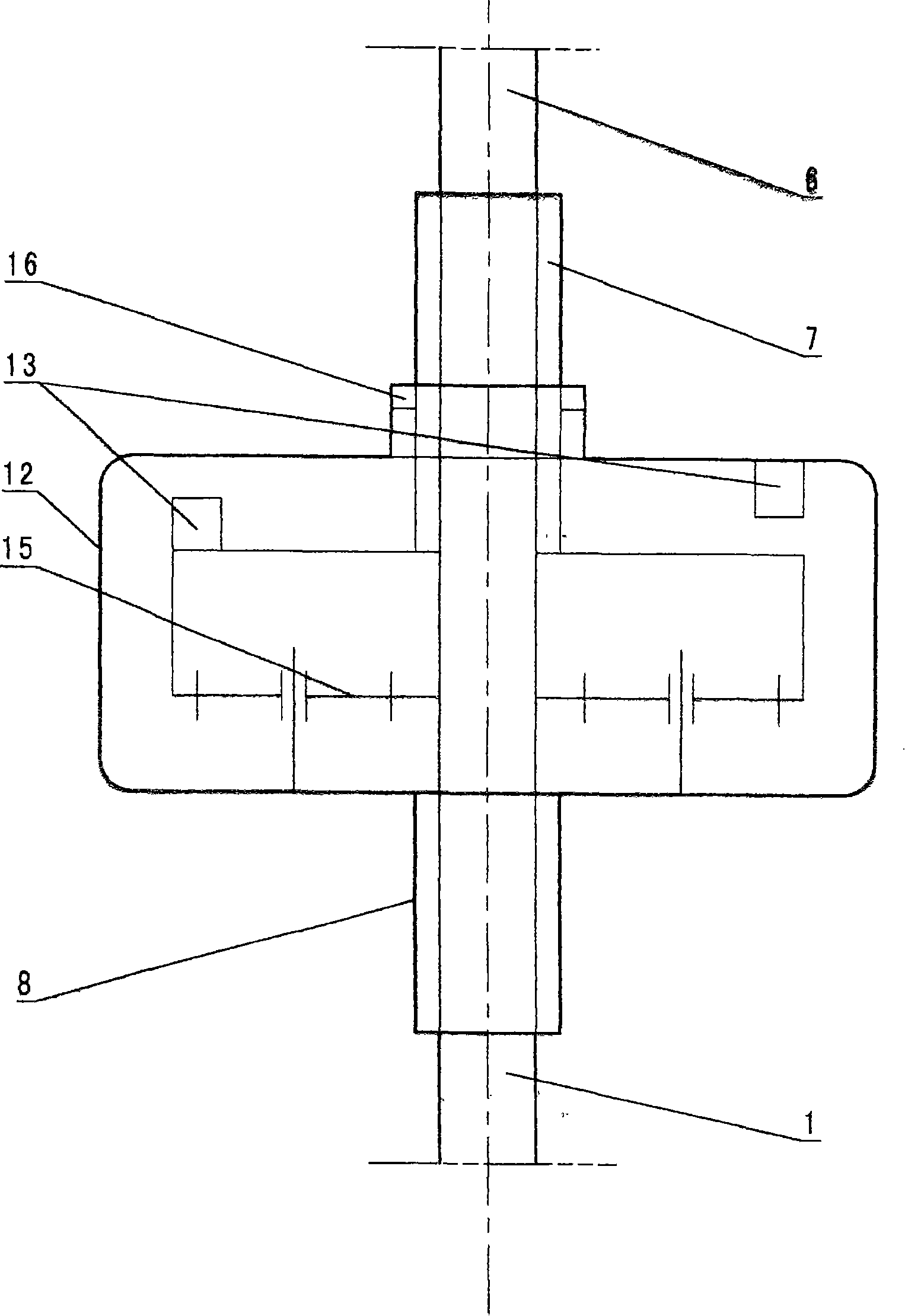

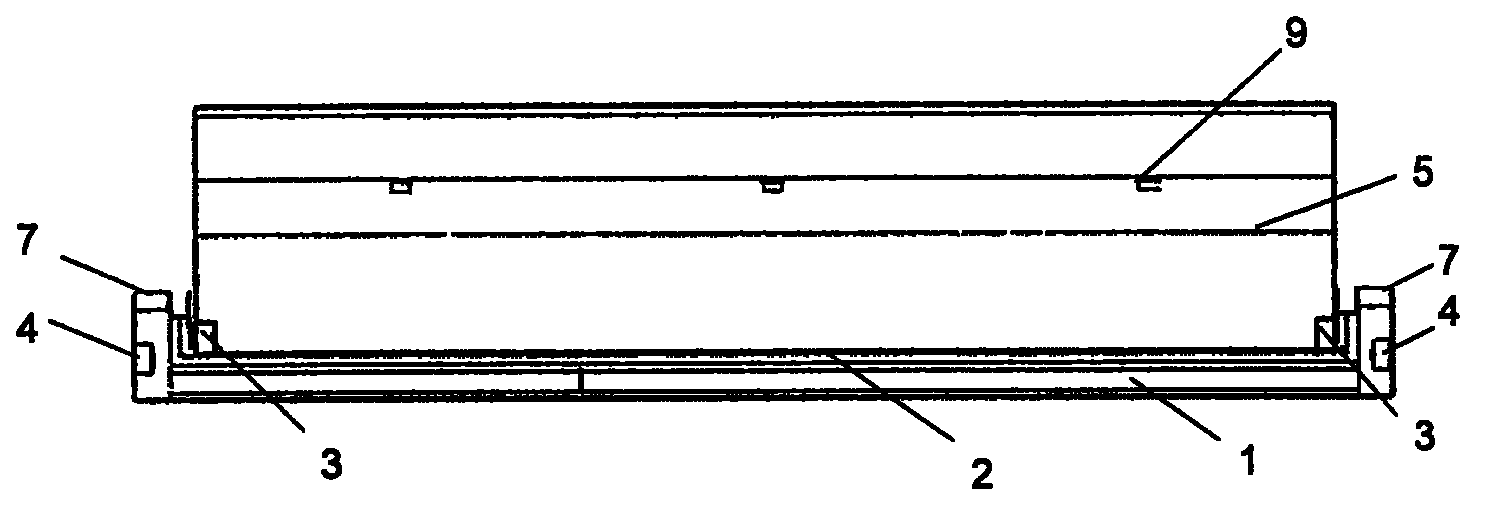

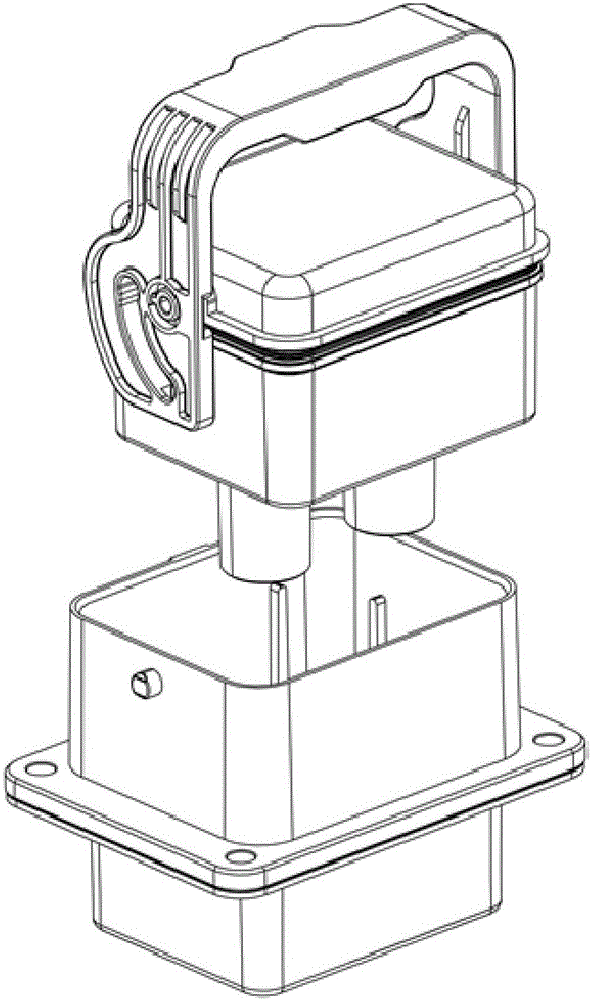

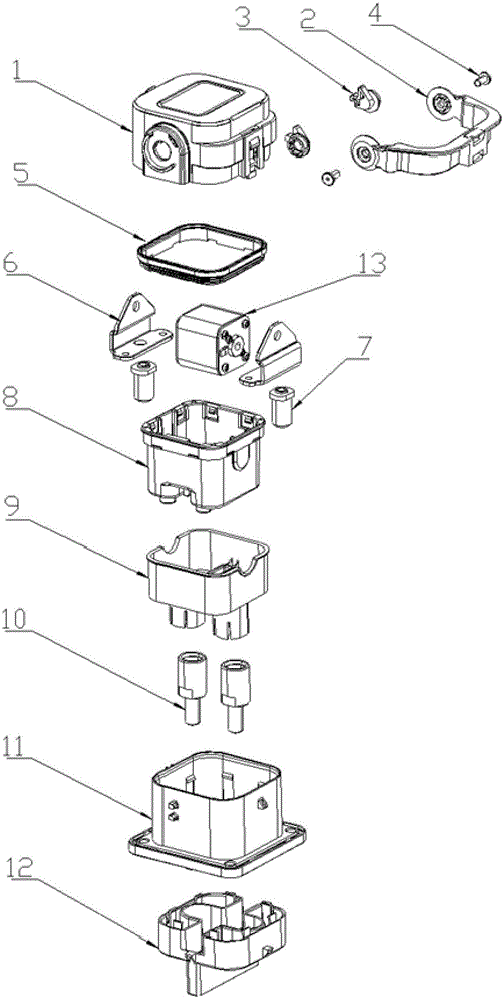

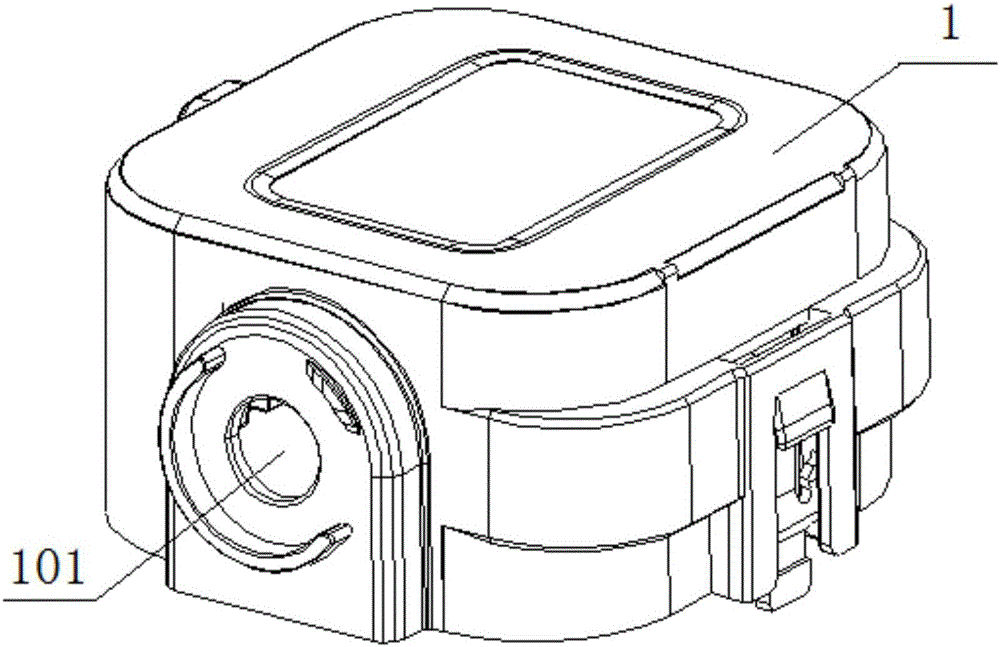

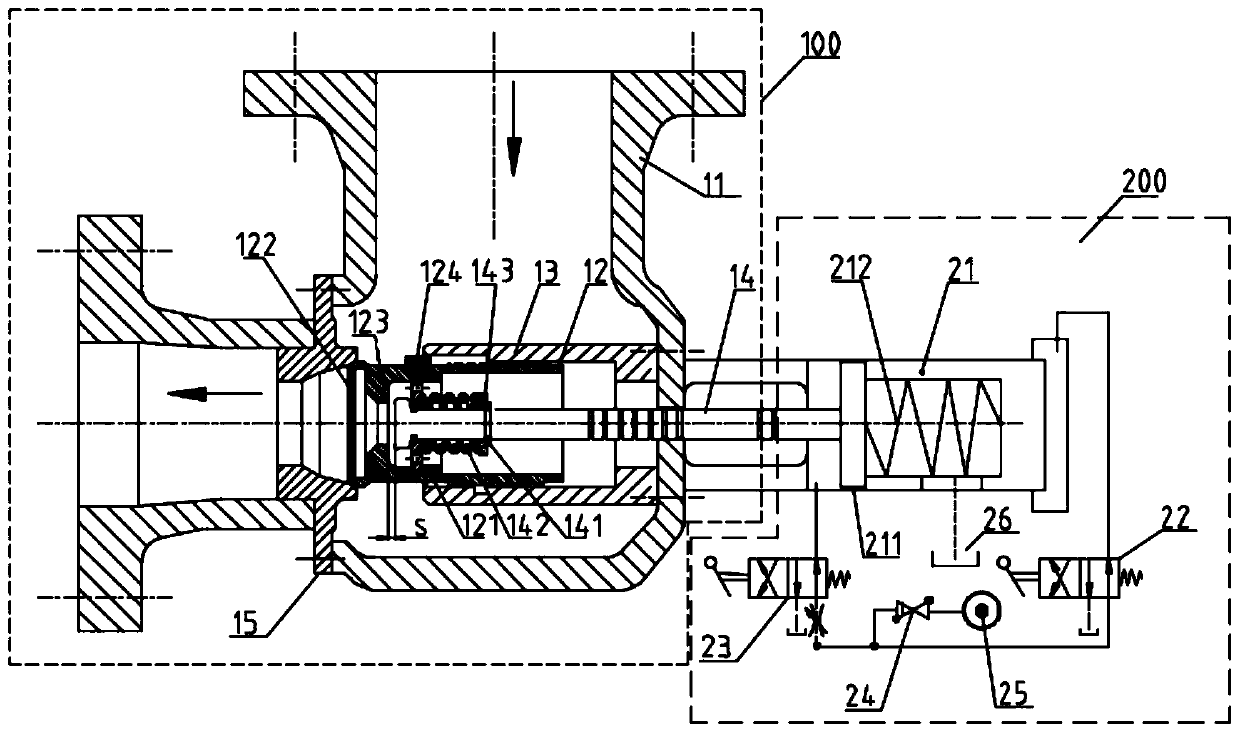

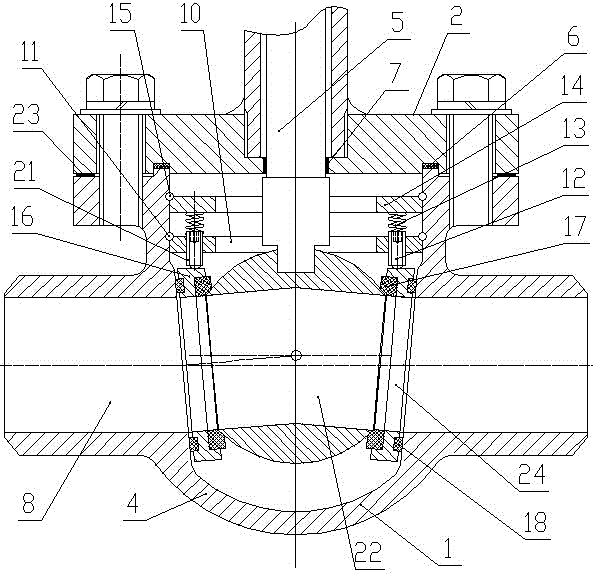

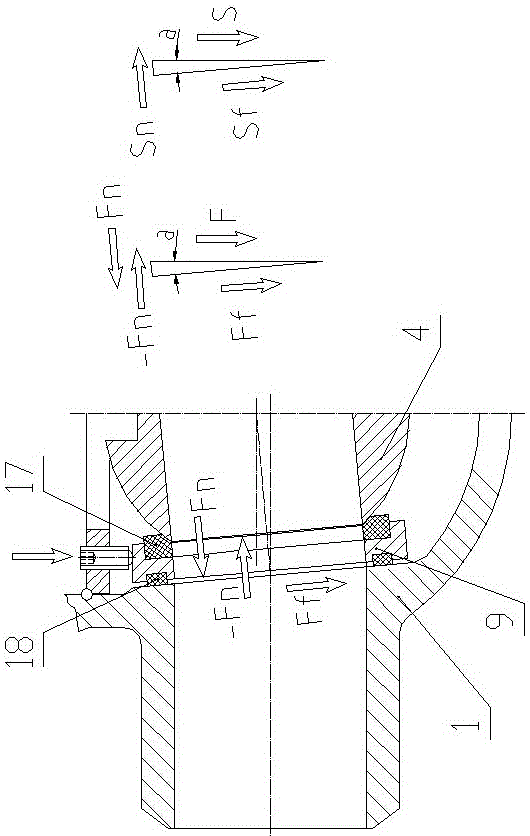

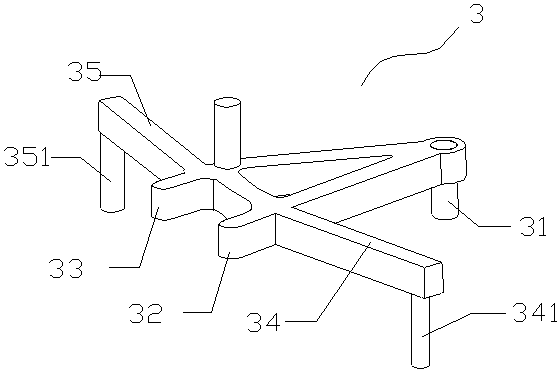

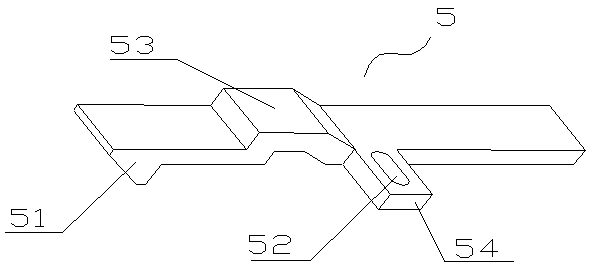

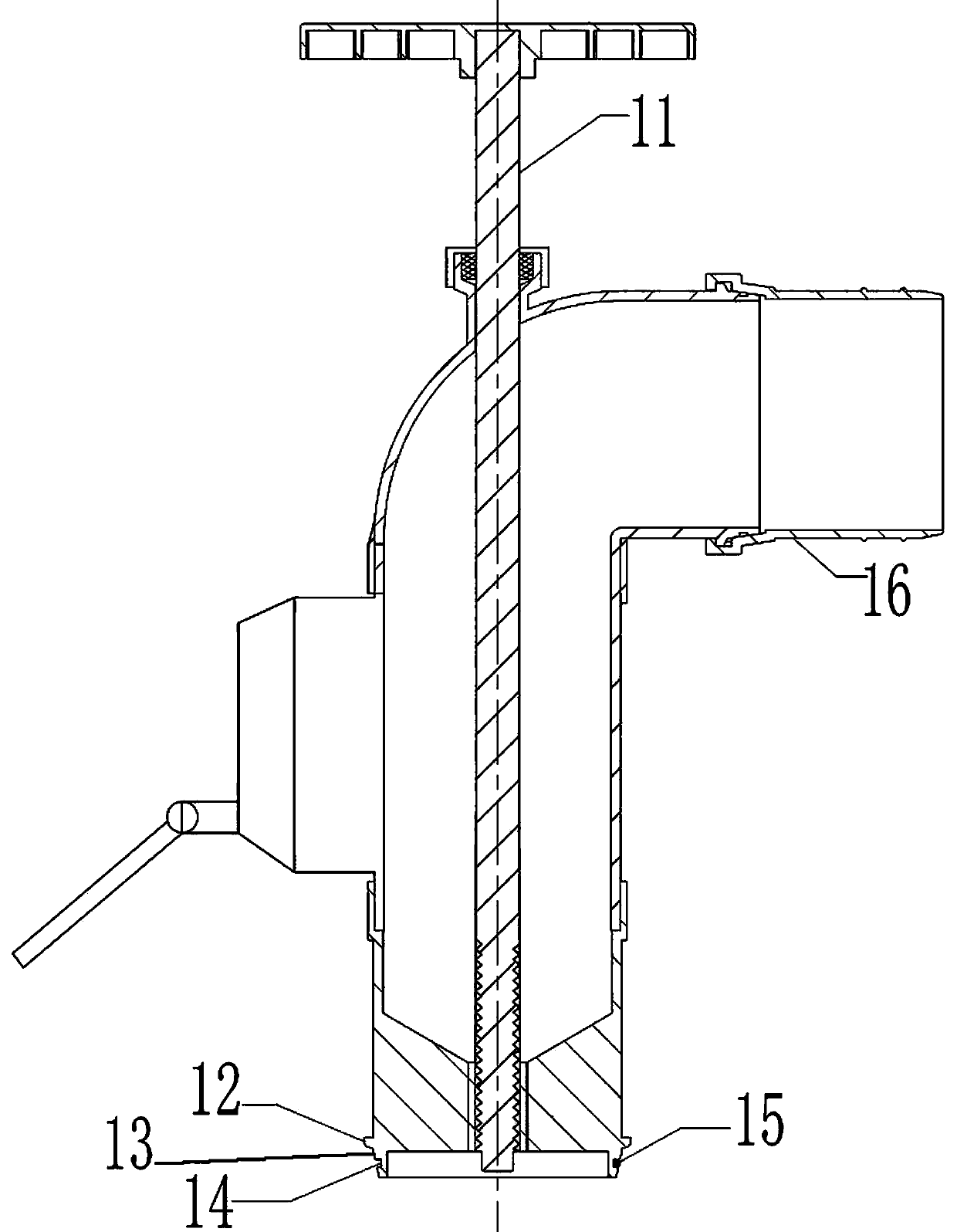

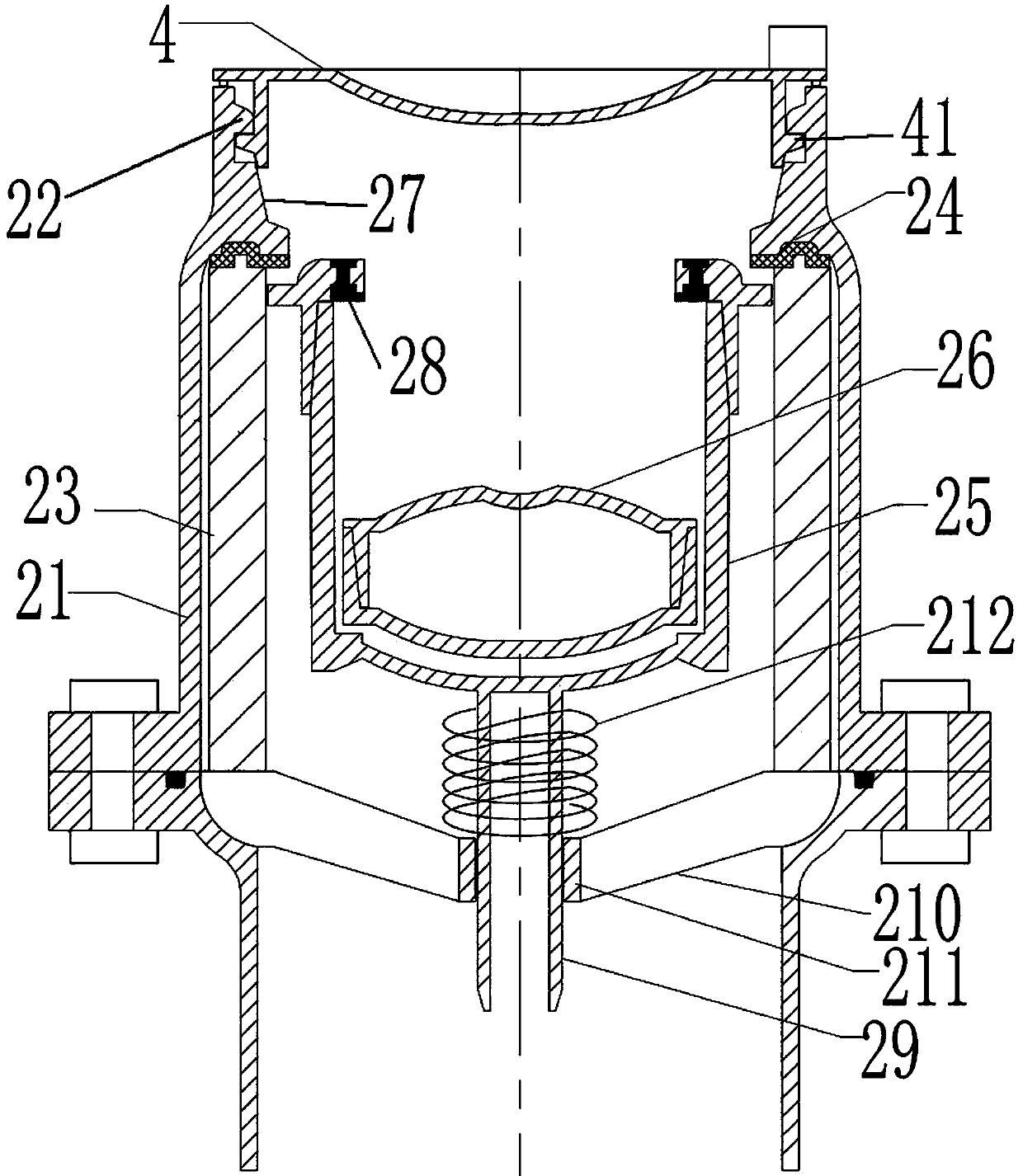

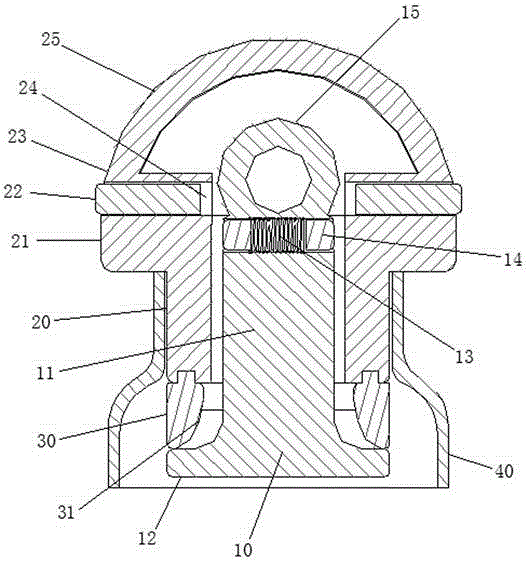

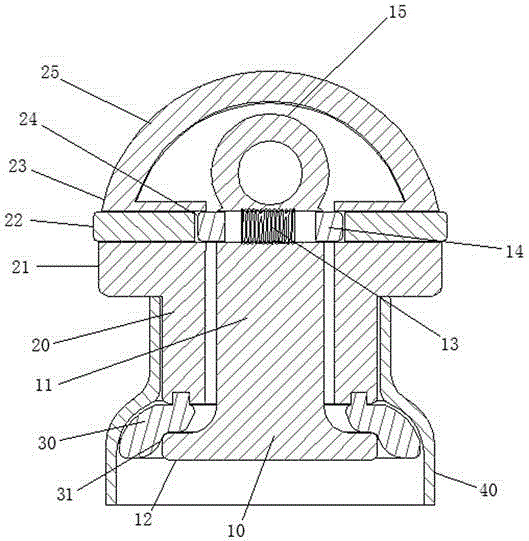

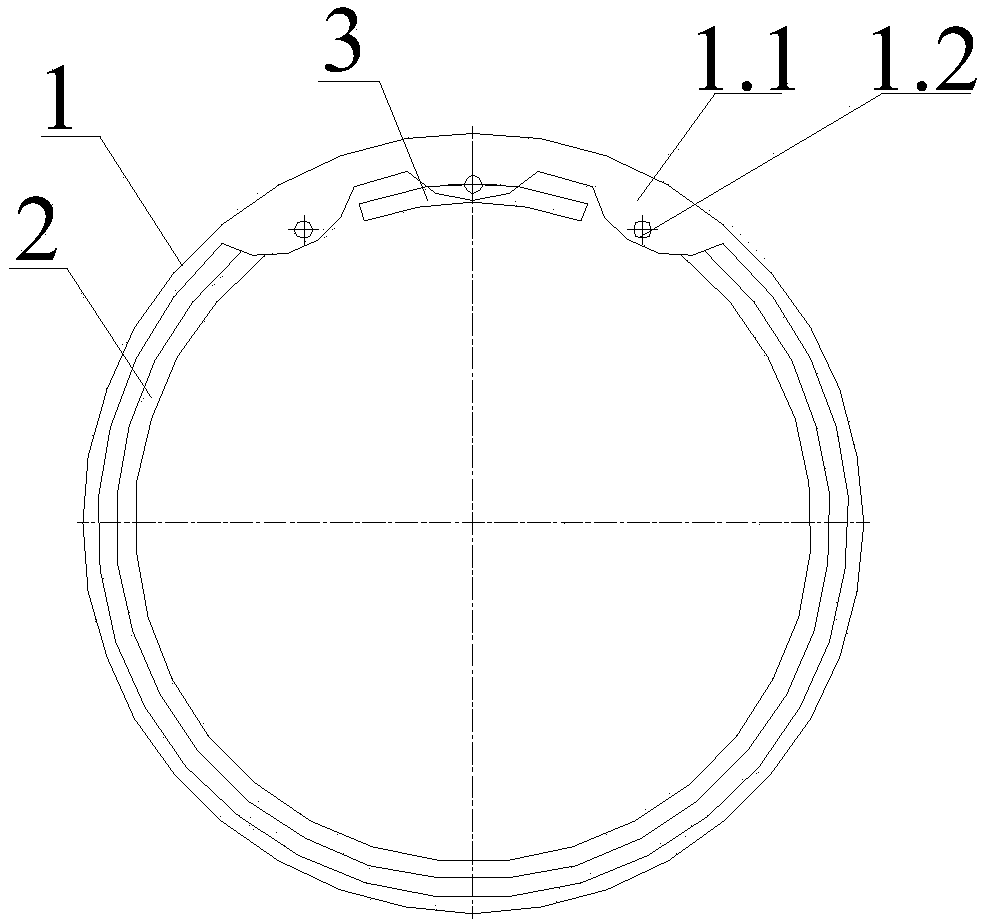

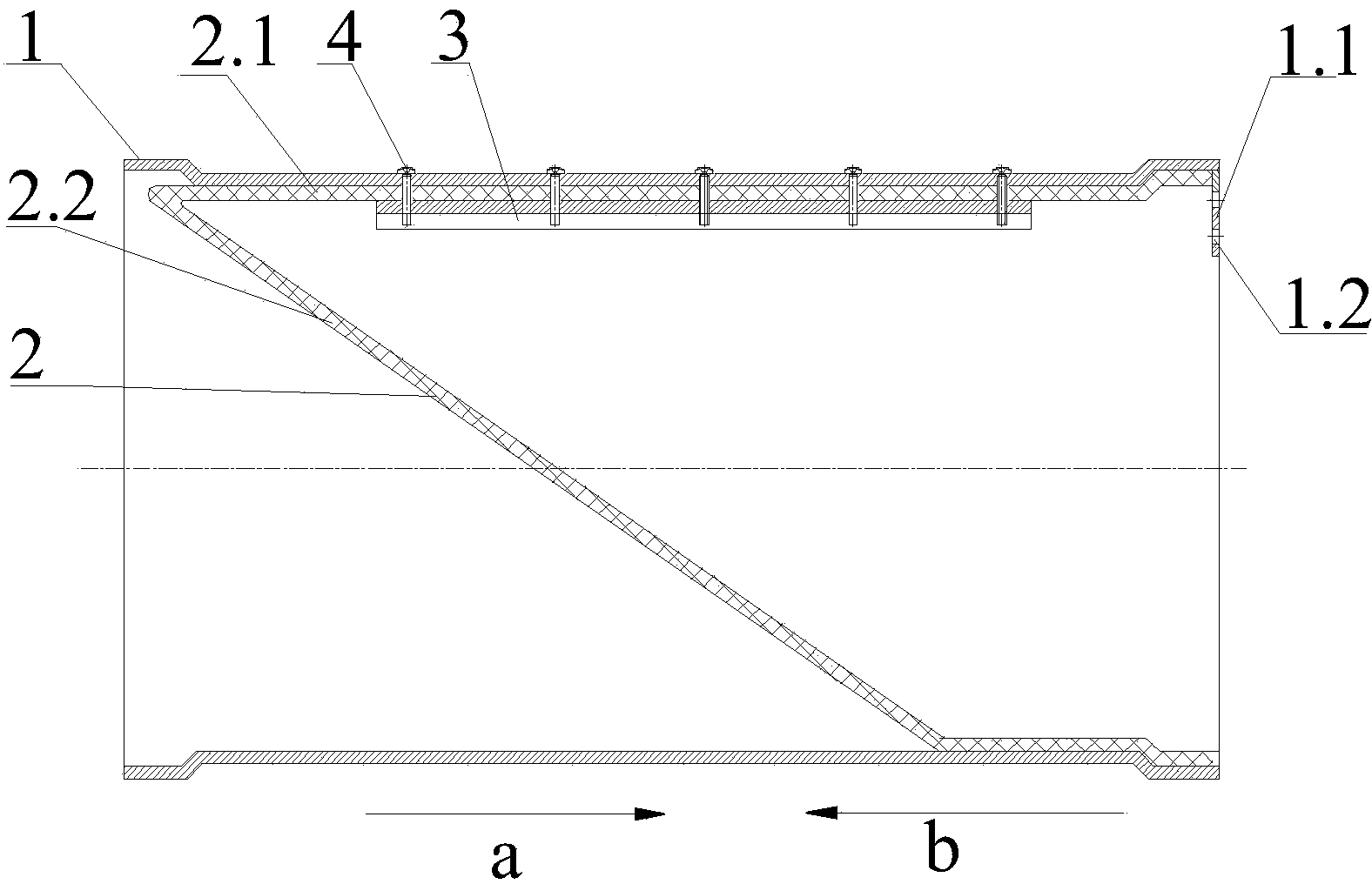

Fully automatic retarding clutch for washing machine

InactiveCN101173469ASmall opening forceReduce manufacturing costOther washing machinesToothed gearingsControl systemEngineering

The fully automatic deceleration clutch for washing machines relates to the technical field of washing machines. and the output shaft are respectively connected with the double drive gear mechanism, the brake wheel and the output shaft sleeve are opposite to each other, and the two-way drive is proportional, repeatedly swings and rotates, and relatively powerfully rubs and swings. In the dehydration working condition, through the locking function of the clutch device, the output shaft and the output shaft sleeve can be automatically combined, and at the same time, they can perform high-speed unidirectional continuous rotation and centrifugal dehydration. The structure is simple, the performance of the deceleration clutch of the conventional washing machine is improved, the structure of the control system is simplified, the noise of the washing machine is reduced, and the efficiency and service life of the washing machine are improved.

Owner:NINGGUO JULONG IND

Fully automatic retarding clutch for washing machine

InactiveCN101173470ASmall opening forceReduce manufacturing costOther washing machinesToothed gearingsControl systemEngineering

The invention relates to a full-automatic decelerating clutch for a washing machine, belonging to the technical field of washing machines, comprising an input shaft, an output shaft, an output shaft housing, an input shaft housing, a brake wheel and a double drive gear mechanism. The invention is characterized in that: the double drive gear mechanism is arranged inside the brake wheel, and the input shaft, the output shaft housing and the output shaft are respectively connected with the double drive gear mechanism; the brake wheel and the output shaft housing are reverse mutually, are dual-way driven in proportion, repeatedly swing and rotate, and rub and swing with a relative strength; under a dehydration working condition, via the locking function of the clutch, the output shaft is automatically combined with the output shaft housing, and simultaneously the output shaft and the output shaft housing continuously rotate with high speed in an unidirectional way, and the centrifugal dehydration is processed. The invention has the advantages of boasting simple structure, improving the performance of a decelerating clutch for a conventional washing machine, simplifying the structure of control system, reducing the noise of the washing machine and improving the efficacy and the service life of the washing machine.

Owner:NINGGUO JULONG IND

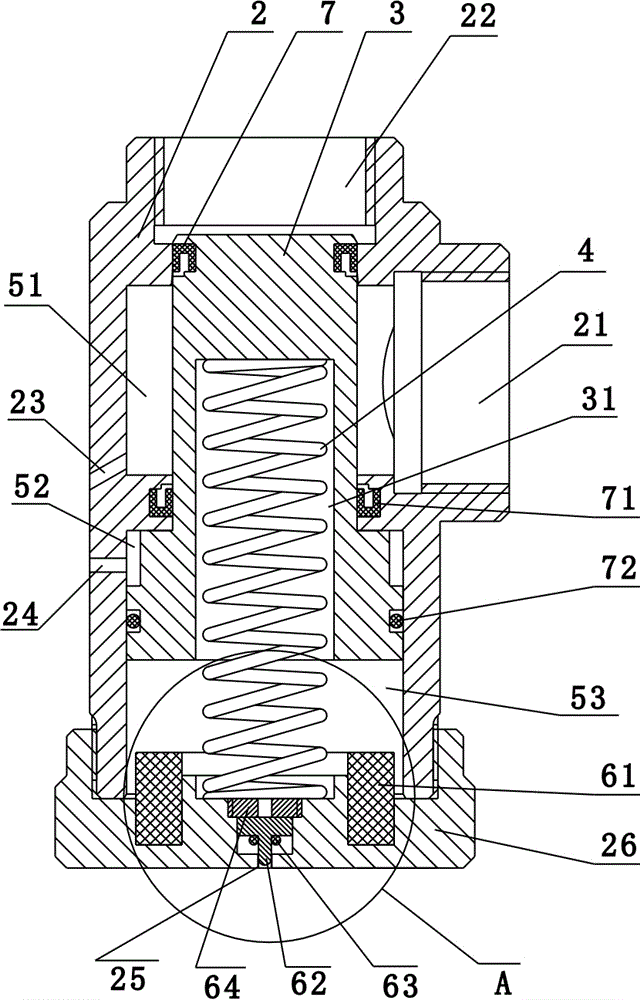

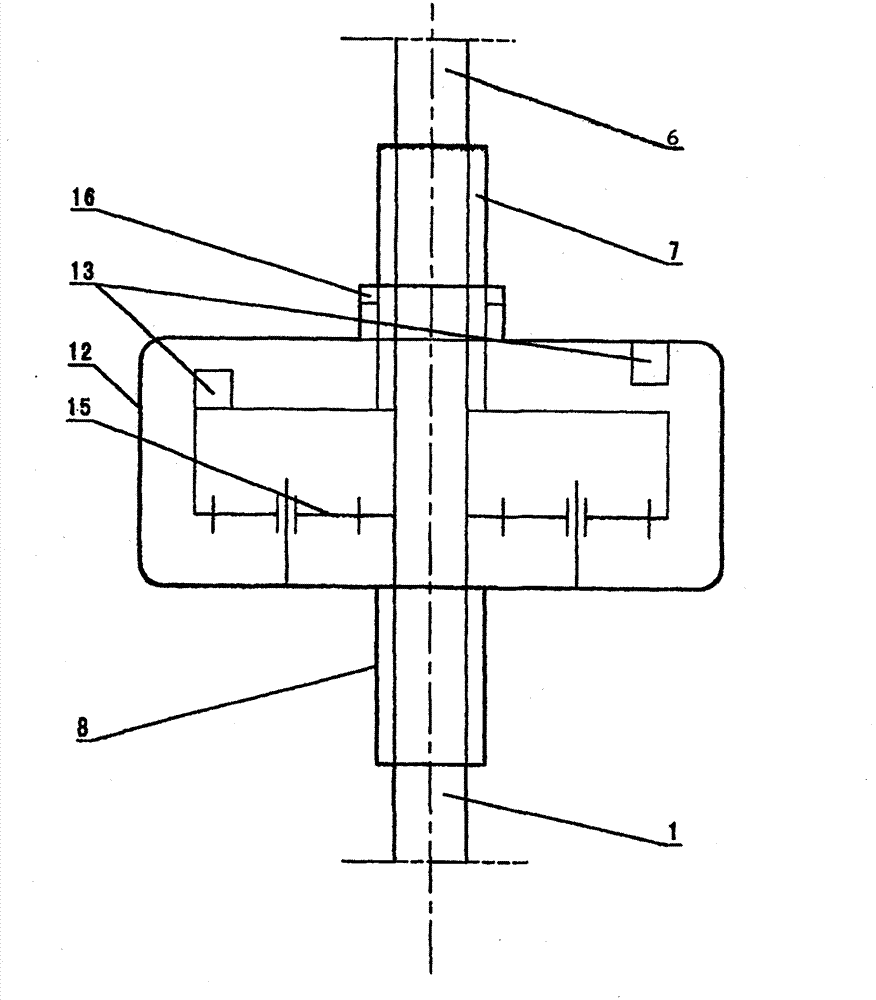

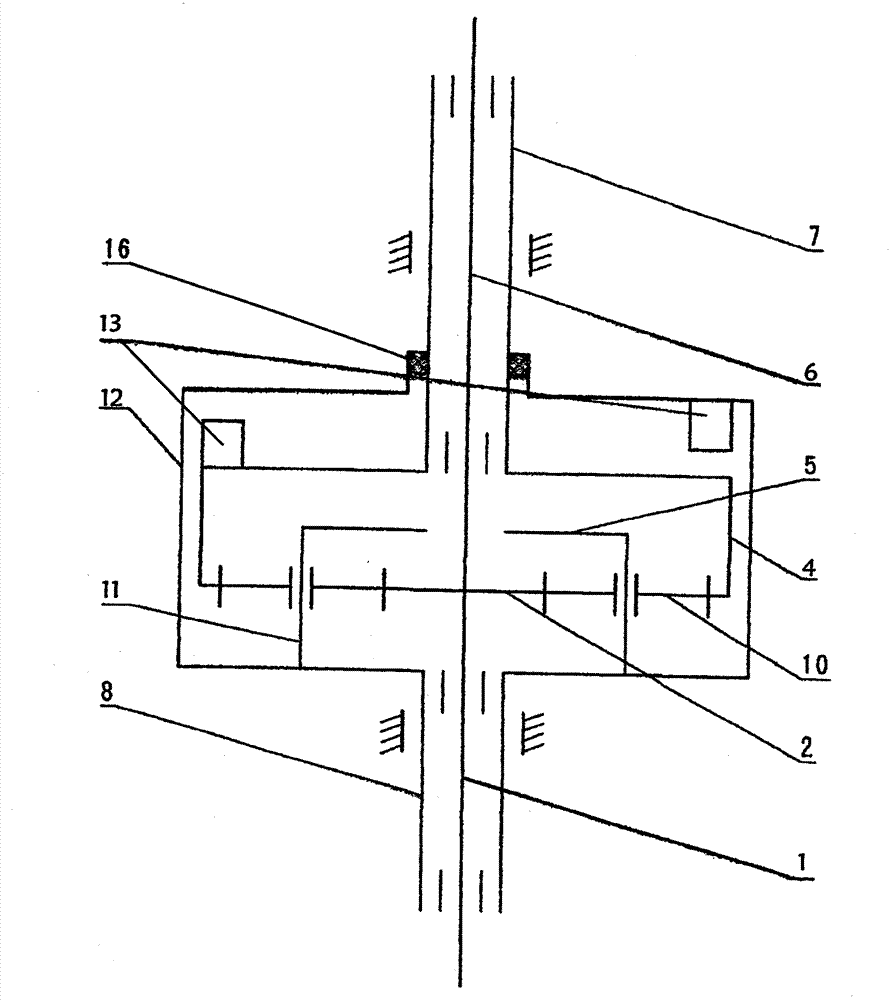

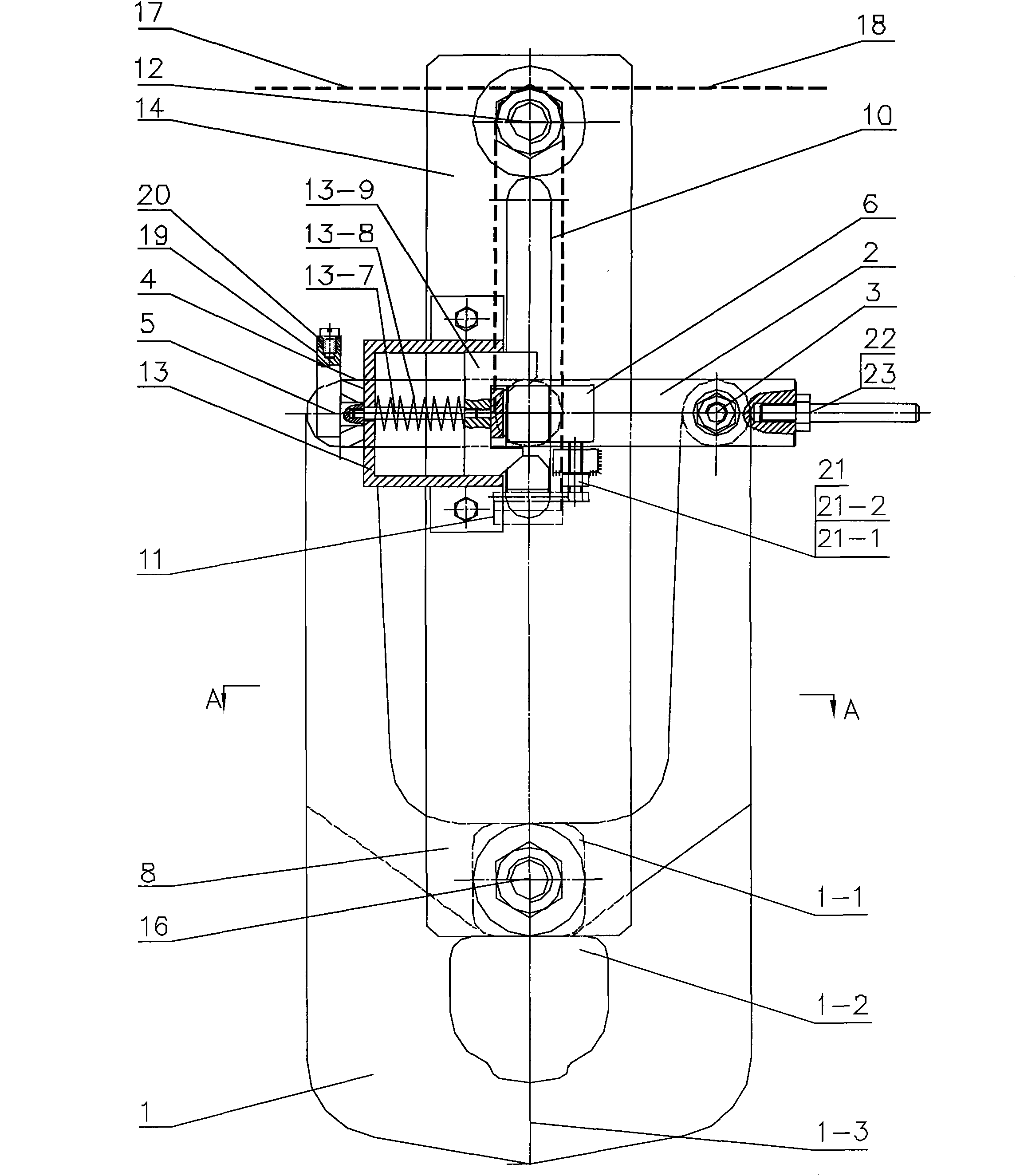

Full automatic speed reducing clutch for washing machine

InactiveCN1425823ASmall opening forceEliminate the effects ofOther washing machinesTextiles and paperGear wheelEngineering

The present invention relates to washing machine technology. The fully automatic speed reducing clutch consists of input shaft, input shaft sleeve, outupt shaft, output shaft sleeve, brake wheel and double-driven gear mechanism inside the brake wheel. The input shaft, the output shaft sleeve and the output shaft are connected separately to the double-driven gear mechanism; and between the brake wheel and the output shaft sleeve there is clutch unit. During washing, the output shaft and the outpuer shaft sleeve are rotated in opposite directions and in certain ratio to form repeated oscillation and rotation with strong kneading force. During dewatering, the clutch unit meshes the output shaft and the outupt shaft sleeve for high speed rotation in the same direction for centrifugal dewatering. The present invention makes washing machine simple, low in noise and long in service life.

Owner:ANHUI JULONG TRANSMISSION TECH

Tong-type automatic unhooking device

The invention discloses a tong-type automatic unhooking device which belongs to the technical field of mechanical lifting and towing devices. The invention is characterized in that two tong pieces are symmetrically arranged; one end of each tong piece is hinged with one end of a connecting rod; the other end of the connecting rod is connected with a sliding block shaft; one end of the sliding block shaft is connected with an opening sliding block; the sliding block shaft and the opening sliding block are arranged in a sliding chute on a first drawplate and a sliding chute on a second drawplate; a post rod is also arranged in the sliding chute; one side of the post rod, which is different from the sliding block shaft, is connected with a connecting shaft; the other end of the sliding block shaft is locked in a self-locking device; the self-locking device is arranged on the outer side surface of the first drawplate; the inner side surfaces of the first drawplate and second drawplate are connected with a bracket; the bracket is connected with a drive unit linear stepping motor; one end of the first drawplate is connected with one end of the second drawplate through an axis pin; and the other ends of the first drawplate and second drawplate are hinged with the tong pieces. The device has the advantages of simple structure, small opening force, convenient operation, safe and reliable operation, accurate unhooking landing point and favorable centering performance, and can be remotely controlled.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

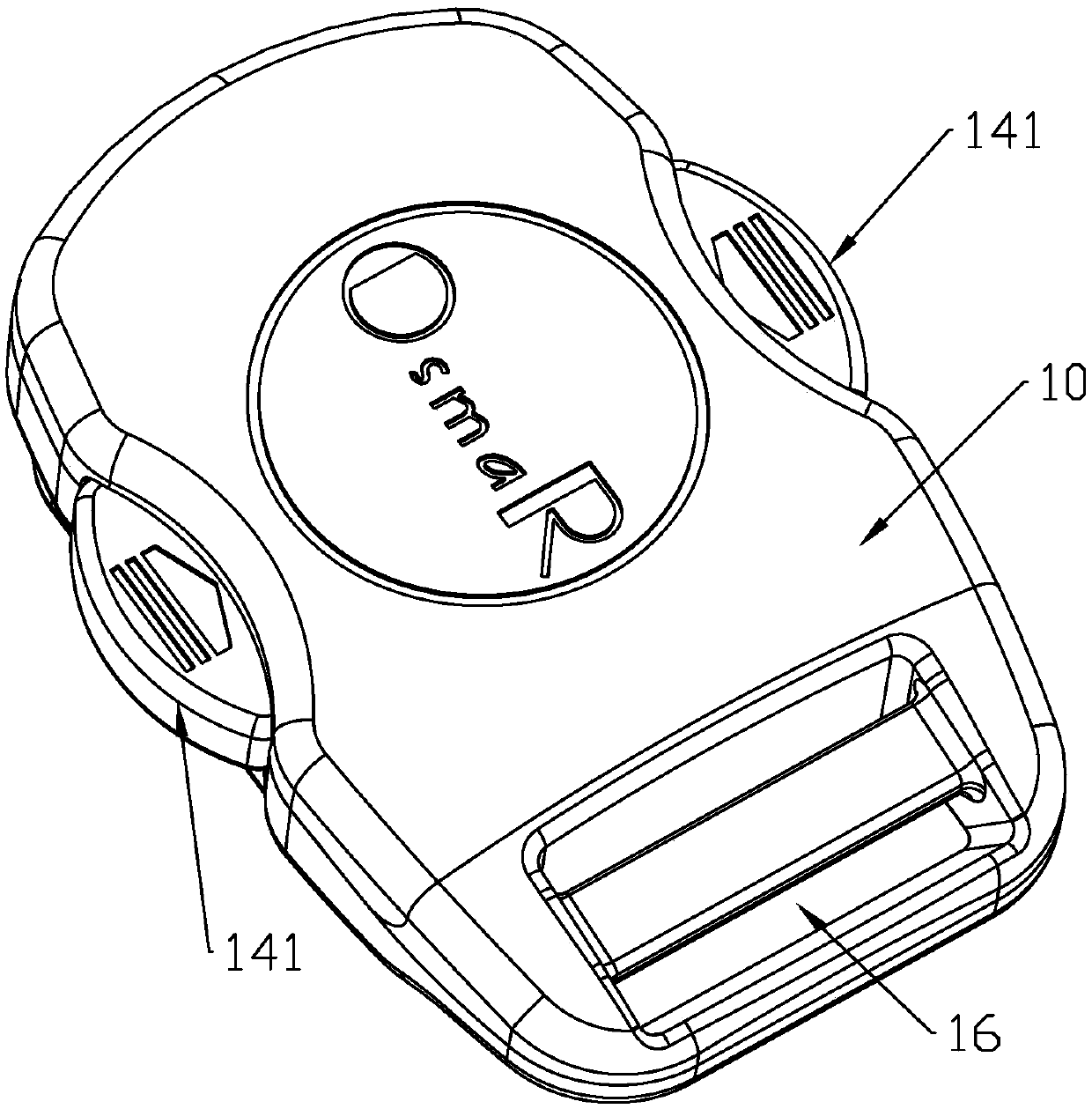

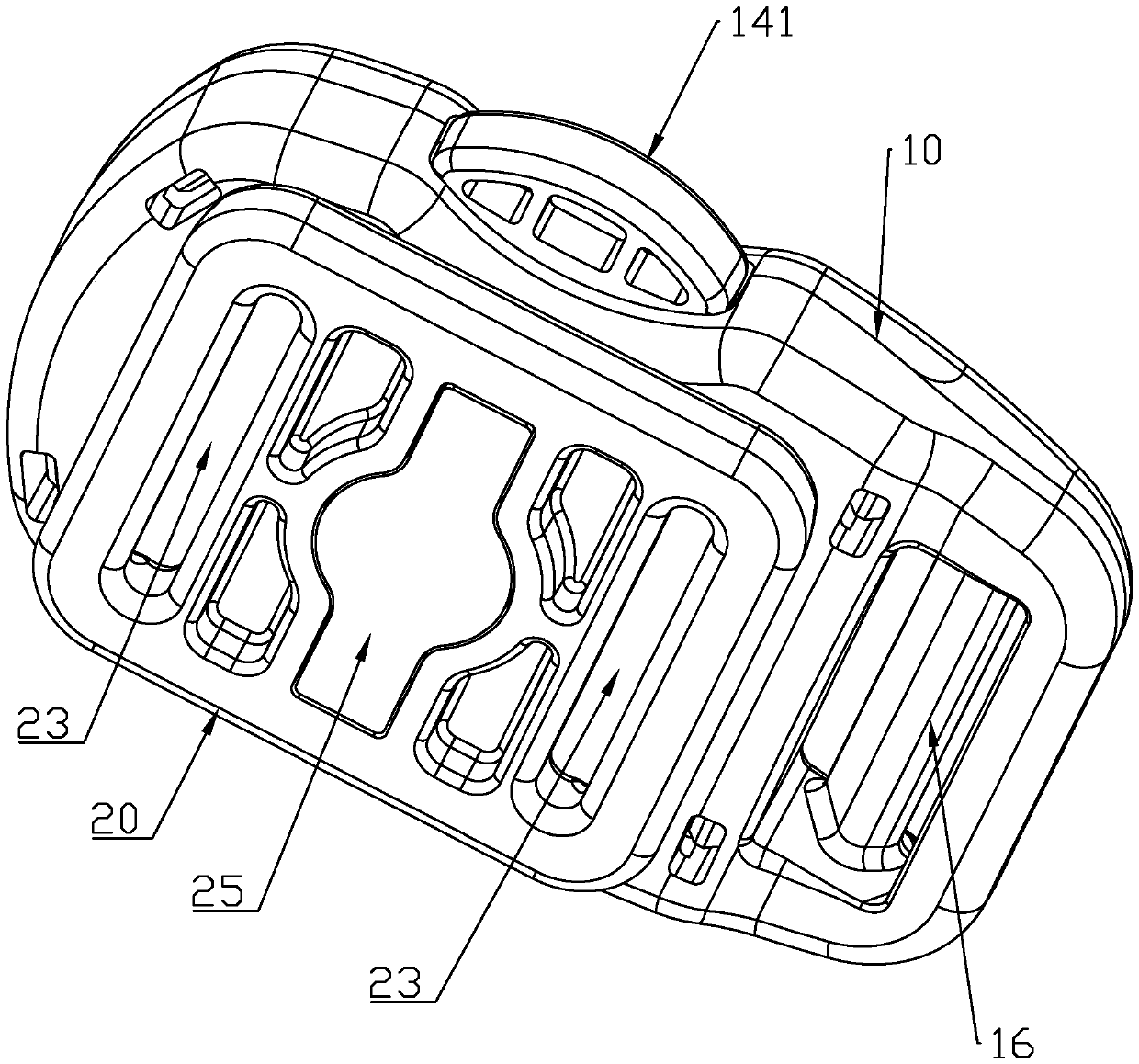

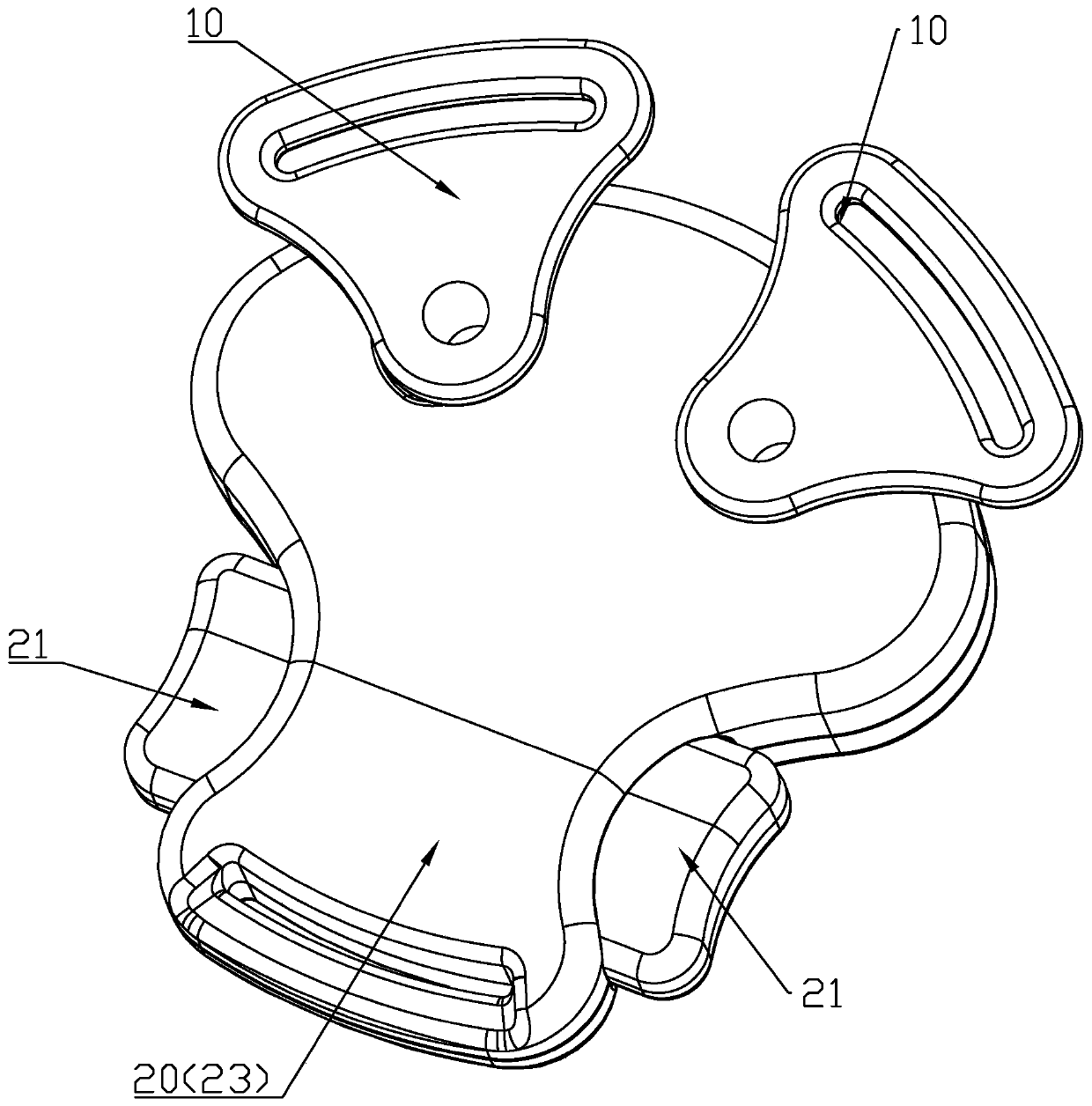

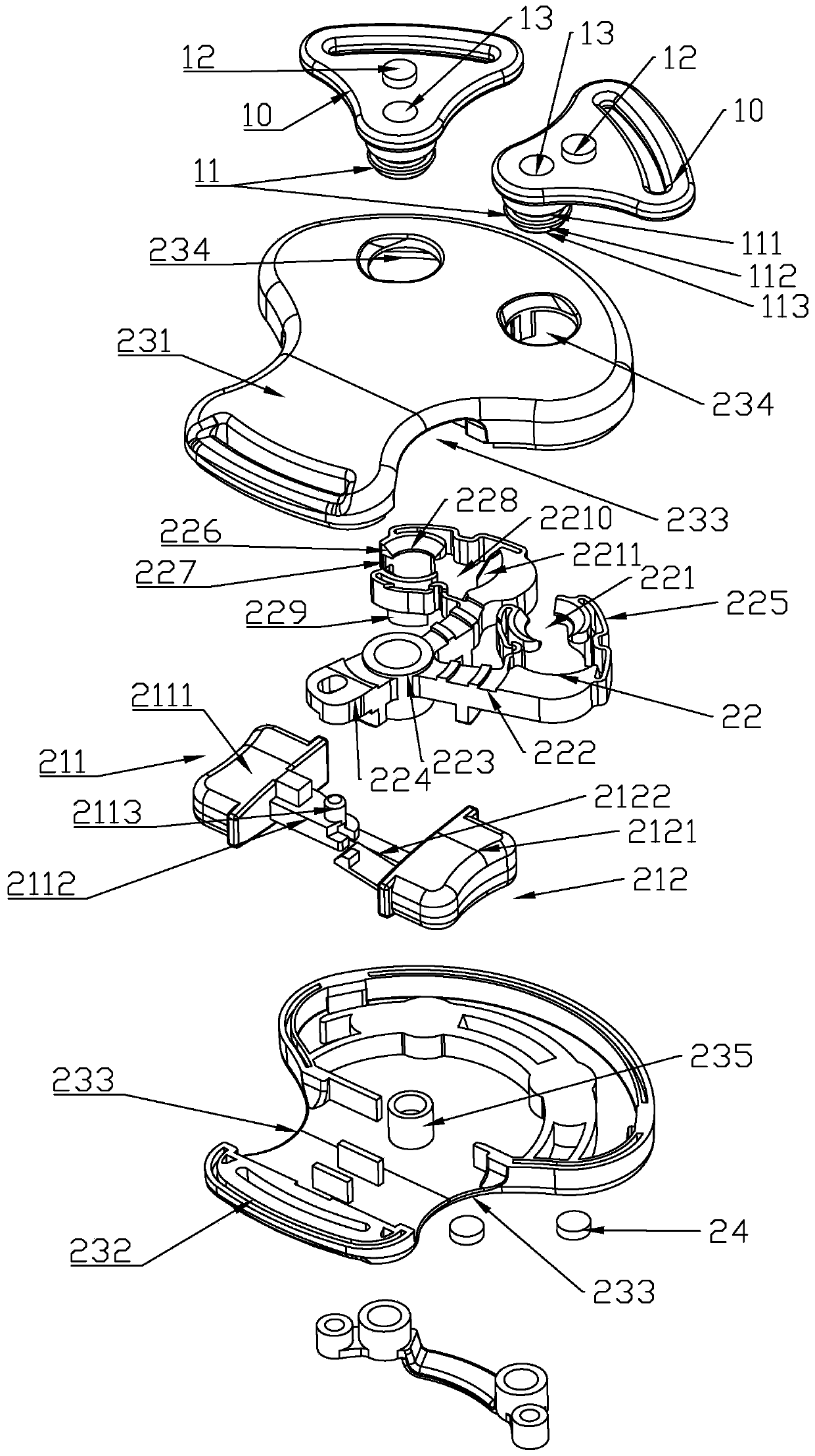

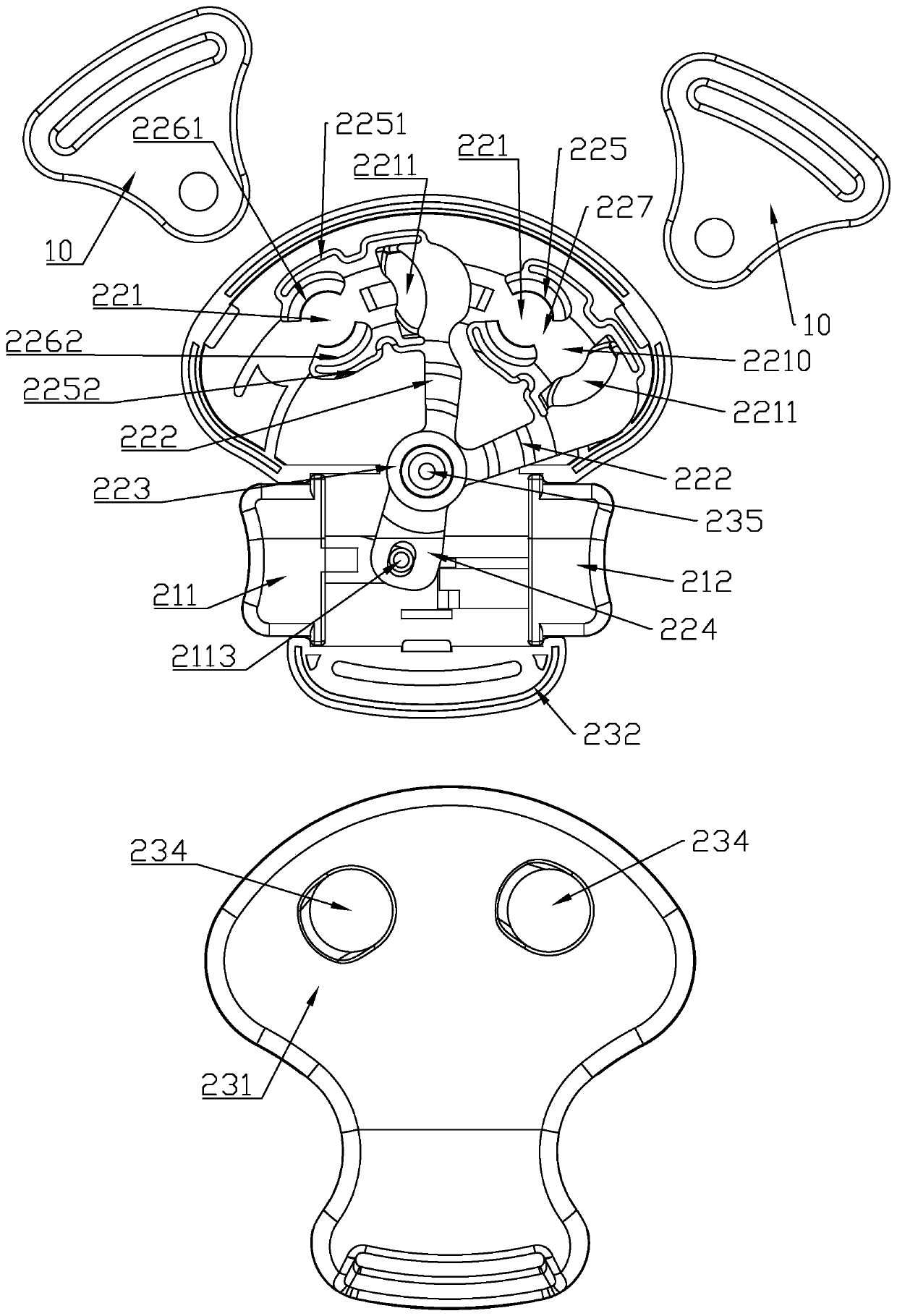

Magnetic buckle

A magnetic buckle comprises a buckle seat assembly and a lock catch assembly, wherein a first magnet is arranged in the buckle seat assembly, a lock hole corresponding to the first magnet is formed inone side of the buckle seat assembly, facing the lock catch assembly, the size of the lock hole is adjustable, a lock bolt capable of being inserted into the lock hole is arranged on one side of thelock catch assembly, facing the buckle seat assembly, a second magnet corresponding to the lock bolt is arranged in the lock catch assembly, pressing parts are respectively arranged on two opposite sides of the buckle seat assembly, an unlocking part linked by the pressing parts is arranged in the buckle seat assembly, and the unlocking part faces the lock hole; when the lock hole of the buckle seat assembly is close to the lock bolt of the lock catch assembly, the first magnet and the second magnet attract each other to guide the lock bolt in entering the lock hole so as to achieve locking; when the pressing parts are pressed oppositely, the unlocking part moves towards the combined parts of the lock bolt and the buckle seat assembly so as to space the combined parts of the lock bolt andthe buckle seat assembly and reduce the attraction force between the first magnet and the second magnet so as to facilitate the separation of the buckle seat assembly and the lock catch assembly.

Owner:LIAN YANG PLASTIC (SHEN ZHEN) CO LTD

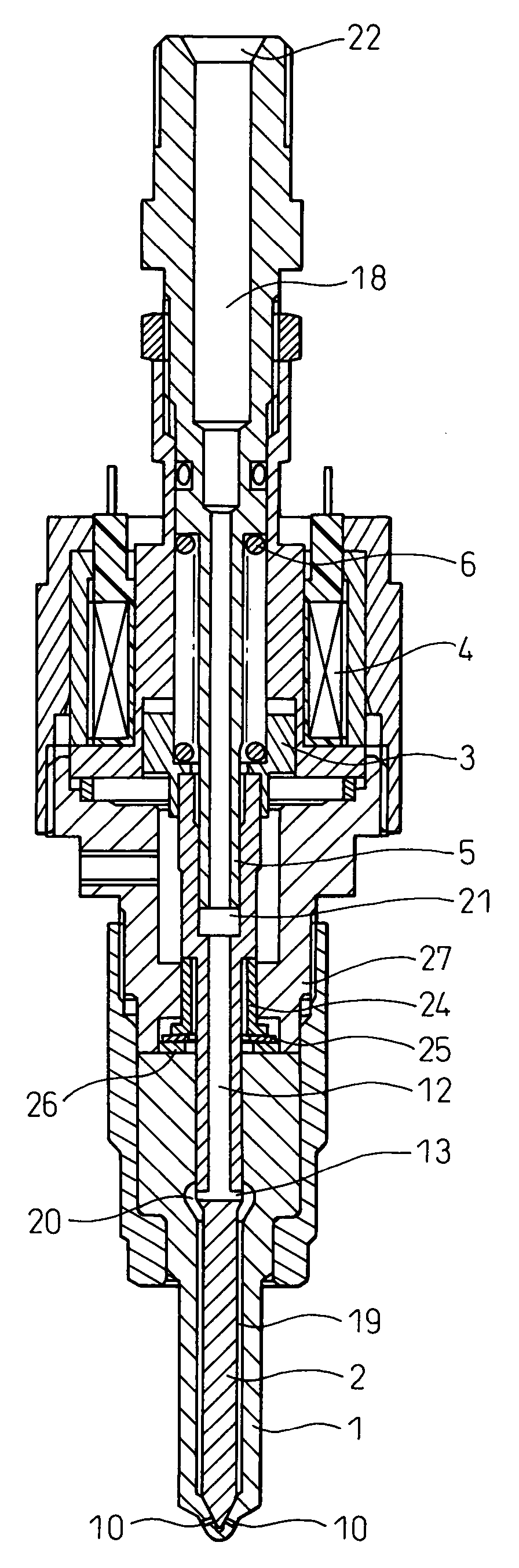

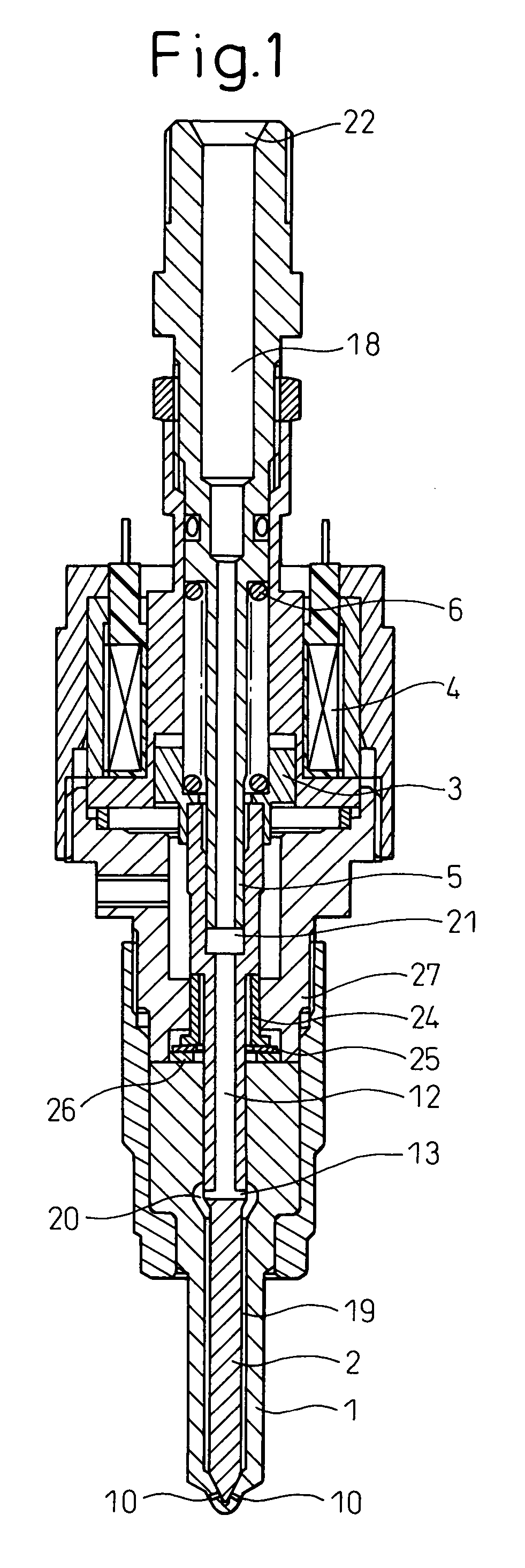

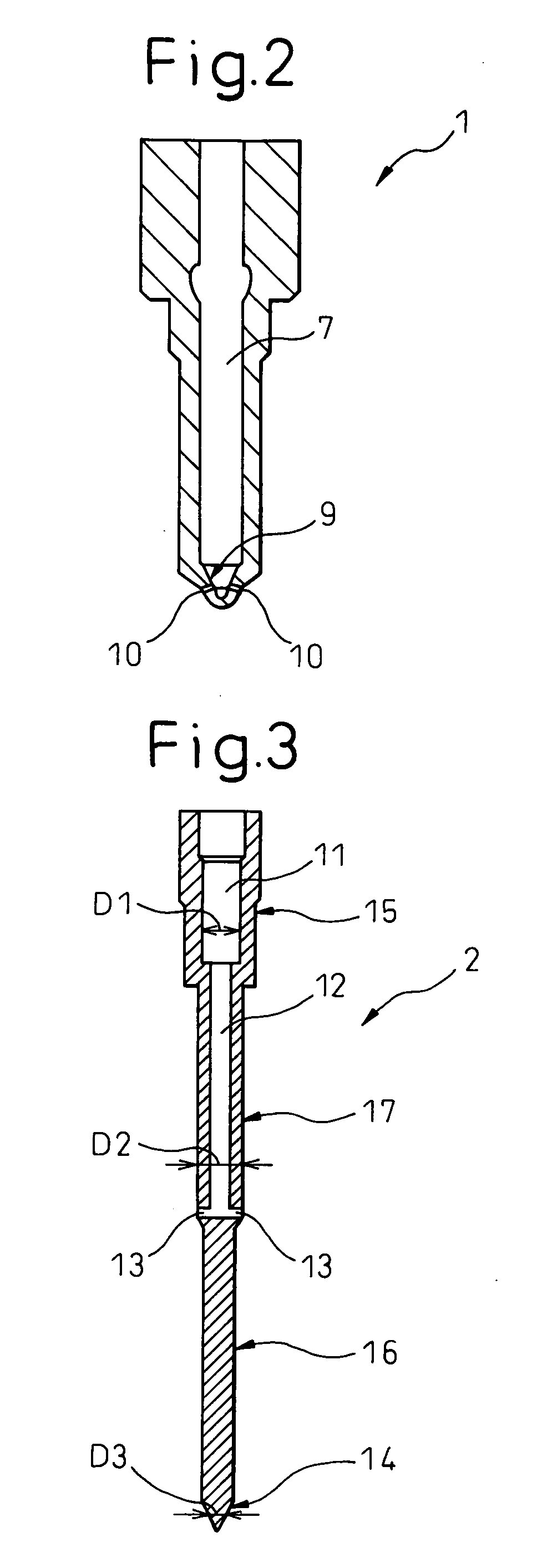

Fuel injection valve

InactiveUS20050072865A1Great opening forceImprove performanceOperating means/releasing devices for valvesSpray nozzlesThermodynamicsMechanics

A fuel injection valve includes a fuel injection port, a needle for cutting the fuel flow into the fuel injection port and a needle mover for moving the needle away from the fuel injection port and allowing the fuel to flow into the fuel injection port. When the needle is moved away from the fuel injection port by the needle mover, the force is applied by a force applicator to the needle away from the fuel injection port only during the period when the needle is moved away from the fuel injection port to less than a predetermined degree.

Owner:TOYOTA JIDOSHA KK +1

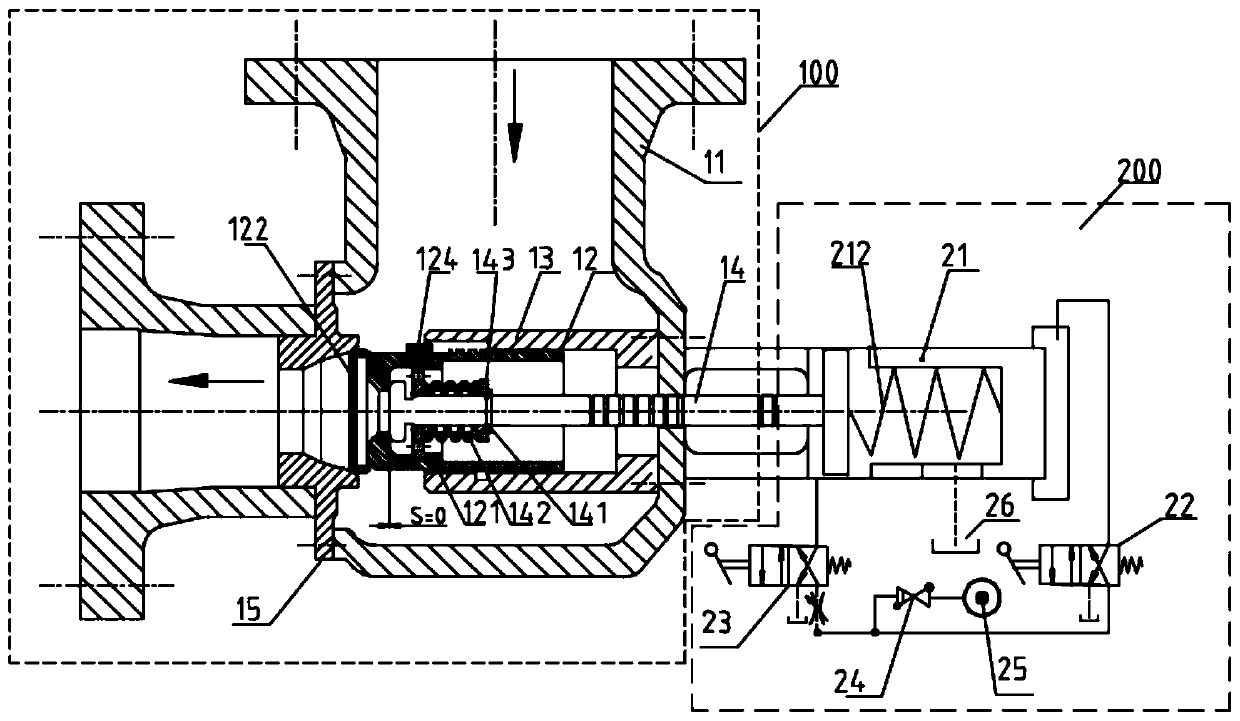

Fully automatic retarding clutch for washing machine

InactiveCN101173471ASmall opening forceReduce manufacturing costOther washing machinesToothed gearingsControl systemEngineering

The invention relates to a full-automatic decelerating clutch for a washing machine, belonging to the technical field of washing machines, comprising an input shaft, an output shaft, an output shaft housing, an input shaft housing, a brake wheel and a double drive gear mechanism. The invention is characterized in that: the double drive gear mechanism is arranged inside the brake wheel, and the input shaft, the output shaft housing and the output shaft are respectively connected with the double drive gear mechanism; the brake wheel and the output shaft housing are reverse mutually, are dual-way driven in proportion, repeatedly swing and rotate, and rub and swing with a relative strength; under a dehydration working condition, via the locking function of the clutch, the output shaft is automatically combined with the output shaft housing, and simultaneously the output shaft and the output shaft housing continuously rotate with high speed in an unidirectional way, and the centrifugal dehydration is processed. The invention has the advantages of simple structure, improving the performance of a decelerating clutch for a conventional washing machine, simplifying the structure of control system, reducing the noise of the washing machine and improving the efficacy and the service life of the washing machine.

Owner:NINGGUO JULONG IND

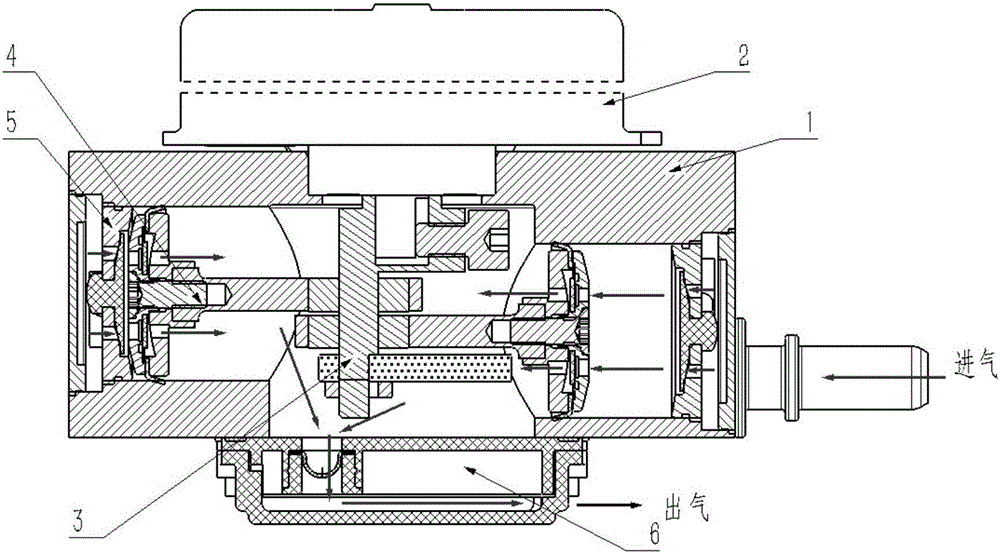

Combined piston type electronic vacuum pump for automobile

InactiveCN105804967AEvenly sealedEven by forceEccentric-shaftsPositive displacement pump componentsDynamic balanceEngineering

The invention discloses a combined piston type electronic vacuum pump for an automobile. The combined piston type electronic vacuum pump comprises a valve body, an electric motor assembly, a noise reduction and exhaust assembly, an eccentric shaft assembly, two piston assemblies and two air inlet one-way valves. The valve body is provided with a center inner cavity, a motor mounting hole is formed in the upper end face of the valve body, the valve body is provided with a left ladder hole and a right ladder hole, and the left ladder hole, the right ladder hole and the motor mounting hole are all communicated with the center inner cavity; a combined type dynamic balance transmission eccentric shaft assembly is mounted in the center inner cavity, the center inner cavity is connected with the noise reduction and exhaust assembly for carrying out covering and sealing, and the electric motor assembly is mounted in the motor mounting hole; and the end face of the left ladder hole and the end face of the right ladder hole are connected with end covers for sealing, the piston assemblies and the air inlet one-way valves are arranged in the left ladder hole and the right ladder hole, and the electric motor assembly is mounted on the left ladder hole and the right ladder hole, and is connected with the eccentric shaft assembly to drive the assembly to rotate. A new transmission balance mechanism, a piston structure and the like are adopted in the vacuum pump, the assembly cost and the machining cost are reduced, the assembly safety is improved, sealing of the pump is obviously improved, the noise of the pump is obviously lowered, the service life of the pump is obviously prolonged, and various requirements of automobile use can be met.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

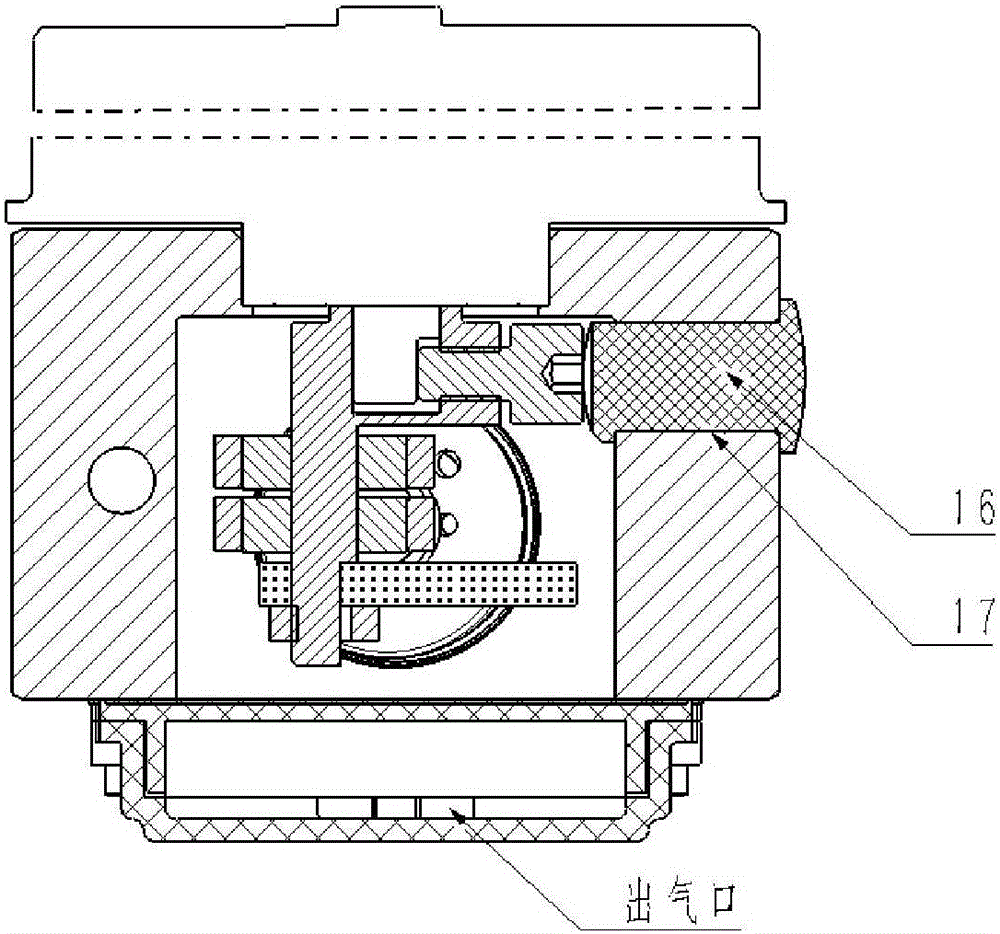

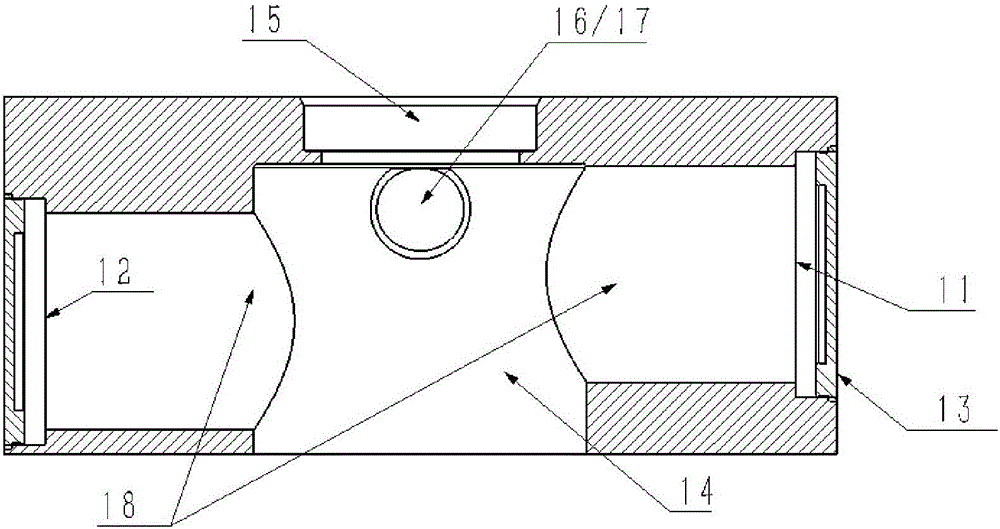

Integrated selection valve

InactiveCN106090396ANo stuck phenomenonAvoid strong impactOperating means/releasing devices for valvesLift valveAssembly structurePiston

The invention discloses an integrated selection valve capable of being connected and matched with a drive device. The selection valve comprises a valve body, a piston capable of moving in the valve body and a reset piece. The valve body is provided with an air inlet and an air outlet. The piston is connected in the valve body in a sealing manner. A first space is formed between the upper portion of the piston and the inner wall of the valve body. The air inlet communicates with the first space. The valve body is provided with a first channel communicating with the first space and the drive device. A second space is formed between the lower portion of the piston and the inner wall of the valve body. The valve body is provided with a second channel communicating with the second space and the drive device. A third space is further formed between the bottom of the piston and the valve body and internally provided with a buffering structure capable of buffering the piston when the piston moves along the valve body. The integrated selection valve is small in opening force and good in sealing performance, action tests of 500 times can be achieved, the assembled structure is simple, and the service life is long.

Owner:浙江信达可恩消防股份有限公司

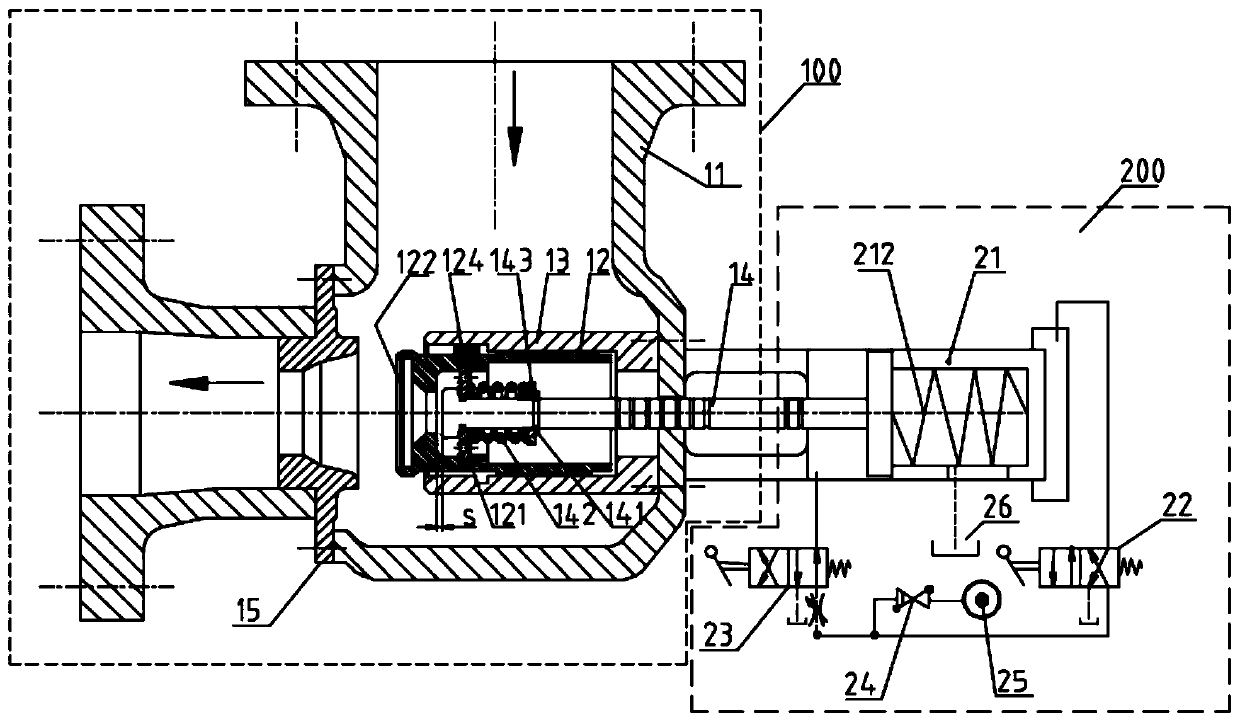

Full-automatic deceleration clutch for washing machine

InactiveCN102787468ASmall opening forceReduce manufacturing costOther washing machinesTextiles and paperControl systemEngineering

The invention discloses a full-automatic deceleration clutch for a washing machine and relates to the technical field of washing machines. The full-automatic deceleration clutch is mainly composed of an input shaft, an output shaft, an output shaft sleeve, an input shaft sleeve, a brake wheel and a dual drive gear mechanism installed in the brake wheel. The input shaft, the output shaft sleeve and the output shaft are respectively connected with the dual drive gear mechanism, and the brake wheel and the output shaft sleeve are in reverse directions, are driven in a bi-directional mode in proportion, repeatedly swing and rotate and perform relative strong-force twisting. On dehydration working conditions, by locking effect of a clutch device, the output shaft and the output shaft sleeve can be automatically combined with each other and perform high-speed unidirectional continuous rotation simultaneously, and centrifugal dehydration is performed. The full-automatic deceleration clutch is simple in structure, the performance is improved on the basis of a deceleration clutch of a conventional washing machine, a structure of a control system is simplified, the noise of the washing machine is lowered, the effect of the washing machine is improved, and the service life of the washing machine is prolonged.

Owner:NINGGUO JULONG IND

Tinplate tear-off lid forming process

The invention provides a tinplate tear-off lid forming process which comprises the following steps: cold rolling: carrying out preliminary cold rolling and secondary cold rolling in sequence on a tinplate; wave shearing of a coiled material: cutting a tinplate coiled material, and cutting off boundary materials of a wave-shaped plate; printing and coating: coating the inner and outer surfaces of the plate with films, and drying the films; lid punching: punching the plate to form a lid blank, and carrying out stretching and cooling; edge curling: pre-forming a countersunk rib, and inwards curling the edge of the lid blank into a closed groove edge to form a base lid; gluing: carrying out gluing and then drying; blistering: blistering the surface of the base lid for 3 times, so as to form a rivet fastener with a cavity; line engraving; riveting: riveting a pull ring with the rivet fastener on the base lid; embossing. The tinplate tear-off lid forming process has the beneficial effects that by the adoption of a tinplate material which is cold-rolled twice for manufacturing the tear-off lid, the pressure resistance and the corrosion resistance of the tear-off lid are improved, and the opening force of the tear-off lid is reduced; furthermore, the material thickness is reduced, so that the cost is reduced, and environmental protection is facilitated.

Owner:青岛北琪实业有限公司

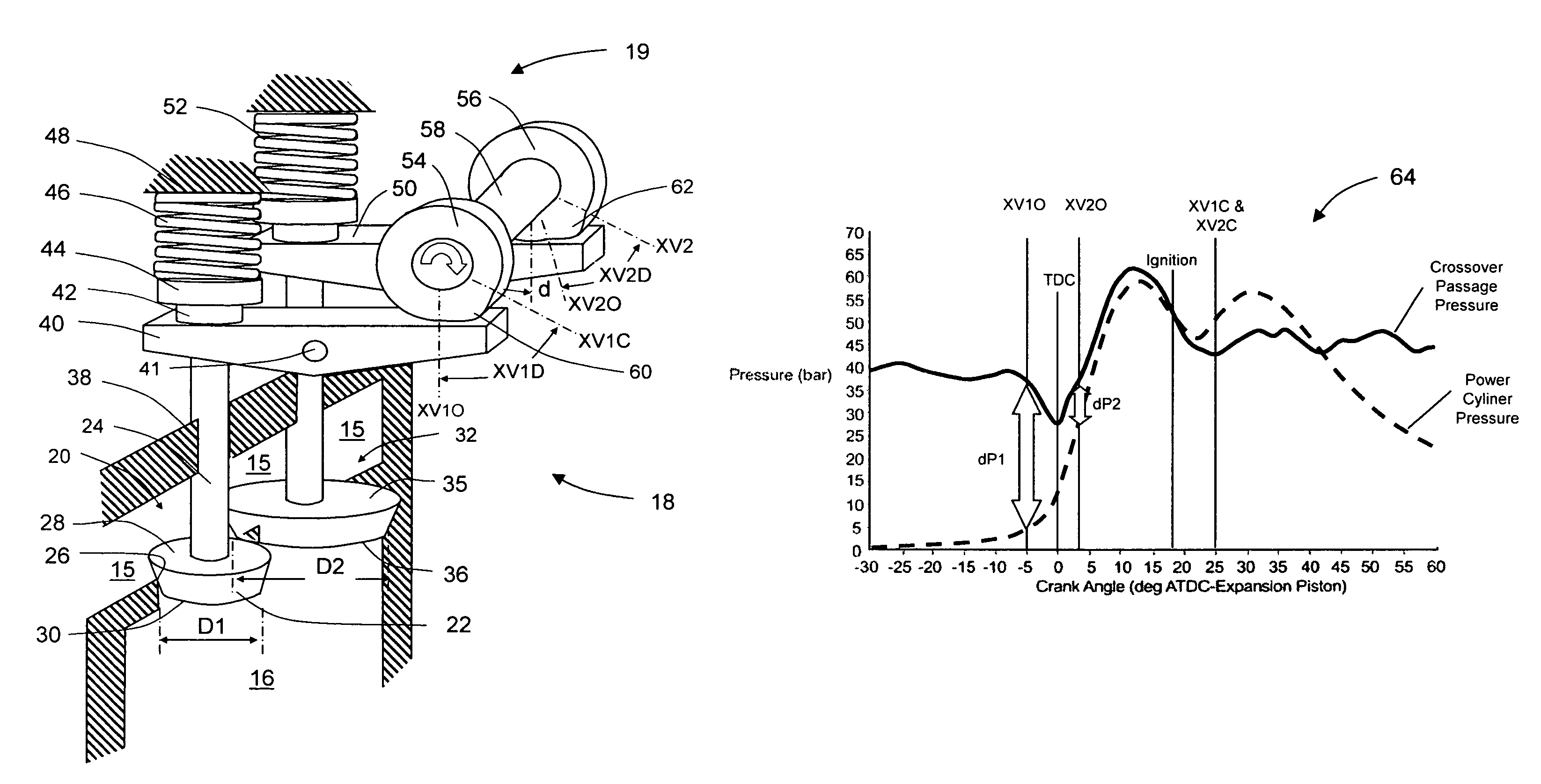

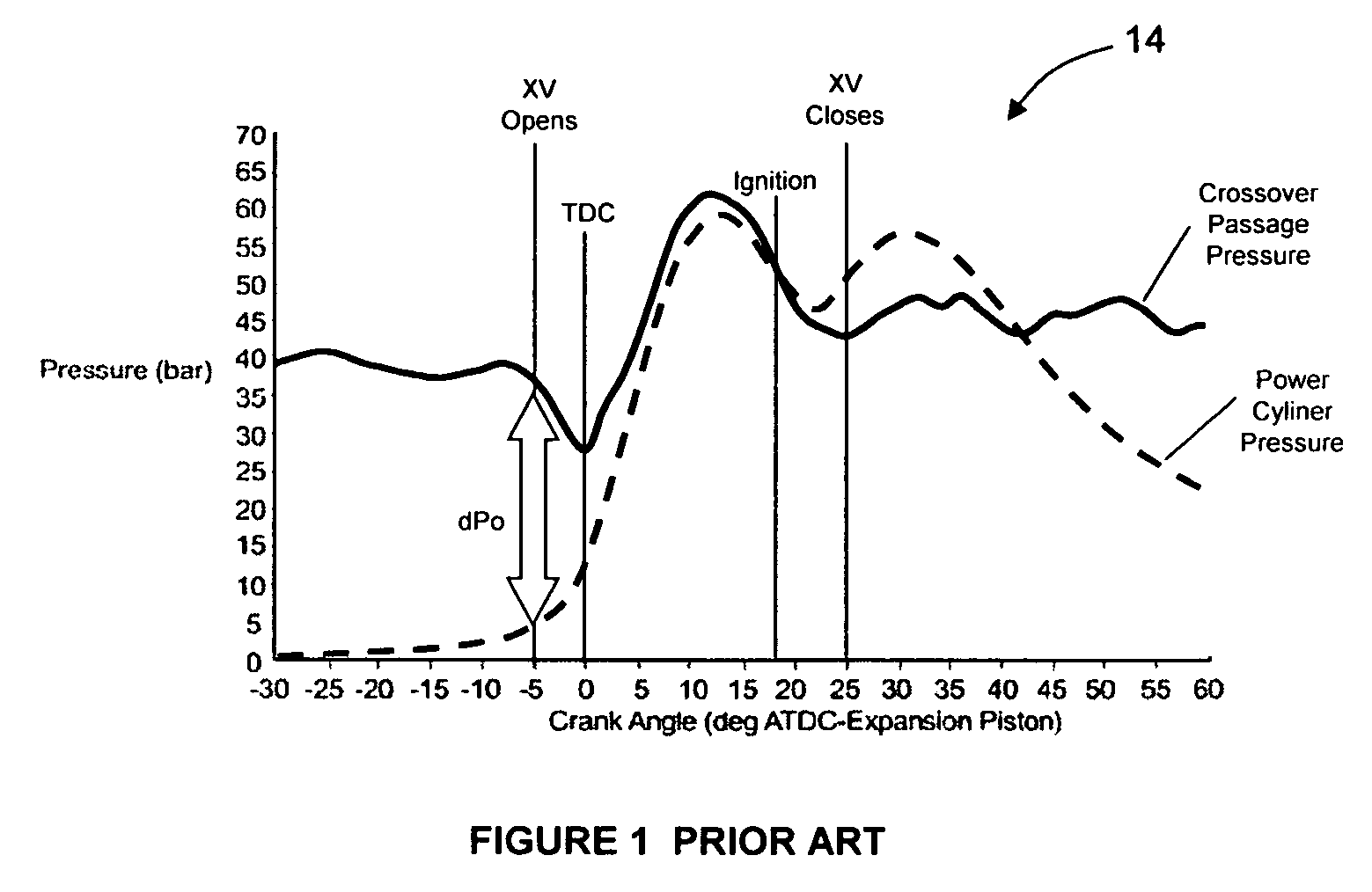

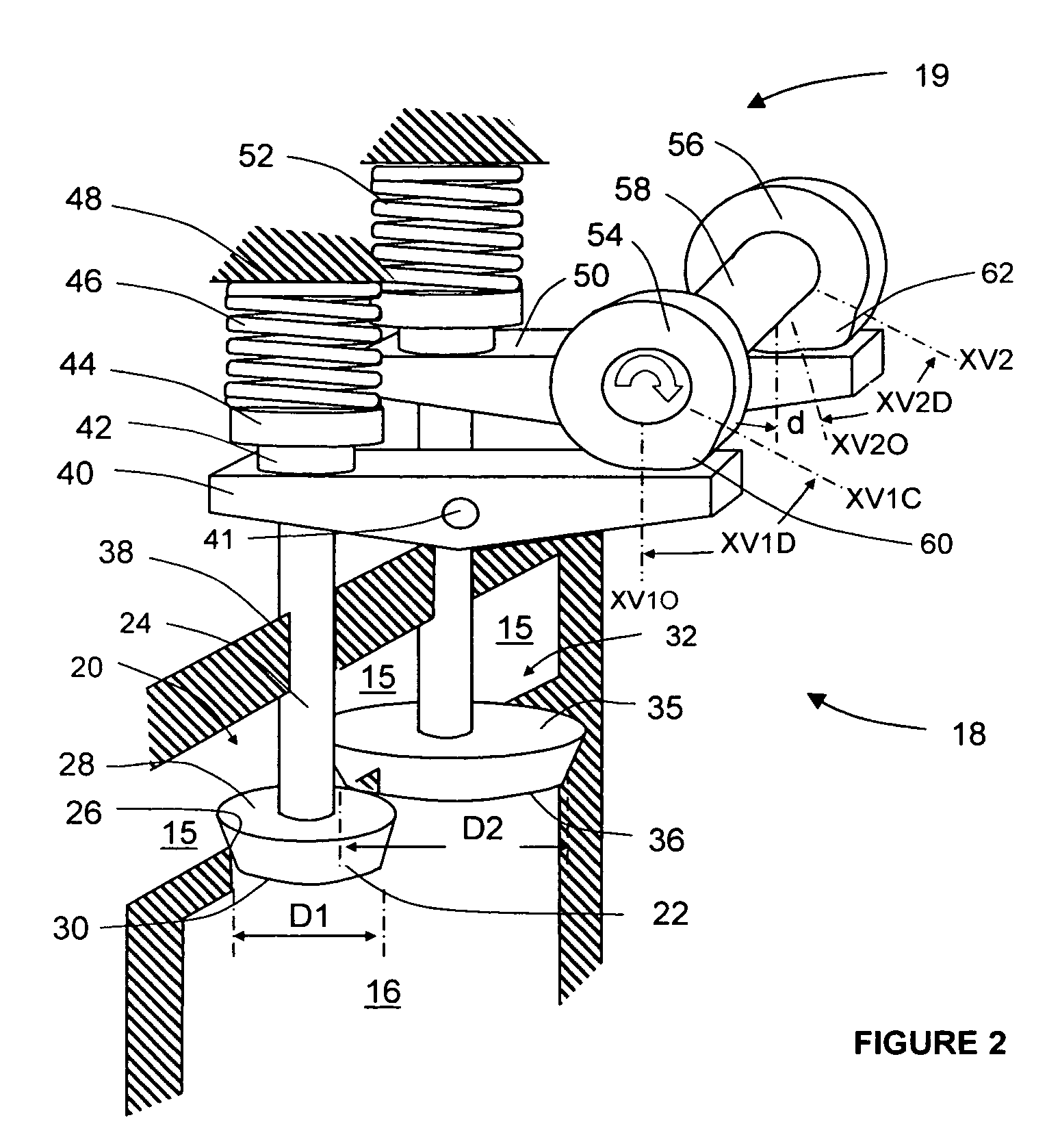

Crossover valve systems

InactiveUS8272357B2Reduction in overall flow area and capacityIncrease the cross-sectional areaCombustion enginesLift valveDifferential pressureValve opening

Crossover valve systems and corresponding methods offer an effective means to overcome large opening pressure force, or provide reasonable gas flow area, or both. In an exemplary embodiment, a crossover valve system for a split-cycle engine having a power cylinder and a crossover passage comprises first and second crossover valves, each valve opening outwardly away from the power cylinder and providing fluid communication between the power cylinder and the crossover passage, with the diameter of the second crossover valve being larger than the diameter of the first crossover valve; and an actuation mechanism operative to open the first crossover valve, then the second crossover valve after a predetermined delay to allow a certain rise in the pressure inside the power cylinder, resulting in much smaller differential pressure forces across the crossover valves, larger flow areas, or both.

Owner:LGD TECH LLC

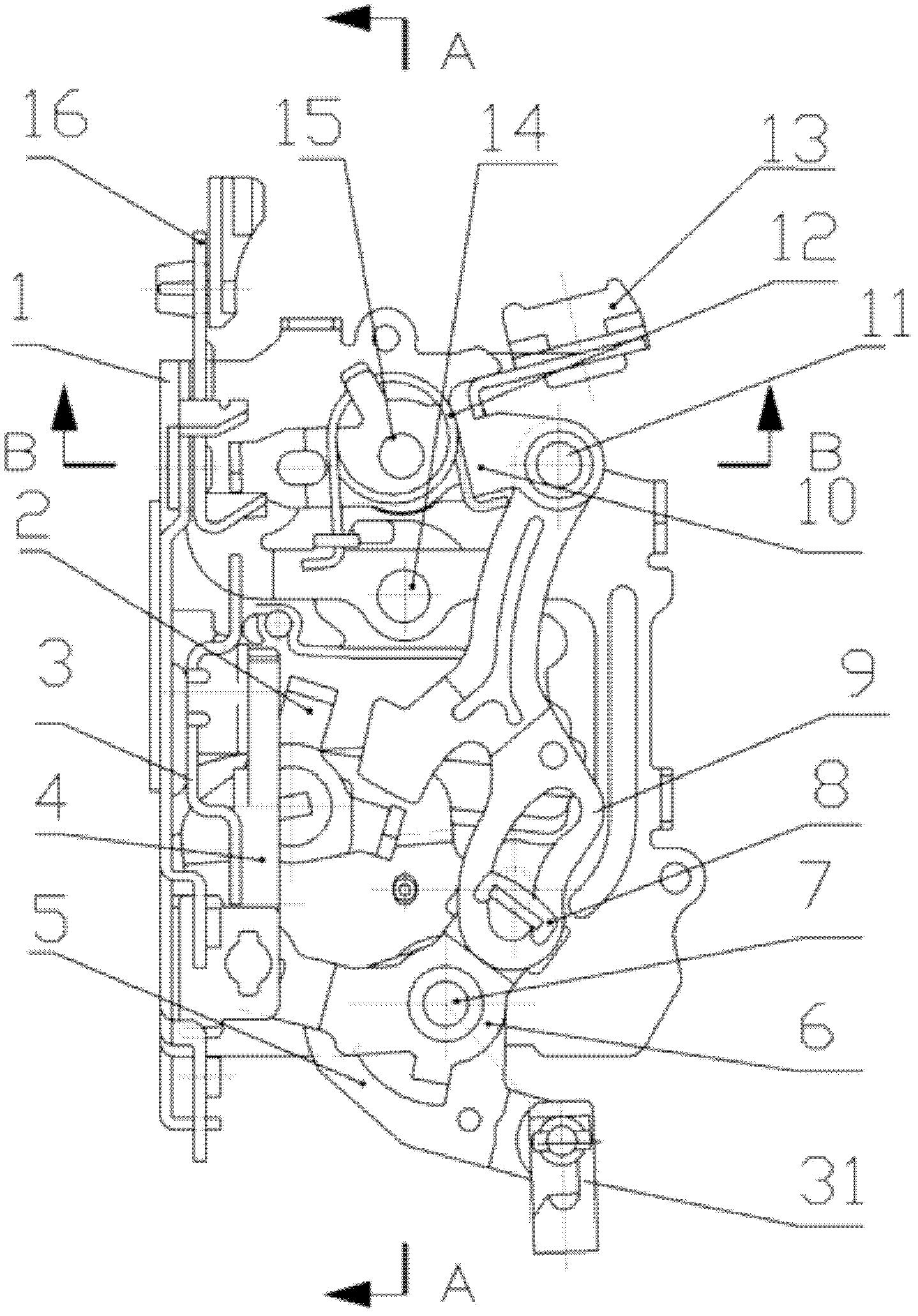

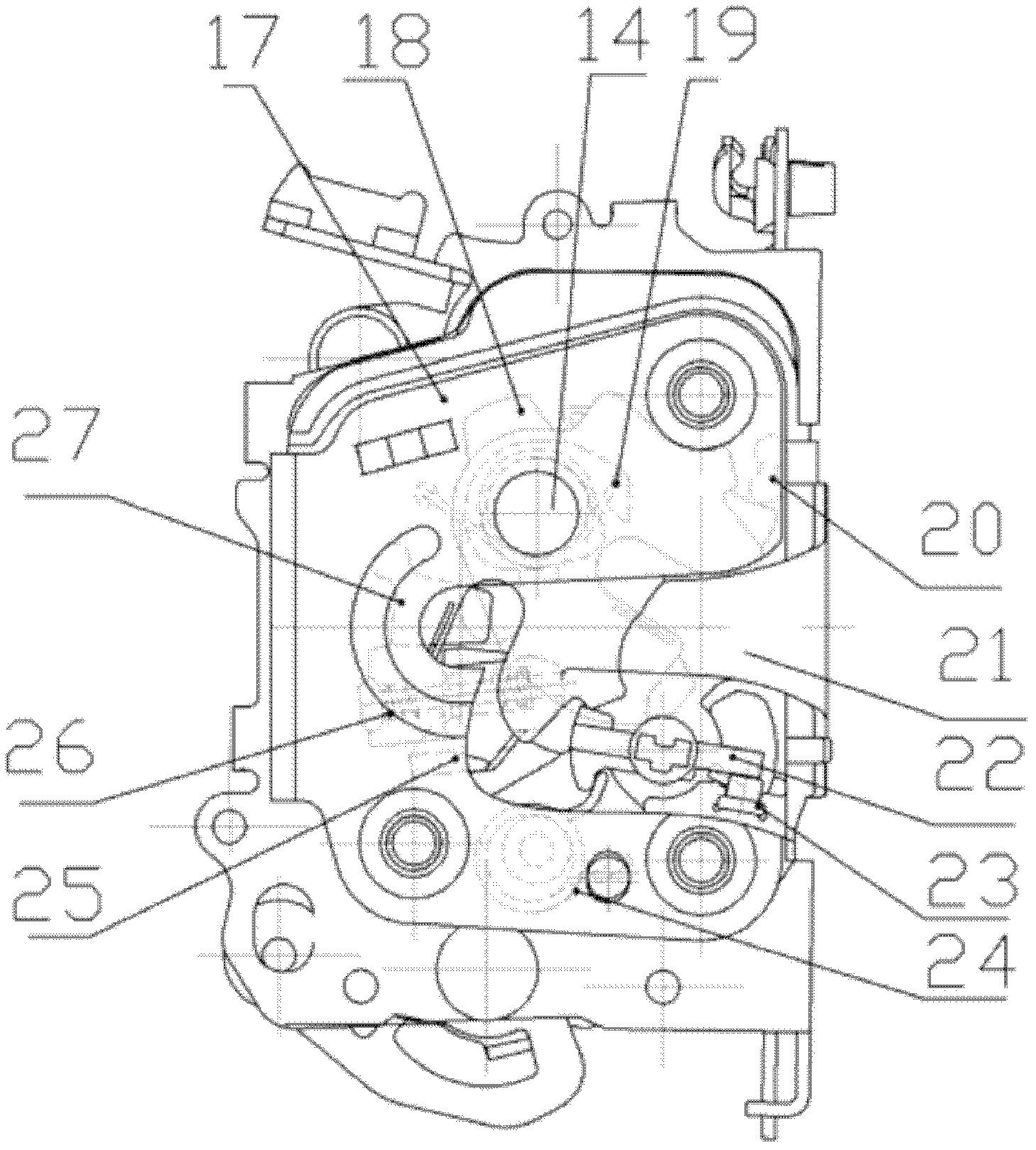

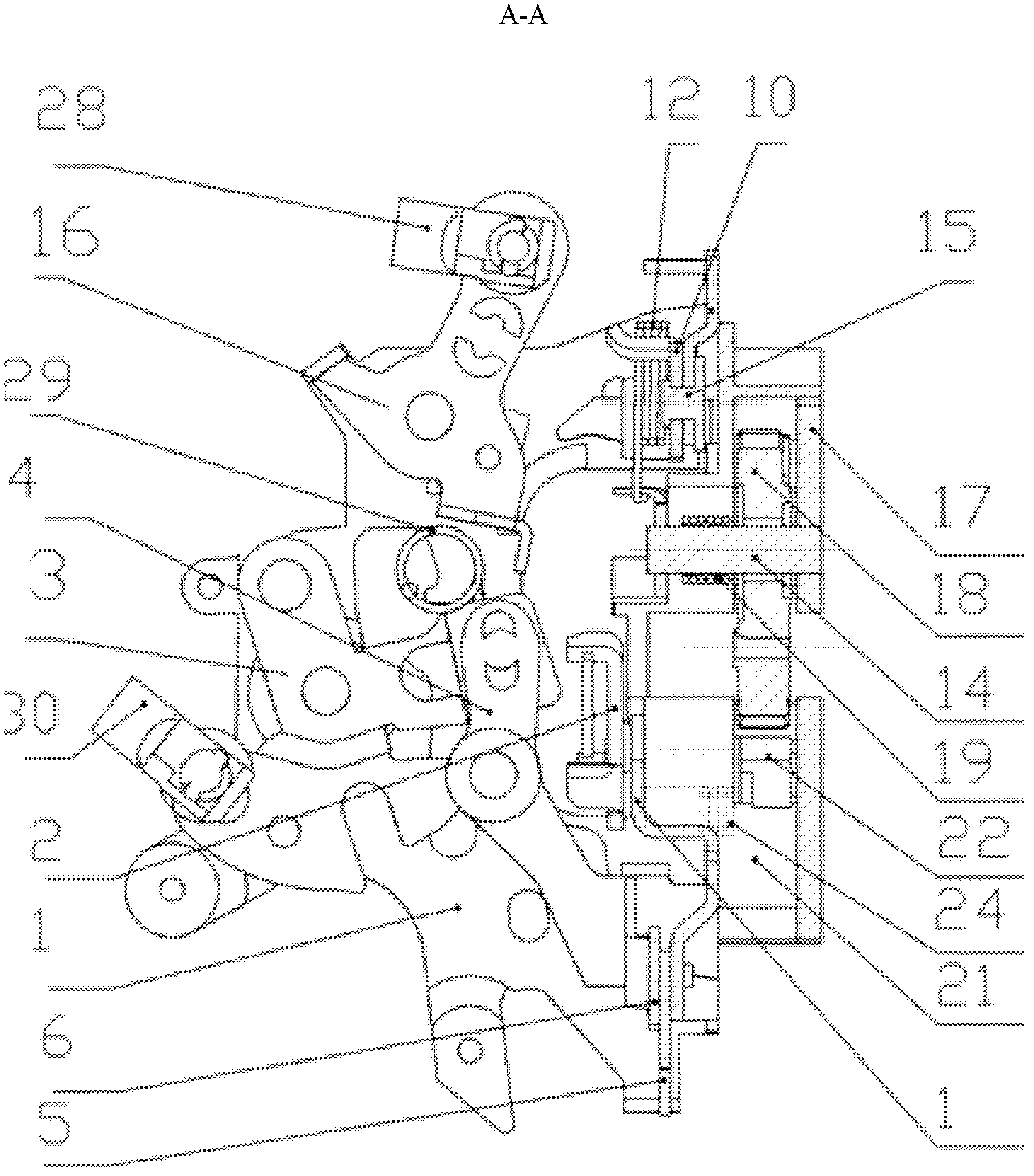

Automobile left front door lock

An automobile left front door lock comprises a left lock body bottom plate, a left lock body and a ratchet shaft. The left lock body is arranged inside the left lock body bottom plate, and the ratchet shaft and a left pawl are arranged inside the left lock body. The left lock body bottom plate, a left ratchet and a left lock body seat plate are connected together in a riveting mode through the ratchet shaft, and one end of the left pawl is connected with a left pawl linkage plate in a riveting mode. The left lock body seat plate is respectively connected with a left internal-open rocker arm, a left external-open rocker arm, a left internal locking rocker arm and a left external locking rocker arm in a riveting mode. The left external-open rocker arm is provided with a left pull rod connector. The left external-open rocker arm is provided with a left external-open pushing plate. The left internal locking rocker arm is provided with a left external locking linkage arm, and the left external locking rocker arm is provided with a left internal locking linkage arm. A bayonet in the left internal locking linkage arm enables the left external-open pushing plate and the left external locking linkage arm to be connected together. After an assembly hole position and a connecting mode are changed, the automobile left front door lock can be widely used as automobile front door locks of various types, opening force is small, quality is stable, production cost is low, and producing and using are convenient.

Owner:江苏金鼎汽车锁制造有限公司

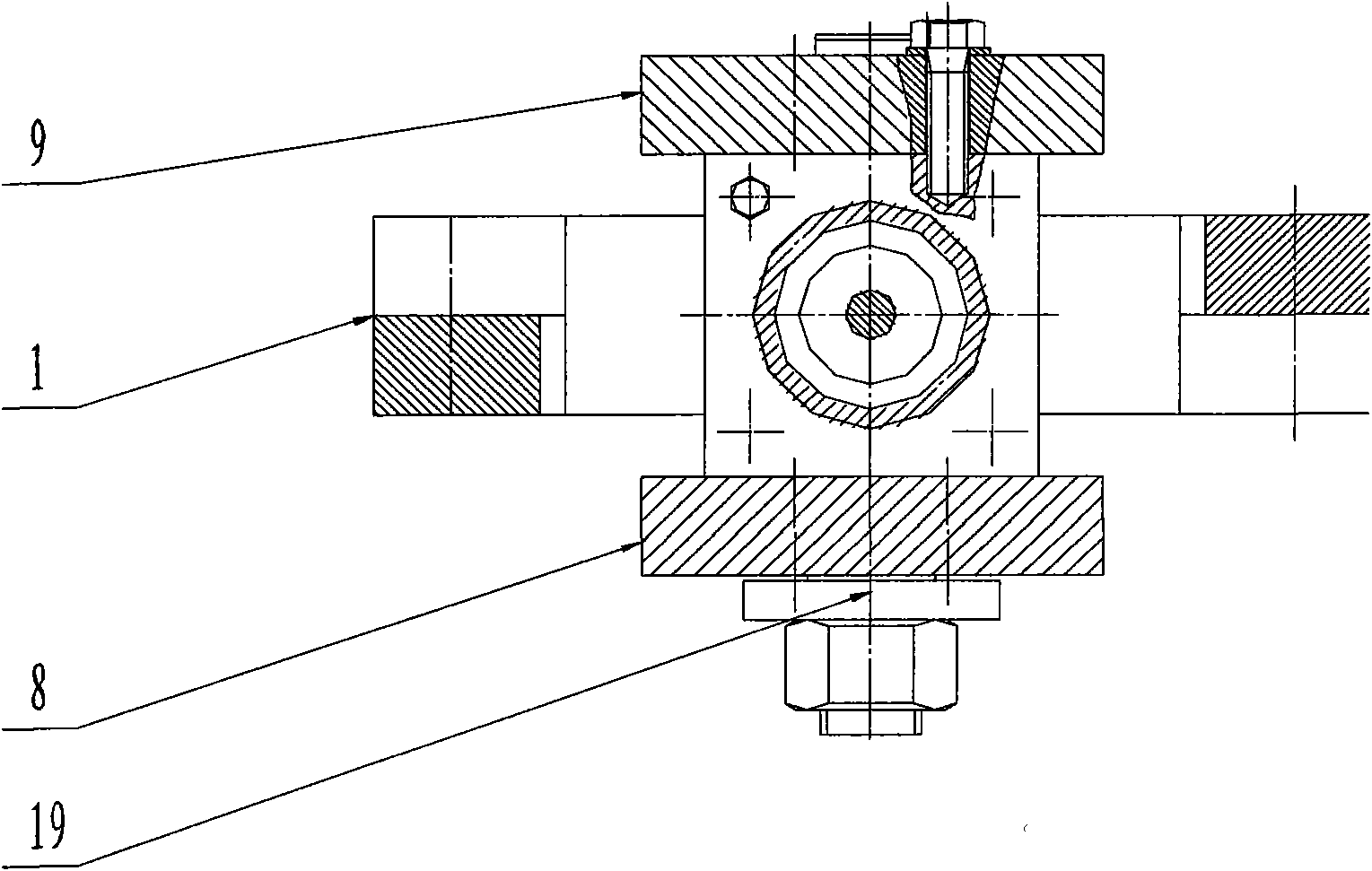

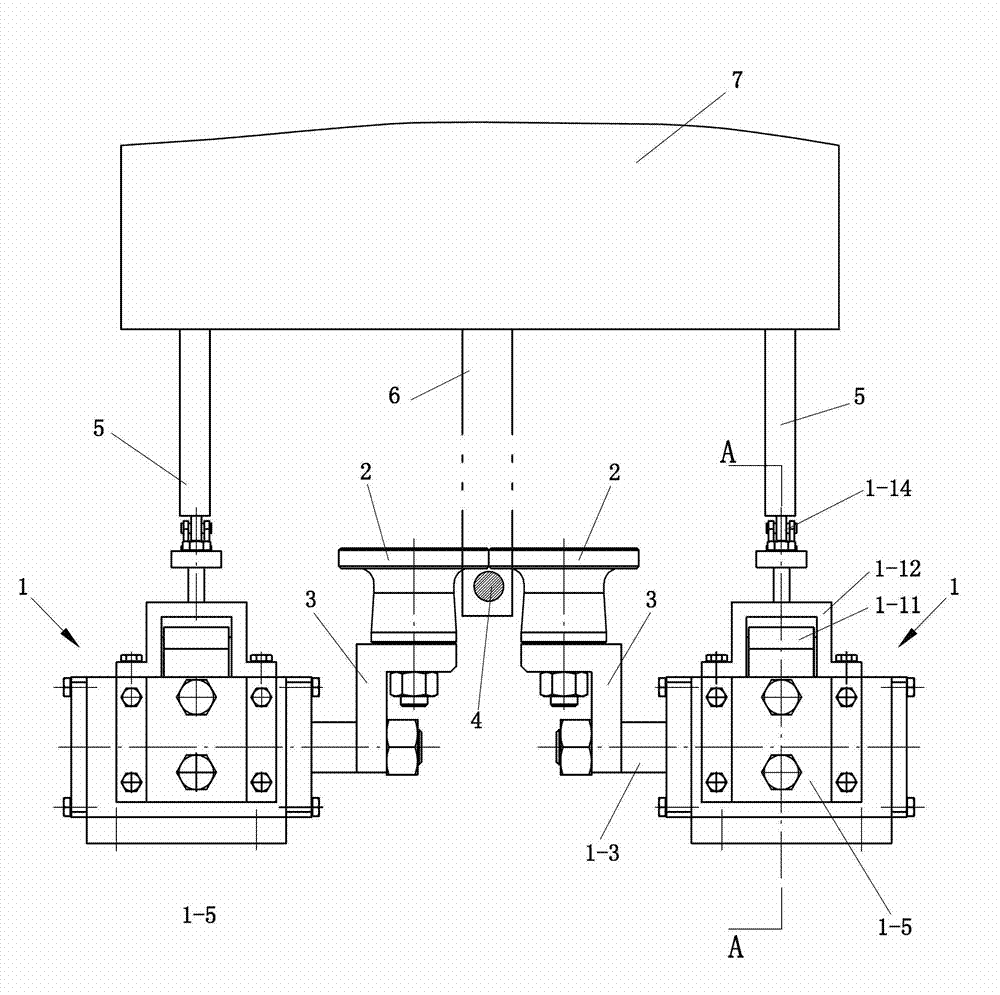

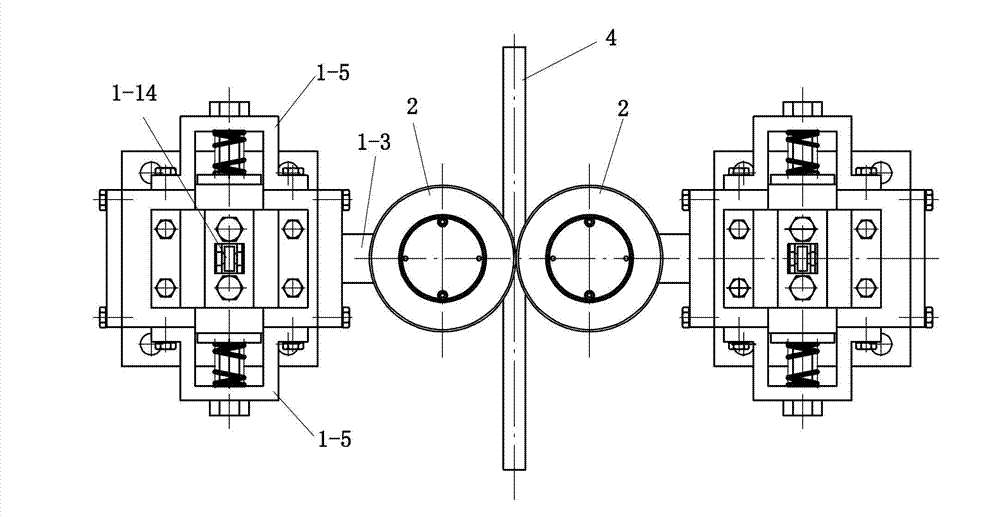

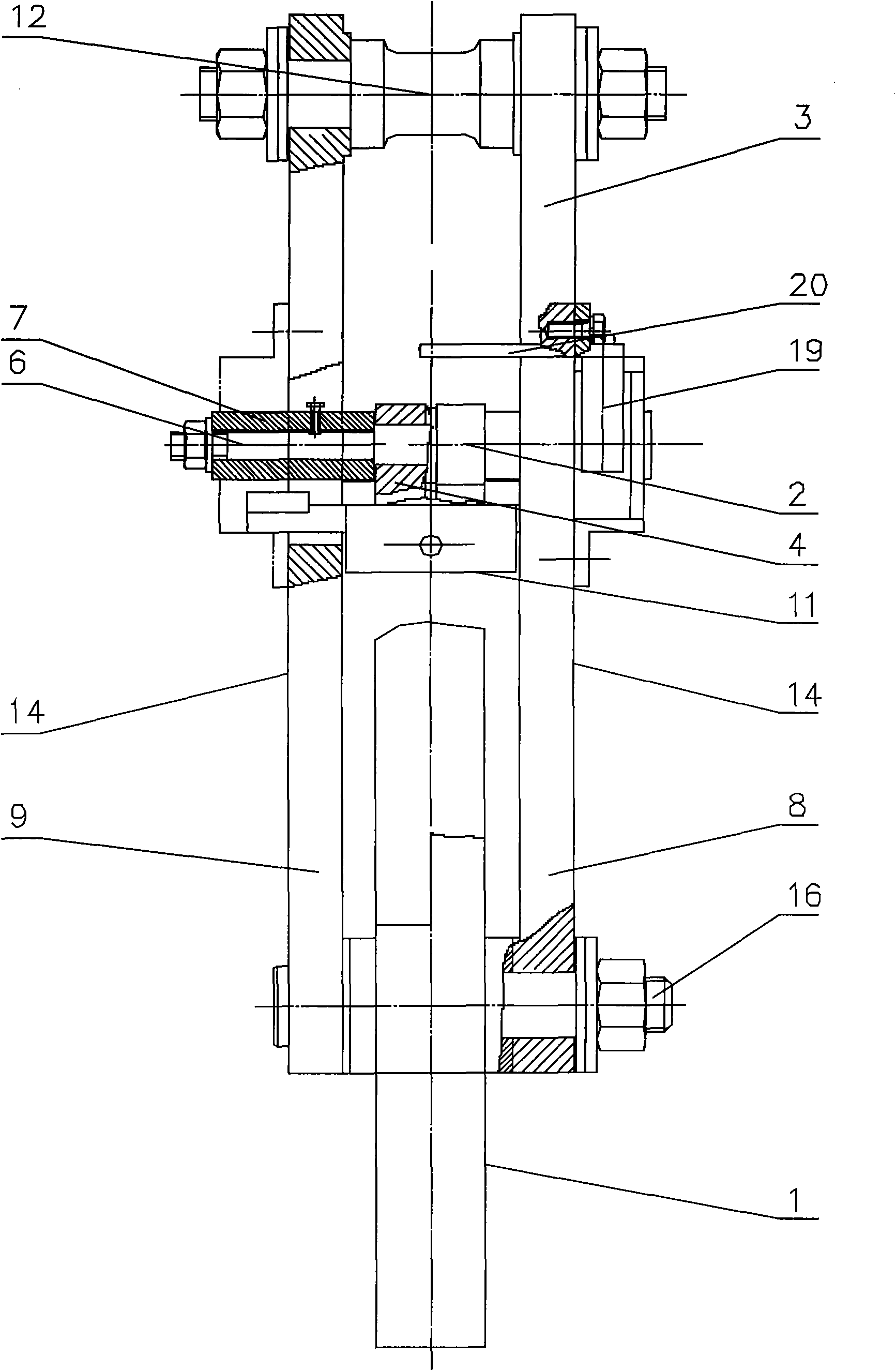

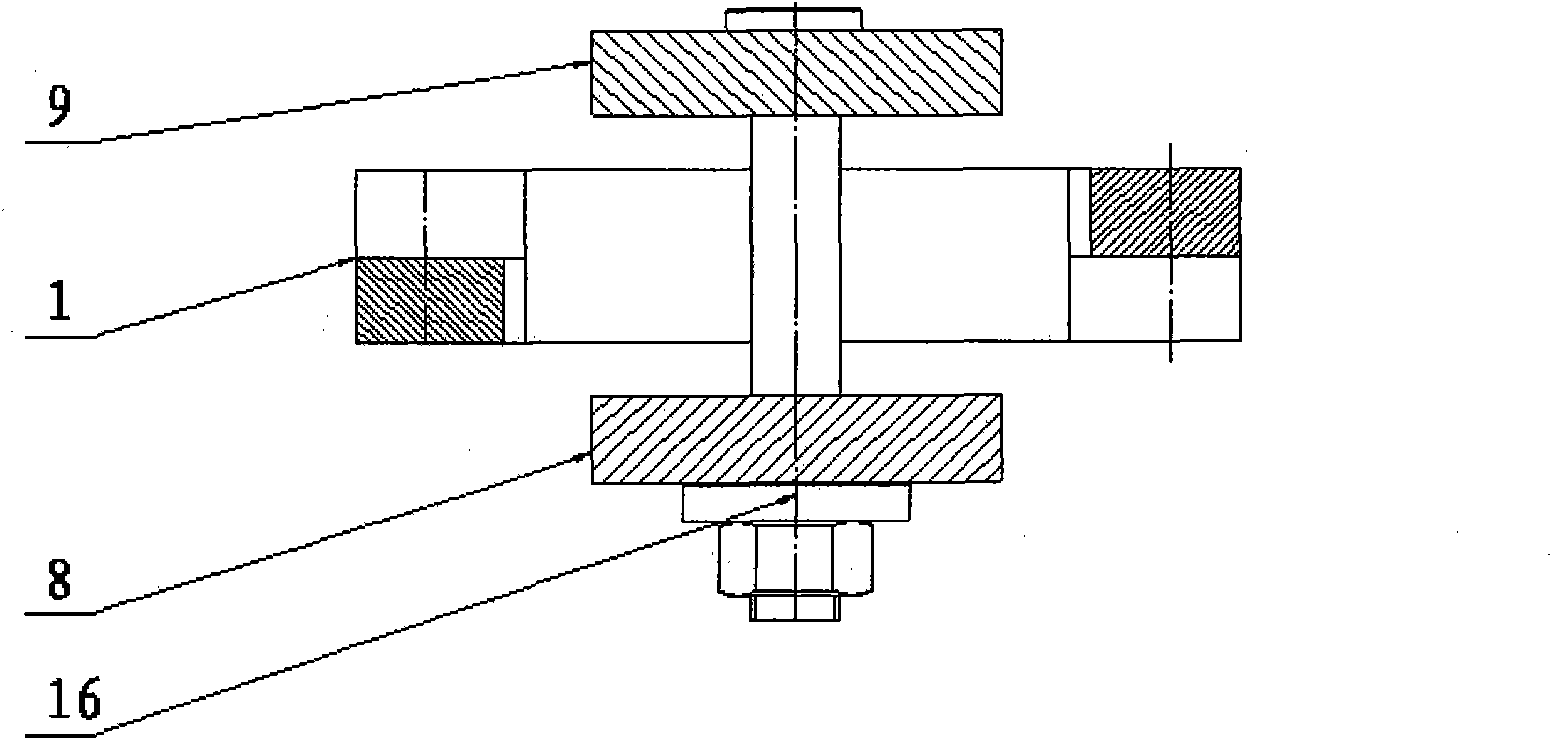

Rope pressing device of endless rope continuous-traction system

InactiveCN103158720ASmall opening forceAvoid forceWinding mechanismsLocomotivesTraction systemEngineering

The invention discloses a rope pressing device of an endless rope continuous-traction system. The rope pressing device comprises a pair of rope pressing wheels. Each one of the rope pressing wheels is provided with an opening / closing mechanism, and the opening / closing mechanism comprises a cylinder body, a piston, a piston compression spring, two side frames, two translational blocks respectively with two wedge-shaped heads, an upper-frame, a lifting block between the two wedge-shaped heads of the two translational blocks, a pair of translational guide rods, and a pair of lifting guide rods; opposite surfaces of the two translational blocks are respectively provided with locating pins; the locating pins pass through pin holes of the cylinder body and are located at the back of the piston; the two translational guide rods are fixedly connected respectively to the corresponding parts of the cylinder body; translational springs are arranged between the side frames and the translational blocks; the two lifting guide rods respectively pass through the upper-frame and are fixedly connected to the lifting block; lifting compression springs are arranged between the lifting block and the cylinder body; an idler wheel base is fixed between upper parts of the two lifting guide rods; and an idler wheel is hinged to the idler wheel base. Two supports are fixed respectively to heads of two piston rods. The two rope pressing wheels are fixed respectively to the two supports. The rope pressing device can be used under complex conditions and has good rope pressing effects.

Owner:CHANGZHOU DEV & MFR CENT

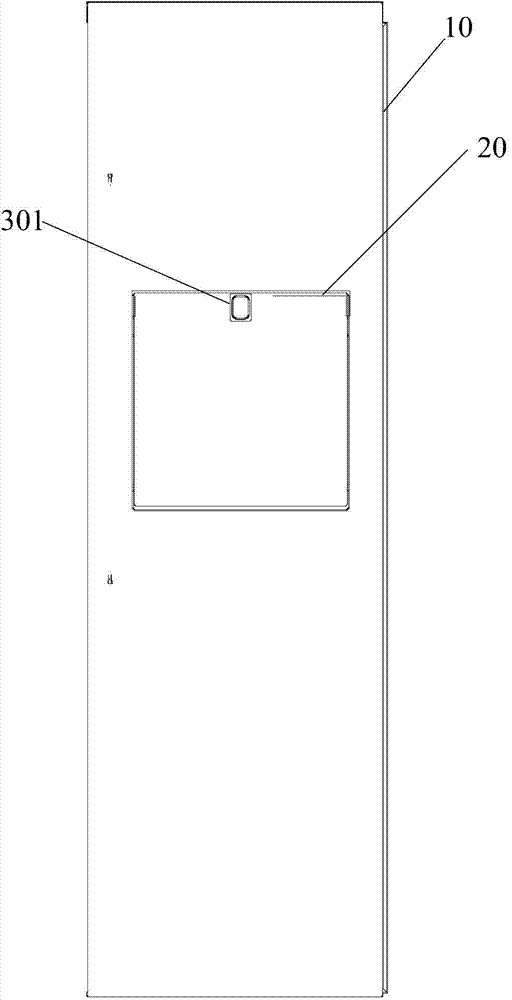

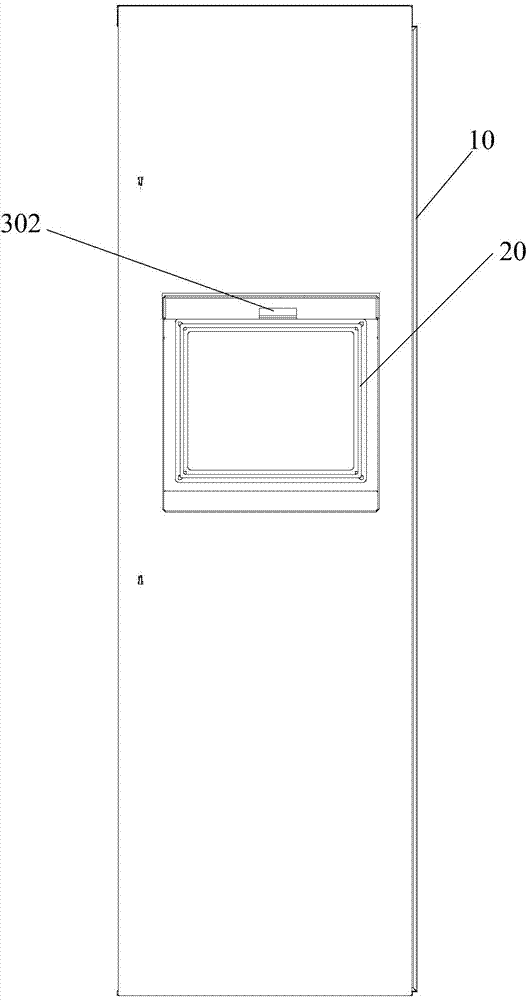

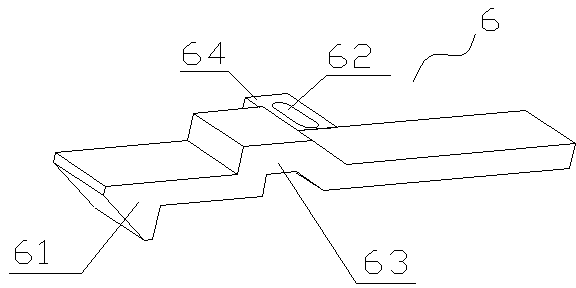

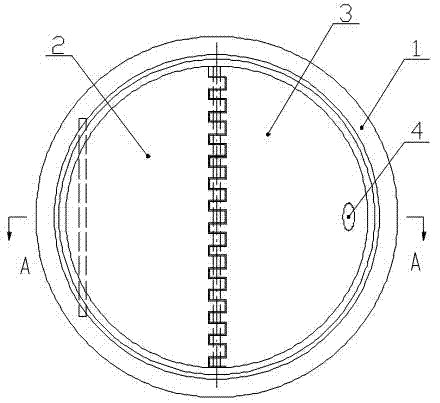

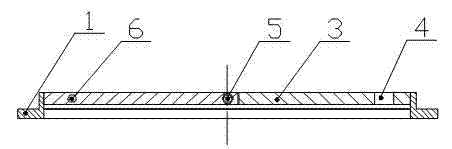

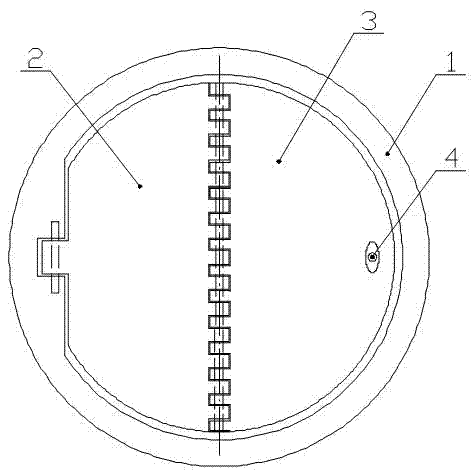

Refrigerator bar counter opening and closing structure and refrigerator bar counter

ActiveCN104236224ASimple structureSimple preparation processDomestic cooling apparatusLighting and heating apparatusMechanical engineering

The invention provides a refrigerator bar counter opening and closing structure which is installed between a refrigerator door body and a bar counter door and used for opening or closing the bar counter door. The refrigerator bar counter opening and closing structure comprises an opening and closing assembly and an opening and closing hanging column, wherein the opening and closing assembly comprises an opening and closing base and an opening and closing hook, the opening and closing base is arranged on the bar counter door, the opening and closing hook is arranged on the opening and closing base, the opening and closing hanging column is arranged on the refrigerator door body, the bar counter door is closed and buckled on the refrigerator door body when the opening and closing hook is inserted into the opening and closing hanging column, and the bar counter door is opened and separated from the refrigerator door body when the opening and closing hook is separated from the opening and closing hanging column. Accordingly, the invention further provides a refrigerator bar counter. According to the technical scheme, a locking mechanism can be prevented from being locked dead, the phenomenon that the bar counter door can not be opened is avoided, the number of parts is small, the manufacturing process is simple, and cost is saved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

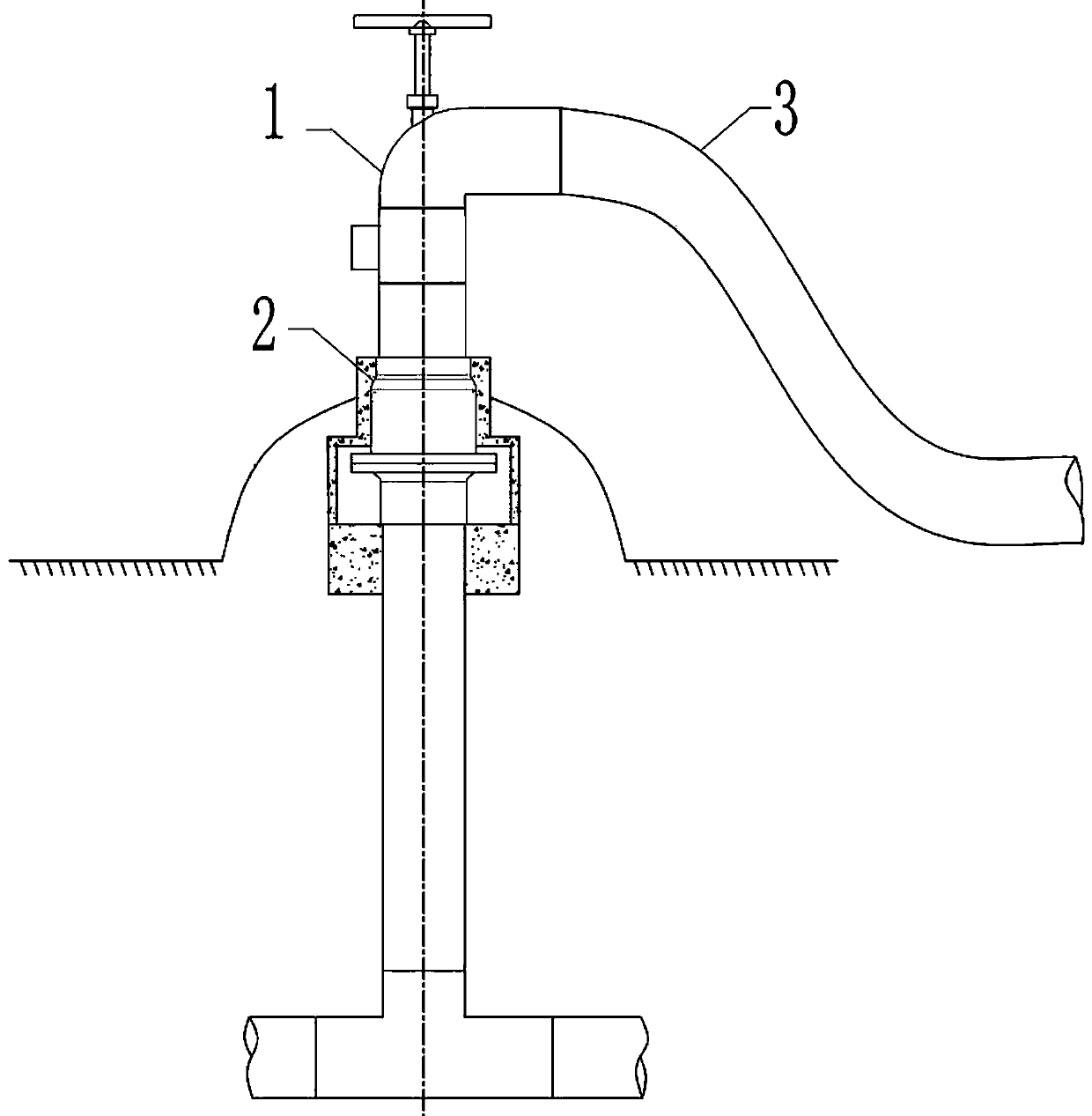

Umbrella-shaped valve and combined-floating-body type hydrant

InactiveCN106382378ADoes not affect farmingRealize automatic shutdown functionOperating means/releasing devices for valvesWatering devicesRubber ringEngineering

An umbrella-shaped valve is mainly composed of a valve plate and a guide rod. A concave push valve seat is arranged at the center of the top face of the valve plate. The outer edge of the valve plate is provided with a water stop rubber ring, a water stop rubber ring reserved hole and a reserved groove. The top face of the water stop rubber ring is provided with a convex ring water stop line with an inclination angle. The valve plate is of a trapezoidal-cross-section hollow structure. A bottom seal cover is arranged at the bottom of a hollow area and is of a circular-arc-shaped structure. The center of the bottom seal cover is of a cylindrical internally-threaded structure. The guide rod is arranged in the cylindrical internally-threaded structure. Threads on the upper portion of the guide rod are connected with the cylindrical internally-threaded structure in a glue joint manner.

Owner:宋庆波

Buckle

The invention provides a buckle, wherein the buckle is provided with an unlocking linkage member that is linked by an unlocking operation member, the limitation on a spring bolt is released by disengaging an elastic adjusting hole from a fixing hole, so that the spring bolt can freely enter and exit a locking hole for unlocking, in the process of disengaging the elastic adjusting hole from the fixing hole, and sucked portions of a first magnet and a second magnet are removed by a guide portion, so that the first magnet and the second magnet are separated by a certain distance, thereby reducingthe suction between the magnets to reduce the opening force. Further, a lead-out surface disposed on the guide portion can guide the spring bolt to move toward a direction away from a second connecting module, and can further assist a first connecting module and the second connecting module to separate from each other. Further, the buckle is further provided with a third magnet, after the elasticadjusting hole is disengaged from the fixing hole, the third magnet can move to a position corresponding to the first magnet to generate repulsive interaction on the first magnet, so that the springbolt can be rejected out from the locking hole to separate the first connecting module from the second connecting module.

Owner:LIAN YANG PLASTIC (SHEN ZHEN) CO LTD

Full-automatic speed reduction clutch of washing machine

InactiveCN101200849ASmall opening forceReduce manufacturing costToothed gearingsOther washing machinesEngineeringClutch

The invention provides a washing machine automatic deceleration clutch and relates to the washing machine technical field. The invention consists essentially of an input shaft, an output shaft, an output shaft sleeve, an input shaft sleeve, a brake wheel and a double-driving gear mechanism. The input shaft, the output shaft sleeve and the output shaft are respectively linked with the double-driving gear mechanism. The brake wheel and the output shaft sleeve are mutually reverse and are driven towards two directions according to proportions, swing and rotate repeatedly and entwist relatively and strongly. The output shaft and the output shaft sleeve can automatically combine through the locking effect of the clutch device during the dehydration condition and continuously rotate towards one direction with high speed for the centrifugal dewatering at the same time. With simple structure, the invention improves the performance of the deceleration clutch of a conventional washing machine, simplifies the structure of an operation system, lowers the noise of the washing machine and improves the washing machine functions and the service life.

Owner:NINGGUO JULONG IND

Nested type top overflowing gate

A nested type top overflowing gate is mainly characterized in that a large gate leaf is in movable nested connection with a small gate leaf, and a flip bucket is arranged at the upper end of the small gate leaf in the downstream side direction, so that water flow can overflow from the top of the gate to form open weir flow, and water diversion capability can be improved while washout force is decreased; and clear upper-layer flood resources can be used to enter downstream along with main flow while bed load sediment is still blocked in an original riverway, and vibration of the gate caused by the washout force can be avoided. The nested type top overflowing gate is flexible and convenient to open and close and small in gate opening force. Meanwhile, the nested type top overflowing gate can be used normally on the basis of not changing other water gate buildings such as water gate bottom plates, gate piers and opening and closing equipment but the gate, and is less in investment, good in flood resource use effect and high in feasibility.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

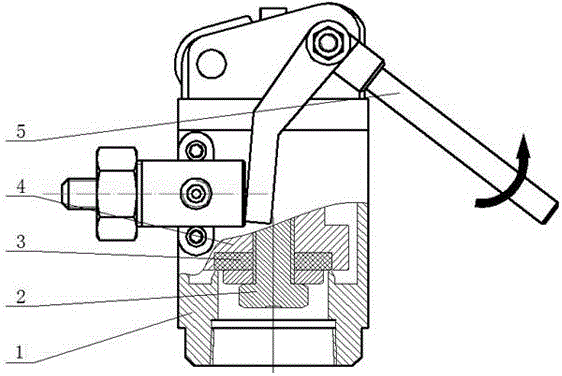

Opening and closing mechanism of high-voltage part hand-operated maintenance switch

InactiveCN105161330ASmall opening forceUniform opening forceElectric switchesMechanical engineeringHigh voltage

The invention discloses an opening and closing mechanism of a high-voltage part hand-operated maintenance switch. The opening and closing mechanism comprises a base, an upper cover housing sleeving the base, and a handle fixed to the upper cover housing through a bolt rotating shaft. Two ends of the handle are provided with splines, and through the splines, the handle is connected with gear sectors similarly provided with splines. The gear sectors are engaged with fixed teeth arranged on the base. Compared with the guide rail type opening and closing mechanism, the opening and closing mechanism provided by the invention is small and even in opening force and is convenient and rapid, and the mechanism provided by the invention is more sturdy and durable.

Owner:SHANGHAI ALSON ELECTRIC

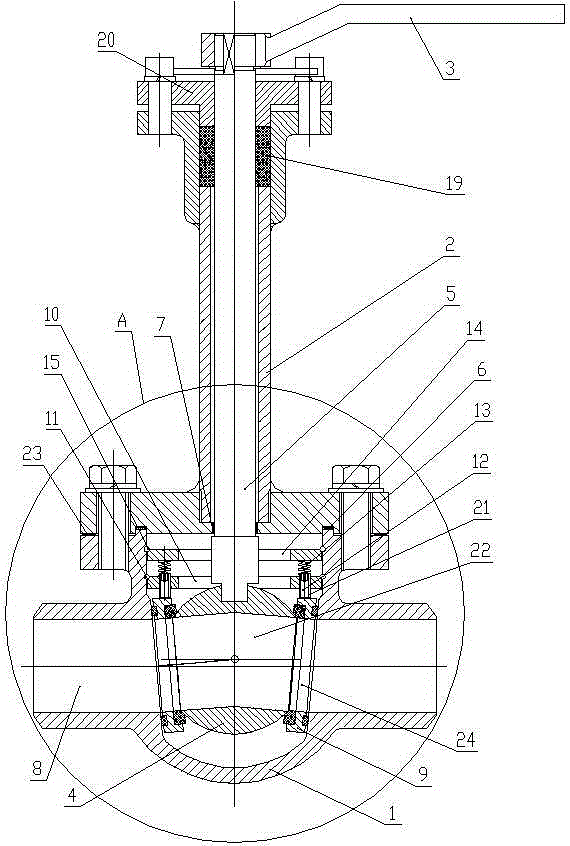

Steam turbine and quick-closing valve thereof

PendingCN110500414AImprove coordinationReduce the impact of stabilityOperating means/releasing devices for valvesMachines/enginesValve seatSteam turbine

The invention provides a steam turbine and a quick-closing valve thereof. The quick-closing valve comprises a housing, a valve seat, a valve element and a valve rod, wherein the housing is equipped with a steam inlet and a steam outlet; the valve seat is arranged at the steam outlet, and communicates with the steam outlet; the valve element is arranged in the housing and is opposite to the valve element; one end of the valve rod is connected to the valve element, and the other end of the valve rod penetrates through the housing and then is connected to a drive mechanism; the valve element comprises a valve disc of a hollow cylindrical structure, one end of the valve disc is opposite to the valve seat, and is equipped with an end surface, and the other end of the valve disc is open; a sleeve sleeves outside the valve disc; and one end, away from the valve seat, of the sleeve is fixedly arranged on the housing. The quick-closing valve adopts a hollow valve element structure, and improvescoordination of gravity distribution of the quick-closing valve; and opening force is relatively small while the valve disc and the valve seat are separated, and the dimension of the valve rod drivemechanism can be reduced, so that the integral dimension of the quick-closing valve is reduced.

Owner:浙江华元汽轮机械有限公司

Low-temperature ball valve of pre-tightening sliding valve seat structure

The invention provides a low-temperature ball valve of a pre-tightening sliding valve seat structure. The low-temperature ball valve comprises a valve body, a long-neck valve deck, two sliding valve seats, a handle, a ball and a valve rod. The valve body is provided with a floating pressing mechanism which is arranged above the two sliding valve seats and used for pressing the two sliding valve seats. The floating pressing mechanism comprises a horizontal supporting plate and a guide plate located below the supporting plate. The center of the supporting plate and the center of the guide plate are both provided with through holes which the valve rod penetrates. Guide holes are formed in the left side and the right side of the guide plate respectively. At least two guide holes are formed in the same side. A casing pipe is arranged in each guide hole in a sliding manner. Adjusting screws are connected into the casing pipes in a threaded manner. Compression springs are arranged between the lower surface of the supporting plate and the upper ends of the casing pipes. The lower ends of the adjusting screws extend out of the casing pipes and are in compression joint fit with the sliding valve seats. The low-temperature ball valve is simple in structure, reliable in work, easy to operate, good in sealing performance, small in opening force, capable of achieving complete seal under the low-temperature working condition, convenient to maintain and long in service life.

Owner:KAIFENG RUIKE VALVE

Dishwasher door locking device

InactiveCN102846291ANo need to overcome elasticEasy to open the doorTableware washing/rinsing machine detailsWing fastenersMechanical engineering

Owner:领致热能新电器(江苏)股份有限公司

Folded anti-theft well lid

InactiveCN102877489AEasy to openEasy to open the second halfArtificial islandsUnderwater structuresEngineeringMechanical engineering

Owner:FUZHOU PLANNING DESIGN & RES INST

Combination floating body type multifunctional hydrant

PendingCN107725801ASolve the problem of running vibrationSolve technical problems of water leakageOperating means/releasing devices for valvesWatering devicesRubber ringWater stop

A combination floating body type multifunctional hydrant comprises an upper hydrant body and a lower hydrant body. The lower end of the lower hydrant body is connected with a three-way standpipe of anunderground pipeline, a screw rod I is vertically screwed on the upper hydrant, the lower hydrant comprises a valve housing, a large floating body, a small floating body, a water stop rubber ring IIand a water stop rubber ring III. By the adoption of water stop technology of the floating body valve, the self-closing function of the lower hydrant is achieved by utilizing the buoyancy of the waterin the pipeline, and the technical problems of manual-closing and frequent water leakage caused by the neglect of management of traditional hydrants are thoroughly solved; meanwhile, because when thecombination floating body type multifunctional hydrant is opening, firstly the small floating body is pushed down to discharge flow and reduce pressure, and then the large floating body is moved downand totally open, the twice-opening technology greatly decreases opening force. The flow can respectively pass through the outside and inside of the large floating body, the water flow is unhindered,the top surface of the small floating body is small, so that the condition for forming vacuum negative pressure is eliminated, the problem of hydrant run vibration caused by hindered water flow and vacuum negative pressure is thoroughly solved.

Owner:宋庆波

Clean stripping aluminum foil easy opening cover

InactiveCN105480571ASmall opening forceAvoid pollutionPackagingMetal layered productsEngineeringCarvacryl acetate

The invention discloses an easy opening heat sealing film. The easy opening heat sealing film is prepared by 70-90% of ethylene-acrylate copolymer and 10-30% of ethylene-vinyl acetate copolymer. The heat sealing film solves such defects as high heat sealing temperature and easy generation of dead sealing, and is low in opening force and free of rupture and burrs during opening.

Owner:惠州宝柏包装有限公司

Propped-open type container seal plug

The invention discloses a propped-open type container seal plug. The propped-open type container seal plug comprises a cylindrical inner plug, an annular outer plug and an elastic seal component, wherein the cylindrical inner plug adopts an inverted T-shaped structure and comprises a plug rod and a linear base at the bottom of the plug rod, the elastic seal component is arranged between the annular outer plug and the base, the elastic seal component is an annular elastic seal component, the cross section of the elastic seal component is herringbone, the outer surface of the elastic seal component is arranged into a vertical plane, the inner surface of the elastic seal component is arranged into a cambered surface which extends from the inner side of the top of the elastic seal component to the outer side of the bottom of the elastic seal component, and the bottom of the cambered surface is tangent with and forms linear contact with the upper surface of the outer end of the base. The propped-open type container seal plug has the advantages of being more convenient to use, being more labor-saving, being smaller in structure and the like.

Owner:邵晖

Clamp unhooking device

The invention discloses a clamp unhooking device, belonging to the technical field of the mechanical lifting and drawing equipment. The clamp unhooking device is characterized in that two clamp pieces are arranged symmetrically, one end of each clamp piece is hinged with one end of a connecting rod through a hinge, the other end of the connecting rod is connected with a slider shaft; one end of the slider shaft is connected with an opening slider; the slider shaft and the opening slider are arranged in the chutes of a first pulling plate and a second pulling plate correspondingly, mandrils are also arranged in the chutes; the other end of the slider shaft is locked in a self-locking device; the self-locking device is arranged on the lateral surface of the first pulling plate, one end of the first pulling plate and one end of the second pulling plate are connected through a hinge pin; the other end of the first pulling plate and the other end of the second pulling plate are hinged on the two sides of each clamp piece through hinges, and an unlocking rope and an unhooking rope are arranged between the pulling plates. The clamp unhooking device has simple structure, small opening force, simple and convenient operation, safe and reliable work and accurate unhooking point of fall, and can be used in the fields requiring high centering and accurate unloading position.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

Internally-arranged tapered rubber check valve

InactiveCN104110516APrevent backflowPrevent escapeCheck valvesThin material handlingProduct gasSewage

The invention relates to an internally-arranged tapered rubber check valve, and belongs to the technical field of water supply and drainage equipment. The internally-arranged tapered rubber check valve comprises a pipe body. A tapered rubber film sealing and stopping the pipe body is fixed inside the pipe body. According to the internally-arranged tapered rubber check valve, back flow of sewage is effectively prevented, and smelly gas is better prevented from being escaping due to the fact that the check valve is arranged inside a pipeline. The check valve is opened or closed mainly by bending the lower portion of the tapered rubber film, the opening force is small, and sealing is reliable.

Owner:WUHAN SHENGYU DRAINING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com