Low-temperature ball valve of pre-tightening sliding valve seat structure

A sliding valve and ball valve technology, applied in valve devices, engine components, cocks including cut-off devices, etc., can solve problems such as hindering the rotation of the ball, pressure imbalance, affecting the sealing effect, etc., to reduce the conveying speed and the opening force. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

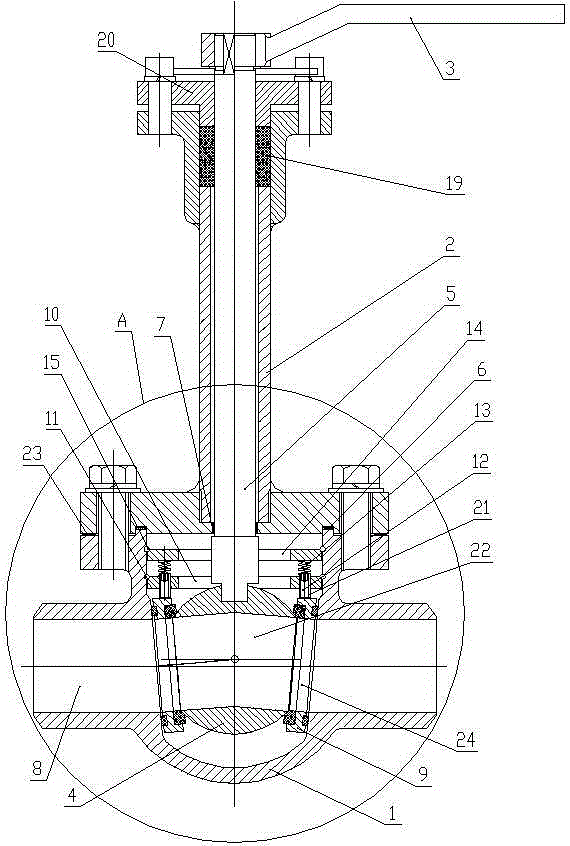

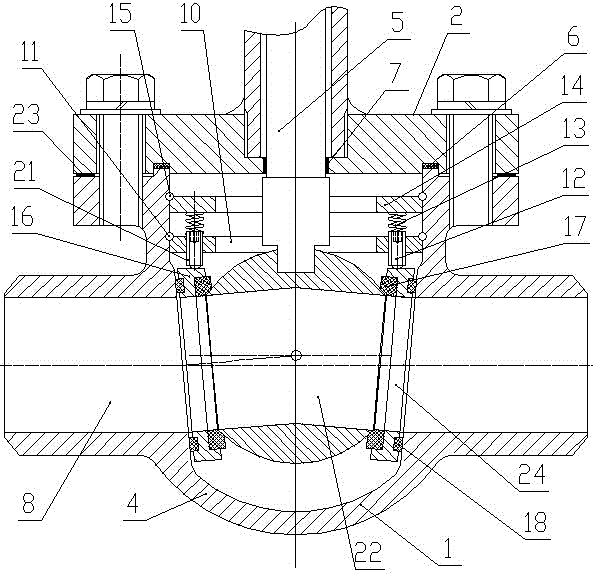

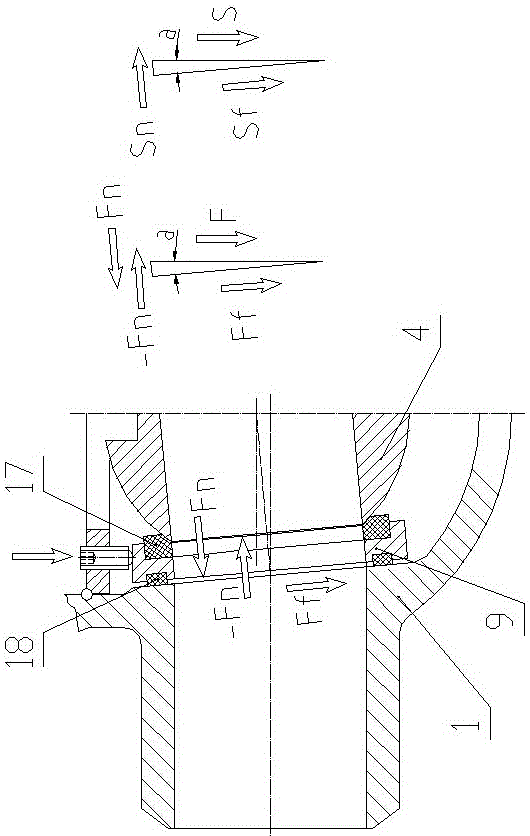

[0019] Such as figure 1 and figure 2As shown, the cryogenic ball valve with a pre-tightened sliding seat structure includes a valve body 1, a long-necked bonnet 2, a handle 3, a ball 4 and a valve stem 5. The top of the valve body 1 is open and connected to the lower end of the long-necked bonnet 2. The connection surface between the valve body 1 and the long-necked bonnet 2 is provided with a sealing ring 6, the interior of the valve body 1 is hollow and the left and right sides of the valve body 1 are respectively provided with pipe connection ports 8, the valve stem 5 and The long-necked bonnet 2 is coaxially arranged, the valve stem 5 is coaxially inserted in the long-necked bonnet 2 and extends into the valve body 1, the valve stem 5 and the long-necked bonnet 2 are rotated and sealed, and the valve The upper end of the rod 5 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com