Patents

Literature

77results about How to "Short washing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

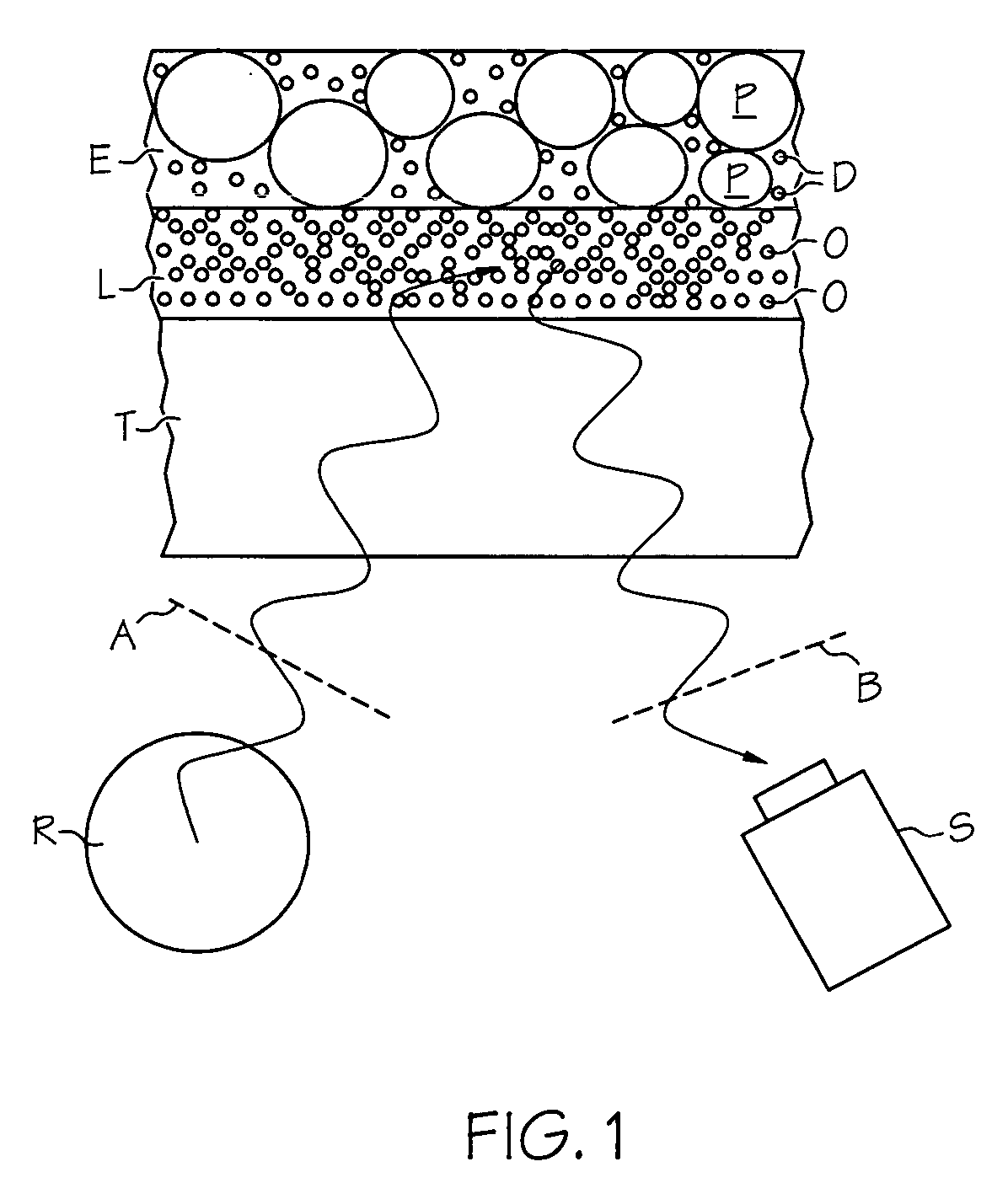

Diffusion layer for an enzyme-based sensor application

InactiveUS20060121547A1Rapid oxygen recovery timeShort washing timeBioreactor/fermenter combinationsBiological substance pretreatmentsPolymer chemistryDiffusion layer

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

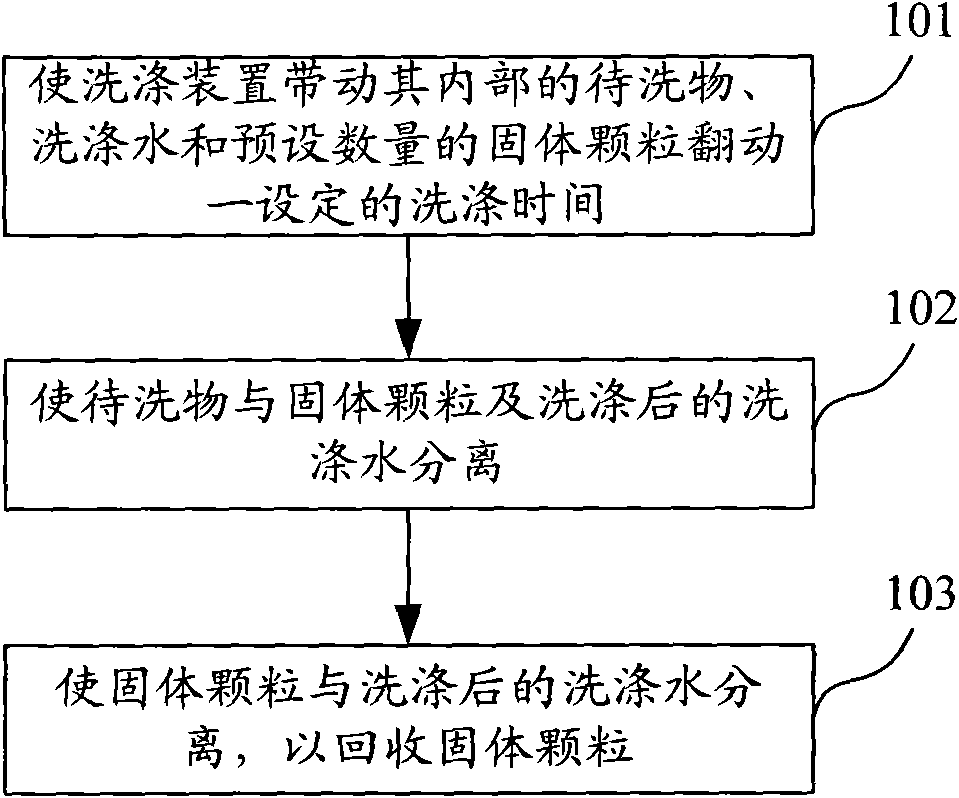

Washing method

InactiveCN101886321AReduce wearImprove washing effectOther washing machinesWashing machine with receptaclesSolid particleProcess engineering

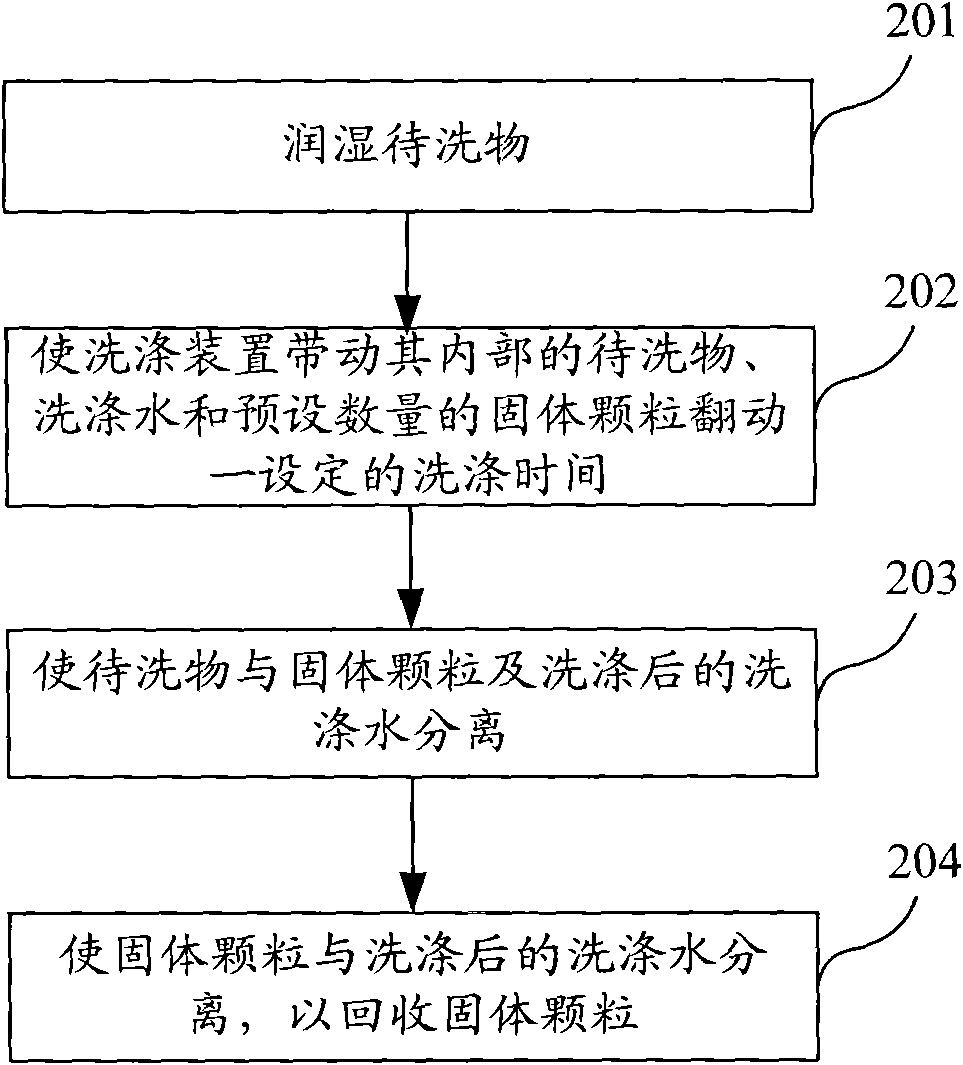

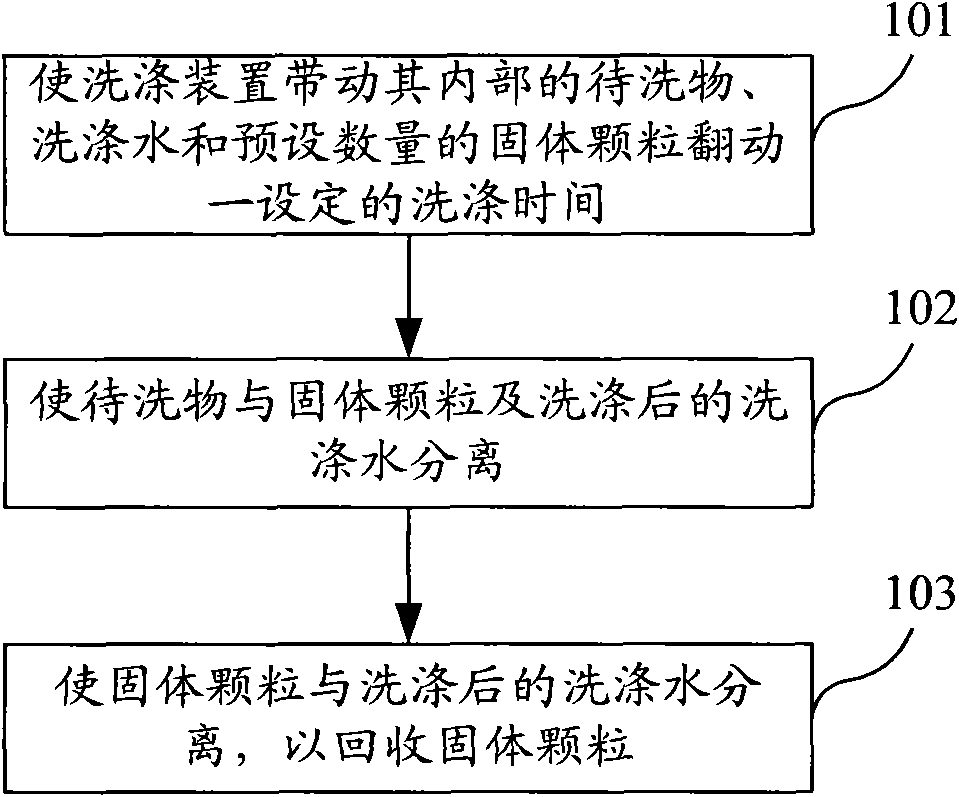

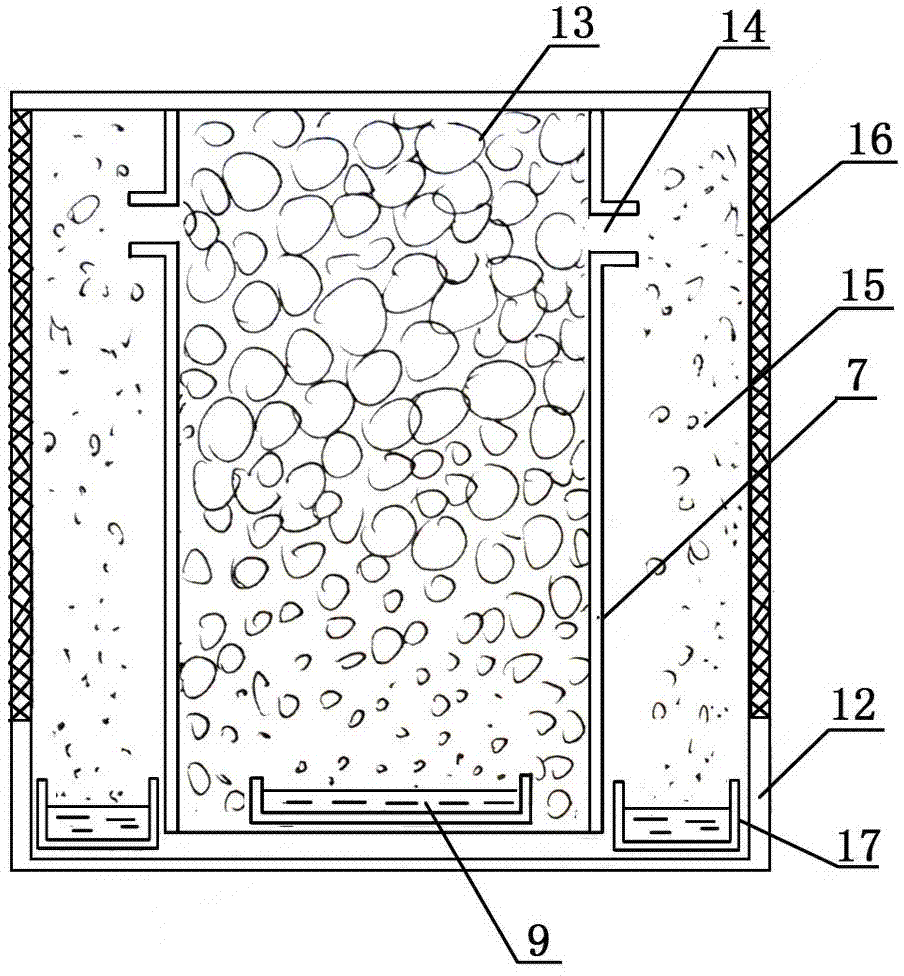

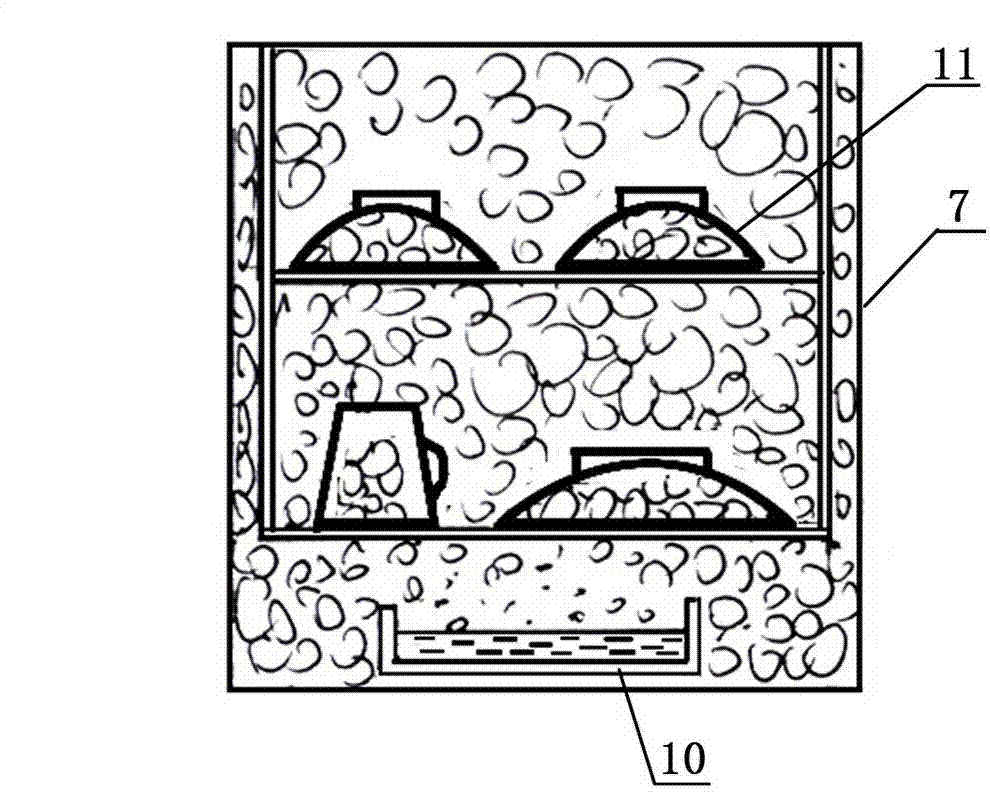

The invention relates to a washing method. The method comprises the following steps: leading a washing device to drive objects to be washed in the washing device, washing water and a preset number of solid particles to flip for a set washing time; leading the objects to be washed to be separated from the solid particles and the washing water after washing; and leading the solid particles to be separated from the washing water after washing for recovering the solid particles. The washing method adopts the solid particles as washing media, thereby having good washing effect and saving water; and the solid particles are recovered after the washing is finished, thereby reducing the washing cost, leading the washing time to be short and causing small abrasion to clothes.

Owner:HAIER GRP CORP +1

Method and device for controllable foam cleaning for washing, disinfection and sterilization

ActiveCN103191880AImprove efficiencyControl penetrationWashing processesOther washing machinesMode of actionInternal pressure

The invention relates to a method and a device for controllable foam cleaning for washing, disinfection and sterilization. A heating component is used for heating a working solution to generate foams, and a lot of foams are directly formed in a cleaning room or introduced to the cleaning room from the outside; through the effective control of foam cleaning, the dirt, harmful substances and microorganisms which are attached to cleaning objects in the cleaning room are in sufficient contact with effective ingredients on the foam surface in the cleaning room, separated, destroyed or killed by various modes of action, separated from the surface of a cleaned object together with foams along with the decrease of internal pressure and temperature of the cleaning room, and then discharged out from the cleaning room. Compared with the traditional product, the cleaning device designed according to the technology is higher in efficiency, shorter in washing time, lower in energy consumption, less in water consumption and lower in noise and product cost. The method and the device are suitable for cleaning, disinfection or sterilization of various cleaning objects such as tableware, medical appliances, clothes, industrial parts, antiques and antiquities, pets, animals and human skin.

Owner:河北合盛科技有限公司

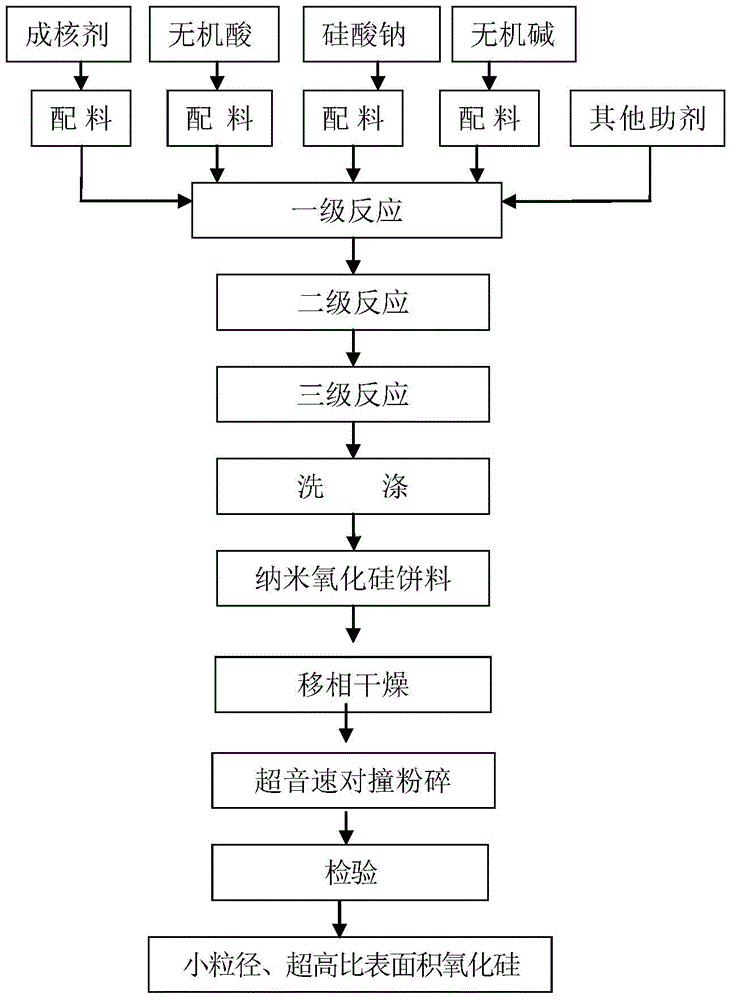

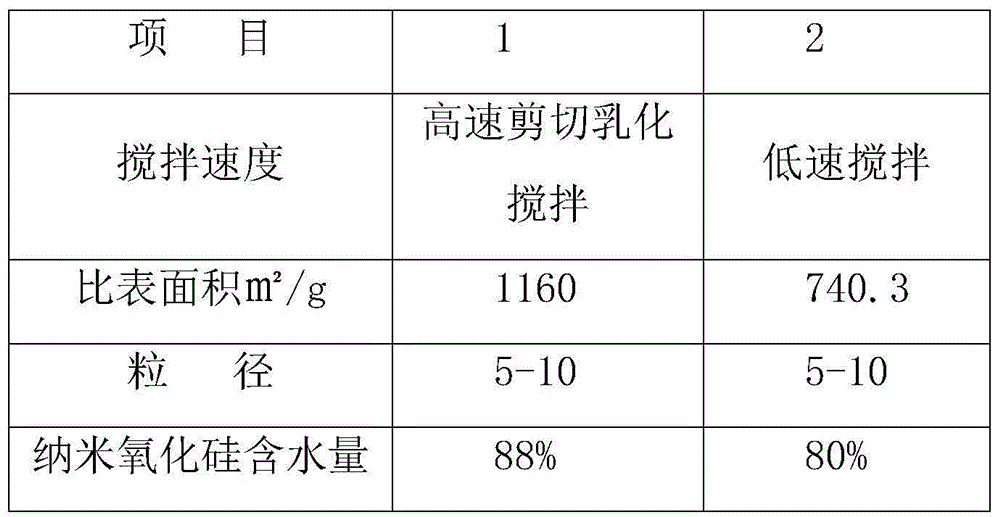

Small-particle-size ultrahigh-specific-area nano silicon oxide

ActiveCN104828828AConcentration Stable EquilibriumLow reaction temperatureSilicaNanotechnologyStrong acidsOxide

The invention discloses a small-particle-size ultrahigh-specific-area nano silicon oxide which is prepared by the following steps: adding metered inorganic acid, water glass, a nucleator, a dispersing agent and pure water into a reaction vessel, and emulsifying and stirring by high-speed shearing to perform primary reaction; added metered primary reaction product, inorganic acid and a nucleator into a reaction vessel, stirring at low speed to perform secondary reaction; regulating the pH value of the reaction product after secondary reaction to less than 3, and carrying out aging reaction under such conditions to stably form the particles; and carrying out deacidifying-desalting washing on the product under strong acid conditions to obtain the small-particle-size ultrahigh-specific-area nano silicon oxide. The particle size of the nano silicon oxide can reach 5-10nm, and the specific area is up to 600-1160 m<2> / g. The nano silicon oxide has small particle size and ultrahigh specific area, and thus, has excellent effects when being applied to multiple fields.

Owner:上饶市安纳拓新材料有限公司

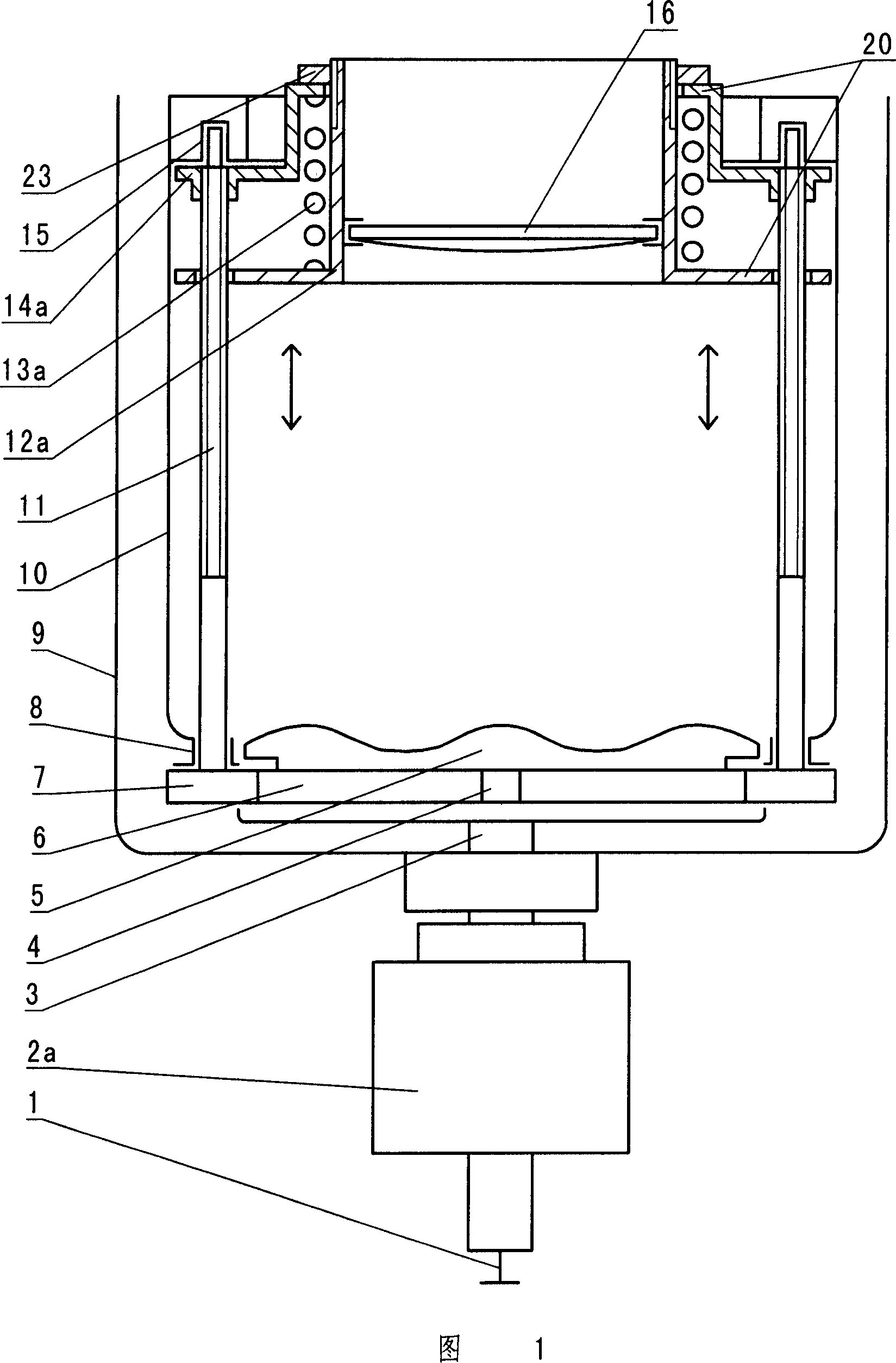

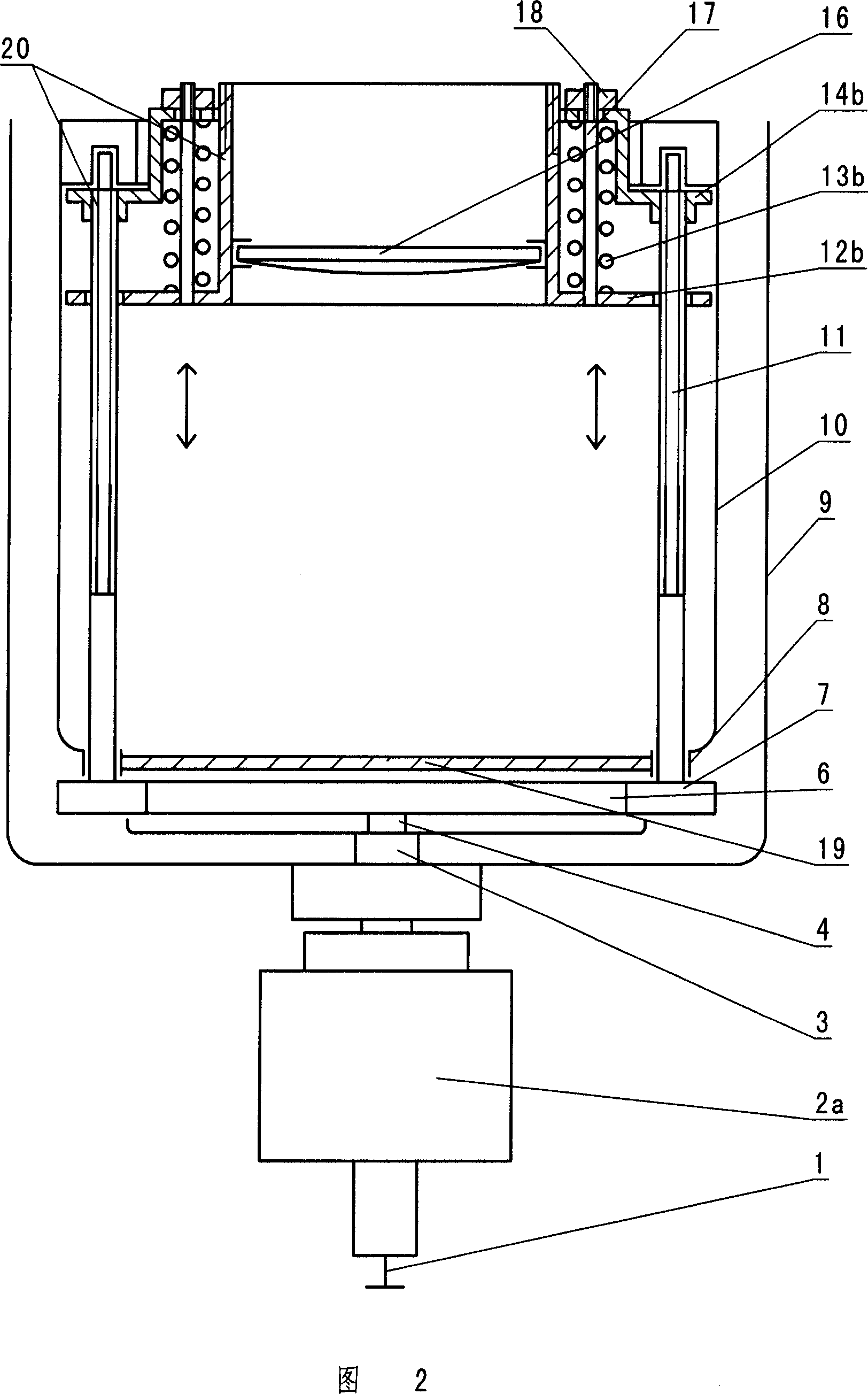

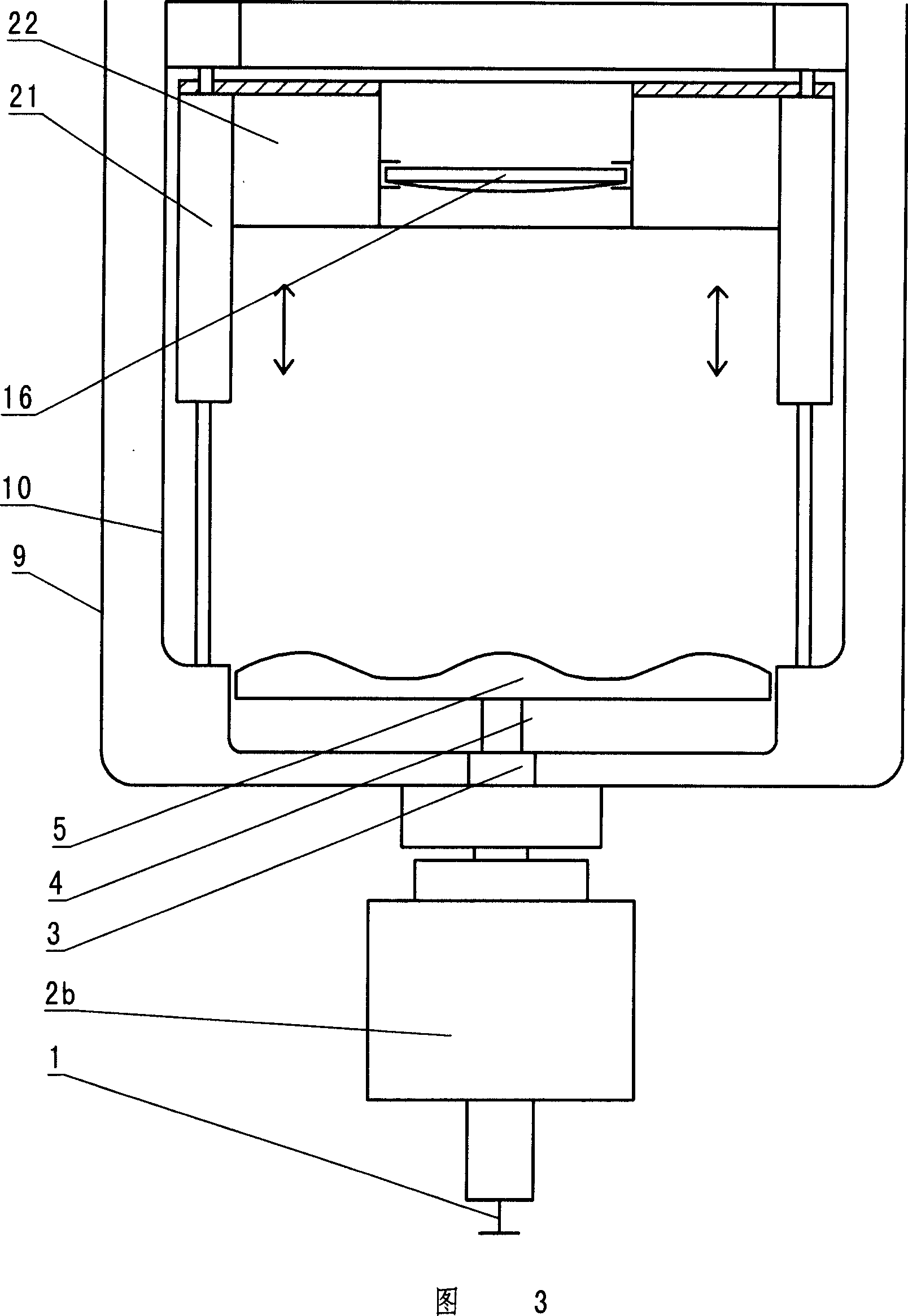

Washing mode of washing machine and fully automatic washing machine

InactiveCN1986942ASignificant comprehensive benefitsImprove washing qualityWashing machine with receptaclesTextiles and paperReduction driveReciprocating motion

A washing mode of washer is characterized by that an axially reciprocating pressure disc is arranged in a washing drum for generating both bidirectionally rotary water stream and axially reciprocating pressure water stream to flush, beat and press the object to be washed. A full-automatic washer with said washing mode is composed of an external drum, an internal drum, a speed reducer or speed-reducing clutch with output axle and axle sleeve, a waving wheel or bottom plate, and an axially reciprocating pressure disc unit in said internal drum.

Owner:ANHUI JULONG TRANSMISSION TECH

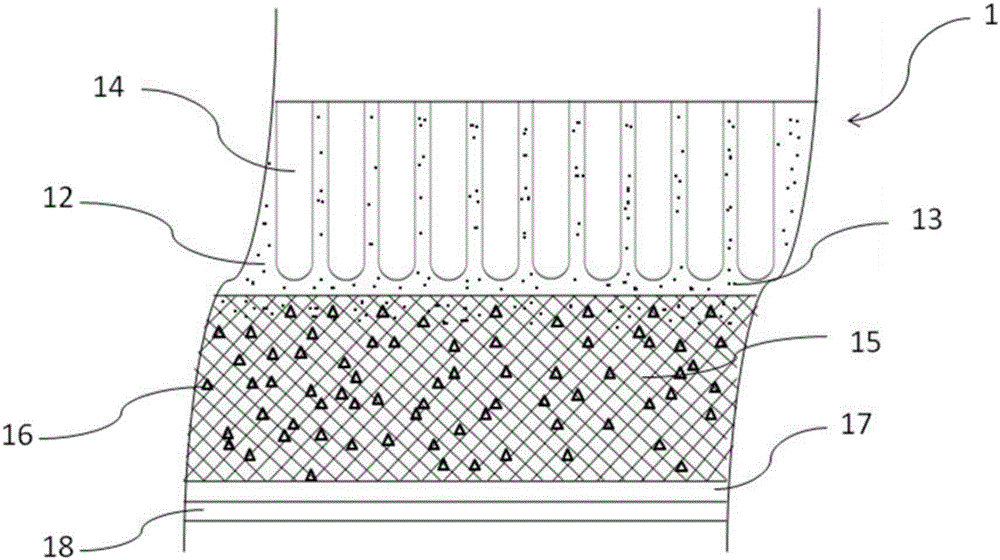

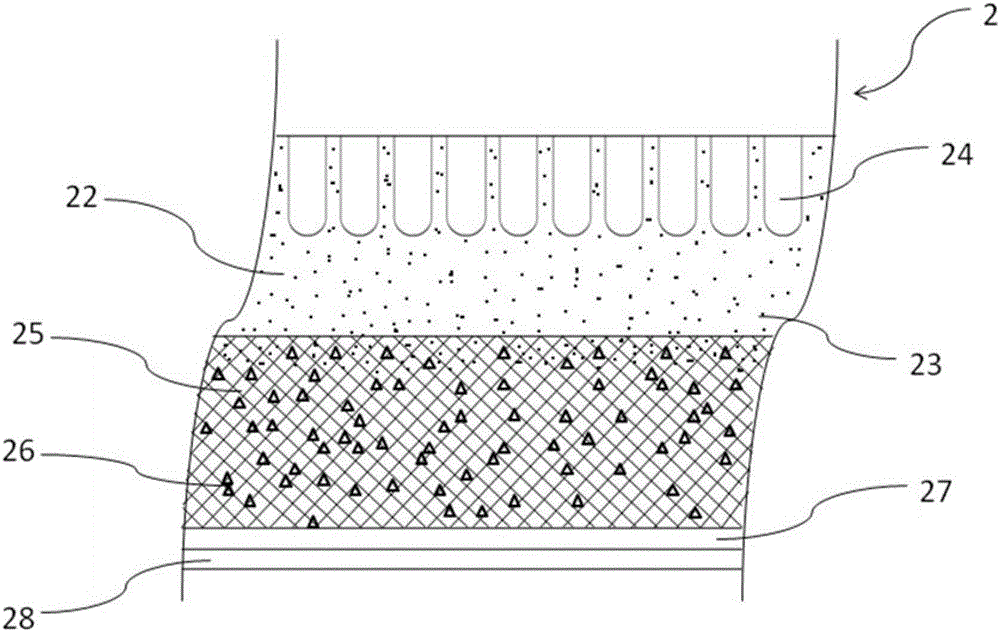

Polishing pad and preparation method thereof

ActiveCN106826541AGood water permeabilityGood and stable polishing effectGrinding devicesLapping toolsMetallurgyAdhesive

The invention discloses a polishing pad. The polishing pad comprises a base material and a polishing layer arranged on the base material, wherein the base material is formed after infiltration with a water-soluble adhesive; the polishing layer comprises a coating body and multiple cylindrical holes, and the coating body is full of three-dimensional through structure holes; the cylindrical holes are longitudinally distributed in the coating body; the top end of each cylindrical hole is connected with the top surface of the coating body, and a space is formed between the bottom end of each cylindrical hole and the bottom surface of the coating body; the height of the space is smaller than 1 / 4 of the height of the coating body. The polishing pad can well store chips produced in the storage and polishing process, prevents a polishing assembly from being scratched and is beneficial to improvement of the polishing effect and long in service life. The invention further discloses a preparation method of the polishing pad. Non-woven fabric is infiltrated into the water-soluble adhesive, dried and subjected to hot roller ironing treatment, a surfactant is applied to the back side, then, the surface is coated with a polyurethane solution, then, the non-woven fabric enters a coagulation bath and is subjected to water washing, drying and surface treatment, and the polishing pad is obtained. The process is simple, the coagulation and water washing efficiency is high, and the production efficiency is greatly improved.

Owner:河南惠强新能源材料科技股份有限公司

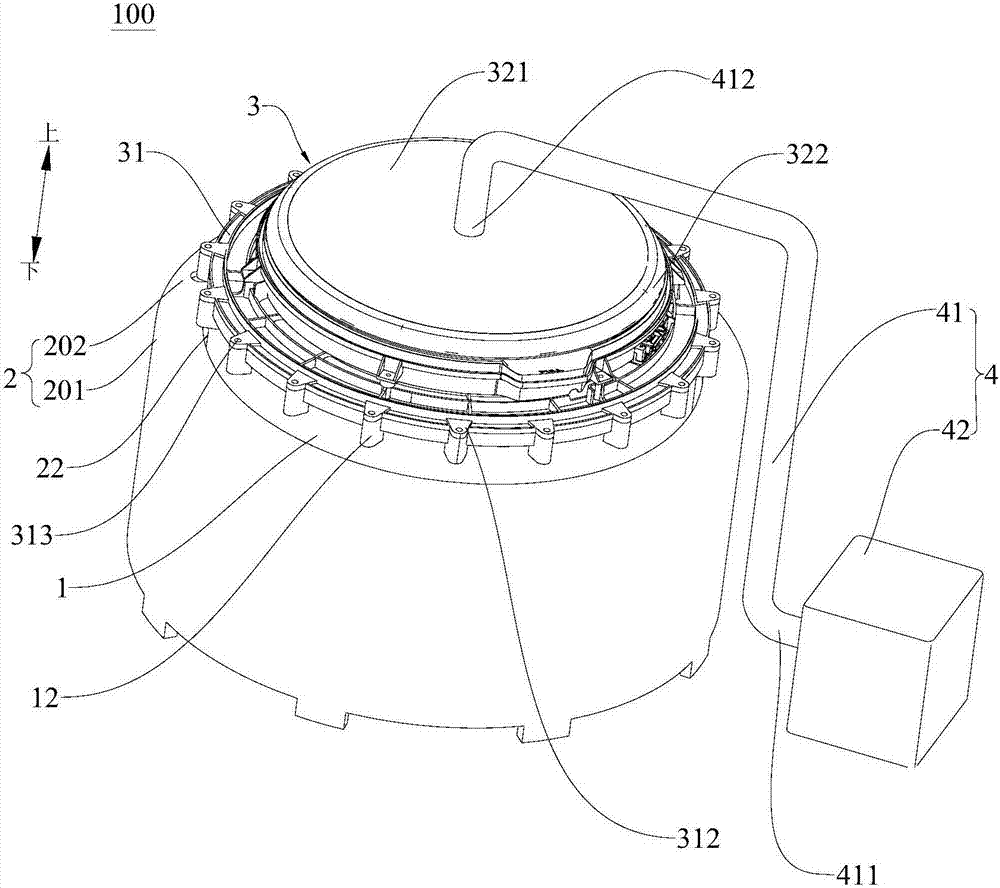

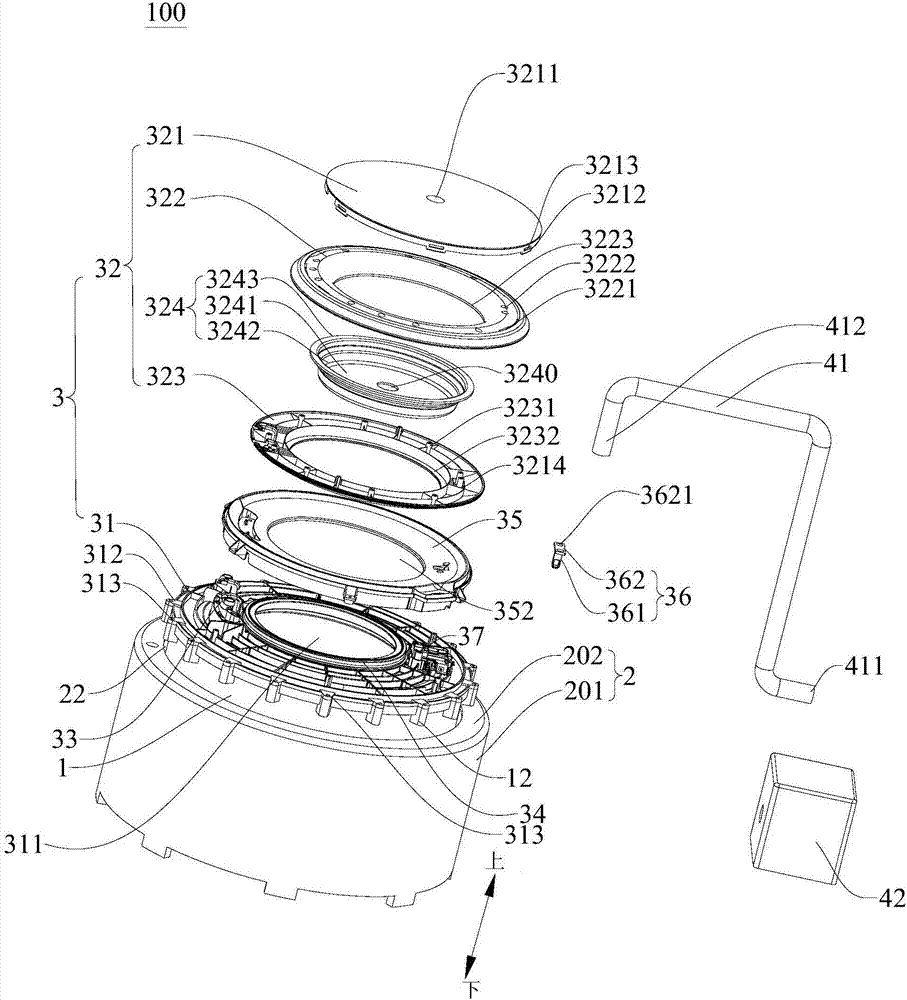

Washing machine and washing method of washing machine

ActiveCN107190454AReduce power consumptionReduce use costOther washing machinesWashing machine with receptaclesWater storageWater flow

The invention discloses a washing machine and a washing method of the washing machine. The washing machine comprises a washing barrel, an outer barrel, and a door body assembly and an air exhaust system. Washing space is defined in the washing barrel. The outer barrel is arranged outside the washing barrel, water storage space is defined between the outer barrel and the washing barrel, the water storage space is communicated with the washing space, and the water storage space is communicated with external atmosphere. The door body assembly is arranged on the washing barrel to open and close the washing space. The air exhaust system comprises an air exhaust pipe and an air exhaust device, the first end of the air exhaust pipe is communicated with the air exhaust device, the second end of the air exhaust pipe is suitable for being communicated with the washing space, and the air exhaust device is configured to carry out air exhaust on the washing space to enable the air pressure in the washing space to be smaller than the pressure of the external atmosphere. According to the washing machine, washing water in the washing barrel strongly rolls and flows through the pressure difference between the water storage space and the washing space, therefore, dirt on clothes can be removed under washing of strong currents, and the washing effect is achieved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

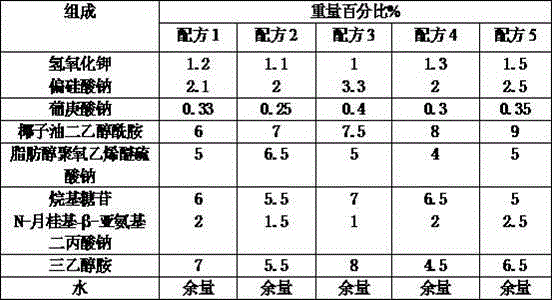

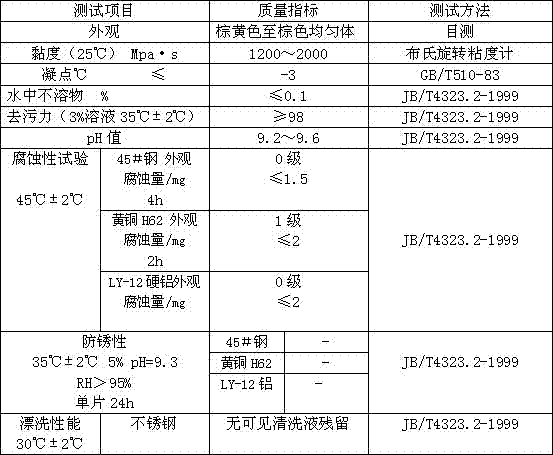

Efficient and environmentally friendly industrial heavy oil stain cleaning agent

ActiveCN105623890ASuperior emulsificationShort washing timeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsChemistryTriethanolamine

The present invention relates to the technical field of industrial cleaning agents, and in particular relates to an efficient and environmentally friendly industrial heavy oil stain cleaning agent which comprises or contains potassium hydroxide, sodium metasilicate, sodium glucoheptonate, coconut diethanolamide, polyoxyethylene fatty alcohol ether sodium sulfate, alkyl glucosides, N-dodecyl-beta-iminodipropionic acid monosodium salt, triethanolamine and deionized water. The efficient and environmentally friendly industrial heavy oil stain cleaning agent has the advantages of fast cleaning speed, good cleaning effect, saving energy, reducing cost, wide application range and the like, can be used for surface heavy oil stain cleaning of a variety of large equipment and machinery parts. Meanwhile, the raw material formula is free of phosphates and nitrites, and surfactants biologically difficult to degrade, and is ecological and environmentally friendly.

Owner:南京精锐新材料有限公司

Barrel plating method of trivalent color zinc

The invention relates to the field of electroplating, in particular to a barrel plating method of trivalent color zinc. The barrel plating method comprises the steps of step I, carrying out thermal degreasing; step II, carrying out pickling; step III, carrying out electroplating; step IV, carrying out bright dipping; step V, carrying out trivalent color zinc plating; step VI, cleaning with hot water; and step VII, placing a treated product in a tray. According to the barrel plating method, a new product is subjected to oil removing and derusing through clean water cleaning and pickling, the technological process is reduced, and the cost is reduced.

Owner:CHONGQING PENGLEI AUTO PARTS CO LTD

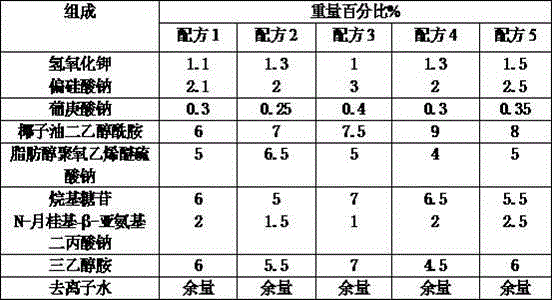

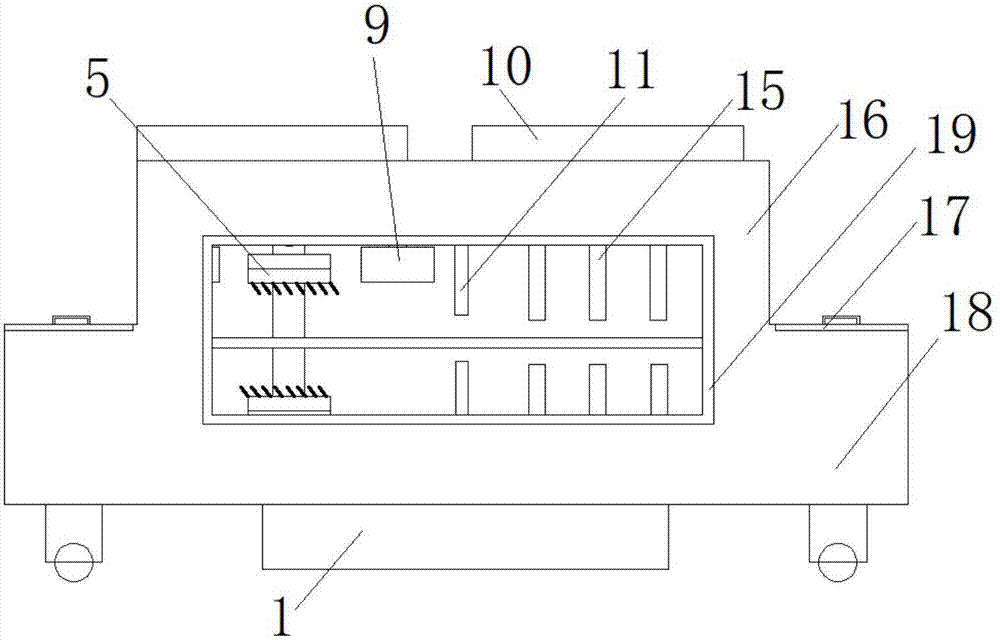

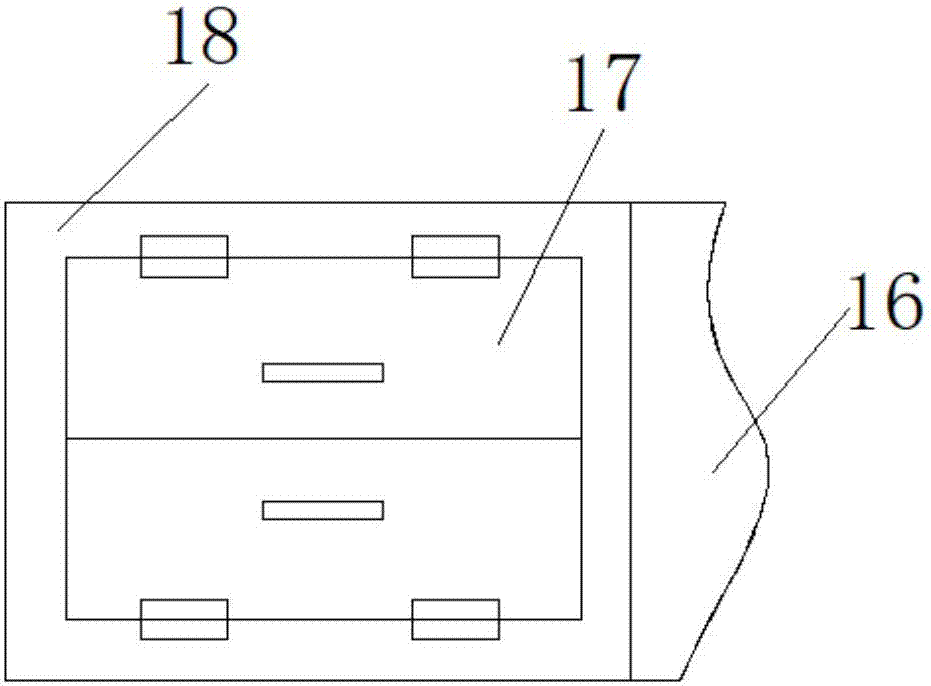

Washing and disinfection device for medical tools

PendingCN107214135AImprove drying efficiencyReduce residual bacteriaDrying gas arrangementsCleaning using liquidsWater savingEngineering

The invention discloses a washing and disinfecting device for medical tools, which comprises a base box and a cleaning box. The top of the side inner wall is connected with electric slide rails by bolts, and the same hollow sliding bearing platform is slidably connected between the two electric slide rails, and rectangular mounting holes are opened on both sides of the top of the cleaning box. The medical tool of the present invention moves on the top of the base box, which saves human resources, and at the same time connects washing, disinfection and drying, and the washing time is shorter. In the case of saving water resources, the effect of quick cleaning is achieved, and the drying efficiency of the medical tool is high. When the medical tools are in the cleaning box, the ultraviolet light is continuously irradiated to sterilize, which reduces the residual bacteria on the medical tools, makes the washing and disinfection efficient, and does not affect the frequency of use of the medical tools, reducing the burden on the hospital.

Owner:湖南丹尼尔智能科技有限公司

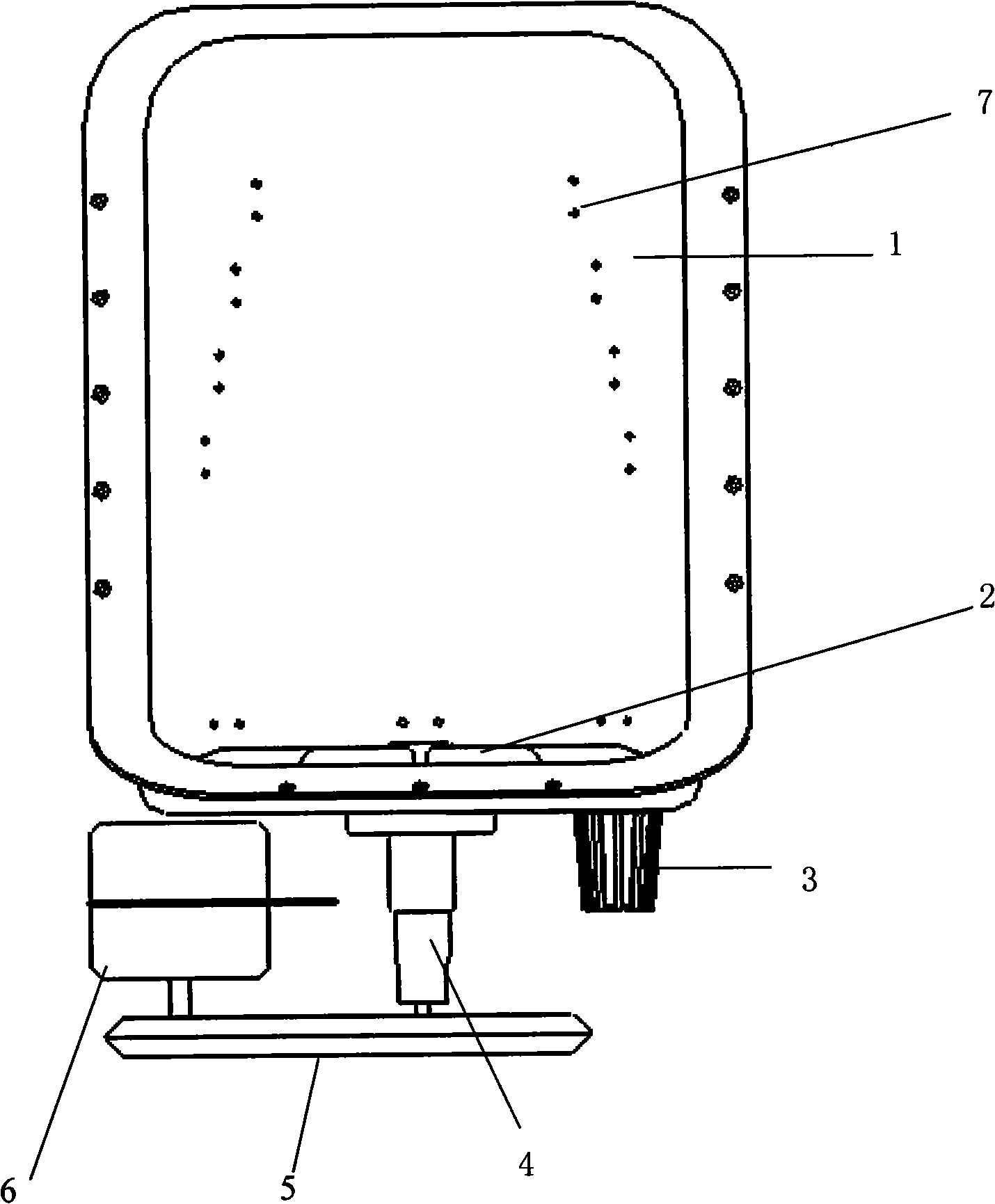

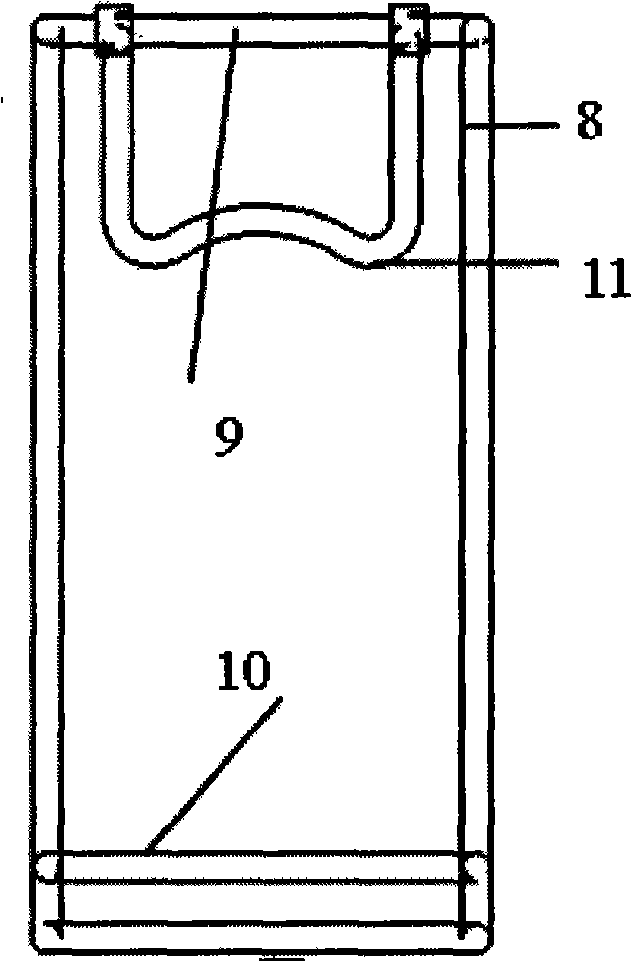

Rotational flow flushing type domestic bowl-washing machine

InactiveCN101278823AAccelerate agencySimple organizationTableware washing/rinsing machinesProcess engineeringRotational flow

The invention provides a rotary flushing type household dishwasher, which comprises a mounting bracket of tableware, a heating system, a disinfecting system, a solid dirt filtering mechanism and a discharging system. The invention is characterized in that the dishwasher also comprises a wave-wheel washing mechanism and a washing container for filling water; the wave-wheel washing mechanism comprises a motor and a wave wheel, the wave wheel is arranged at the bottom of the washing container and the motor is arranged below the washing container; the mounting bracket of tableware is arranged in the washing container; the wave wheel rotates under the driving of the motor and produces rotating flow in the water-filled washing container, thus achieving the flushing type washing of the tableware in the relative movement between the water body and the tableware. The dishwasher has no need of caring the washing of dead-angle, speeds up the washing process, simplifies the operation and the mechanism of the whole dishwasher and reduces the washing time and cost, thus achieving the aim of energy saving and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

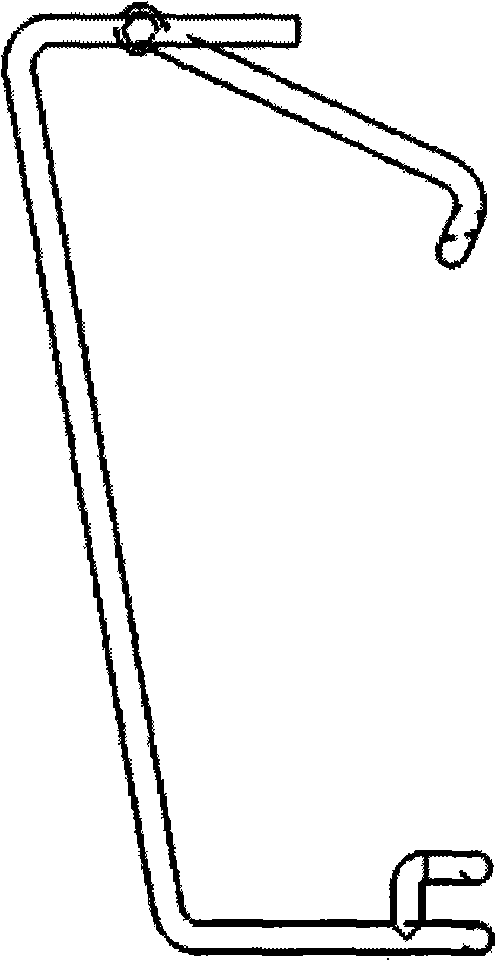

Bidirectional lateral washing method for filter cake of filter press

The invention discloses a bidirectional lateral washing method for a filter cake of a filter press. A three-way left pipeline and a three-way right pipeline are arranged on the two sides of a thrust plate of the filter press to realize bidirectional lateral washing, wherein the three-way left pipeline is provided with a left valve and is connected with a washing pump; the three-way right pipeline is provided with a right valve and is connected with the washing pump; the three-way left pipeline is provided with a left drain valve and is connected with a drain pipe; the three-way right pipeline is provided with a right drain valve and is connected with the drain pipe; upper rinsing holes and lower rinsing holes are formed at four corners of a filter plate; an upper liquid inlet hole and a lower liquid inlet hole are formed on one side of the filter plate; one side of the filter plate is connected with a filter chamber; and the filter plate is installed on a main beam and is transversely arranged along lateral holes. When the filter cake is washed by the bidirectional lateral washing method for the filter cake of the filter press, beneficial effects are as follows: the purity of the filter cake is quickly improved, the recycling rate of filtrate is quickly improved, the energy is saved, the cost is reduced, and the production efficiency is improved.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

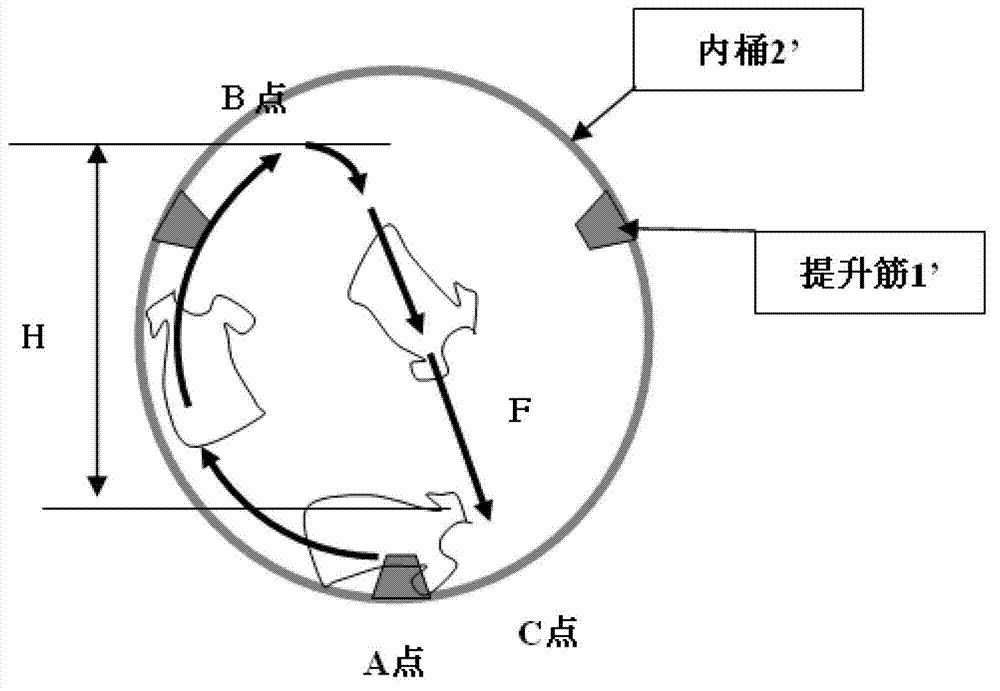

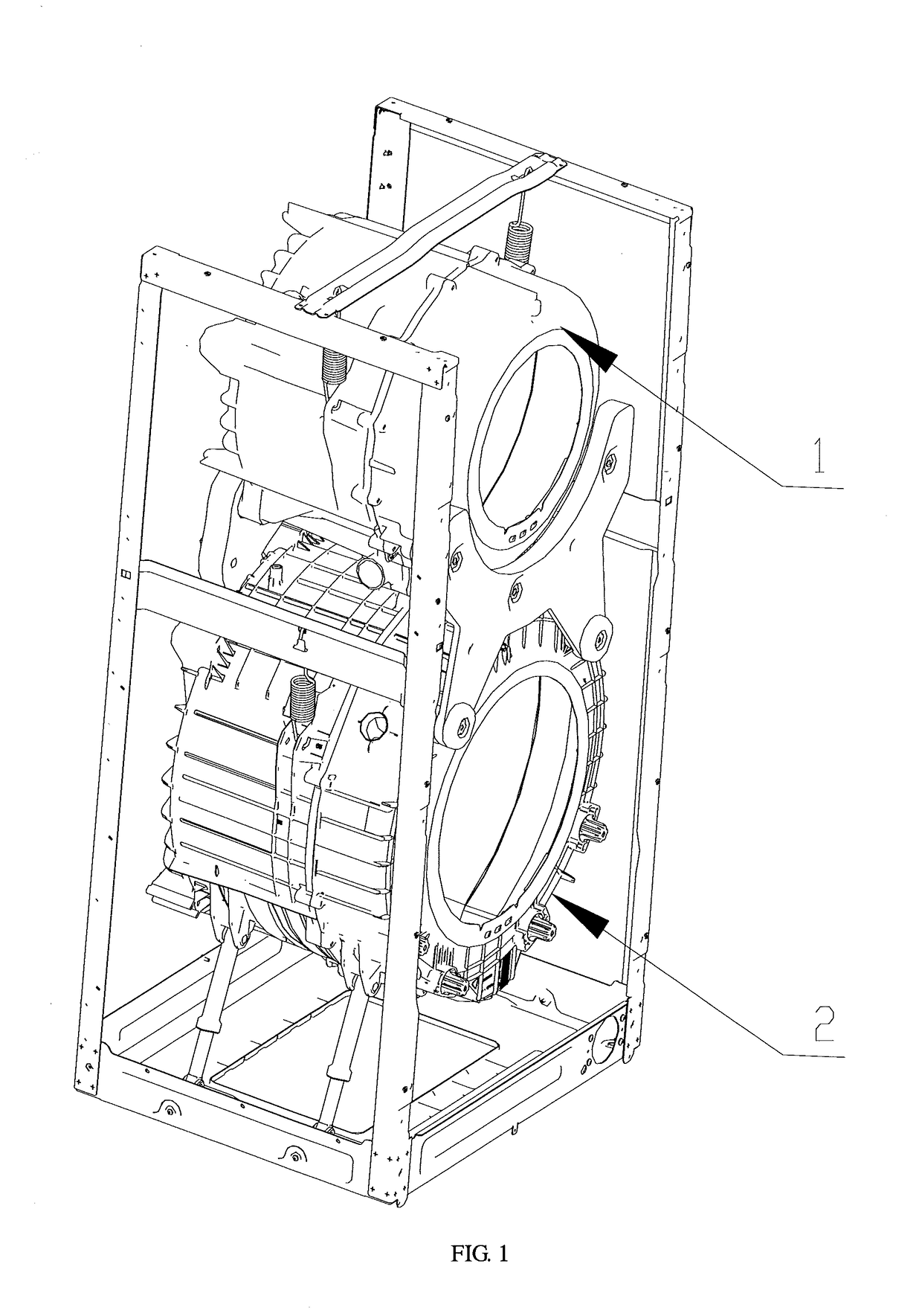

Roller washing machine and control method thereof

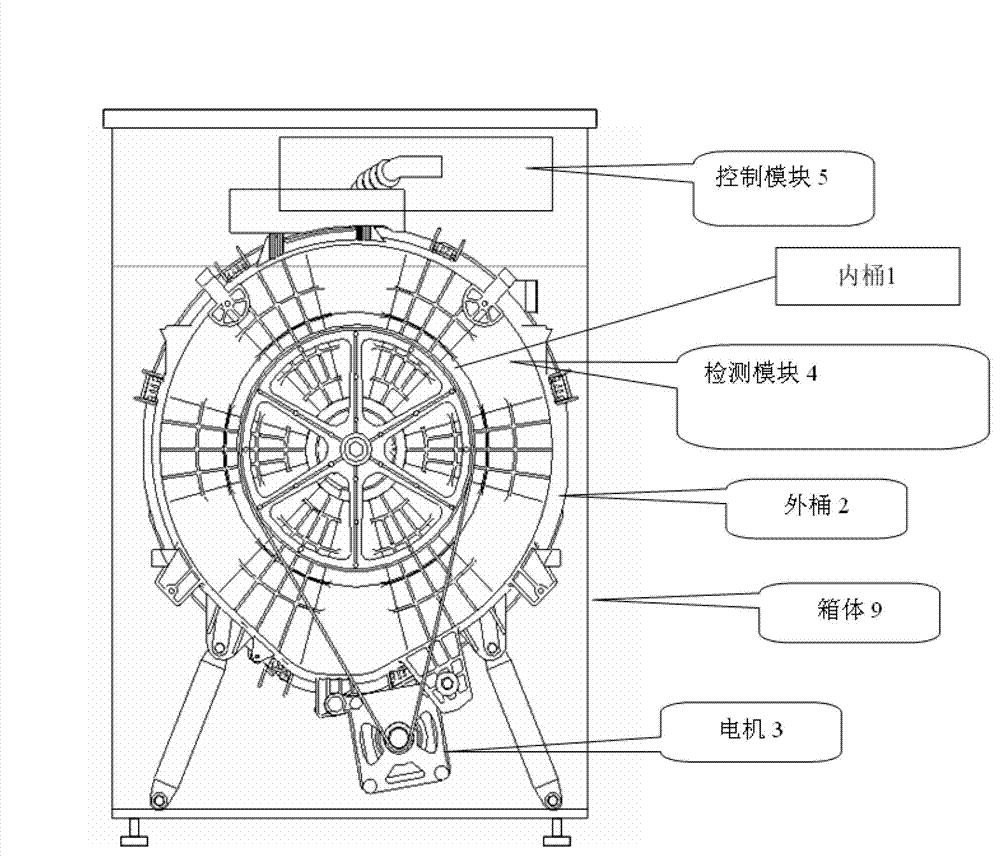

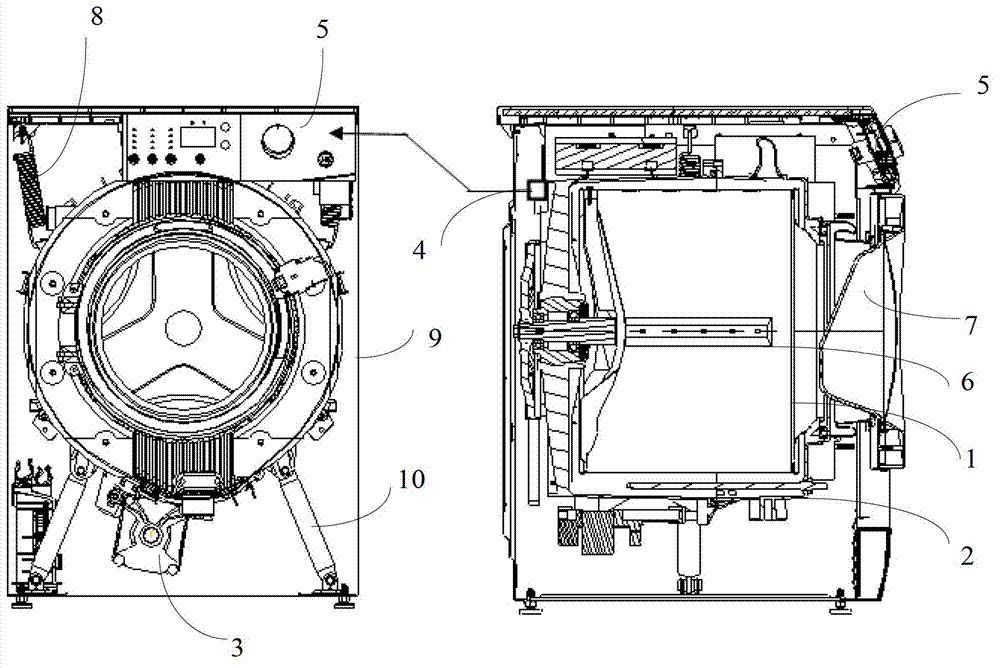

ActiveCN103088601AShort washing timeImprove cleaning rateOther washing machinesControl devices for washing apparatusElectric machineEngineering

The invention discloses a roller washing machine which comprises an inner barrel, a motor, a detecting module and a control module, wherein an outer barrel. The inner barrel is arranged inside the outer barrel, and the inner barrel and the outer barrel are arranged with the same shaft, the motor is connected with the inner barrel, the inner barrel is driven to rotate relatively to the outer barrel by the motor, the detecting module is arranged outside of the outer barrel, shocks of the outer barrel are detected to produce detecting signals by the detecting module, the control module is connected with the detecting module and the motor, the detecting signals are disposed by the control module to obtain a washing state of clothes inside the inner barrel, and a rotating speed of the motor is controlled according to the washing state of the clothes. The roller washing machine has the advantages of being short in washing time, high in cleaning rate, saving in energy and environment-friendly. The invention further discloses a control method of the roller washing machine.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

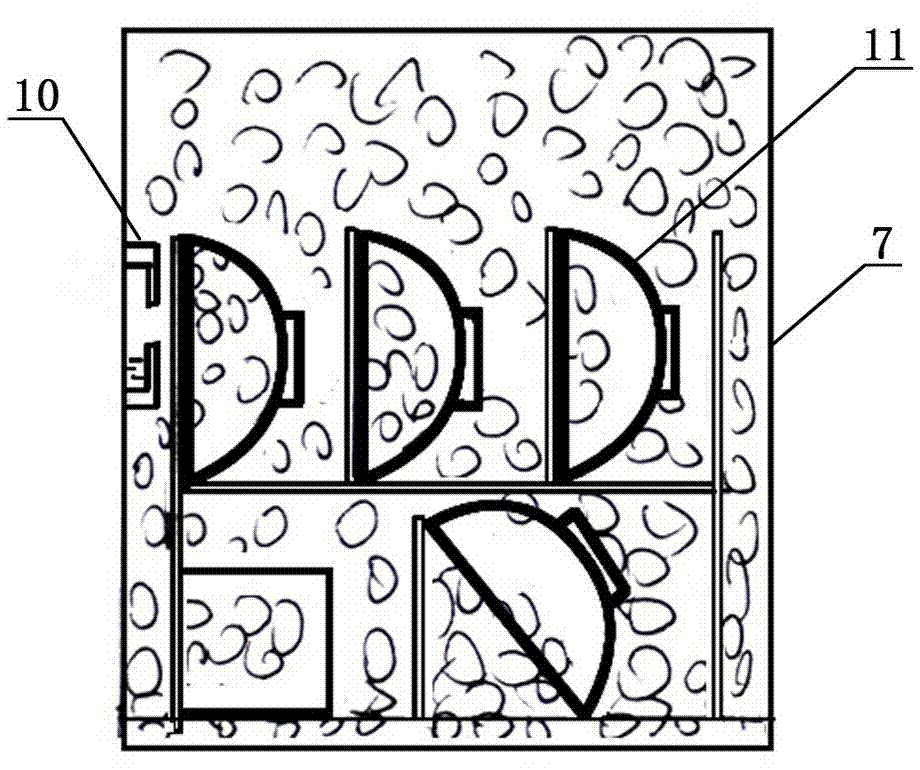

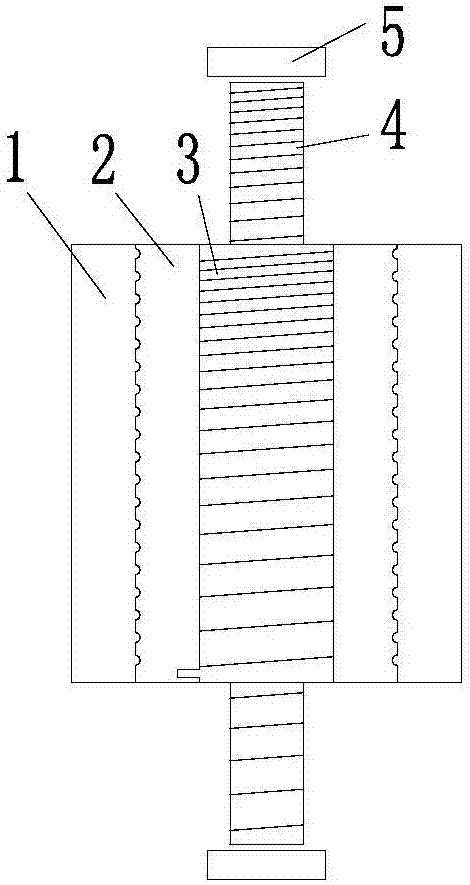

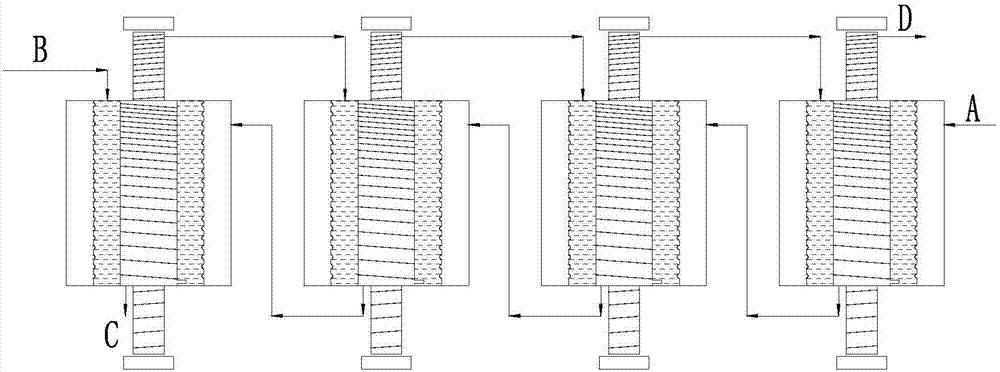

A kind of scrubber and washing device and the method for purifying polyolefin catalyst

The invention relates to the field of separation and purification, and discloses a scrubber, a washing device and a method for purifying polyolefin catalysts. The scrubber includes a first chamber and a second chamber separated by a first partition and a second partition and the third chamber, wherein the first partition is provided with a plurality of small holes that allow the materials in the first chamber to pass through and can prevent most of the materials in the second chamber from entering the first chamber, the second partition The bottom of the plate is provided with an opening, the first chamber and the second chamber are respectively provided with feed ports, and a separation mechanism is provided in the third chamber, and the separation mechanism can make the washed material and the washed agent separation, the third chamber is also provided with at least two outlets for discharging the washed materials and detergent out of the washer respectively. The method of the invention has the advantages of short washing time, high impurity extraction rate and small solvent consumption, and can realize dynamic cycle continuous washing and purification process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Scrubber, washing device, and method for purifying polyolefin catalyst

The invention discloses a scrubber, a washing device and a method for purifying a polyolefin catalyst, belonging to the field of separation and purification. The scrubber comprises a first cavity, a second cavity and a third cavity separated by a first separator plate and a second separator plate, wherein the first separator plate is provided with a plurality of small holes allowing materials in the first cavity to pass through but preventing most of materials in the second cavity from entering the first cavity; the bottom of the second separator plate is provided with an opening; the first cavity and the second cavity are respectively provided with a feed inlet; a separating mechanism is arranged in the third cavity and can separate washed materials from a washing agent through extruding;and the third cavity is also provided with at least two discharge outlets used for respectively discharging the washed materials and the washing agent from discharge outlets of the scrubber. The method provided by the invention has the advantages of short washing time, high impurity recovery rate and low solvent usage amount, and can realize dynamically circulating and continuous washing and purifying.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rack plating method of trivalent color zinc

The invention relates to the field of electroplating, in particular to a rack plating method of trivalent color zinc. The rack plating method comprises the steps of step I, carrying out thermal degreasing; step II, carrying out primary electrolytic degreasing; step III, carrying out ultrasonic degreasing; step IV, carrying out pickling; step V, carrying out last-stage electrolysis; step VI, carrying out electroplating; step VII, carrying out bright dipping; step VIII, carrying out trivalent color zinc plating; step IX, cleaning with hot water; and step X, placing a treated product in a tray. According to the rack plating method, surface treatment is carried out on a product which has thick grease and is high in rusting degree through combination of thermal degreasing, primary electrolytic degreasing, ultrasonic degreasing and final last-stage electrolysis, the effect is good, and after the product is electroplated, bubbles are avoided.

Owner:CHONGQING PENGLEI AUTO PARTS CO LTD

Dewaxing and degreasing cleaner, and preparation method and application thereof

The invention relates to a cleaner, and discloses a dewaxing and degreasing cleaner, and a preparation method and an application thereof. The dewaxing and degreasing cleaner comprises triethanolamine, cocoanut fatty acid diethanolamide, polyoxyethylene fatty alcohol sodium sulfate, sodium dodecyl sulfate, complexing agents, metal corrosion inhibitors, preservative and the balance water; the mass ratio of the cocoanut fatty acid diethanolamide, the polyoxyethylene fatty alcohol sodium sulfate and the sodium dodecyl sulfate is 4-10:2-8:0.1-2. In the dewaxing and degreasing cleaner disclosed by the invention, the cocoanut fatty acid diethanolamide, the polyoxyethylene fatty alcohol sodium sulfate and the sodium dodecyl sulfate are creatively used as surfactants, and the surface tension can be reduced effectively through mutual synergistic effect; and in order to ensure that the optimal effect of the surfactants is achieved, other components are selected preferably, and the values of the components are optimized. According to the dewaxing and degreasing cleaner disclosed by the invention, the purposes of dewaxing and degreasing are achieved at 30-40 DEG C, and the effect is good.

Owner:HUNAN UNIV OF TECH

Detergent Compositions Comprising Metalloproteases

InactiveUS20160145540A1Promote resultsImprove propertiesBiochemical fibre treatmentNon-surface-active detergent compositionsProteinase activityPolynucleotide

The present invention relates to the use of and compositions comprising isolated polypeptides having protease activity and polynucleotides encoding the polypeptides. The invention also relates to cleaning compositions, and the use of the polypeptides in cleaning processes.

Owner:NOVOZYMES AS

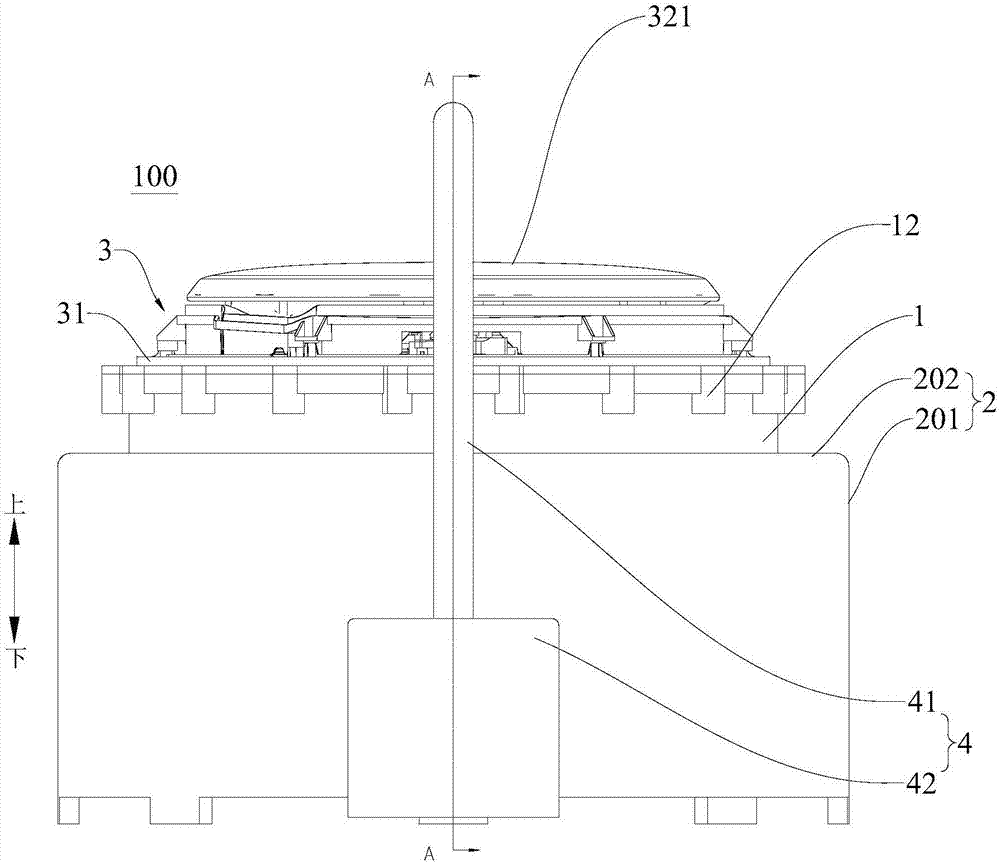

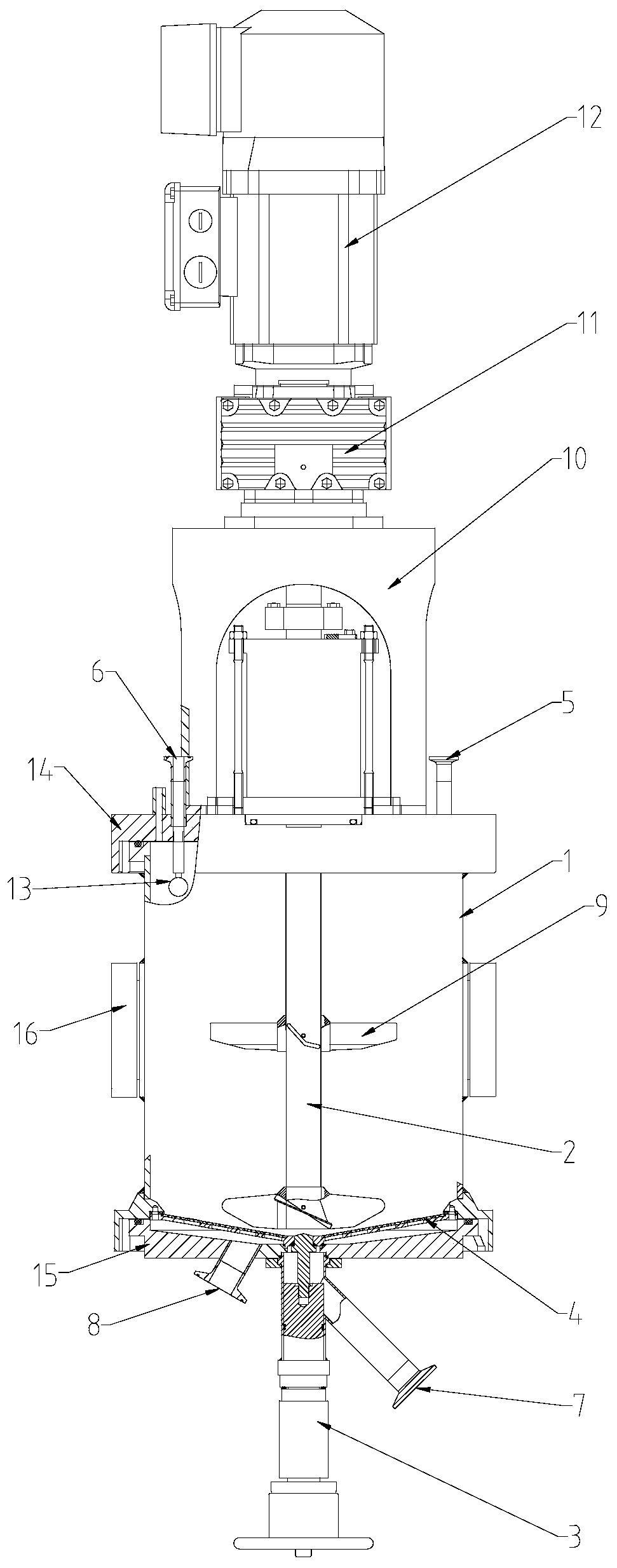

Washing and filtering device

PendingCN110639883AAvoid pollutionAvoid lostCleaning using liquidsStationary filtering element filtersElectric machinerySlurry

The invention discloses a washing and filtering device which comprises a tank body. An upper tank cover is arranged at the top of the tank body, a lower tank cover is arranged at the bottom of the tank body, a stirring rod is arranged in the tank body, a stirring paddle is arranged on the stirring rod, a motor is arranged above the upper tank cover, a speed reducer is arranged below the motor, thespeed reducer is connected with the motor, the speed reducer is connected with the upper tank cover through a mechanical seal, the upper tank cover is provided with a feeding port and a cleaning liquid port, and the feeding port communicates with the inside and outside the tank body, the cleaning liquid port communicates with the inside and outside of the tank body, a spraying ball is arranged atone end, in the tank body, of the cleaning liquid port, a washing turbid liquid outlet is arranged on the lower tank cover, the washing turbid liquid outlet communicates with the inside and outside of the tank body, a filter plate is arranged at the bottom of the inner side of the tank body, the filter plate is connected with the lower tank cover through a tank bottom valve, and a slurry outlet is arranged on the tank bottom valve. The washing and filtering device manufactured by adopting the technical scheme can complete washing and filtering processes, and can avoid pollution and loss of materials in the material transfer process.

Owner:上海迪化科技股份有限公司

Laundry liquid containing kiwifruit enzyme and plant extract and preparation method of laundry liquid

InactiveCN106675806AHigh affinityAchieve antibacterial and anti-inflammatory effectsInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBleachLaundry

The invention discloses a laundry liquid containing kiwifruit enzyme and plant extract and a preparation method of the laundry liquid. The laundry liquid comprises the following components by weight: 8-12% of kiwifruit enzyme, 16-22% of plant extract, 8-10% of alkyl glycoside, 0.5-1% of disodium ethylenediamine tetraacetate, 1-1.5% of hydroxyethyl cellulose, 0.2-0.3% of spice, 2-3% of sodium chloride, 1-2% of ginger juice, 0.5-1% of artemisia vulgaris liquid and the balance of purified water, wherein the plant extract is a mixture composed of sapindus mukorossi extract and gleditsia sinensis extract at a weight ratio of (5-6):(3-5). The laundry liquid containing kiwifruit enzyme and plant extract proposed by the invention is natural and free of phosphorus, fluorescent agent and bleaching agent, and has advantages of being efficient in decontamination, natural and antibacterial, safe, environmentally friendly, promoting skin wound healing, and being mild and non-irritating to skin and the like.

Owner:HEFEI NORMAL UNIV

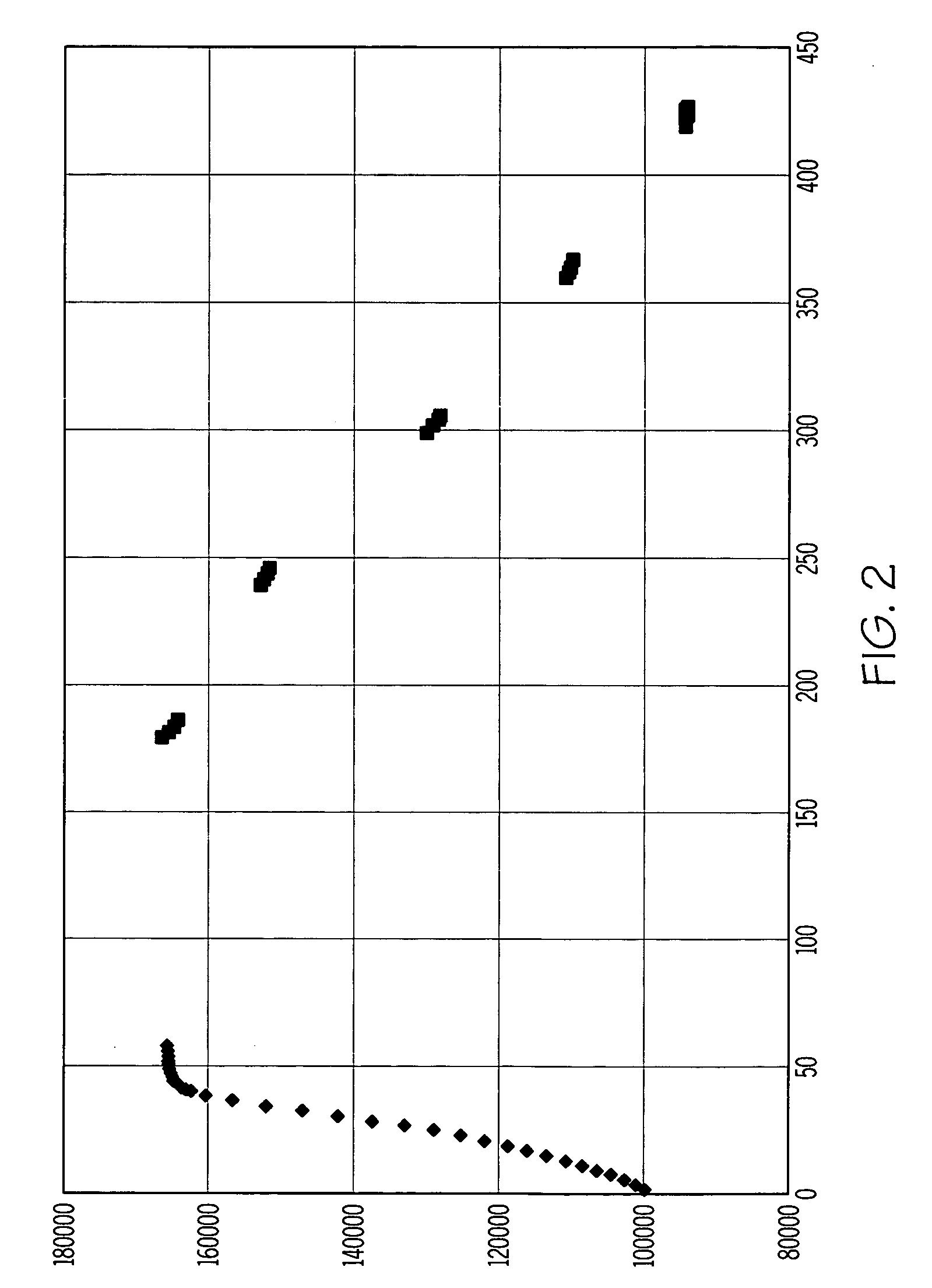

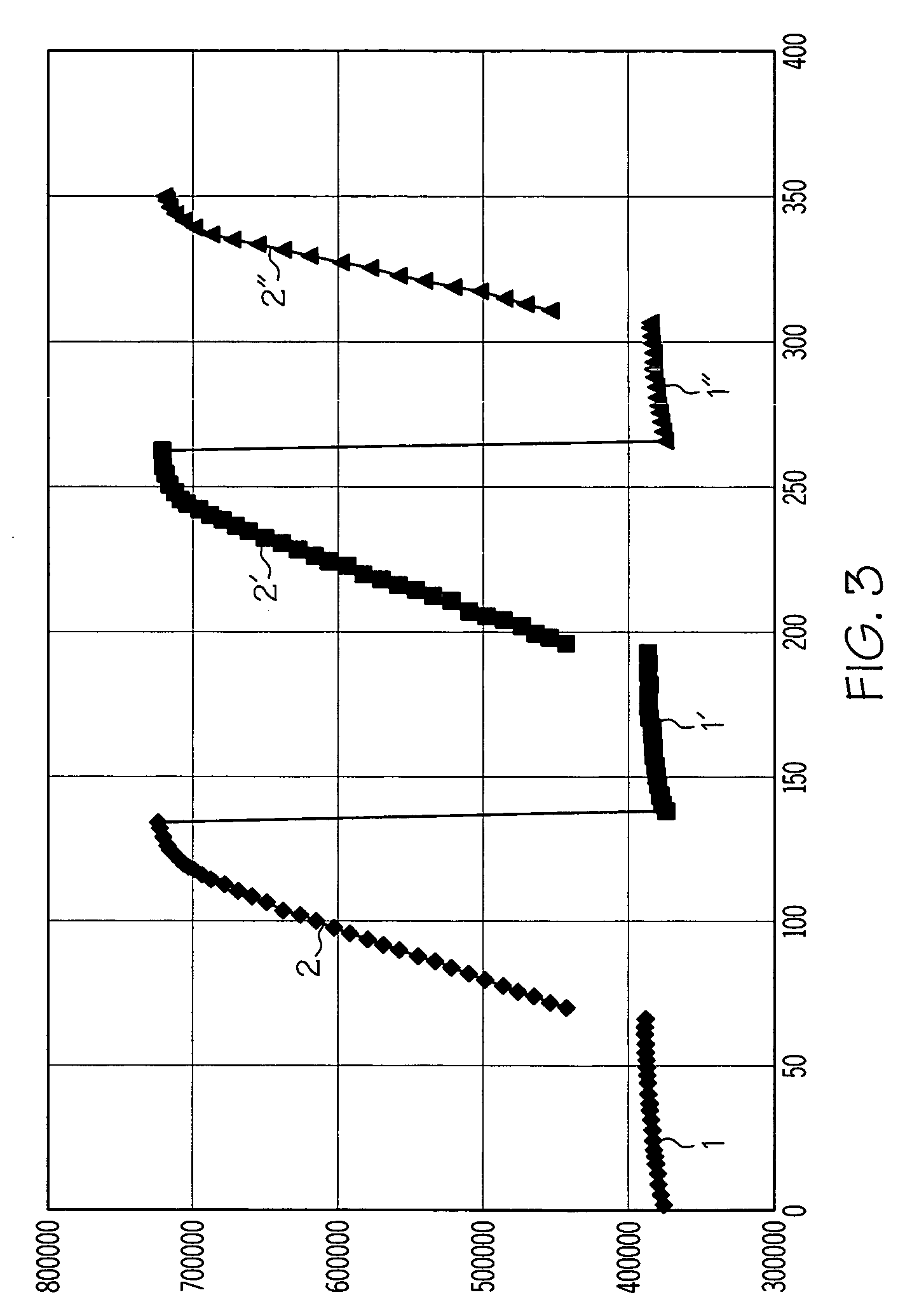

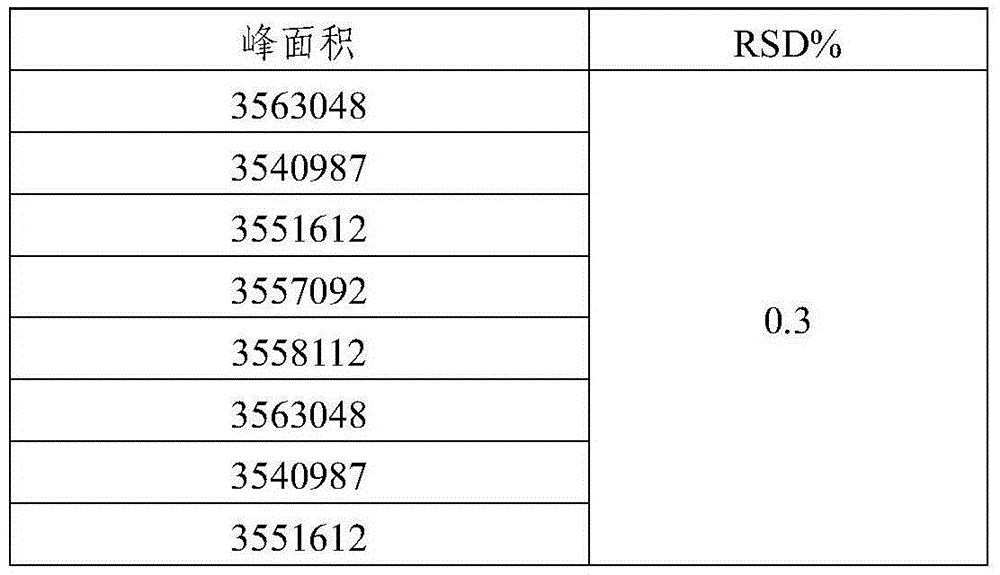

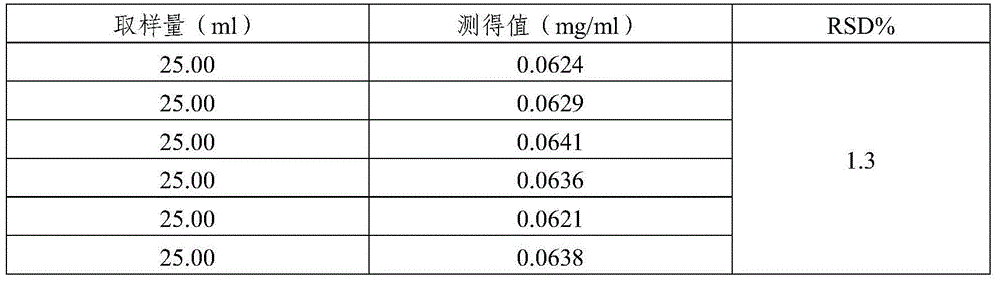

Content measurement method for Lingqijia oral solution

InactiveCN104931607AHigh molecular weightIncrease in sizeComponent separationTest sampleOral solutions

The invention relates to a content measurement method for Lingqijia oral solution. The method comprises the following steps of creating a chromatographic condition, preparing a reference solution and preparing and detecting a test sample solution. The accuracy, the precision and the durability of the method for detecting content by adopting an evaporative light chromatograph are consistent with corresponding standards, so that the method is feasible.

Owner:HEILONGJIANG ZBD PHARMA

Washing method capable of improving textile color fastness

ActiveCN103469638AImprove adsorption capacityIncrease concentrationDry-cleaning apparatus for textilesDyeing processTextile printerEnvironmental resistance

The invention relates to a washing method capable of improving textile color fastness and belongs to the technical field of textile printing, dyeing and finishing. According to the washing method, the preparation of washing liquids in a washing technology of a dyed textile is changed, and in the whole washing step, the textile is washed sequentially by an acid washing liquid, a solvent washing liquid, a soap washing liquid and a neutralization acid washing liquid, wherein each washing liquid is formed by mixing a high-proportion alcohol-type organic solvent, a small amount of water and a washing reagent, so that the problems of low textile color fastness and large water amount of a conventional pure water washing technology are solved. The washing method is capable of not only enhancing the color fastness, the brightness and the softness of the textile, but also greatly reducing the use amounts of water and washing reagents, the washing time is shorter, the production cost is reduced and the economic benefit is enhanced; besides, the pollution to environment can be greatly lowered by recycling the alcohol-type organic solvents, so that the washing method is safe, energy-saving, economical and environment-friendly and has remarkable social and economic benefits.

Owner:WUHAN TEXTILE UNIV +1

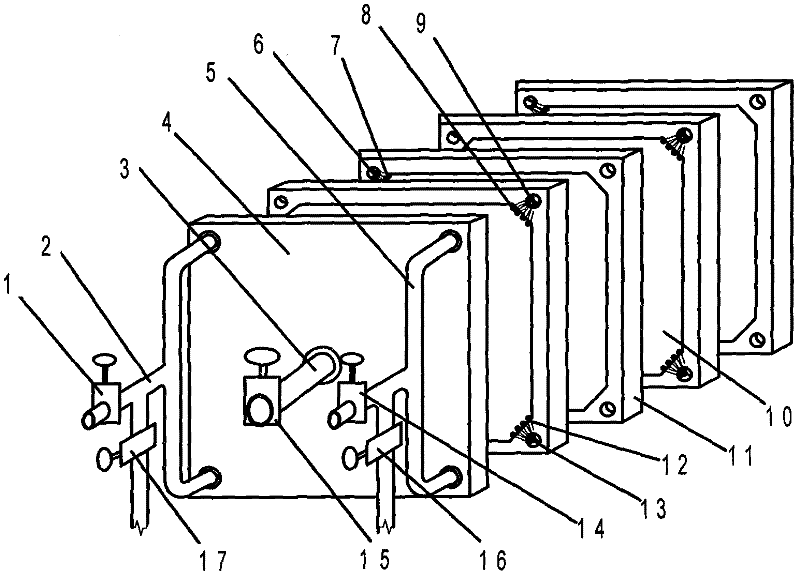

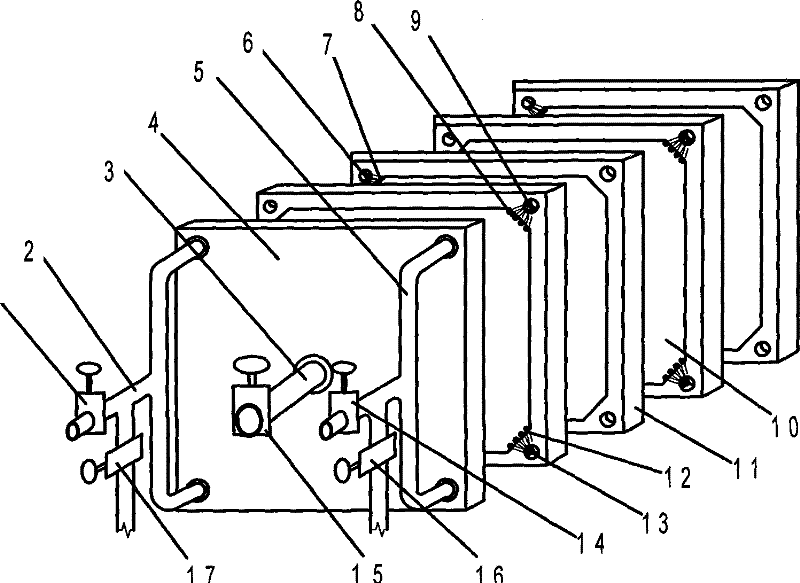

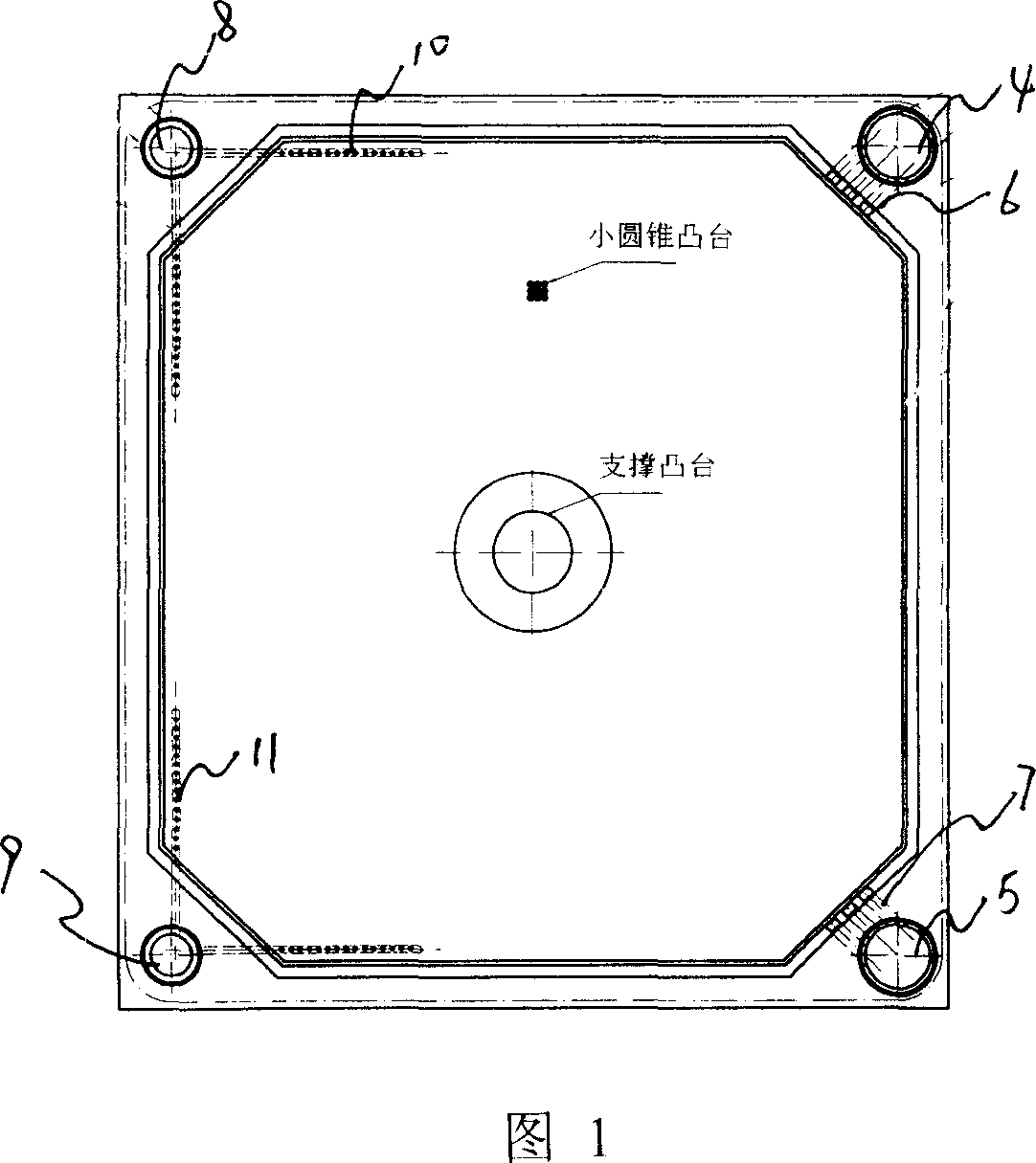

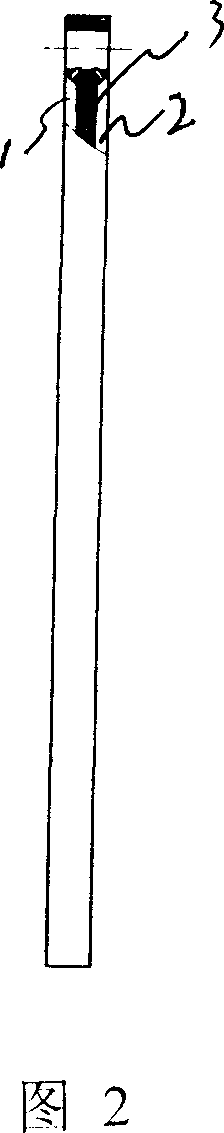

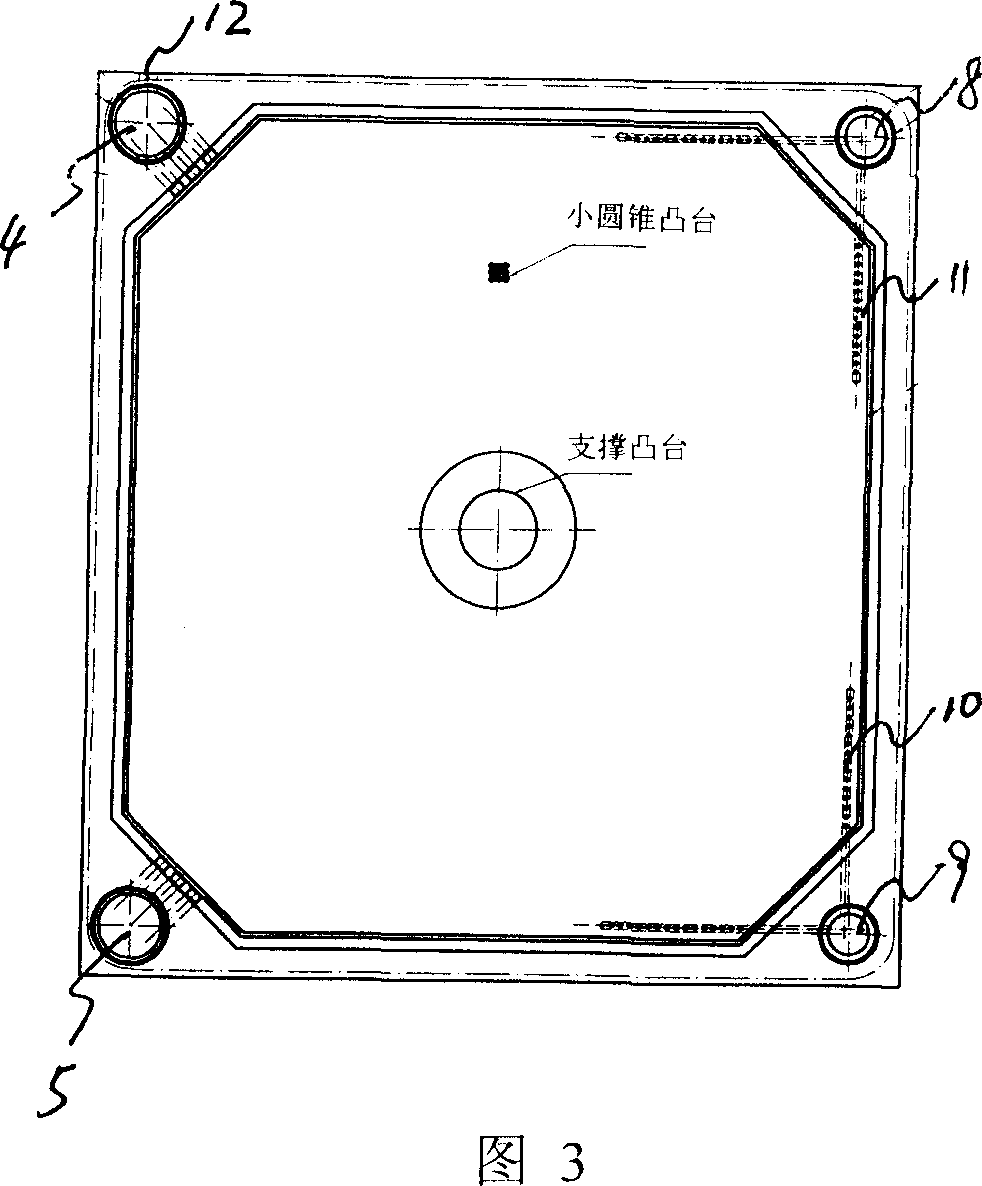

Double-corner charge built-in filter cloth and filter plate and charging liquid-spraying mode

ActiveCN101073720AResidue reductionReduce manufacturing costFiltration separationEngineeringCloth filter

Owner:杭州兴源环保设备有限公司

Industrial low-temperature whitening washing powder

InactiveCN101705161AReduce dosageReduce wearNon-surface-active detergent compositionsAmylaseTriclosan

The invention discloses an industrial low-temperature whitening washing powder, which is prepared from the following components according to a certain proportion: powdery pentahydrate sodium metasilicate, sodium carboxymethylcellulose, sodium nitrilotriacetic acid, lipase, amylase, protease, fluorescent agent, fatty alcohol-polyoxyethylene ether, amphoteric imidazoline, triclosan disinfectant, sodium perborate monohydrate, non-phosphorous additive and fatty acid potassium. The preparation method of the brightened goods washing detergent comprises the steps of firstly putting the weighted powdery pentahydrate sodium metasilicate, sodium perborate monohydrate, fatty acid potassium and sodium carboxymethylcellulose into a stirring kettle through a filter screen for 10 minutes; while stirring, simultaneously adding the non-phosphorous additive to the stirring kettle for three times, and continuously stirring for 3 minutes; pre-stirring the triclosan disinfectant, the amphoteric imidazoline and the fatty alcohol-polyoxyethylene ether for 4 minutes, and adding thetriclosan disinfectant, the amphoteric imidazoline and the fatty alcohol-polyoxyethylene ether to the stirring kettle for stirring for 4 minutes; adding the sodium carboxymethylcellulose to the stirring kettle through the filter screen for stirring for 5 minutes; uniformly scattering the lipase, the amylase and the protease into the stirring kettle for stirring for 3 minutes; and finally putting the fluorescent agent into the stirring kettle for stirring for 4 minutes.

Owner:DALIAN SANDAAOKE CHEM

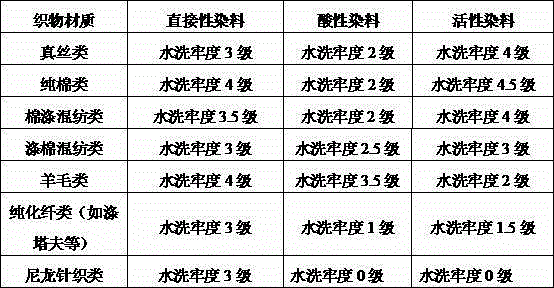

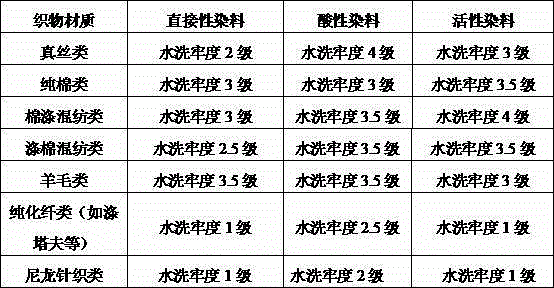

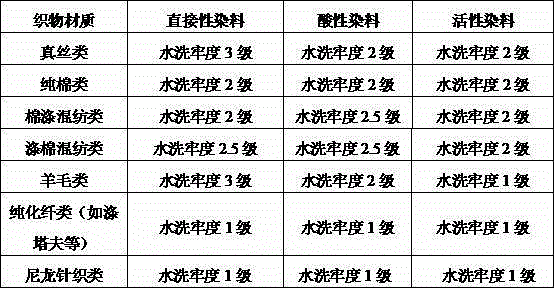

Digital printing dyeing treatment agent, preparation method and application method

A digital printing dyeing treatment agent, preparation method and application method, which is prepared by using cationic auxiliary agent, cationic etherification agent, humectant, organic solvent and water to prepare coupling cationic graft modifier and spray it on the pretreated fabric On the back, after drying and digital printing, soak in the coupling reaction agent prepared by reactant, organic acid and water, the reaction solution of color developer prepared by color developer and water, and the color fixation reaction prepared by color fixer and water The solution was colored for 30 seconds, and finally washed with water. The invention has the advantages of fast digital dyeing process at room temperature without high temperature, and can use direct dyes, acid dyes and reactive dyes to dye various fibers.

Owner:舜天嘉诚(天津)新材料科技发展股份有限公司

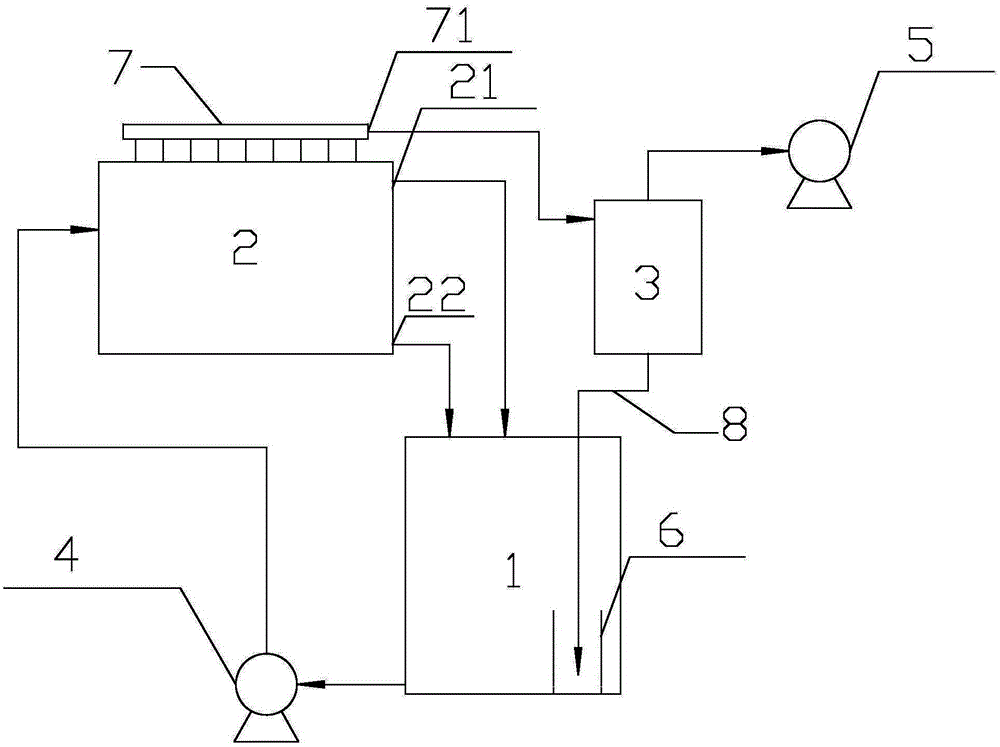

Filter cloth online circulation washing system and method of titanium dioxide water washing leaf filter

ActiveCN105413302AShorten washing timeReduce lossFiltration separationHydrofluoric acidVapor–liquid separator

The invention discloses a filter cloth online circulation washing system and method of a titanium dioxide water washing leaf filter. The system comprises a hydrofluoric acid storage tank, a filter cloth washing tank, and a gas-liquid separator; the bottom of the hydrofluoric acid storage tank is provided with a liquid sealed groove; the material outlet of the hydrofluoric acid storage tank is connected to the liquid inlet of the filter cloth washing tank, a hydrofluoric acid pump is arranged between the hydrofluoric acid storage tank and the filter cloth washing tank, the upper part of the filter cloth washing tank is provided with a liquid overflow opening, the liquid overflow opening is connected to the hydrofluoric acid storage tank, a leaf filtering machine is arranged in the filter cloth washing tank, the gas outlet of the leaf filtering machine is connected to the gas-liquid separator, the gas outlet of the gas-liquid separator is connected to a vacuum pump, and the liquid outlet of the gas-liquid separator is connected to a liquid outlet pipe, which is inserted to the bottom of the liquid sealed groove in the hydrofluoric acid storage tank. The washing time of filter cloth is short, the washing efficiency is high, the water washing of titanium dioxide can be carried out successfully, the production efficiency of titanium dioxide is improved, at the same time, the hydrofluoric acid washing liquid can be repeatedly used, the loss of hydrofluoric acid washing liquid is avoided, the consumption of hydrofluoric acid is reduced, and the pollution to the environment is reduced.

Owner:PANZHIHUA DONGFANG TITANIUM IND

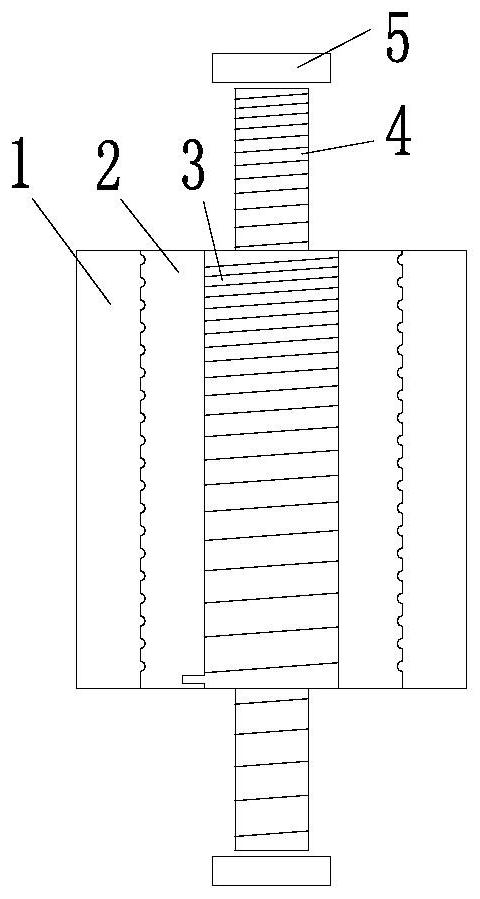

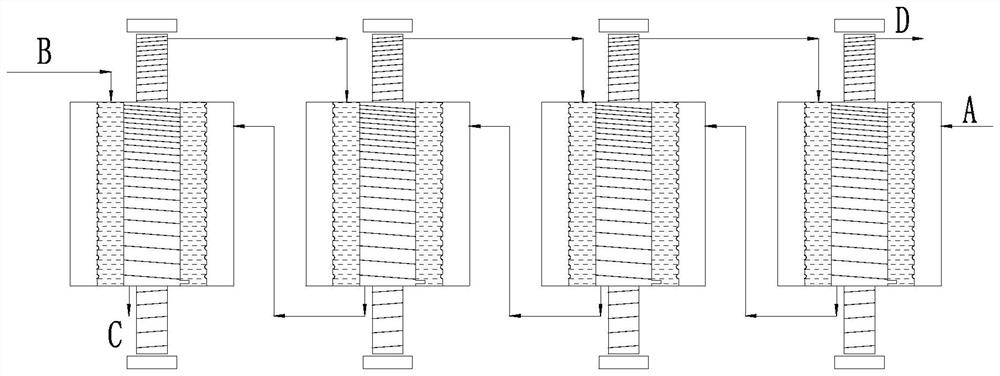

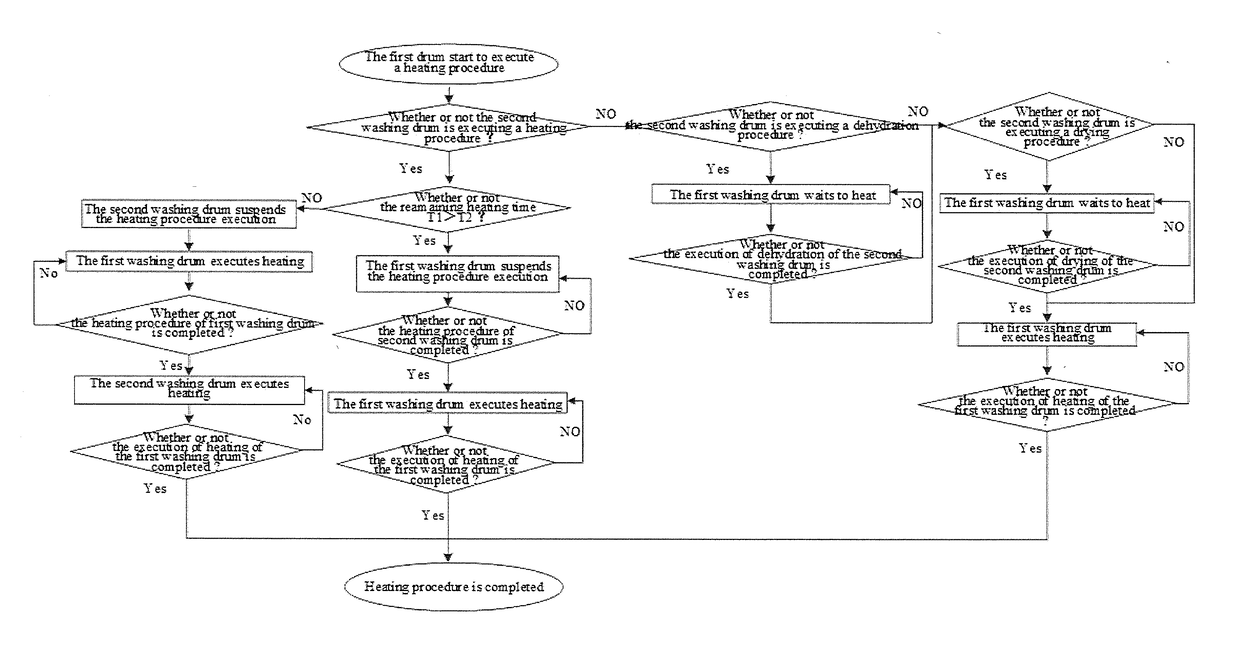

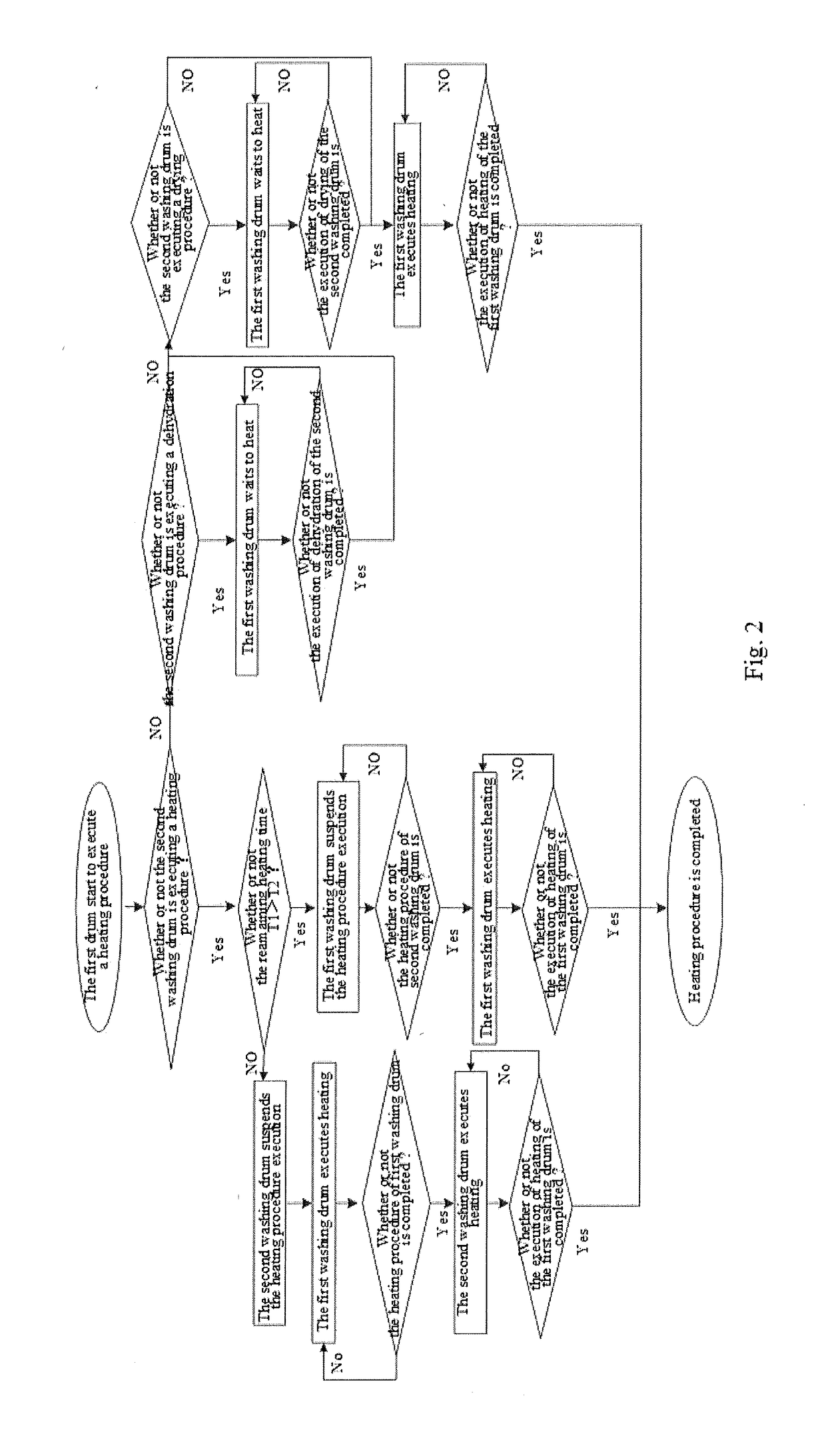

A replenishment control method of a multi-drum washing machine

ActiveUS20170342625A1Shorten waiting timeEasily realizeOther washing machinesControl devices for washing apparatusProcess engineeringWater level

A water replenishment control method for a multi-drum washing machine. The washing machine comprises at least a first washing drum and a second washing drum. While the first washing drum is in a washing process, if the water level of washing water is lower than a set value, then a water replenishment process is executed, and before that, it is necessary to determine whether or not the second washing drum is executing a water replenishment process; if yes, the first washing drum pauses the water replenishment process, and the second washing drum executes precedence preferentially; if no, the first washing drum executes water replenishment process and terminates it when the water level of the washing water reaches a set water level.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

A kind of multifunctional scrubbing oxygen particle and preparation method thereof

ActiveCN103343056BReduce contentIncrease contentSurface-active detergent compositionsOrganic/inorganic per-compounds compounding agentsCelluloseCarboxymethyl cellulose

The invention discloses multifunctional washing oxygen granules and a preparation method thereof. The invention solves the problems of poor washing effect and harm to the human body in the existing washing product. The oxygen granules comprise sulfonic acid, sodium carbonate, sodium sulfate, sodium peroxycarbonate and sodium carboxymethyl cellulose. The preparation method of the oxygen granules comprises the following steps: (1) preparing the following raw materials in percentage by mass: 5-10% of sulfonic acid, 25-35% of sodium carbonate, 10-25% of sodium sulfate, 20-60% of sodium peroxycarbonate and 1-5% of sodium carboxymethyl cellulose; (2) sequentially mixing the sulfonic acid, sodium carbonate, sodium sulfate, sodium peroxycarbonate and sodium carboxymethyl cellulose under anhydrous and low constant temperature conditions to obtain a mixture; (3) granulating the mixture at low temperature; and (4) drying the obtained granules at constant temperature. The technique is simple; and the oxygen granules prepared by the method have favorable washing effect and high capacities of stain removal, sterilization, bleaching and odor removal.

Owner:四川绿洁科技有限公司

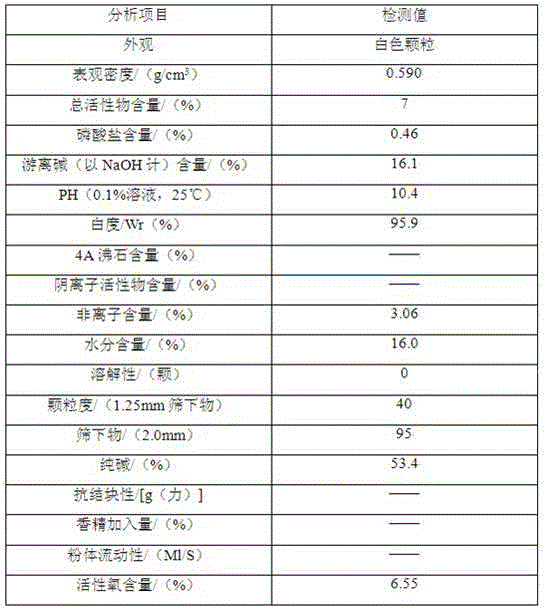

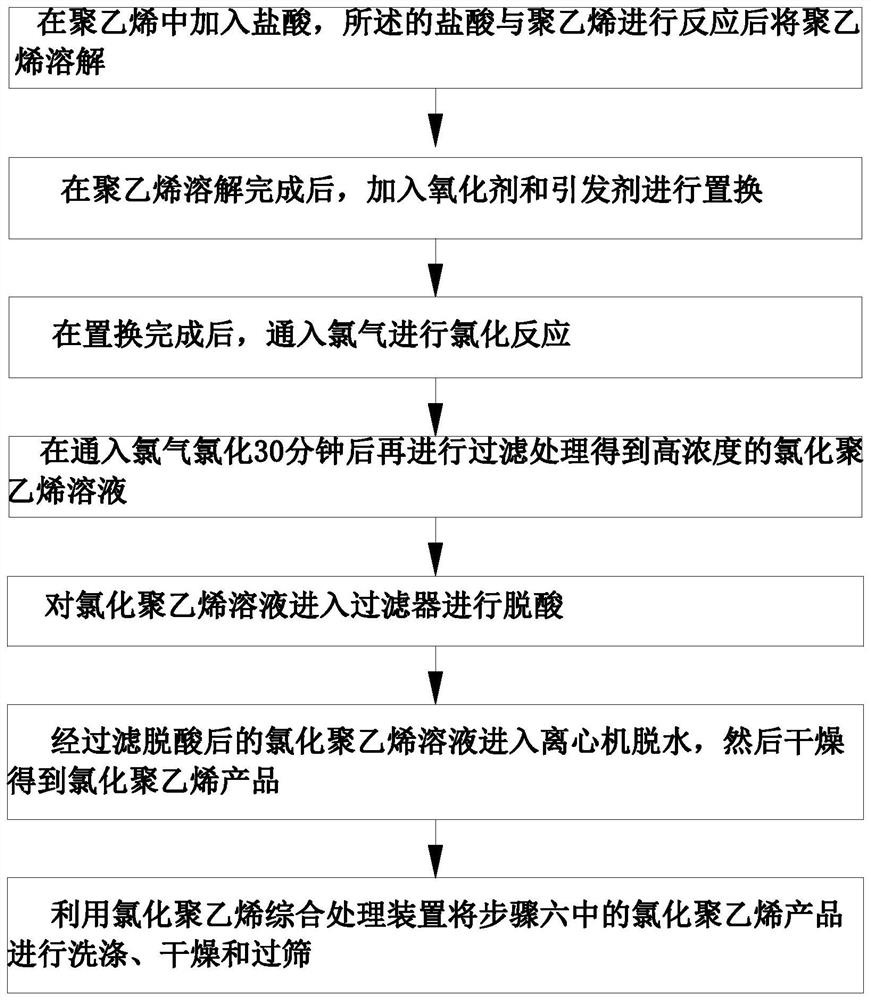

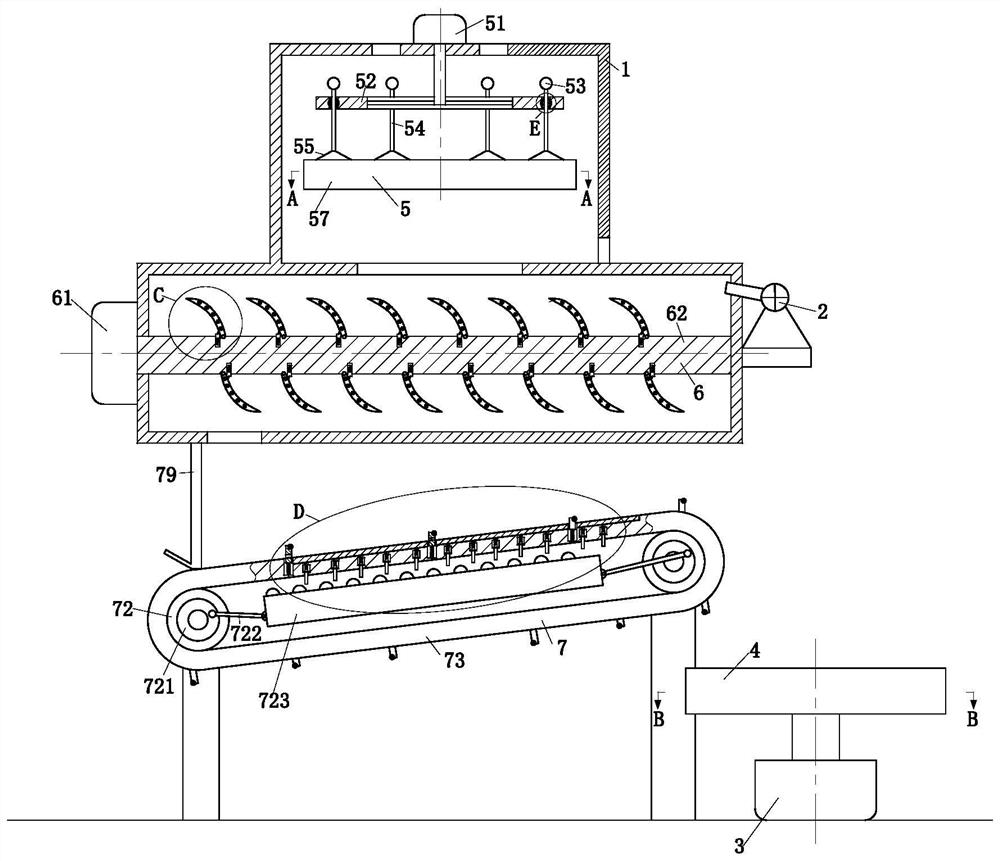

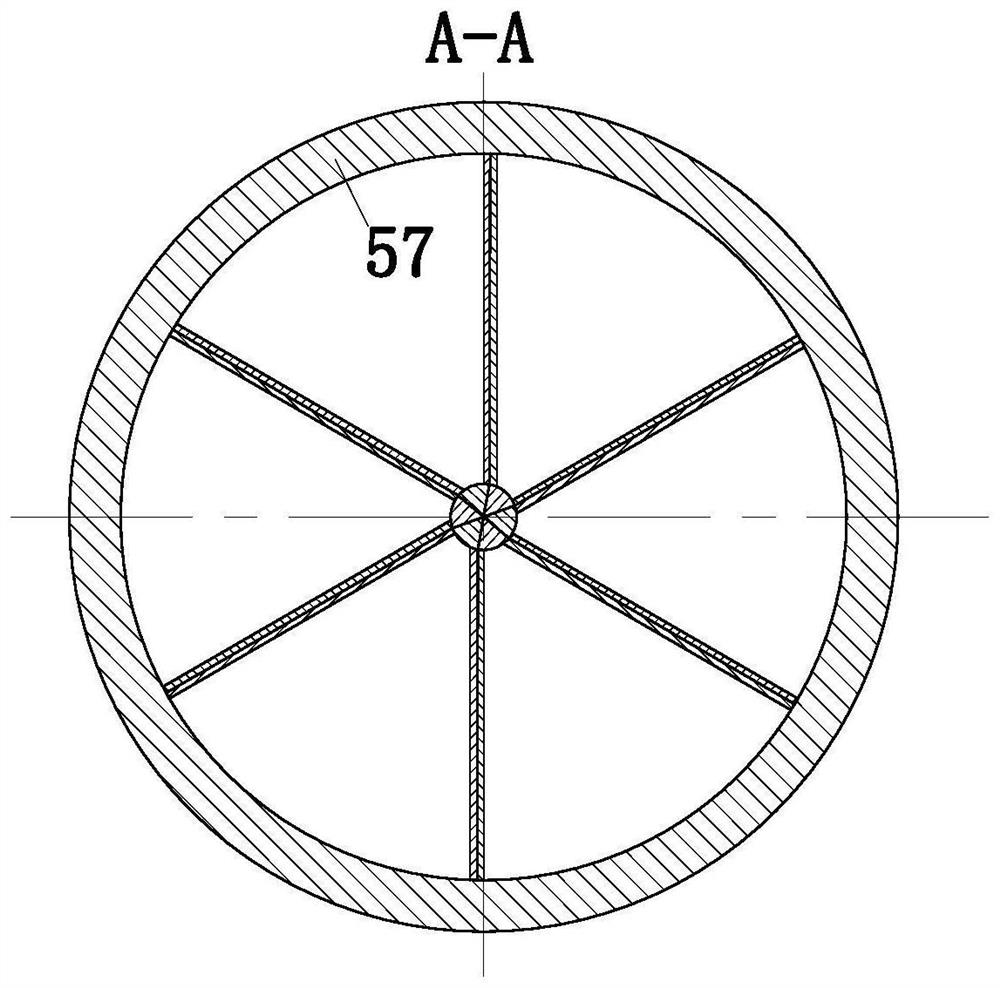

A kind of chlorinated polyethylene production process

The invention belongs to the technical field of chlorinated polyethylene preparation, and particularly relates to a production process of chlorinated polyethylene. The process comprises the followingsteps: adding hydrochloric acid into the polyethylene, carrying out a reaction on the hydrochloric acid and the polyethylene, and then dissolving the polyethylene; after the polyethylene is dissolved,adding an oxidizing agent and an initiator for replacement; after the replacement is completed, introducing chlorine to carry out a chlorination reaction; after the chlorination is carried out through the introduction of the chlorine for 30 minutes, carrying out filtration treatment to obtain a high-concentration chlorinated polyethylene solution; feeding the chlorinated polyethylene solution into a filter for deacidification; feeding the chlorinated polyethylene solution subjected to filtration and deacidification into a centrifugal machine for dewatering, and then carrying out drying to obtain a chlorinated polyethylene product; and carrying out washing, drying and sieving on the chlorinated polyethylene product obtained in the step 6 through a chlorinated polyethylene comprehensive treatment device. The process is mainly used for producing chlorinated polyethylene on a large scale, and the three working procedures comprising washing, drying and sieving of chlorinated polyethylene are integrated into one device, so that the production efficiency is improved.

Owner:广西田东锦桂科技有限公司

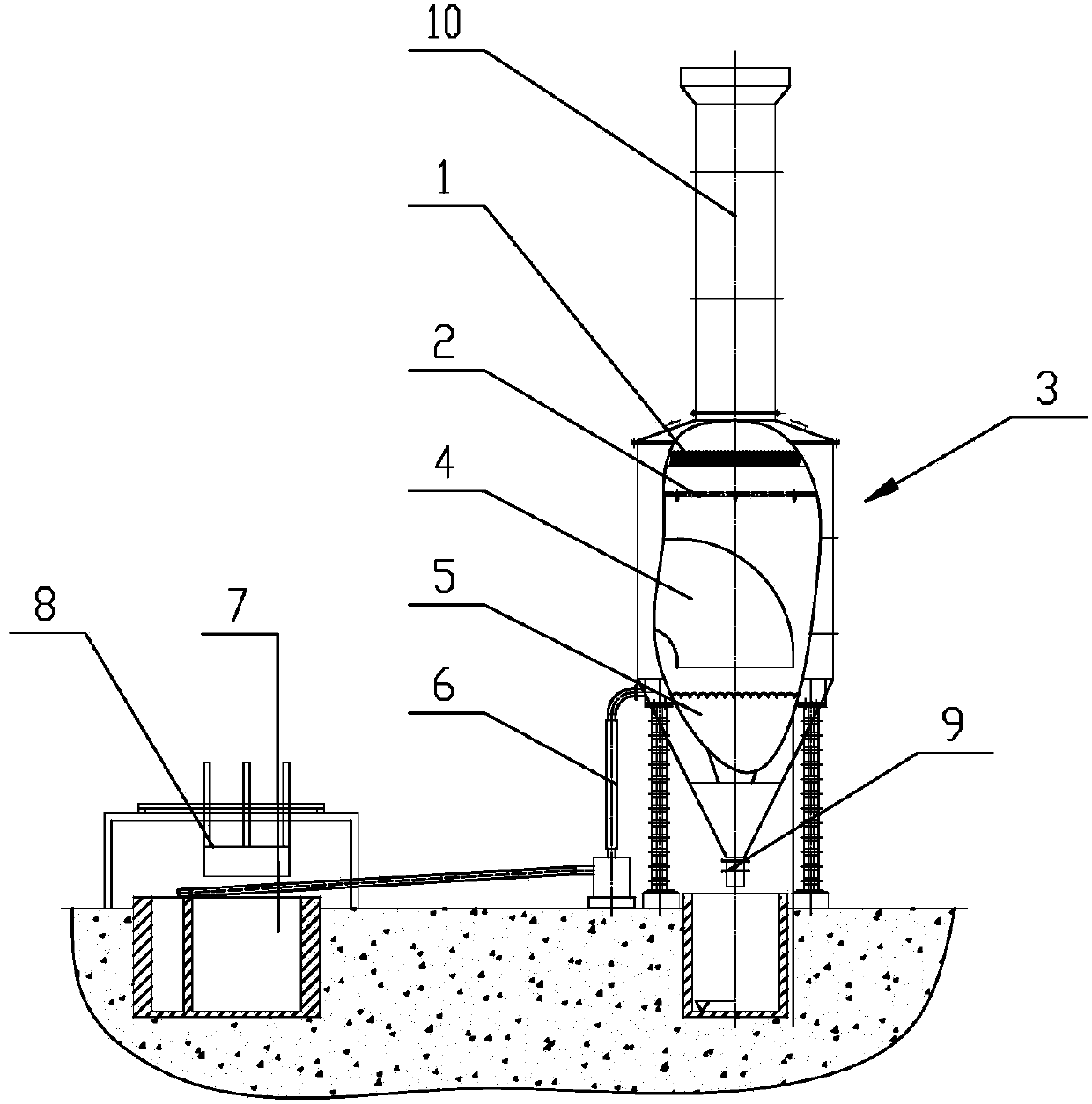

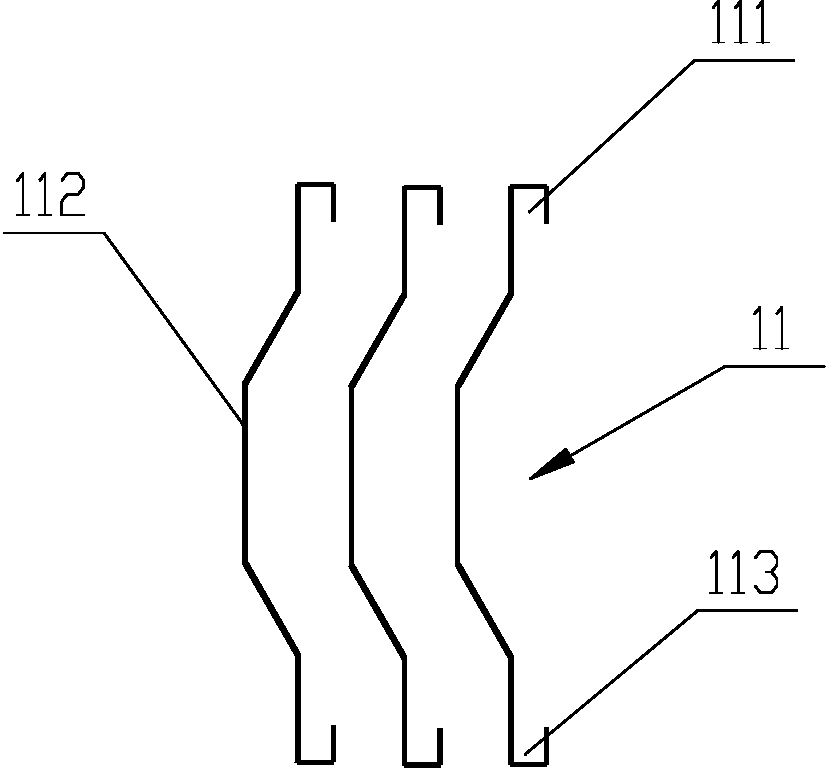

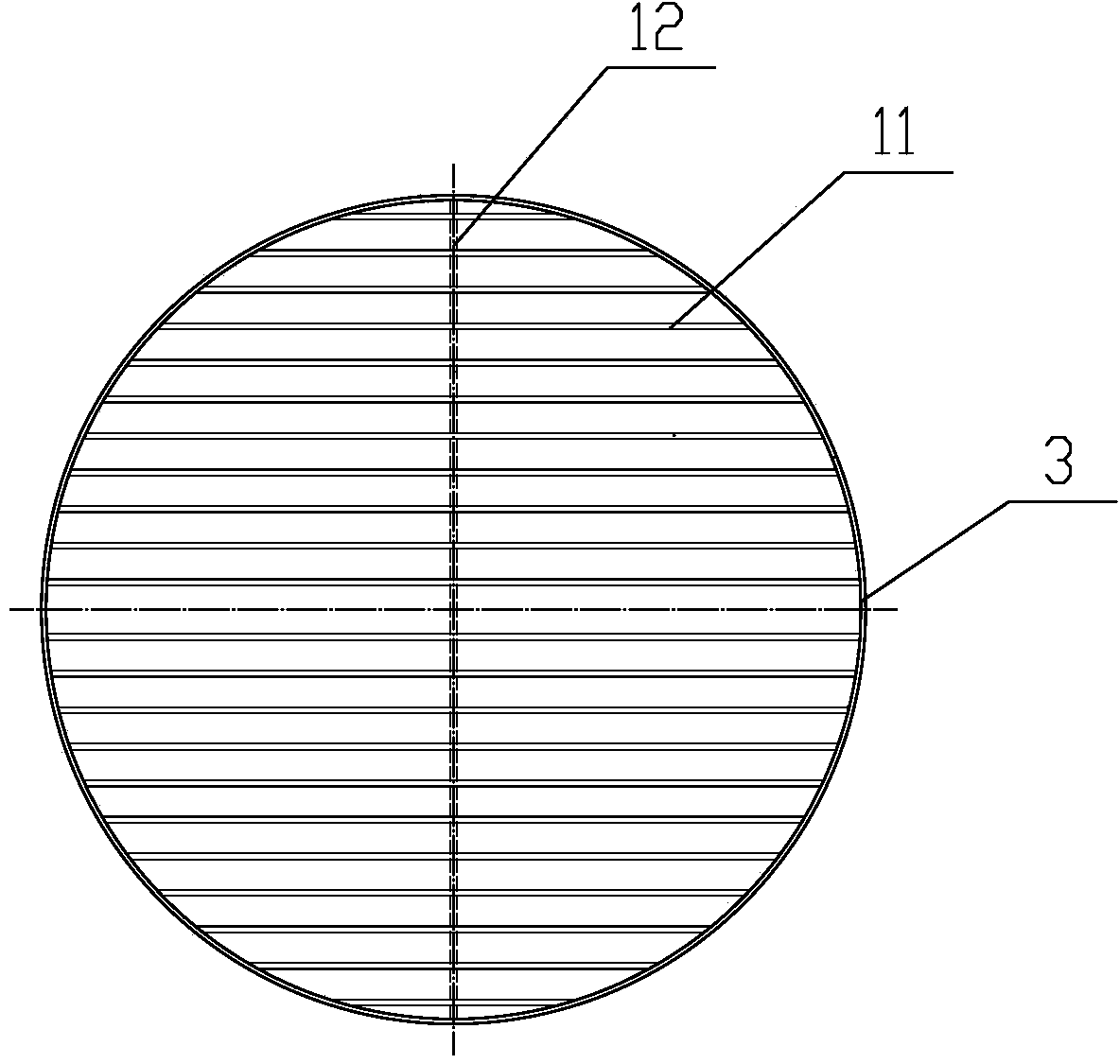

Smoke washing comprehensive utilization system equipment

The invention discloses smoke washing comprehensive utilization system equipment, and relates to the field of environment-friendly equipment. The smoke washing comprehensive utilization system equipment comprises a washing tower, wherein the middle of the washing tower is connected with one end of an overflow pipe, the other end of the overflow pipe is connected with a settling pond, and the settling pond is internally provided with an automatic slag conveyor; the side surface of a tower body of the washing tower is provided with an air inlet pipe, and the air inlet pipe enters the washing tower from the side surface of the tower body of the washing tower, and has a downward opening; an atomization spray device is arranged in the tower body and is arranged on the upper part of the pipe opening of the air inlet pipe, and a gas-liquid separation device is arranged in the tower body and is arranged on the upper part of the atomization spray device; the top of the tower body is provided with a dust collecting air pipe, a washing liquid is placed in the tower body and below the pipe opening of the air inlet pipe, and a liquid surface of the washing liquid is lower than the pipe opening of the overflow pipe. The equipment provided by the invention has the advantages that the technology is reasonable, the operation is convenient, the size is small, the smoke is fully washed, and gas-liquid separation is rapid.

Owner:JIANGSU GUIMING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com