Dewaxing and degreasing cleaner, and preparation method and application thereof

A cleaning agent and dewaxing technology, applied in the field of cleaning agent, can solve the problems of dark surface of workpiece, high washing energy consumption, high washing temperature, etc., and achieve the effect of reducing surface tension, short washing time and low concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment provides a kind of preparation method of dewaxing degreasing cleaning agent, comprises the following steps:

[0038] S1. Calculate and weigh 89.5wt% water according to the above components, add it into the reaction kettle, start the stirrer to stir, and the stirring speed is 150r / min.

[0039] S2. 4wt% coconut fatty acid diethanolamide, 2wt% fatty alcohol polyoxyethylene ether sodium sulfate, 0.1wt% sodium lauryl sulfate, 4wt% triethanolamine, 0.1wt% sodium pyrophosphate, 0.1 Wt% sodium tripolyphosphate, 0.1wt% benzotriazole and 0.1wt% sodium hydroxymethylglycinate are slowly added to the reaction kettle in turn, and stirred until the liquid is light yellow, uniform and transparent liquid, and finally dewaxing Oil cleaner.

[0040] Among them, the purity of triethanolamine is 85% to 100%, the purity of coconut oil fatty acid diethanolamide is 90% to 100%, the purity of fatty alcohol polyoxyethylene ether sodium sulfate is 70% to 100%, and the pur...

Embodiment 2~ Embodiment 10

[0042] Each component and the mass percentage of each component in Example 2-Example 10 and Comparative Example 1-Comparative Example 5 are different from Example 1, and the specific reaction method is the same as Example 1, and will not be repeated one by one. Table 1 shows the components of the dewaxing and degreasing cleaners of Examples 2-15 and Comparative Examples 1-5 and the mass percentage of each component.

[0043] Table 1

[0044] Example

Embodiment 11~24

[0046] Embodiments 11-24 provide the application of a dewaxing and degreasing cleaner on metal workpieces with residual wax and oil stains on the surface. The specific usage method is as follows: Prepare the The obtained dewaxing and degreasing detergent is cleaned in an ultrasonic cleaning tank respectively with the same metal workpiece with residual wax stains and oil stains on the surface, and the polishing paste and oil stains are completely removed by adjusting the concentration and temperature within the same time to reach the cleaning standard , the specific concentration temperature is shown in Table 2.

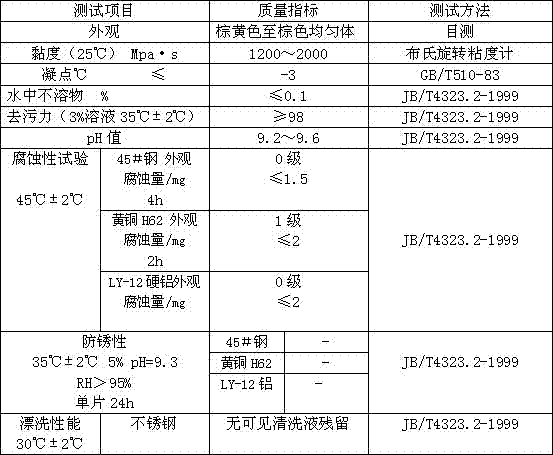

[0047] Table 2

[0048] Example

Dewaxing Degreasing Cleaner

concentration(%)

temperature (°C)

Example 11

Example 1

15

60

Example 12

Example 2

5

20

Example 13

Example 3

6

30

Example 14

Example 4

7

32

Example 15

Example 5

20

60

Example 16

Example 6

5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com