Preparation method of polypyrrole-polycaprolactone-graphene ternary nanocomposite

A nanocomposite material, polycaprolactone technology, applied in the field of graphene composite materials, can solve the problems of poor polarization performance and poor conductivity, and achieve easy doping and uniform dispersion, good compatibility, and specific capacitance value high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

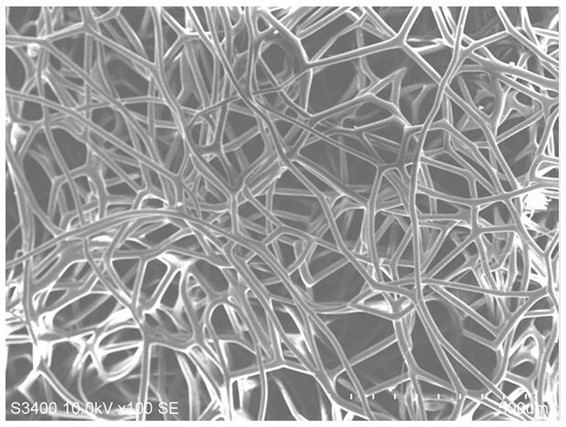

Image

Examples

Embodiment 1

[0020] S1. Preparation of graphene oxide: add 2g of graphite powder into the container, add 1g of NaNO under the conditions of ice-water bath and magnetic stirring 3 and 46mL concentrated sulfuric acid, then slowly add 6gKMnO 4 , keep the temperature of the reaction system not exceeding 20°C, react for 5min, then remove the ice-water bath, raise the temperature to 35°C for 30min, slowly add water with a liquid volume of 92mL in the container dropwise, stir for 15min, after the reaction is completed, add 80mL of 3% and Hydrogen peroxide solution at a temperature of 60°C removes the remaining KMnO from the reaction 4 , until the foam in the reaction system disappeared, the reaction mixture was ultracentrifuged at a speed of 7200rpm for 15min, and the solid part was washed until the pH was neutral, redissolved in water, ultrasonicated for 15min, and the unoxidized graphite residue was filtered out, and finally Freeze-drying can obtain the graphene oxide product;

[0021] S2. Pr...

Embodiment 2

[0025] S1. Preparation of graphene oxide: Add 2.5g of graphite powder into the container, add 1.1g of NaNO under the conditions of ice-water bath and magnetic stirring 3 and 55mL concentrated sulfuric acid, then slowly add 7gKMnO 4 , keep the temperature of the reaction system not exceeding 20°C, react for 6min, then remove the ice-water bath, raise the temperature to 37°C for 30min, slowly add water with a liquid volume of 115mL in the container dropwise, stir for 18min, after the reaction is completed, add 95mL of 3% and Hydrogen peroxide solution at a temperature of 62°C removes the remaining KMnO from the reaction 4 , until the foam in the reaction system disappears, the reaction mixture is ultracentrifuged at 7000rpm for 20min, the solid part is washed until the pH is neutral, redissolved in water, ultrasonicated for 20min, and the unoxidized graphite residue is filtered out, and finally Freeze-drying can obtain the graphene oxide product;

[0026] S2. Preparation of gr...

Embodiment 3

[0029] S1. Preparation of Graphene Oxide: Add 3g of graphite powder into the container, add 1g of NaNO under the conditions of ice-water bath and magnetic stirring 3 and 65mL concentrated sulfuric acid, then slowly add 9gKMnO 4 , keep the temperature of the reaction system not exceeding 20°C, react for 8min, then remove the ice-water bath, raise the temperature to 35°C for 35min, slowly add water with a liquid volume of 140mL in the container dropwise, stir for 12min, after the reaction is completed, add 120mL of 3% and Hydrogen peroxide solution at a temperature of 58°C removes the remaining KMnO from the reaction 4 , until the foam in the reaction system disappears, the reaction mixture is ultracentrifuged at 8000rpm for 13min, the solid part is washed until the pH is neutral, redissolved in water, ultrasonicated for 20min, and the unoxidized graphite residue is filtered out, and finally Freeze-drying can obtain the graphene oxide product;

[0030] S2. Preparation of graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com