Preparation method of battery-grade graphite-activated carbon composite material

A composite material and activated carbon technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve high charge and discharge capacity, low content of inorganic salt impurities, and wide particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

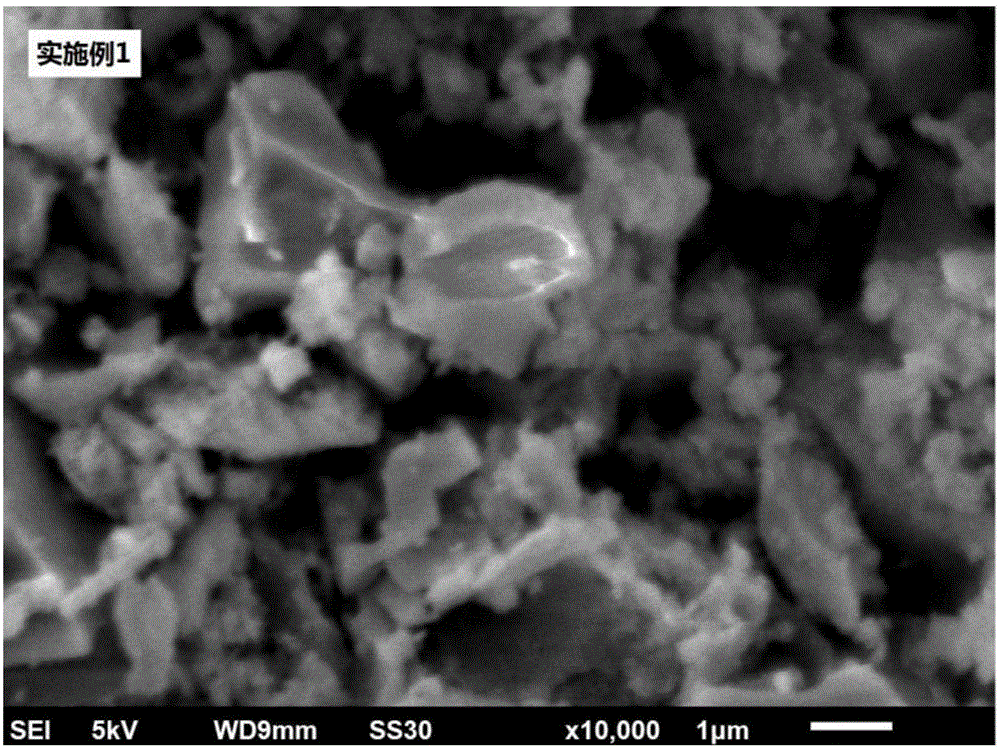

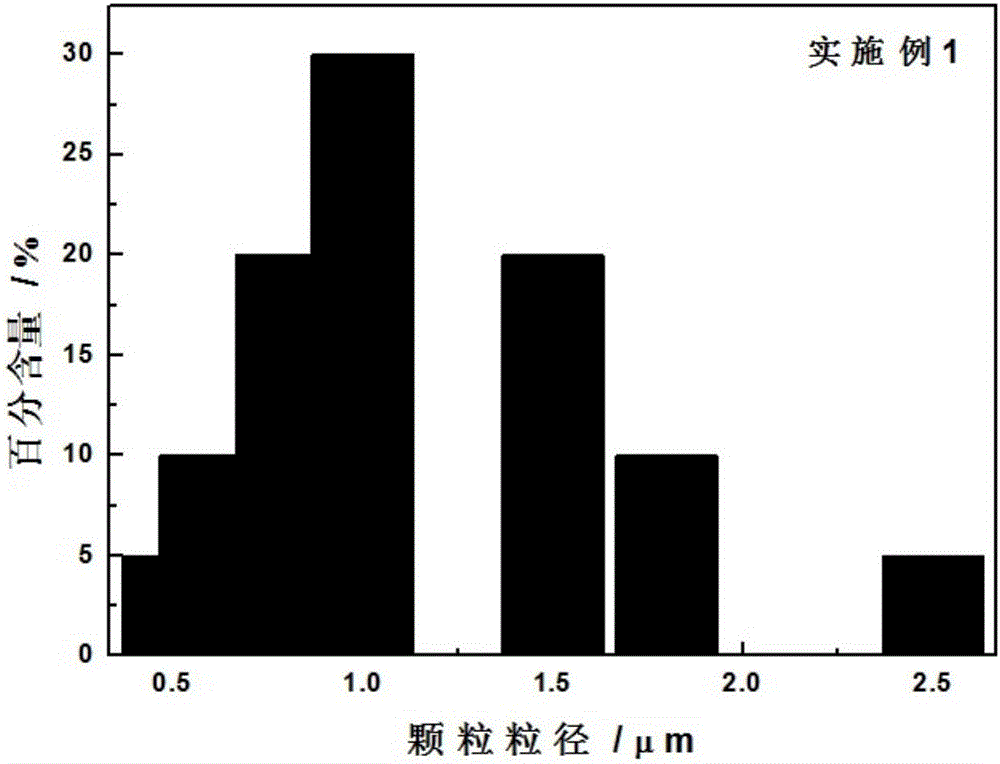

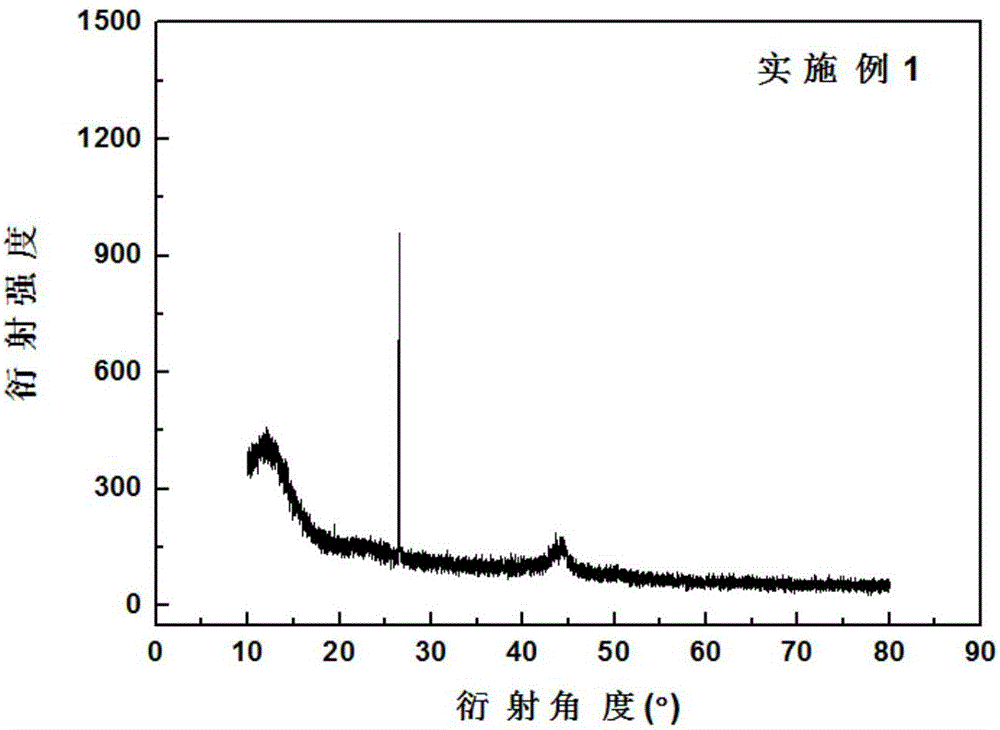

Embodiment 1

[0056] A kind of preparation method of battery grade graphite / activated carbon composite material, its steps and process conditions are:

[0057] The first step is to wash the rice husk with distilled water, put it into a metal can and seal it, put it in a muffle furnace, heat it at a constant temperature of 450°C for 4 hours, and cool it down to room temperature naturally to obtain black solid activated carbon;

[0058] In the second step, the mixture of black solid activated carbon and graphite obtained in the first step is placed in a ball mill tank in a mass ratio of 10:1, and an appropriate amount of hydrochloric acid, sulfuric acid, acetic acid solution, and distilled water are used successively with a concentration of 0.2M. ; under the condition that the material-ball mass ratio is equal to 1:10, ball milling is performed for 3, 2, 1, and 0.5 hours respectively, that is, the ball milling acid is washed 3 or 4 or 5 times, and the ball milling water is washed until the pH ...

Embodiment 2

[0062]A kind of preparation method of battery grade graphite / activated carbon composite material, its steps and process conditions are:

[0063] The first step is to wash the peanut shells with twice-distilled water, put them in a metal can and seal them, put them in a muffle furnace, heat them at a constant temperature of 550°C for 6 hours, and cool them down to room temperature naturally to obtain black solid activated carbon;

[0064] In the second step, the black solid activated carbon obtained in the first step and graphite are placed in a ball milling tank in a mass ratio of 8:1, and are respectively used with appropriate amount of hydrochloric acid, sulfuric acid, acetic acid solution, sulfuric acid, and dihydrochloric acid with a concentration of 0.4M. Secondary distilled water; under the condition that the mass ratio of material to ball is equal to 1:15, ball mill for 2, 1, 0.5, and 3 hours respectively, that is, "ball mill pickling" and "ball mill water washing"; sulf...

Embodiment 3

[0068] A kind of preparation method of battery grade graphite / activated carbon composite material, its steps and process conditions are:

[0069] The first step is to wash the bamboo rods with deionized water, put them into metal cans, seal them, place them in a muffle furnace, heat them at a constant temperature of 650°C for 4 hours, and cool them down to room temperature naturally to obtain black solid activated carbon;

[0070] In the second step, the black solid activated carbon obtained in the first step and the graphite are placed in a ball milling tank in a mass ratio of 6:1, and are successively used with an appropriate amount of hydrochloric acid, sulfuric acid, acetic acid solution, sulfuric acid, and acetic acid solution that have a concentration of 0.6M. Ionized water; ball milling for 1, 0.5, 3, and 2 hours respectively under the condition that the mass ratio of material to ball is equal to 1:20, that is, "ball milling pickling" and "ball milling water washing"; su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com