Scrubber, washing device, and method for purifying polyolefin catalyst

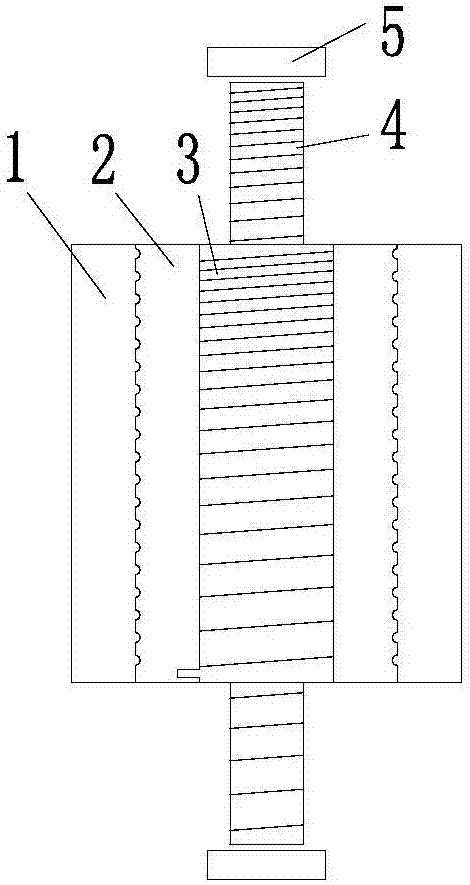

The technology of a polyolefin catalyst and a washing device, which is applied in the field of separation and purification, can solve the problems of long washing time, large amount of solvent and low washing efficiency, and achieve the effects of short washing time, small amount of solvent and high washing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

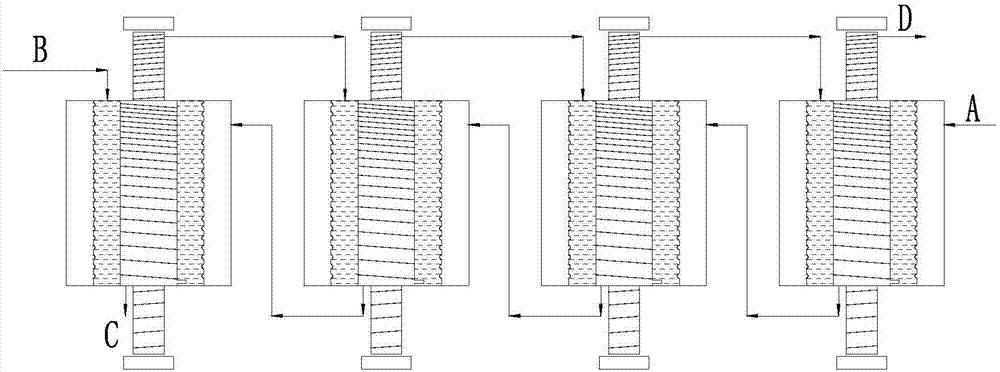

[0040] The washing device comprises 4 aforementioned scrubbers connected in series in succession, so that the material (flow rate is 0.4kg / h) enters the washing device from the feed inlet of the second chamber of the first scrubber (after washing, it is discharged from the last scrubber) The third chamber of the washer is discharged from the discharge port), and at the same time, normal hexane (flow rate is 30kg / h) enters the washing device from the feed port of the first chamber of the last scrubber (after being contacted with the material and washed from the first The third chamber of a scrubber is discharged by the discharge port), and the contact time of each scrubber in the scrubber for the material and normal hexane is 3h. After the material is washed, the content of the polyolefin catalyst in the washed material is measured. The content was 43.1% by weight, and the titanium content was 0.23 mg / mL.

Embodiment 2

[0042] The washing device comprises 3 aforementioned scrubbers connected in series in succession, so that the material (flow rate is 0.5kg / h) enters the washing device from the feed port of the second chamber of the first scrubber (after washing, it is washed from the last scrubber) The third chamber of the washer is discharged from the discharge port), and at the same time, normal hexane (flow rate is 25kg / h) enters the washing device from the feed port of the first chamber of the last scrubber (after contacting with the material and washing, from the first The third chamber of a scrubber is discharged by the discharge port), and the contact time of each scrubber in the scrubber for the material and normal hexane is 4h. After the material is washed, the content of the polyolefin catalyst in the washed material is measured. The content was 41.7% by weight, and the titanium content was 0.27 mg / mL.

Embodiment 3

[0044] The washing device comprises 6 aforementioned scrubbers connected in series in succession, so that the material (flow rate is 1kg / h) enters the washing device from the feed inlet of the second chamber of the first scrubber (after washing, from the last scrubber) The third chamber is discharged by the discharge port), and at the same time, normal hexane (flow rate is 30kg / h) enters this washing device from the feed inlet of the first chamber of the last scrubber (after contacting and washing with the material, from the first The third chamber of each scrubber is discharged from the discharge port), the contact time of the material and n-hexane in each scrubber in the washing device is 2h, after the material is washed, the content of polyolefin catalyst in the washed material is measured. It was 42.5% by weight, and the content of titanium was 0.31 mg / mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com