Patents

Literature

69results about How to "Unobstructed delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

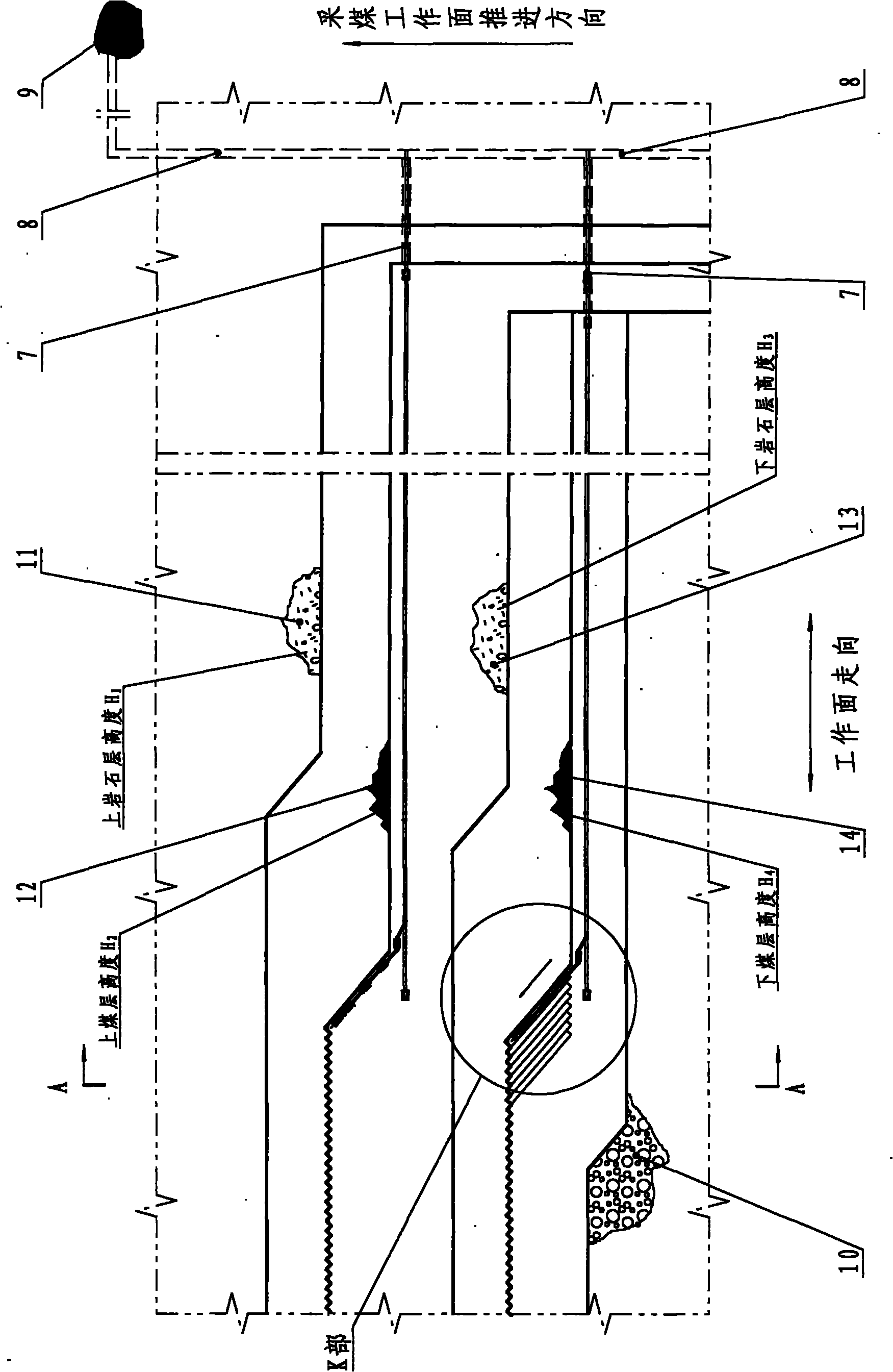

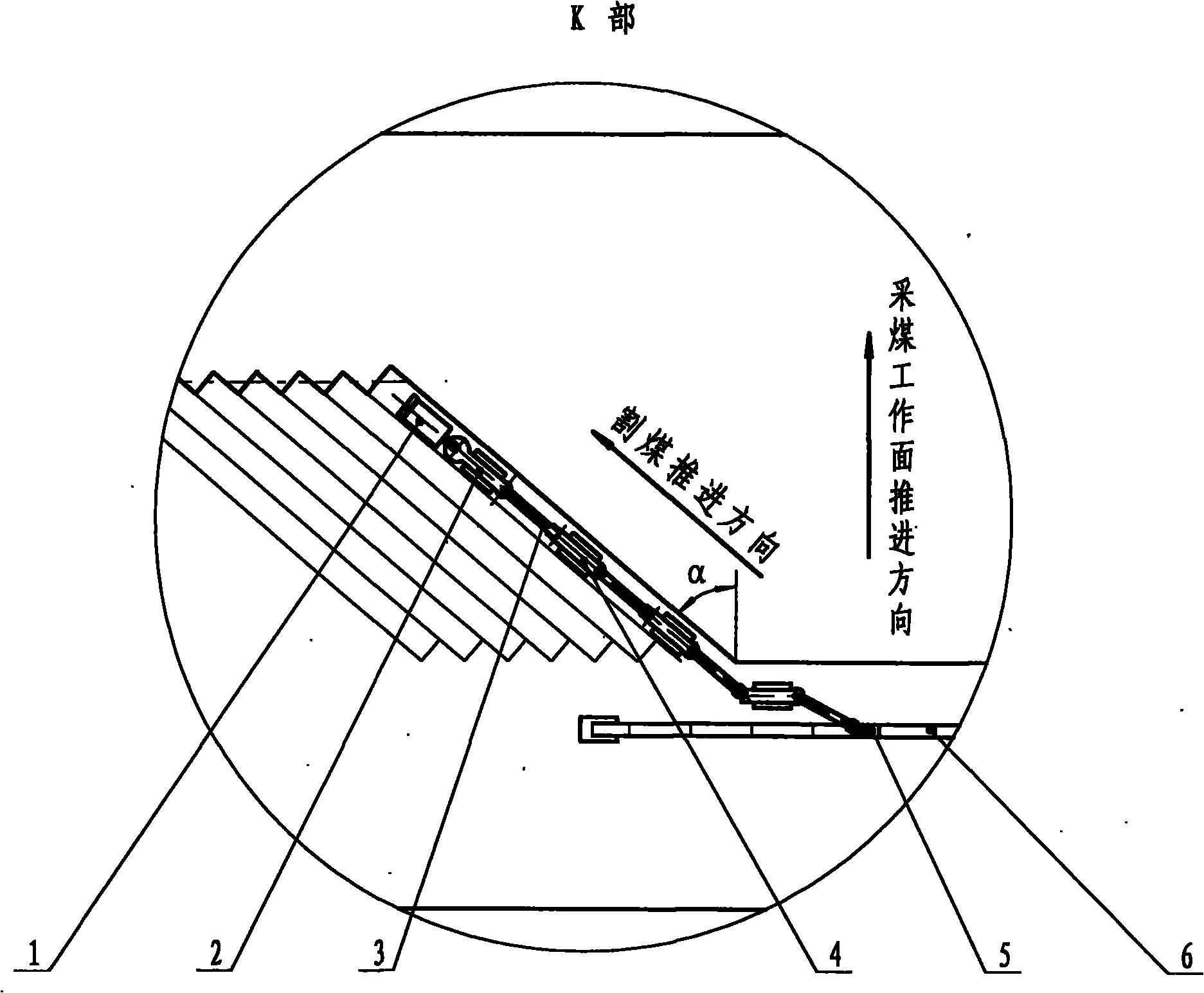

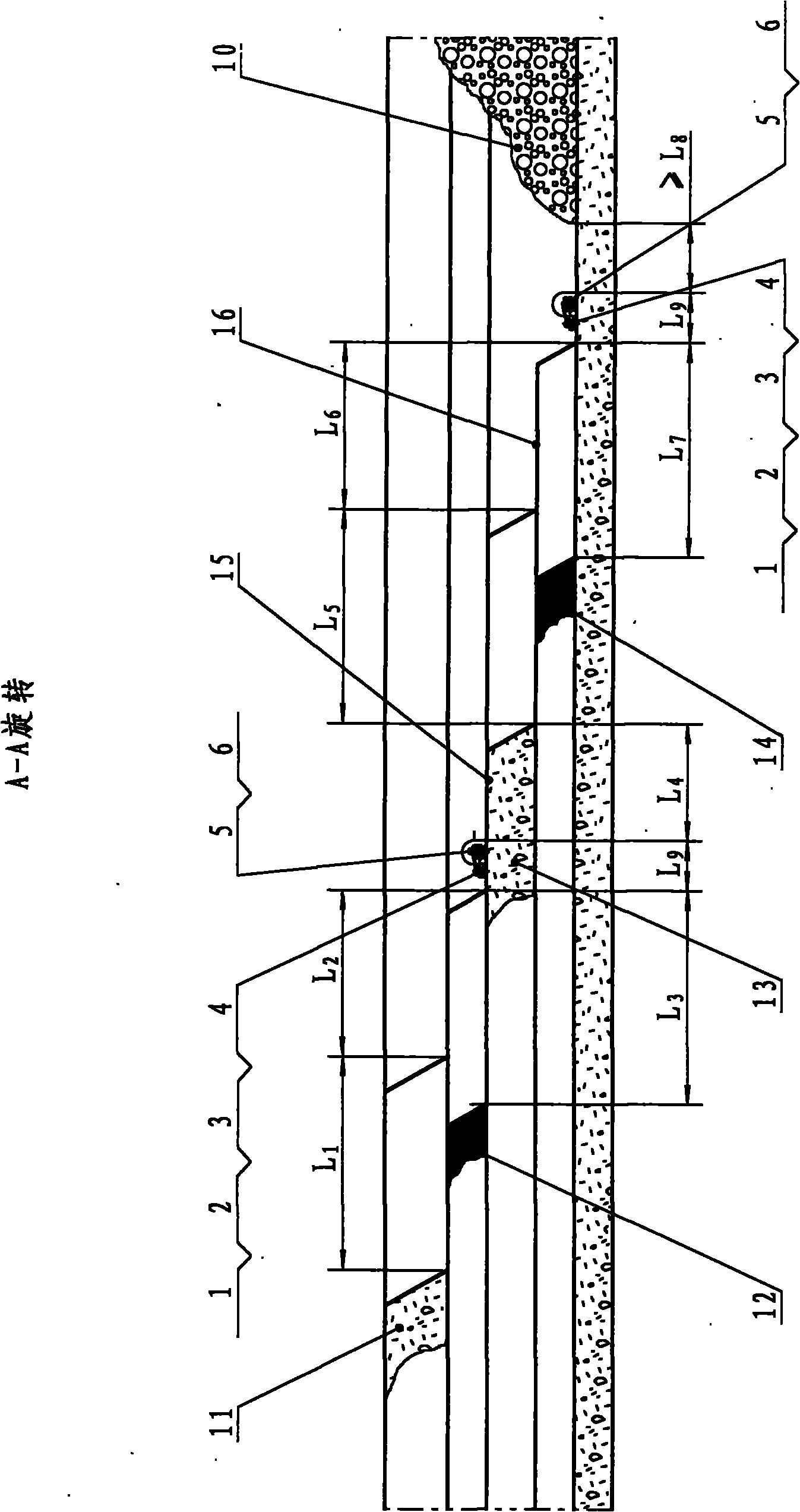

Continuous coal mining process method of open-pit coal mine

The invention relates to a continuous coal mining process method of an open-pit coal mine, the used main devices comprises a continuous coal mining machine, a walking type crushing machine of a continuous conveying machine unit, a bridge type transloading machine, a walking type transloading machine, an unloading car, a working face belt type conveyor, an outward transport heading belt type conveying machine and an outward transport machine lane belt type conveying machine, and the continuous coal mining process method adopts the continuous mining-continuous conveying way, and adopts the automatic mining, crushing, transloading, unloading and transportation. The coal mining method has advanced process, reasonable design, compact and continuous arrangement of the devices, safety, stability and reliability, high excavating efficiency, multi-stage transportation, smooth conveying and small occupied area, and can effectively improve the recovery rate of resources, reduce the consumption of fuel oil, reduce the carbon emission, be applicable to needs on low carbon, energy conservation and environmental protection and be a very ideal continuous coal mining process method of the open-pit coal mine.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

Method for preparing carbon-fixation filling paste from waste concrete

InactiveCN109650805AAffect qualityIncrease carbon sequestrationGas treatmentDispersed particle separationCarbonizationToxic industrial waste

The invention discloses a method for preparing a carbon-fixation filling paste from waste concrete. The method comprises the following steps: industrial waste gas is dedusted, and then is mixed with normal temperature air, a waste concrete and a gangue mixture is crushed in the obtained industrial exhaust gas atmosphere, and coarse aggregates, fine aggregates and fine powder obtained after screening and carbon dioxide in the industrial exhaust gas undergo a carbonization reaction in a carbon fixation chamber; and the carbon-fixation coarse aggregates, the carbon-fixation fine aggregates, a filling paste additive, cement, phase change material microcapsules and water are stirred and mixed to form a filling body mixture, and the industrial exhaust gas is continuously injected in the stirring, mixing and conveying process of the filling paste to make the filling paste and the carbon dioxide in the industrial exhaust gas undergo the carbonization reaction in order to obtain the carbon-fixation filling paste. The carbonization reaction of the waste concrete and carbon dioxide is fully used, so the damages of the waste concrete to the environment are reduced, and the emission of greenhouse gases is reduced; and hydration heat is fully used in the carbonization reaction, so the filling effect of the carbon-fixation filling paste is good.

Owner:XUZHOU UNIV OF TECH

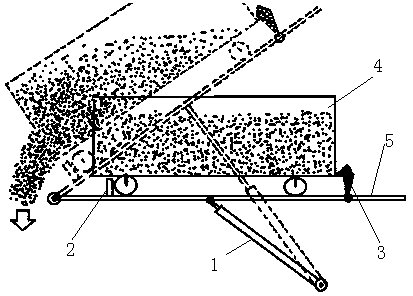

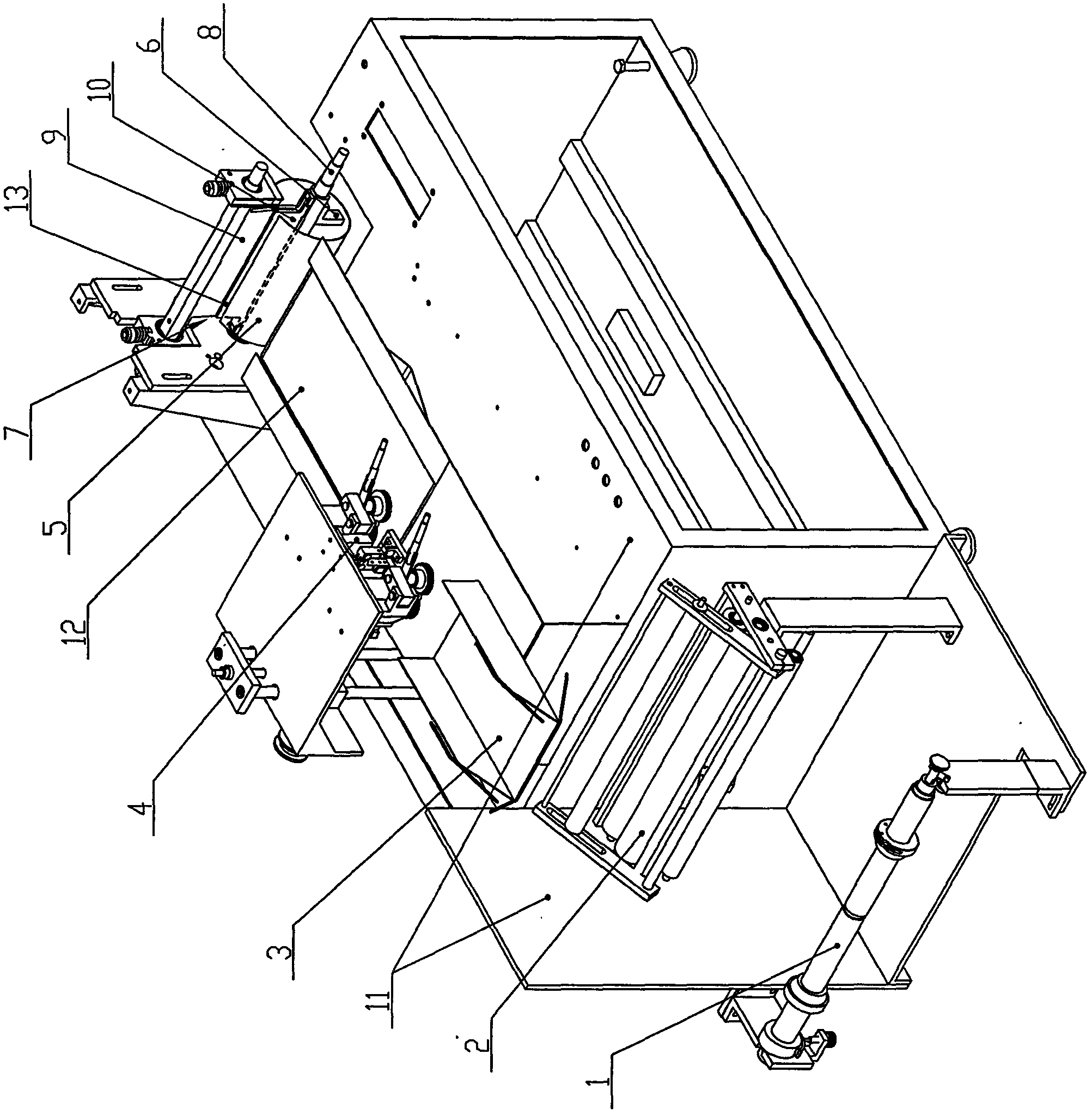

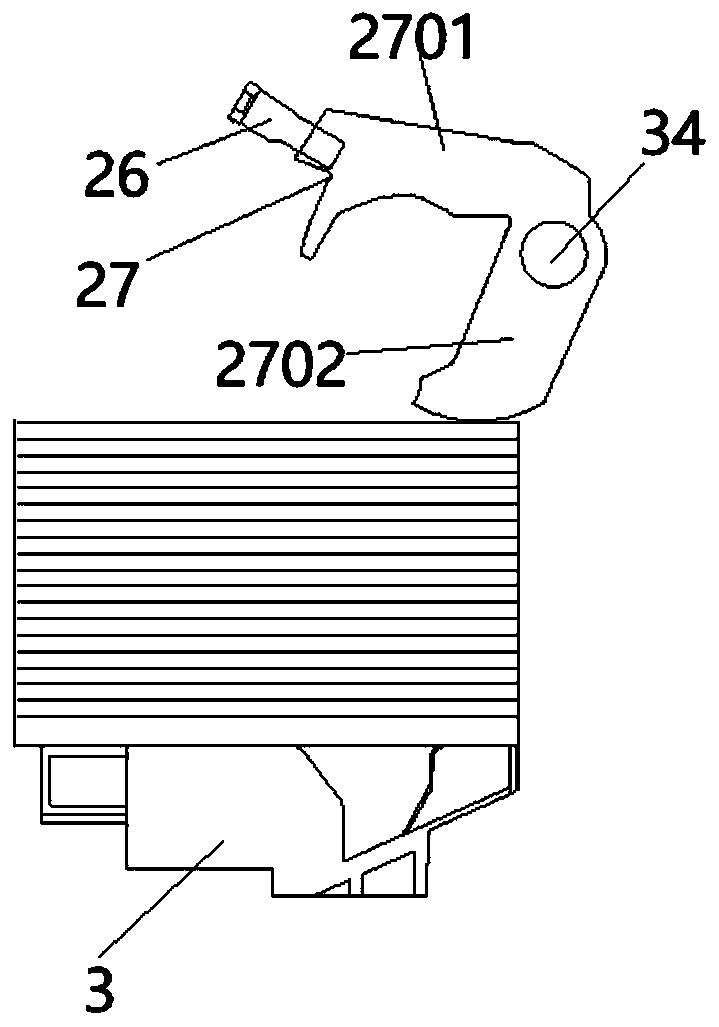

Automatic overturning material discharging device

InactiveCN103449195ASimple and reliable deviceSmooth material deliveryBottle emptyingOperating environmentMechanical engineering

The invention relates to an automatic overturning material discharging device comprising a material tank and a support supporting the material tank. One end of the support is provided with a hinge, and the other end of the support is rotatable. The front end of the support is provided with a slide stopping plate, the rear end of the support is provided with a lock, and a lock groove is formed on the material tank corresponding to the lock. The lower portion of the material tank is provided with a jacking device capable of jacking up the support. According to the an automatic overturning material discharging device, material can slide downwards by utilizing gravity of the material and being jacked up by the jacking device; since the sliding stopping plate and the lock are arranged, the material can be prevented from overturning while being jacked up, production accidents are eliminated, and material waste are further eliminated. The device is simple and reliable, the material can be conveyed smoothly, on-site operating environment is fine, and workload of workers is low.

Owner:YANGZHOU SANDELI CHEM

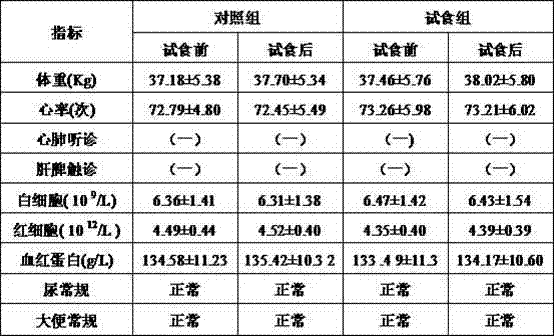

Soft capsule health food with auxiliary memory-improving function

The invention relates to a soft capsule health food with an auxiliary memory-improving function. The product of the invention employs the following components as main raw materials: fish oil, taurine, zinc gluconate, beeswax, vitamin E, gelatin, glycerol, purified water, caramel and titanium dioxide. The method of the invention comprises the steps of mixing, dissolving gelatin, pelleting, shaping, drying, choosing pills and packaging to obtain the soft capsule. The product of the invention is specially prepared for children, has an auxiliary memory-improving function for children and a health care efficacy of supplementing nutrition for brain, and has the advantages of a high pertinence and an obvious effect of improving memory. In addition, the preparation method of the invention adopts a process which obviates a pill washing step, and the product of the invention has a stable quality and is a health food with good taste and convenience in carrying and eating.

Owner:BY HEALTH CO LTD

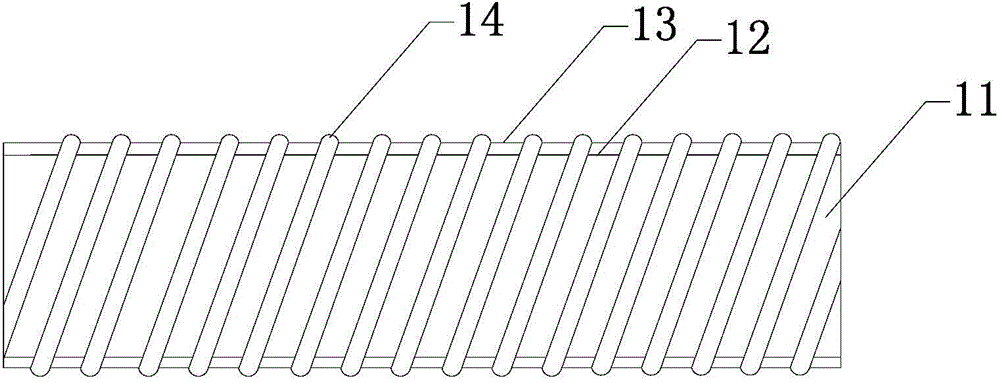

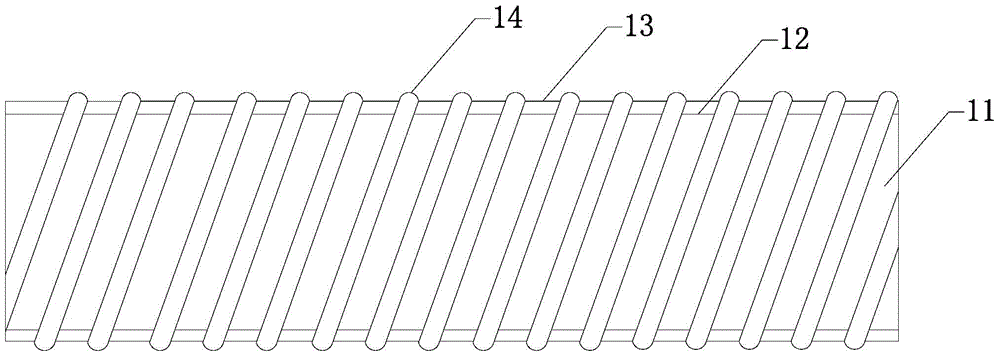

Small-caliber plastic rib spiral tube without adhesive-bonded joint and production process for small-caliber plastic rib spiral tube without adhesive-bonded joint

InactiveCN104595589AImprove product qualityUnobstructed deliveryFlexible pipesTubular articlesSmooth surfaceSmall caliber

The invention discloses a small-caliber plastic rib spiral tube without an adhesive-bonded joint. The small-caliber plastic rib spiral tube comprises a plastic rib tube body, wherein the inner diameter of the plastic rib tube body is 6-16 mm; the inner wall of the plastic rib tube body is a smooth surface which is integrally molded; the outer wall of the plastic rib tube body is a smooth surface which is integrally molded; a spiral plastic rib which is wound on a tube body is arranged on the outer wall of the plastic rib tube body. A production process for the small-caliber plastic rib spiral tube without adhesive-bonded joint comprises the following steps: extruding a plastic rib tube material from an extrusion head, forming the plastic rib tube body in a plastic rib tube forming channel; after the spiral plastic rib material enters from a spiral material injection channel of a fixed sleeve, extruding the spiral plastic rib material from the spiral material extruding channel of a rotary sleeve and winding the spiral plastic rib material on the plastic rib tube body to form the plastic rib spiral tube without then adhesive-bonded joint. The plastic rib spiral tube is smooth in in-tube inner wall, and free of the adhesive-bonded joint, so that the product quality is greatly improved and relatively stable; the plastic rib spiral tube is free of the adhesive-bonded joints, so that the material conveying is relatively smooth and free of residues.

Owner:张雁

Storage battery plate additive and preparation method thereof

InactiveCN106972173AExtended service lifeIncrease the use of functionsCell electrodesPorosityAgricultural engineering

The invention discloses a storage battery plate additive. The storage battery plate additive is prepared from, by weight, 20-40 parts of modified graphene, 18-27 parts of tetrabasic lead sulfate, 23-42 parts of vapor phase method nano-silica, 5-12 parts of 2,6-di-tert-4-butylated hydroxytoluene, 3-8 parts of 2-sulfydryl-benzimidazole and 10-20 parts of purified water. The storage battery plate additive can increase the specific area and the porosity of a lead-acid storage battery plate, enhance the strength of the plate, improve the conductivity of the plate, increase the surface utilization rate of active materials, effectively reduce the lead sulfate particle size, lower polarization, improve the lead sulfate-to-cathode lead conversion efficiency, and achieve the purposes of improving the charging receptivity and prolonging the service life of the storage battery.

Owner:明光市裕阳新材料有限公司

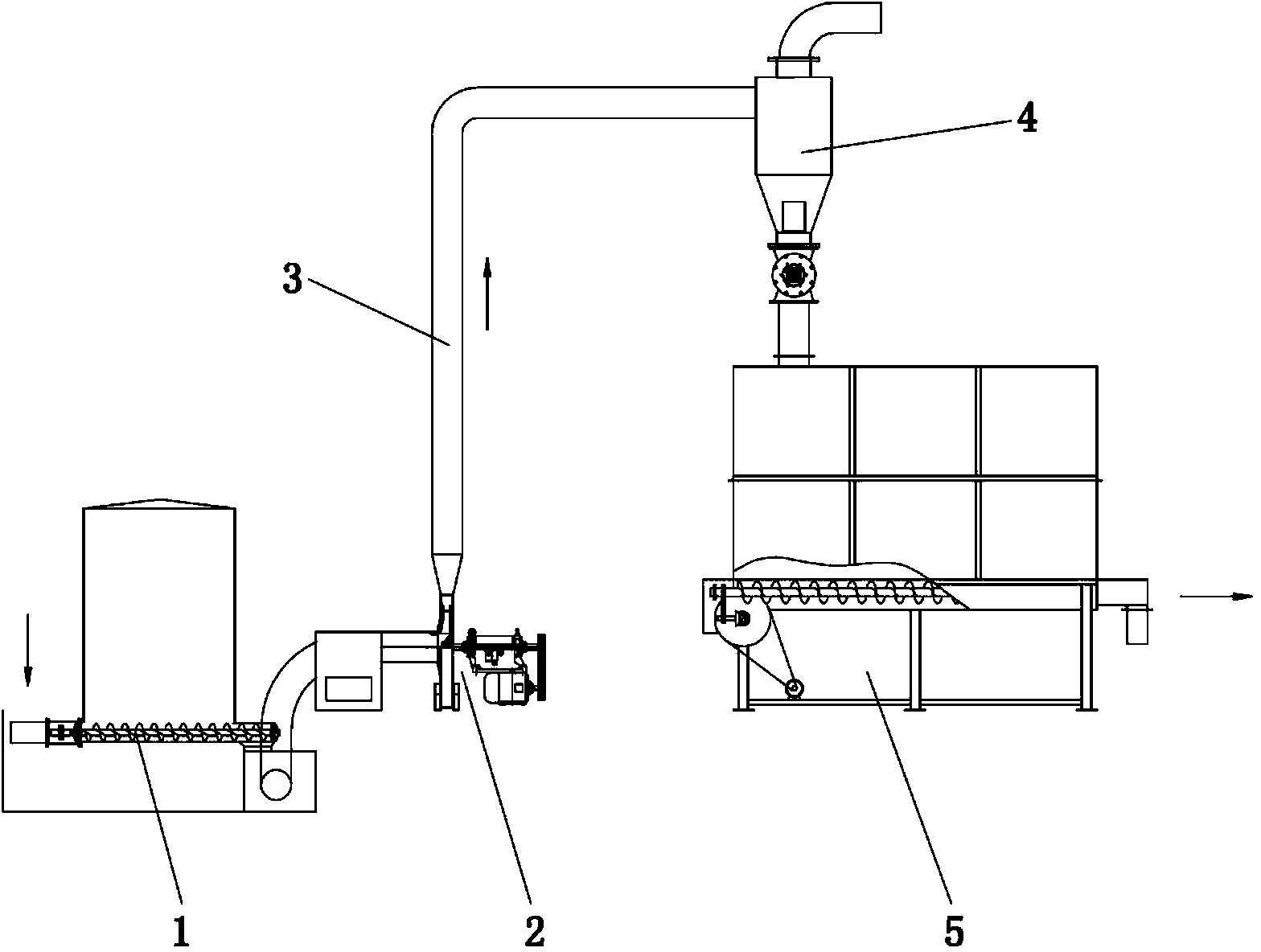

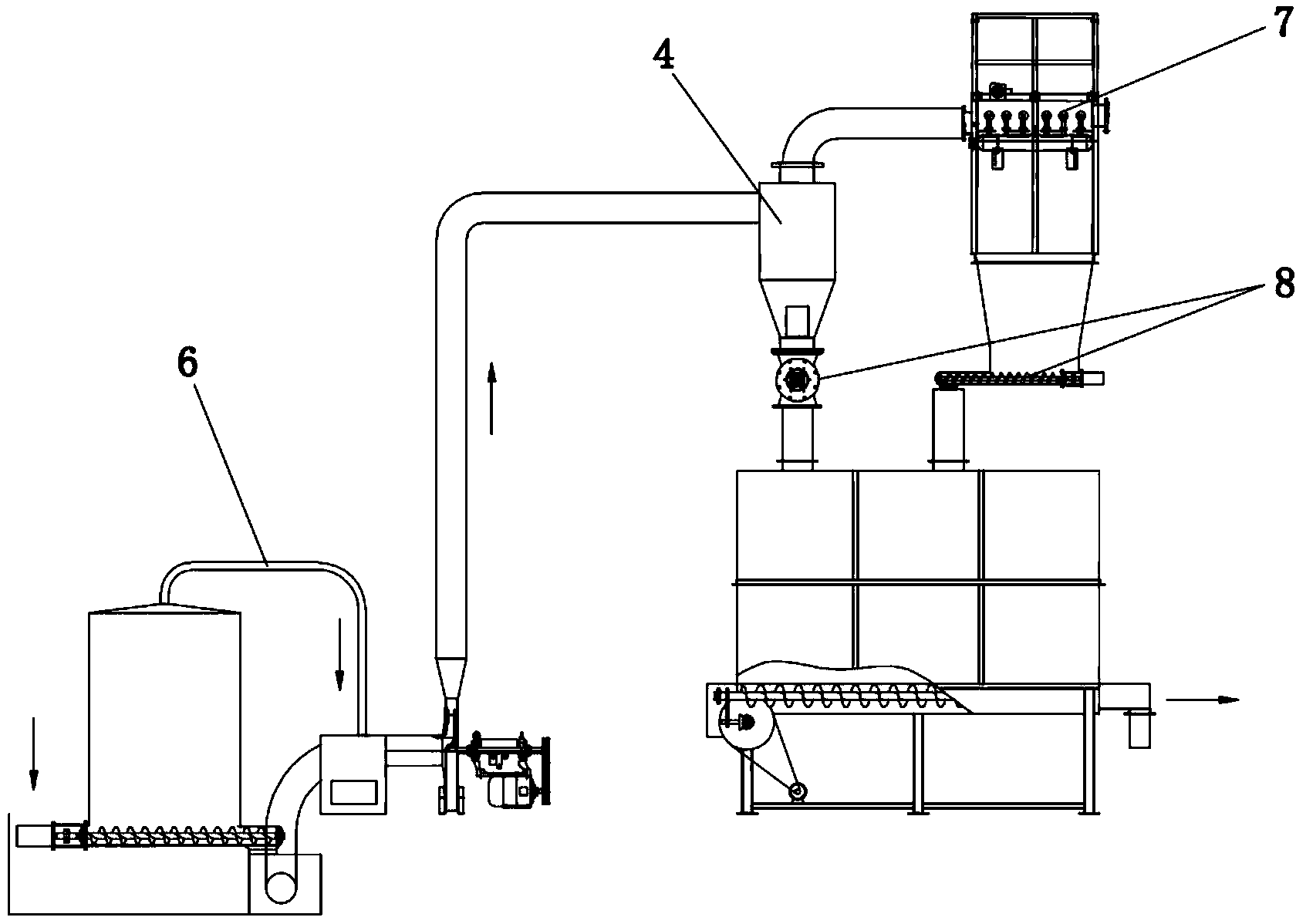

Biomass wood powder conveying system

InactiveCN103528086AIncrease storage capacityWith storage functionBulk conveyorsLump/pulverulent fuel feeder/distributionCycloneAir volume

The invention discloses a biomass wood powder conveying system. The biomass wood powder conveying system comprises a spiral conveyer and an induced draft fan, wherein biomass wood powder is conveyed into the induced draft fan through the spiral conveyer, an outlet of the induced draft fan is connected with a cyclone separator, a discharge outlet of the cyclone separator is connected with a stokehole bin, the biomass wood powder is conveyed into the cyclone separator under the action of the induced draft fan, air is pumped and separated from the biomass wood powder by the cyclone separator, and the biomass wood powder without air falls into the stokehole bin. According to the biomass wood powder conveying system, a storage function is achieved, the storage volume of fuel can be increased continuously, real-time manual feeding is not needed, and labor cost is saved; due to the fact that the fuel conveyed by the induced draft fan is not directly provided for a terminal equipment furnace, the air volume of the induced draft fan is not influenced by the load condition of the terminal equipment, a constant wind speed is maintained, conveying can be carried out smoothly, and blocking is avoided; due to the fact that clean air is separated from the biomass wood powder by the cyclone separator before the fuel enters the stokehole bin, pollution to the environment is reduced.

Owner:GUANGZHOU DEVOTION THERMAL TECH

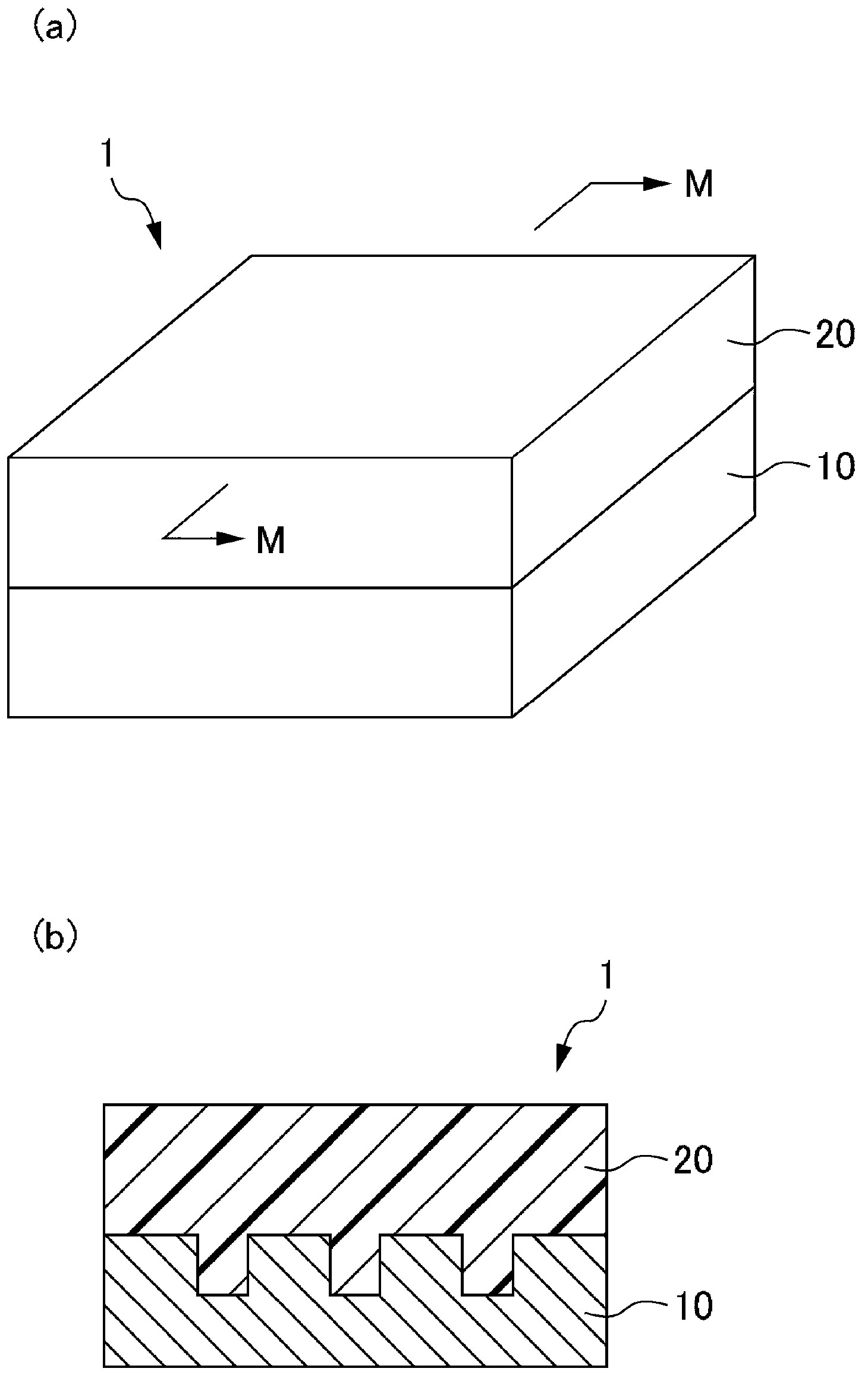

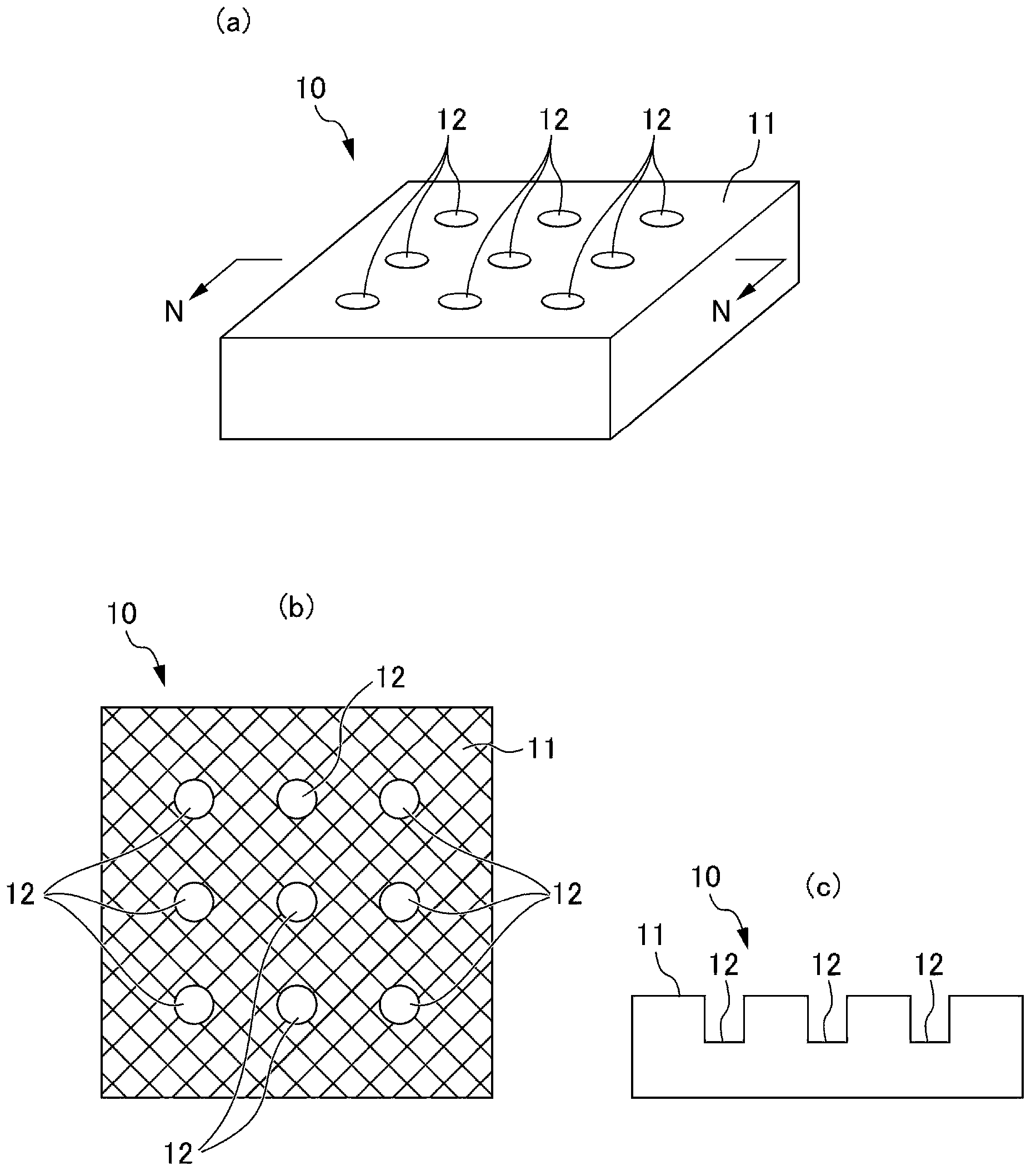

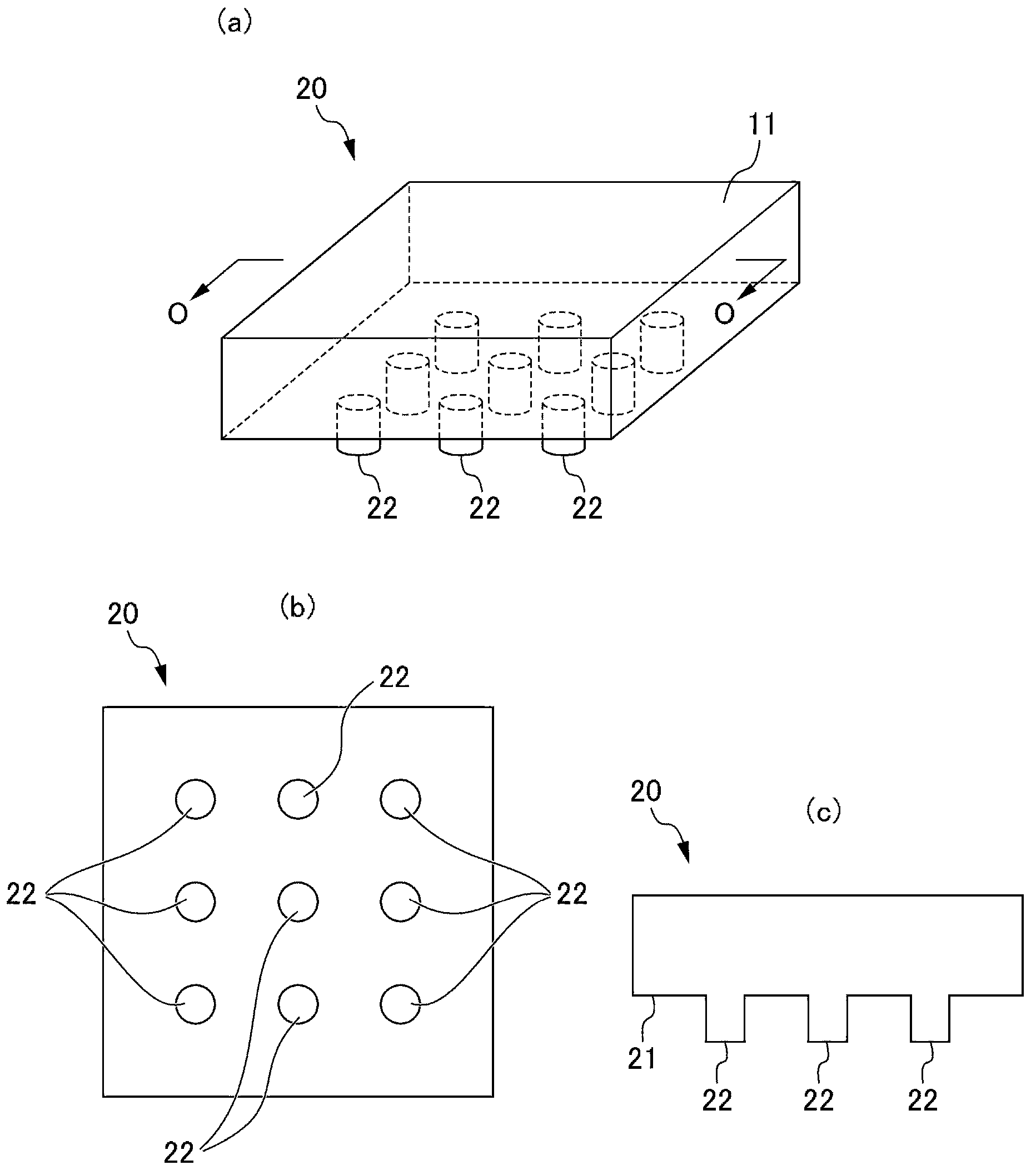

Insert molded body and radiation structure

The present invention provides an insert molded body and a radiation structure. The insert molded body can be manufactured by a method with high production efficiency. The adhesion force between a resin member and a metal member is sufficient, and the heat transmission between the resin member and the metal member is smooth. The insert molded body has the resin member and the metal member. The metal member includes two or more engaging holes. The engaging holes are formed on the mating surface of the resin member in a dispersed form. The resin member has a convex portion which is inserted into the engaging holes. At least one engaging hole has the opening area more than?? 0.44 mm<2> and less than 19.63 mm<2>. The area surrounded by the outer peripheral of ??the bonding surface of the resin member and the metal member is S1, the sum of the opening area of the engaging hole on the engagement surface is S2, and the proportion of S2 / S1 meet a specific inequality (I).

Owner:POLYPLASTICS CO LTD

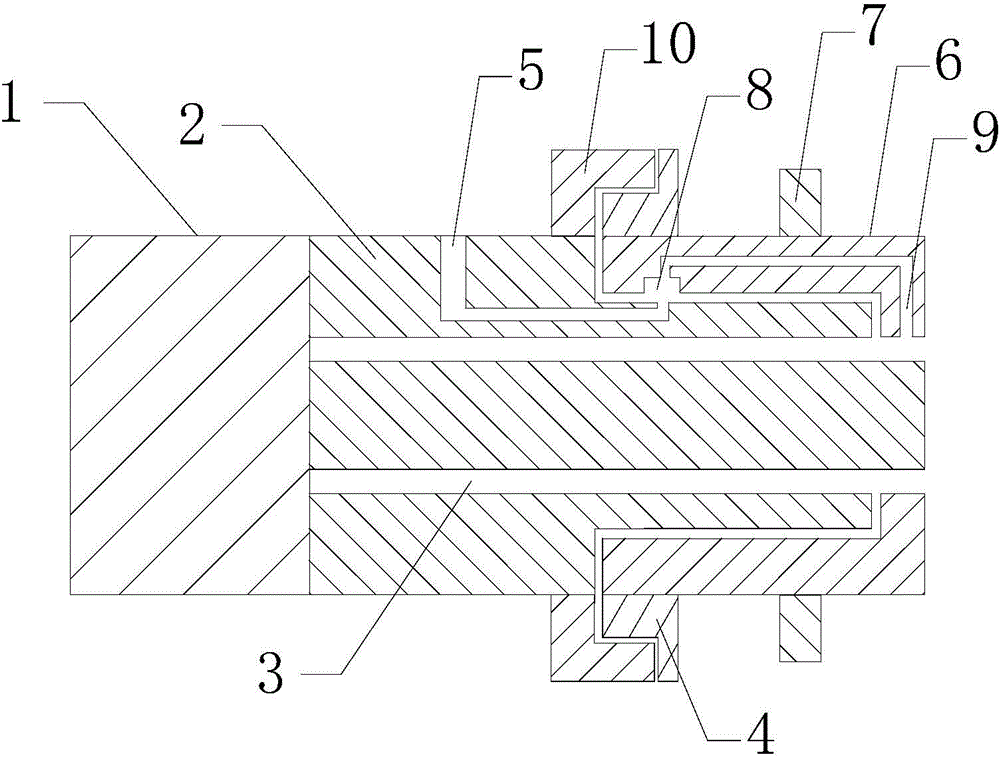

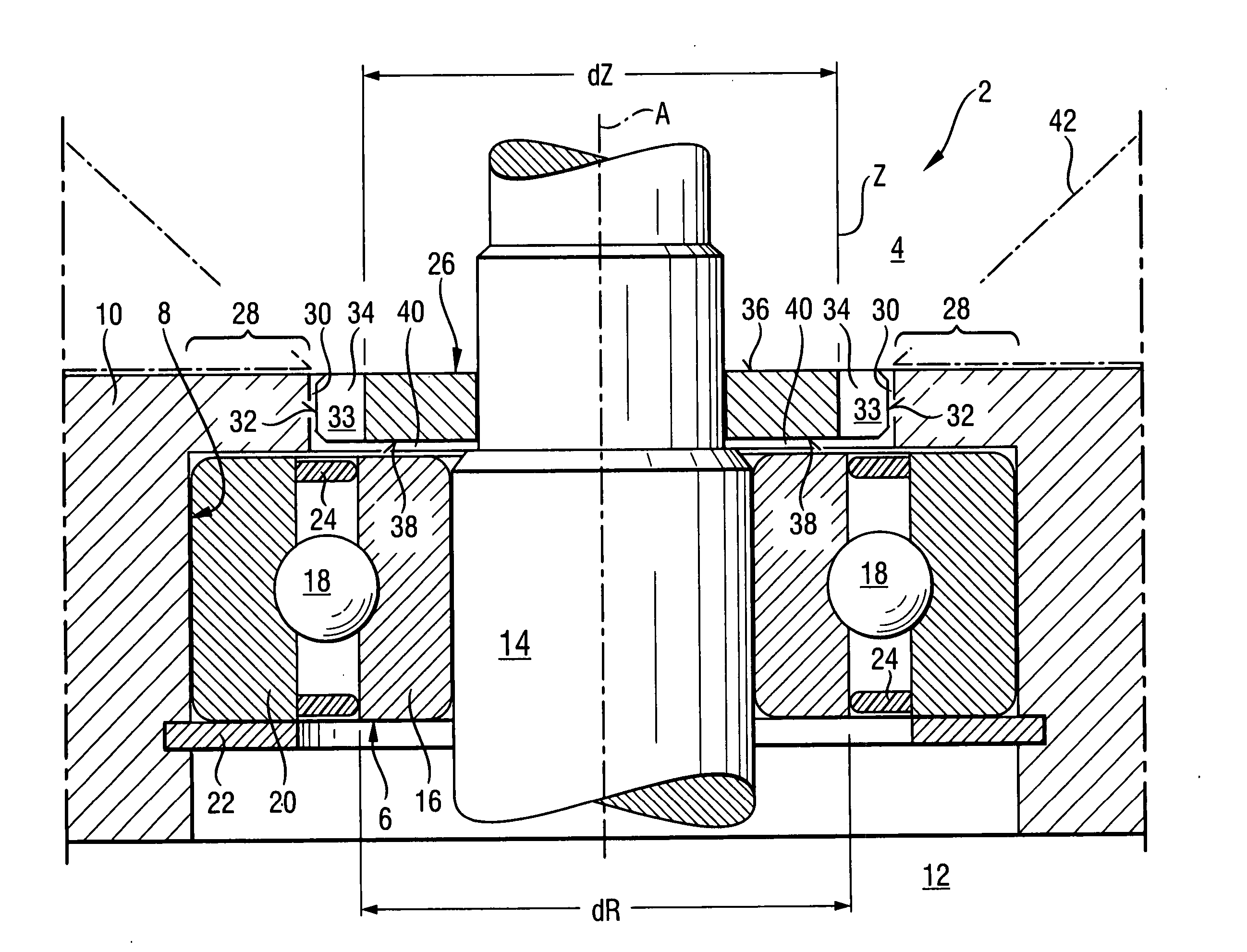

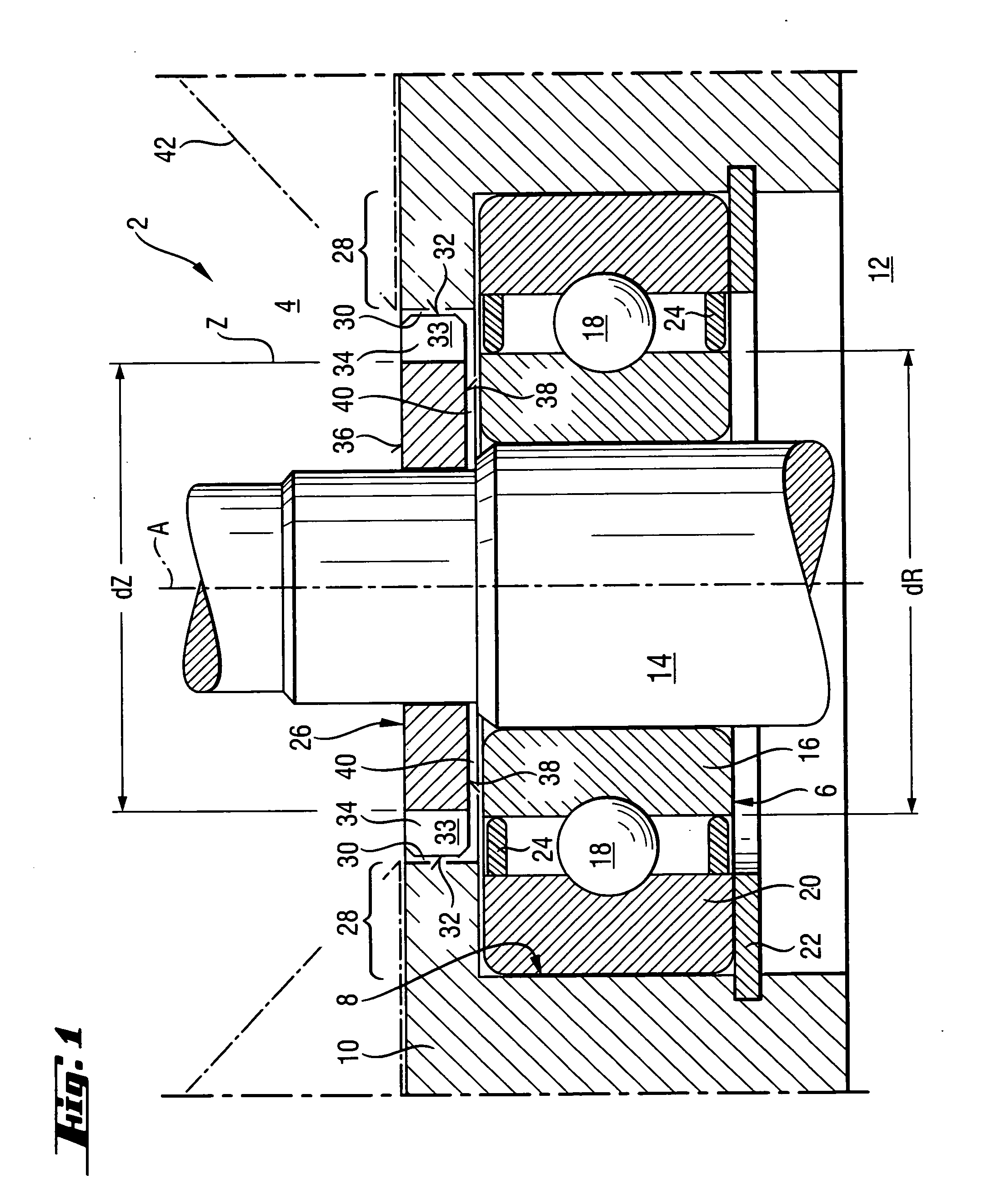

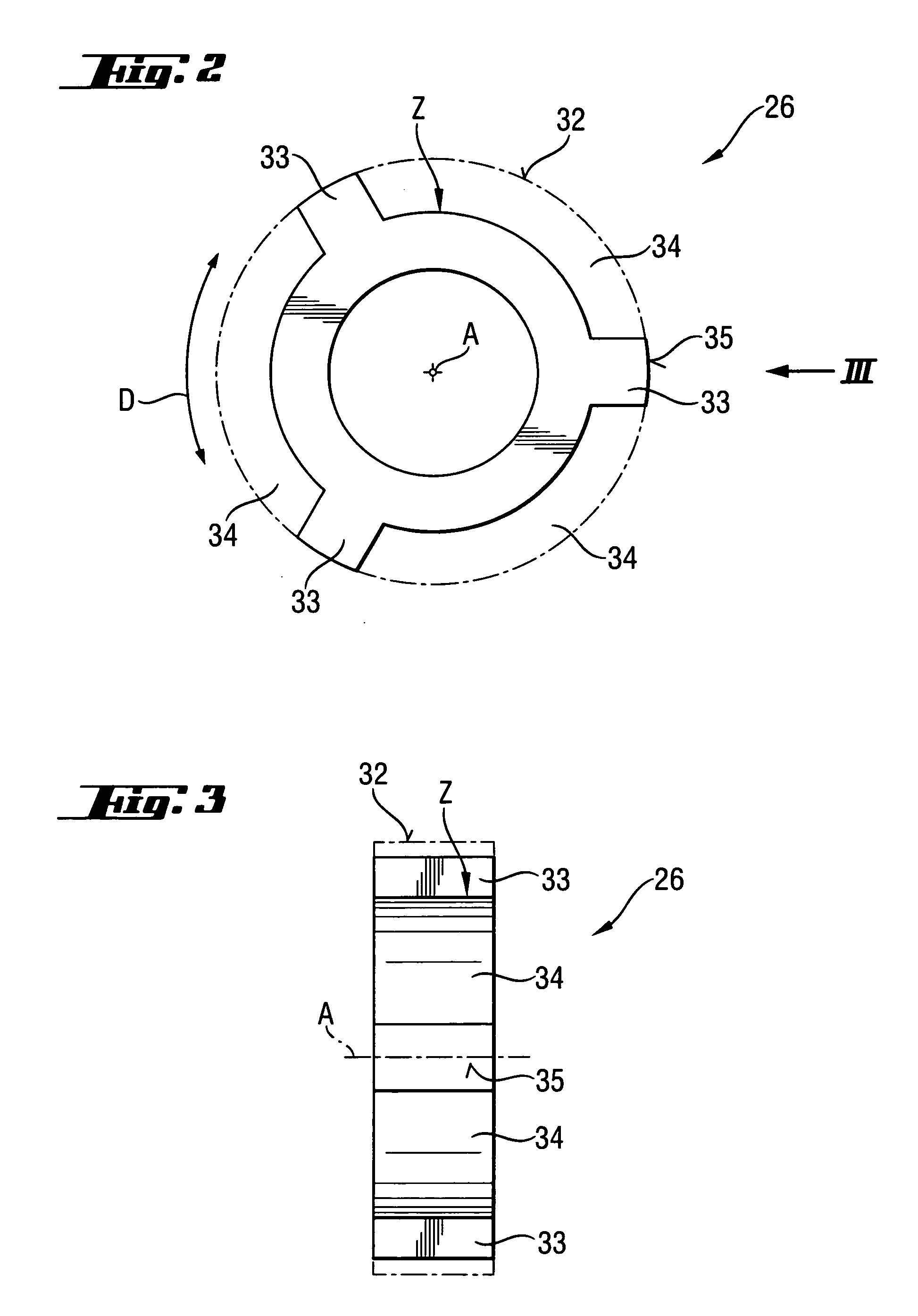

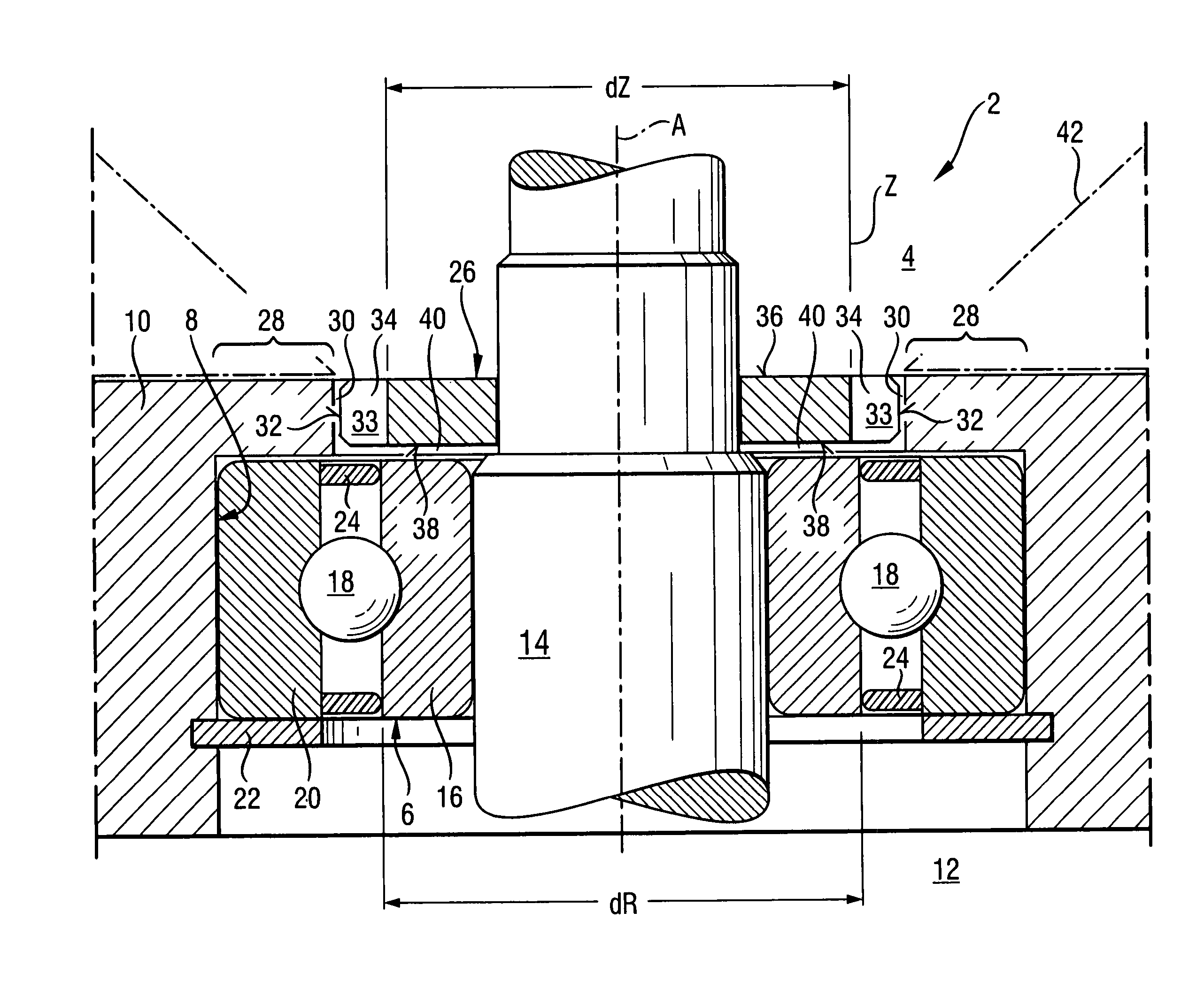

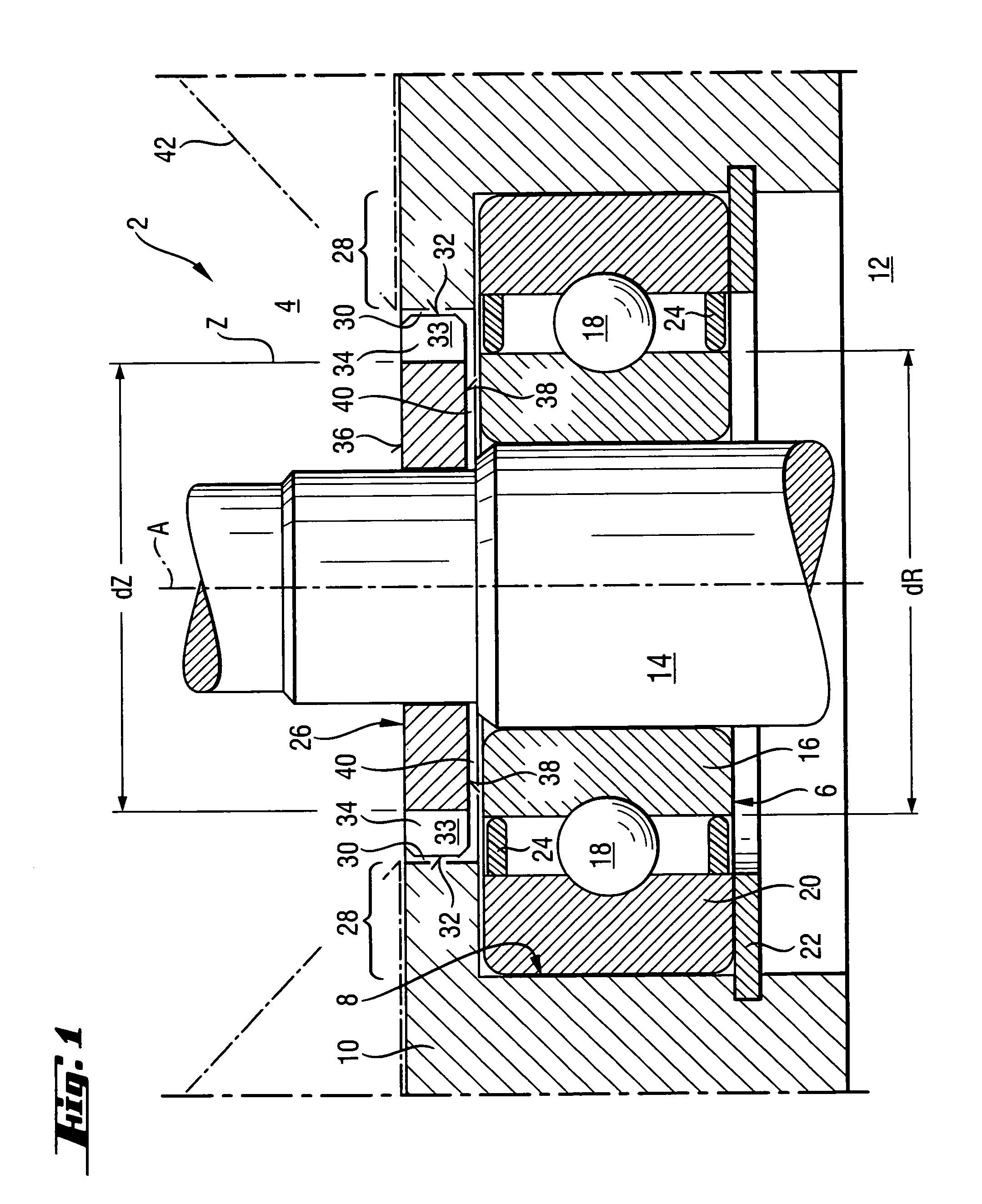

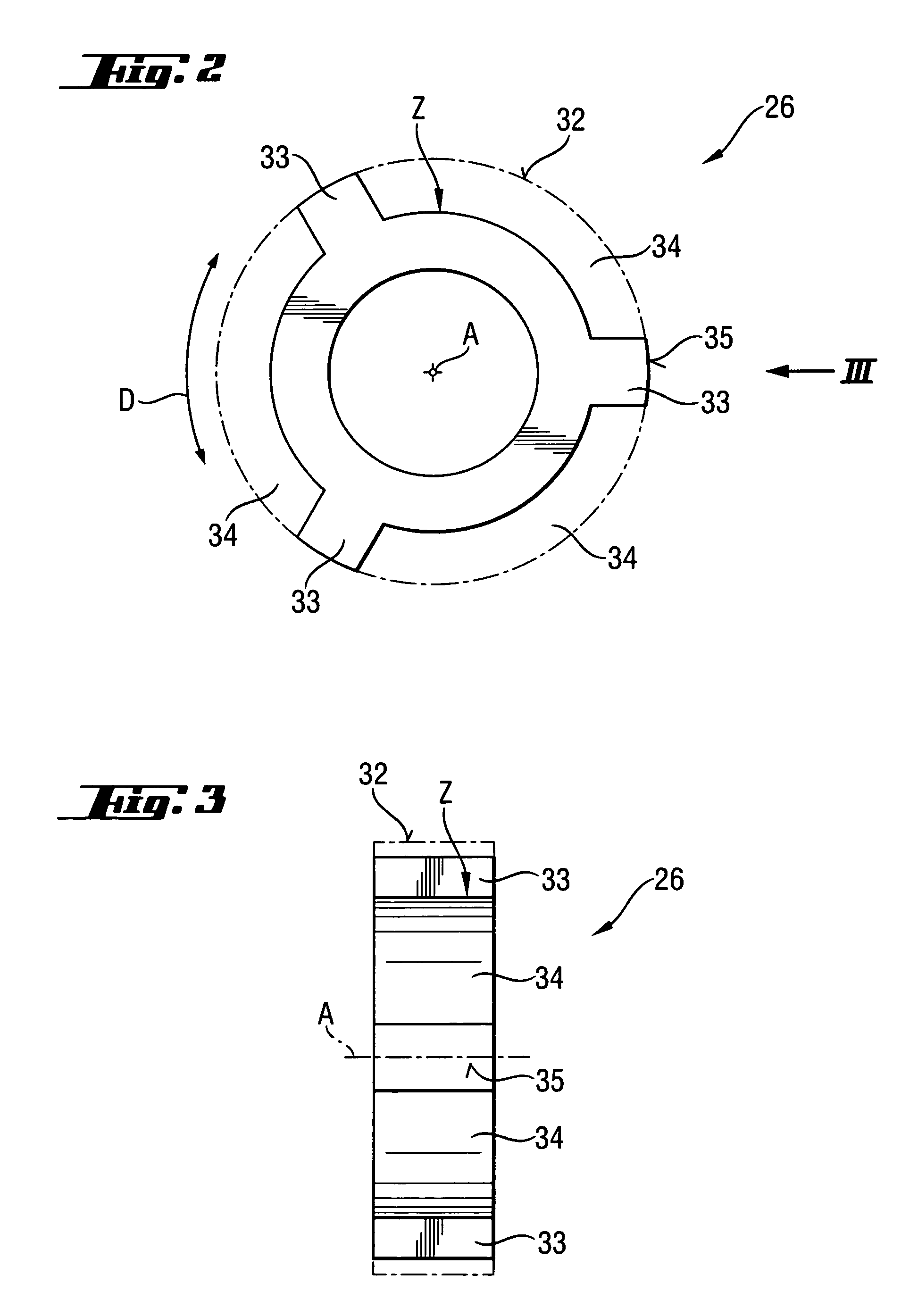

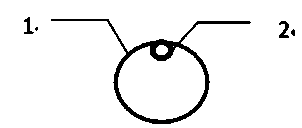

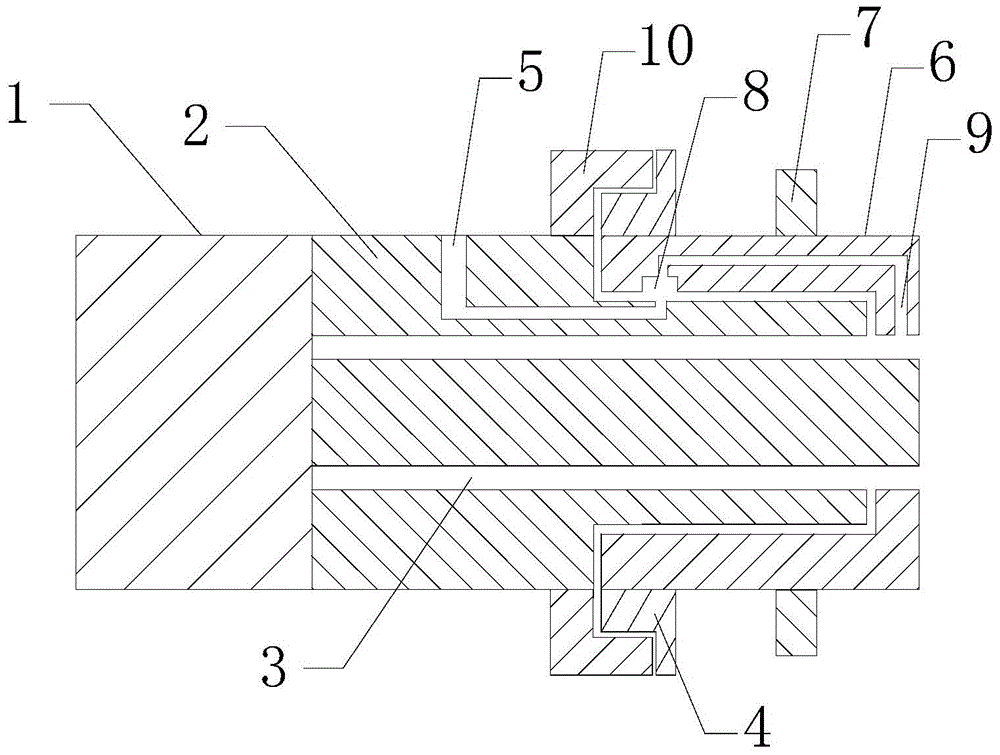

Shaft bearing seal

InactiveUS20080075401A1Effective forceImprove lubricantEngine sealsBall bearingsMechanical engineeringAeration

A seal (2) for a bearing (6) that rotatably supports a shaft (14) extending through a housing opening (8) of a housing element (10) that limits, at least partially, a lubricant-receiving chamber (4), includes a sealing ring (26) retainable between the housing element (10) and the shaft (14) and forming together with a limiting element (28) an annular gap (30), and having aeration recesses (34) which connect the annular gap (30) with the grease-containing chamber (4).

Owner:HILTI AG

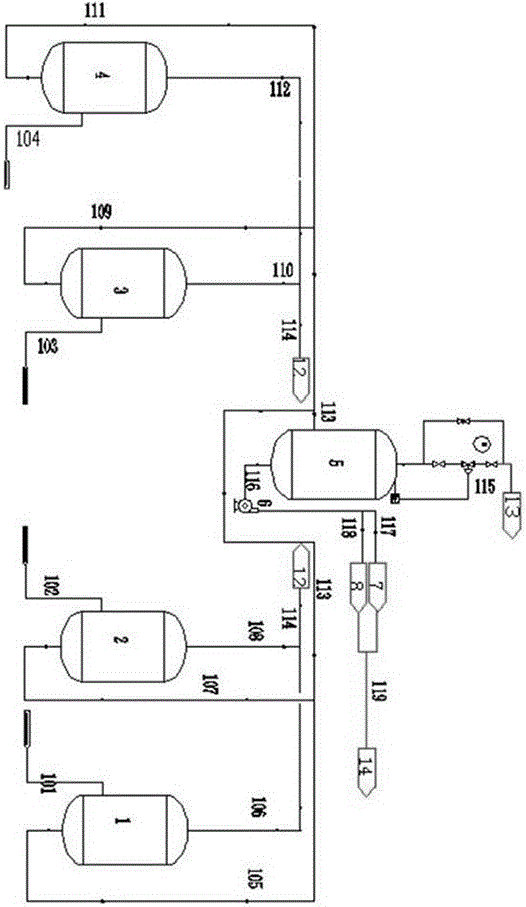

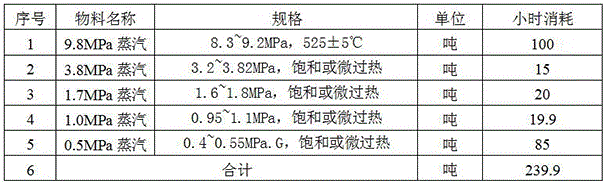

Coal-derived ethylene glycol steam condensate heat recycling system and method

PendingCN106765005AFull recovery of waste heatUnobstructed deliveryFeed-water heatersLower gradeLow graded

The invention relates to the field of coal-derived ethylene glycol, in particular to a coal-derived ethylene glycol steam condensate heat recycling system and method. The coal-derived ethylene glycol steam condensate heat recycling system comprises a high-grade steam flashing unit, a low-grade steam flashing unit and a far heat supply unit taking low-grade steam condensate as heat. The high-grade steam flashing unit inputs steam obtained through flashing of 0.8 MPa condensate, 1.5 MPa condensate of a rectification system, 1.5 MPa condensate of a reaction system and 3.6 MPa condensate in different flashing tanks into a 0.5 MPa steam pipeline net, the obtained 0.4 MPa condensate is subjected to further flashing, 0.2 MPa steam enters a 0.2 MPa steam pipeline net, and the obtained condensate is heated and then fed into a thermoelectric medium pressure steam boiler to serve as supplementary water for the boiler. The coal-derived ethylene glycol steam condensate heat recycling system and method realize cascade use of steam condensate, effective recycling of steam condensate of different regions and different pressure grades is realized through the high-grade flashing unit, pipeline flow resistance and energy waste in the steam condensate collecting process are reduced, and the waste heat of the steam condensate is fully recycled.

Owner:安阳永金化工有限公司

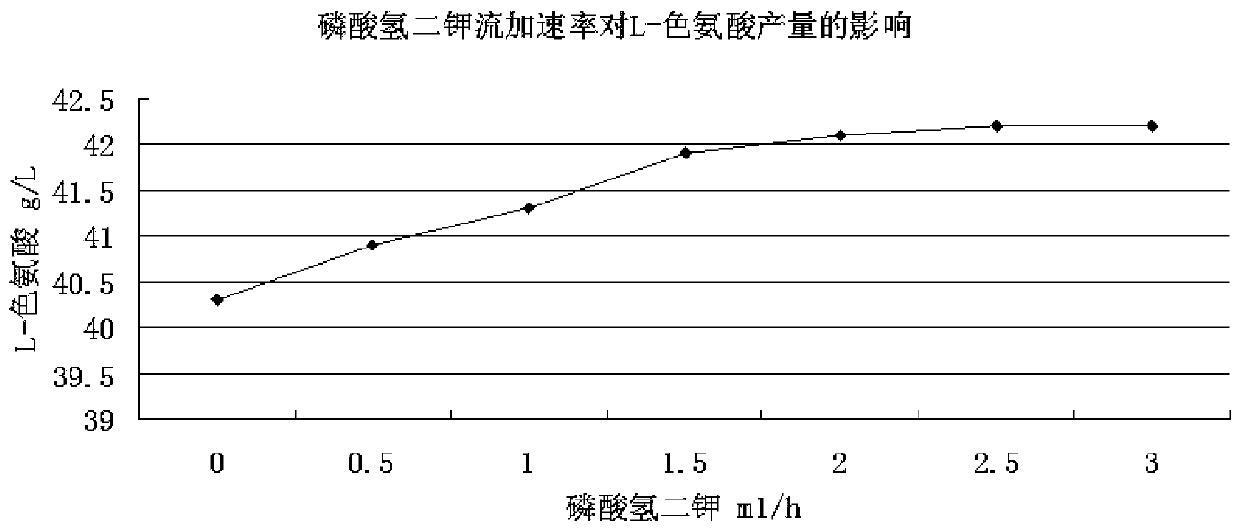

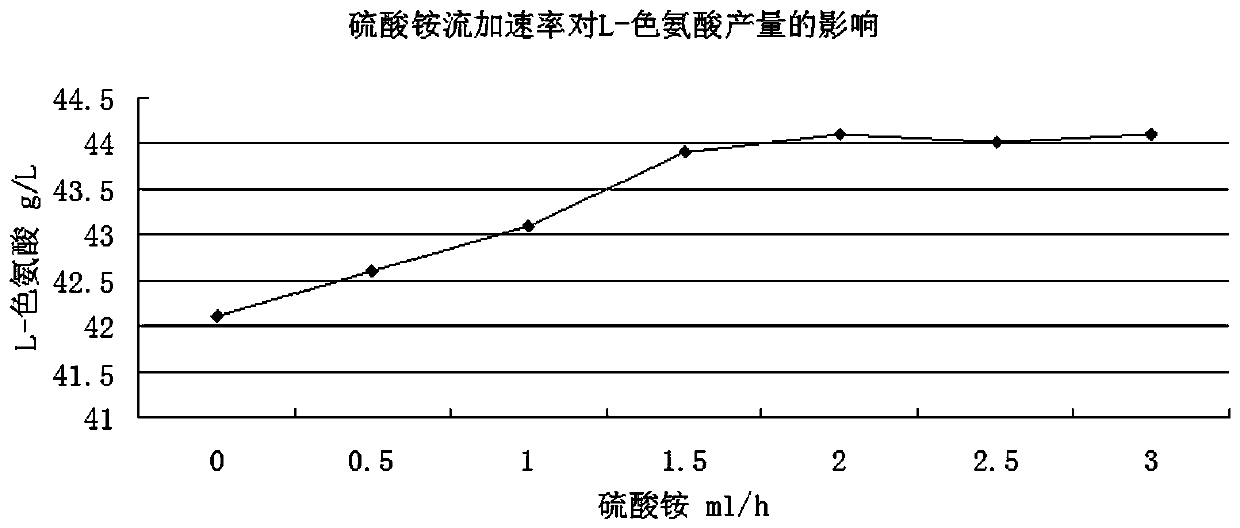

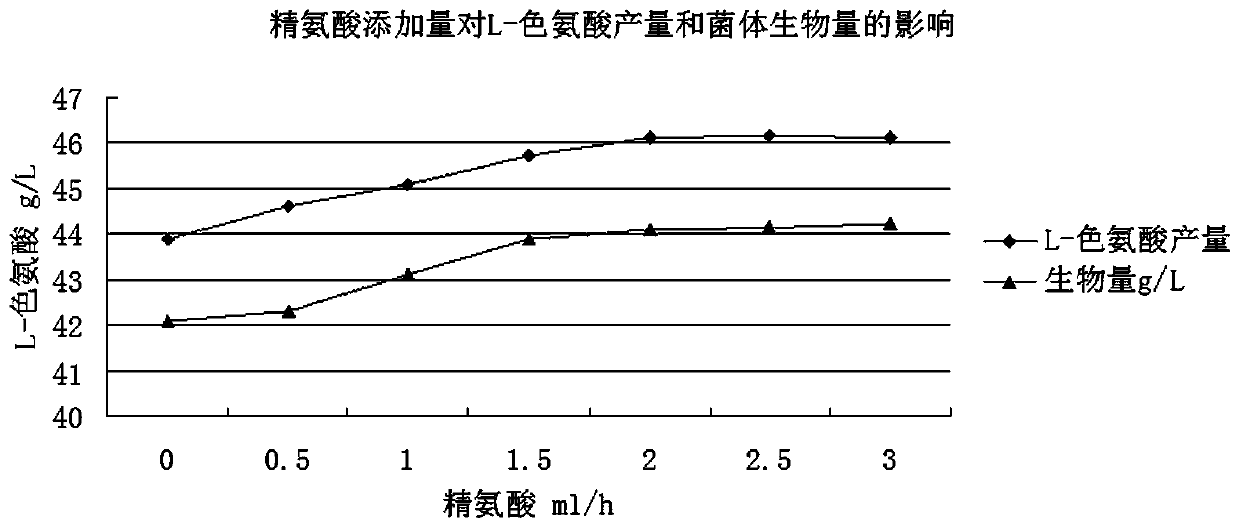

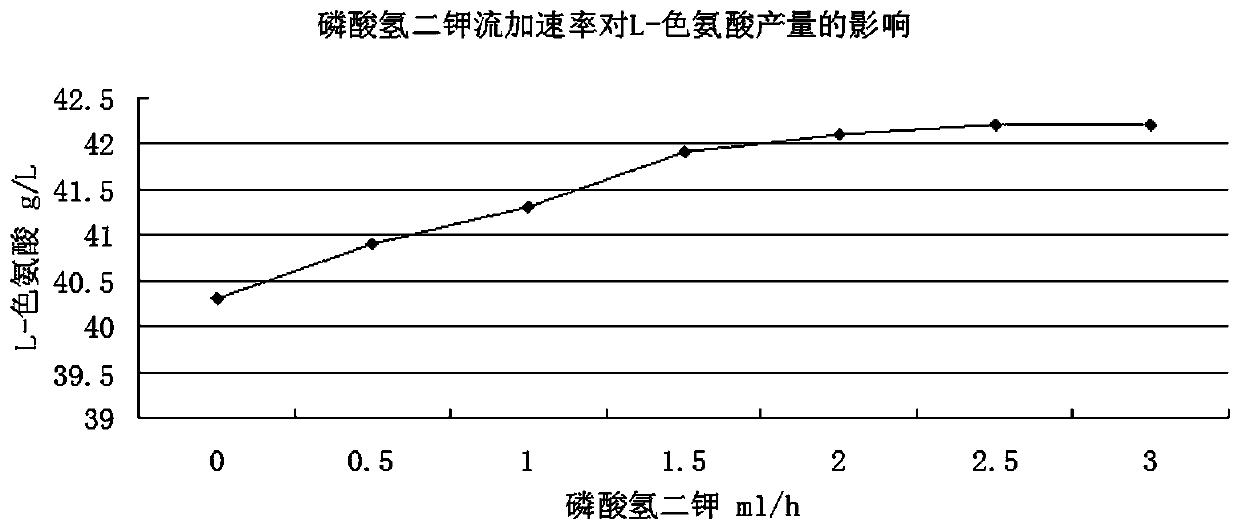

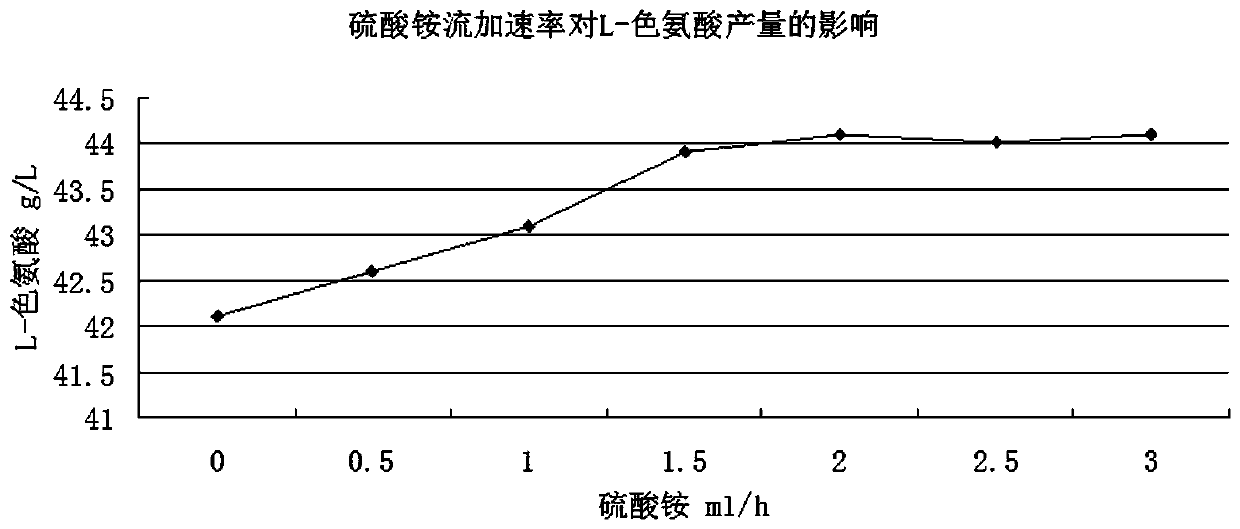

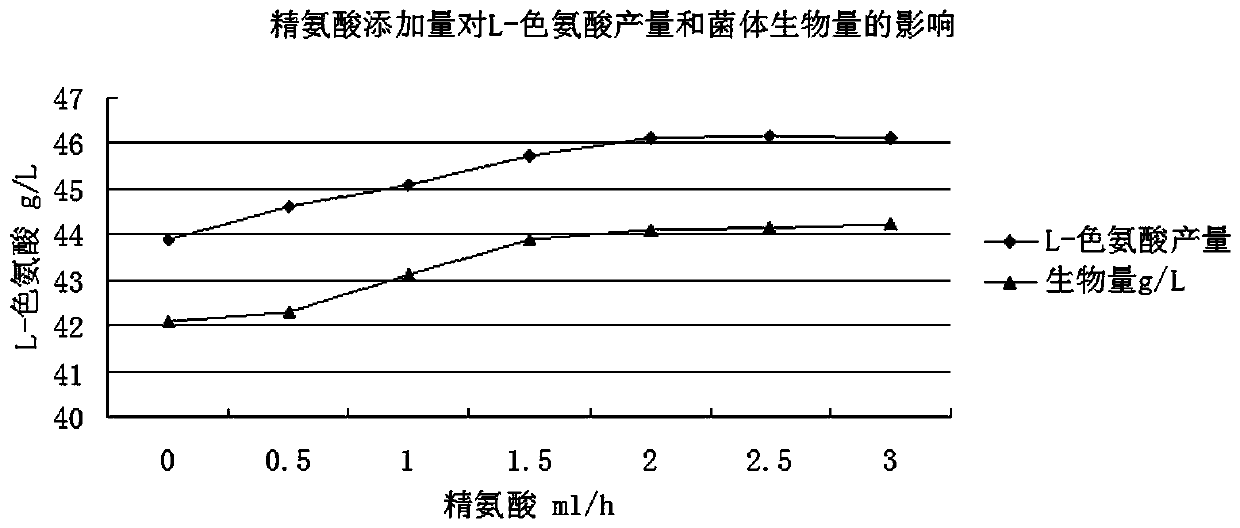

Method for producing tryptophan through fermentation of fed-batch culture liquid

PendingCN110541014AReduce generationSmooth circulationBacteriaMicroorganism based processesMicroorganismArginine

The invention belongs to the technical field of microbial fermentation, and discloses a method for producing tryptophan through fermentation of fed-batch culture liquid. In the culture process of a fermentation tank, the tryptophan is produced through a fed-batch dipotassium phosphate solution or an ammonium sulfate solution or an arginine aqueous solution in a fed-batch mode, and culture is conducted for 40 h and then completed. Under the conditions of not additionally arranging any additional equipment and not increasing any manpower input, the fermentation cycle is prolonged, the labor intensity is lowered, and the yield of the tryptophan is significantly increased.

Owner:XINJIANG FUFENG BIOTECH

Air pollutant detector based on graphene infrared emission unit

ActiveCN111678881AImprove thermal conductivityFast conductionMaterial analysis by optical meansCoatingsMicrosphereMaterials science

The invention provides an air pollutant detector based on a graphene infrared emission unit. Multi-infrared radiation is realized by utilizing a wrinkle-shaped structure of graphene microspheres in amulti-infrared emission coating under the cohesion and combination effects of macromolecules, the heat generation effect of a graphene layer, the insulation effect of an insulation aluminum-silicon compound and cooperation of small-molecule high-radiation inorganic particles; the detection unit is used for receiving infrared light which is emitted from the infrared emission unit and passes throughgas to be detected after being filtered by an optical filter, so that the detection of air pollutants is realized; and the optical filter of the gas detection device can be replaced, and the gas detection device is used for detecting various gases and is simple to operate and low in cost.

Owner:ZHEJIANG UNIV OF TECH

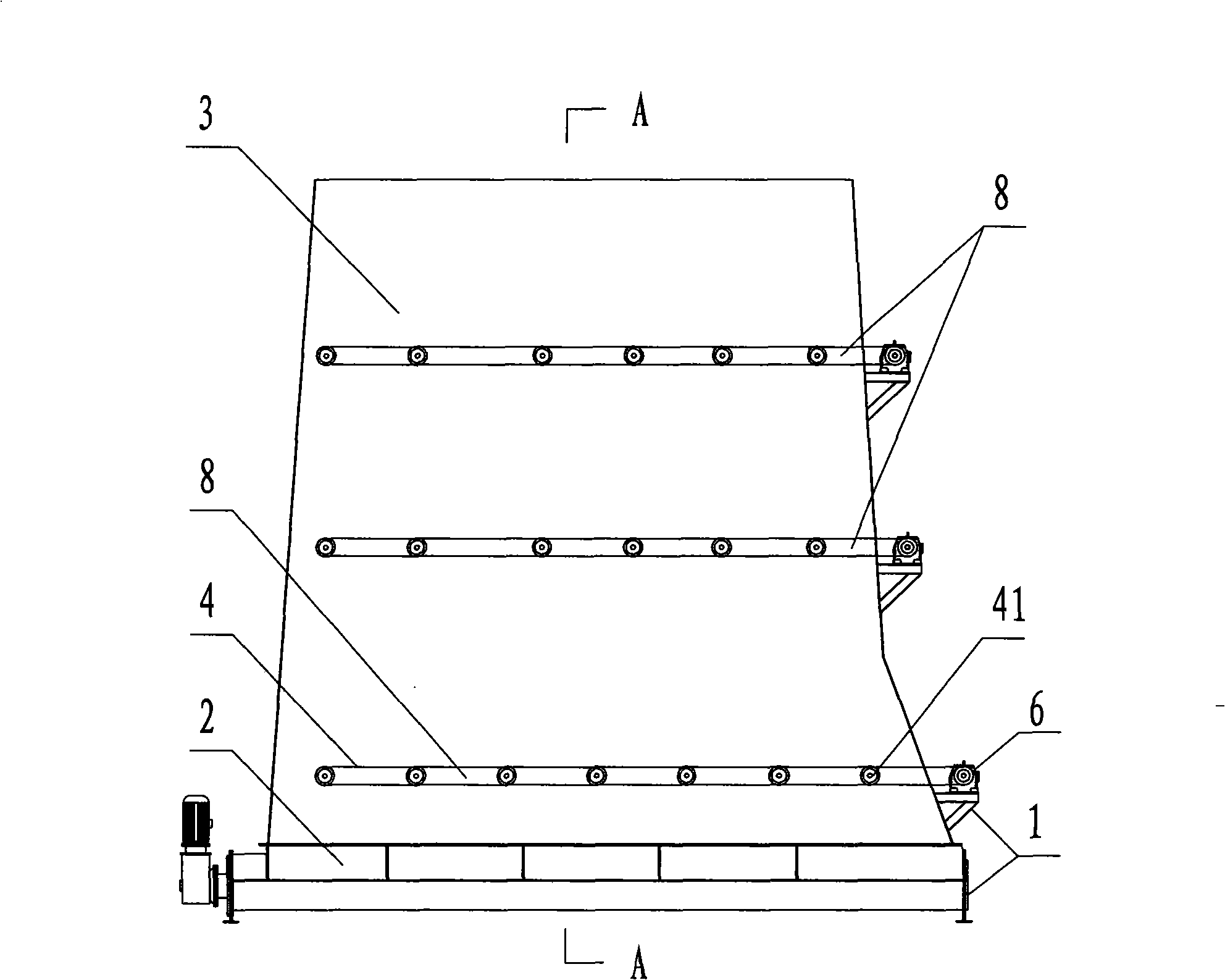

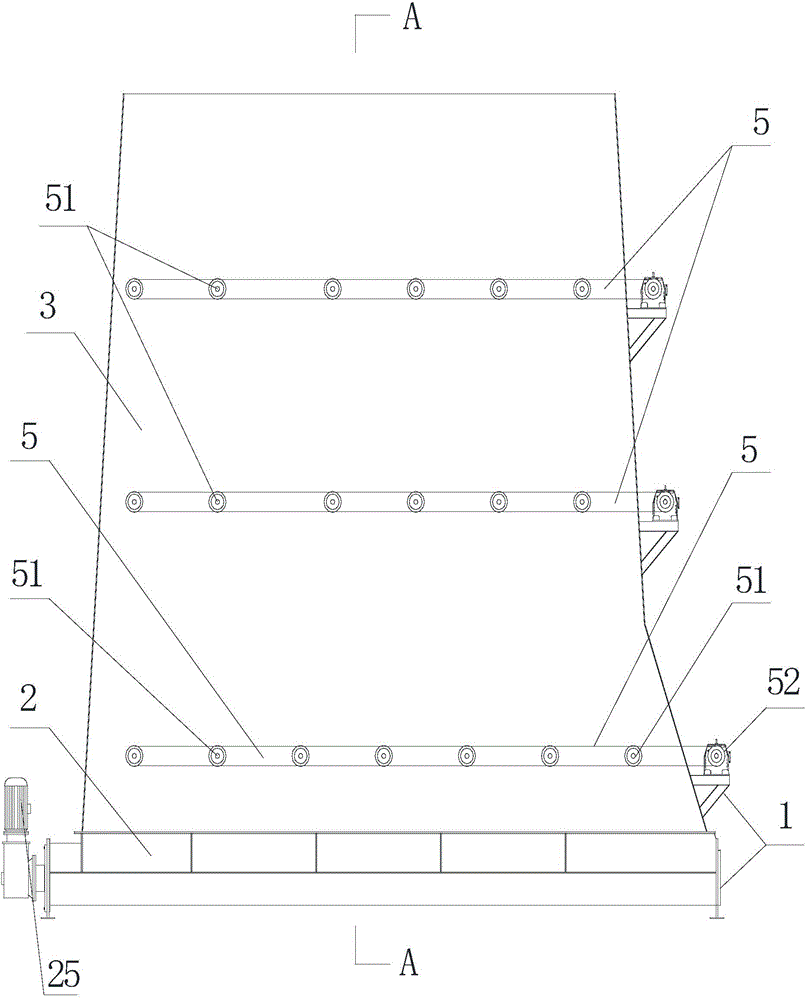

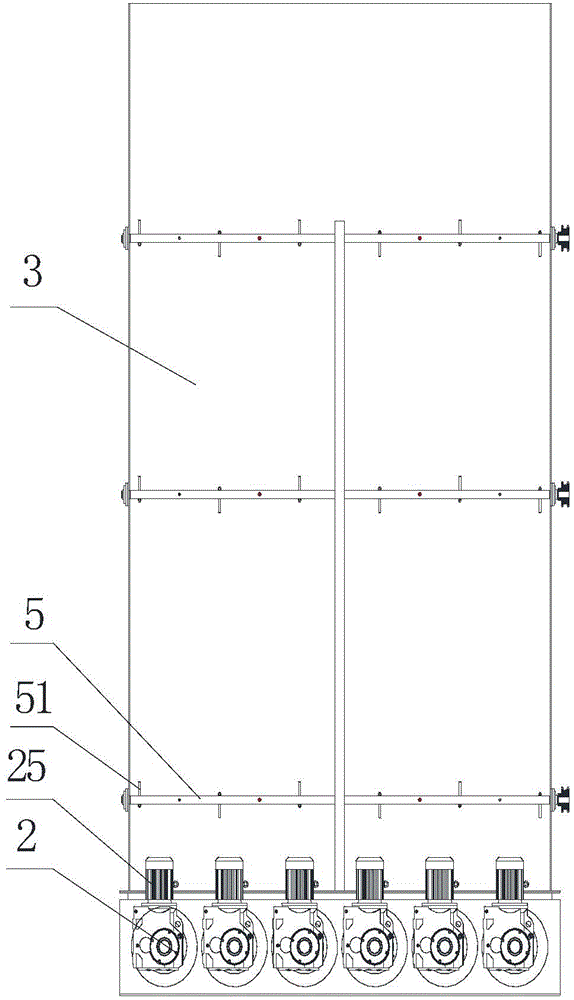

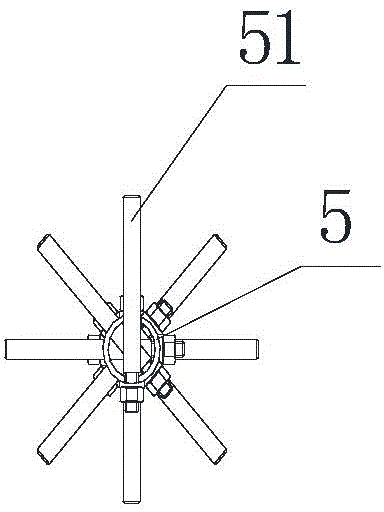

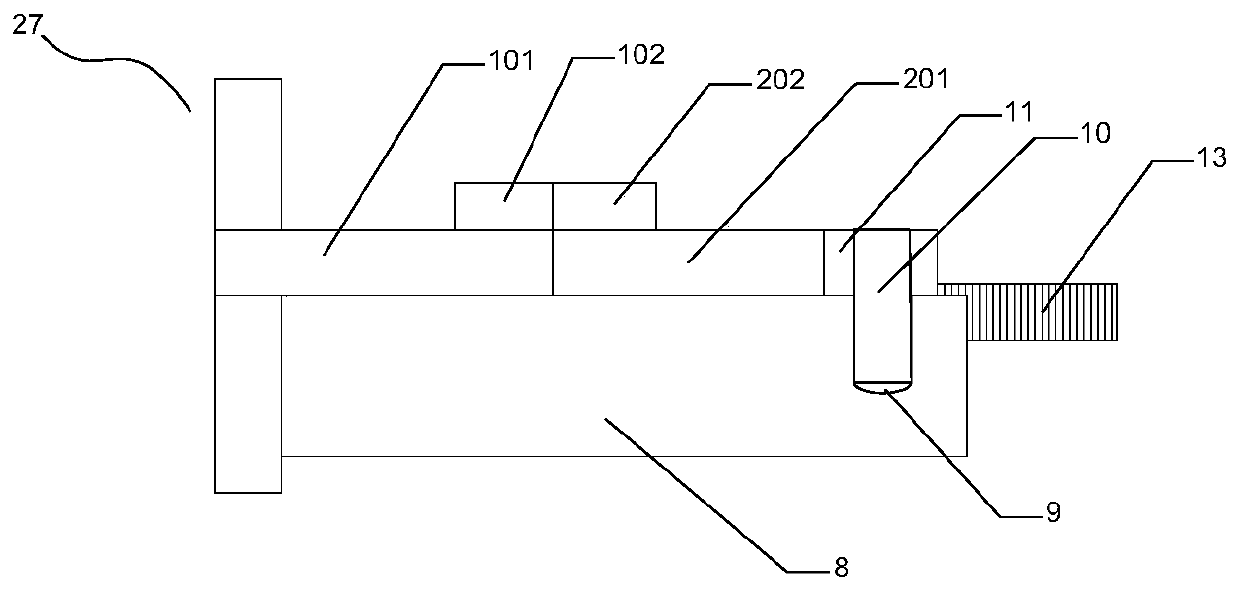

Helical material transport machine

InactiveCN101314441AUnobstructed deliveryPrevent archingLarge containersLoading/unloadingElectric machineryEngineering

The invention discloses a helical material conveyer, comprising a helical material conveying unit arranged on a frame, wherein, a storage hopper is arranged above the helical material conveying unit. A loosening device is arranged on the junction of the storage hopper and the helical material conveying unit, and comprises a plurality of horizontally arranged stirring shaft components which are movably arranged on the storage hopper and are driven by a motor to operate. The middle part and the upper part of the storage hopper are also provided with a loosening device respectively for progressively loosening layer upon layer, thereby enhancing the loosening effect of materials. The invention has the loosening device arranged on the junction of the storage hopper and the helical material conveying unit, can loosen the constrictive material under the stir of a stirring shaft of the loosening device, thereby preventing the arch camber phenomenon of the materials, ensuring smooth conveying of the materials, realizing the feeding with low hopper pressure and low resistance, and reducing the energy consumption.

Owner:钱尧翎

Shaft bearing seal

A seal (2) for a bearing (6) that rotatably supports a shaft (14) extending through a housing opening (8) of a housing element (10) that limits, at least partially, a lubricant-receiving chamber (4), includes a sealing ring (26) retainable between the housing element (10) and the shaft (14) and forming together with a limiting element (28) an annular gap (30), and having aeration recesses (34) which connect the annular gap (30) with the grease-containing chamber (4).

Owner:HILTI AG

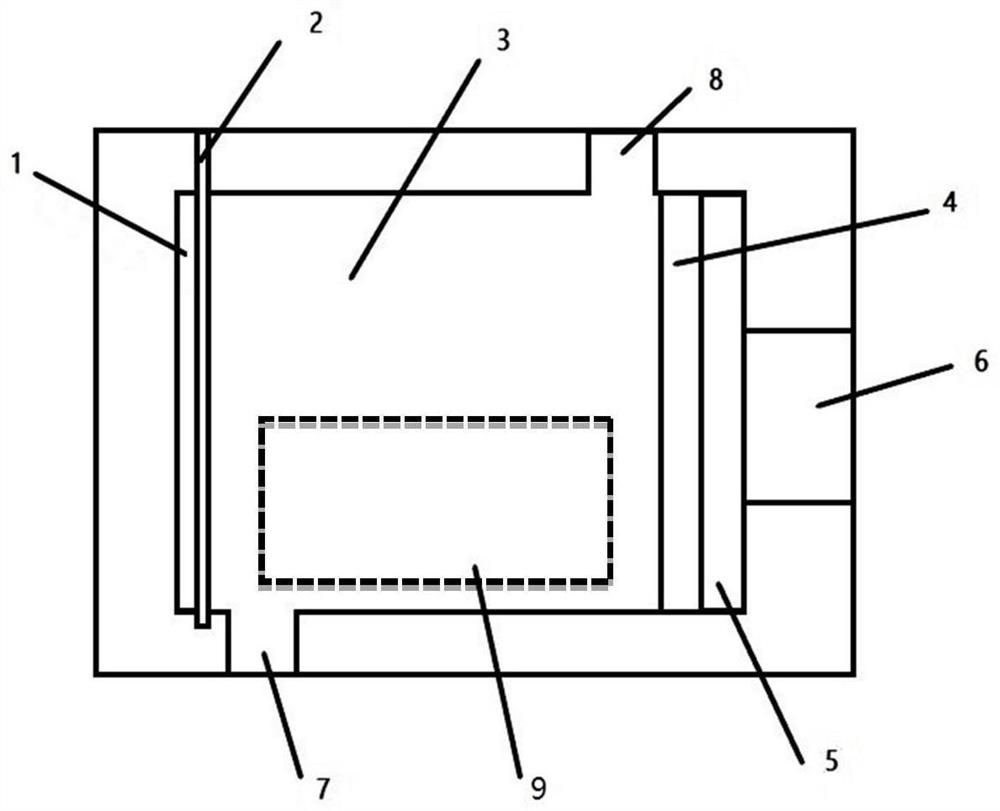

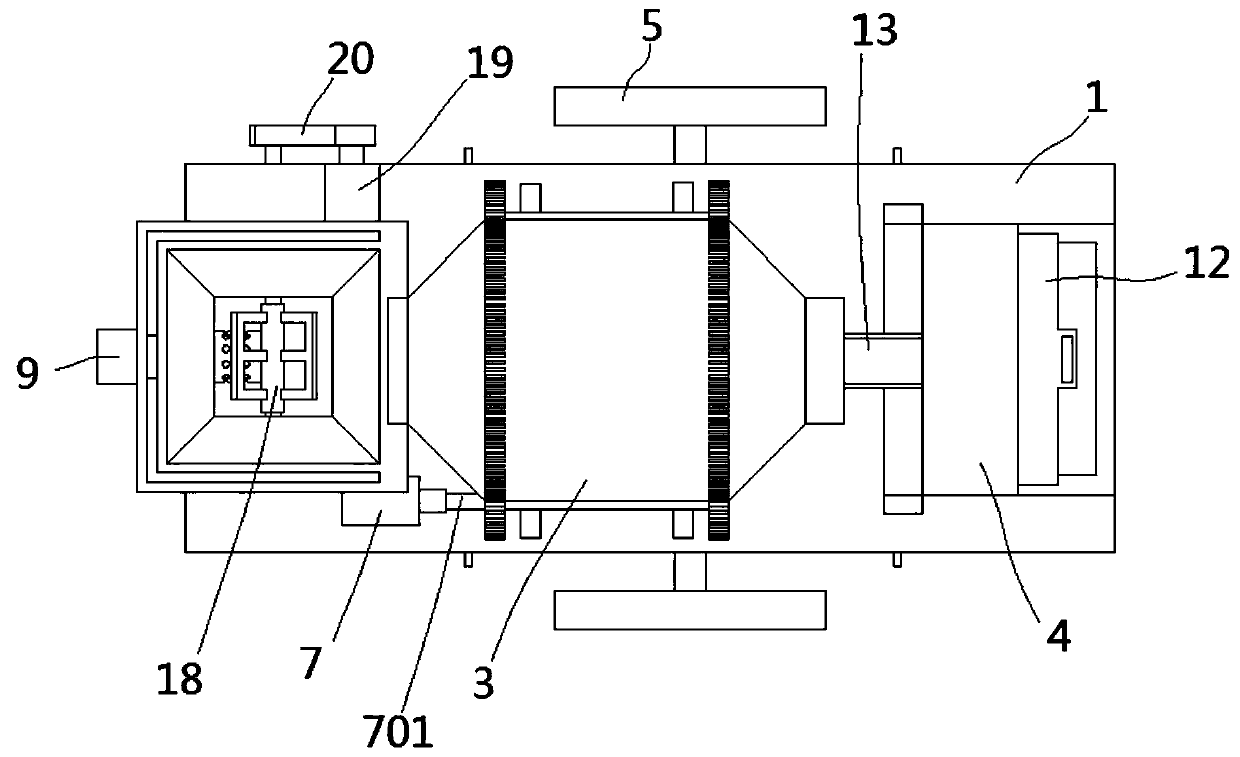

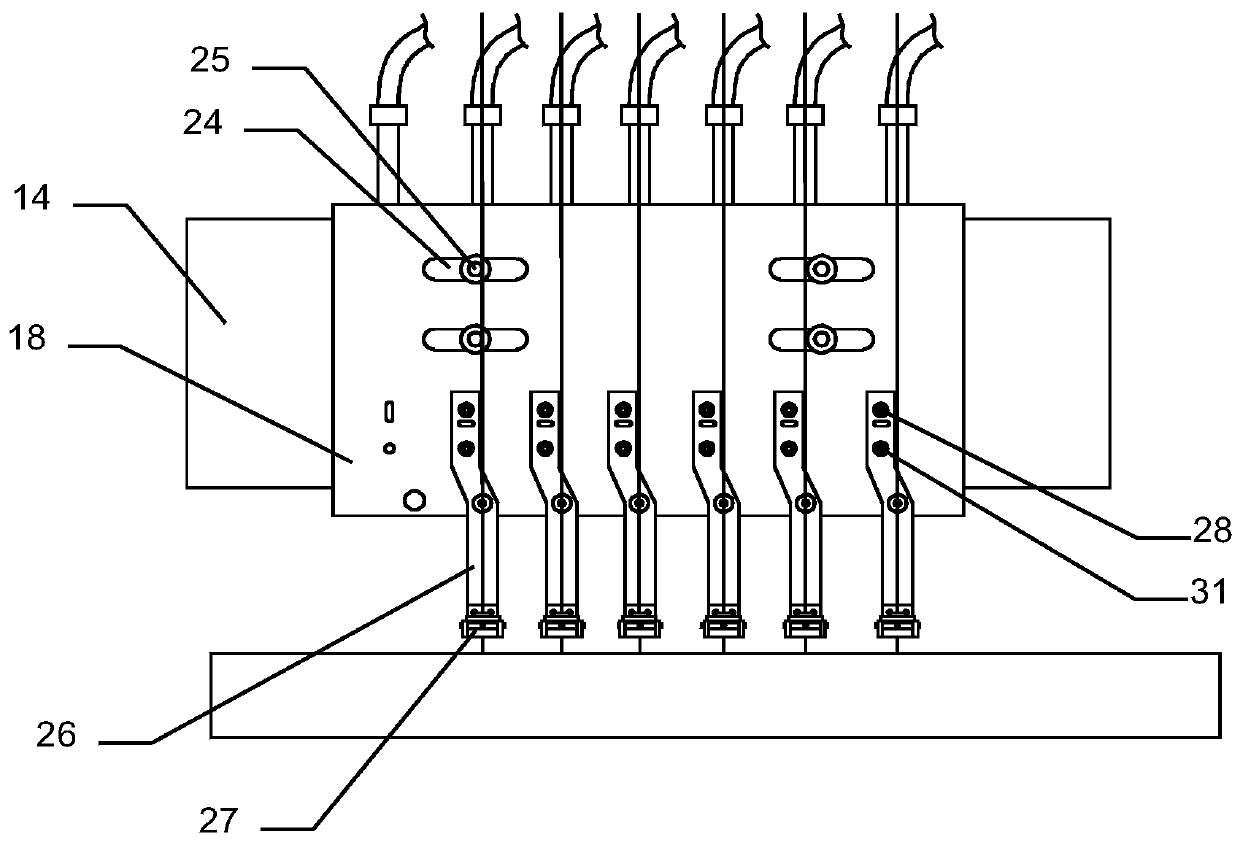

Lower-film-walking packing mechanism

InactiveCN104229212AUnobstructed deliverySimple structureWrapping material feeding apparatusWrapper twisting/gatheringEngineeringMechanical engineering

The invention discloses a lower-film-walking packing mechanism. The lower-film-walking packing mechanism comprises a frame (11), an uncoiling device (1), a molding device (3), a middle sealing device (4) and a sealing-cutting device (7), wherein the uncoiling device (1) is arranged on the lower part of the frame (11); the opening of the molding device (3) faces upwards; a support drum (5) is arranged on a tool-sealing revolving shaft (8) of the sealing-cutting device (7) through a fixed seat (6). According to the lower-film-walking packing mechanism, the support drum is used for stably supporting a packing film and large-sized medicine in the packing film, so that smooth conveying is facilitated; the lower-film-walking packing mechanism has the advantages of simple and practical structure, stability in working and running, rapidness and smoothness in conveying and high production efficiency, and is suitable for pillow type packing of large-sized medicine.

Owner:瑞安市海创机械有限公司

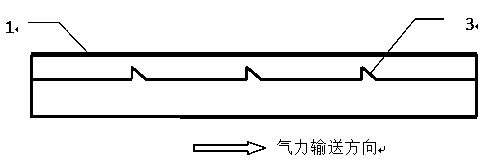

Material fluidization pressurization tube device

InactiveCN103449188AUnobstructed fluidizationUnobstructed deliveryBulk conveyorsEngineeringFluidization

The invention relates to a material fluidization pressurization tube device which consists of double sleeves: a conveyed material fluidized big pipe and a double-sleeve inner pipe. The conveyed material fluidized big pipe and the double-sleeve inner pipe are in a connection relation that the double-sleeve inner pipe is arranged in the conveyed material fluidized big pipe; throttling orifices are uniformly arranged at equal intervals inside the double-sleeve inner pipe; and double-sleeve inner pipe; through holes are uniformly formed at equal intervals in the rear parts of the throttling orifices on the pipe wall of the double-sleeve inner pipe. The material fluidization pressurization tube device can be widely applied to the field of material fluidization sending.

Owner:YUNNAN HUAYUN TIANLANG ENVIRONMENTAL PROTECTION

Plastic rib spiral pipe without adhesive-bonded joints and manufacturing technique thereof

InactiveCN104633308AImprove product qualityUnobstructed deliveryRigid pipesSmooth surfaceEngineering

The invention discloses a plastic rib spiral pipe without adhesive-bonded joints and manufacturing technique thereof. The plastic rib spiral pipe without the adhesive-bonded joints and the manufacturing technique thereof comprise a plastic rib spiral pipe body, the inner wall of the plastic rib spiral pipe body is a one-piece smooth surface, the outer wall of the plastic rib spiral pipe body is a one-piece smooth surface, and spiral plastic ribs wind around the outer wall of the plastic rib spiral pipe. The manufacturing technique of the plastic rib spiral pipe without the adhesive-bonded joints comprises the steps that plastic rib pipe materials are extruded from the head of an extruder, and the plastic rib pipe body is formed in a plastic rib pipe forming channel; meanwhile, spiral plastic rib materials enter a spiral plastic rib material injection channel of a fixed sleeve, then the spiral plastic rib materials are extruded from a spiral-shaped material extruding channel of a spiral sleeve and wind around the plastic rib pipe body, and the plastic rib spiral pipe without the adhesive-bonded joints is formed. The plastic rib spiral pipe without the adhesive-bonded joints and the manufacturing technique thereof have the advantages that the inner wall of the plastic rib spiral pipe is smooth and no adhesive-bonded joints exist, so that the product quality is greatly improved and the stability is achieved; due to the fact that no adhesive-bonded joints exist on the plastic rib spiral pipe, the conveying of the materials are more smooth and no residues exist.

Owner:张雁

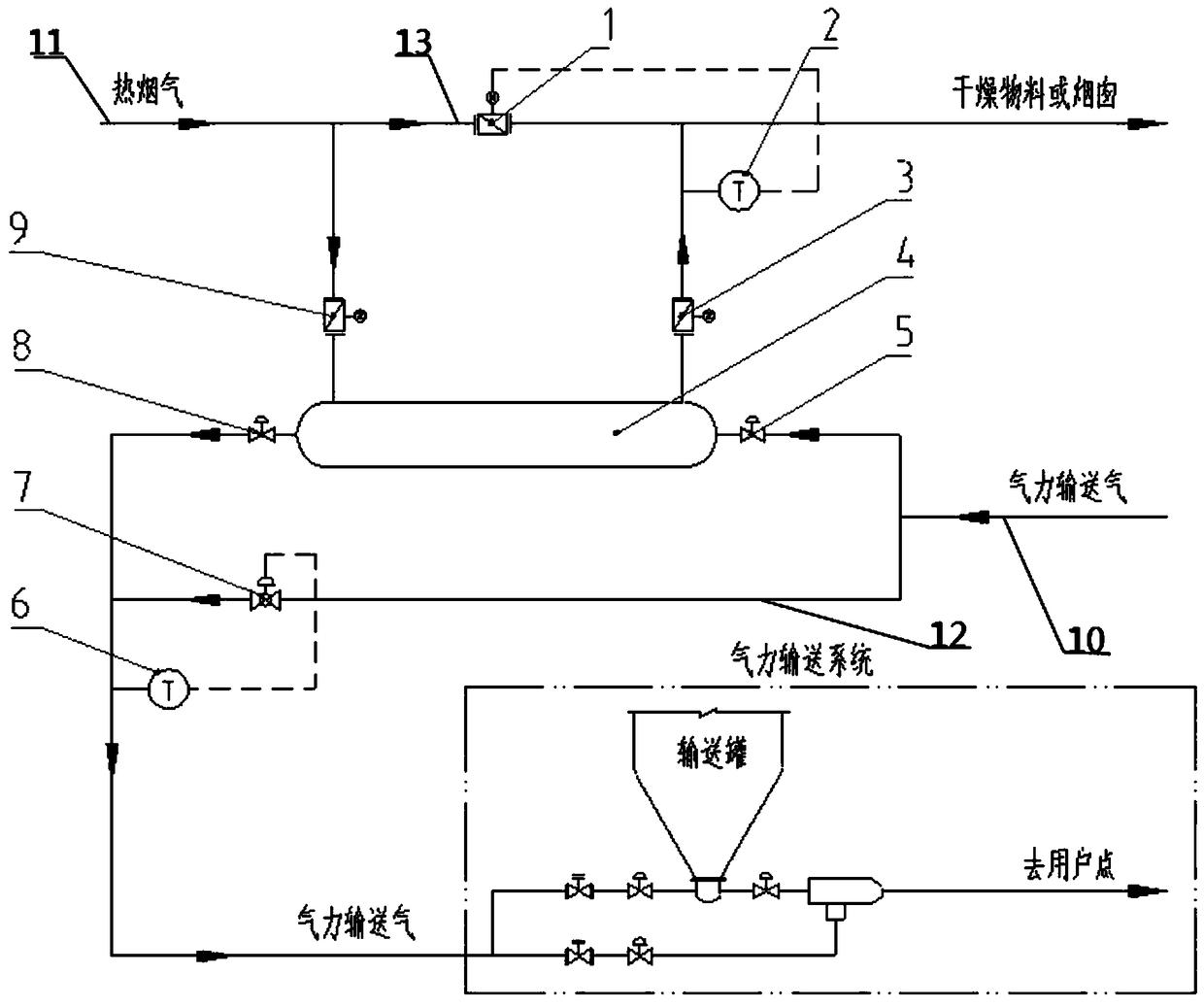

Powdery material preheating pneumatic transmission device and technology

The invention relates to the technical field of powdery material pneumatic transmission, in particular to a pulverized coal, slag powder, cement and other powdery materials preheating pneumatic transmission device and technology. A pneumatic transmission pipeline is divided into two branches; a pneumatic transmission gas preheating branch passes through a preheater, the other branch is a pneumatictransmission gas bypass pipe, and the two branches converge into a total pipeline at the outlet of the preheater; a hot exhaust gas pipeline is divided into two branches, a hot exhaust gas preheatingbranch passes through the preheater, the other branch is an exhaust gas bypass pipe, and the two branches converge into a total pipeline at the outlet of the preheater; a pneumatic transmission gas inlet cut-off valve and a pneumatic transmission gas outlet cut-off valve are arranged at the ends, entering and exiting the preheater, of the pneumatic transmission gas preheating branch; and an exhaust gas inlet cut-off valve and an exhaust gas outlet cut-off valve are arranged at the ends, entering and exiting the preheater, of the hot exhaust gas preheating branch. The powdery material preheating pneumatic transmission device preheats pneumatic transmission gas and increases the solid-gas ratio of pneumatic transmission to realize the purposes of energy conservation and consumption reduction and long-distance transmission.

Owner:鞍钢集团工程技术有限公司

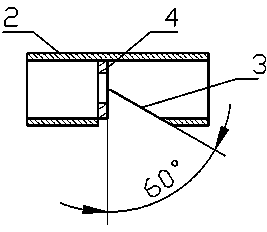

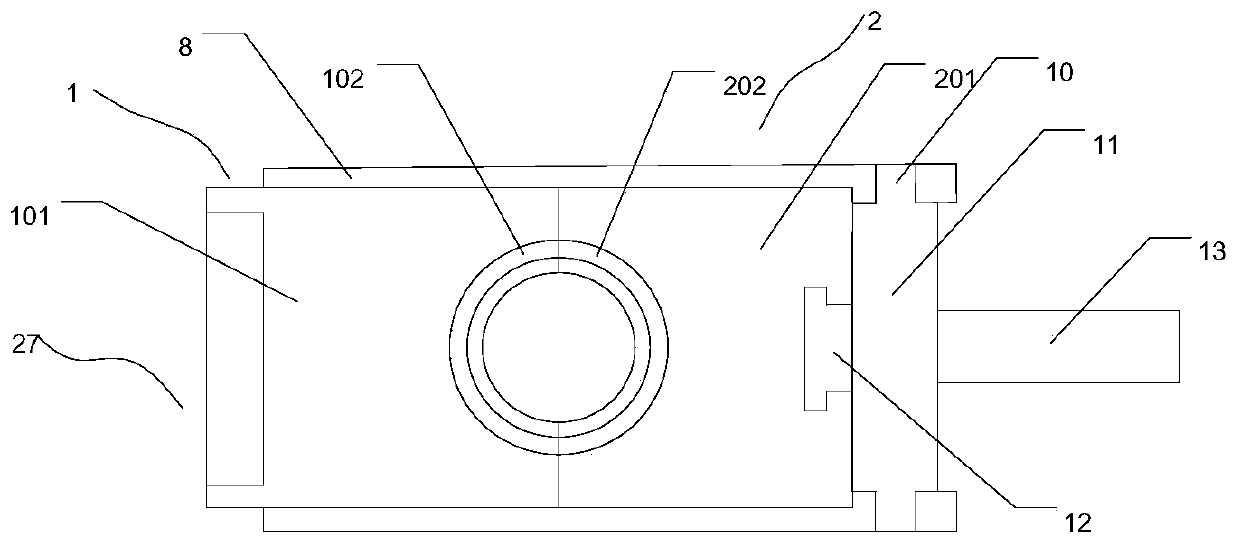

Power head structure for horizontal directional drilling machine

ActiveCN103437706AUnobstructed deliveryChange connection relationshipConstructionsDirectional drillingEngineeringDirectional drilling

The invention discloses a power head structure for a horizontal directional drilling machine, and belongs to the technical field of horizontal directional drilling machines. On the basis of an original structure, a cover body (9) is additionally arranged, the cover body (9) is arranged on the outer side of a power head main shaft (16), the front end of the cover body (9) is installed at the rear end of a power head box body (15), the center of a rear base plate is provided with a circular installation hole, meanwhile, a connecting shaft (18), a V-type combined sealing ring (19), a pressing flange (10) and a central spindle (8) are further arranged in the cover body (9), and the connecting shaft (18), the V-type combined sealing ring (19), the pressing flange (10) and the central spindle (8) are sequentially installed between a slime pump input connector (4) and the power head main shaft (16). According to the power head structure, the power head main shaft (16) is guaranteed to slide in a front-and-back mode relative to the power head box body (15), meanwhile, the position of the slime pump input connector (4) is fixed, slime in a slime input soft pipe (3) installed on the slime pump input connector (4) is guaranteed to be smoothly delivered, the phenomena of buckling and even breaking caused by non-timely movement in the original structure are avoided, and the construction progress is ensured.

Owner:XUZHOU XUGONG FOUND CONSTR MACHINERY

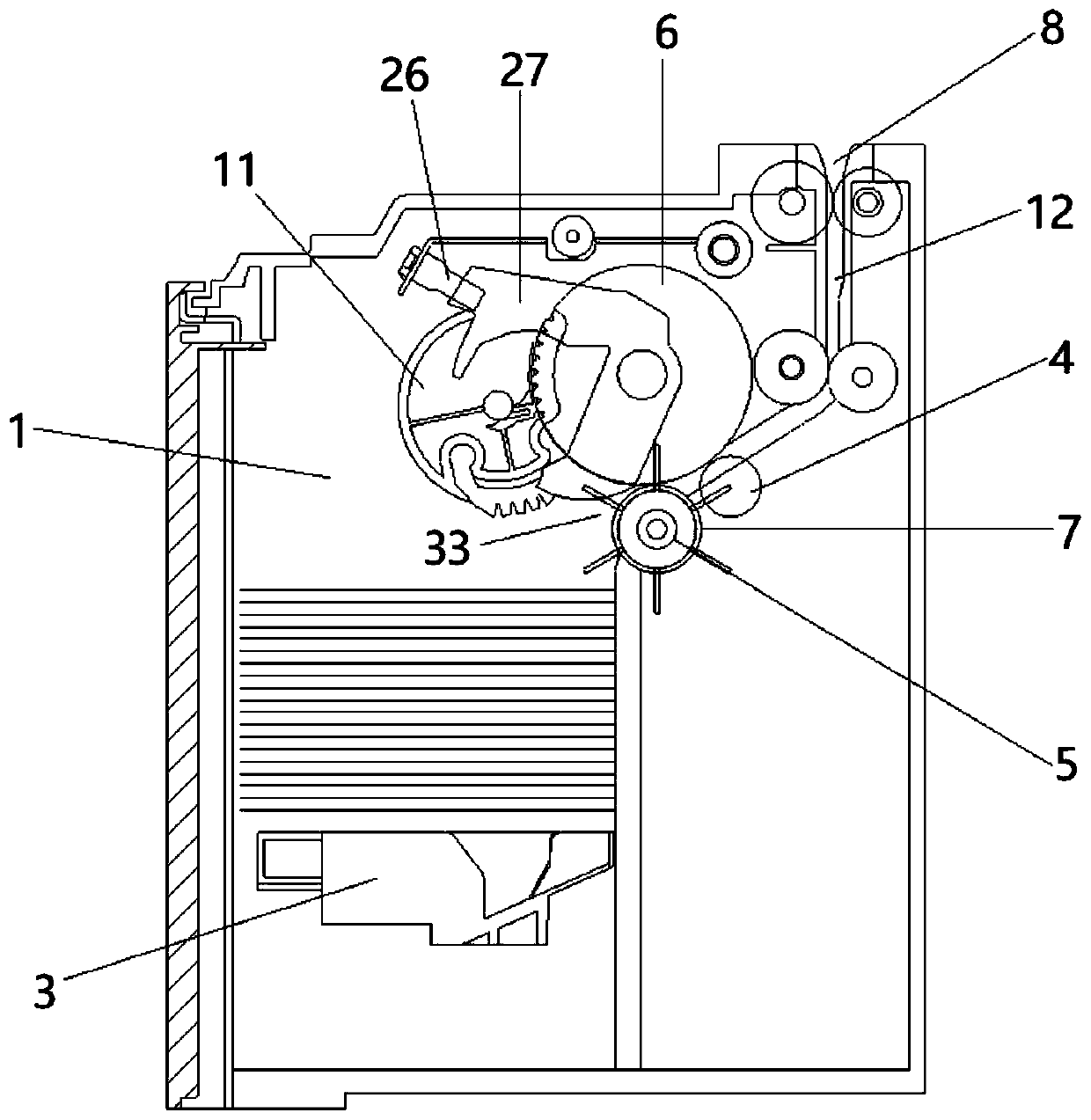

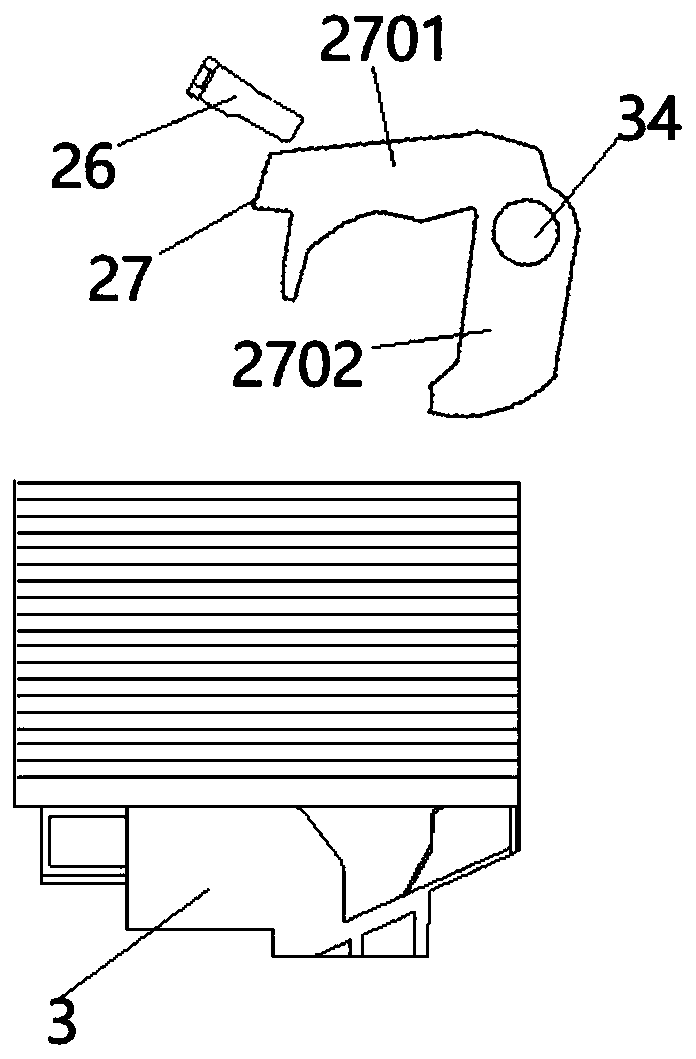

Paper money pushing and pressing mechanism and paper money depositing and withdrawing box

PendingCN110246264AUnobstructed deliveryCoin/currency accepting devicesPulp and paper industryPosition control

Owner:SHANGHAI GOOAO ELECTRONIC TECHNOLOGY CORP

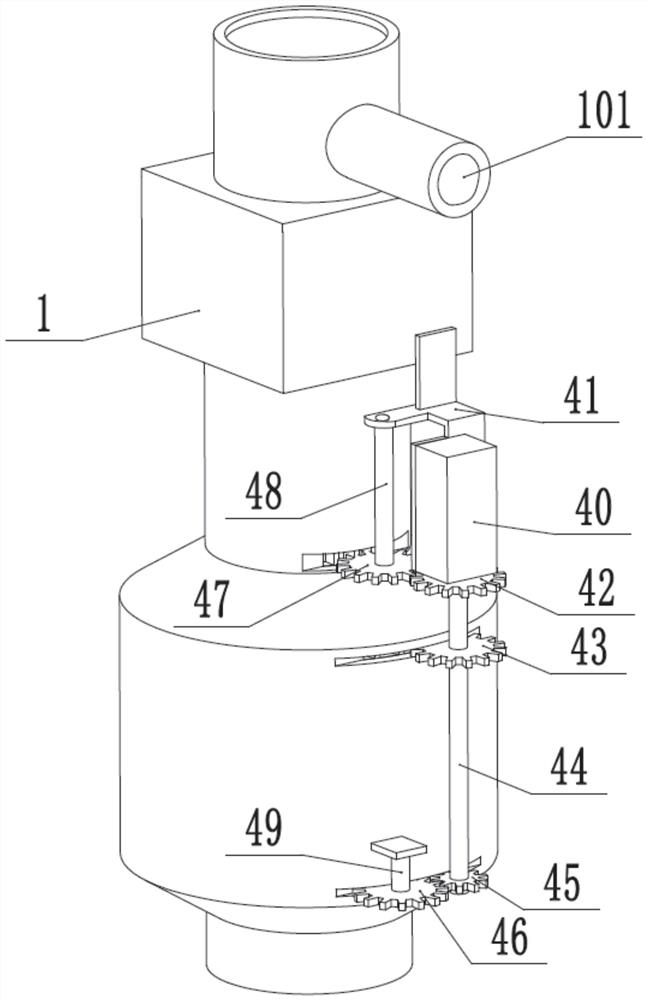

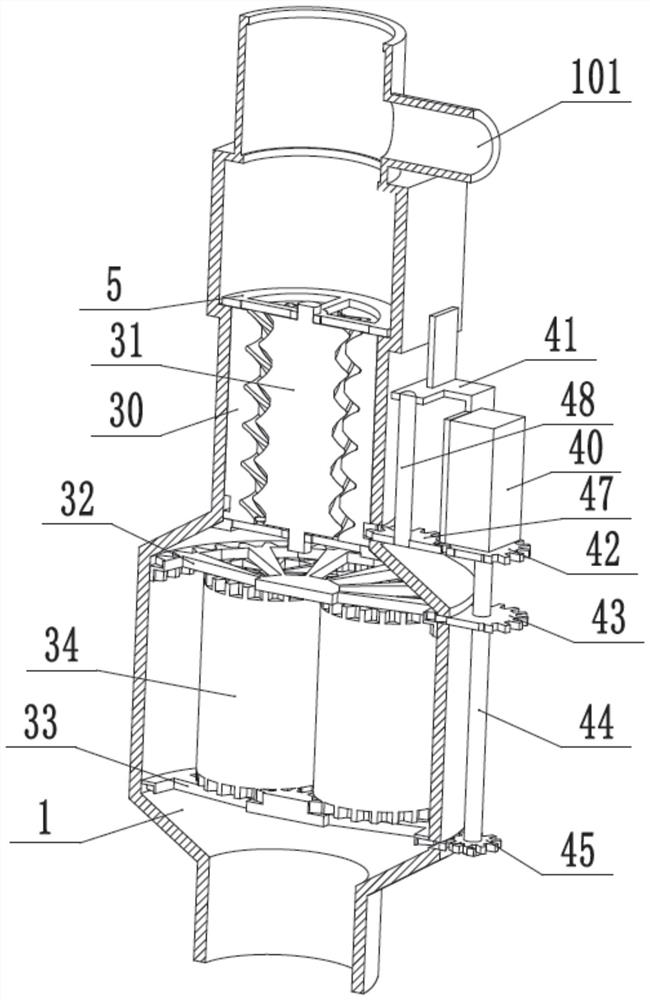

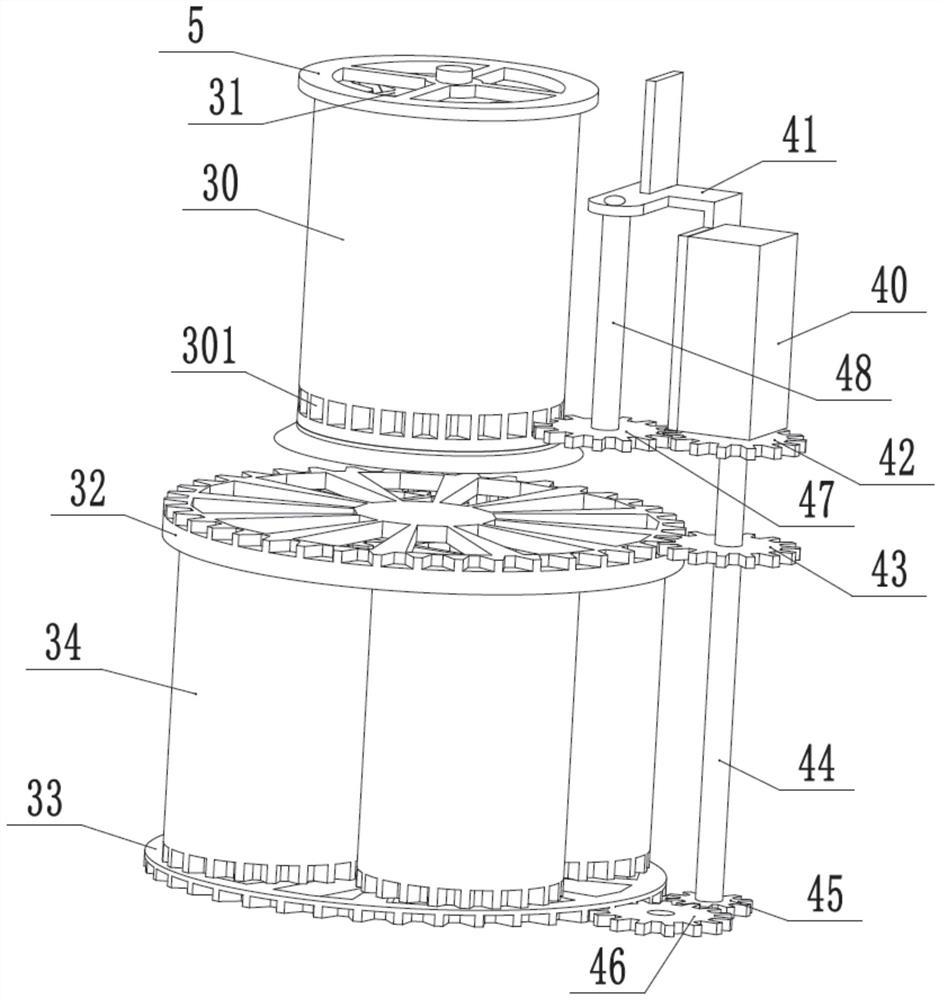

Automatic garbage crushing equipment

ActiveCN112144619AAvoid clogged sewers, etc.Unobstructed deliveryDomestic plumbingStructural engineeringMechanical engineering

The invention discloses automatic garbage crushing equipment. The automatic garbage crushing equipment comprises a shell, a grinding and crushing mechanism, a power driving mechanism and a transmission mechanism, the shell is of a hollow structure with openings in the two ends, and a water inlet is formed in the upper portion of the shell; the grinding and crushing mechanism comprises a grinding assembly, a first cutting assembly, a second cutting assembly and a third cutting assembly; and the grinding assembly, the first cutting assembly, the third cutting assembly and the second cutting assembly are sequentially and rotationally installed in the shell from top to bottom. According to the automatic garbage crushing equipment, automatic thorough crushing of garbage is achieved so as to prevent large pieces of garbage and the like from blocking a sewer and influencing garbage discharge.

Owner:湖南翰坤实业有限公司

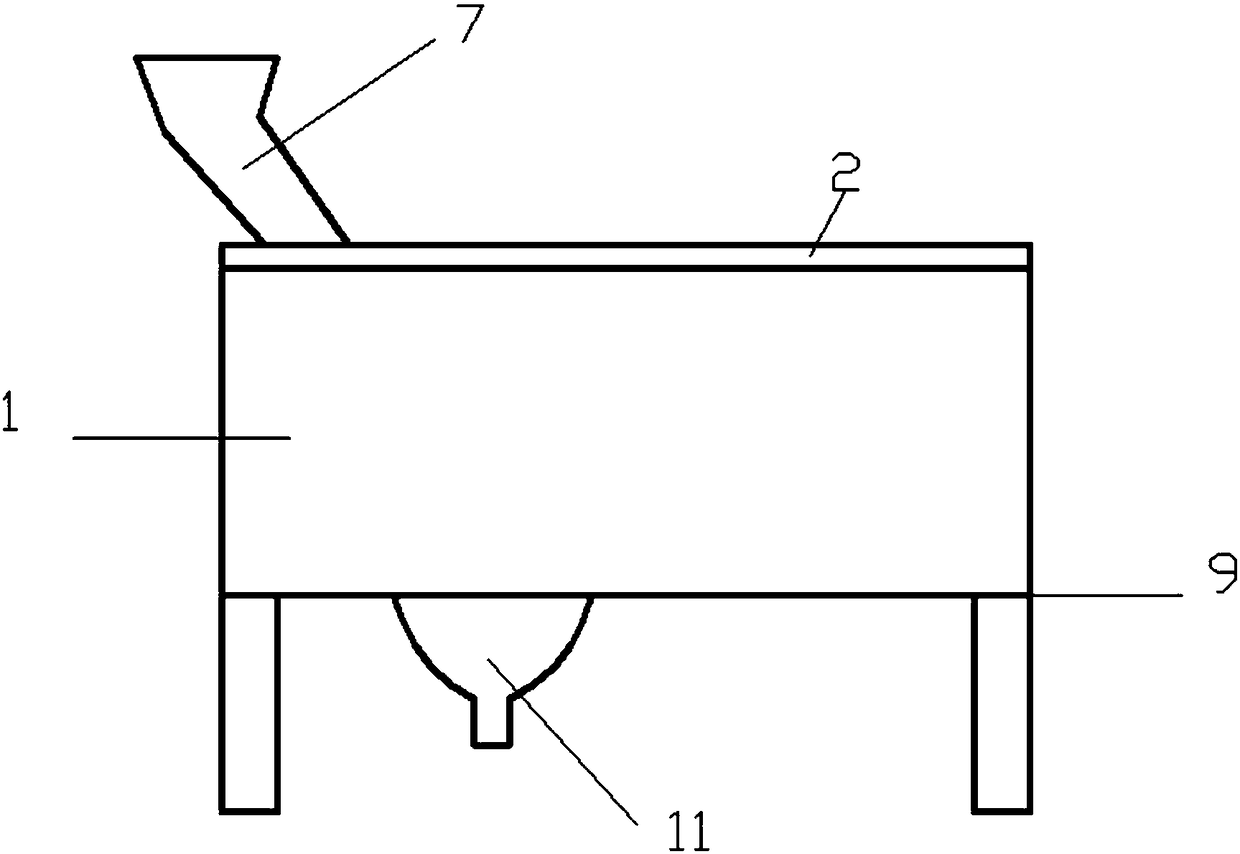

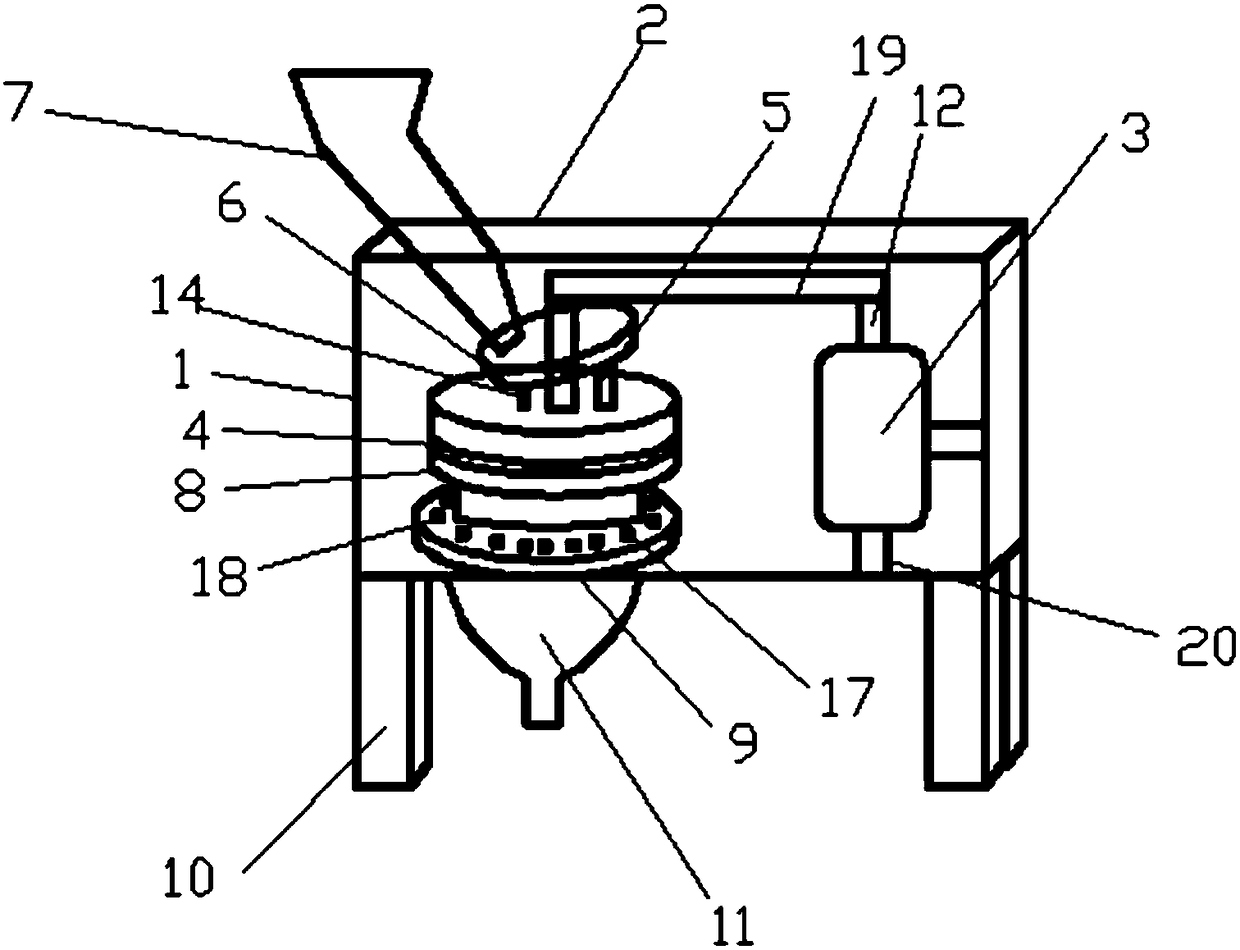

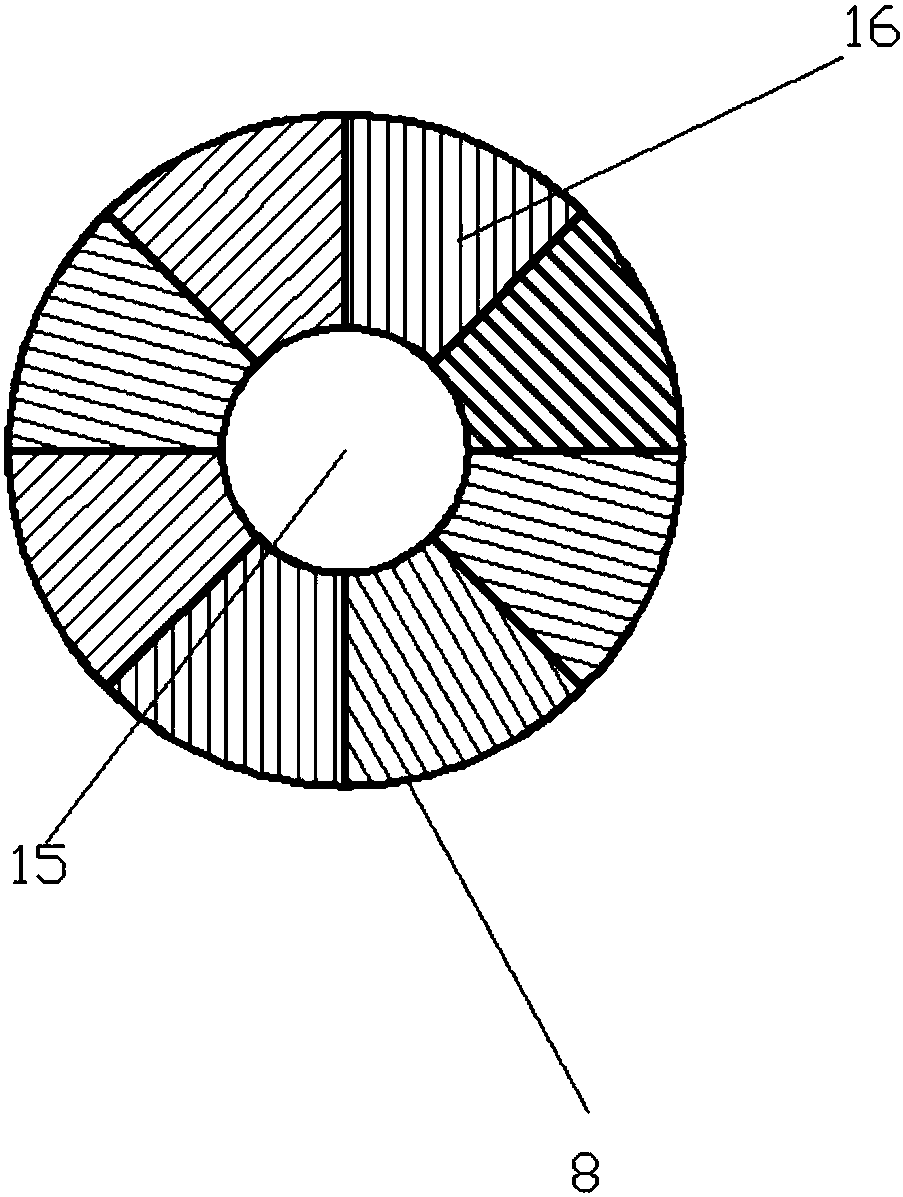

Laterally-vertical type grinder of calcium carbonate

InactiveCN108514921AUnobstructed inflowFavorable cutting and grindingCocoaGrain treatmentsMetallurgyCentrifugal force

The invention provides a laterally-vertical type grinder of calcium carbonate, relates to the technical field of grinding of calcium carbonate, and solves the problem of insufficient grinding. According to the traditional stone grinding principle, a grinding disc is divided into two parts, namely an upper grinding disc and a lower grinding disc, and the upper grinding disc and the lower grinding disc are meshed together to increase the grinding area, so that the grinding is more sufficient; raw materials enter an annular material containing tray through a feeding channel and then flow into a grinding chamber of the grinding disc through a charging channel so as to be uniformly scattered around; the upper grinding disc is driven to rotate by virtue of transmission of a motor belt, the raw materials are ground into powder, and the powder continuously enters eight-zone diagonal line type grinding patterns through instantaneous tooth gaps generated by mutual engagement and staggered arrangement of the grinding patterns of the upper grinding disc and the grinding patterns of the lower grinding disc so as to be ground again for many times, thereby forming finished products; the finishedproducts flow to the edge of the lower grinding disc through the gully of the eight-zone diagonal line type grinding patterns; and as the centrifugal force generated by rotation of the upper grindingdisc, the finished products fall on a chassis and then flow into a funnel-shaped discharging channel through screen holes in the chassis. The grinder provided by the invention is simple and safe in operation and ingenious in design, and the grinding work is more sufficiently and efficiently completed by adopting a mode of grinding the raw materials for many times.

Owner:苏州圣亚精密机械有限公司

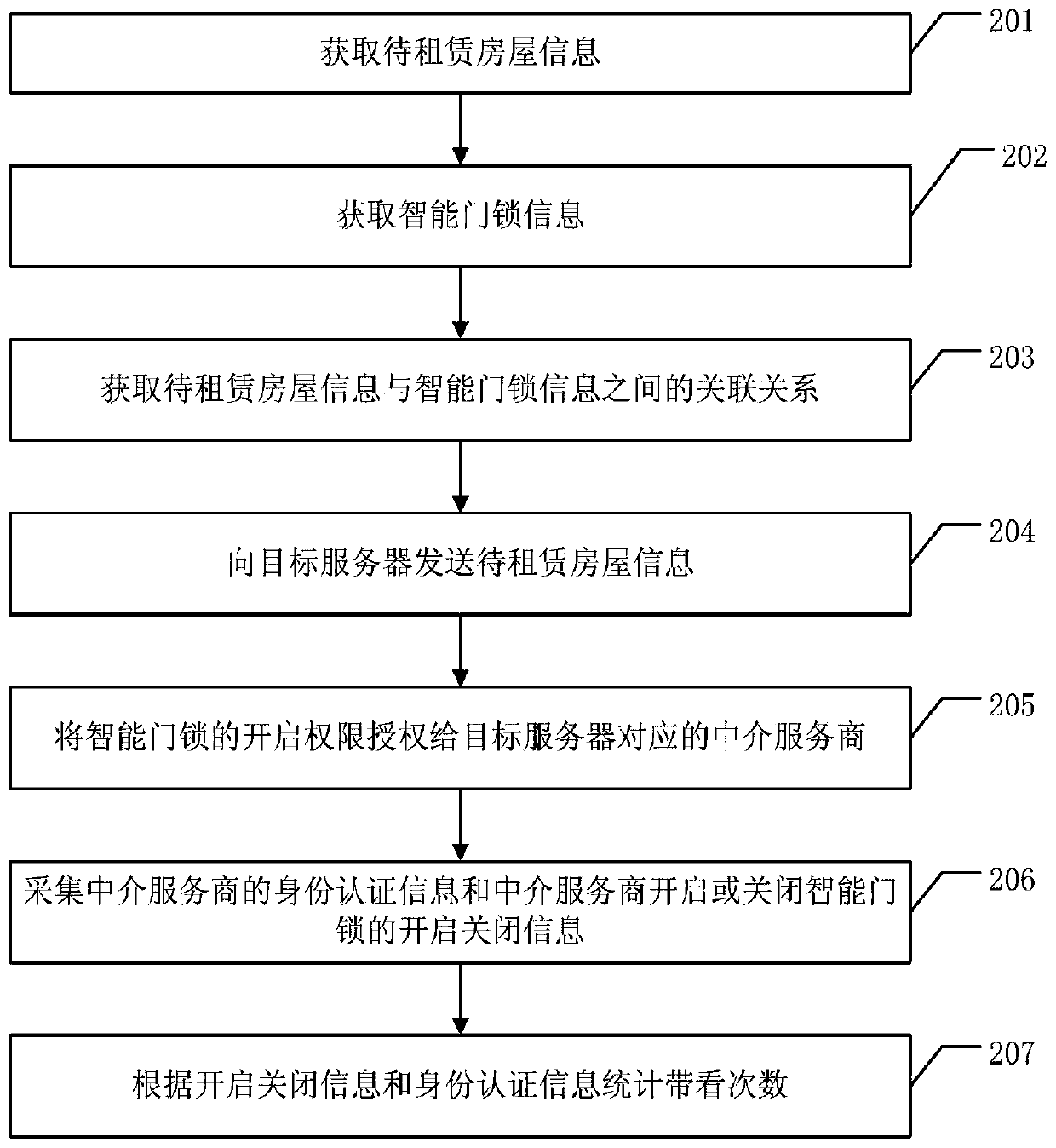

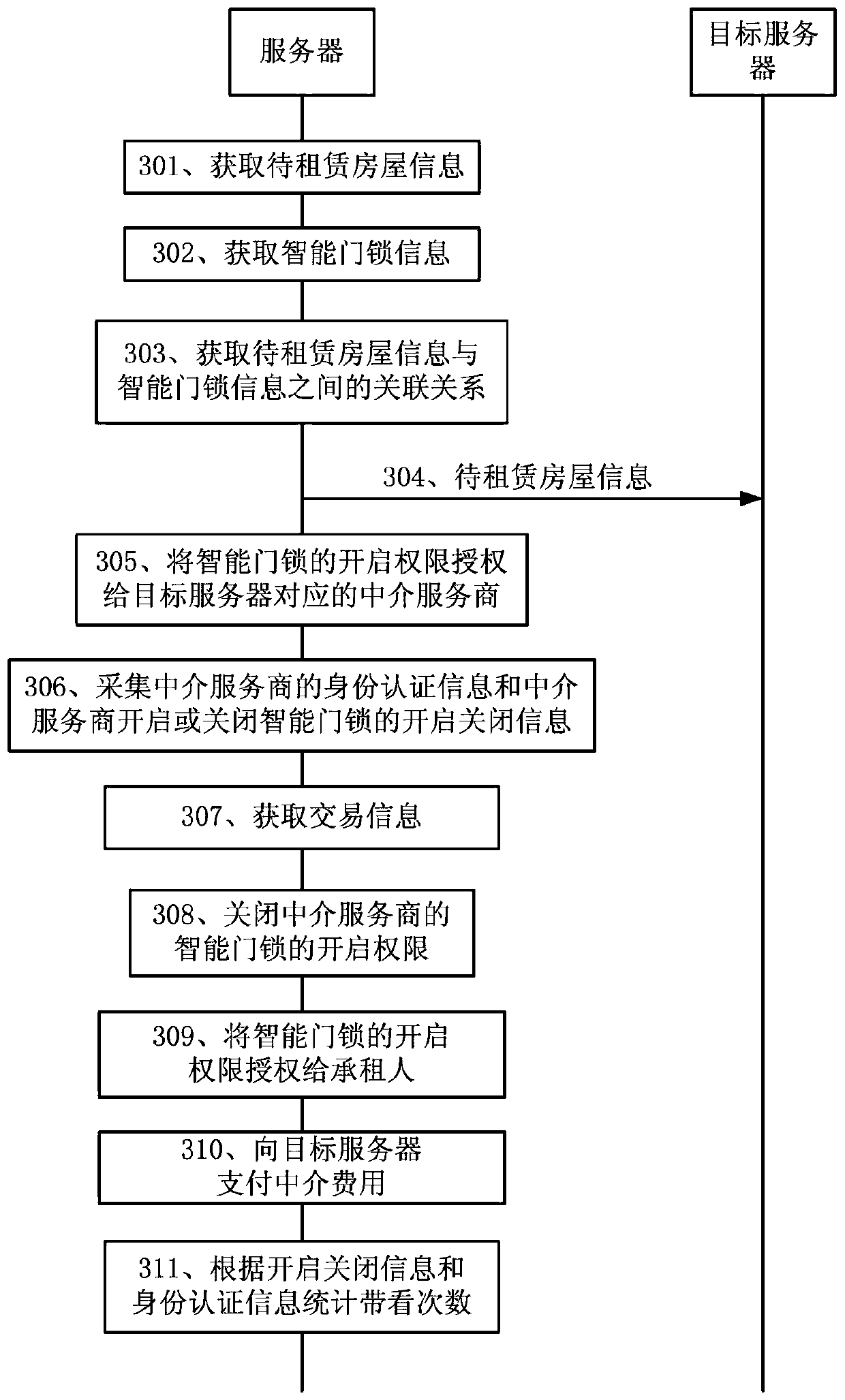

House lease management method and server

ActiveCN110634217AUnobstructed deliveryImprove leasing efficiencyIndividual entry/exit registersComputer scienceAuthentication information

The embodiment of the invention discloses a house lease management method so that the landlord can know the number of times of visiting a to-be-leased house by customers under guidance of an intermediary service provider. The method comprises the steps that: a server acquires to-be-leased house information, intelligent door lock information and an association relationship between the to-be-leasedhouse information and the intelligent door lock information; to-be-leased house information is sent to a target server; an intermediary service provider corresponding to the target server is authorized with the opening permission of the intelligent door lock; identity authentication information of the intermediary service provider and opening and closing information of opening or closing the intelligent door lock by the intermediary service provider are collected; and statistics of the visiting frequency is carried out based on the opening and closing information and the identity authentication information. Therefore, the landlord can check the number of times of visiting a to-be-leased house by customers under guidance of an intermediary service provider by the server and obtain the number of times of visiting a to-be-leased house by customers under guidance of an intermediary service provider; the information is transmitted between the landlord and the intermediary service provider smoothly; and the leasing efficiency of the to-be-leased house is improved.

Owner:深圳市新系区块链技术有限公司

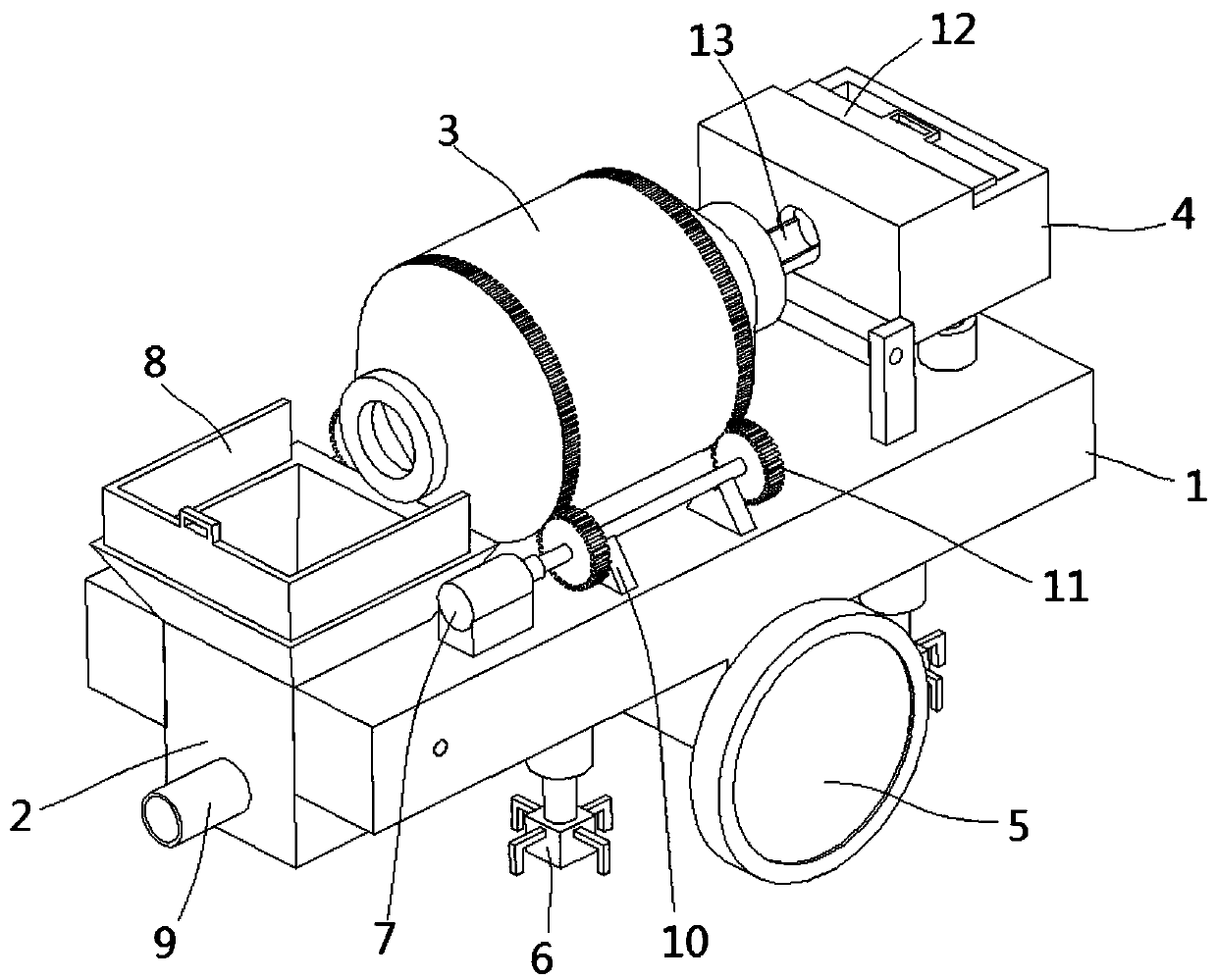

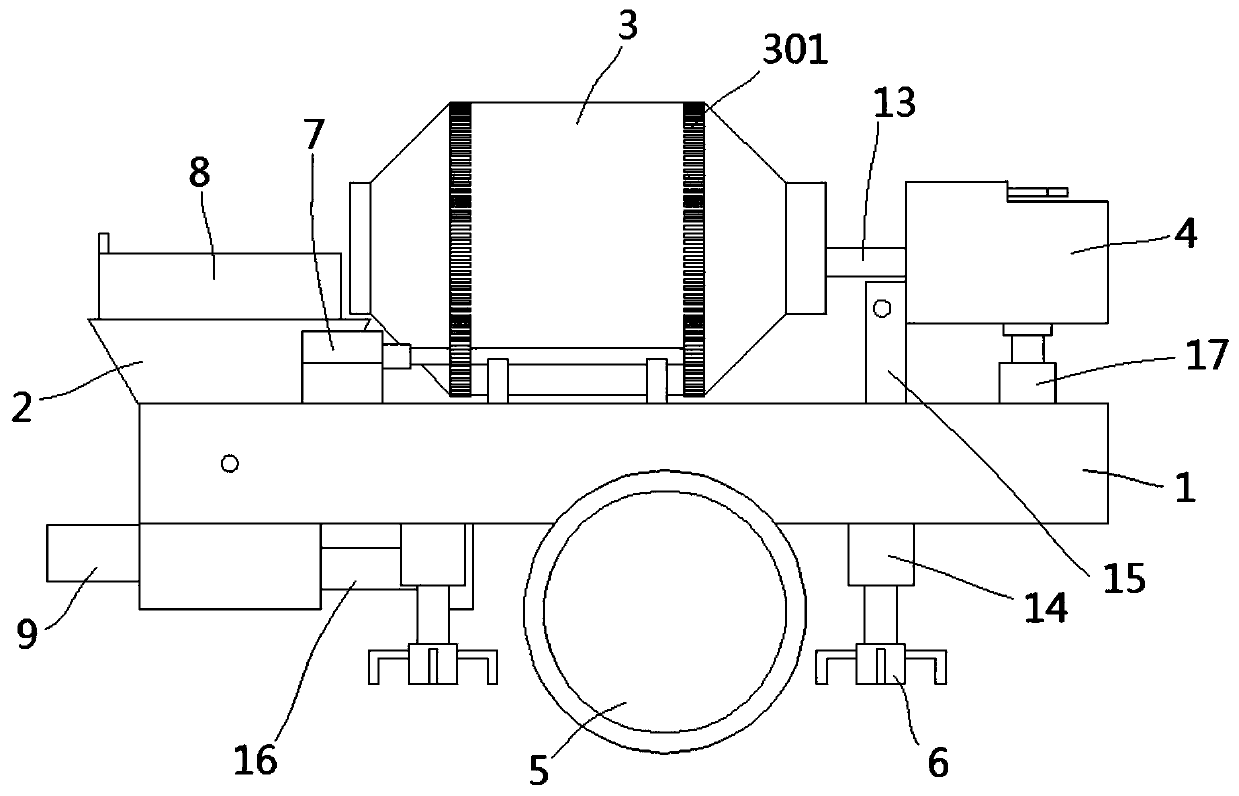

Concrete pumping device

InactiveCN109537900APromote circulationAvoid cloggingBuilding material handlingEngineeringMechanical engineering

The invention discloses a concrete pumping device and relates to the technical field of pumping equipment. The device comprises a base, a conveying hopper, a stirring roller and a feeding hopper, andmultiple wheels are rotatably connected to one surface of the base; a groove is formed in one surface of the base; the inner wall of the groove is fixedly connected with one surface of the conveying hopper; multiple first hydraulic rods are fixed to one surface of the base; a supporting block is fixed to the other end of each first hydraulic rod; multiple second hydraulic rods are fixed to one surface of the base; a T-shaped slide block is fixed to the other end of each second hydraulic rod; one surface of each T-shaped slide block is slidingly connected with one surface of the feeding hopper;a first motor is fixed to one surface of the base. According to the concrete pumping device, a stirring assembly is arranged in the conveying hopper, a filter cylinder is arranged on a conveying pipe, blocking is avoided, baffles are arranged on the conveying hopper and the feeding hopper, so that materials are prevented from being scattered, four supports are arranged on the supporting blocks, so that the stability of the pumping device is improved, and the concrete pumping device has the advantage of stable working.

Owner:FOSHAN UNIVERSITY

Technology for producing and extracting tryptophan

ActiveCN110592154AReduce generationSmooth circulationOrganic chemistryBacteriaBiotechnologyTryptophan

The invention belongs to the technical field of biology, and discloses a technology for producing and extracting tryptophan. The technology comprises a fermentation working procedure and an extractionworking procedure. The production technology is further improved, so that the yield of the tryptophan is increased, and besides, the fed-batch effects are guaranteed; a traditional tryptophan fermentation liquid extracting technology is improved through a membrane technique, thalli protein in the fermentation liquid is removed through a decolorization membrane, and the fermentation liquid is clarified; and macromolecule protein and pigment are subjected to classified removal through the decolorization membrane, and finally concentration is performed under the condition of normal temperature and zero phase changes through a concentration membrane.

Owner:XINJIANG FUFENG BIOTECH

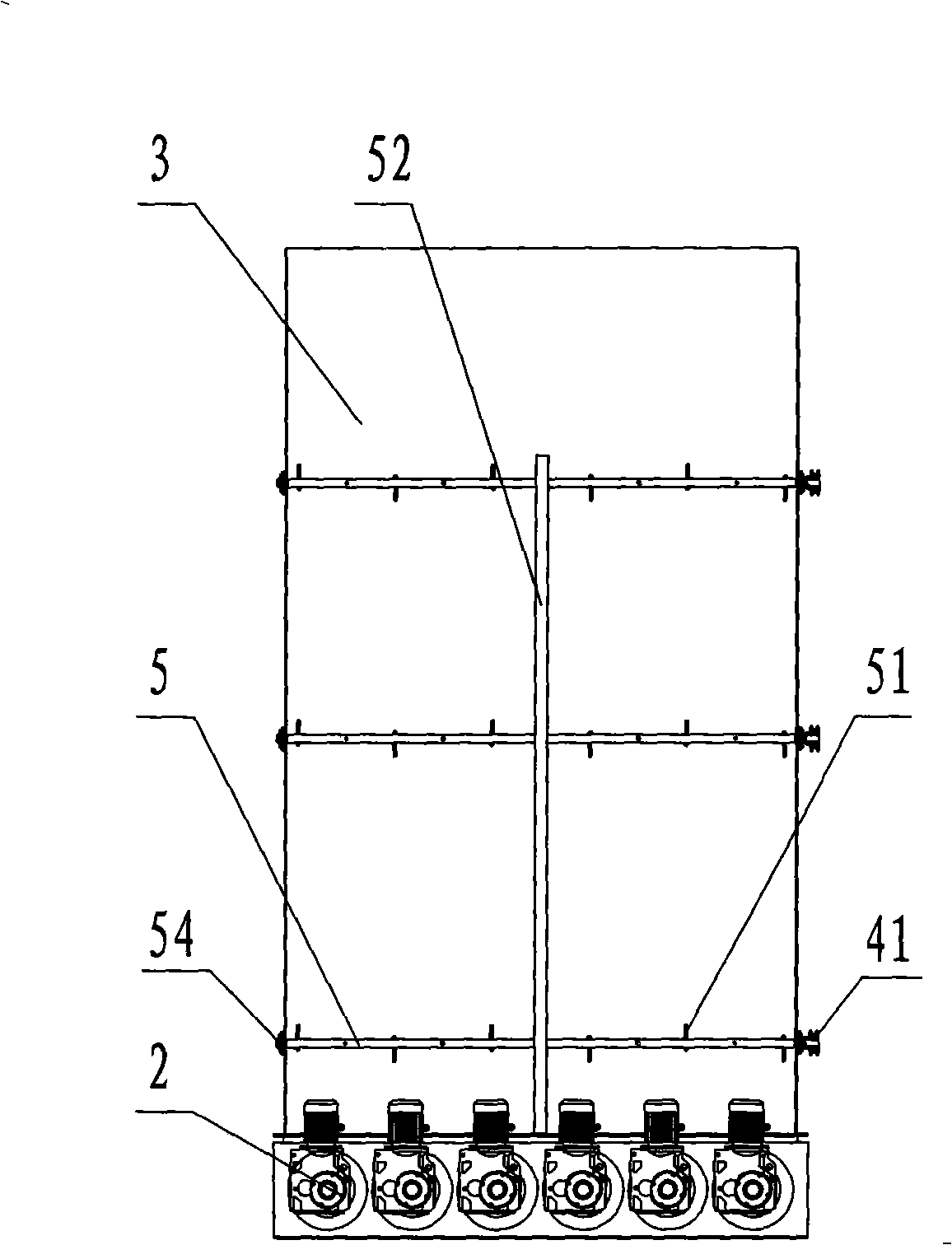

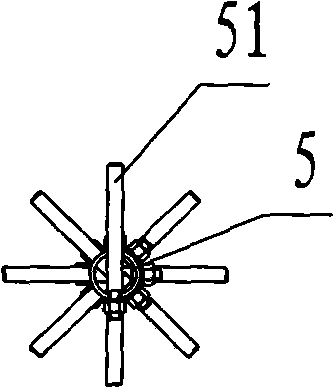

Screw material conveyor

InactiveCN104609213APrevent archingUnobstructed deliveryLarge containersLoading/unloadingEngineeringContinuous feeding

The invention discloses a screw material conveyor, the arching phenomenon of material occurs in the conveying process can be solved, and the influence to continuous feeding of equipment is avoided. The screw material conveyor comprises a conveyor body, a stock bin is arranged in the conveyor body, conveying mechanisms are arranged below the stock bin which is in the conveyor body, and the conveying mechanisms are provided with conveying screws; stirring shafts are arranged in the stock bin, the stirring shafts are all provided with multiple stirring rake rods, and the stirring rake rods are arranged on the stirring shafts in an eccentric mode; the axial directions of the stirring shafts are perpendicular to the axial directions of the conveying screws, each conveying mechanism comprises a shell, an arc groove is formed in the shell, the conveying screws are all shaftless screws, and the conveying screws are located in the corresponding grooves; anti-arching portions used for preventing the conveying screws from arching are arranged above the two sides of each groove of the corresponding shell, and the conveying screws are limited in intervals enclosed by the anti-arching portions and the grooves.

Owner:ZHEJIANG ZOKSEN ENVIRO ENERGY EQUIP

Aeolian sand filling material for mine filling and preparation method thereof

The invention provides an aeolian sand filling material for mine filling and a preparation method of the aeolian sand filling material. The aeolian sand filling material comprises the following components: 25-60 parts of aeolian sand, 3-20 parts of gangue, 3-25 parts of cement, 10-25 parts of fly ash and 20-30 parts of water. Wherein the gangue is crushed gangue particles, and the particle size of the gangue particles is not larger than 10 mm. And the mass fraction of the slurry of the aeolian sand filling material is 70-80%. The aeolian sand filling material provided by the invention is prepared from the aeolian sand, the gangue, the fly ash, the cement and the water as raw materials, and the performance of the aeolian sand filling material can achieve the effect of a pure cement cementing material; and compared with the existing single aggregate aeolian sand filling, the mine filling material has the advantages of stable slurry structure, small bleeding of the filling material, no need of dehydration underground, good suspension property and high filling material strength. And in the long-distance pipeline conveying process, the slurry flow state stability is high, and pipeline conveying is smooth.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

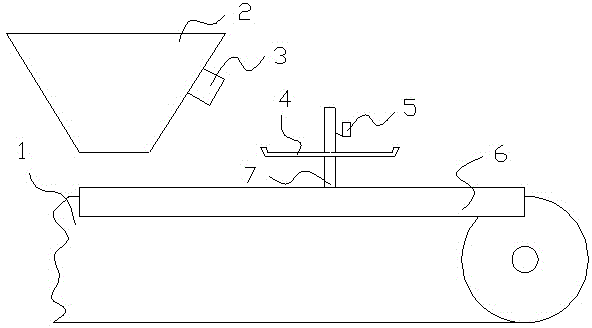

Efficient feeding device

The invention discloses an efficient feeding device. The device comprises a belt conveyer (1) and a hopper (2), wherein the belt conveyer comprises a conveying belt and a rolling shaft, the hopper (2) is provided with a vibrator (3), and the efficient feeding device also comprises a material measuring plate (4), a travel switch (5), baffle plates (6) and a range pole (7), the baffle plates (6) are fixedly connected at the two sides of the belt conveyer (1), the travel switch (5) is fixedly connected to the range pole (7), the material measuring plate (4) is sleeved on the range pole (7) and can move along the range pole (7), and the range pole (7) is connected with the belt conveyer (1). When a material is conveyed through the belt conveyer, the material measuring plate is jacked up by the material to contact the travel switch, so that the vibrator is closed, and when the material is blocked and the belt conveyer conveys no material, the travel switch falls, the vibrator (3) vibrates the hopper to ensure smooth and stable material conveying, such that an energy source is saved, and meanwhile, the operating efficiency is improved.

Owner:铜陵翔宇商贸有限公司

Steel wire non-contact type gas wiping and galvanizing device

ActiveCN110172659AWipe to achieveGuarantee product qualityHot-dipping/immersion processesFixed frameEngineering

The invention belongs to the technical field of steel wire zinc plating, and provides a steel wire non-contact type gas wiping and galvanizing device. The device comprises a fixing frame, a strip-shaped through hole is transversely formed in the gas collecting box, a first fixing bolt is arranged in the strip-shaped through hole in a sliding mode, the first fixing bolt penetrates through the strip-shaped through hole and is locked on the fixing frame, one end of the connecting pipe is communicated with the gas collecting tank, and the gas knife is communicated with the other end of the connecting pipe. According to the technical scheme, the problems that in the prior art, the positions of the steel wire and the air knife are easy to deviate and are not easy to adjust are solved.

Owner:河间市宝泽龙金属材料有限公司

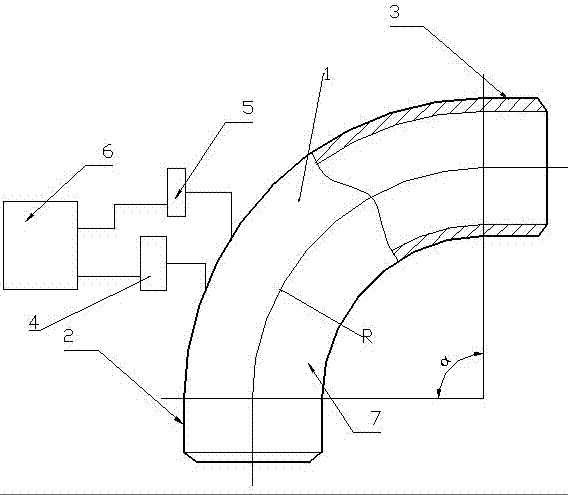

Butt welding seamless alloy steel high-temperature high-pressure elbow with straight pipe sections

PendingCN106989243AFacilitated releaseEasy to weldPipe protection against damage/wearNon-disconnectible pipe-jointsButt weldingStraight tube

The invention discloses a butt welding seamless alloy steel high-temperature high-pressure elbow with straight pipe sections, and relates to the field of transportation pipelines. The elbow comprises a pipeline, a flow speed sensor, a pressure sensor and a display device. The pipeline comprises the first straight pipe section, a bent section and the second straight pipe section. The first straight pipe section and the second straight pipe section are located at the two ends of the bent section correspondingly and fixedly connected with the bent section. The flow speed sensor is located at the end, close to the first straight pipe section, of the bent section, one end of the flow speed sensor is connected with the bent section through a circuit, the other end of the flow speed sensor is connected with the display device through a circuit, the pressure sensor is located at the end, close to the second straight pipe section, of the bent section, one end of the pressure sensor is connected with the bent section through a circuit, and the other end of the pressure sensor is connected with the display device through a circuit. Convenience can be brought to a pipeline construction site and pipeline welding, the flow speed and pressure in the pipeline can be measured and controlled in real time, and pipe maintenance work is facilitated.

Owner:江苏兴洋管业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com