Method for producing tryptophan through fermentation of fed-batch culture liquid

A technology of fed-feed culture and tryptophan, applied in the field of microbial fermentation, can solve the problems of unsuitability for large-scale popularization, increased metabolic flow, and high cost, and achieves the effects of smooth energy circulation and transmission, stable growth cycle, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for fermented production of tryptophan with fed culture broth, which comprises the following steps:

[0038] Step 1): The L-tryptophan engineered bacteria Escherichia coli ( E. coli ) TRTH, cultured to a certain concentration of bacterial liquid;

[0039] Step 2): Inoculate the bacterial liquid obtained in step 1) with 0.5% inoculum in a shake flask containing a first-level seed culture medium, and cultivate it at 36°C at 100-200 rpm for 10-20 hours;

[0040] Step 3): Inoculate the first-level shake flask seeds obtained in step 2) in the seed tank of the second-level seed culture medium at a 5% inoculum amount, control the air volume 5-10L / min, rotate speed 200-400rpm, and temperature 35-37 ℃, tank pressure 0.05-0.08MPa, pH value controlled at 6.5-6.8 by ammonia water, culture for 10-20h;

[0041] Step 4): The secondary fermentor seed (OD 600 Value is 11) Inoculate in a fermenter equipped with fermentation medium with 7% inoculum, rotate speed 400rpm, temperature 36℃...

Embodiment 2

[0051] A method for fermented production of tryptophan with fed culture broth, which comprises the following steps:

[0052] Step 1): The L-tryptophan engineered bacteria Escherichia coli ( E. coli ) TRTH, cultured to a certain concentration of bacterial liquid;

[0053] Step 2): Inoculate the bacterial liquid obtained in step 1) with 0.1%-1% of the inoculum amount in a shake flask containing a first-level seed culture medium, and cultivate it at 36°C at 100-200rpm for 10-20h;

[0054] Step 3): Inoculate the first-level shake flask seeds obtained in step 2) in the seed tank of the second-level seed culture medium at an inoculum of 1%-10%, control the air volume at 5-10L / min, rotate at 200-400rpm and temperature 35-37℃, tank pressure 0.05-0.08MPa, pH value controlled at 6.5-6.8 by ammonia water, culture for 10-20h;

[0055] Step 4): The secondary fermentor seed (OD 600 Value is 12) Inoculate in a fermenter equipped with fermentation medium with 6% inoculum, rotate at 300rpm, temperat...

Embodiment 3

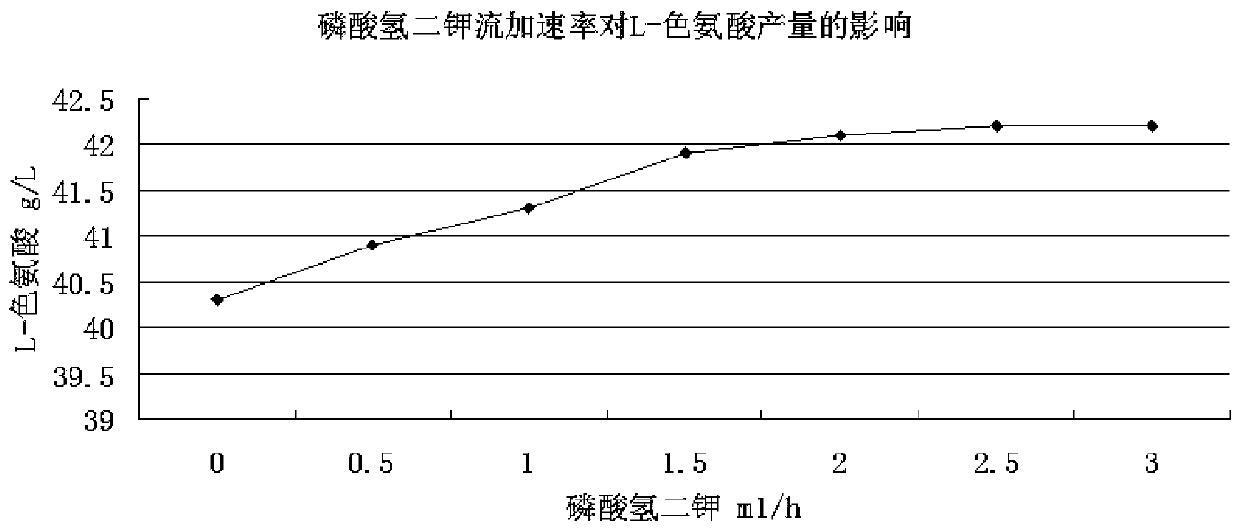

[0065] 1. The effect of the amount of dipotassium hydrogen phosphate added on the production of L-tryptophan.

[0066] The fermentation process is the same as in Example 1, without the step of culture solution. First, verify the effect of adding potassium hydrogen phosphate solution on fermentation through experiments, such as figure 1 As mentioned, with the increase of the amount of dipotassium hydrogen phosphate, the content of L-tryptophan in the fermentation broth will increase accordingly. When the flow rate is 2ml / h, it basically reaches the peak value. Continue to increase the flow rate, which has no effect on the tryptophan output Significantly higher, the influence trend of dipotassium hydrogen phosphate on bacterial biomass is similar to that of tryptophan (not shown in the figure). The main reason is that the inflow of dipotassium hydrogen phosphate solution can increase the bacterial biomass, thereby increasing the tryptophan The yield.

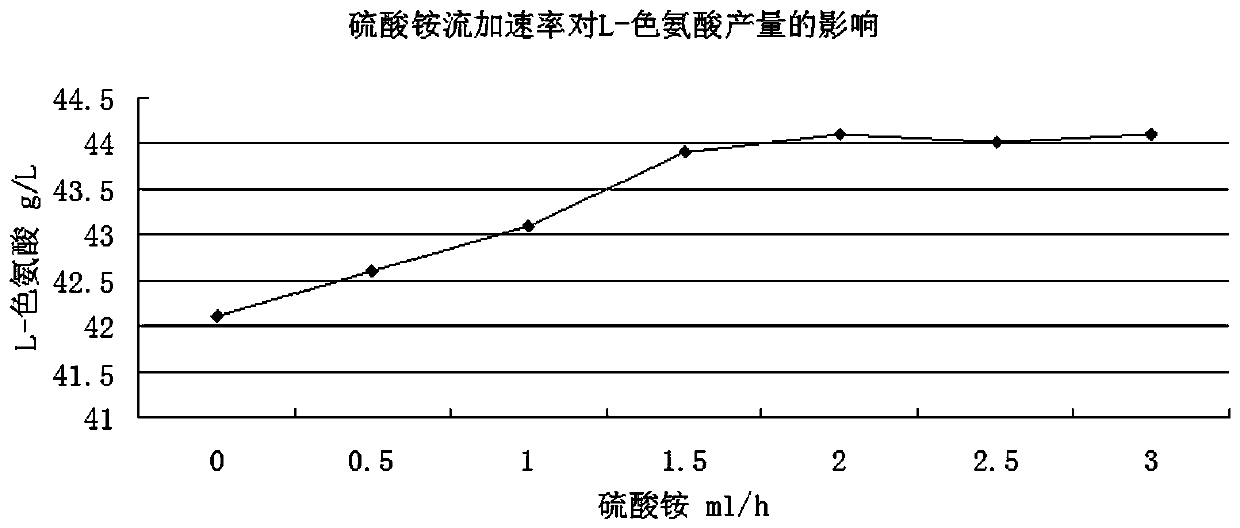

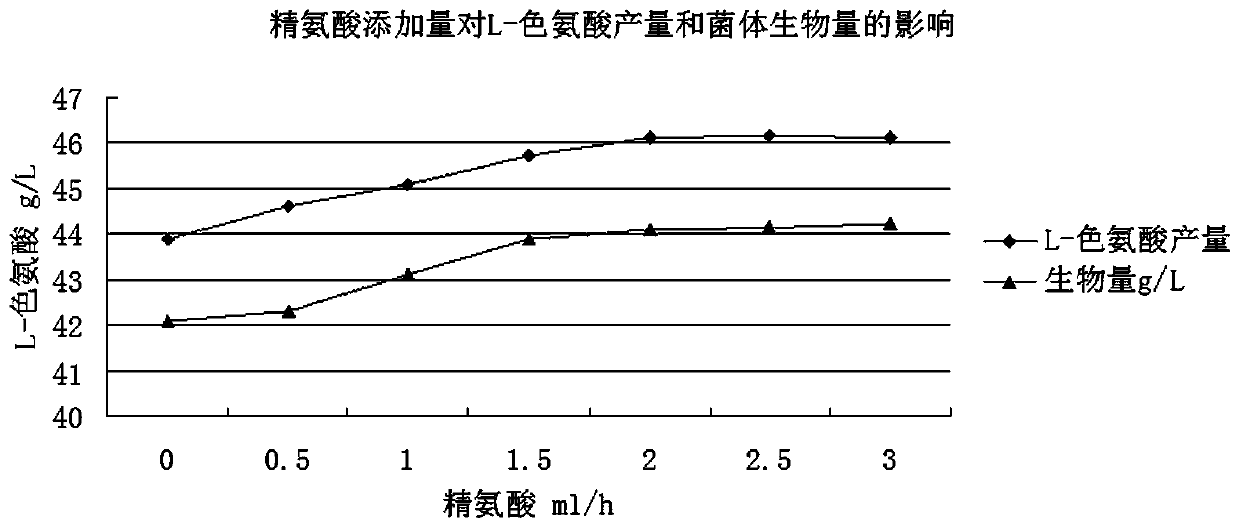

[0067] 2. The effect of ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com