Patents

Literature

340results about How to "Effective force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

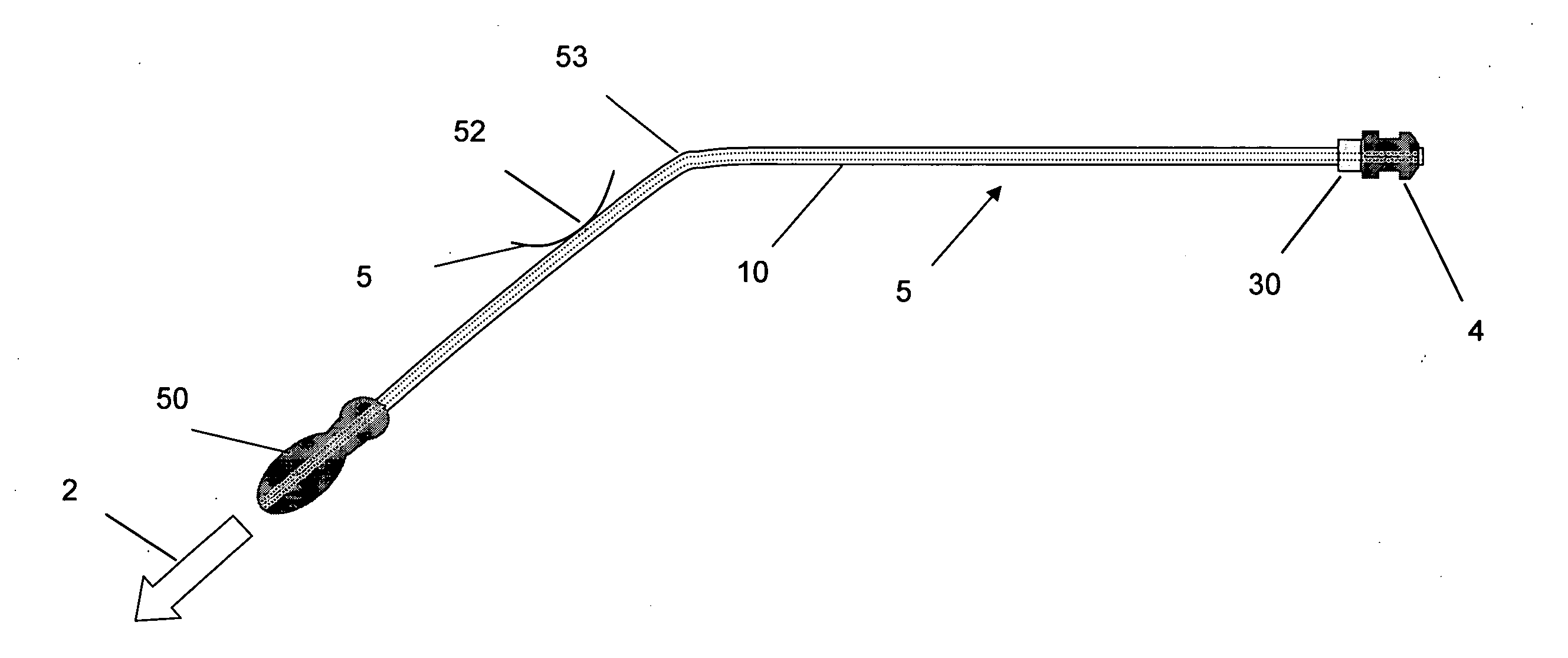

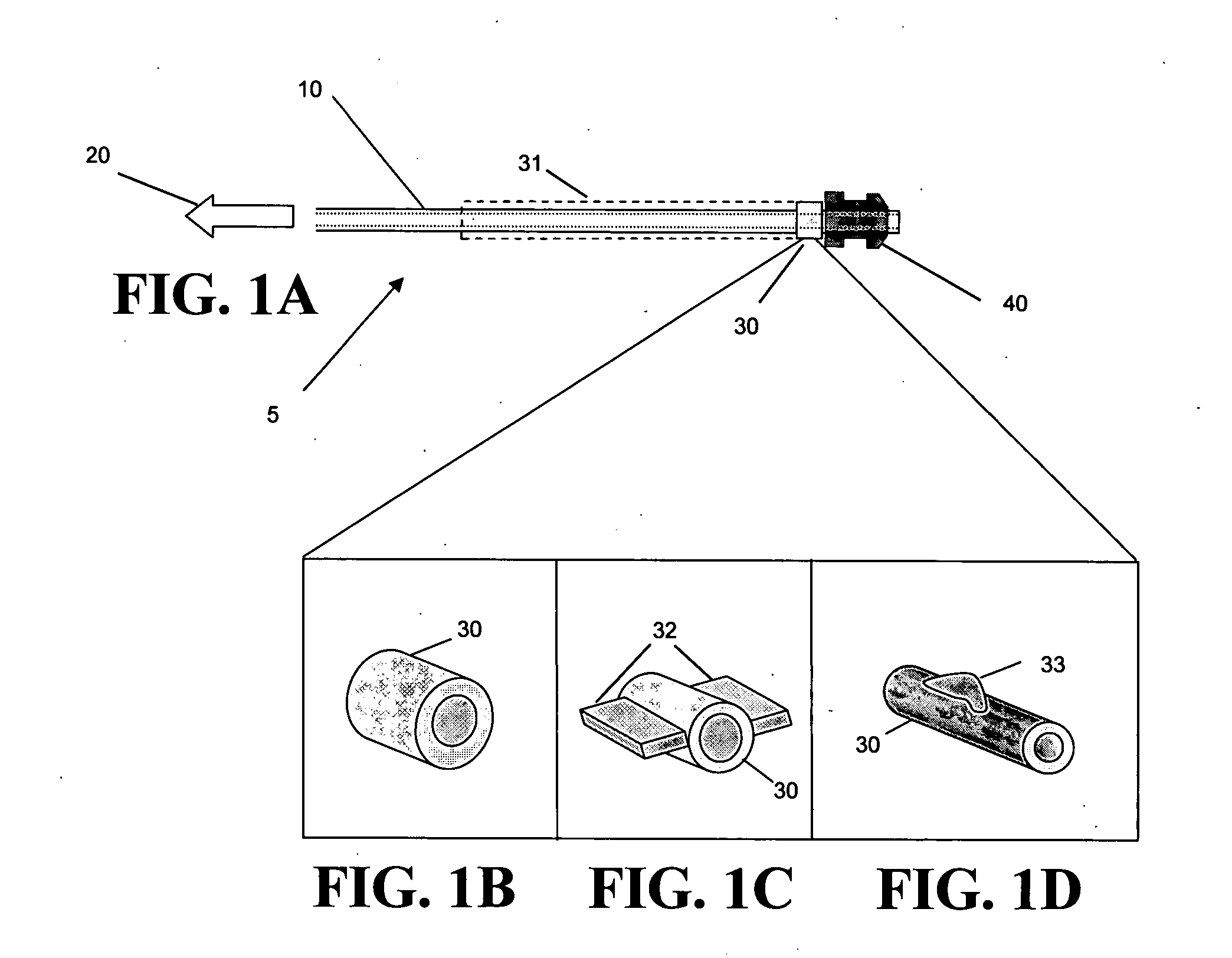

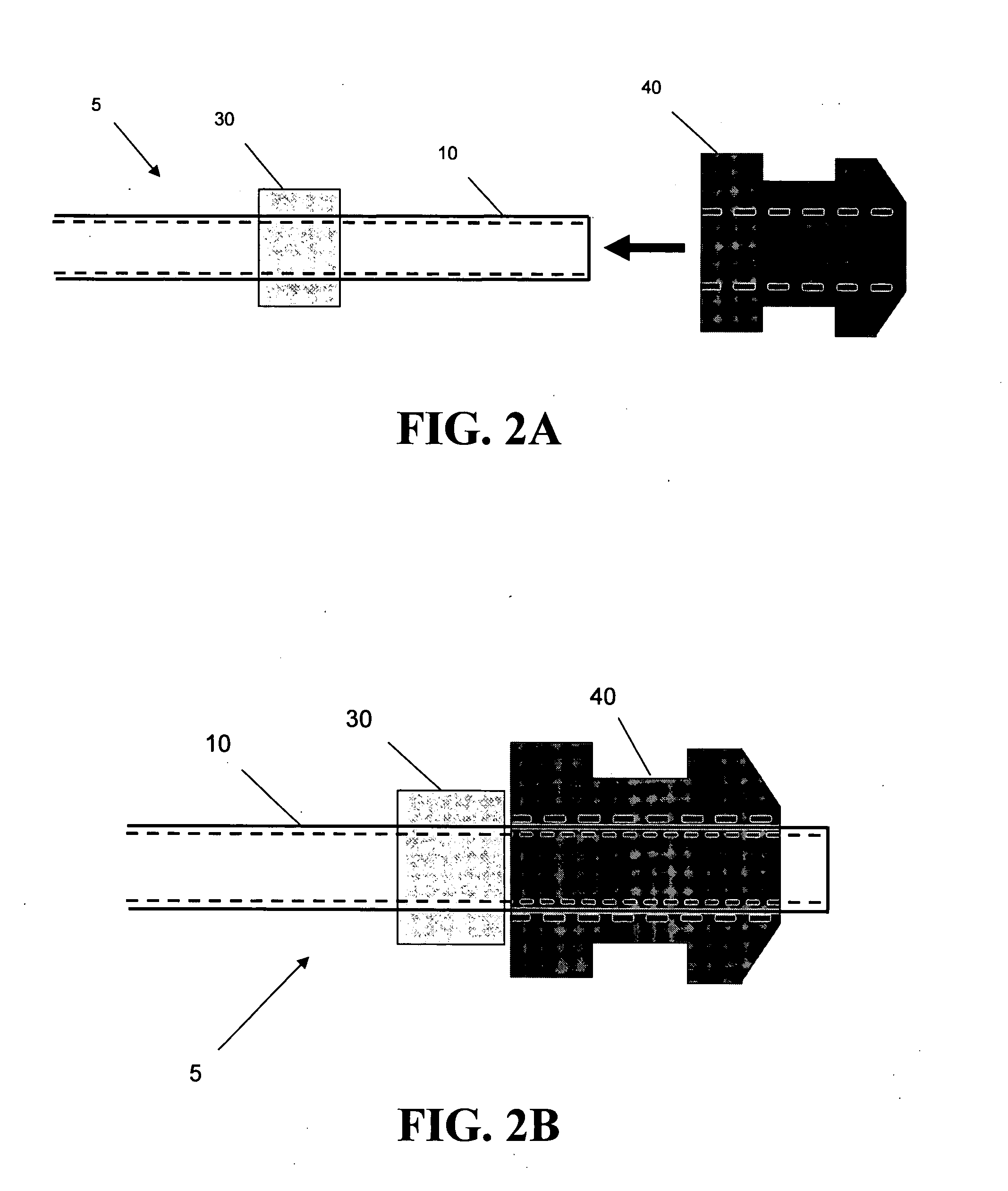

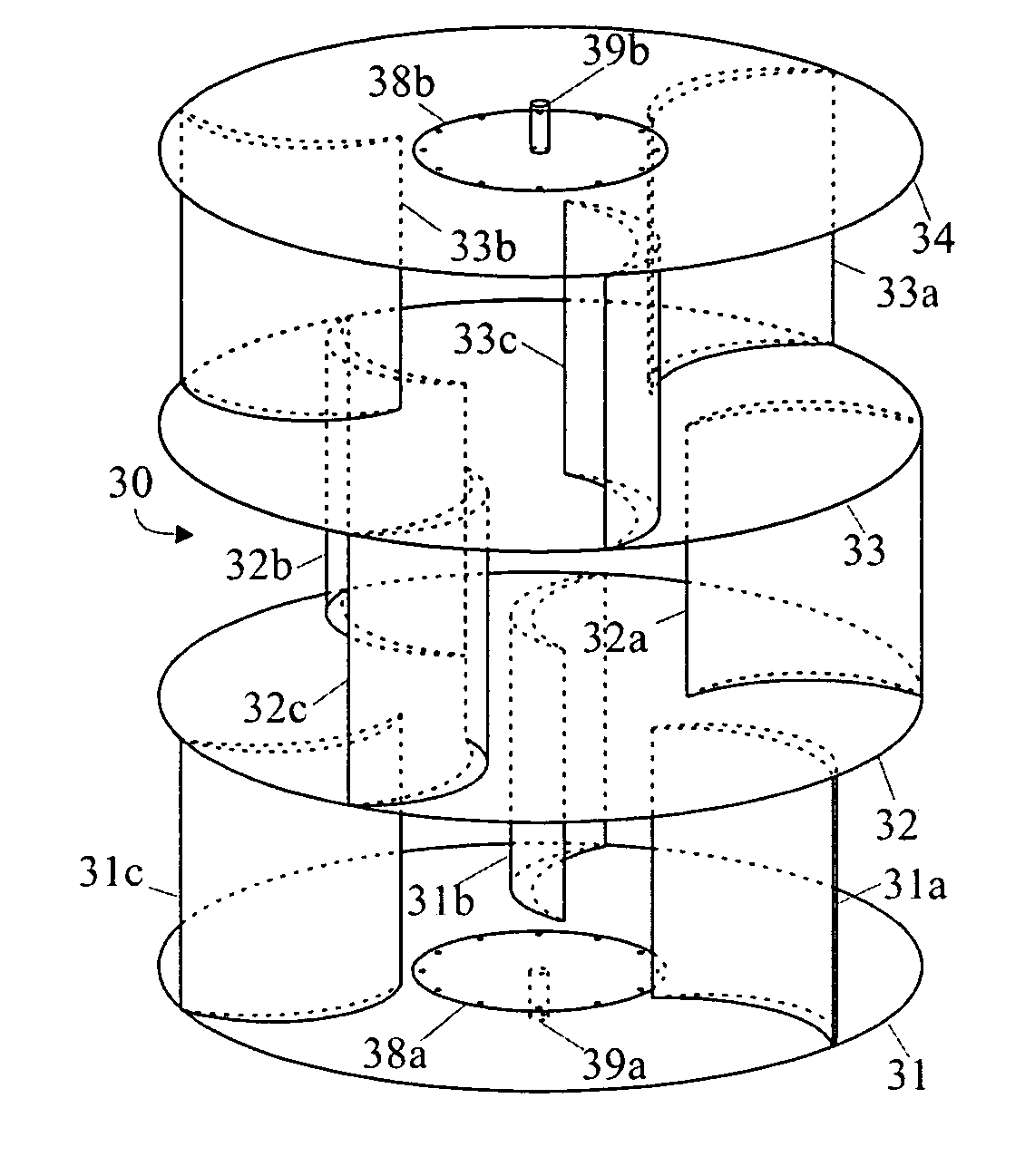

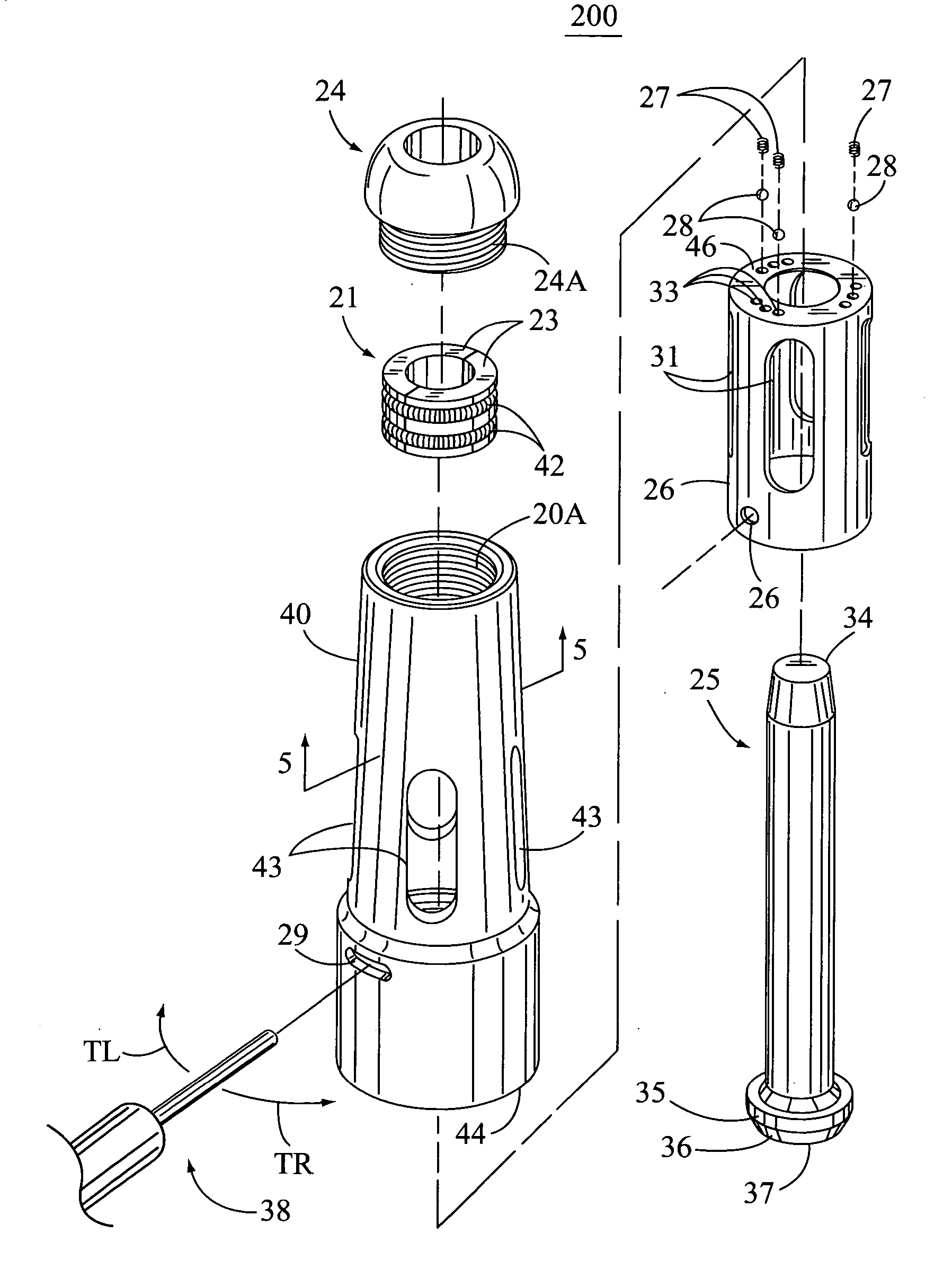

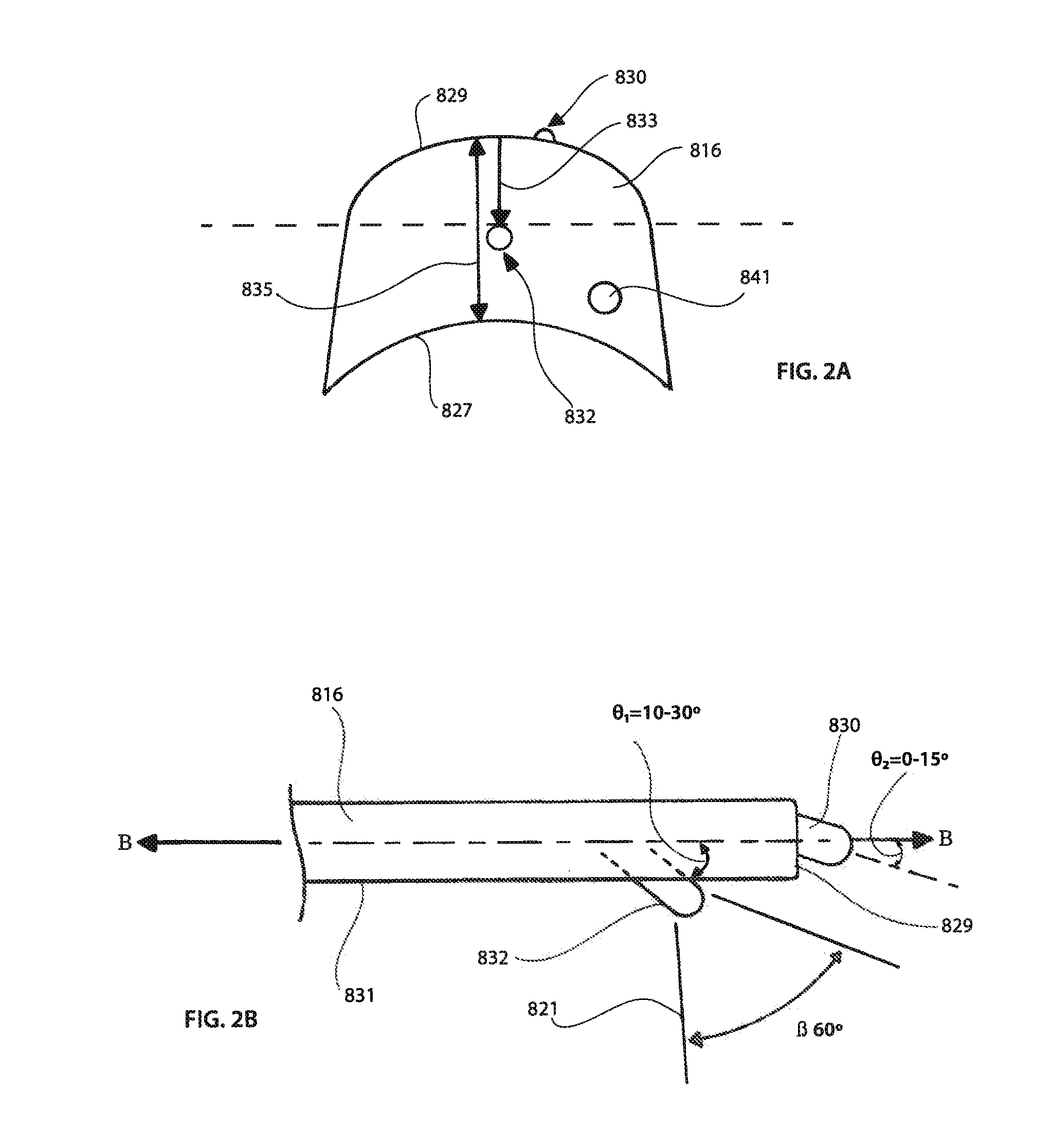

Tube, stent and collar insertion device

InactiveUS20080051804A1Exceptionally streamlinedImprove visualizationEar treatmentEar canalInsertion device

A surgical device and method designed to make insertion of pressure equalization tubes for effusion of the inner ear faster, more reliable, and safer by combining the placement of the pressure equalization tube with suction of the inner ear, decreasing the number of instruments and instrument passes into and out of the ear canal. A surgical insertion tool permits the direct coaxial insertion of the stent through the surgically created ostium, and which may be under direct, clear endoscopic control.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

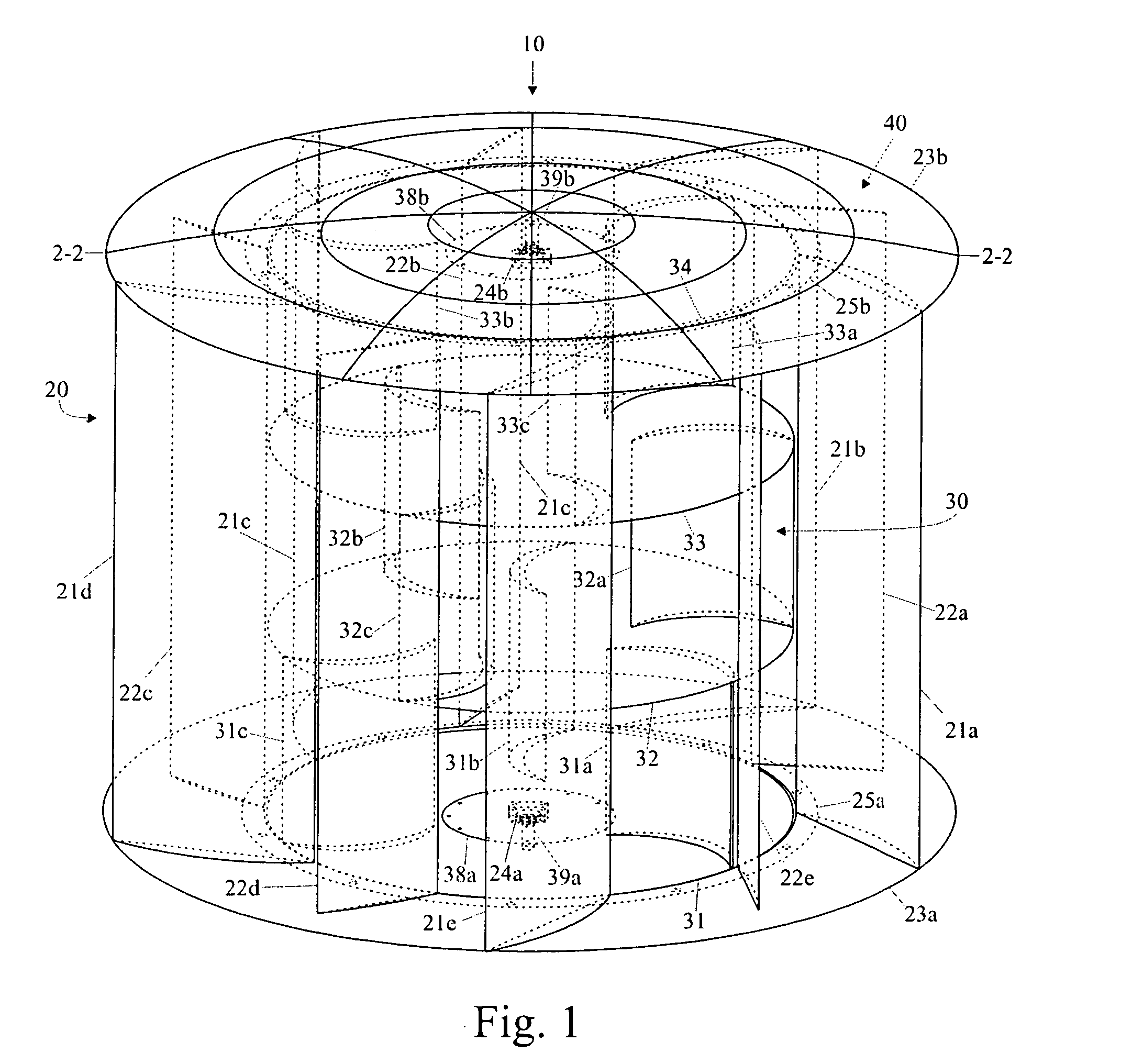

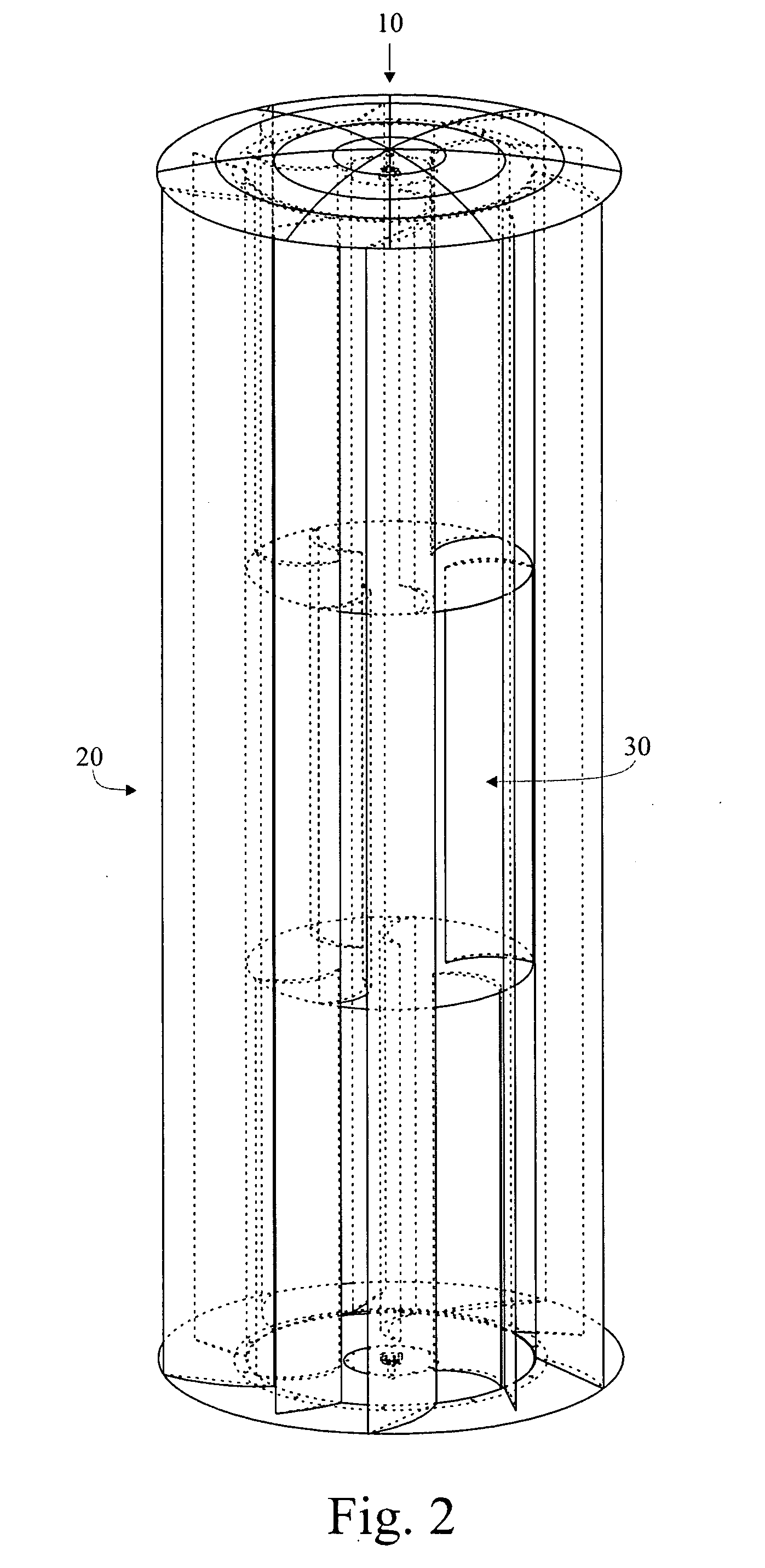

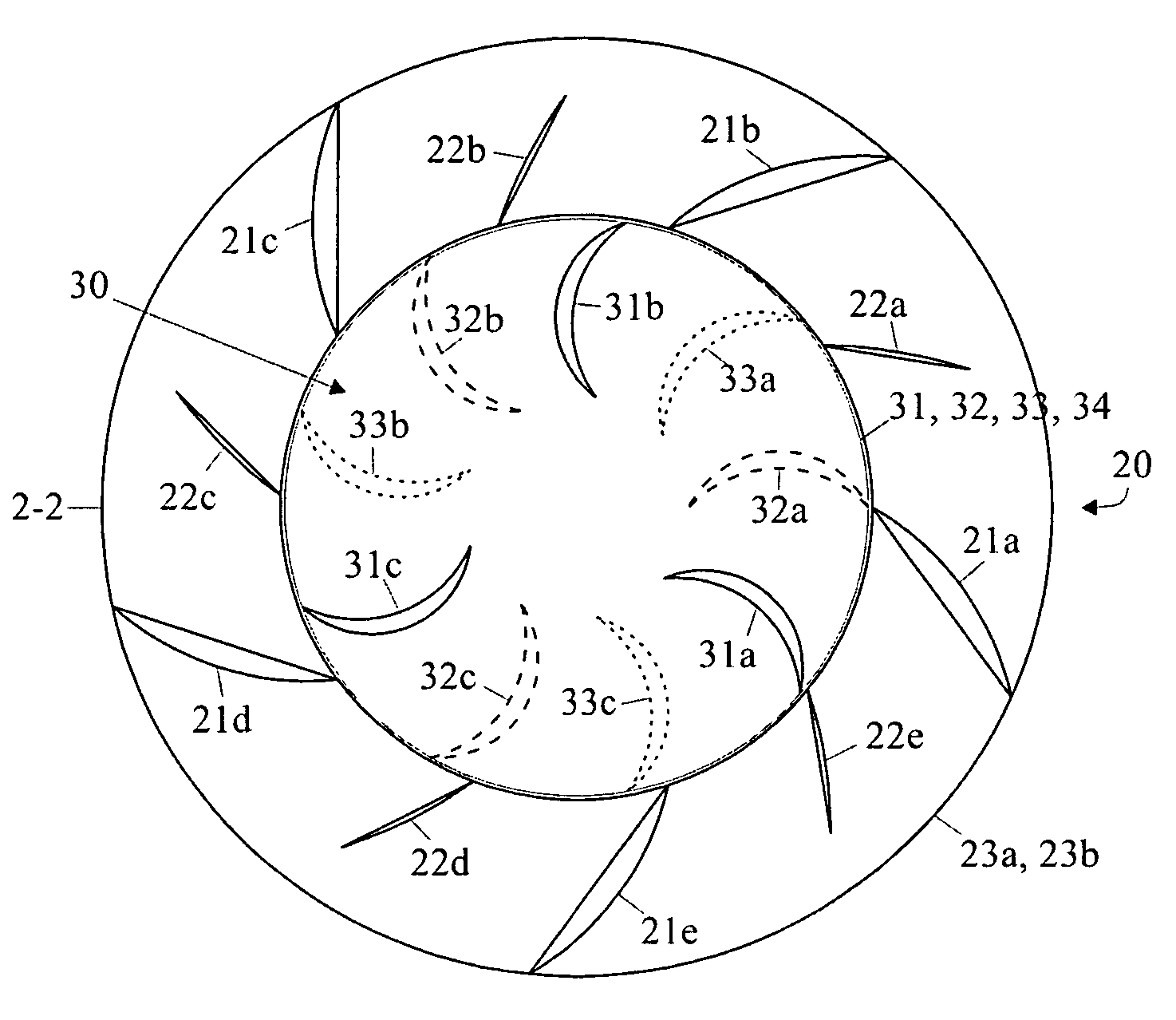

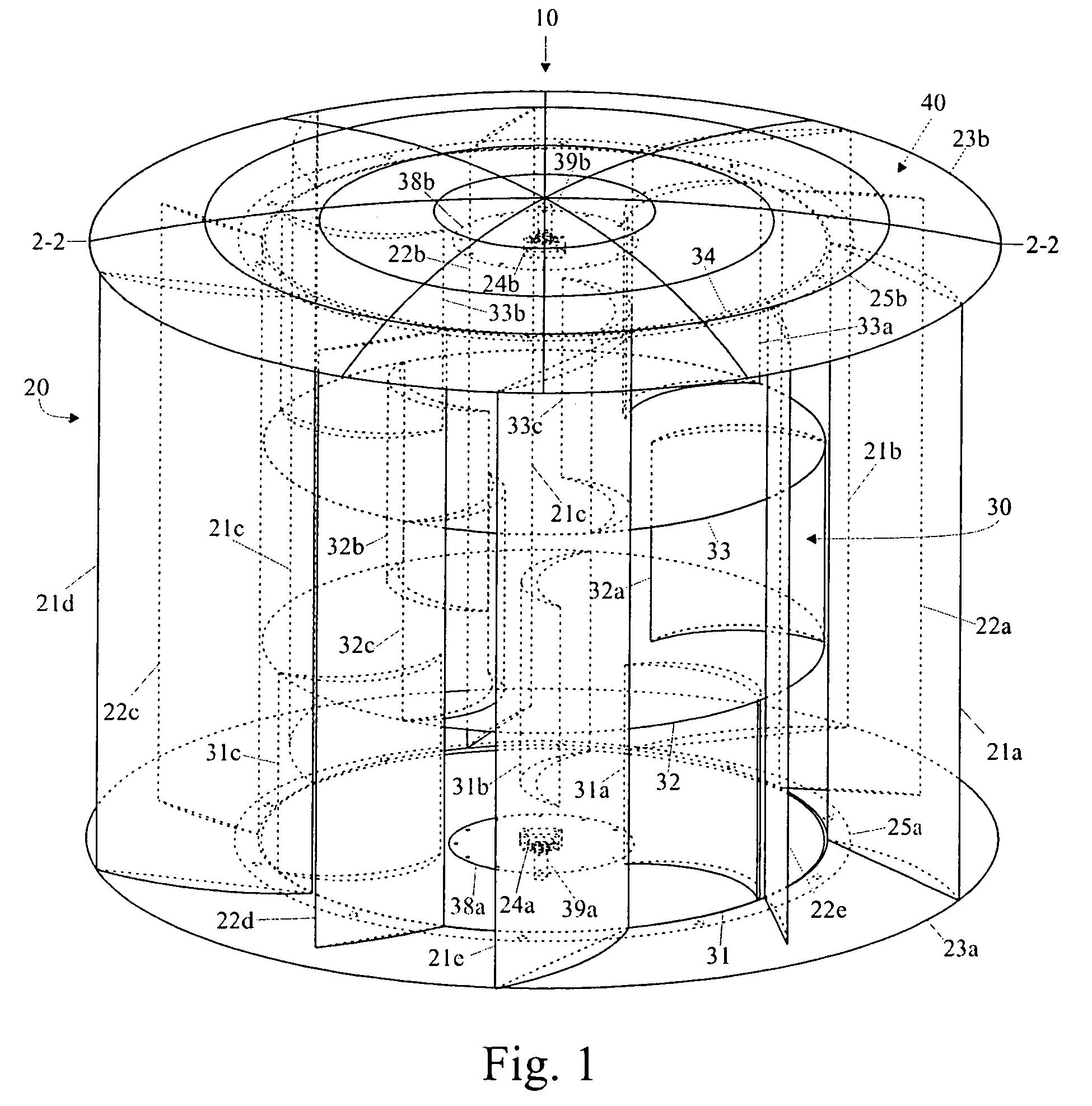

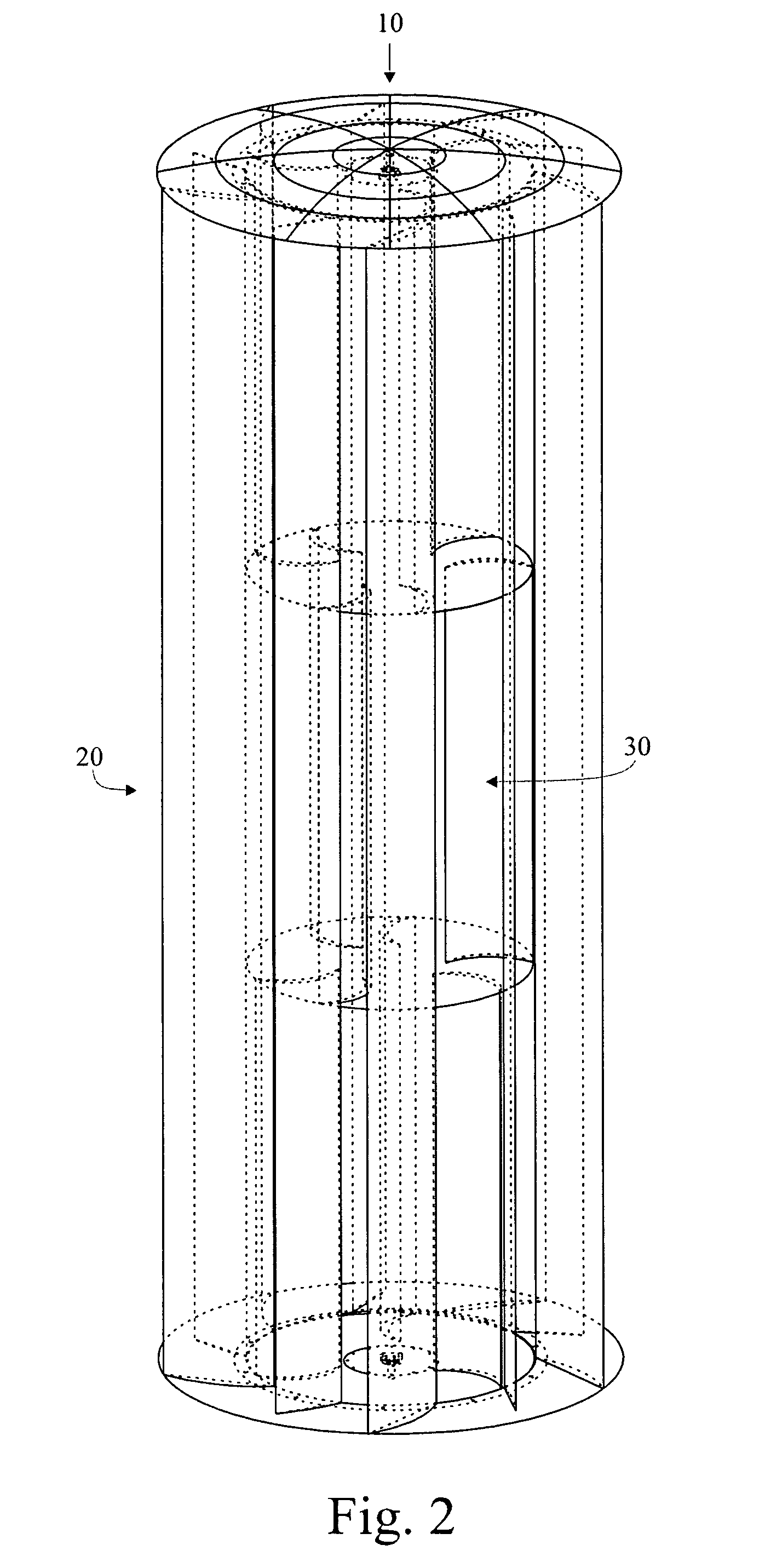

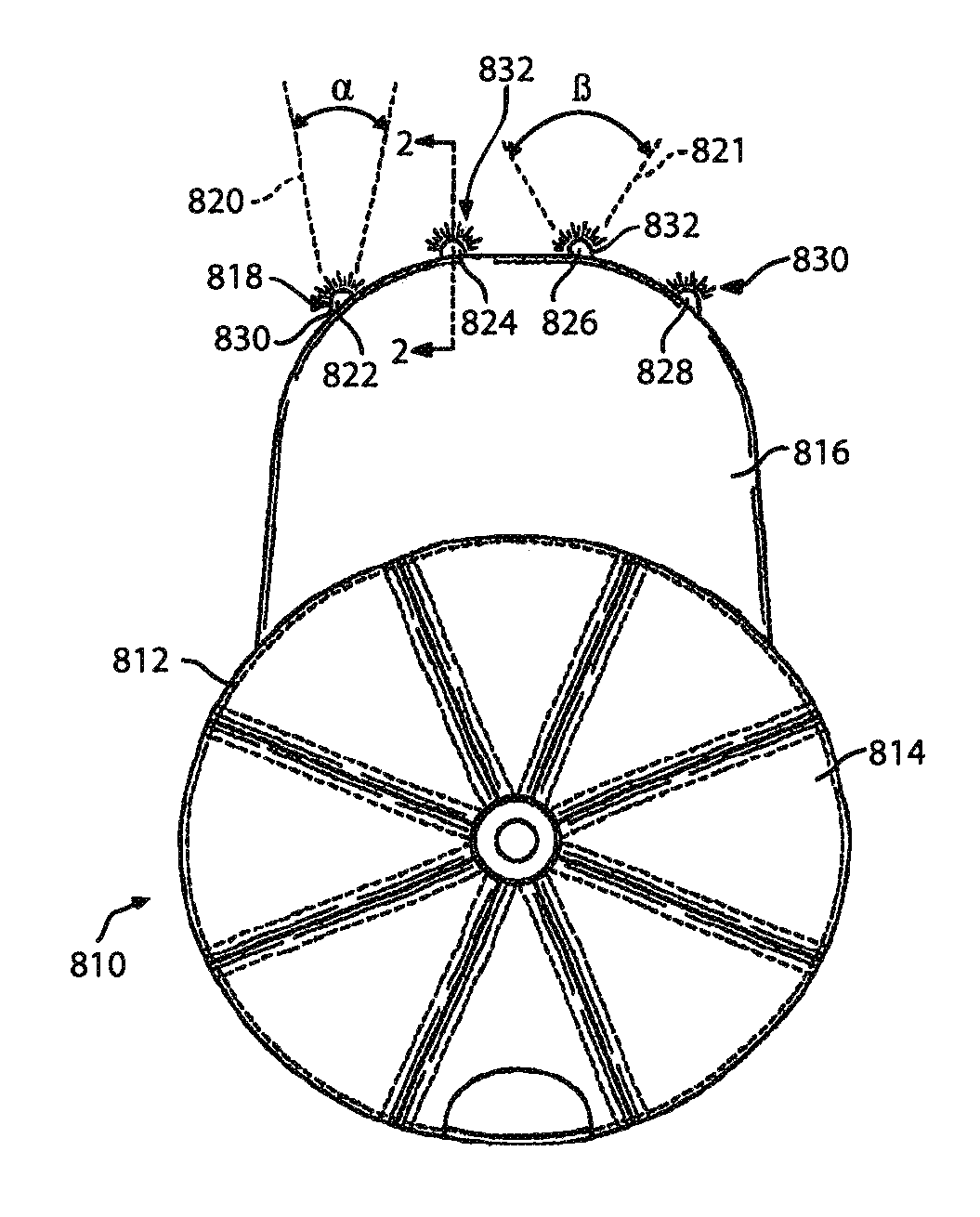

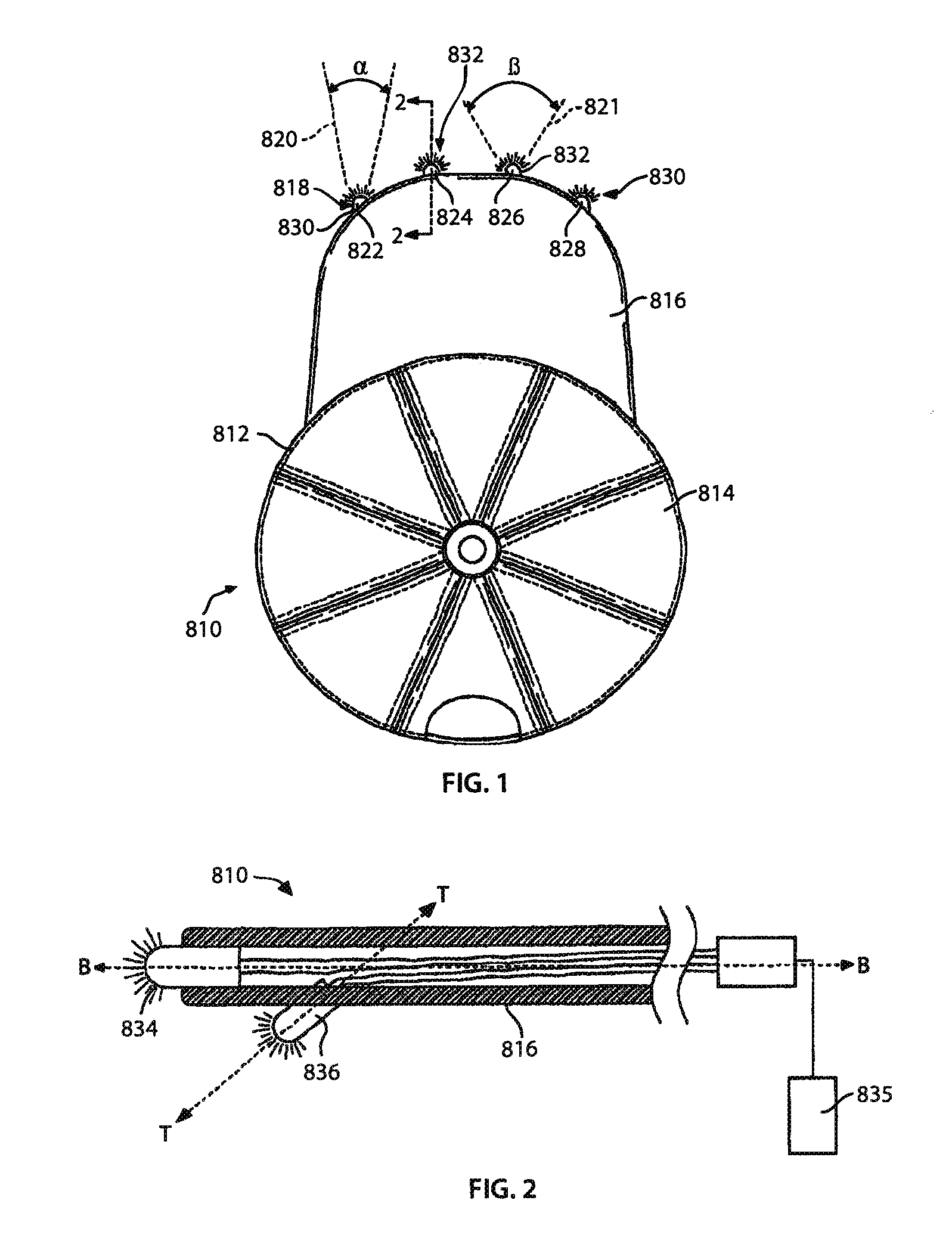

Aerodynamic-hybrid vertical-axis wind turbine

InactiveUS20060275105A1Eliminating salient back pressureEffectively and efficiently harnessingWind motor controlWind motor supports/mountsConvex sideVertical axis wind turbine

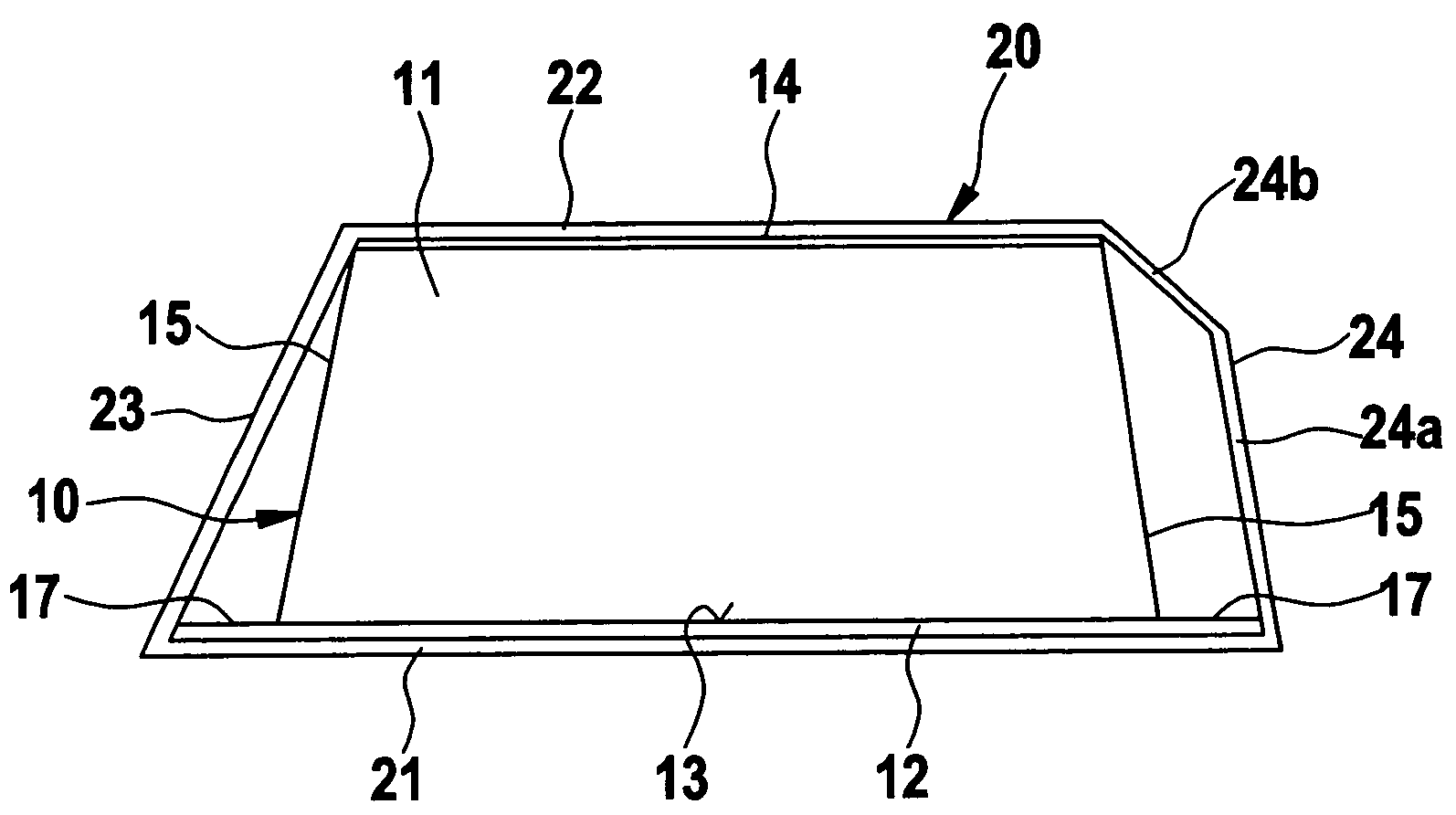

An aerodynamic-hybrid, vertical-axis wind turbine which includes a rotor airfoil and stator blade combination which maximizes energy production by increasing wind velocity and pressure while eliminating back pressure and improving the laminar flow of wind both around and through the device. The rotor airfoils have a horizontal cross-section with a crescent shape including a convex leading side and a concave trailing side with a thicker middle section that tapers to narrower sections at ends. The stator blades have a horizontal cross-section with a planar side and a convex side. Rotor airfoil and stator blade combinations are secured between upper and lower annular sails.

Owner:NOVASTRON

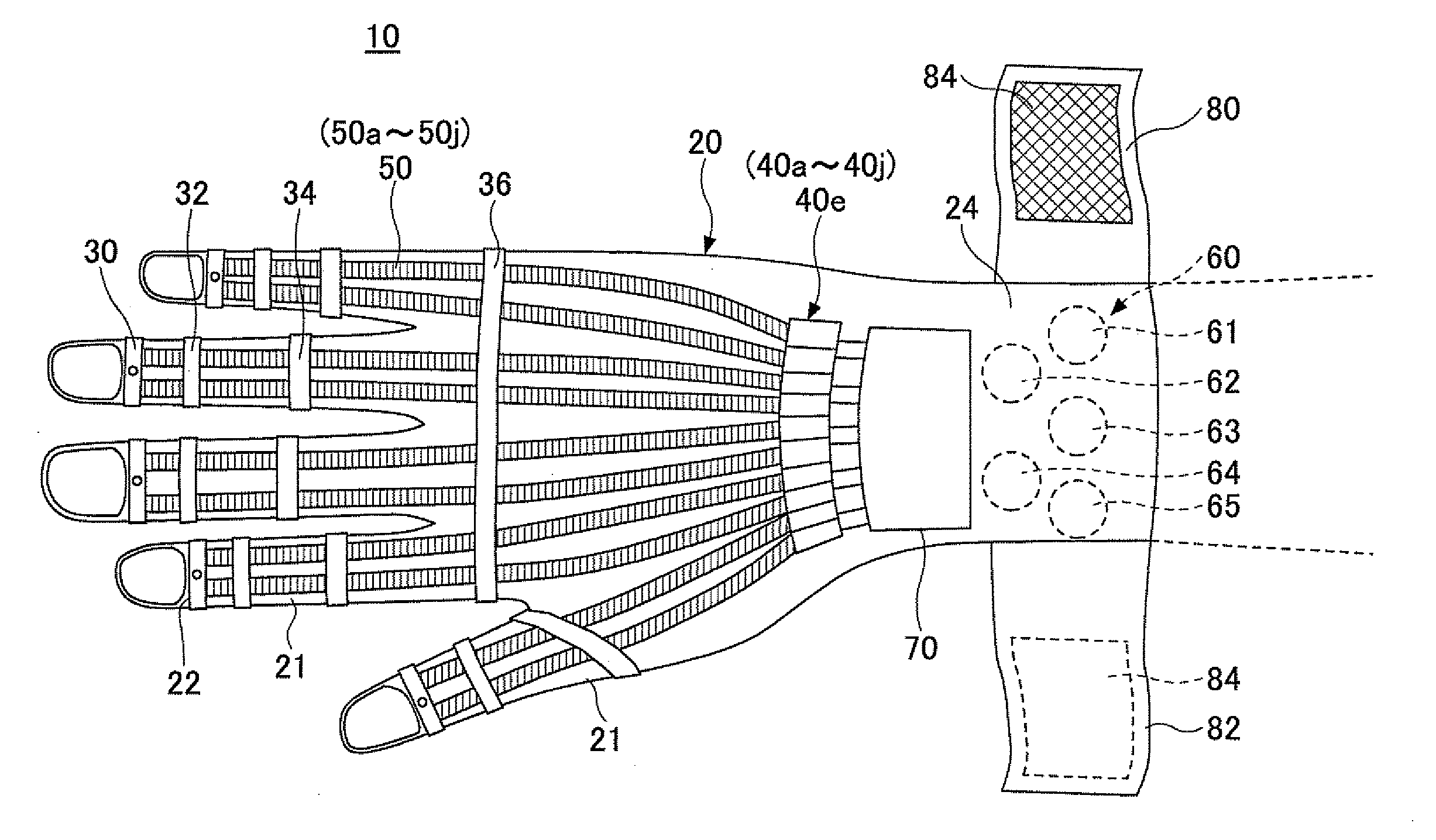

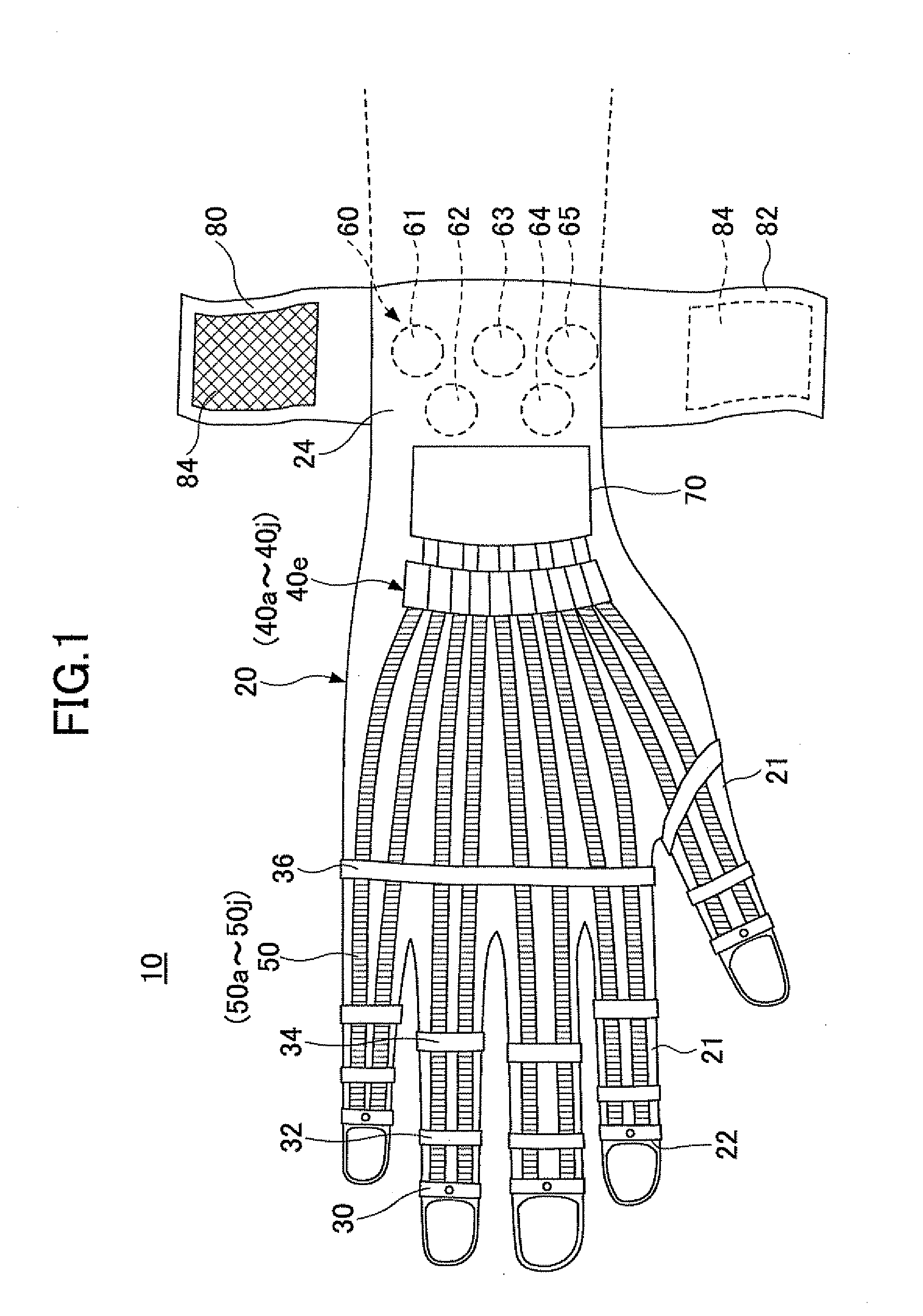

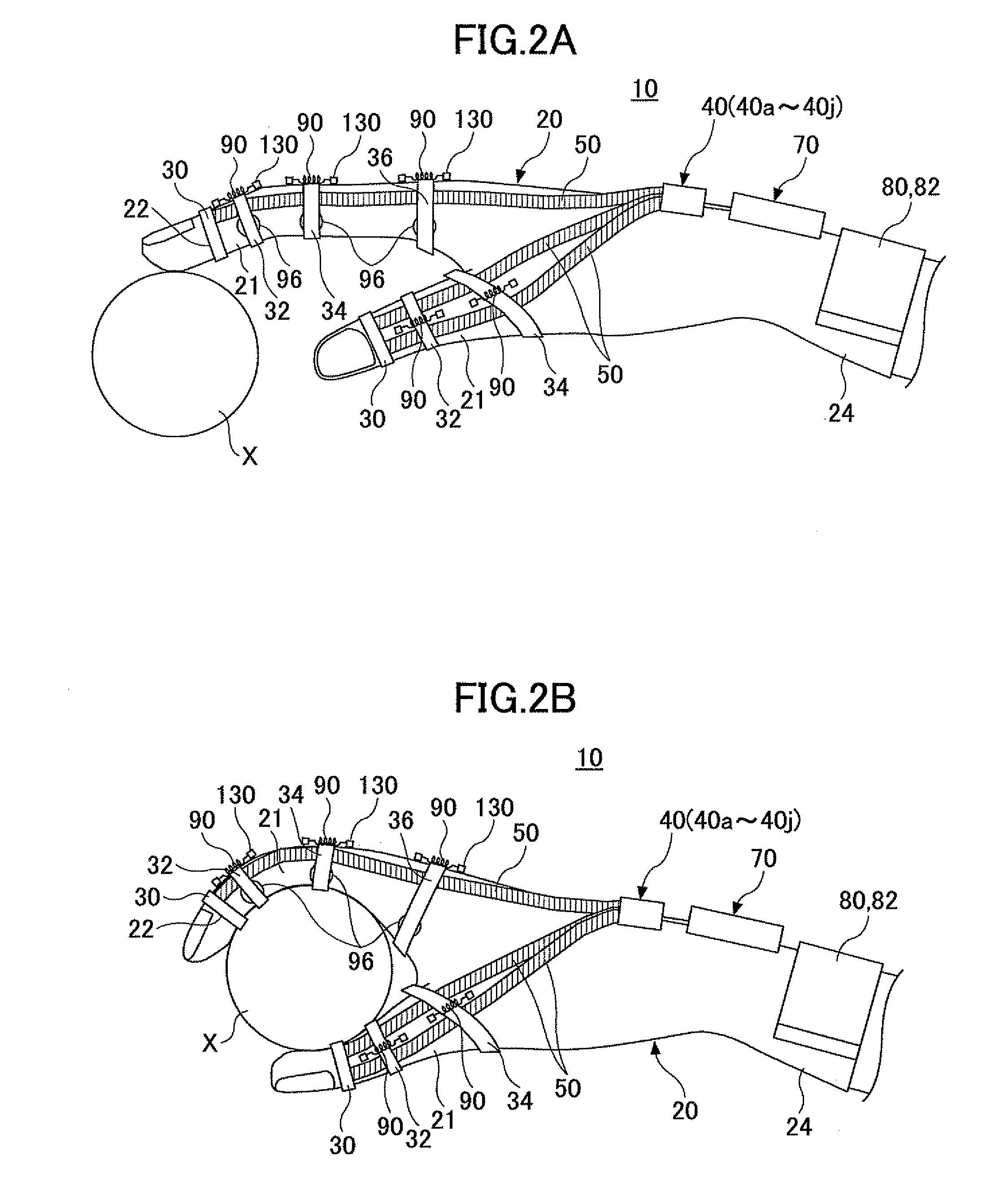

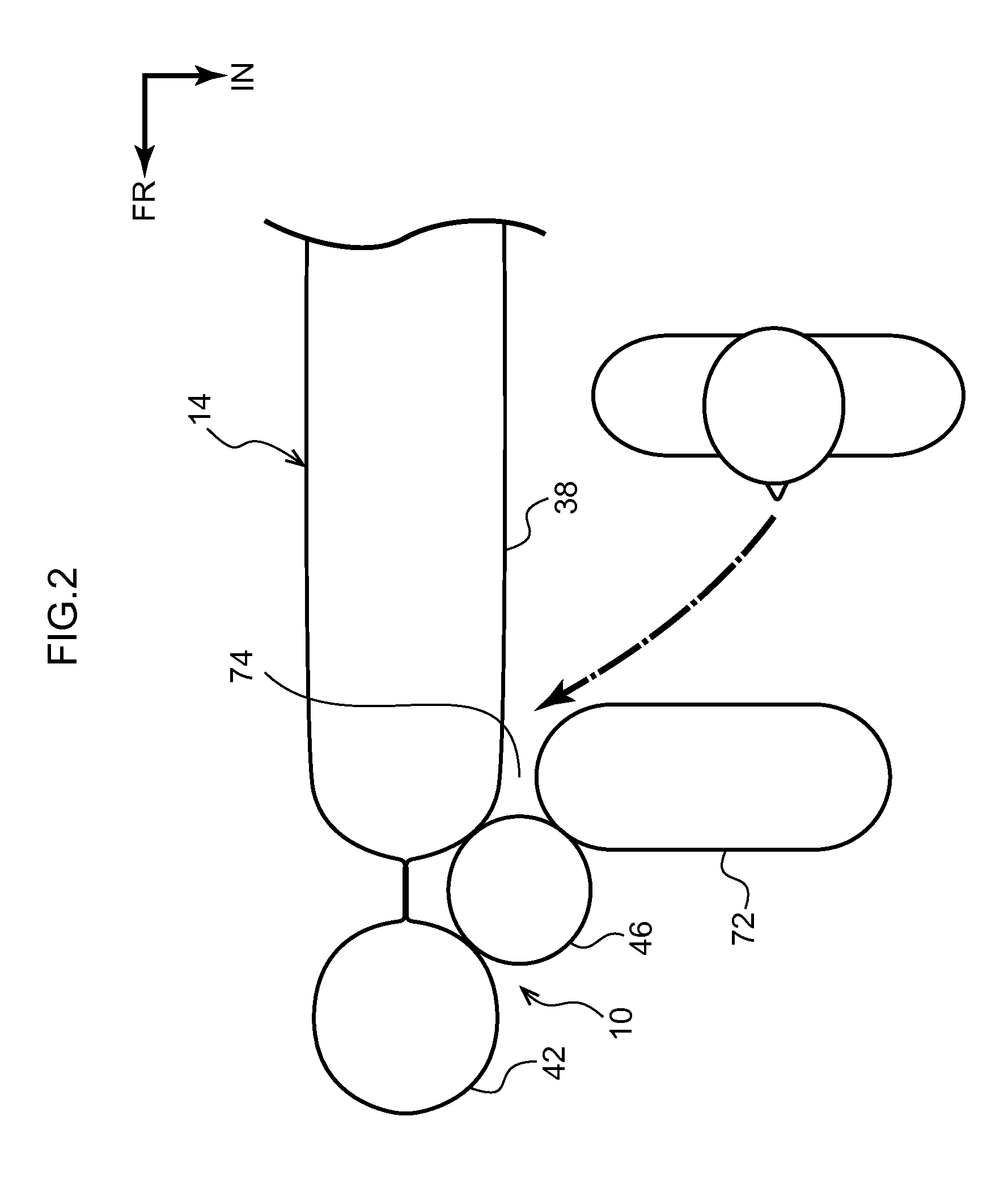

Wearable type movement assisting apparatus

ActiveUS20120029399A1Reduce loadEffectively transmit driving forceElectroencephalographyElectromyographyControl signalEngineering

A wearable type movement assisting apparatus includes a movement assisting glove including a finger insertion part into which a finger of a wearer is inserted, a driving part arranged on a backhand side of the movement assisting glove and configured to drive the finger insertion part, a linear member arranged along the finger insertion part and configured to transmit a driving force of the driving part to the finger insertion part, a biosignal detection part configured to detect a biosignal that causes the finger of the wearer to move, and a control part configured to output a drive control signal to the driving part based on the biosignal detected by the biosignal detection part. The driving part is configured to move the linear member in an extending direction or a bending direction of the finger insertion part based on the drive control signal from the control part.

Owner:CYBERDYNE INC

Aerodynamic-hybrid vertical-axis wind turbine

InactiveUS7329965B2Eliminate back pressureEffective forceWind motor controlWind motor supports/mountsConvex sideVertical axis wind turbine

An aerodynamic-hybrid, vertical-axis wind turbine which includes a rotor airfoil and stator blade combination which maximizes energy production by increasing wind velocity and pressure while eliminating back pressure and improving the laminar flow of wind both around and through the device. The rotor airfoils have a horizontal cross-section with a crescent shape including a convex leading side and a concave trailing side with a thicker middle section that tapers to narrower sections at ends. The stator blades have a horizontal cross-section with a planar side and a convex side. Rotor airfoil and stator blade combinations are secured between upper and lower annular sails.

Owner:NOVASTRON

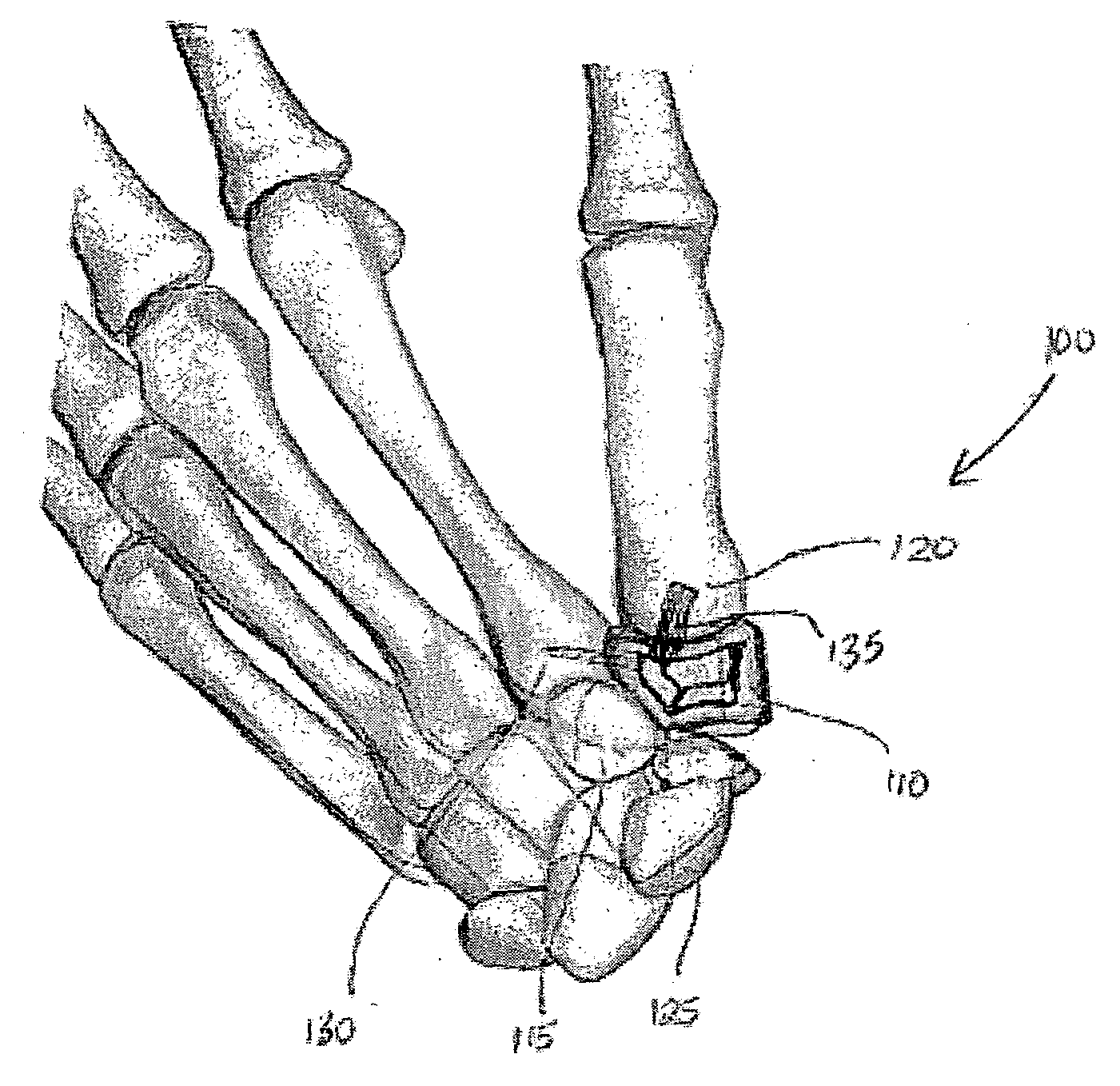

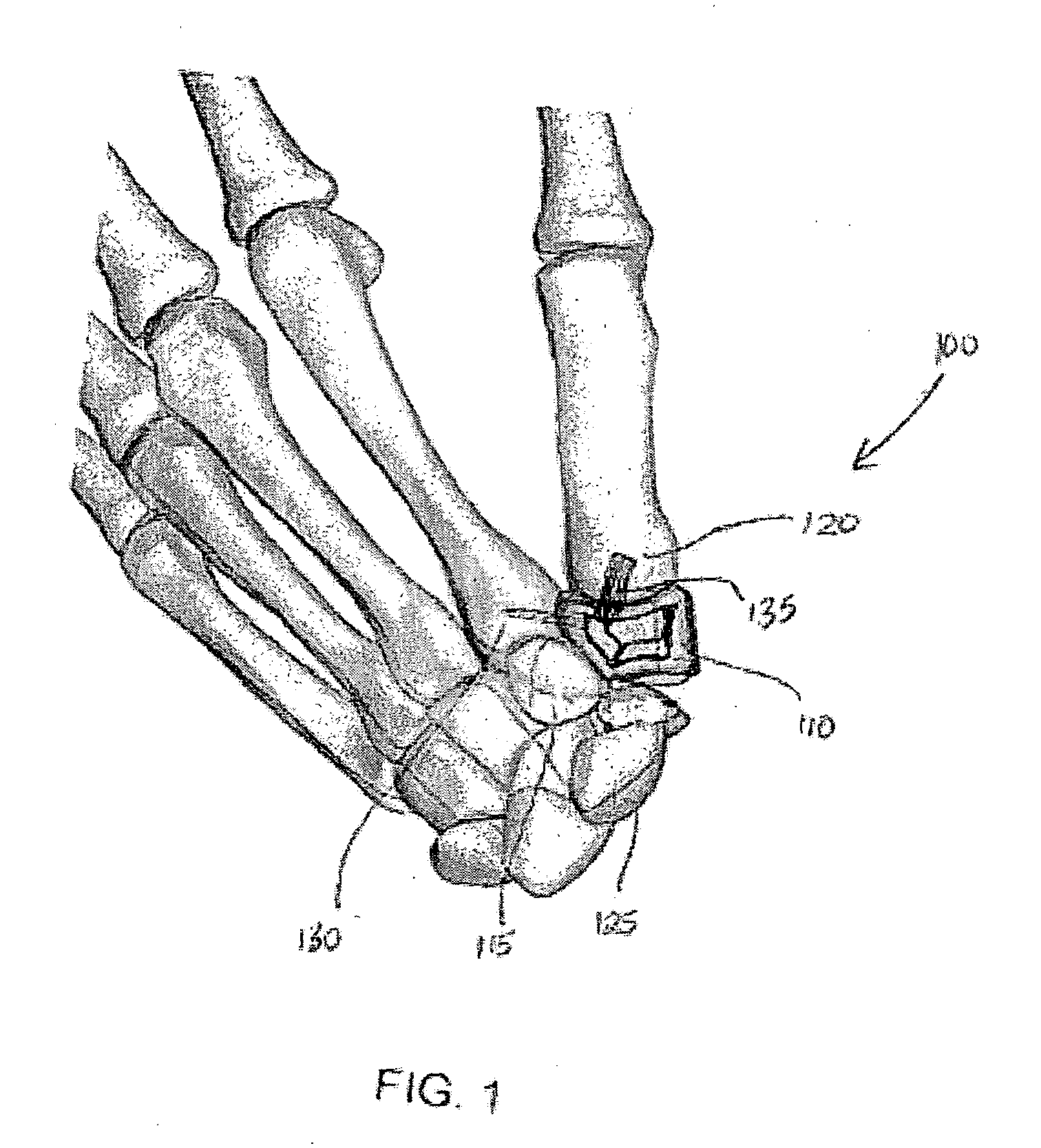

System and method for trapezium bone replacement

ActiveUS20090254190A1Efficiently distribute forceEffective forceSuture equipmentsFinger jointsTrapezium BoneProsthesis

A carpometacarpal joint replacement system for replacing the trapezium bone in the hand is provided. The system includes a trapezial implant for the carpometacarpal joint resulting in replacement of the carpal trapezium bone with a prosthesis having the same anatomical configuration as the trapezium bone. The implant device comprises a plurality of concave surfaces, with the plurality of concave surfaces articulating with the carpal and metacarpal bones.

Owner:EXTREMITY MEDICAL

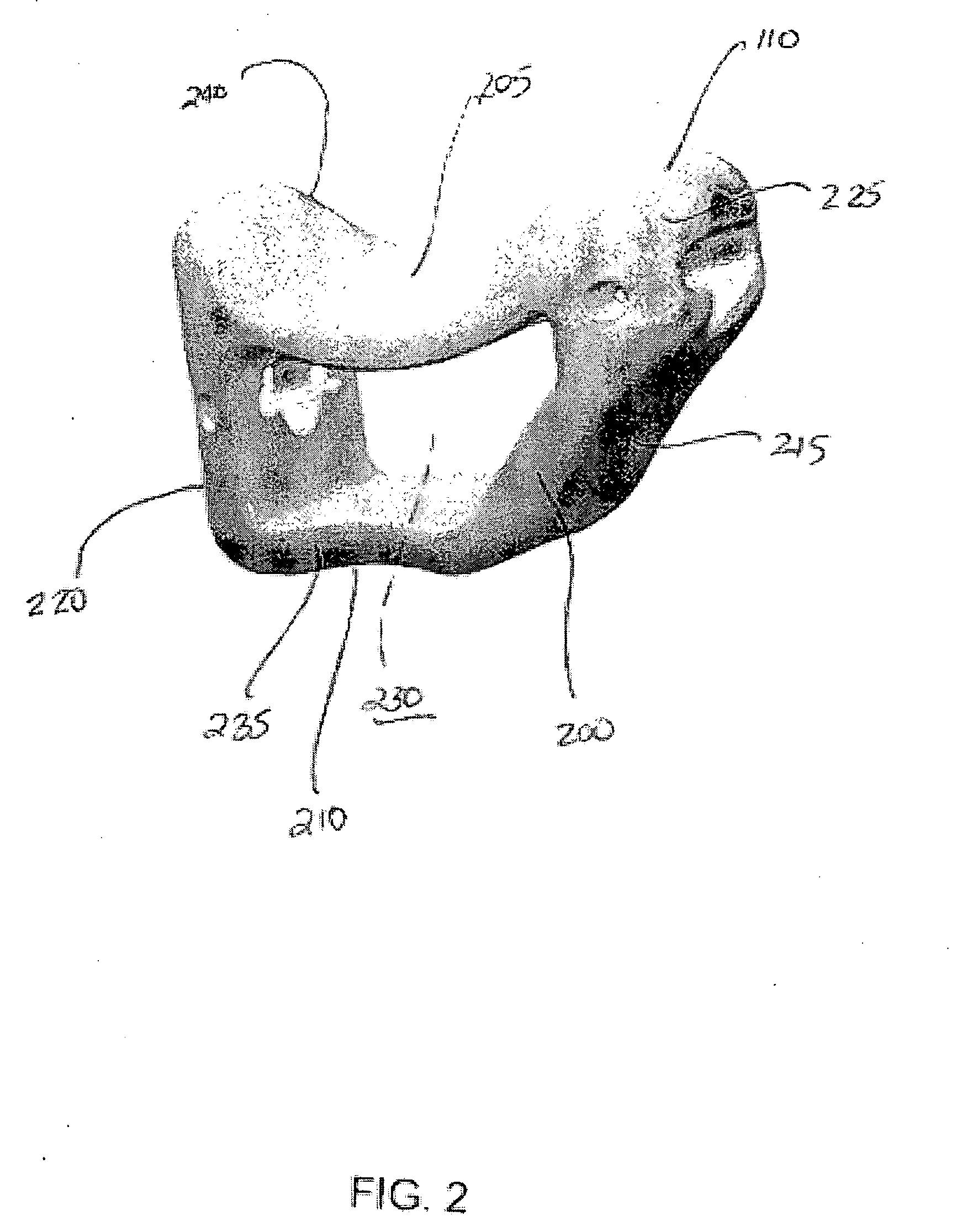

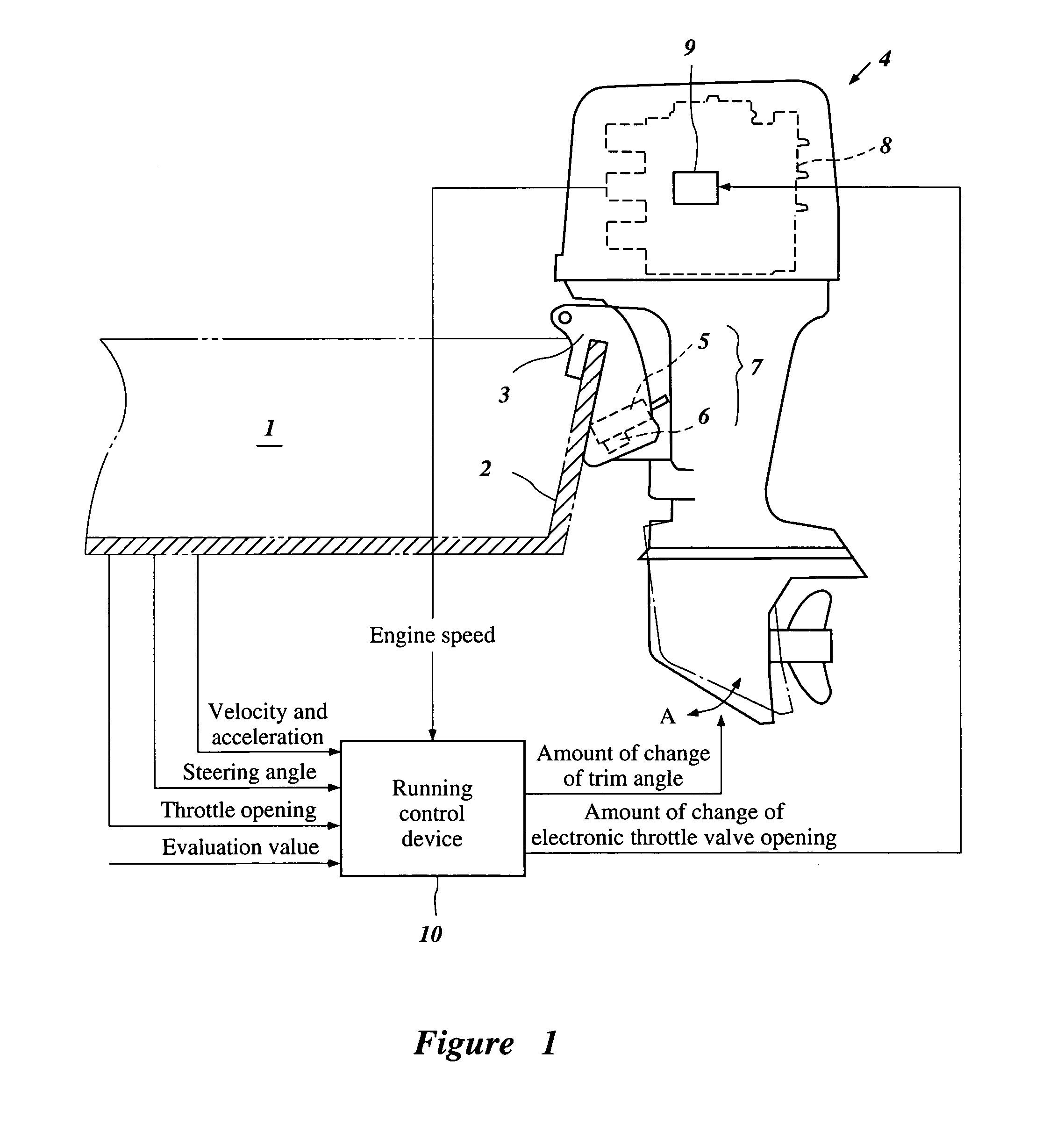

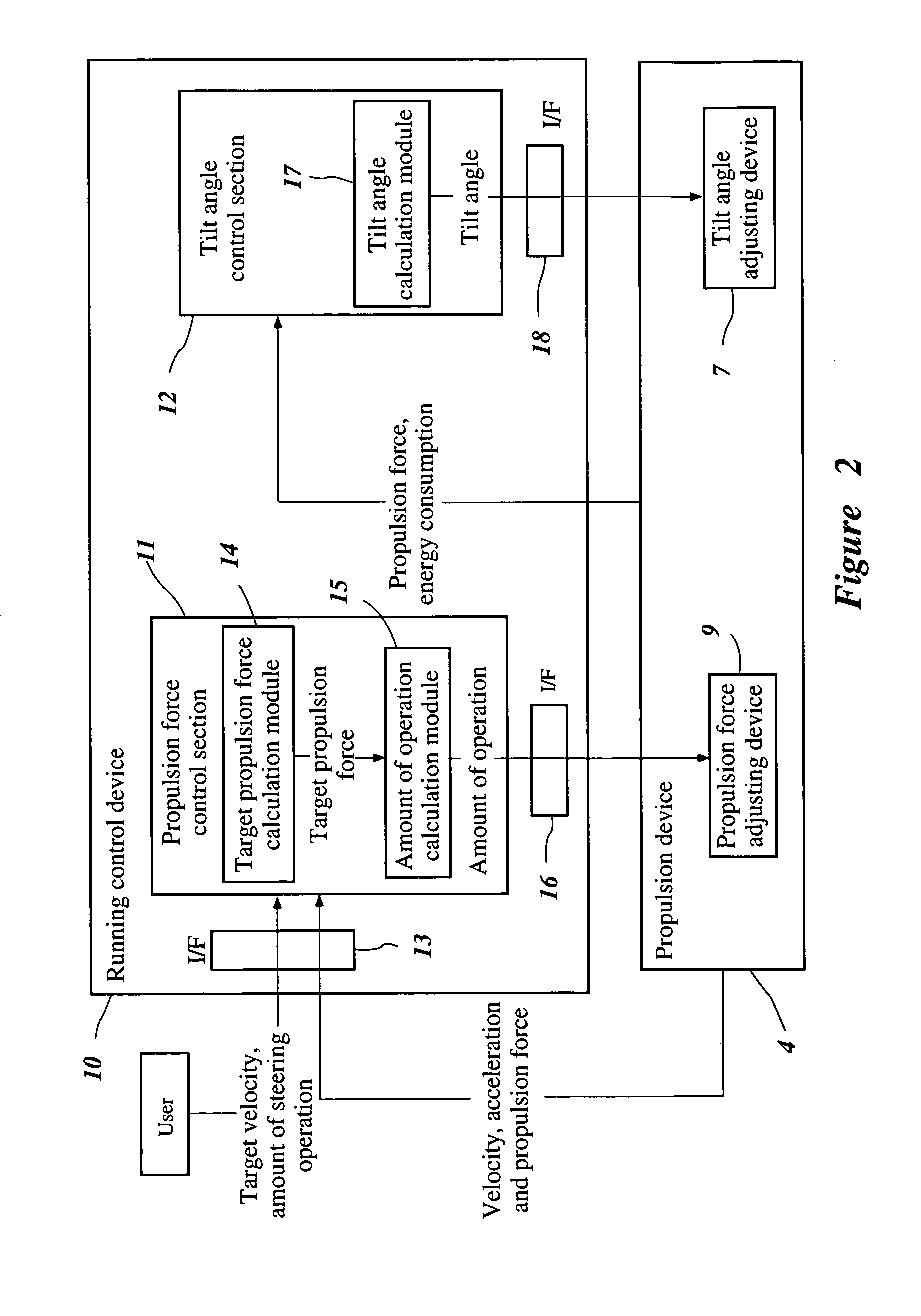

Running control device

InactiveUS6997763B2Fuel consumption is minimizedEasy to manufactureElectrical controlInternal combustion piston enginesComputer moduleWatercraft

A running control device for a watercraft controls propulsion force and tilt angle of a propulsion device relative to the hull of the watercraft. The running control device also sets an optimum trim angle automatically. The running control device includes a propulsion force control section that controls the propulsion force of the propulsion device. The running control device also includes a tilt angle control section that controls the tilt angle of the propulsion device. A target propulsion force calculation module responds to first input information (e.g., watercraft velocity) to calculate a target propulsion force. An amount-of-operation calculation module responds to second input information to calculate an amount of operation of the propulsion device to produce the target propulsion force. The tilt angle control section includes a tilt angle calculation module that determines the tilt angle based on the propulsion force.

Owner:YAMAHA MOTOR CO LTD

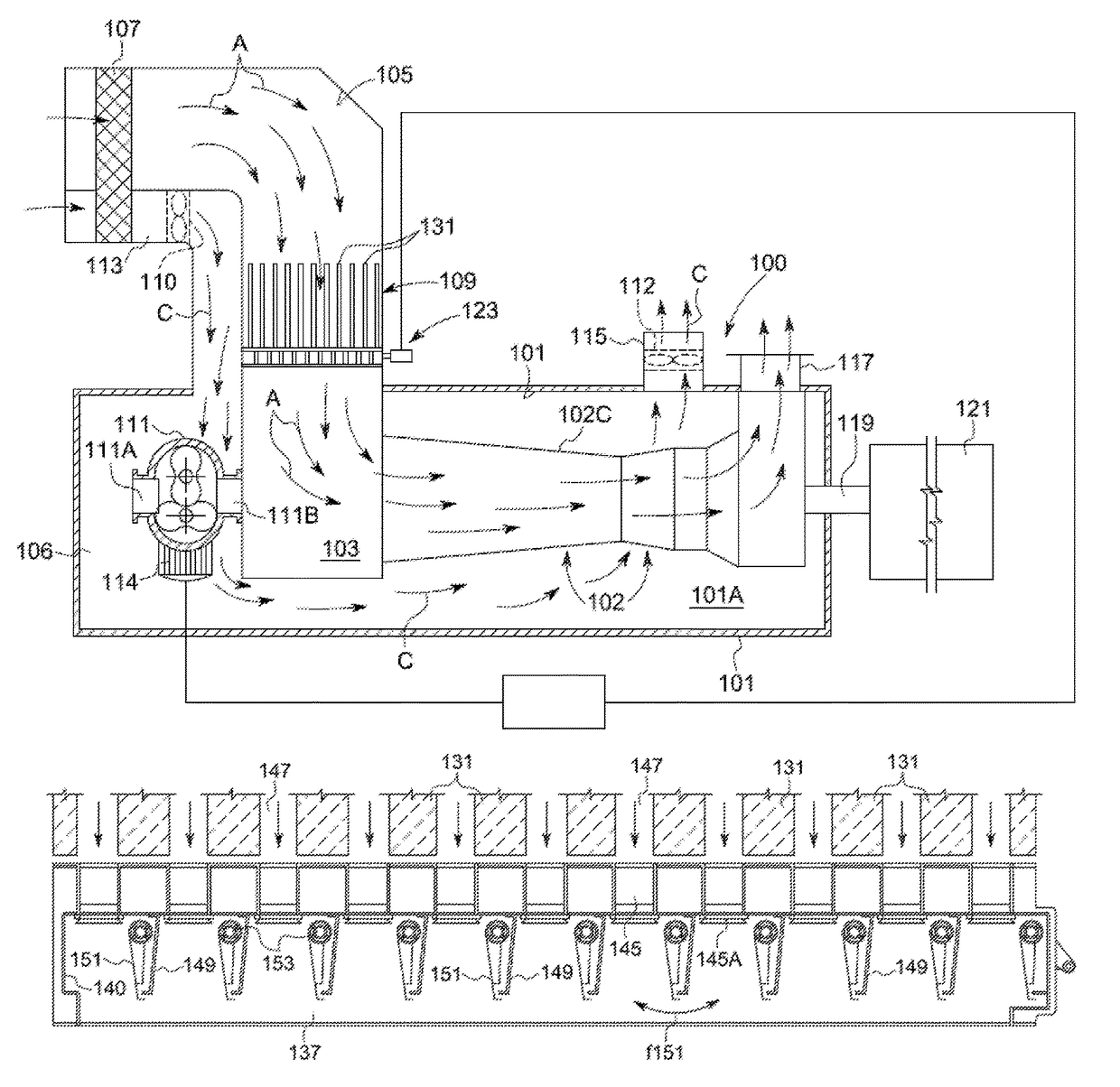

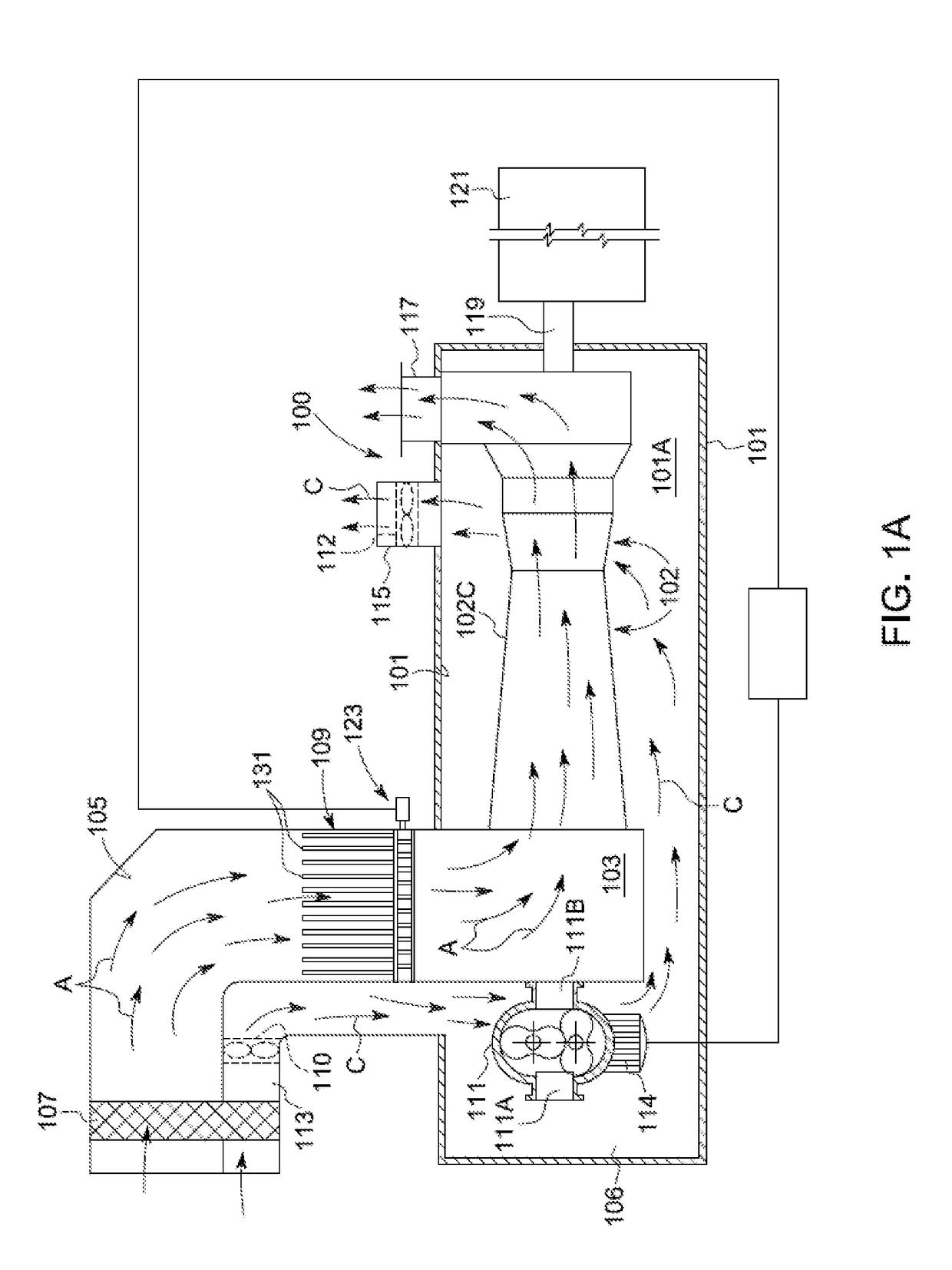

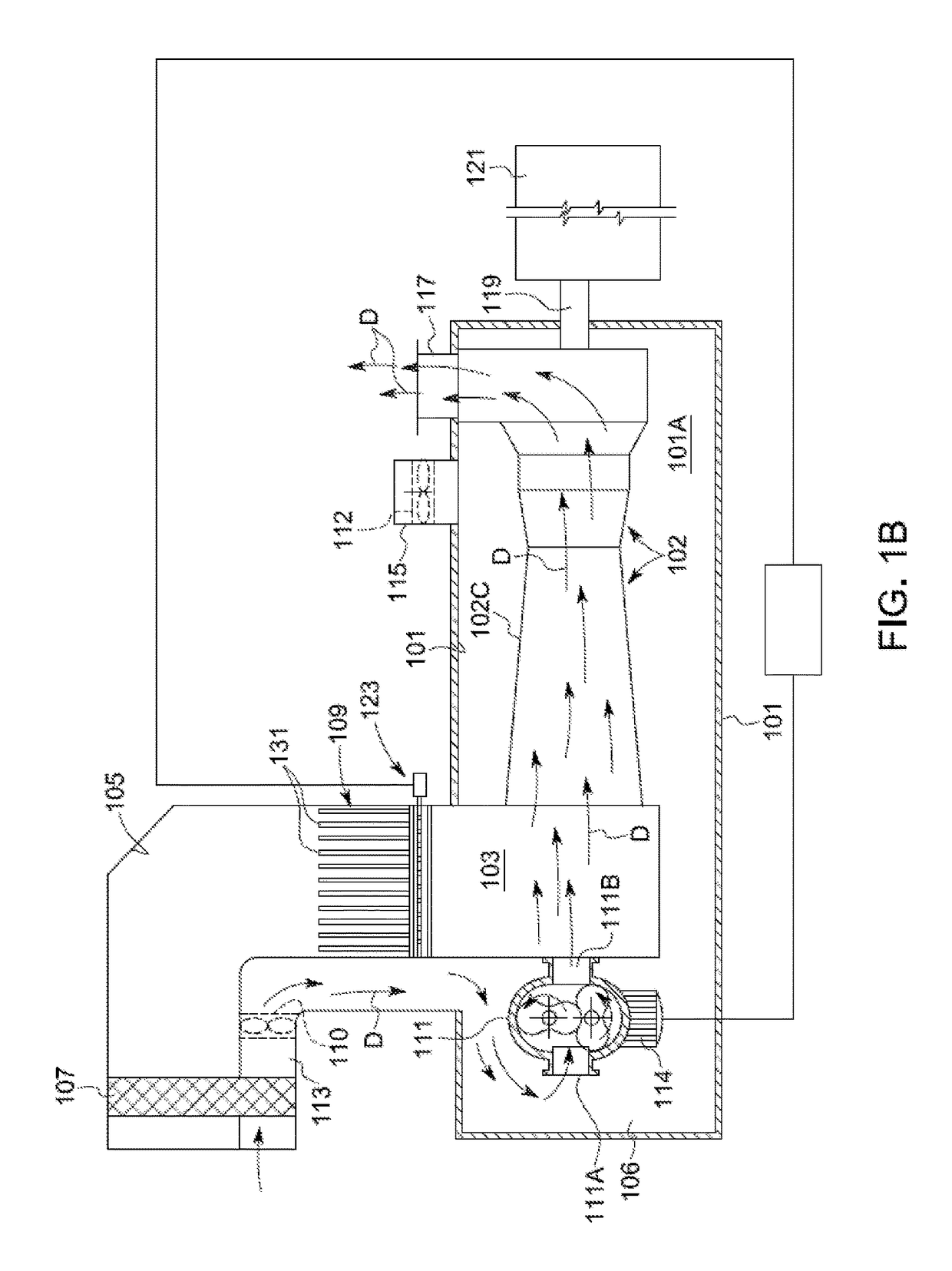

Device and method for gas turbine unlocking

ActiveUS9845730B2Shorten the timeReduce downtimePump componentsTurbine/propulsion engine coolingAviationCombustor

An aeroderivative gas turbine including an air intake plenum; a compressor with a compressor air intake in fluid communication with the air intake plenum; a combustor; a high pressure turbine; a power turbine. A forced air-stream generator is arranged in fluid communication with the air intake plenum. A shutter arrangement is provided in a combustion-air flow path, arranged and controlled to close the combustion-air flow path for pressurizing said air intake plenum by means of the forced air-stream generator to a pressure sufficient to cause pressurized air to flow through the aeroderivative air turbine.

Owner:NUOVO PIGNONE TECH SRL

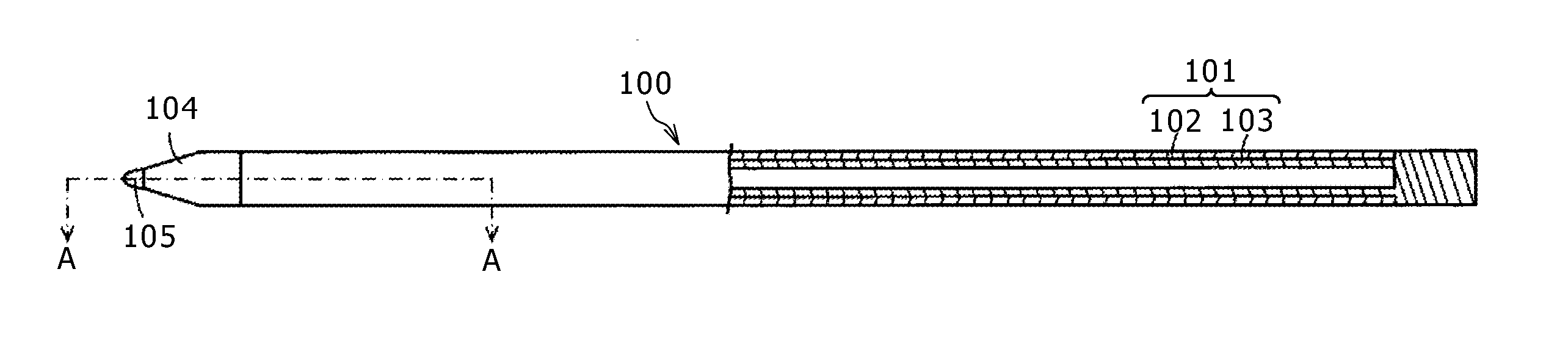

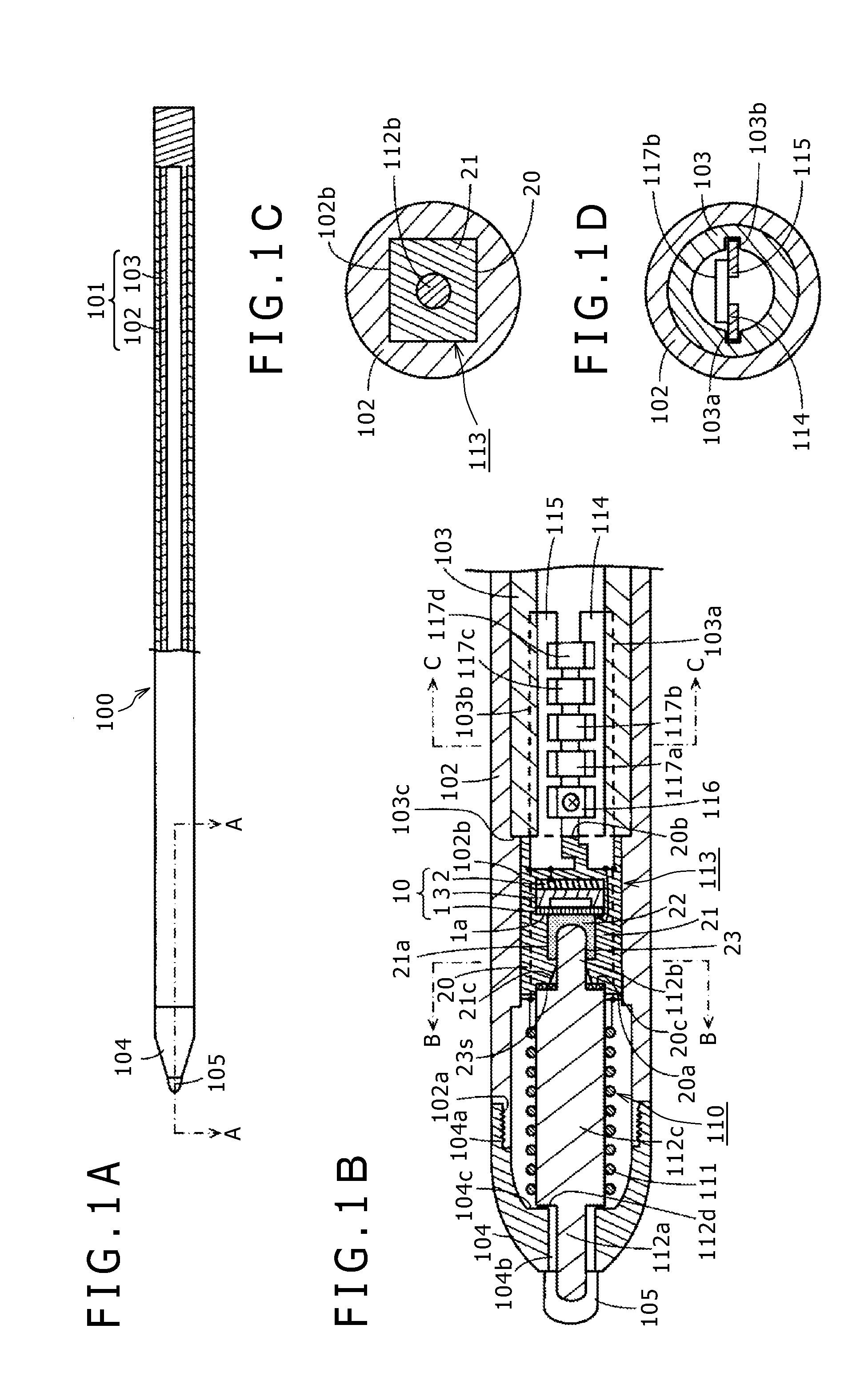

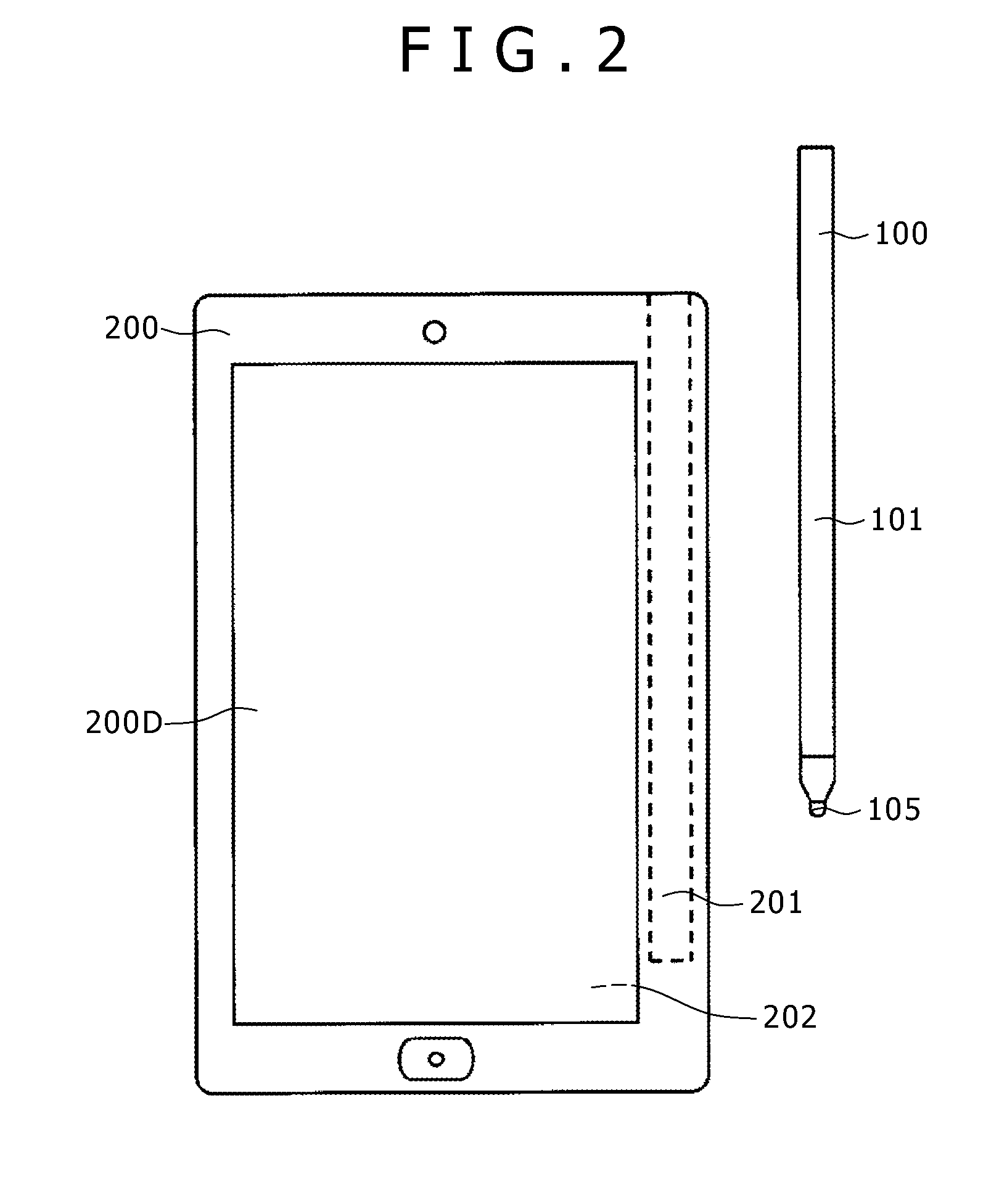

Position indicator

ActiveUS20130199311A1Effective forceCapacitor with electrode area variationFluid pressure measurement by electric/magnetic elementsCapacitanceCapacitor

A position indicator includes a capacitor having a capacitance that changes in correspondence to a force applied to one end part of a housing. The capacitor is configured by a pressure detecting chip that includes a first electrode and a second electrode disposed opposite to the first electrode with a predetermined distance defined therebetween to have capacitance Cv formed between the first electrode and the second electrode. The capacitance Cv changes when the force applied to the one end part of the housing is transmitted to the first electrode to thereby change a relationship (e.g., the distance) between the two electrodes. A pressure transmitting member having predetermined elasticity is disposed on the first electrode such that the force applied to the one end part of the housing is transmitted to the first electrode of the semiconductor element via the pressure transmitting member.

Owner:WACOM CO LTD

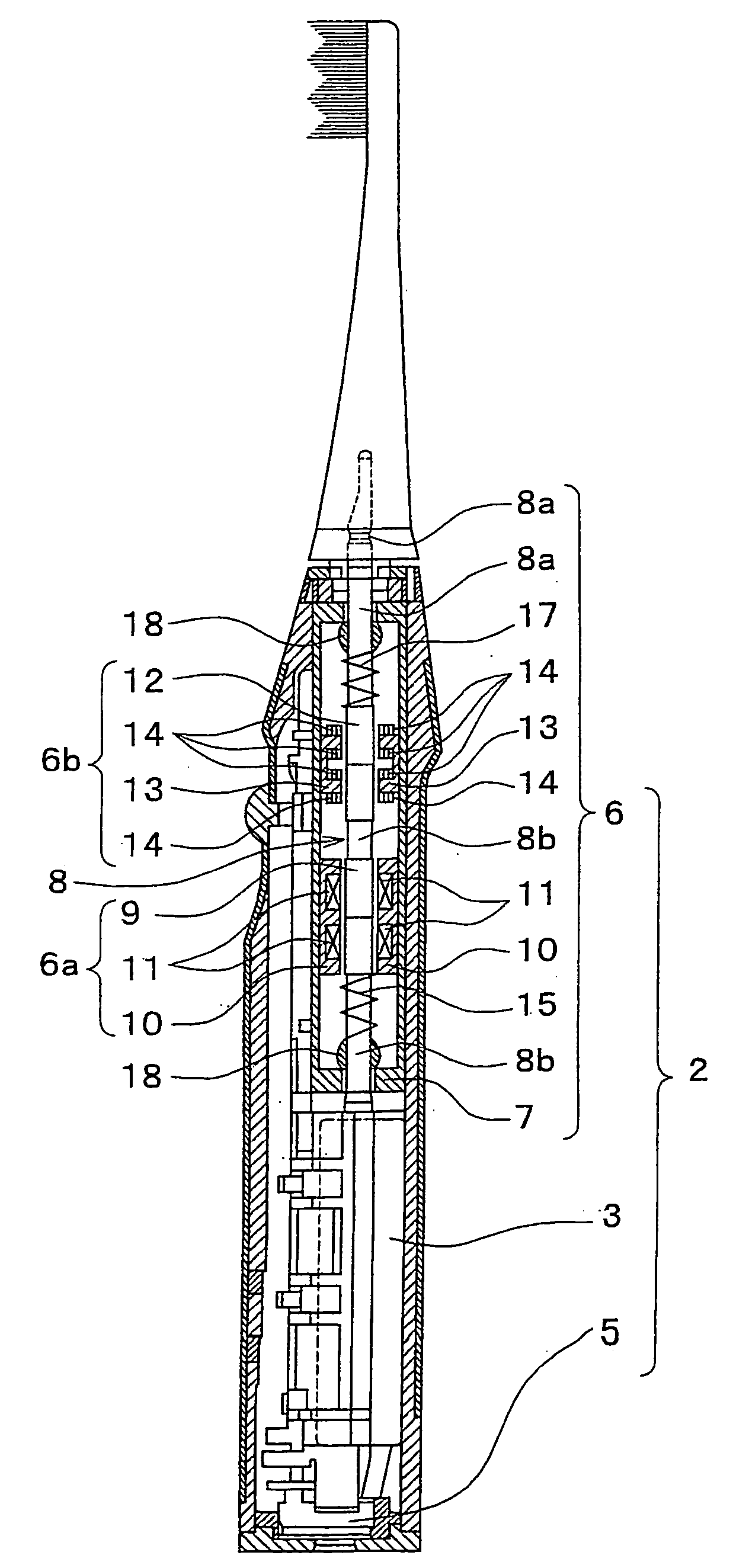

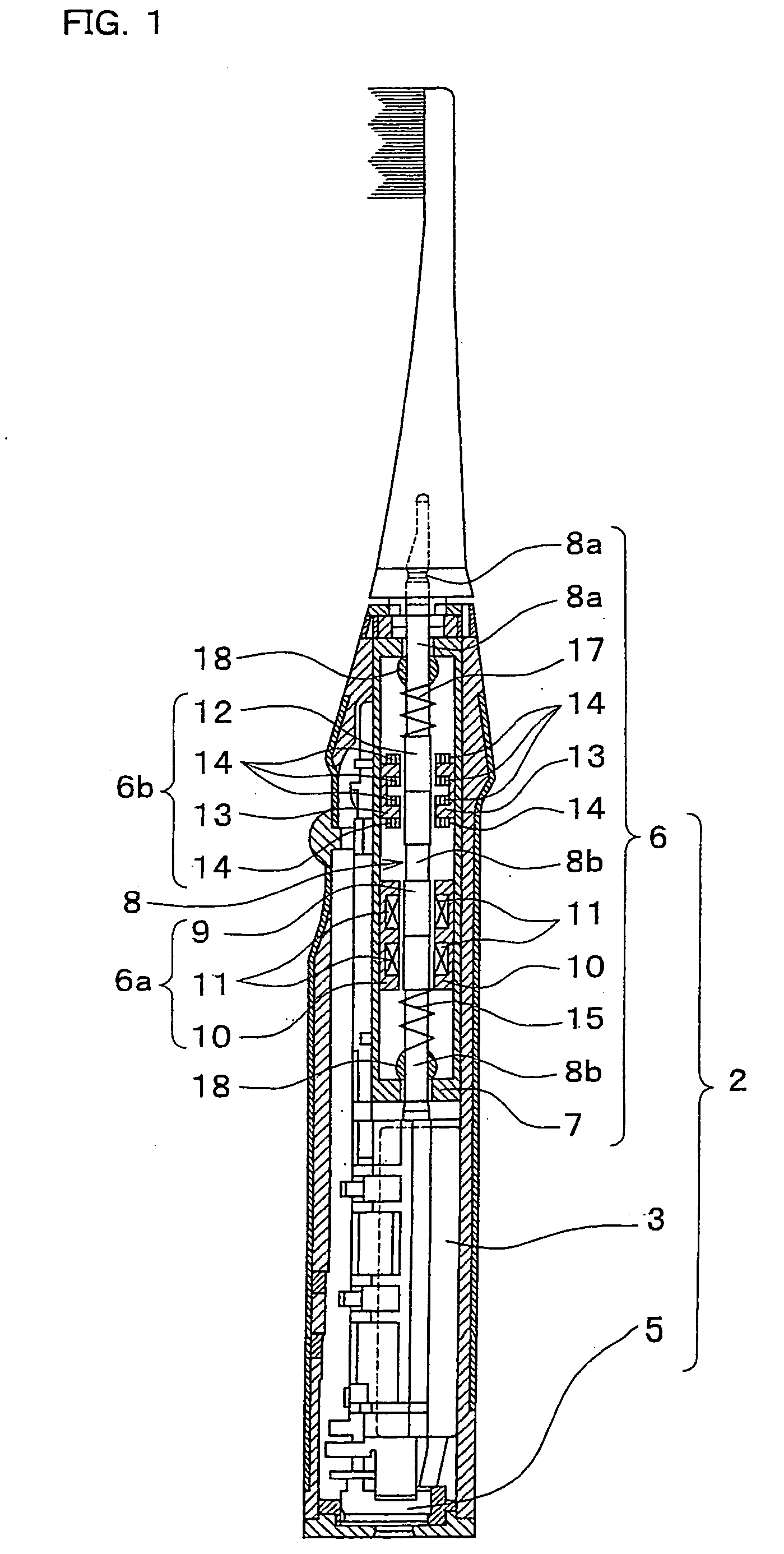

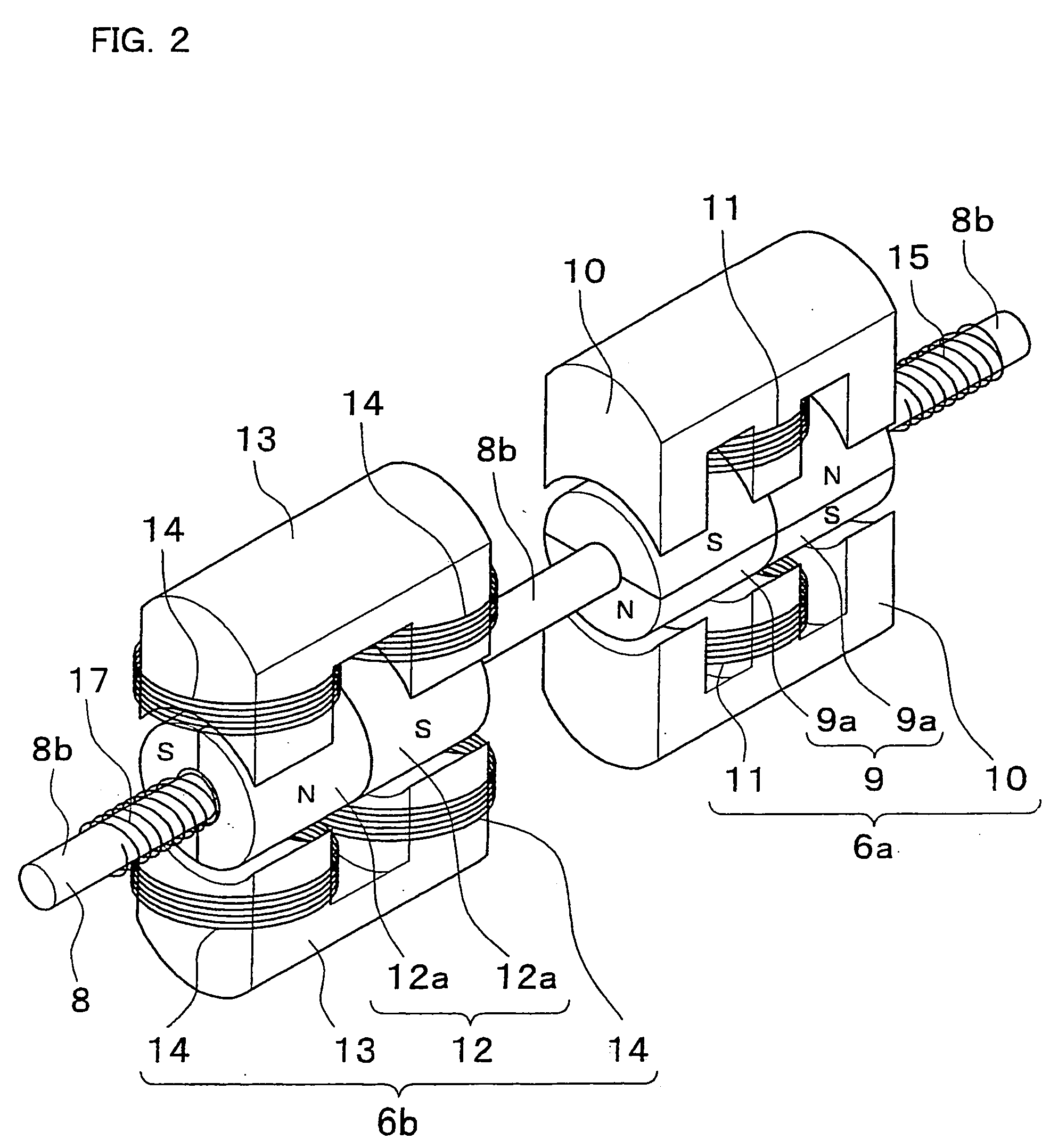

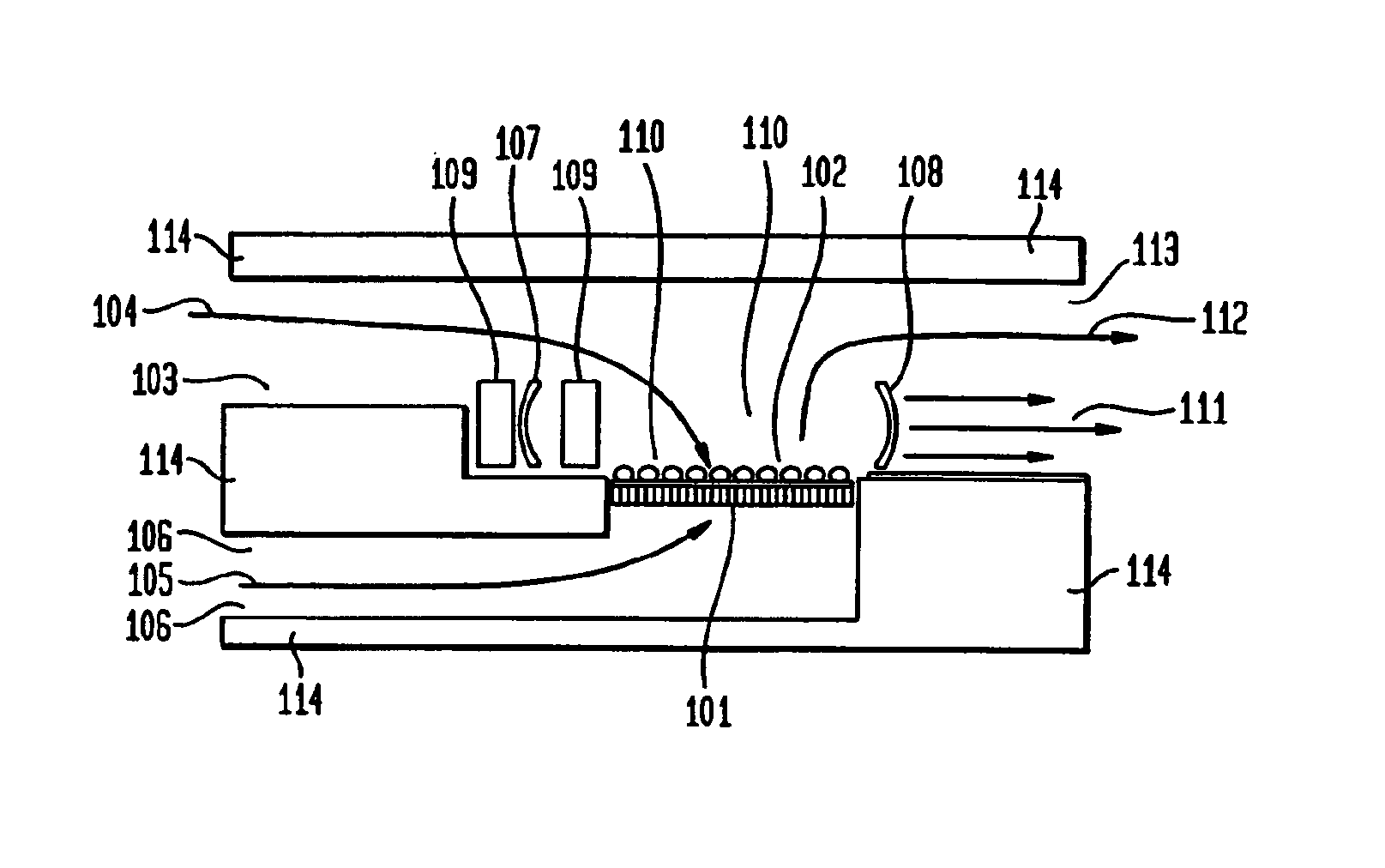

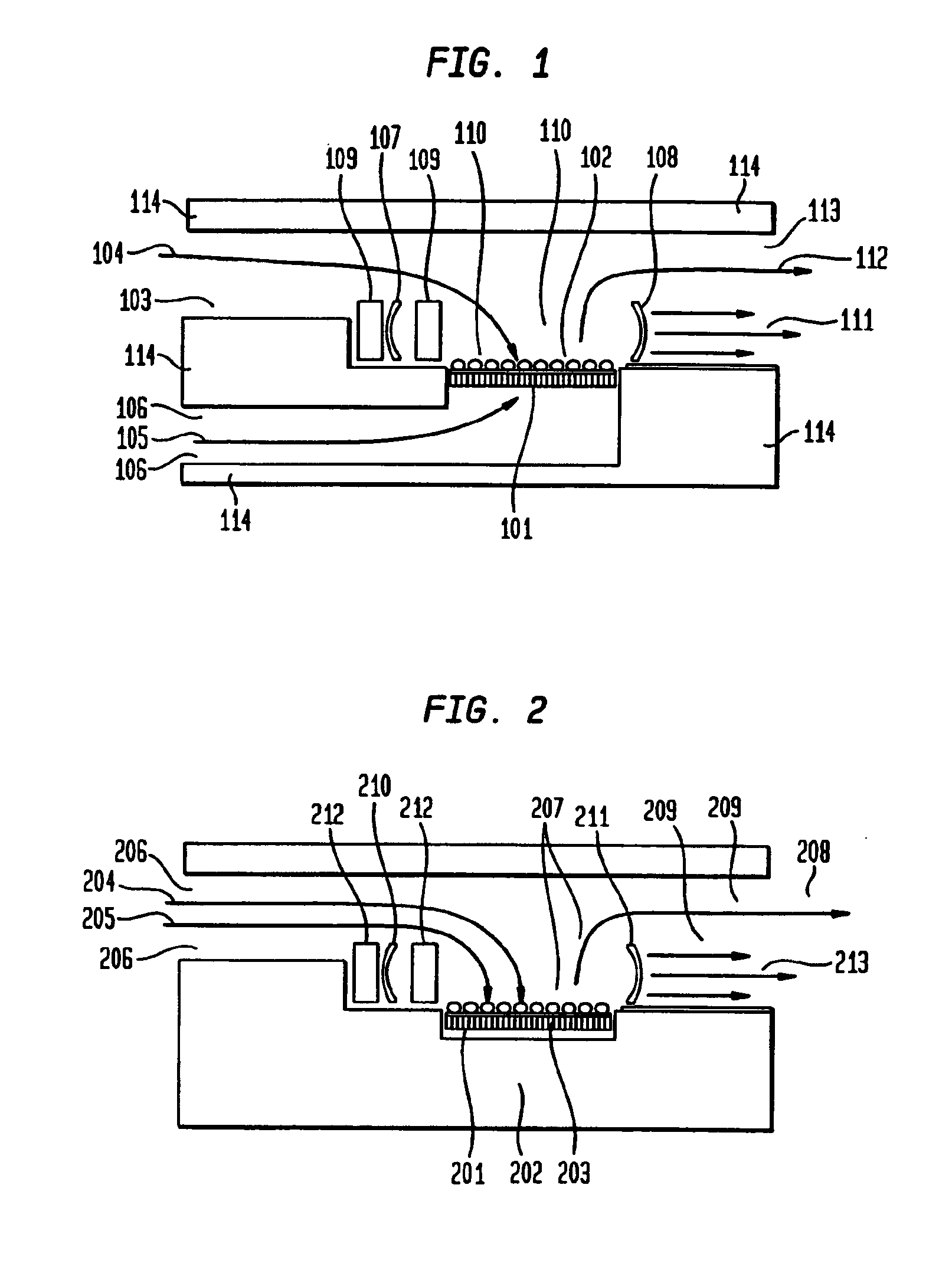

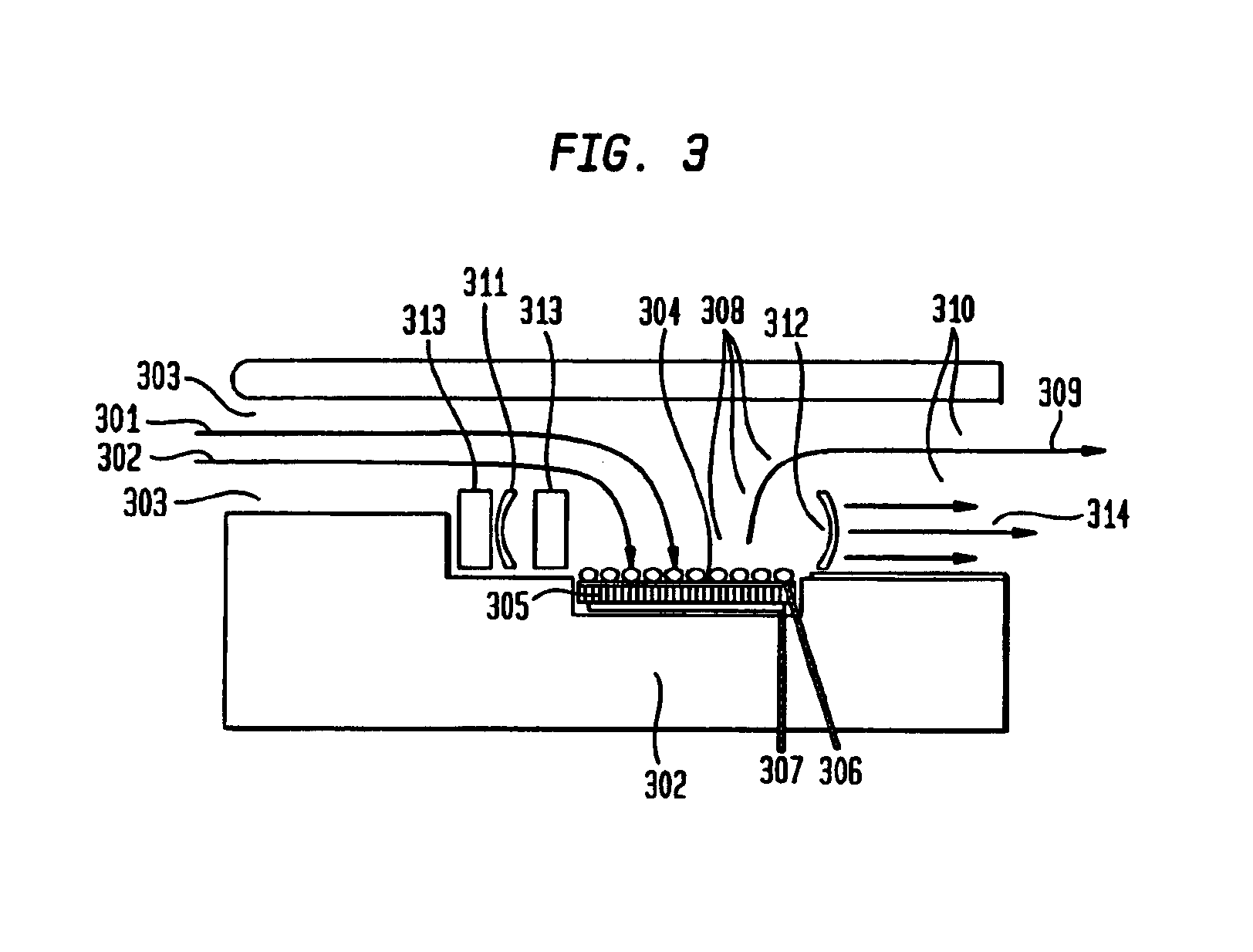

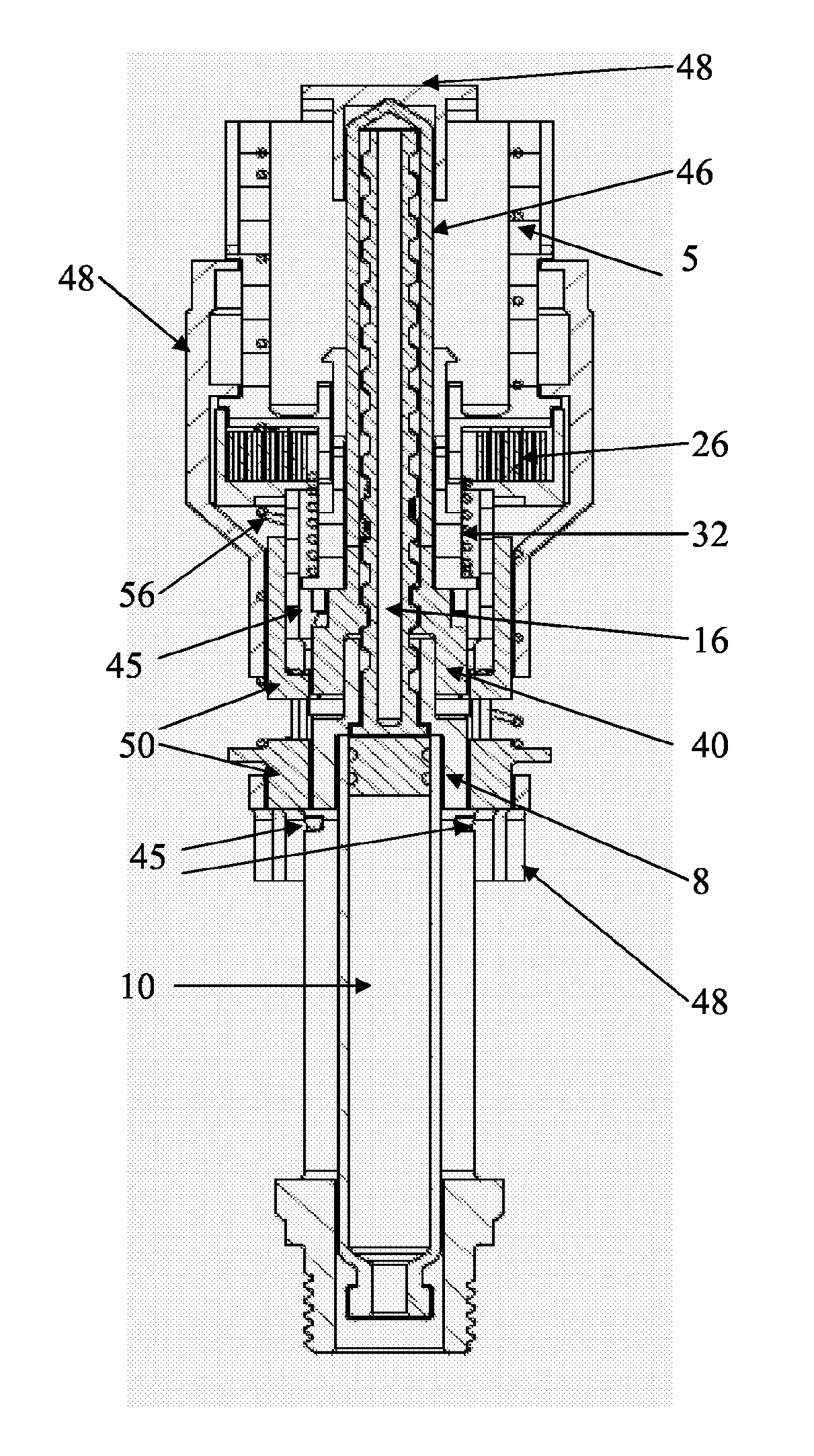

Power toothbrush

InactiveUS20050235438A1Effectively transmit driving forceIncrease speedCarpet cleanersBrush bodiesDriving currentLinear motion

In a power toothbrush, an interchangeable brush head is directly fitted to a front end portion of a drive shaft of an actuator. The actuator comprises a first magnetic circuit for moving the drive shaft reciprocally in an axial direction of the drive shaft, and a second magnetic circuit for rotating the drive shaft around a center axis of the drive shaft. The first magnetic circuit and the second magnetic circuit are independently excited by independent driving current having predetermined frequencies and a predetermined phase difference therebetween. Thus, the brush head fitted to the drive shaft can be moved in a composition of reciprocal linear movement and reciprocal rotation. The actuator does not include conventional mechanical elements such as gears or cams so that the actuator can move the drive shaft much faster than that of the conventional actuator.

Owner:MATSUSHITA ELECTRIC WORKS LTD

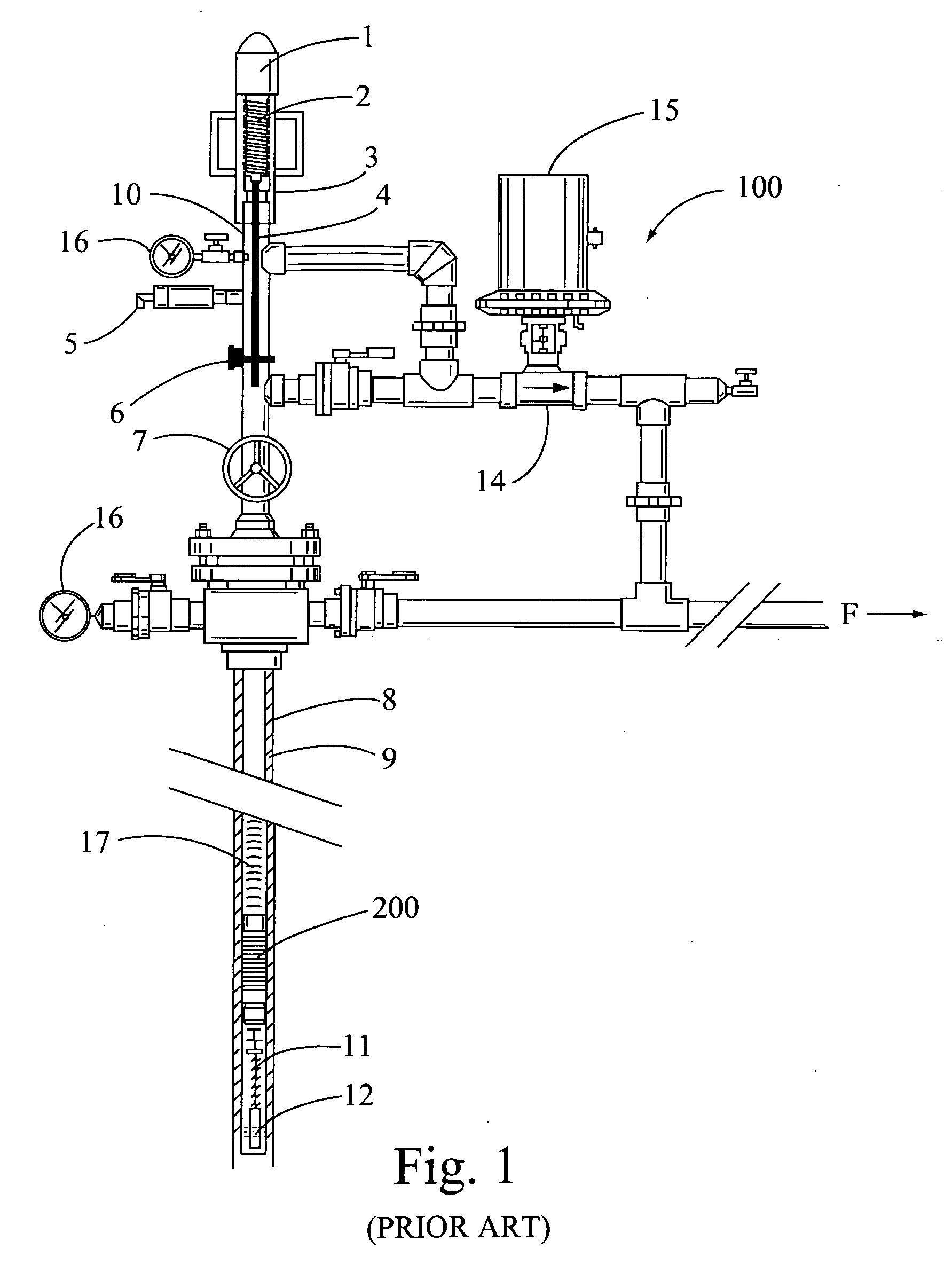

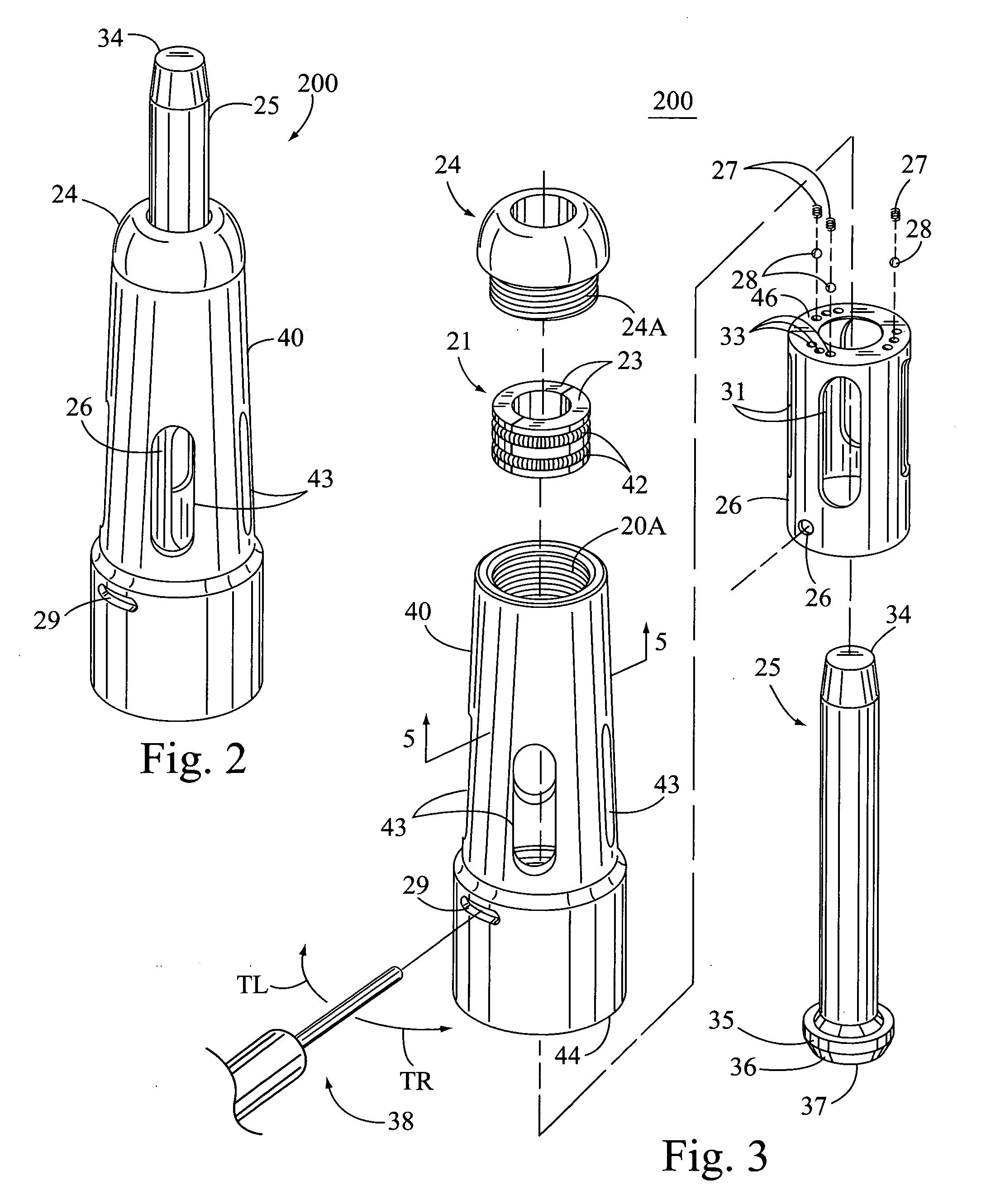

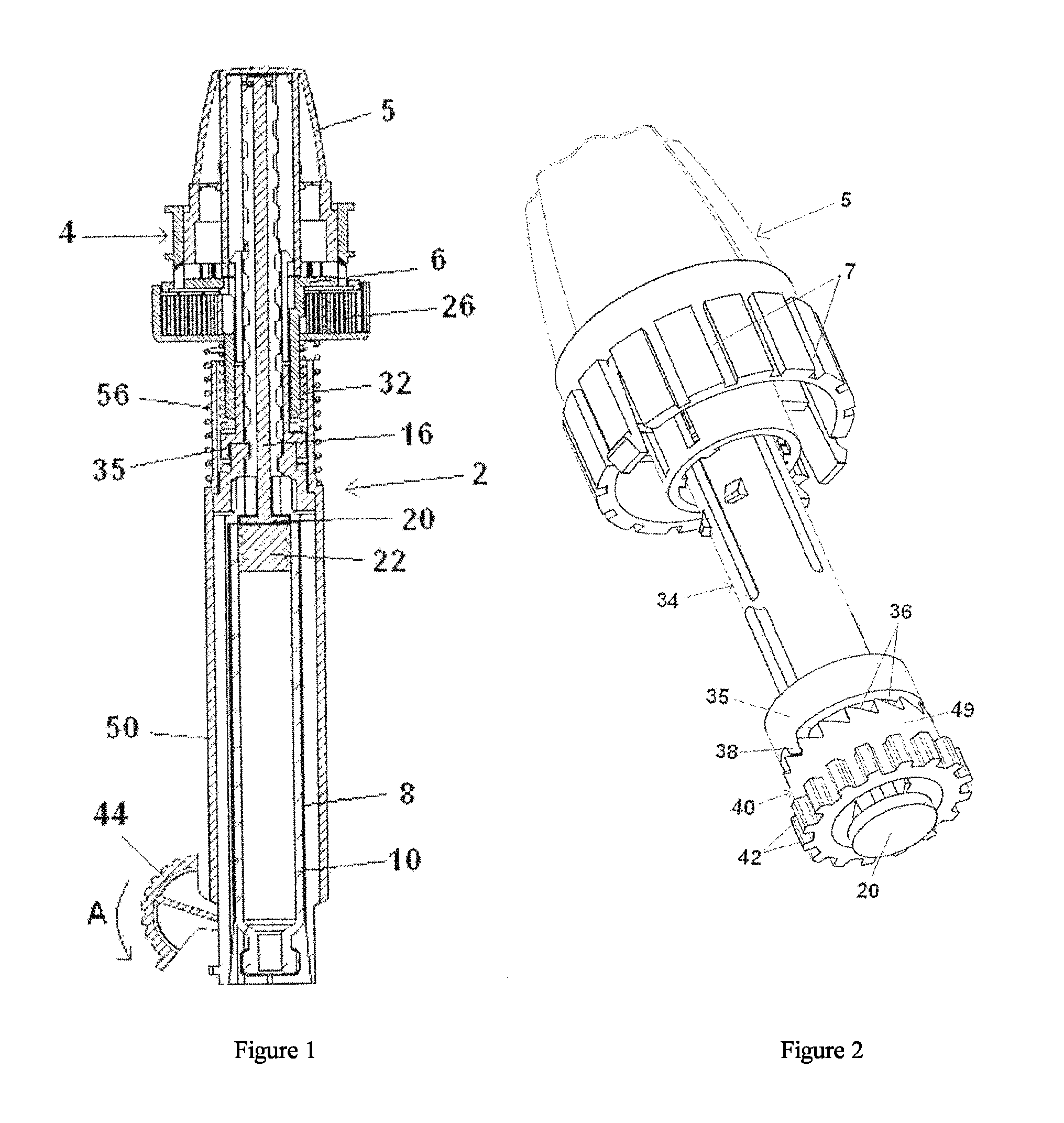

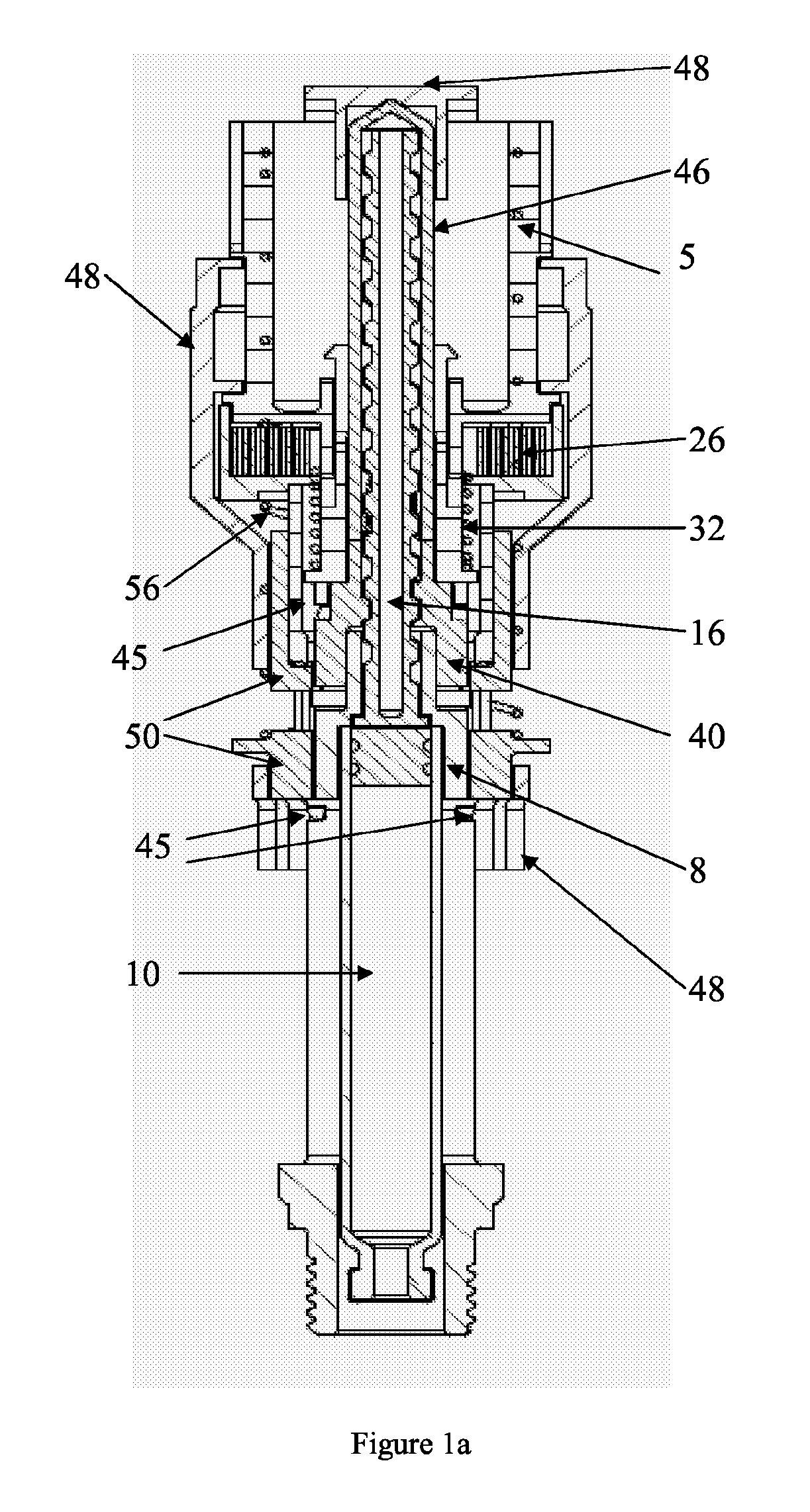

Variable orifice bypass plunger

InactiveUS20050241819A1Improve production efficiencyOptimizes well efficiencyConstructionsFluid removalEngineeringMechanical engineering

An improved plunger mechanism apparatus has a manually adjustable bypass valve to increase well flow production levels in high liquid wells. The plunger's descent rate can be fine tuned in the field by adjusting the orifice opening so that liquid can optimally flow through the plunger core during descent. Efficiency of well flow is increased by the addition of a variable bypass orifice, which can be preset in numerous positions to vary the amount of liquid bypass allowed depending on the well loading parameters. The plunger mechanism of the present invention allows numerous bypass set positions, which can be tuned at a well site and later changed as a function of future well loading parametric changes.

Owner:PCS FERGUSON

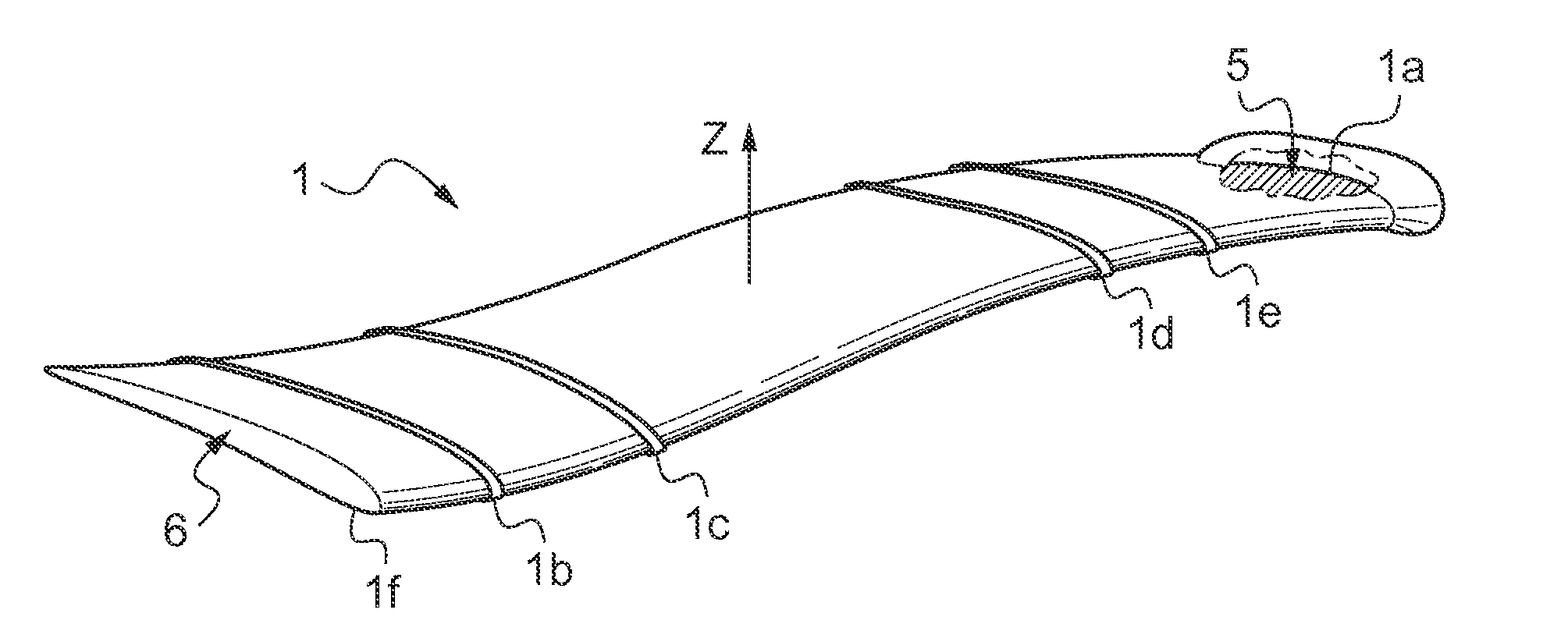

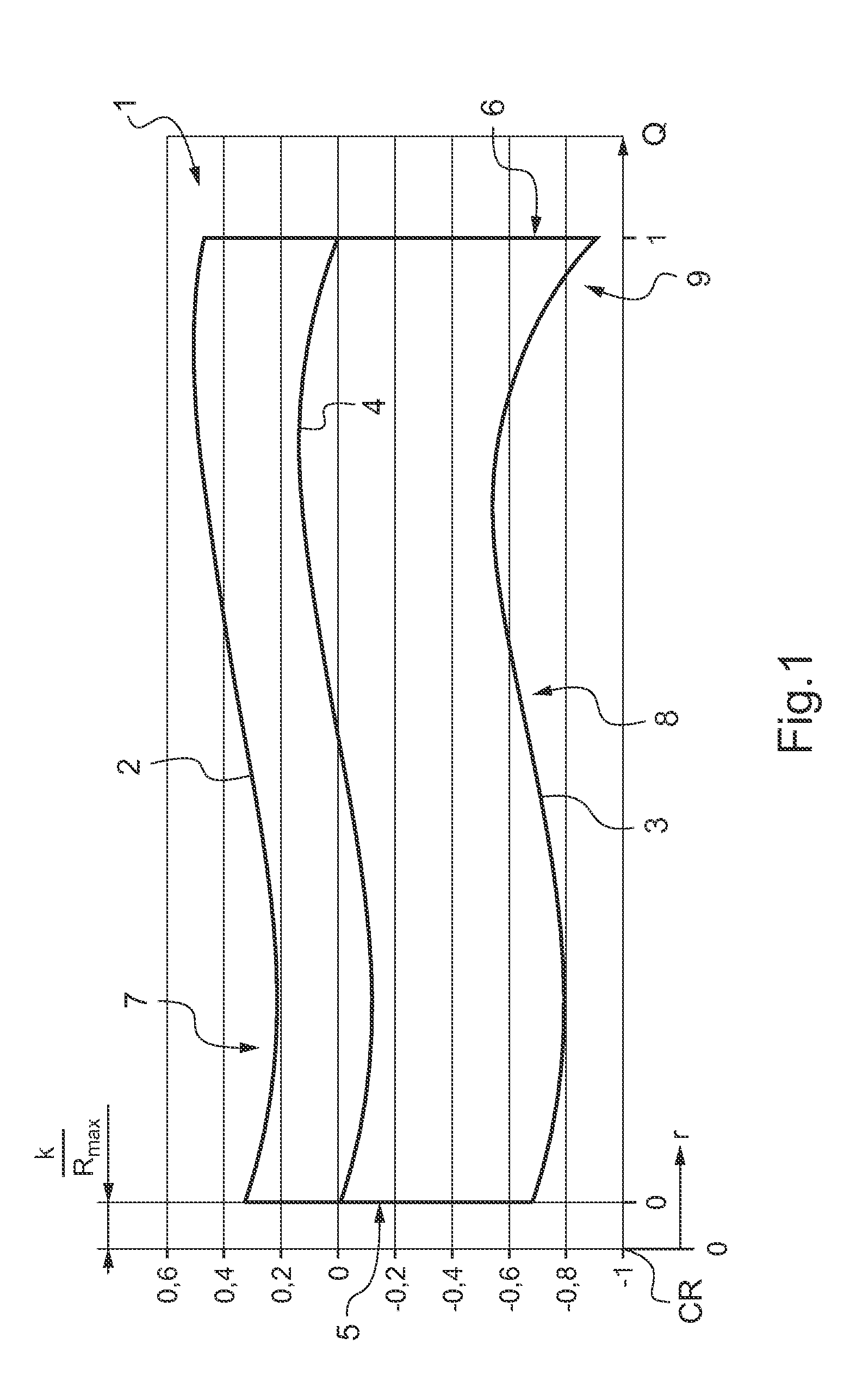

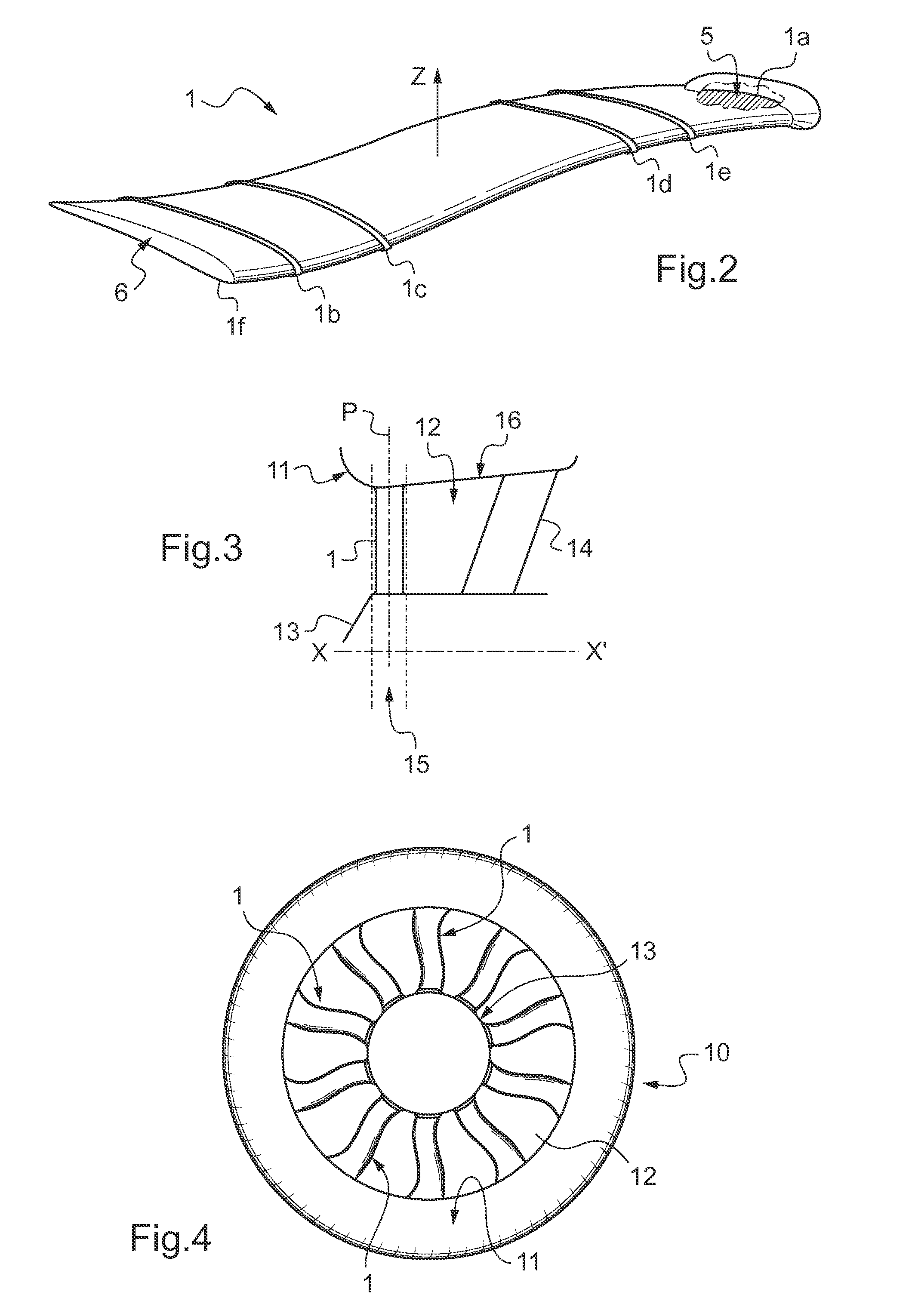

Blade for a helicopter Anti-torque device

ActiveUS20120195767A1Reduce monopole noiseIncrease thickness noisePropellersRotary propellersLeading edgeEngineering

A blade (1) for a tail anti-torque device of a helicopter, said device comprising a ducted rotor (13). The blade (1) has an assembly of sections, a leading edge (2) and a trailing edge (3); a stacking line (4) of the profiles extending at a distance lying in the range 25% to 50% of the chord (C). The stacking line (4) presents a shape that is curved having successively from the root (5) to the end (6) of the blade a back sweep, a forward sweep, and a last back sweep; and a chord (C) that becomes larger going towards the end (6) of the blade (1) over at least the end profile (1a).

Owner:EUROCOPTER

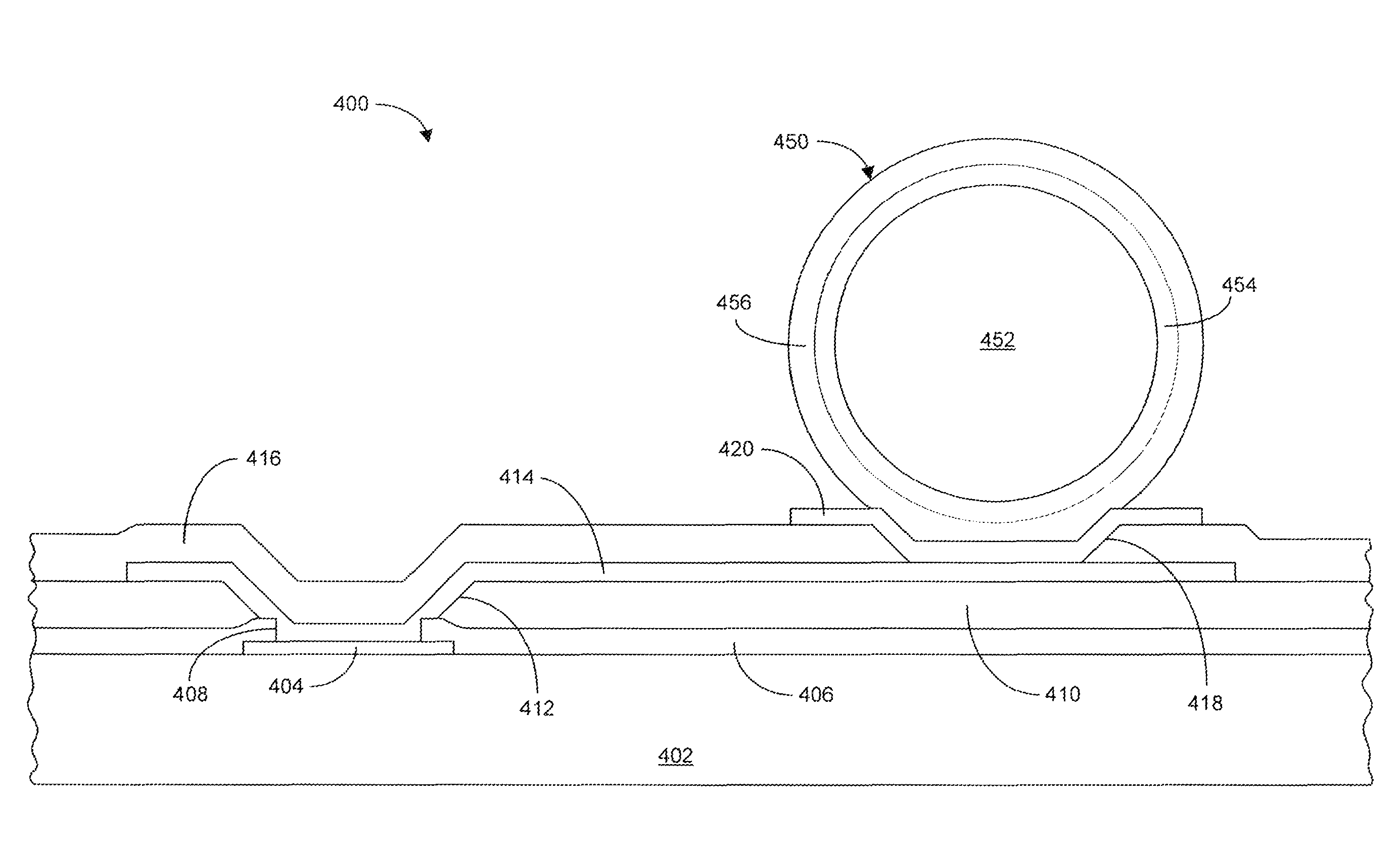

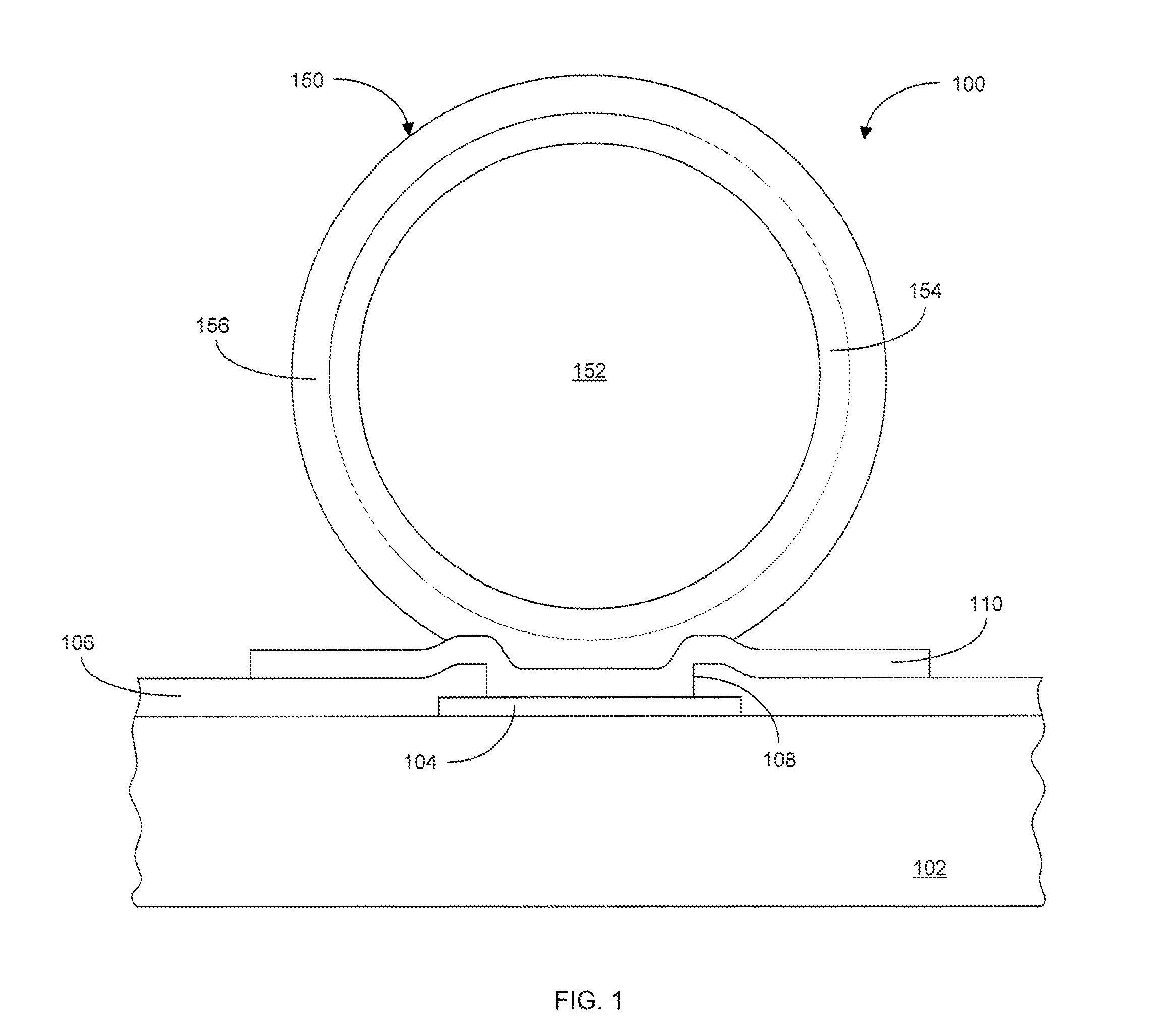

Wafer level package integrated circuit incorporating solder balls containing an organic plastic-core

ActiveUS8035226B1Increase resistanceHigh elongationSemiconductor/solid-state device detailsSolid-state devicesHigh resistanceElectrical resistance and conductance

An integrated circuit including solder balls containing an elastic or resilient material core, a hard or rigid shell substantially enclosing the core, and an electrical contact layer substantially enclosing the shell. The elastic or resilient core serves as a stress buffer layer in a wafer level package (WLP) integrated circuit. The elastic or resilient material core may include an organic plastic material, such as a Divinilbenzene cross-linked co-polymer of relatively high resistance. This material has a relatively good elongation property so that it can effectively absorb forces exerted upon the integrated circuit by, for example, the flexing of a printed circuit board (PCB) or other structure to which the integrated circuit is attached. The hard or rigid shell serves to contain the elastic or resilient core and may include copper. The electrical contact layer serve to provide a good adhesive electrical contact to an under bump metallization (UBM) layer, may include a lead free, Tin-Gold (SnAg) material.

Owner:MAXIM INTEGRATED PROD INC

Headgear having a camera device

InactiveUS20140304891A1Effectively disengages spring forceEliminate the effects ofHatsHeadwear capsEngineeringViewfinder

Headgear is described herein having a camera device mounted to a brim thereof and accessories therefor. The camera device can include a viewfinder, such as a pivoting viewfinder or a viewfinder having a ball-and-socket mounting joint. The frame of reference of the camera device can be indicated to a wearer of the headgear with sighting members mounted to the brim.

Owner:WATERS MICHAEL

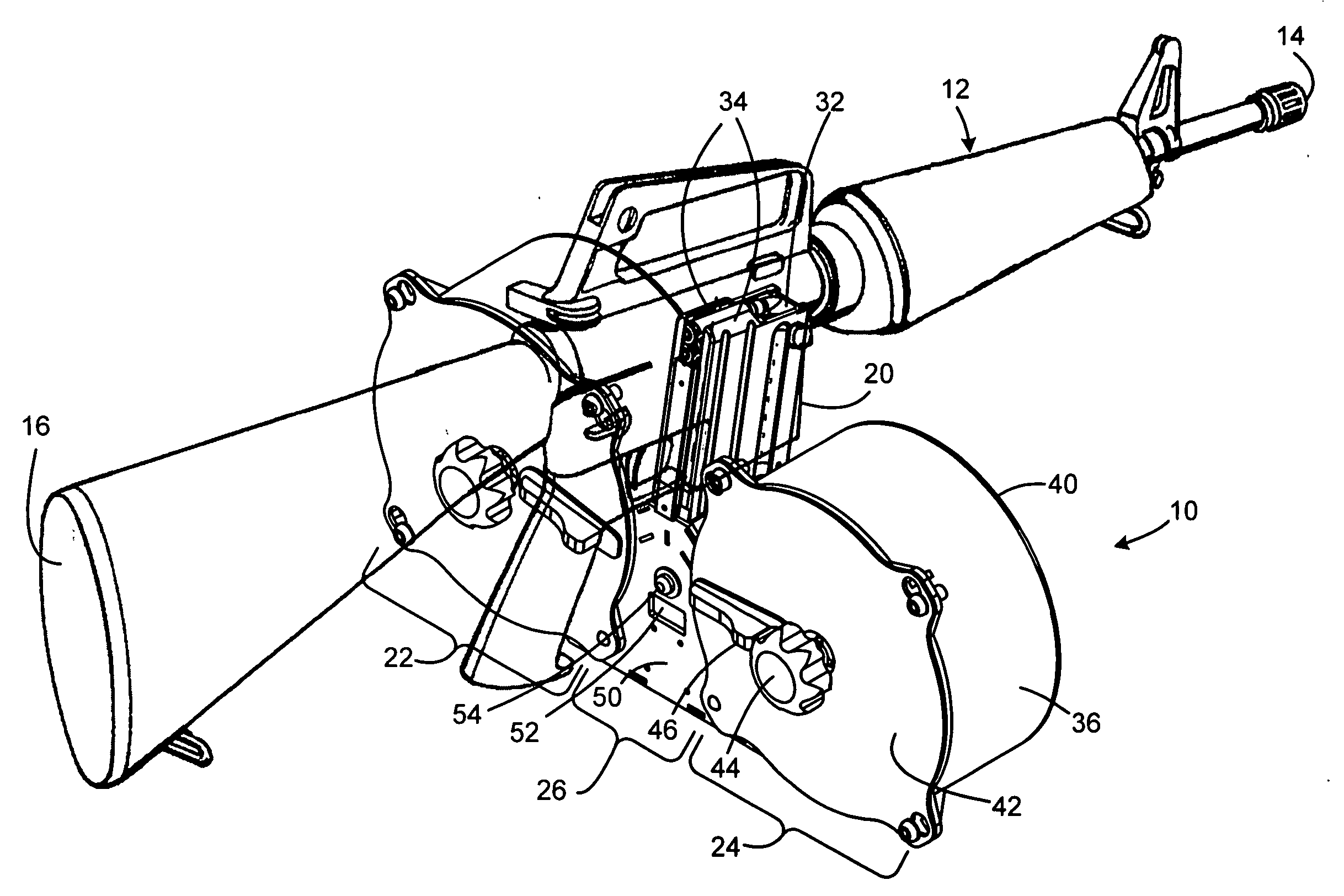

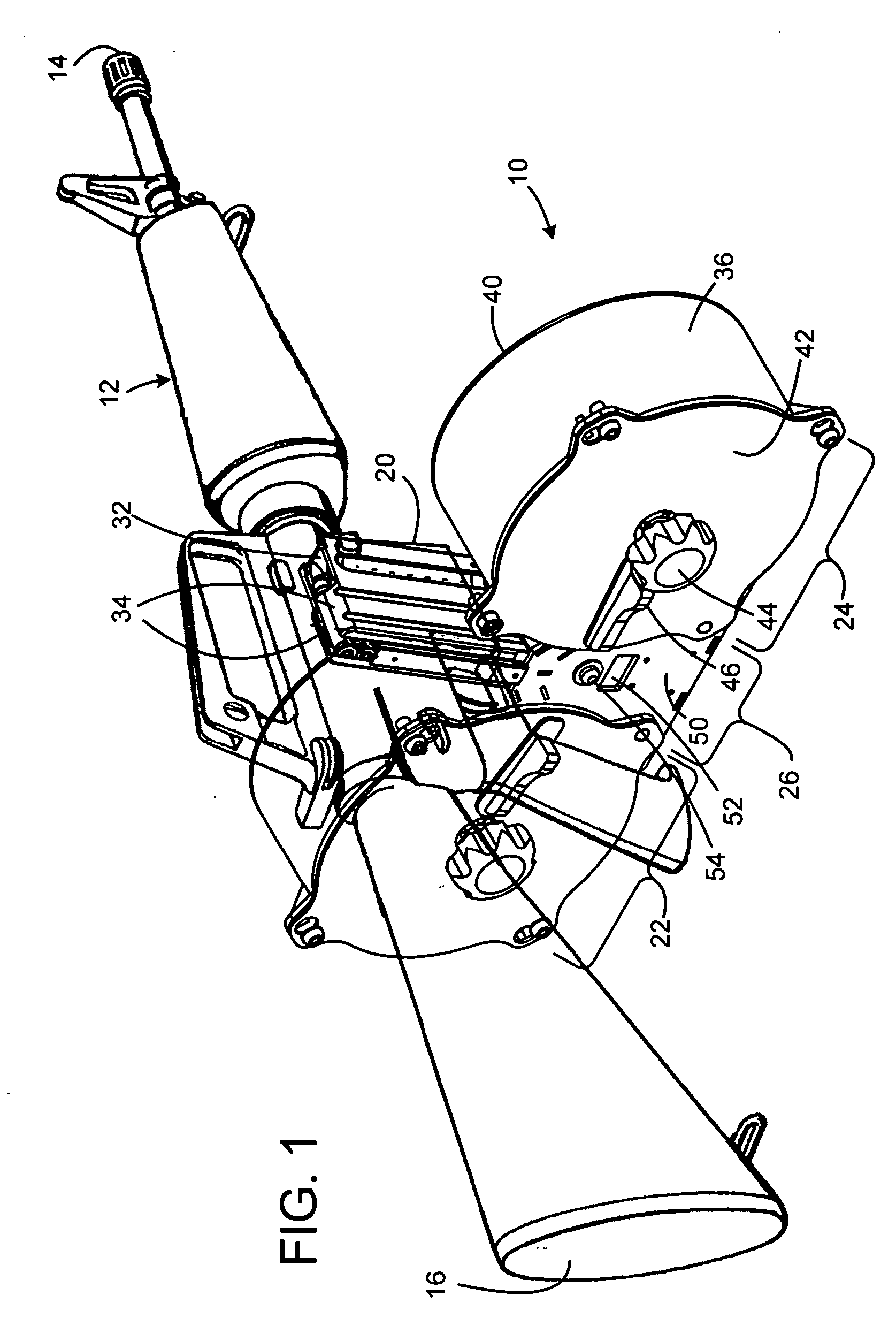

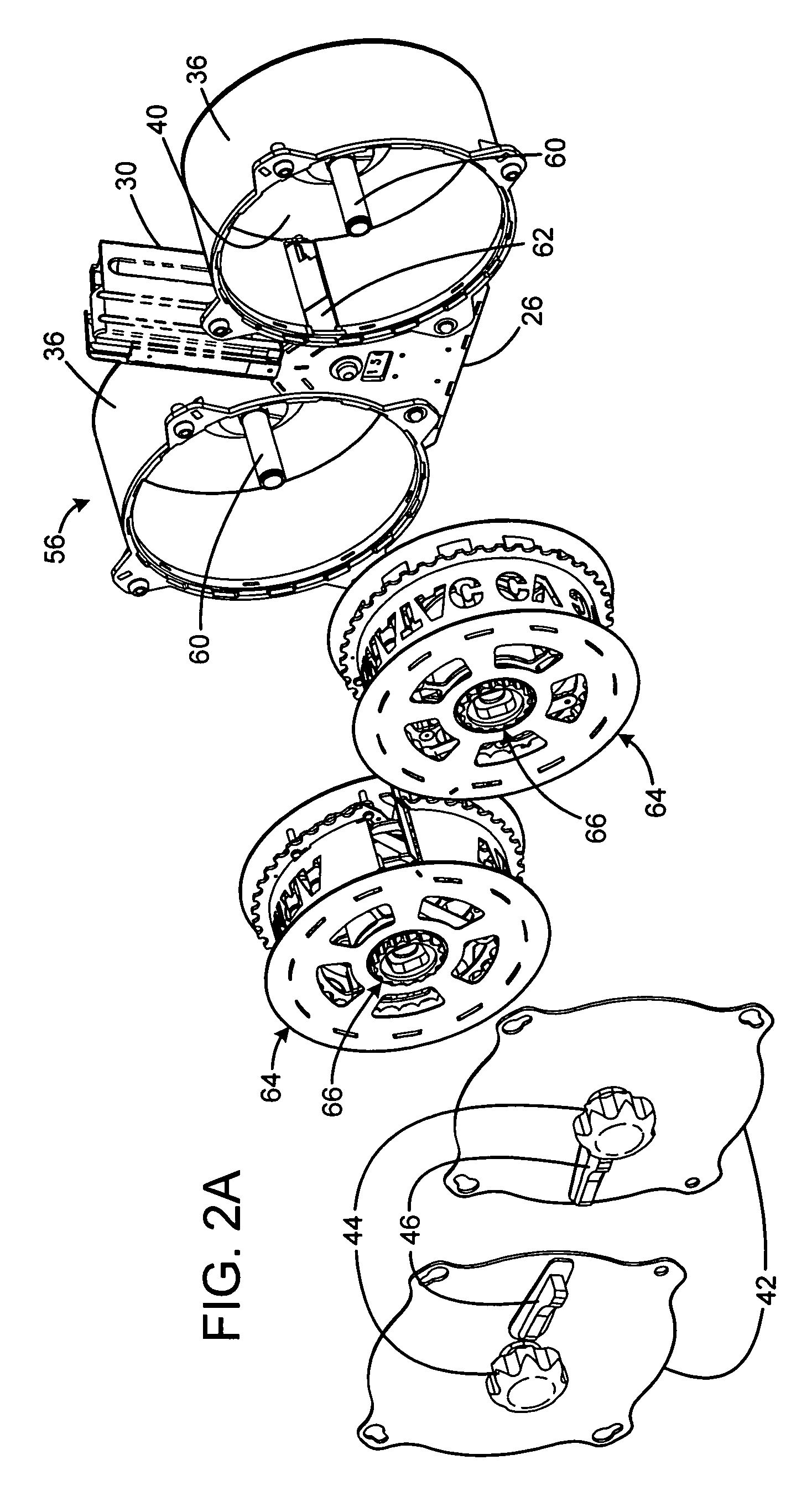

Drum magazine for firearm

ActiveUS20070107592A1Avoid small quantitiesSmall armBreech mechanismsAmmunition loadingEngineeringSprocket

A detachable magazine for storing and delivering ammunition to a firearm having a magazine well. The magazine has a body with a column adapted for insertion into the magazine well. The column has a passage for transmitting ammunition to the firearm. The body includes a drum housing defining a substantially cylindrical chamber communicating with the column passage. A first sprocket element is rotatably received in the chamber and has a serrated periphery, with each serration adapted to receive an ammunition cartridge. A second sprocket element is rotatably received in the chamber, and is concentric with the first sprocket element, having a serrated periphery with each serration adapted to receive an ammunition cartridge. A spring element is connected to at least one of the sprocket elements, and operates to rotatably bias the sprocket elements to transmit cartridges from the drum chamber to the column passage. The magazine may have a pair of drums, and the sprockets may be tapered, to facilitate feeding of tapered cartridges. The magazine may include a counter to indicate the quantity of ammunition consumed or remaining. The magazine may include the ability to power and de-power spring motor.

Owner:ARMATAC INDS

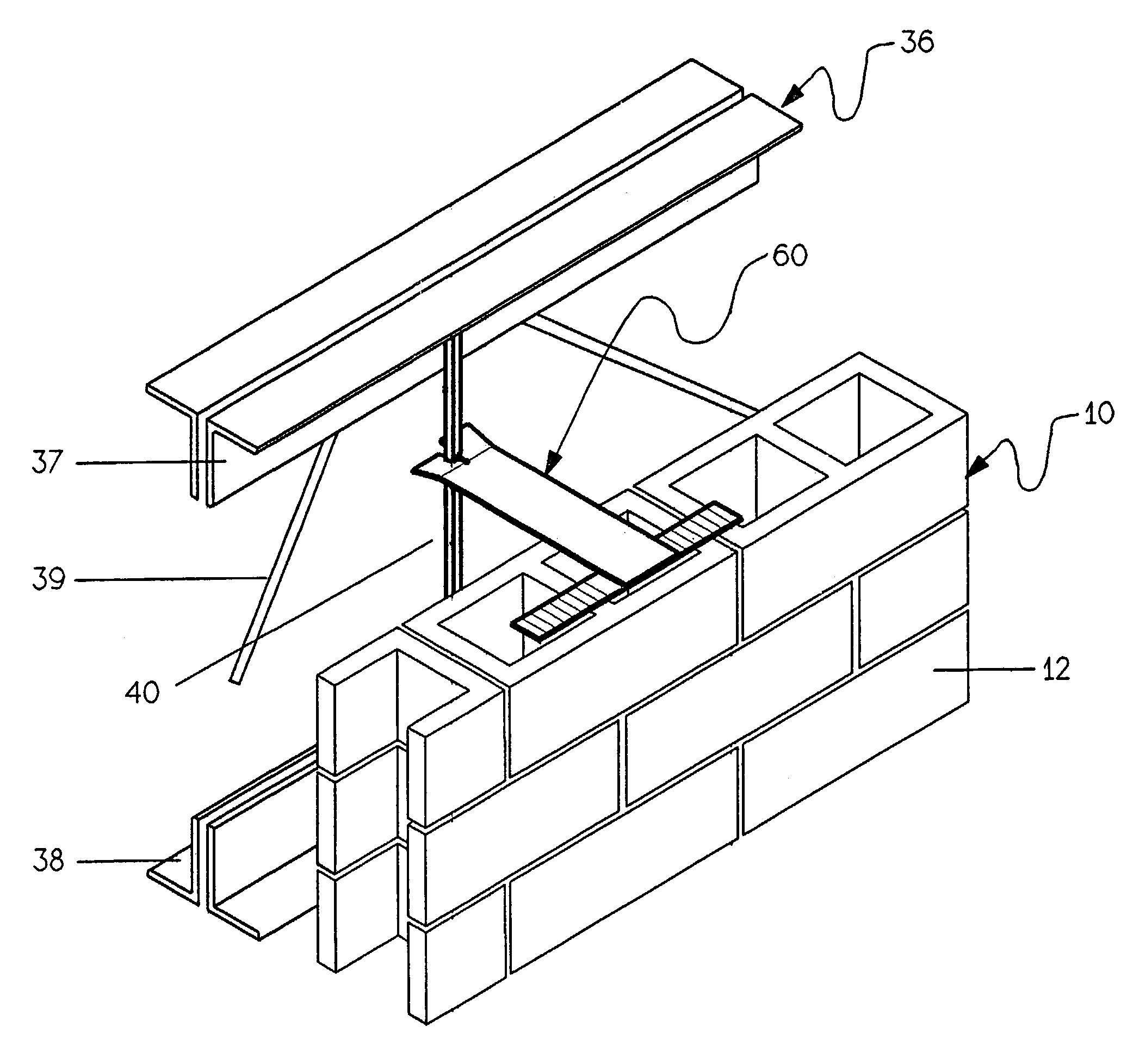

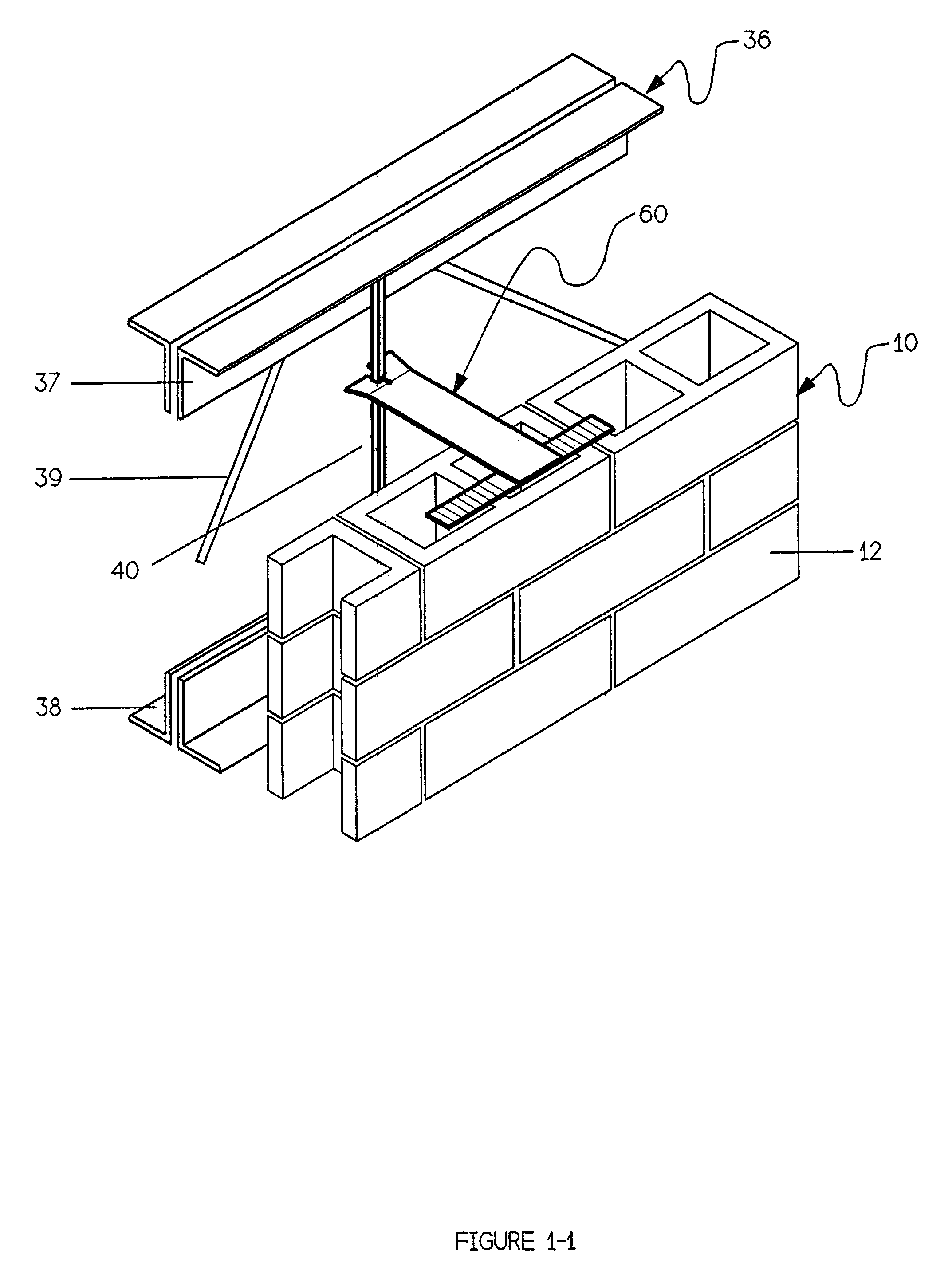

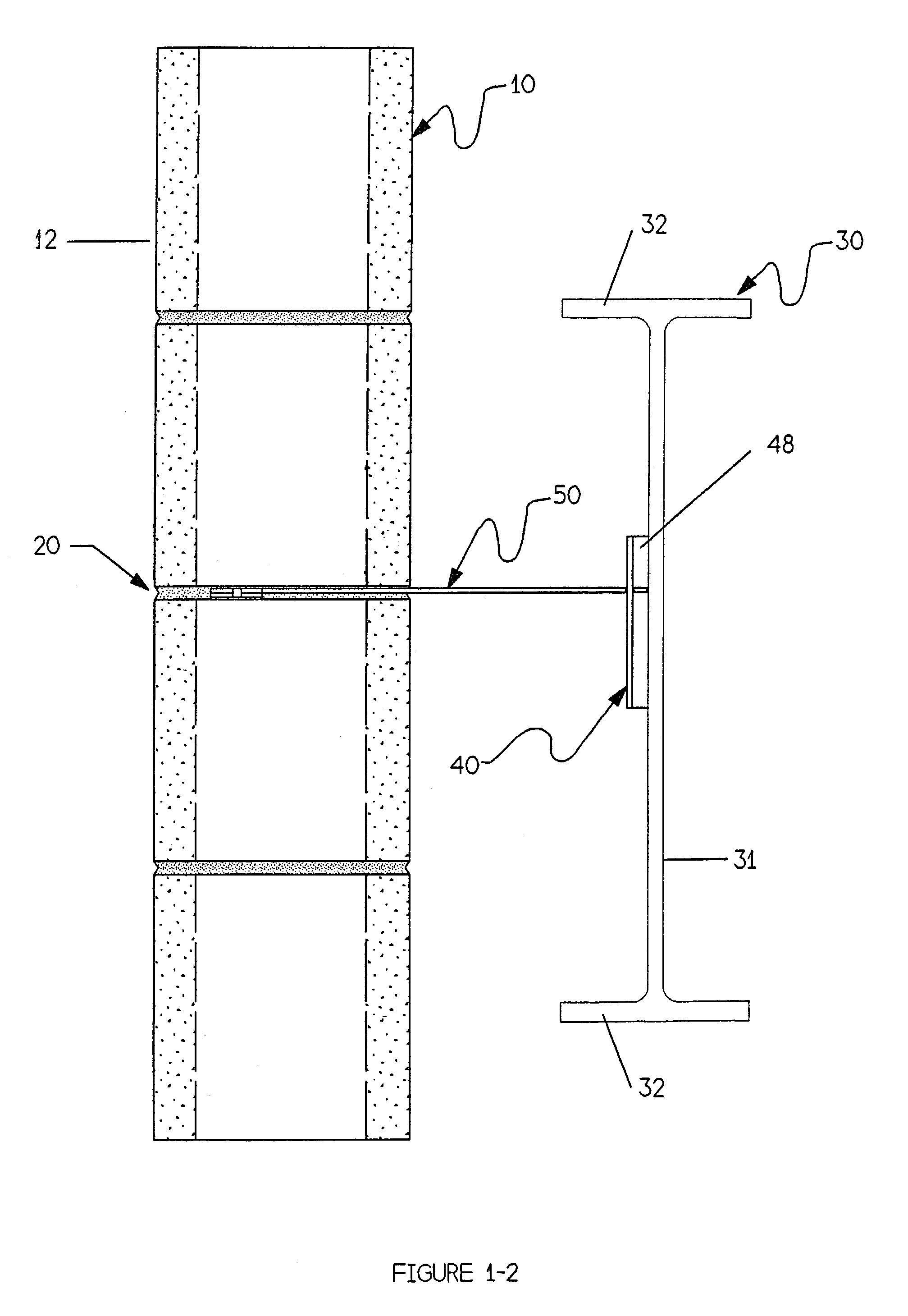

Masonry connectors and twist-on hook and method

InactiveUS7171788B2Effective forceCompensation differenceConstruction materialBuilding repairsEngineeringMultiple point

A connecting device for joining a wall to a building frame, or for joining walls, comprises a hook member. The frame can comprise steel beams, or also comprise a truss having an open web, and a slide rail attached to the truss' chords in a generally plumb orientation. Embodiments of the hook member substantially encircle one or more slide rails and thereby retain the rails. Other embodiments fit within a channel attached to solid steel webs, or concrete frames. The device's other end is positioned over a course of masonry units, and when embedded in mortar, the cells of the masonry units do not require grouting. Other connecting device embodiments comprise an anchor member securely joined to the member, the connecting device providing multiple points of attachment with the masonry, or multiple members joined to the anchor member. The connecting device can be used for new construction, and in renovations using currently existing steel and concrete frames.

Owner:BRONNER JOSEPH

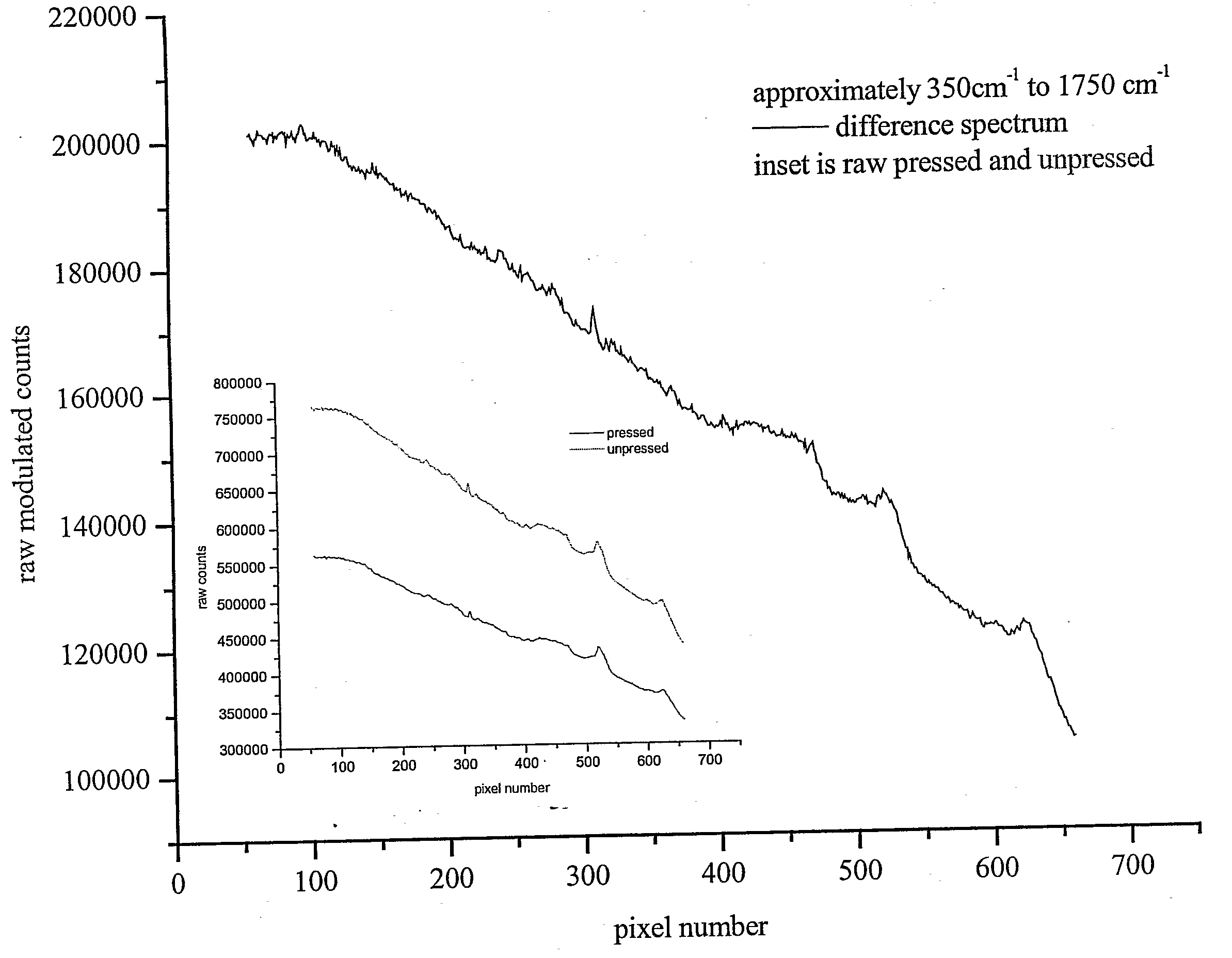

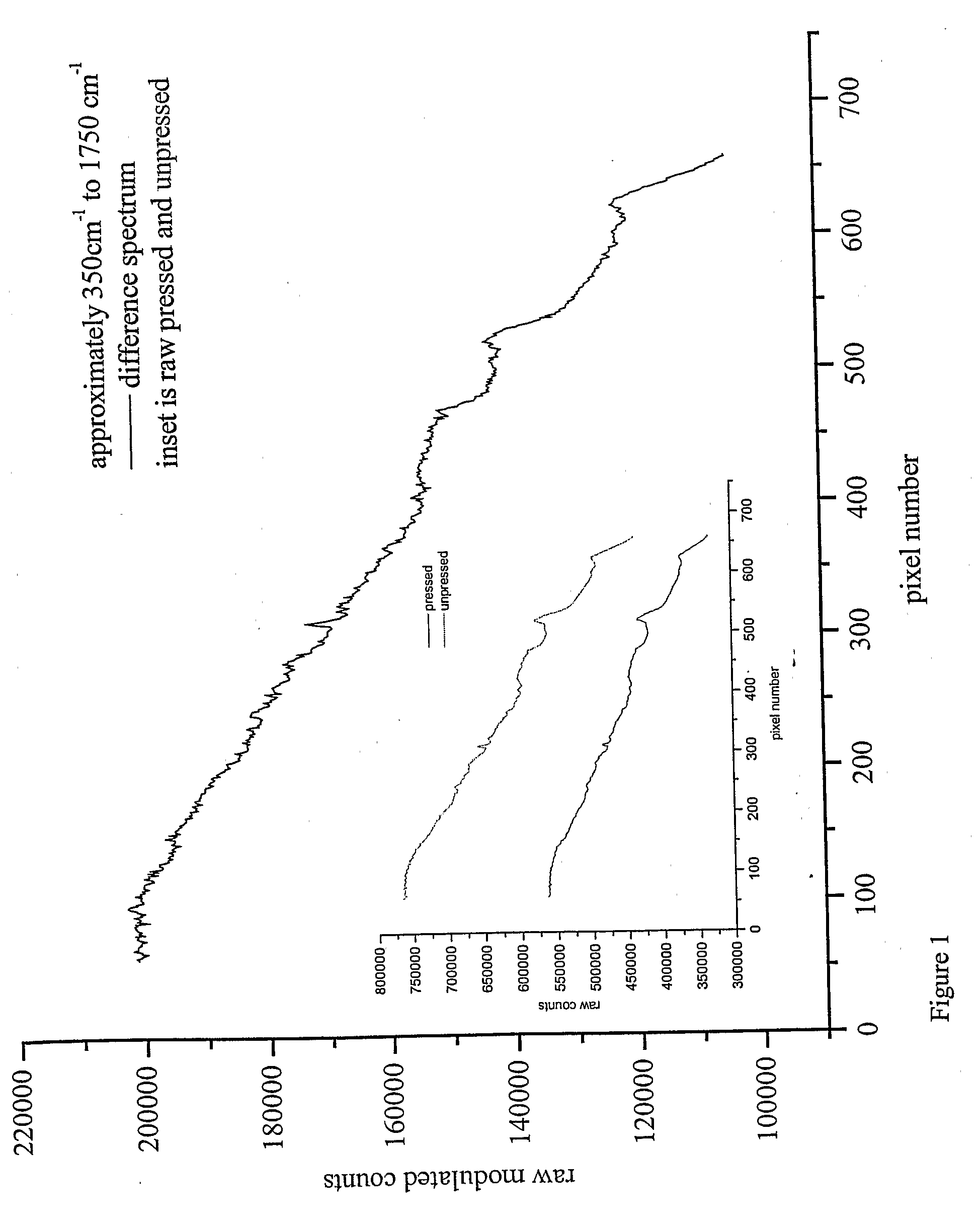

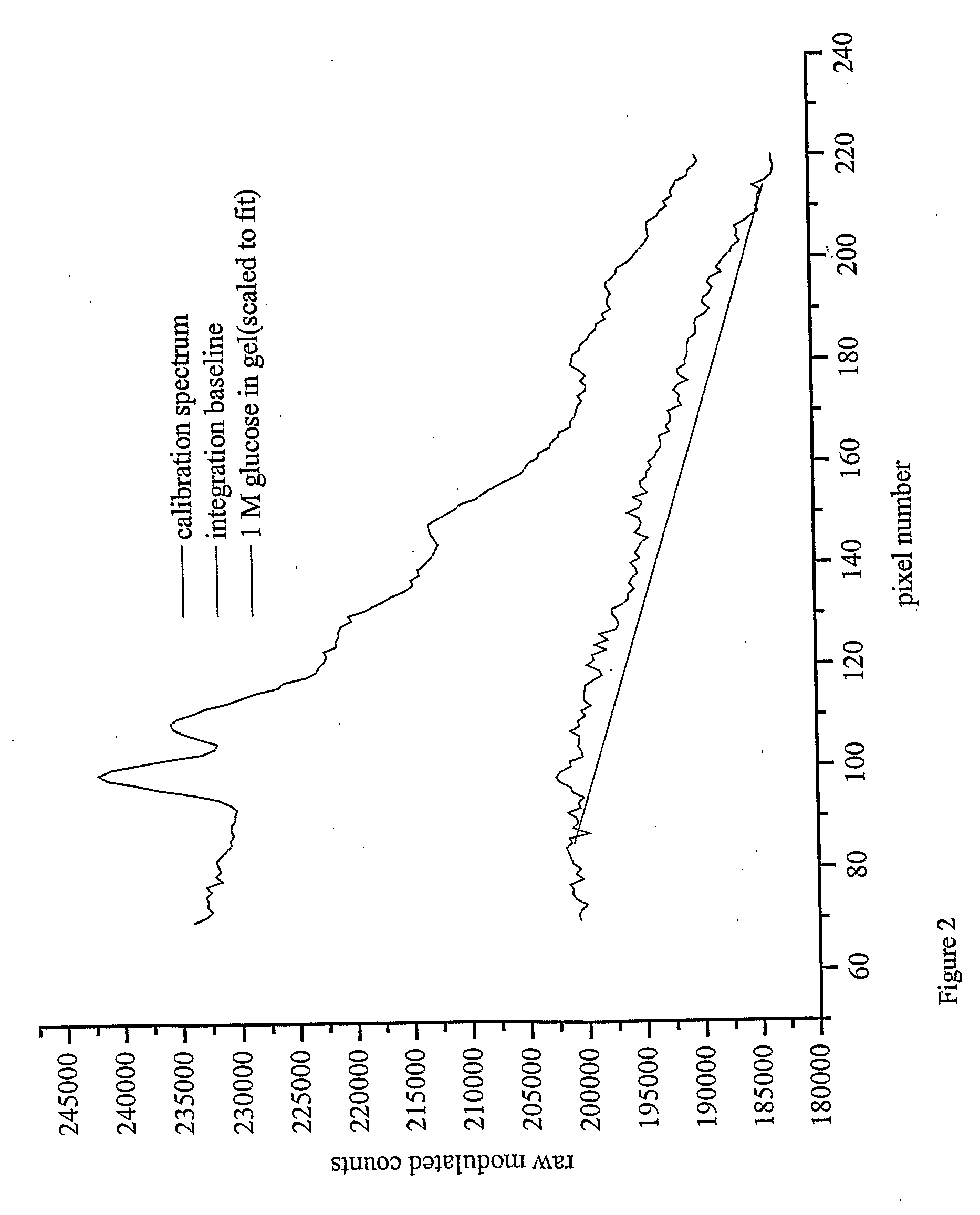

Specialized Human Servo Device And Process For Tissue Modulation Of Human Fingerprints

InactiveUS20080306363A1Facilitate optimal placementEasy to installDiagnostics using lightSensorsAnalyteEngineering

Apparatus and methods for noninvasive spectroscopic measurement of an analyte in a subject that have been optimized for producing uniform and repeatable tissue modulation across test subjects and for the same test subject on different occasions are provided. The apparatus comprises an ergonomically shaped grip that substantially conforms to a subject's hand; a surface for placement of at least one of the subject's fingertips upon grasping the grip; and an optically transparent aperture, or a plurality of apertures, disposed within the surface. A modification to the surface of the apparatus adjacent to the aperture that is detectable via the tactile sense of the subject can be added to provide tactile feedback to the subject to guide correct placement of the fingertip over the aperture. The apparatus and methods can also incorporate feedback methods to guide and optimize placement and conditions of the fingertip to further improve accuracy of measurements.

Owner:LIGHTOUCH MEDICAL

Power generation system

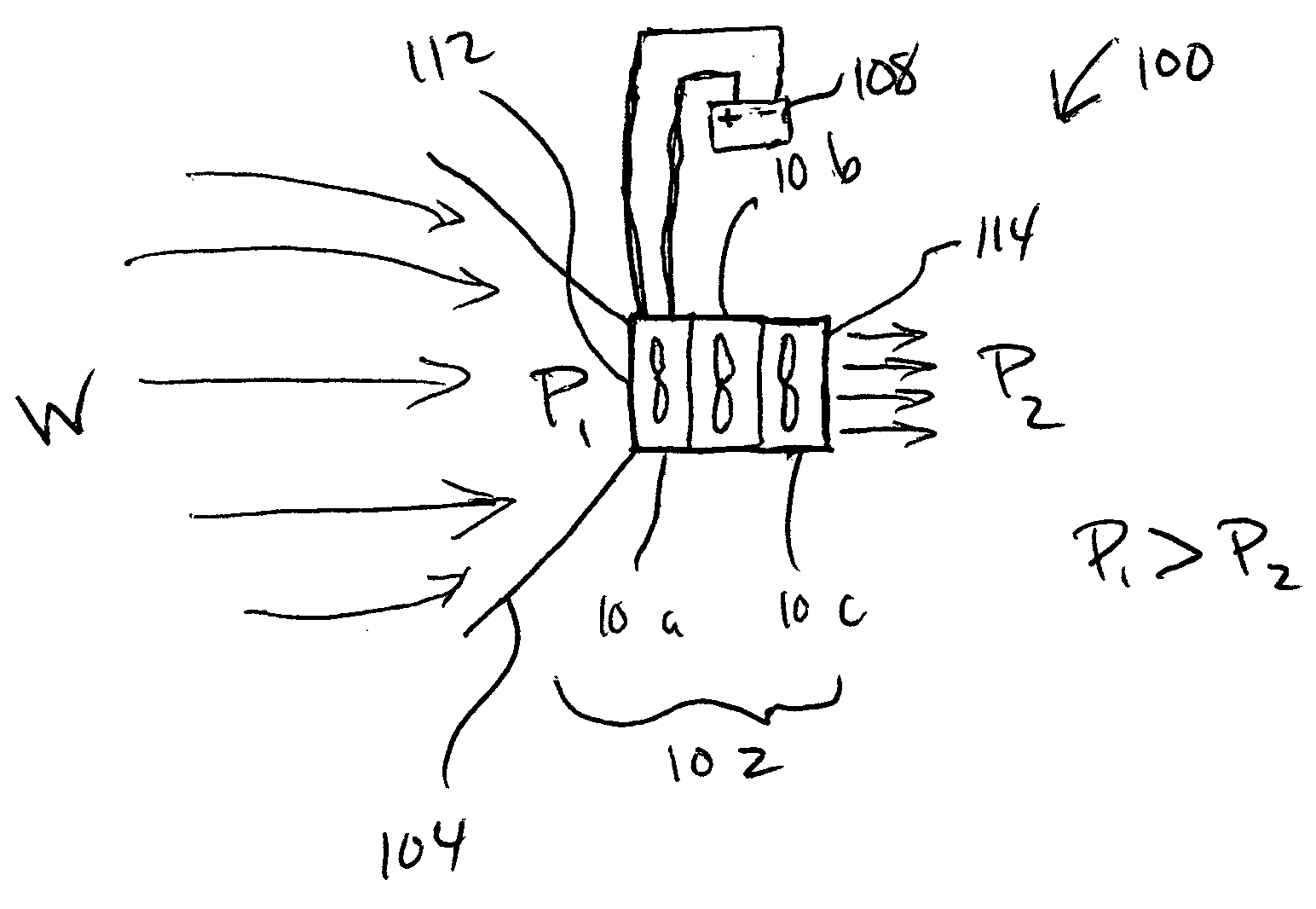

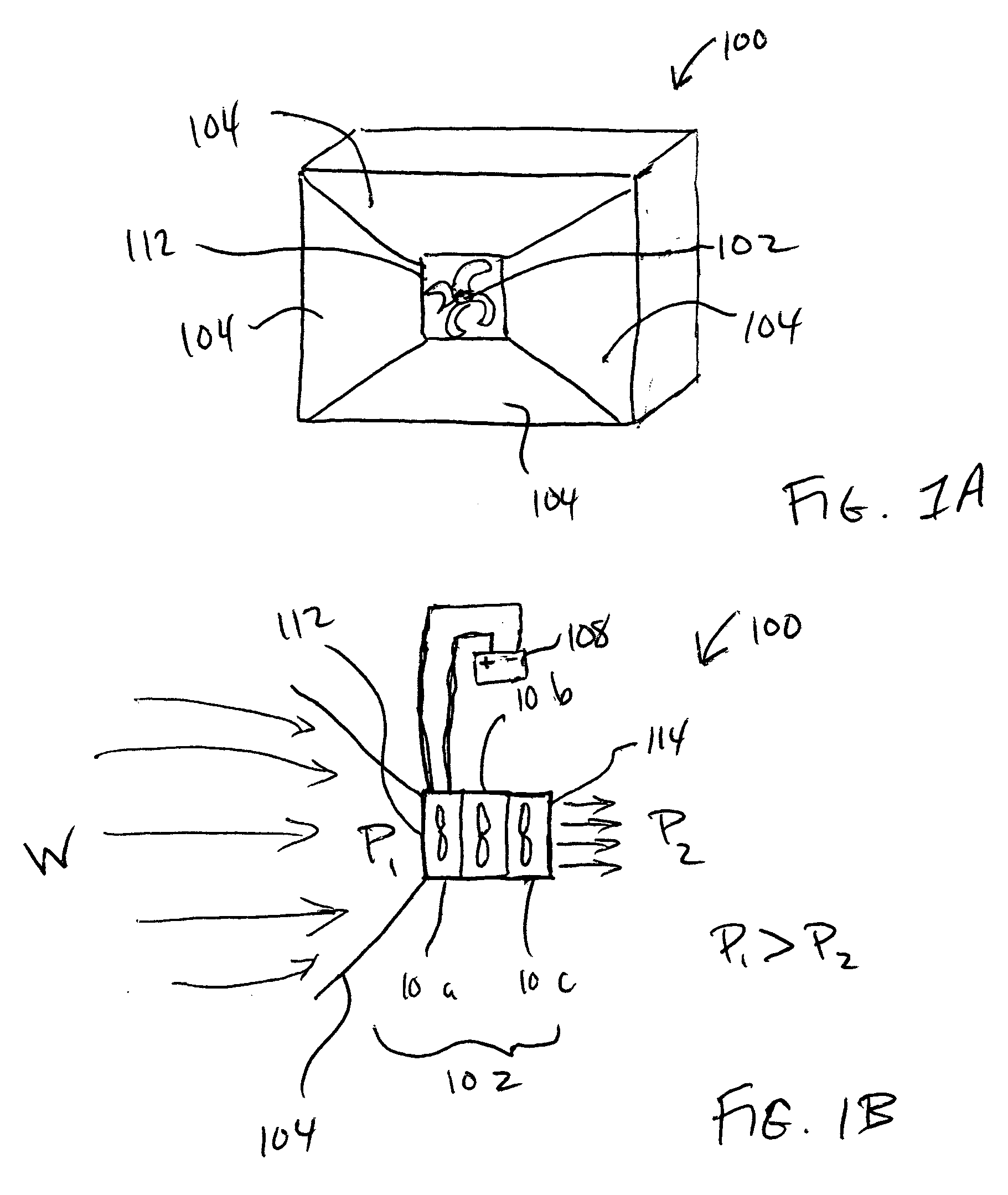

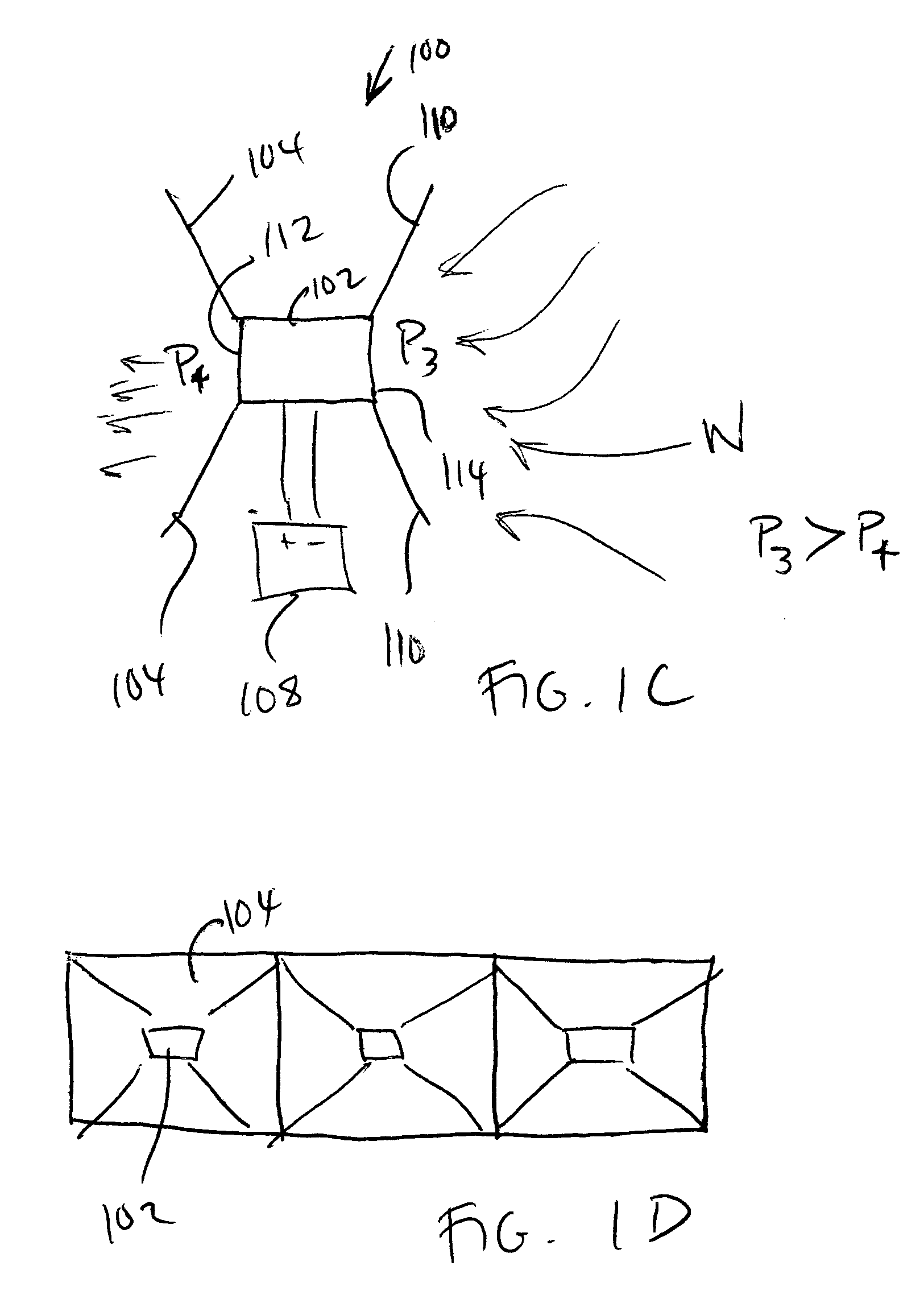

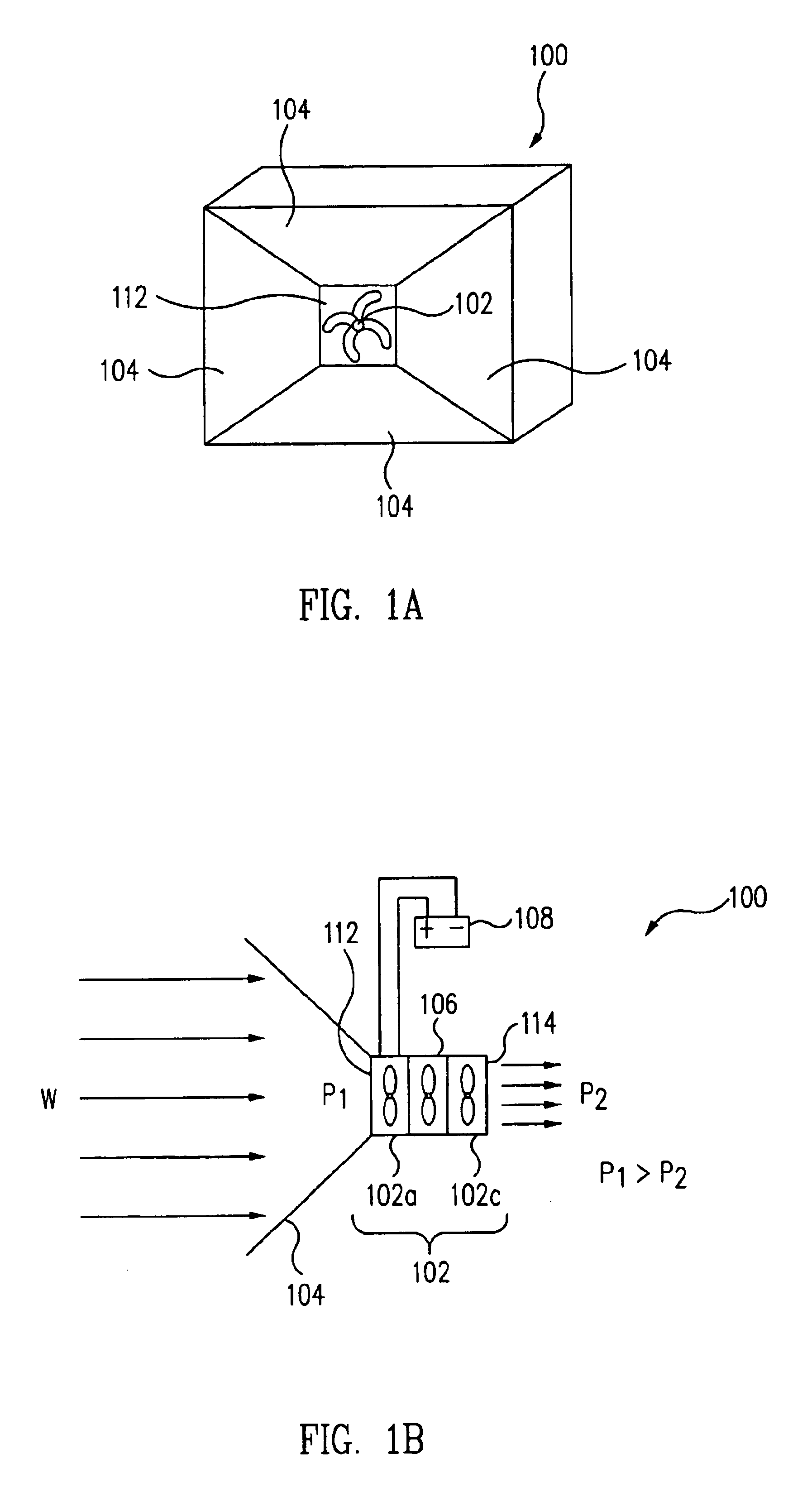

InactiveUS20050074324A1Effective and reliableEffective forcePropellersWind motor controlElectricityEngineering

A wind power system is provided including at least one motor fan having a front face and a rear face. The system also includes a first wind capturing device positioned proximate to the front face. The wind capturing device can be configured to capture wind to create a first pressure proximate to the front face that is greater than a second pressure proximate to the rear face. The pressure difference causes the captured wind to flow across the at least one motor fan from the front face to the rear face.

Owner:WAFERMASTERS

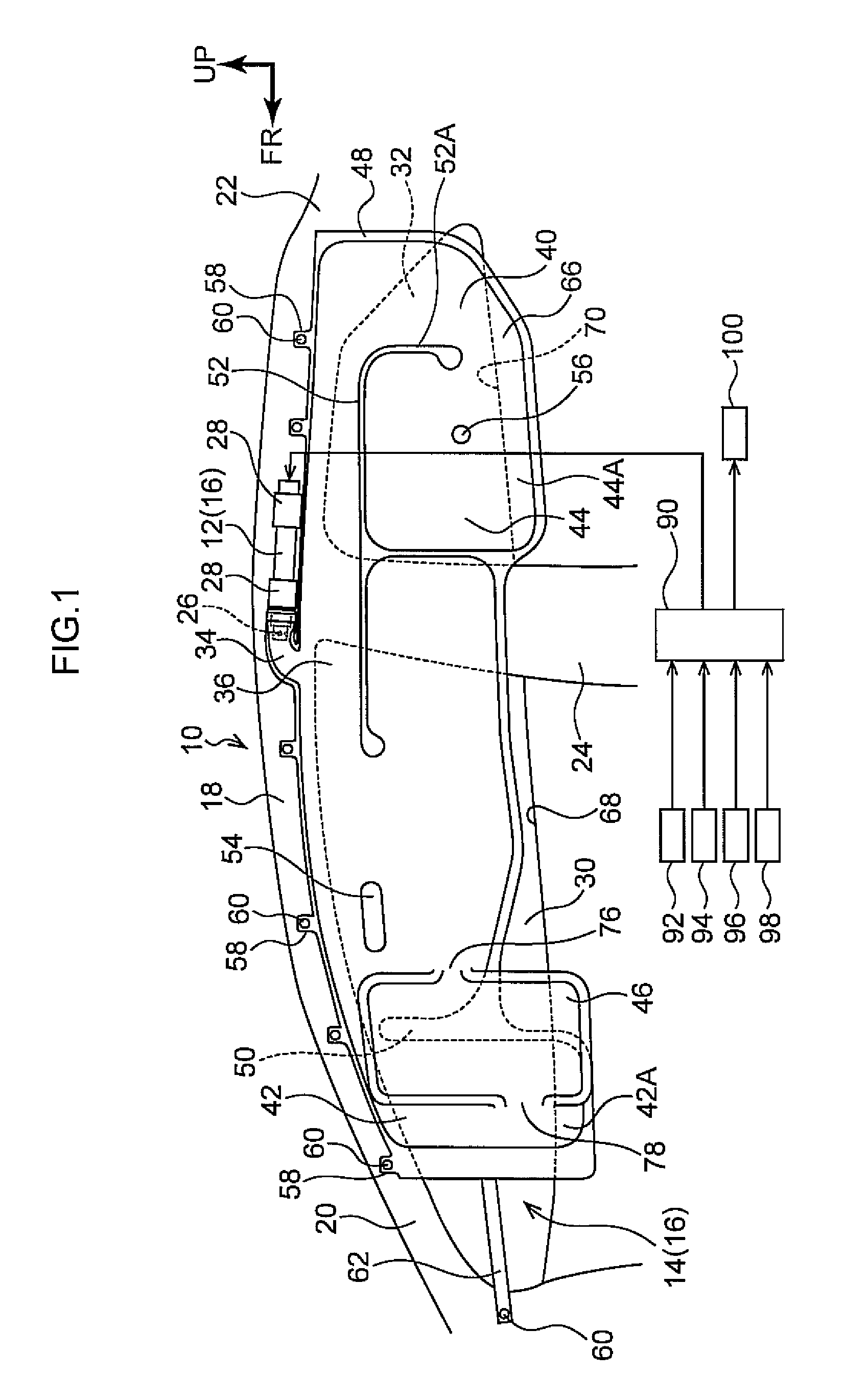

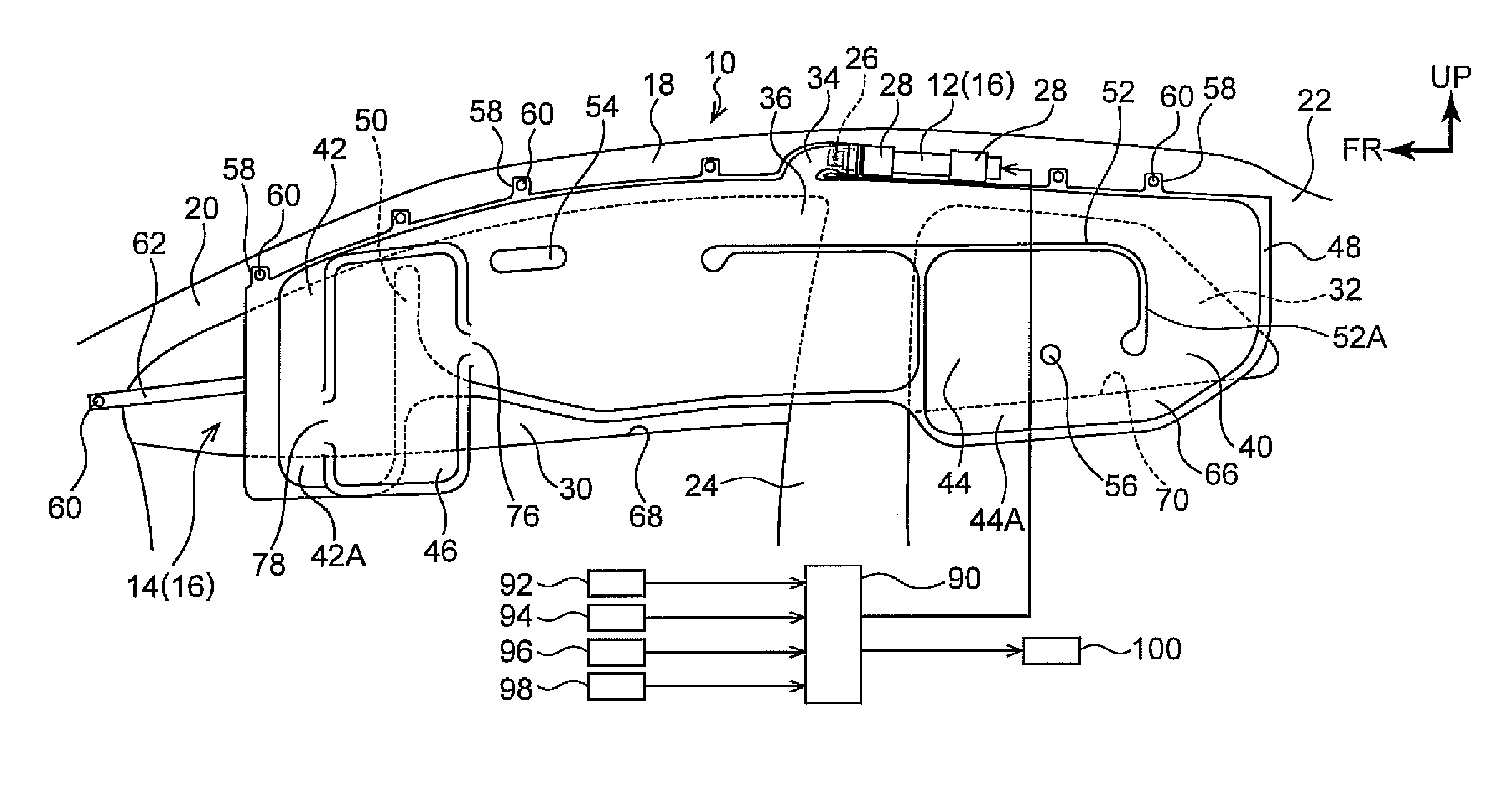

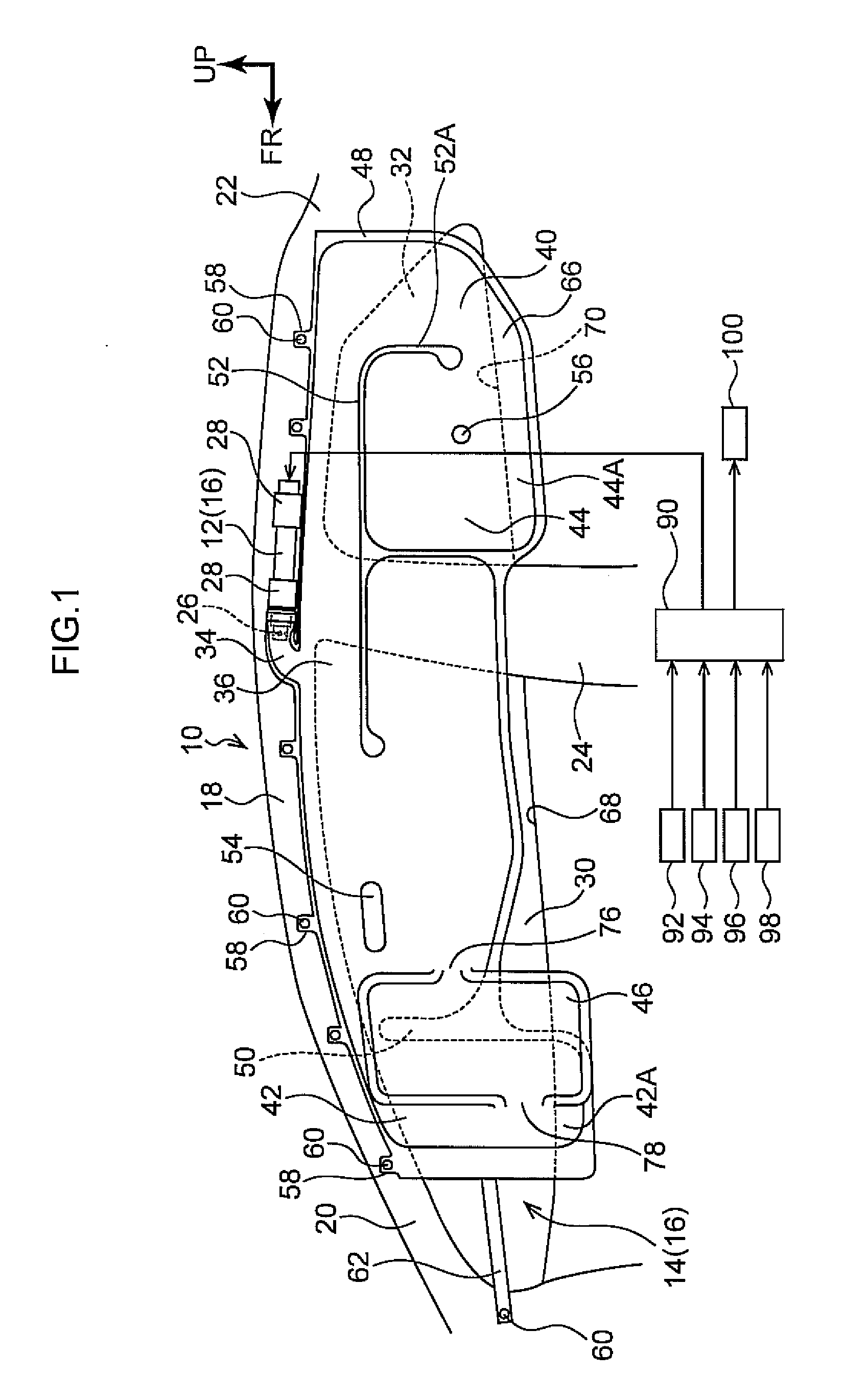

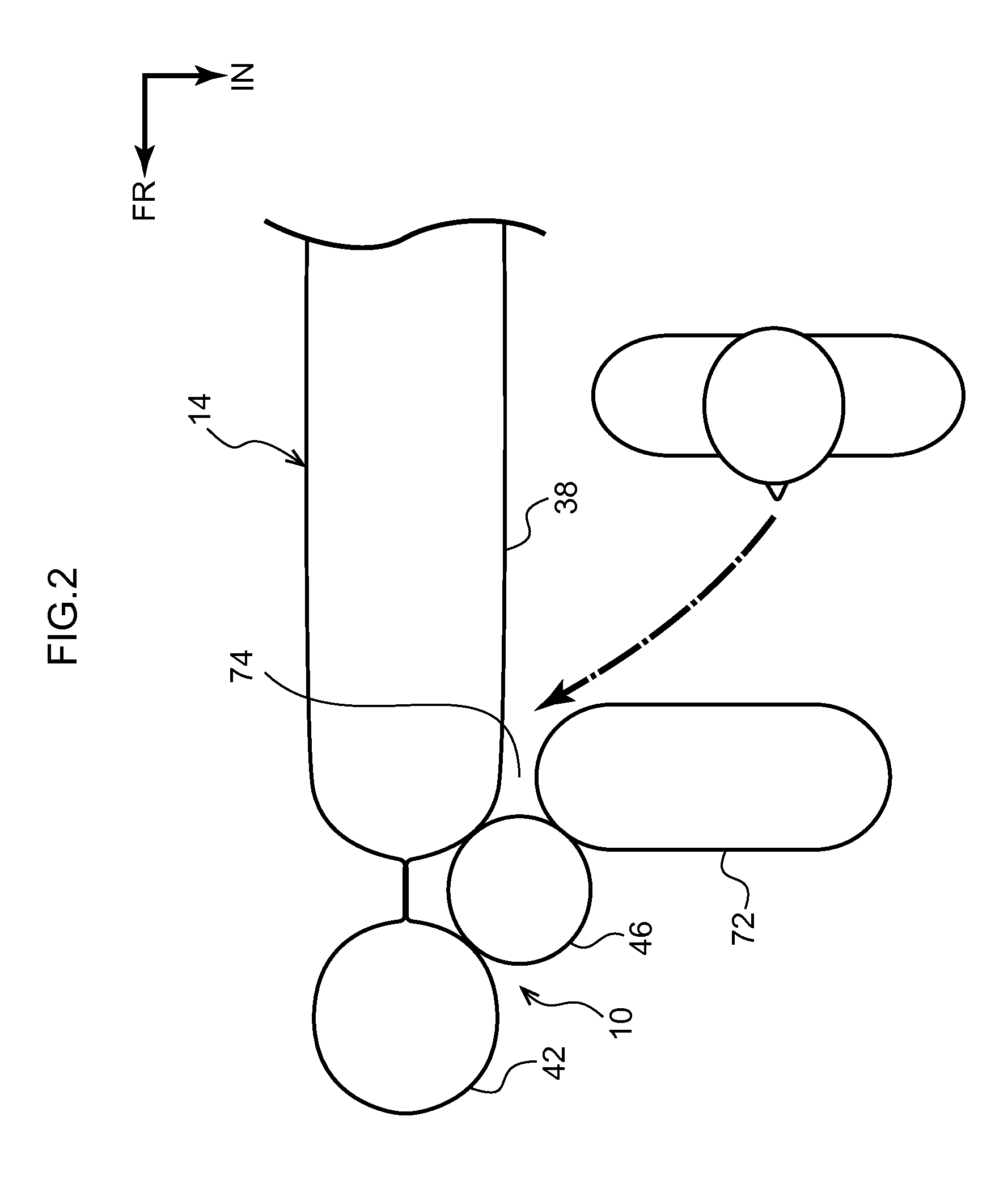

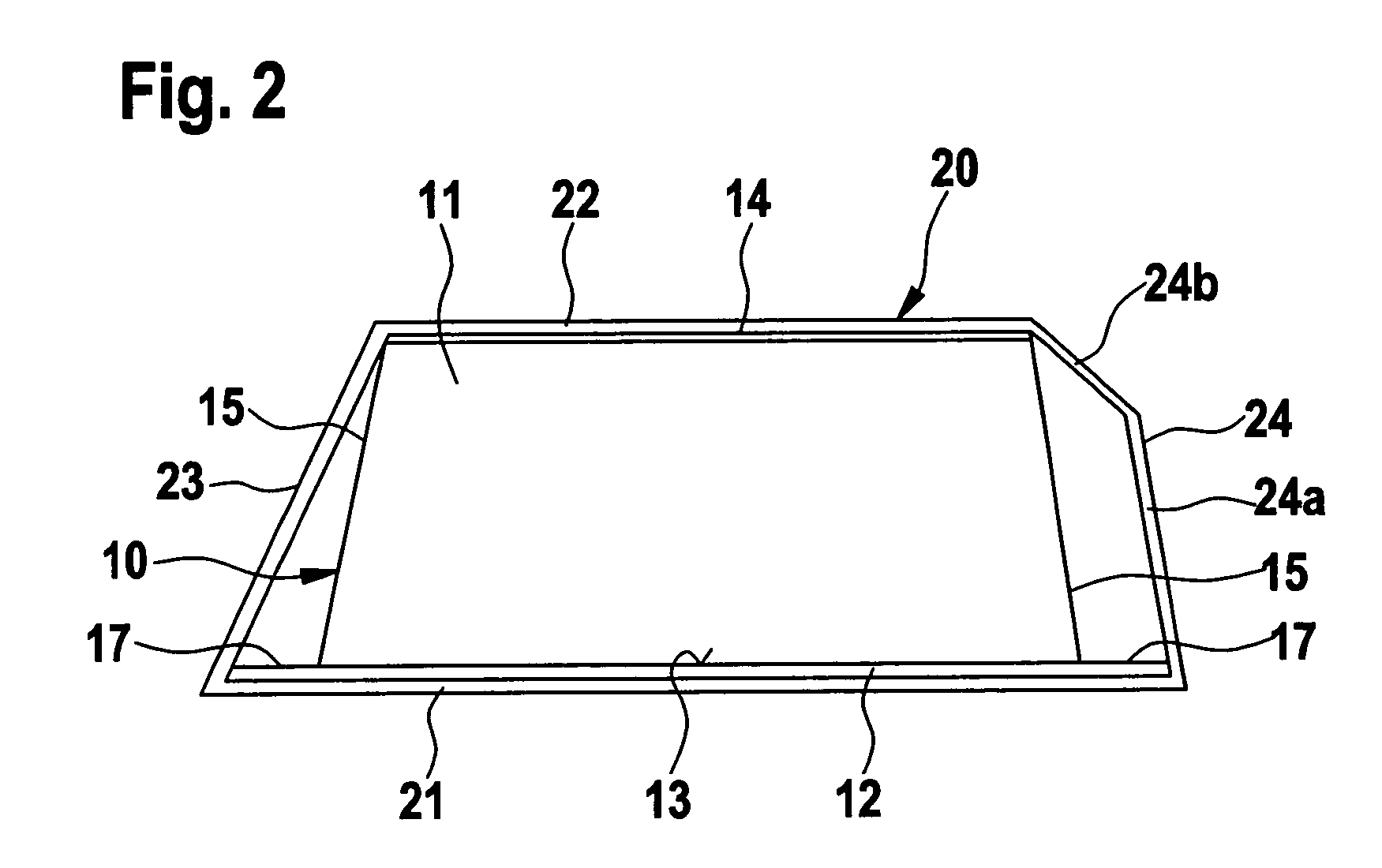

Vehicle curtain airbag device

InactiveUS8967660B2Efficiently escapeSecure spacePedestrian/occupant safety arrangementSteering wheelAirbag

A vehicle curtain airbag device is provided including: a curtain airbag including a main chamber that inflates and deploys to a vehicle width direction inside of a driving-seat-side side window due to being supplied with gas from an inflator installed to a vehicle, a delay chamber that is provided at a vehicle front-rear direction front side of the main chamber, and that completes inflation and deployment later than the main chamber upon receipt of the gas supply, and a sub chamber that is disposed on the vehicle width direction inside of the main chamber and that inflates and deploys so as to block off a gap formed between the main chamber and a driver's seat airbag that is inflated and deployed from a steering wheel; and a controller that inflates and deploys the driver's seat airbag and actuates the inflator in the event of a small overlap collision.

Owner:TOYOTA JIDOSHA KK

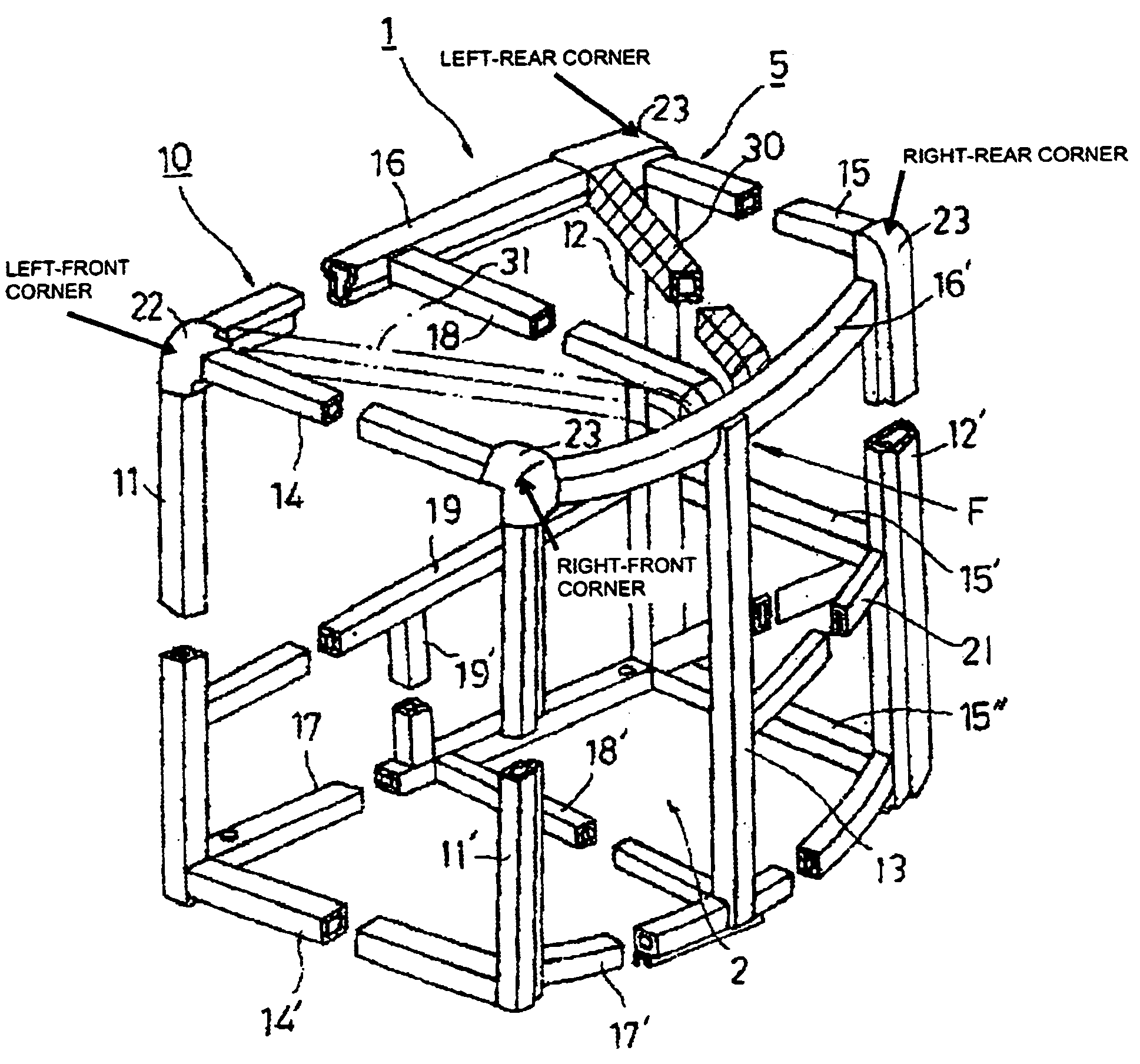

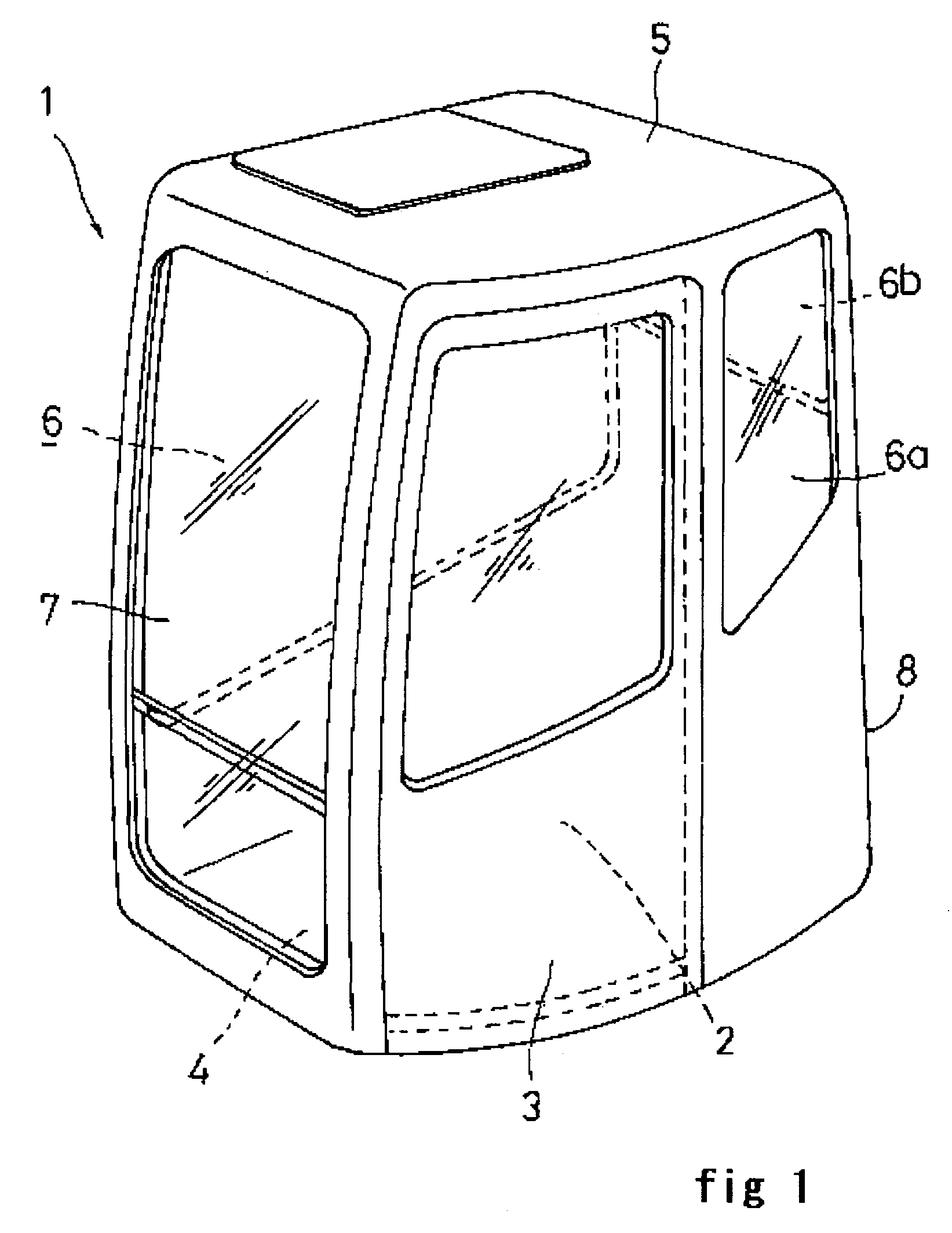

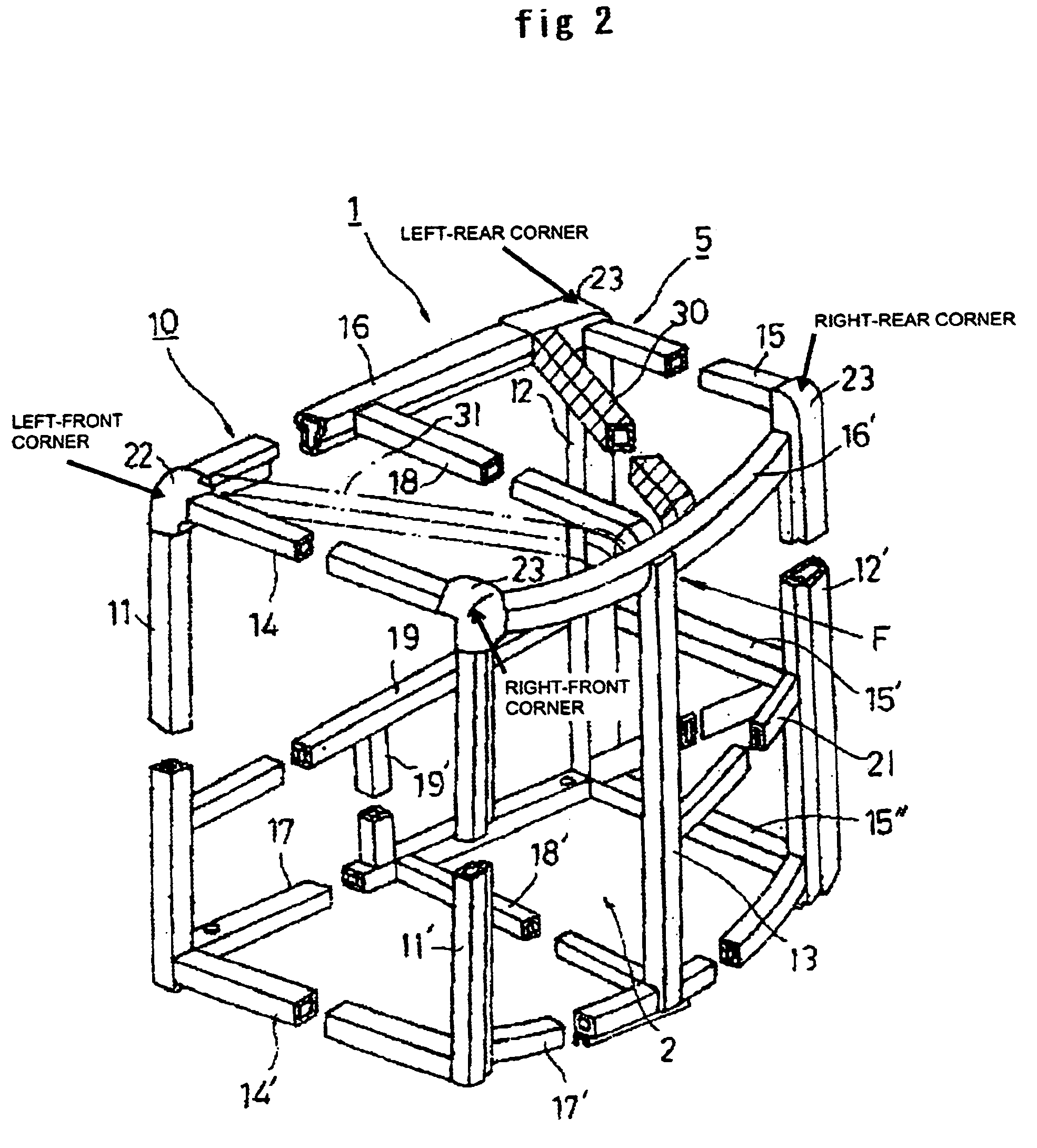

Driver's cab for a work vehicle

ActiveUS7048082B2Effective forceSimple structureVehicle seatsUnderstructuresEngineeringMechanical engineering

The invention provides a driver's cab for a work vehicle which is provided with a function of effectively transferring an external force applied to a ceiling portion to a pillar without making a structure complex, and can achieve a reinforced structure. In a driver's cab (1) in a working vehicle, the driver's cab being structured by a pipe-like member, a connection member (30 (31)) for dispersing a stress is arranged in a support pillar (11 (12)) in an opposite side particularly in the case that an external force is applied to a transverse outer side of a ceiling portion.

Owner:KOMATSU LTD

Vehicle curtain airbag device

InactiveUS20140042732A1Efficiently escapeSecure spacePedestrian/occupant safety arrangementSteering wheelAirbag

A vehicle curtain airbag device is provided including: a curtain airbag including a main chamber that inflates and deploys to a vehicle width direction inside of a driving-seat-side side window due to being supplied with gas from an inflator installed to a vehicle, a delay chamber that is provided at a vehicle front-rear direction front side of the main chamber, and that completes inflation and deployment later than the main chamber upon receipt of the gas supply, and a sub chamber that is disposed on the vehicle width direction inside of the main chamber and that inflates and deploys so as to block off a gap formed between the main chamber and a driver's seat airbag that is inflated and deployed from a steering wheel; and a controller that inflates and deploys the driver's seat airbag and actuates the inflator in the event of a small overlap collision.

Owner:TOYOTA JIDOSHA KK

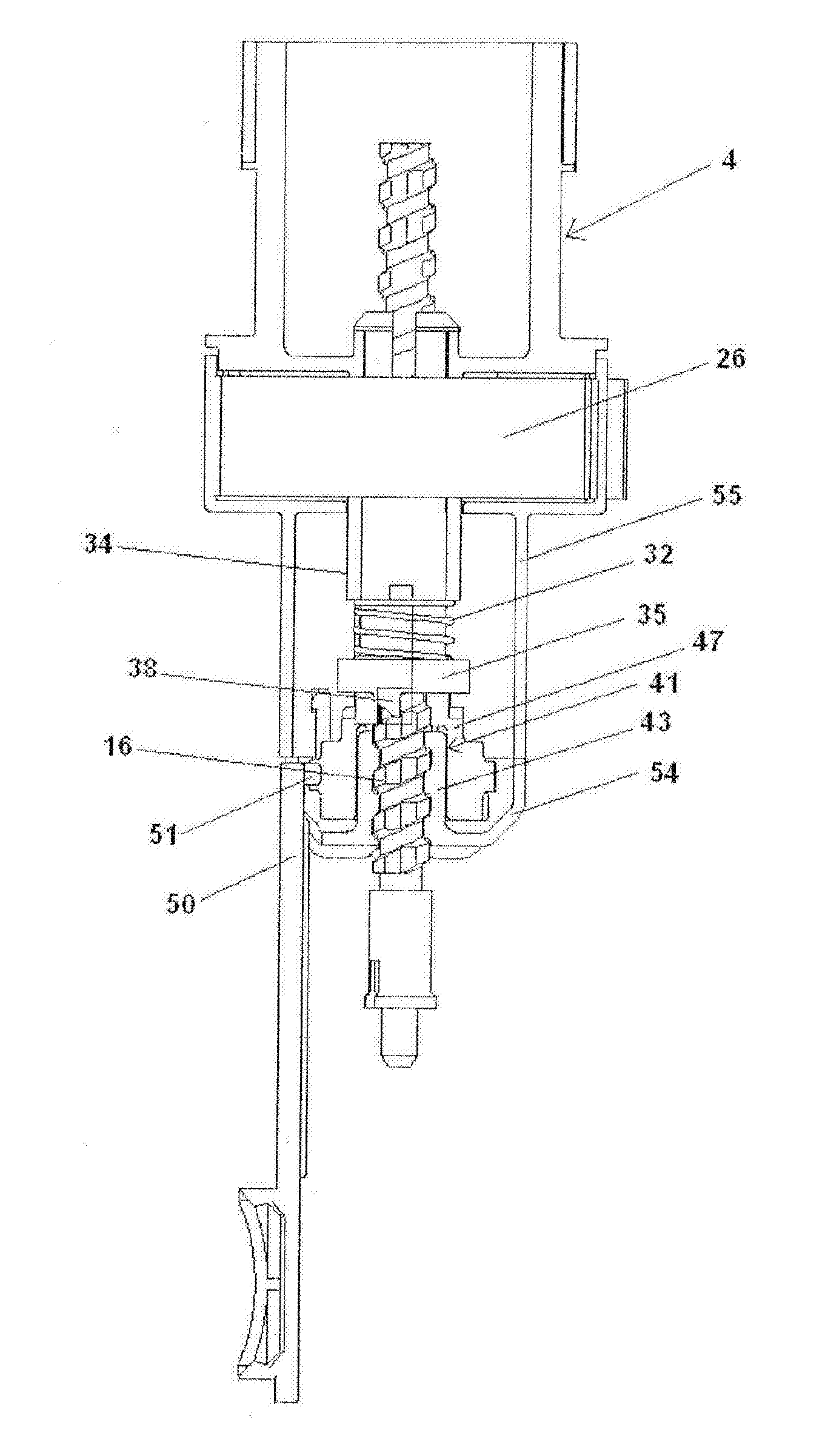

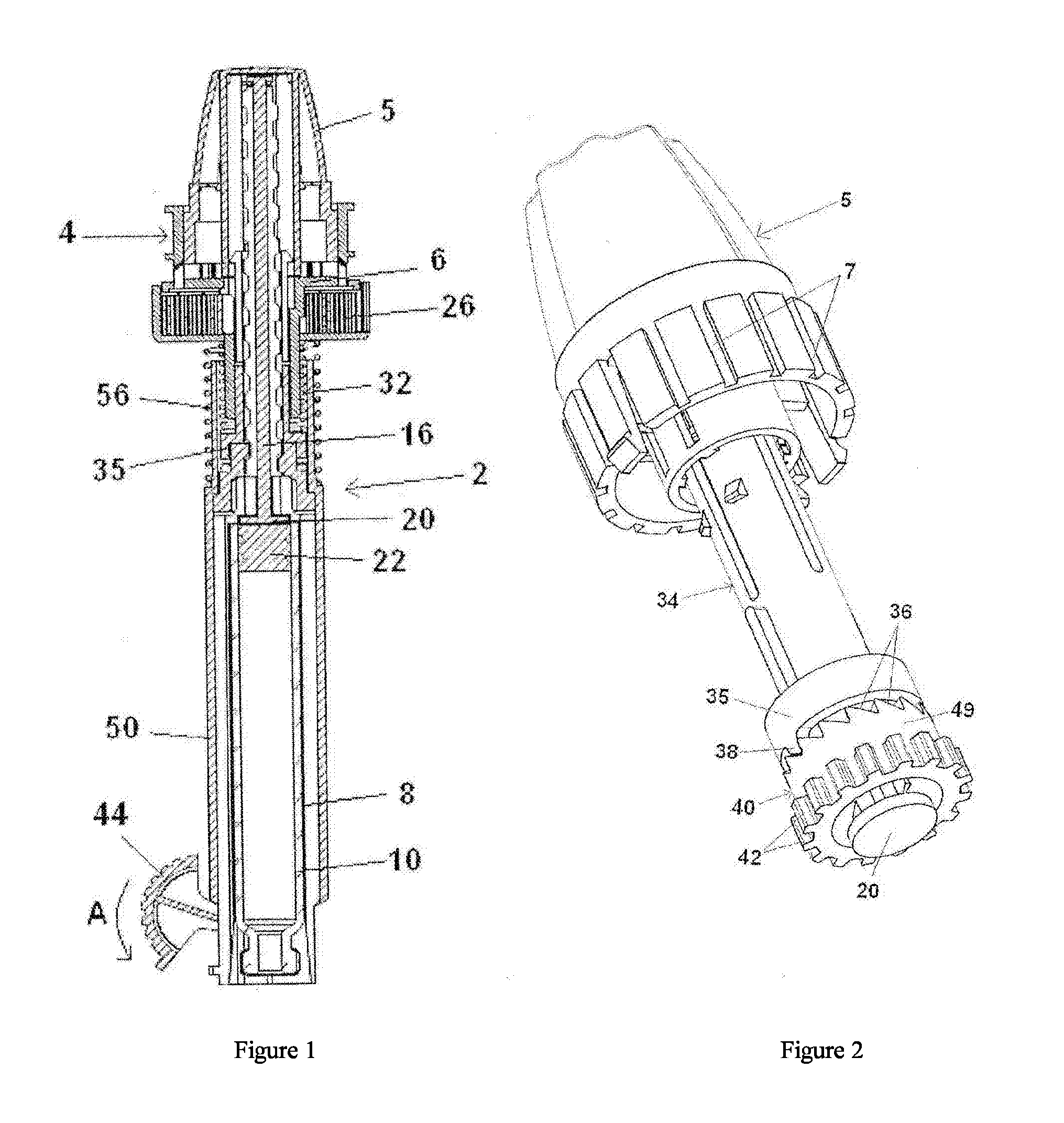

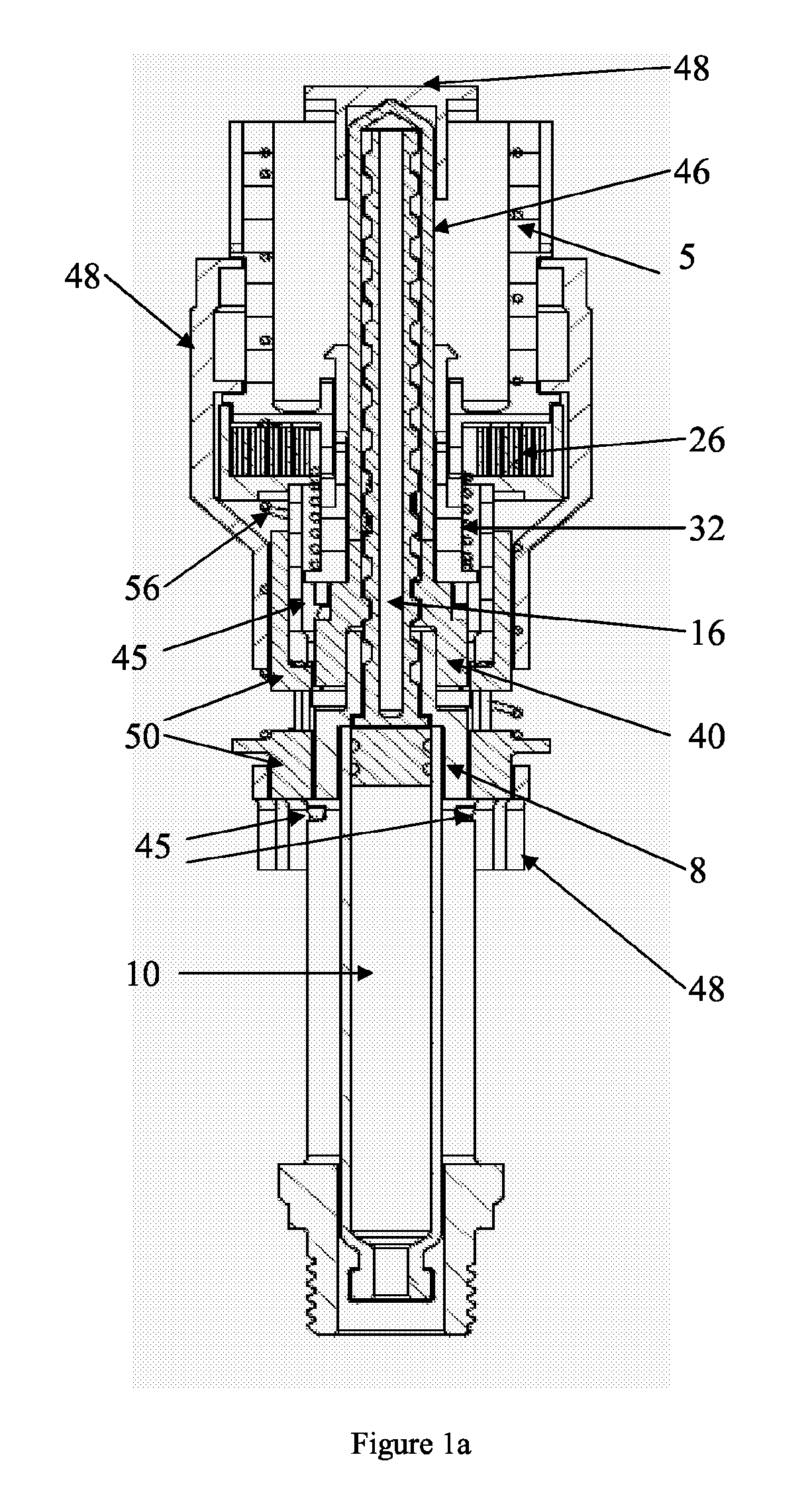

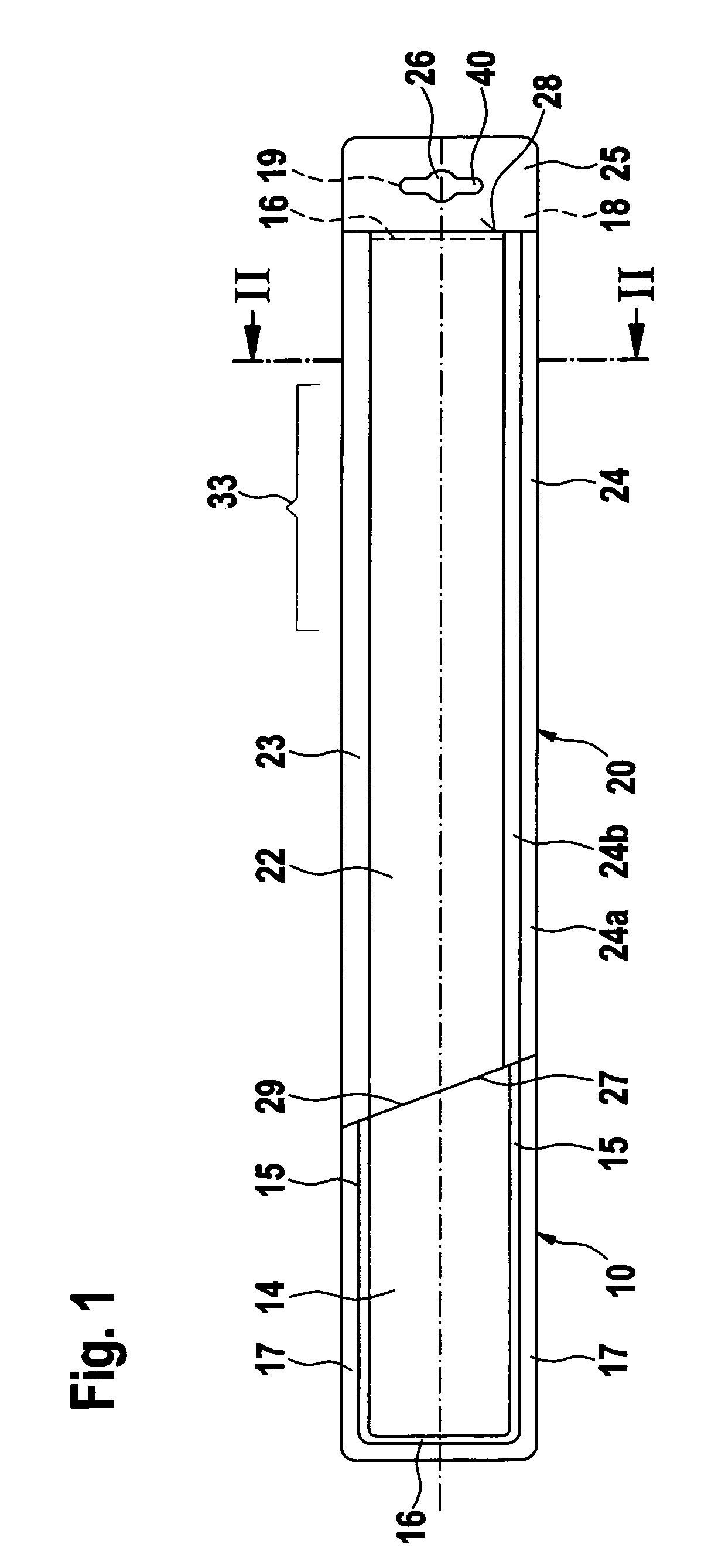

Device for Delivering Medicament

ActiveUS20100186739A1Reduce riskImproves dose and dose-to-dose accuracyRespiratorsAmpoule syringesSpring forceBiomedical engineering

The present invention relates to a device for the delivery of predetermined doses of liquid medicament to a patient, which medicament is intended to be inhaled by the patient or intended to be injected into the body of the patient. The device is adapted to be in a medicament delivery state and in a medicament non-delivery state. When the device is in a medicament delivery state, said device is adapted to drive a piston into a cartridge containing the liquid medicament to be delivered, with a force that is above or equal to a predetermined minimum force value and below a predetermined maximum force value. The minimum force value is the lowest force value needed to deliver the predetermined dose and the maximum force value is the first force value at which it exists a risk of damaging the cartridge or the components of the device. Further, more of the spring force is brought to an efficient output torque ensuring that a predetermined volume of medicament is expelled from a cartridge.

Owner:SHL MEDICAL AG

Power generation system

InactiveUS6932561B2Effective and reliableEffective forcePropellersPump componentsEngineeringPressure difference

A wind power system is provided including at least one generator fan having a front face and a rear face. The system also includes a first wind capturing device positioned proximate to the front face. The wind capturing device can be configured to capture wind to create a first pressure proximate to the front face that is greater than a second pressure proximate to the rear face. The pressure difference causes the captured wind to flow across the at least one generator fan from the front face to the rear face.

Owner:WAFERMASTERS

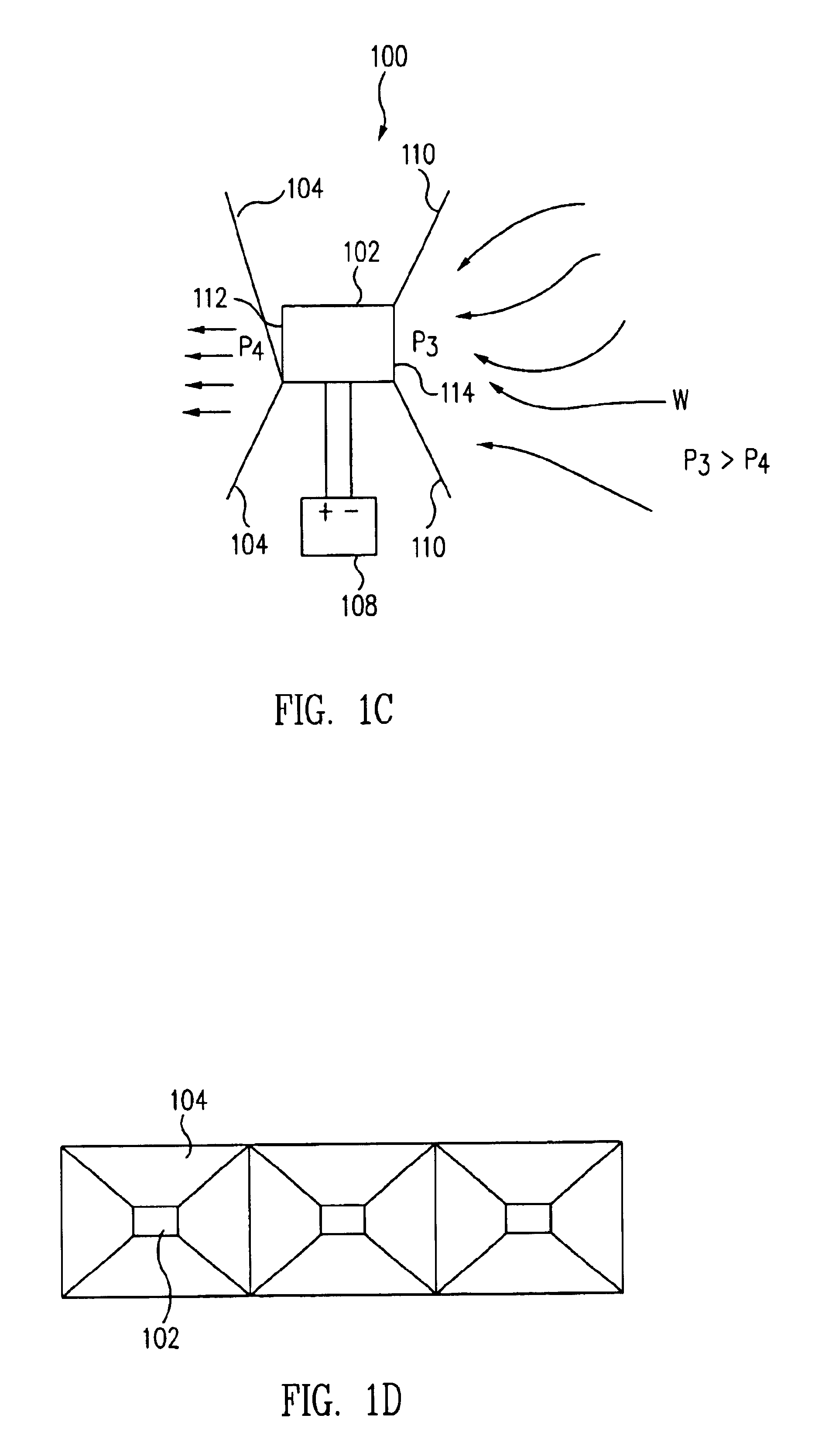

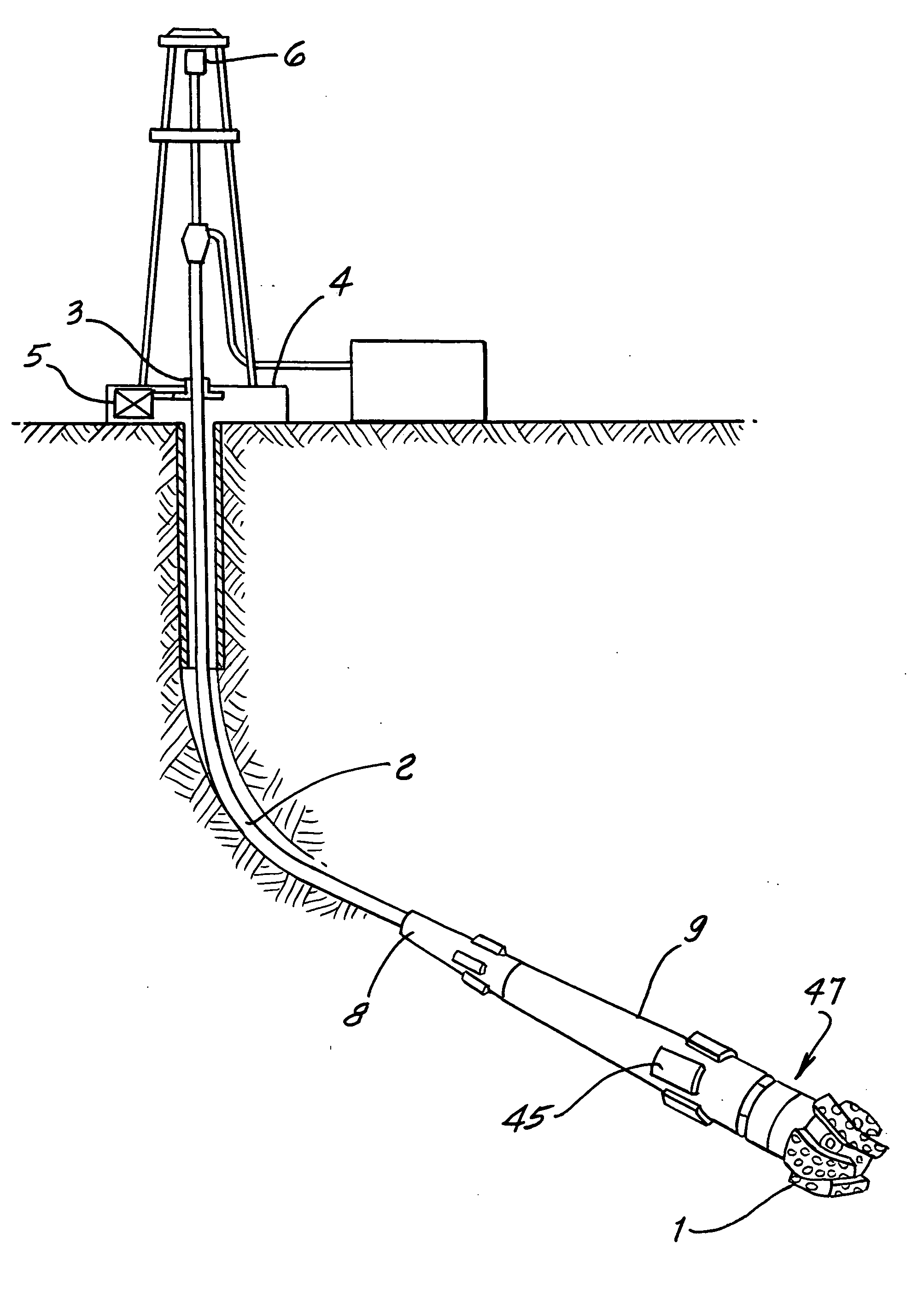

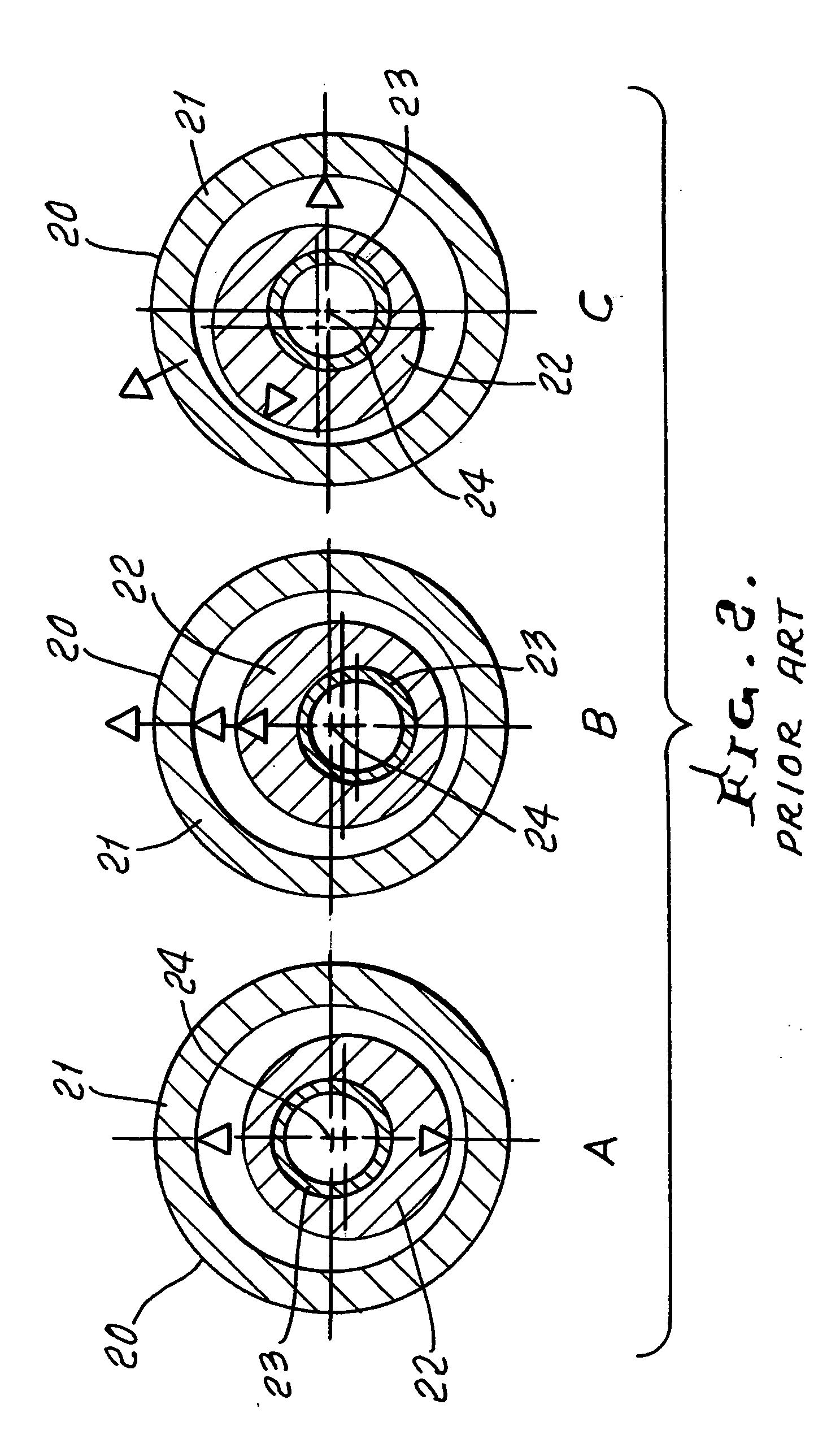

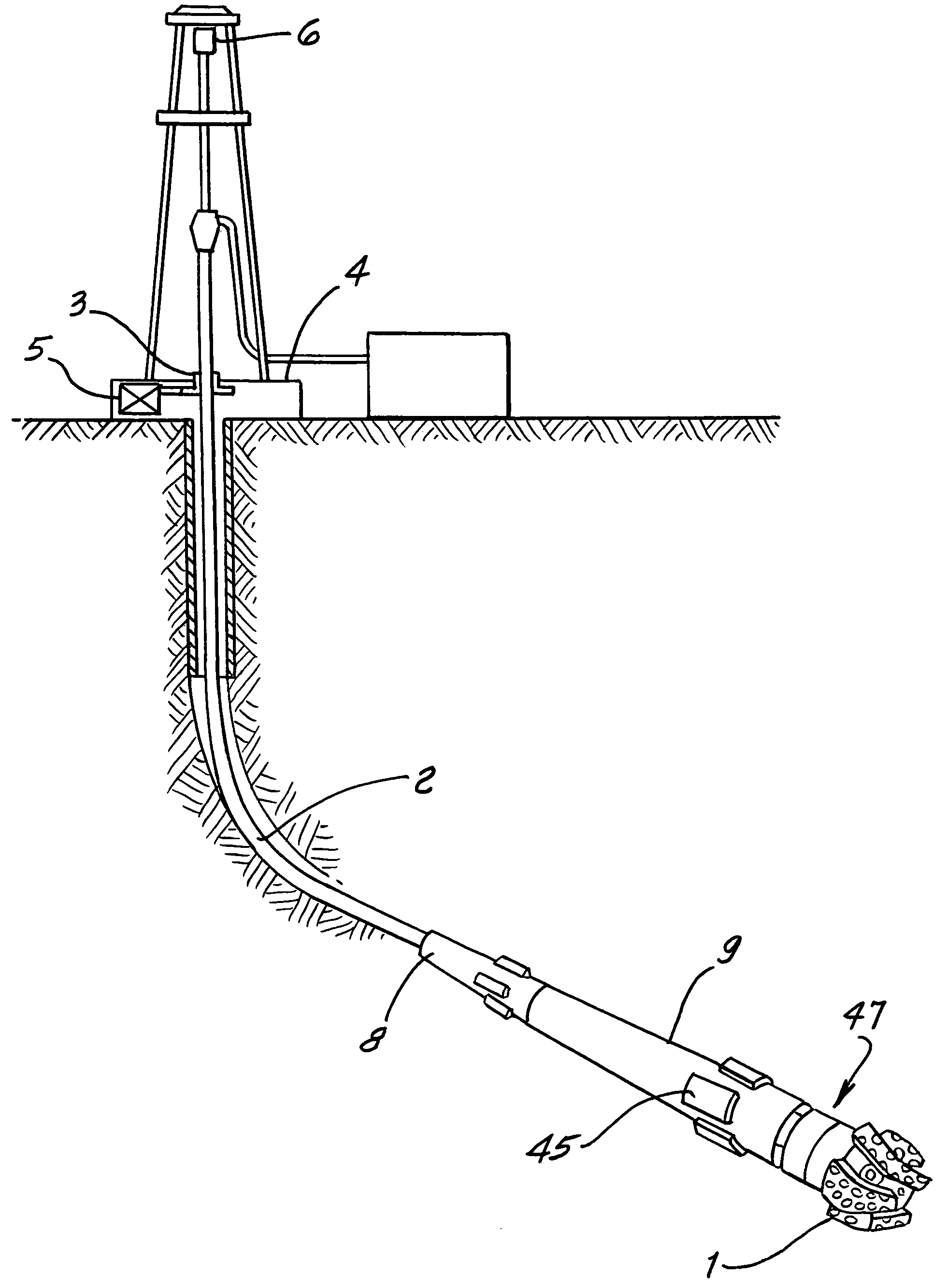

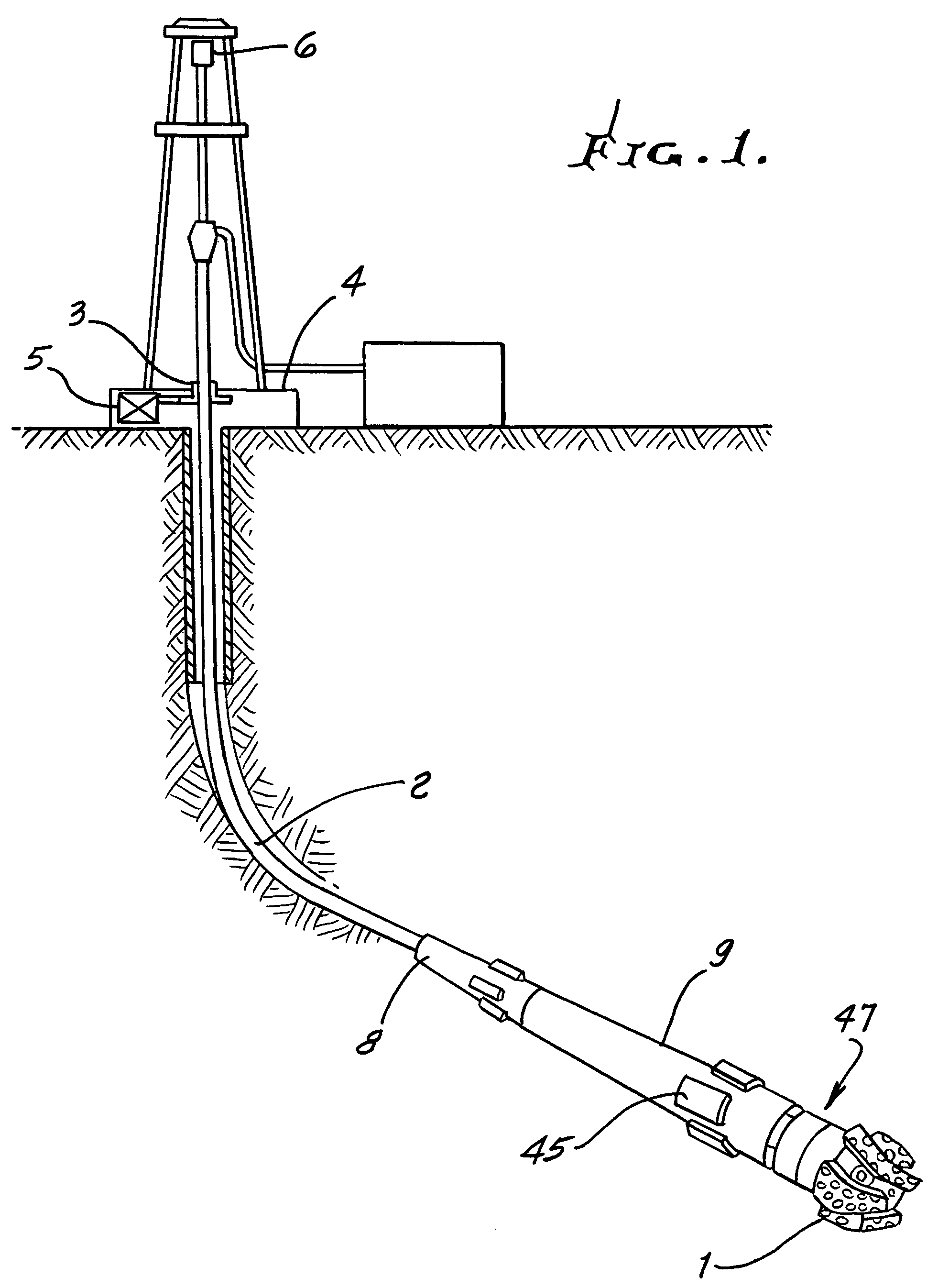

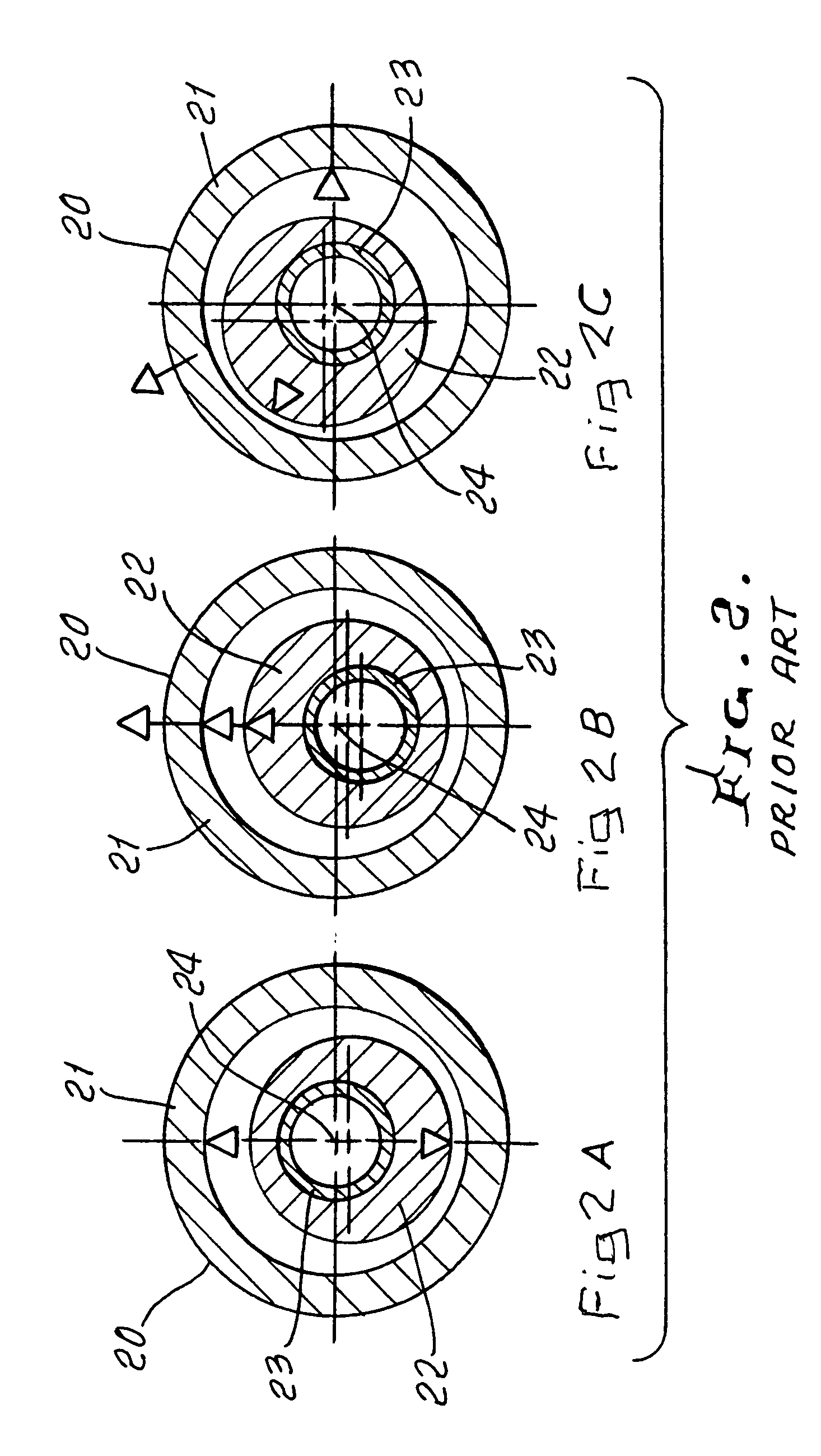

Steerable drilling apparatus having a differential displacement side-force exerting mechanism

An apparatus for steerable rotary drilling of a borehole having a wall in the earth comprising, a mandrel, having a central opening there through for the passage of drilling fluids, said mandrel having a lower connection for operatively connecting to a drill bit structure, said mandrel having an upper connection for operatively connecting to a drill string above said apparatus, and the mandrel having an intermediate portion, an outer housing surrounding longitudinal extent of said mandrel intermediate portion, a differential displacement drive within the outer housing, one or more pairs of radially-extensible, opposed side-force exerting elements controlled by said differential displacement drive to provide for side force exertion against the said borehole wall, said drive including a pair of pistons for activating each pair of radially-extensible opposed side-force elements, one or more displacement transducers for said pair of pistons, control valves within said outer housing for fluid pressure control of said differential displacement drive, and sensing, control and power supply elements to control operation of said control valves, to steer drilling in a desired direction by selective operation of said side force exerting elements.

Owner:SCIENCE DRILLING INTERNATIONAL INC

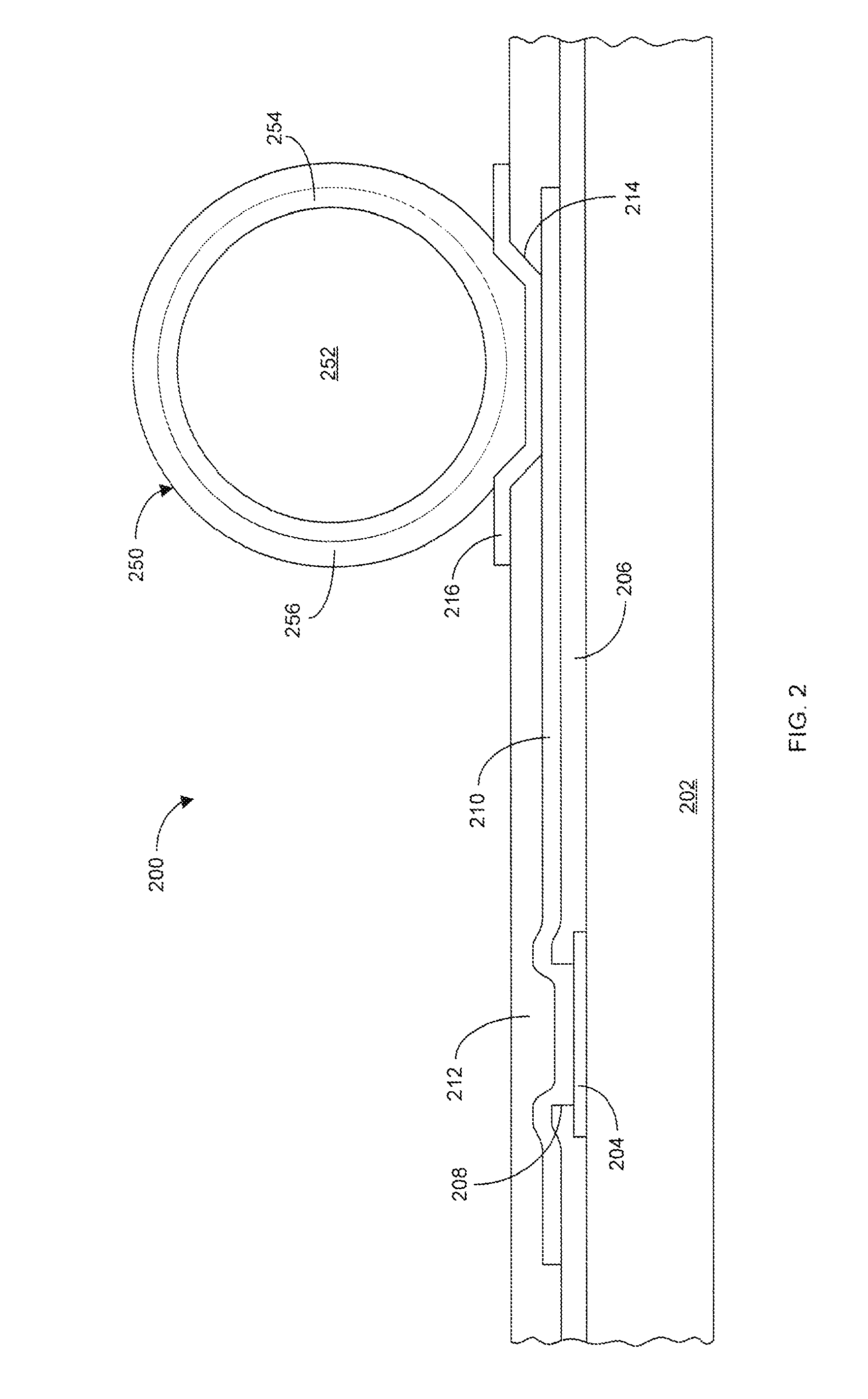

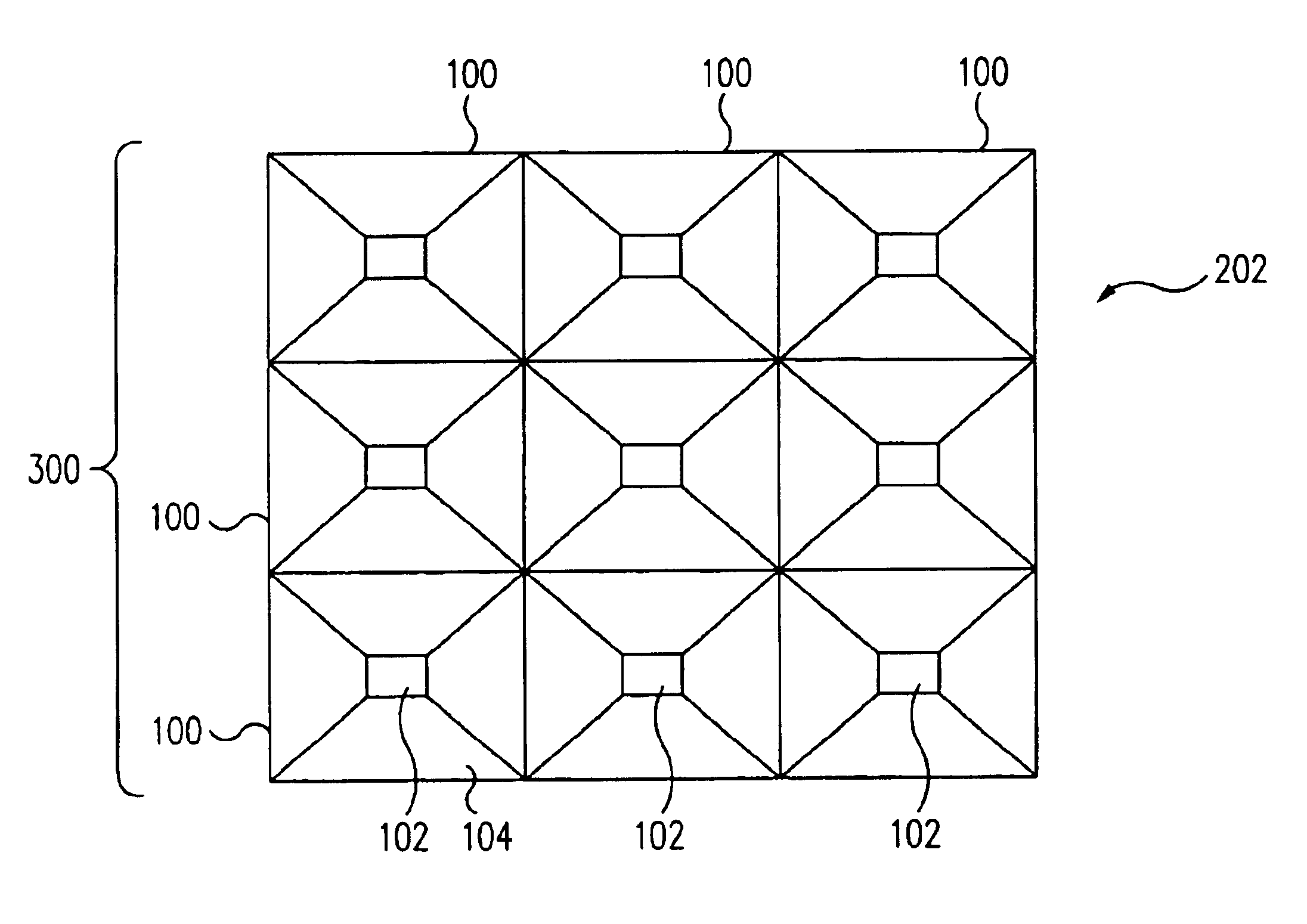

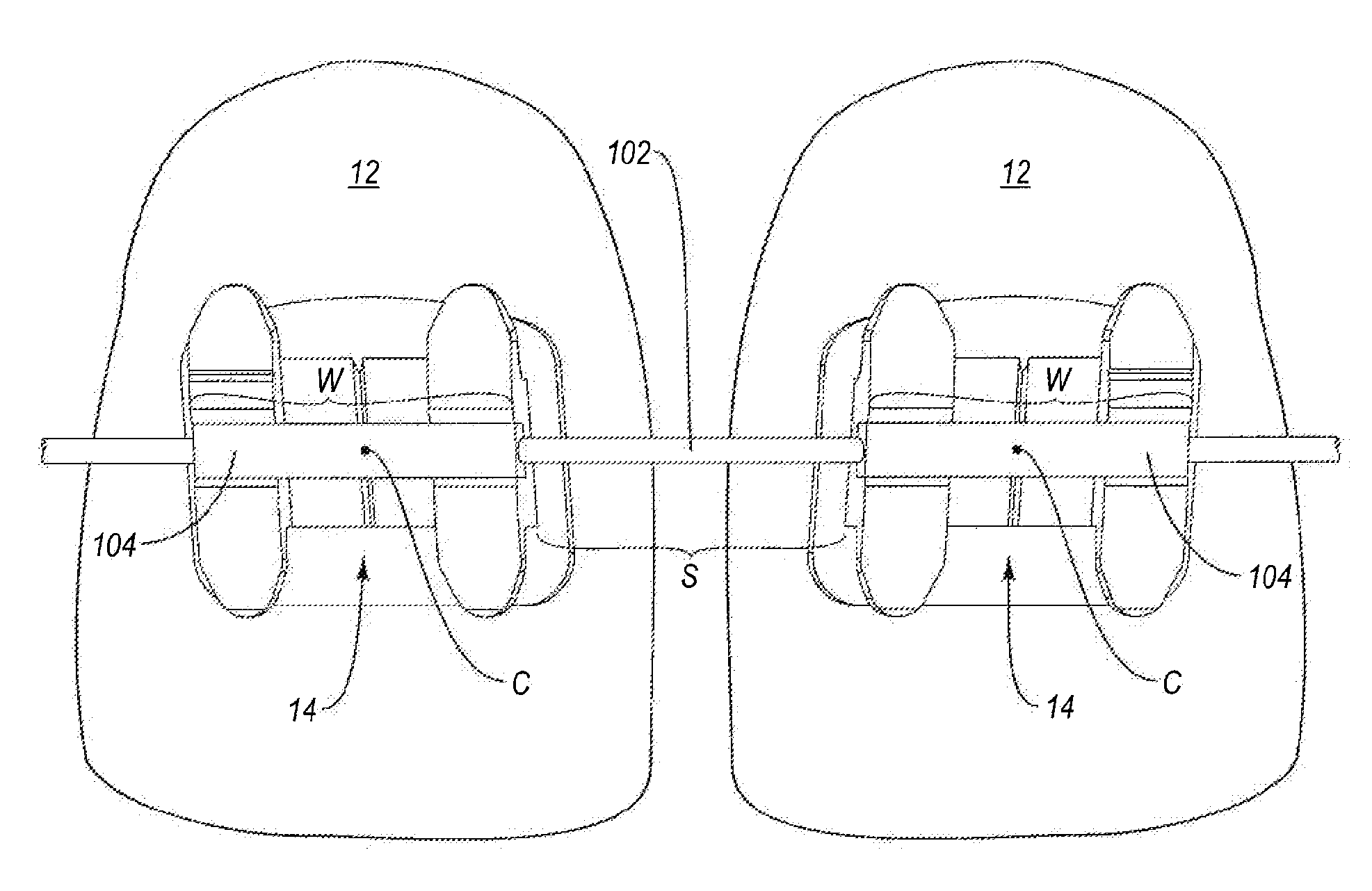

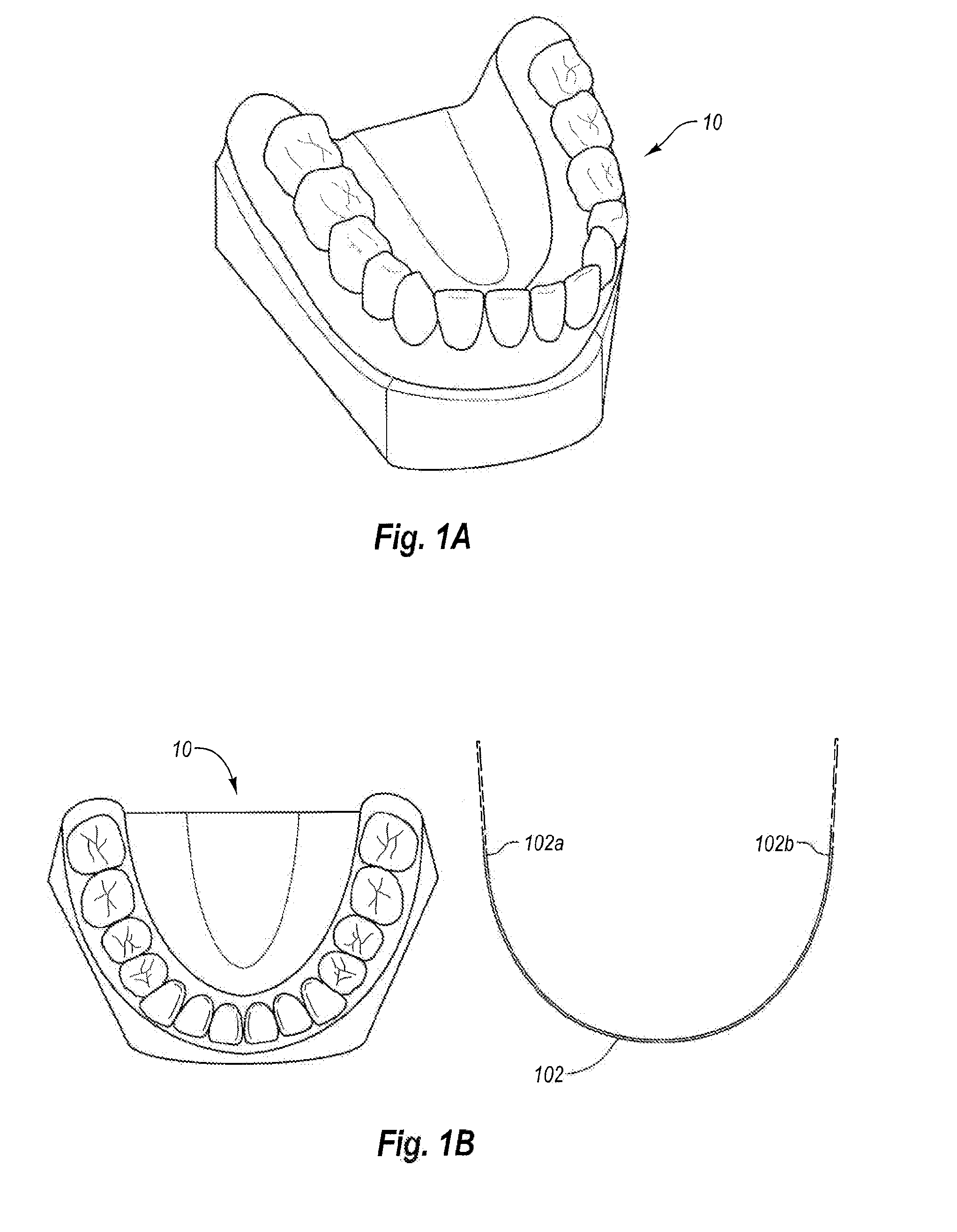

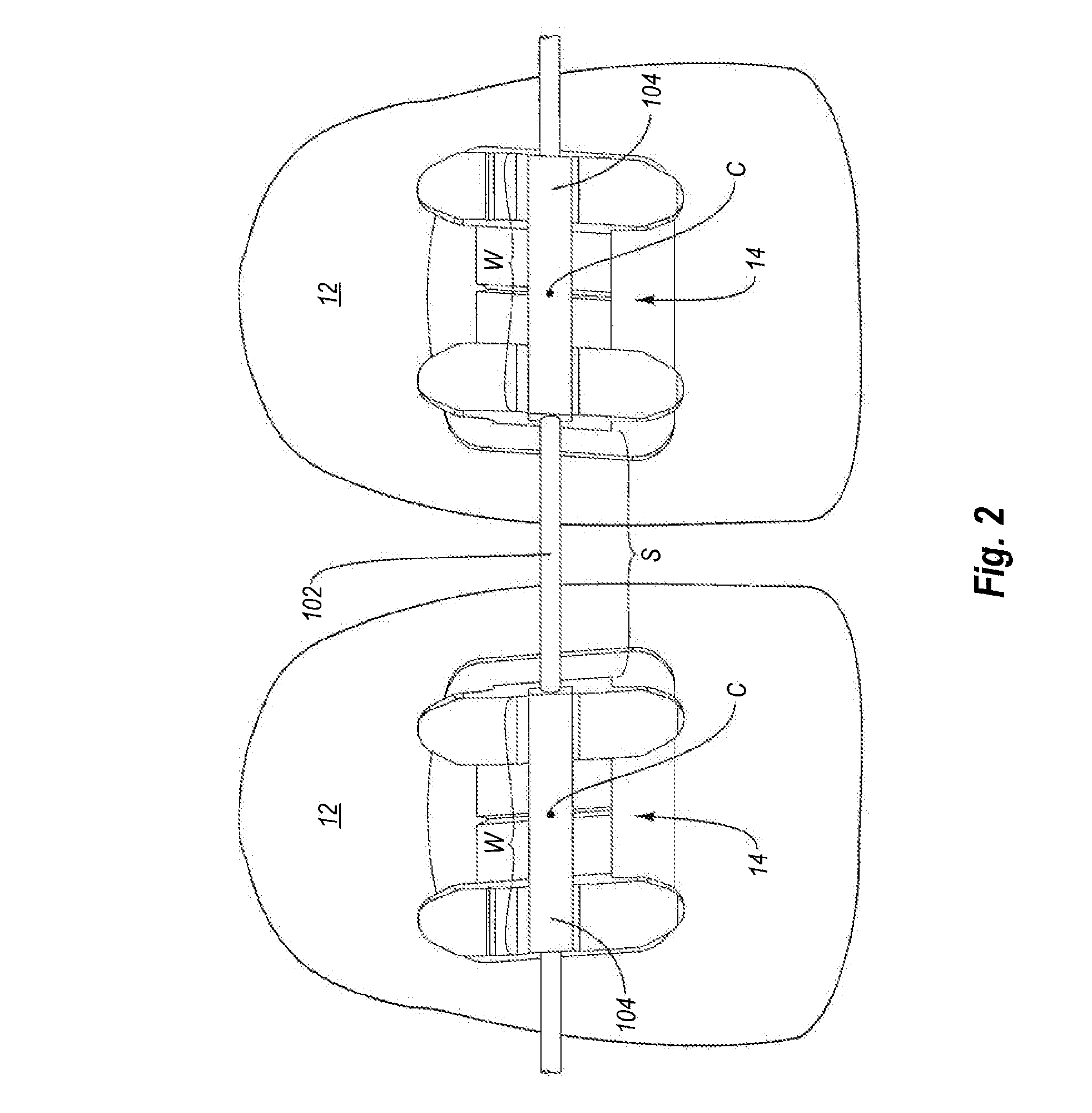

Customized Orthodontic Arch Wire Manufactured Using Model of Patient's Teeth

Customized low force orthodontic arch wires include a core wire (102) formed of a shape memory material and a plurality of bracket engagement blocks (104) disposed in spaced apart relationship along the length of the core wire (102). The particular position of each engagement block (104) along the length of the core wire (102), as well as the length and curvature of the core wire (102), are customized for the particular patient on which the arch wire is to be installed. A physical or electronic custom model of the patient's dental arch is obtained. The customized arch wire is then fabricated according to the specifications determined by reference to the custom model of the patient's teeth.

Owner:ULTRADENT PROD INC

Steerable drilling apparatus having a differential displacement side-force exerting mechanism

InactiveUS7287605B2Effective forceDrilling rodsDirectional drillingEngineeringMechanical engineering

An apparatus for steerable rotary drilling of a borehole having a wall in the earth comprising a mandrel having a central opening there through for the passage of drilling fluids. The mandrel having a lower connection for operatively connecting to a drill bit structure and an upper connection for operatively connecting to a drill string above said apparatus. The mandrel further having an intermediate portion, an outer housing surrounding longitudinal extent of the mandrel intermediate portion, a differential displacement drive within the outer housing, one or more pairs of radially-extensible, opposed side-force exerting elements controlled by the differential displacement drive to provide for side force exertion against the borehole wall.

Owner:SCIENCE DRILLING INTERNATIONAL INC

Packaging unit with slidable casing

ActiveUS7614499B2Preventing the slipping out of the containerAvoid insufficient frictionPackaging vehiclesContainers for machinesMechanical engineering

Owner:ROBERT BOSCH GMBH

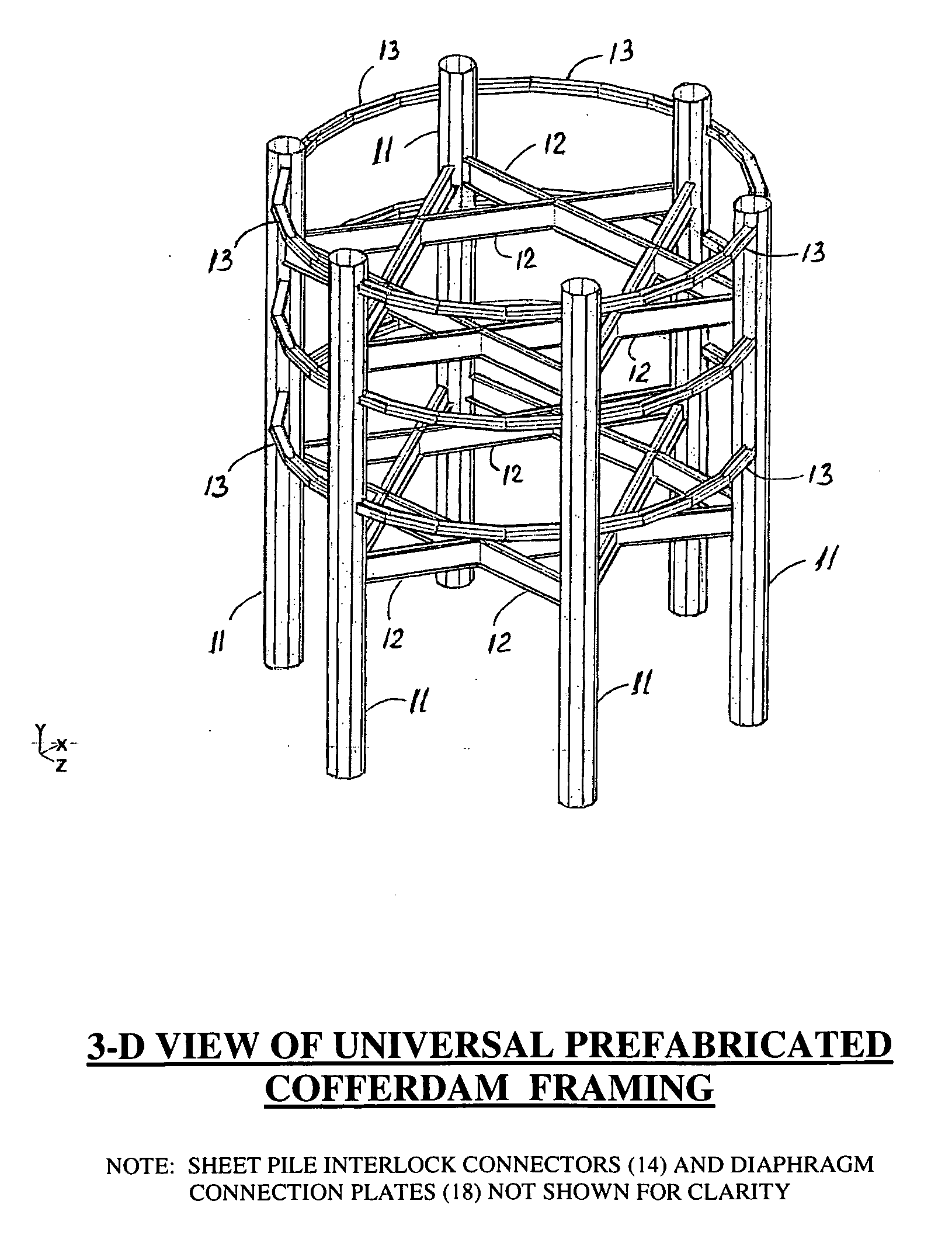

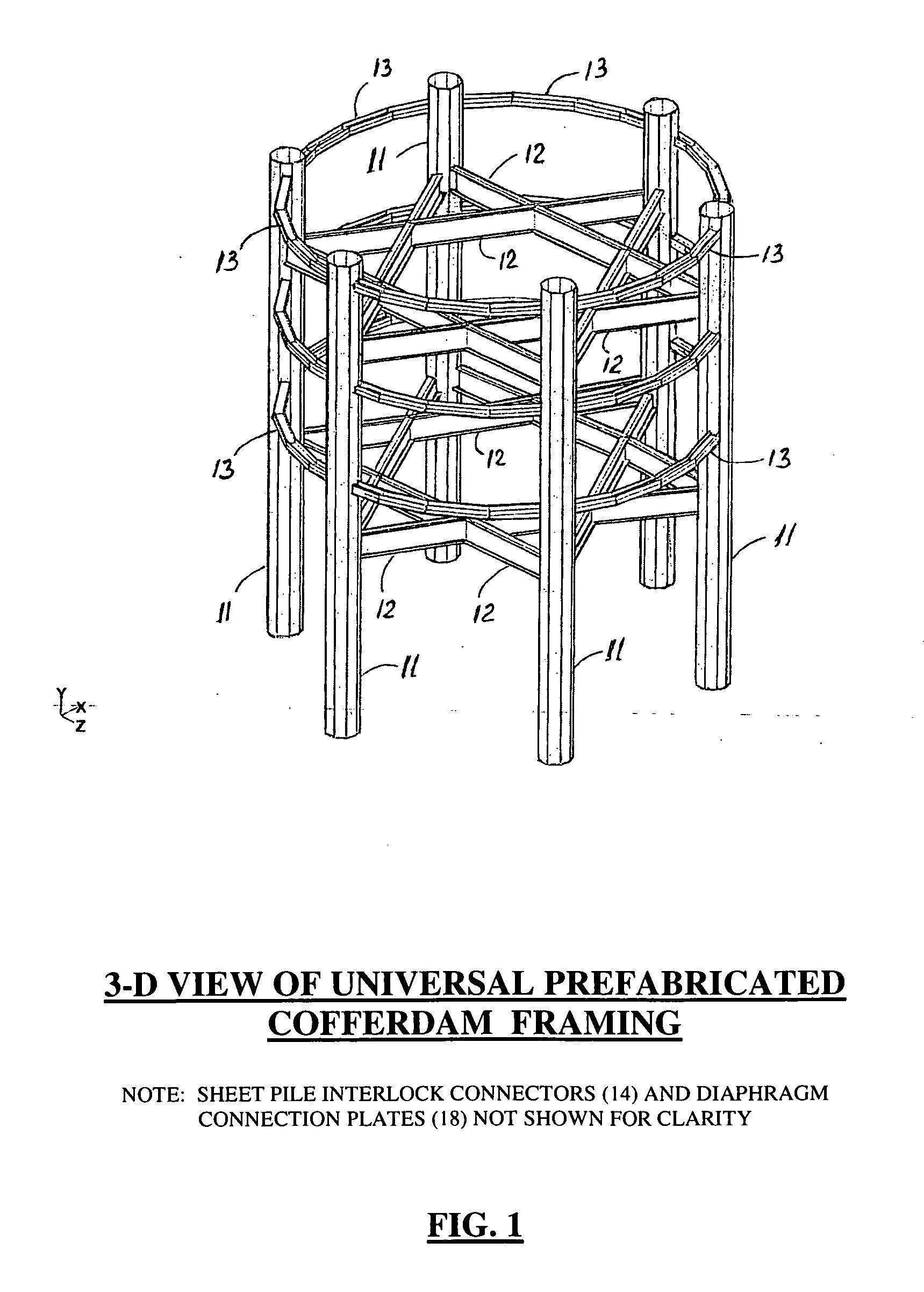

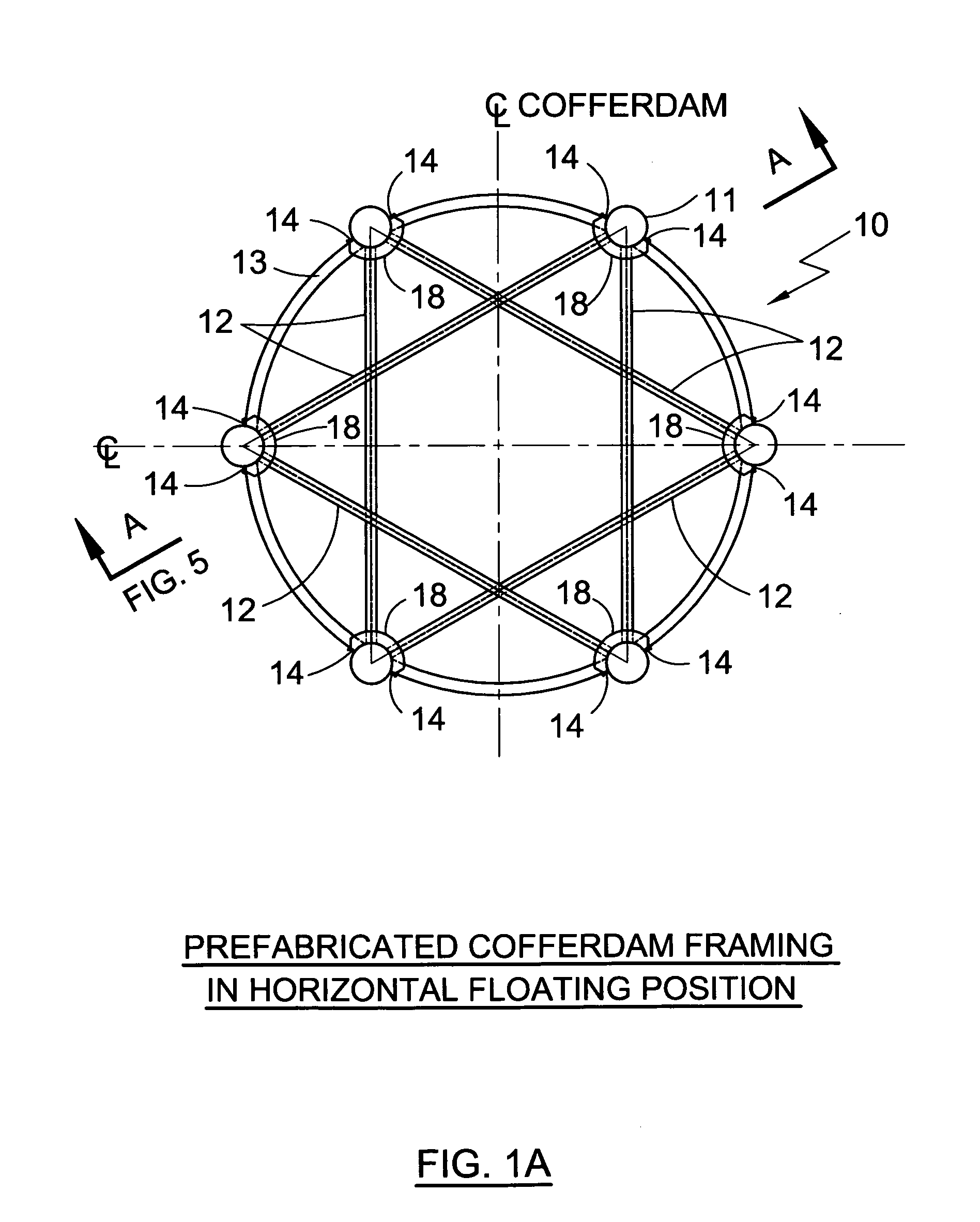

Universal Framed Cofferdam

Universal Framed Cofferdam has prefabricated skeletal steel space framing formed from multiple steel vertical pipes and two levels of horizontal diaphragm trusses rigidly connected to pipe columns. Beams of each diaphragm truss are attached to vertical pipes of the framing with rigid moment connections creating a rigid space frame of the perfectly round form that is used as a false work of the Cofferdam. Wales of the Cofferdam and short pieces of the flat sheet piling are attached to the vertical pipes forming a skeleton of the Cellular structure. The Skeleton of the Universal Framed Cofferdam is prefabricated in the convenience of the Dry Dock and than floated to the site. Buoyancy of the framing allows Cofferdam skeleton transportation without using the barge or otherwise necessary floating devices. Once brought to the site of installation Cofferdam skeleton is installed vertically in position and leveled on the bottom of the river bed. If necessary river silt can be jetted and pumped out of pipe annular space and pipe columns of framing can be simultaneously lowered in position by using vibro—hummer. After space framing installation, rock sockets are predrilled through the annular space of vertical pipes and rock anchors installed. Sheet pile skin of the Cofferdam installed between pipe columns concludes Cofferdam Can erection. Universal Framed Cofferdam Can than filled with compacted gravel and becomes a Hybrid Gravity Caisson / Columnar water front or marine structure that has the best features of the Conventional Cellular Cofferdam and of Columnar Dolphin structure. It has enhanced sliding and overturning stability provided by Rock anchors preloaded by Cofferdam granular fill and has effective mechanism that prevents concave or convex surface of rupture failure that may be suffered by conventional Cellular Cofferdams, and has mechanism that more effectively resists deep surface sliding failure of the Cofferdam base.

Owner:FEYGIN VITAL BORIS +1

Surface catalyst infra red laser

InactiveUS6944202B2High qualityHigh quality of energyHydrogenExcitation process/apparatusHeat rejectionAtomic oxygen

An energy converter reacts hydrocarbons and air on a catalyst configuration to produce a population inversion. A photovoltaic system may extract the radiating energy, and a laser system may extract a significant fraction of the reaction energy in the form of coherent radiation. The flooding of the catalyst adsorption sites with fuel and the choice of catalyst predisposes the adsorbing oxygen molecules to create mono-atomic oxygen hot-atoms, which deposit the considerable energy of oxygen adsorption directly into a reaction channel of adjacent, adsorbed and simple fuel radicals, thereby producing simple, energetic product molecules, concentrating the energy in one or a few modes, and strongly favoring inverted populations. A solid state method to stimulate precursor chemisorbed specie dissociation accelerates the reaction rates, providing a method to greatly intensify pulsed power output, increase efficiency, and to facilitate nano-scale and micro-scale thermal energy heat rejection processes.

Owner:NEOKISMET L L C

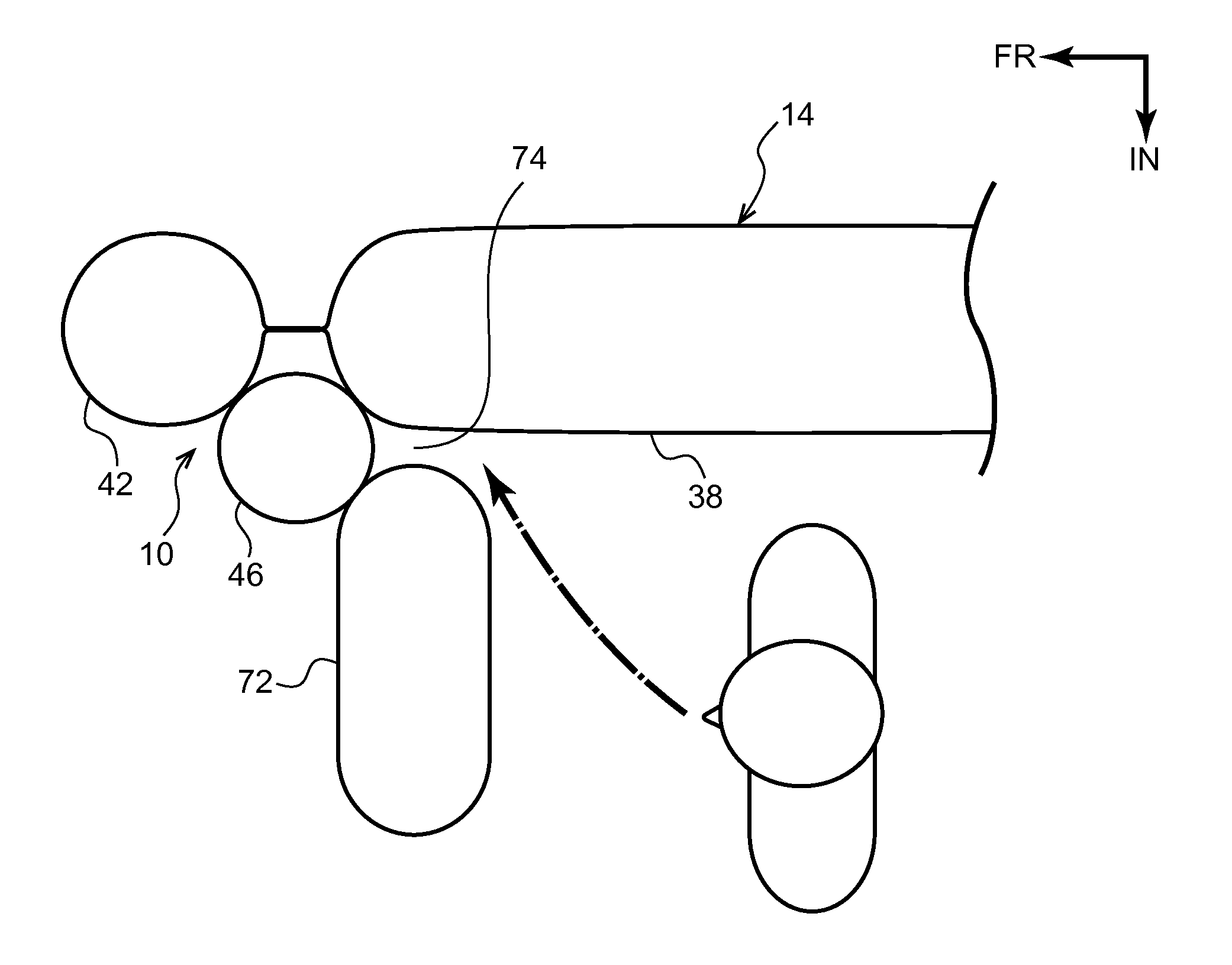

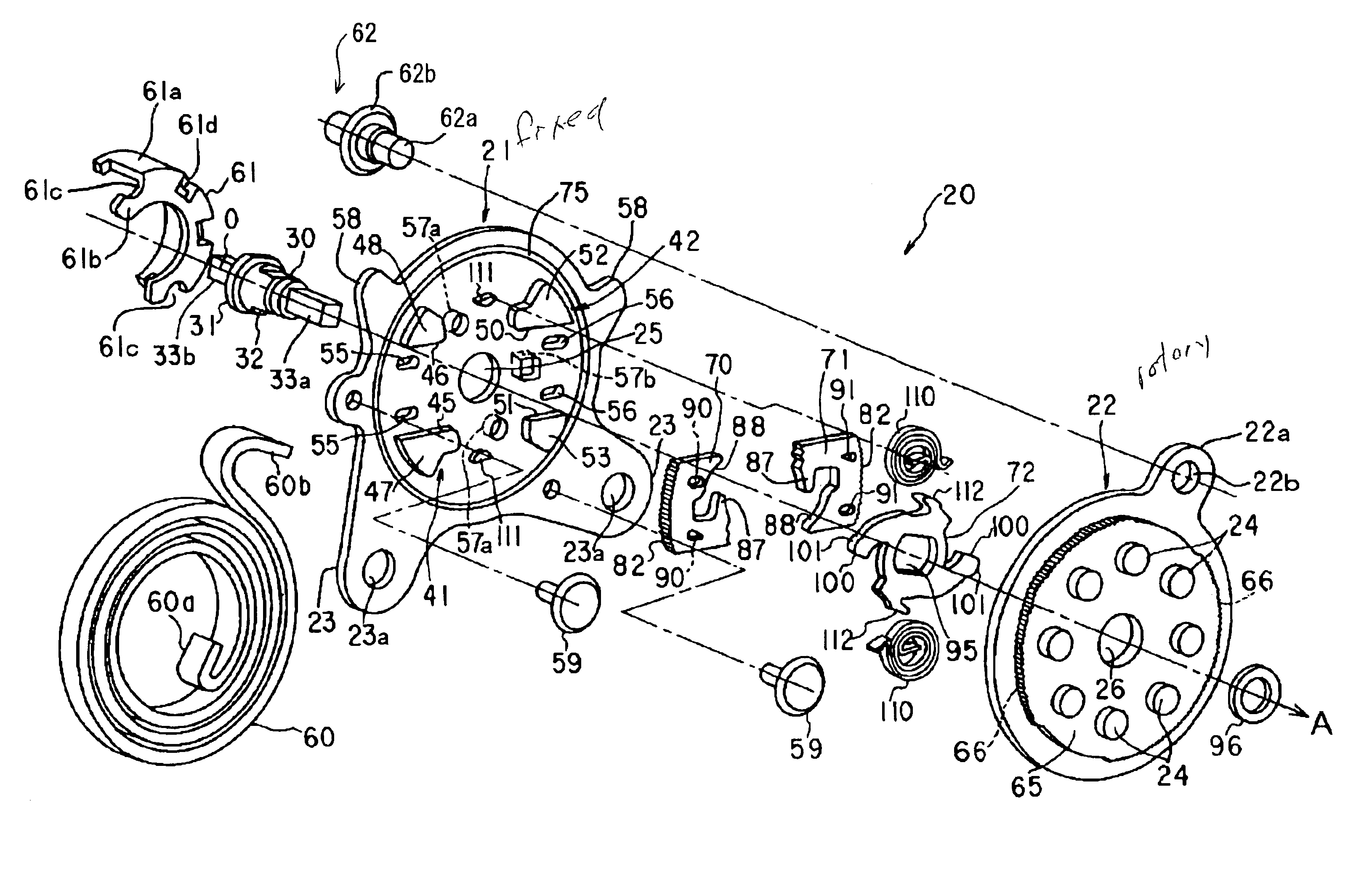

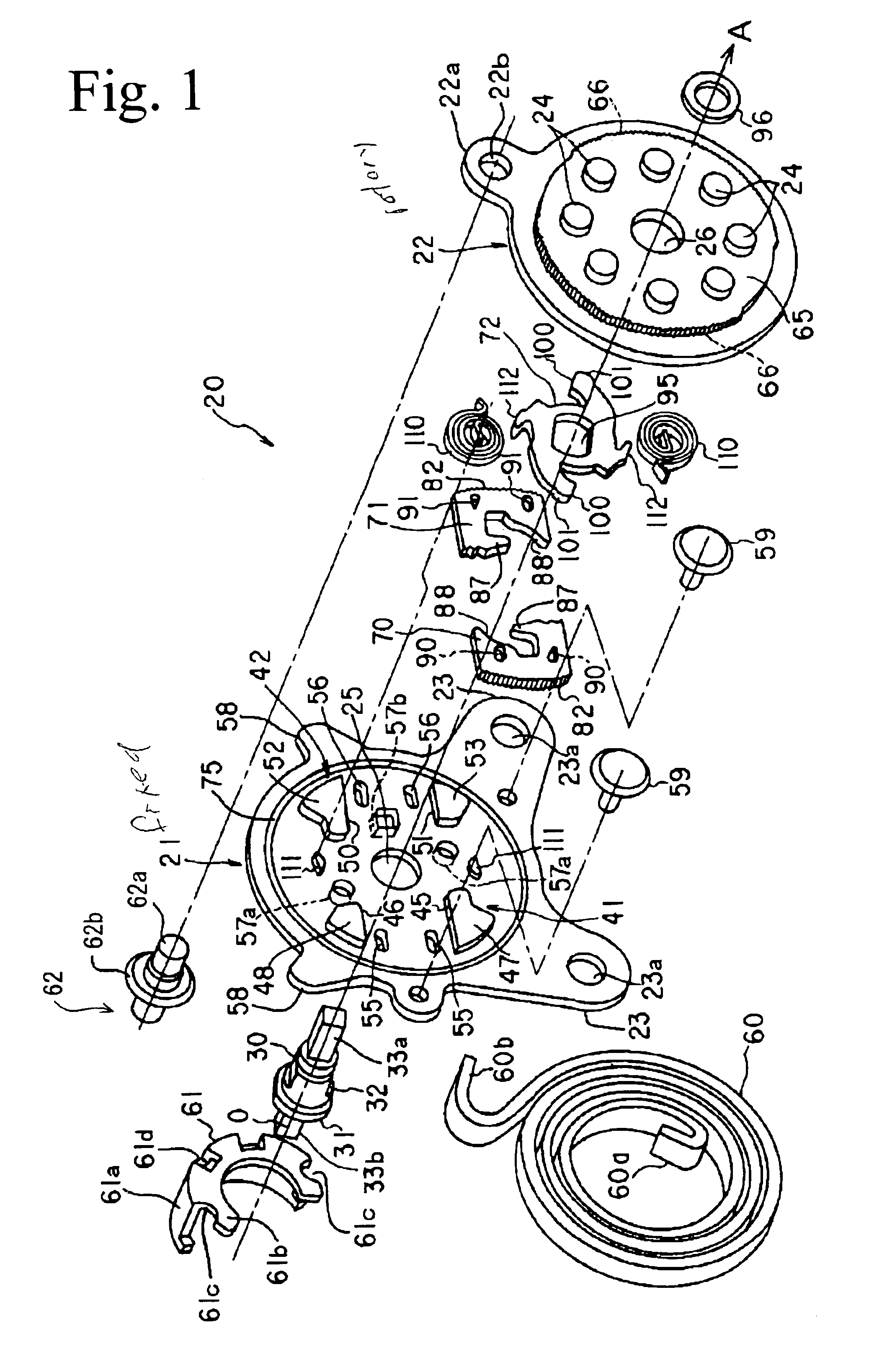

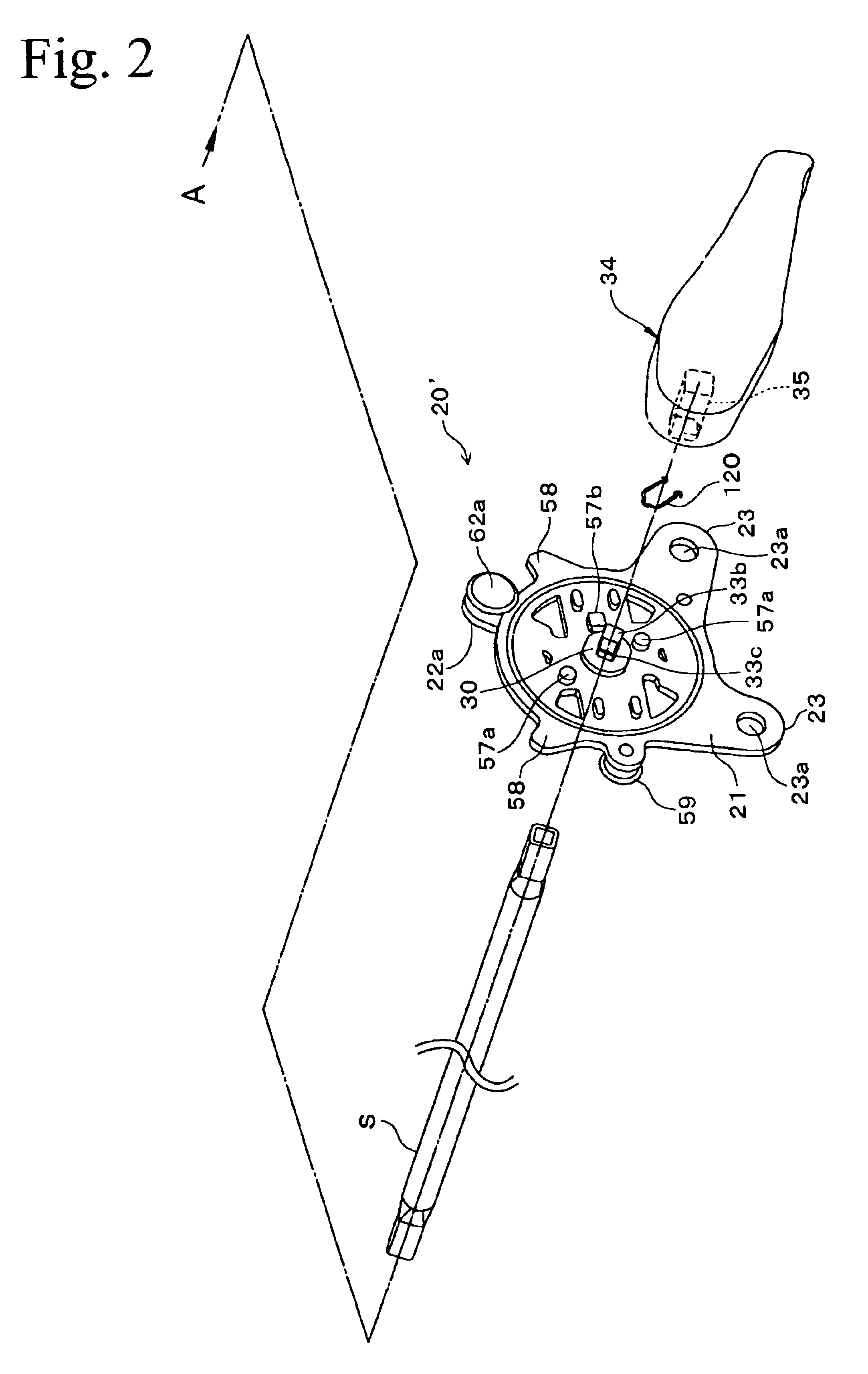

Reclining device

A reclining apparatus (20) is provided with a fixed plate (21) having guide portions (41, 42), a shaft (30), a rotary plate (22) having an internal gear (66), slide gears (70, 71), a cam member (72) and the like. The cam member (72) has a pair of hook portions (100) engaging with a receiving portion (87) in the slide gears (70, 71). The hook portion (100) and the receiving portion (87) are formed in such a shape as to move the slide gears (70, 71) is a direction of canceling a rotational moment applied to the slide gears (70, 71) due to a backward load applied to the seat back when the cam member (72) rotates in a lock canceling direction. A supporting portion (120) preventing the slide gears (70, 71) from moving in a direction of the rotational moment is provided in an opposing portion between the cam member (72) and the slide gears (70, 71).

Owner:NHK SPRING CO LTD

Device for delivering medicament

ActiveUS8617109B2Reduce riskImproves dose and dose-to-dose accuracyAmpoule syringesAutomatic syringesSpring forceBiomedical engineering

The present invention relates to a device for the delivery of predetermined doses of liquid medicament to a patient, which medicament is intended to be inhaled by the patient or intended to be injected into the body of the patient. The device is adapted to be in a medicament delivery state and in a medicament non-delivery state. When the device is in a medicament delivery state, said device is adapted to drive a piston into a cartridge containing the liquid medicament to be delivered, with a force that is above or equal to a predetermined minimum force value and below a predetermined maximum force value. The minimum force value is the lowest force value needed to deliver the predetermined dose and the maximum force value is the first force value at which it exists a risk of damaging the cartridge or the components of the device. Further, more of the spring force is brought to an efficient output torque ensuring that a predetermined volume of medicament is expelled from a cartridge.

Owner:SHL MEDICAL AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com