Universal Framed Cofferdam

a cofferdam and universal frame technology, applied in the direction of caissons, towers, buildings, etc., can solve problems such as unsuitability, and achieve the effects of economic viability, simple production, and prevention of drift and erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

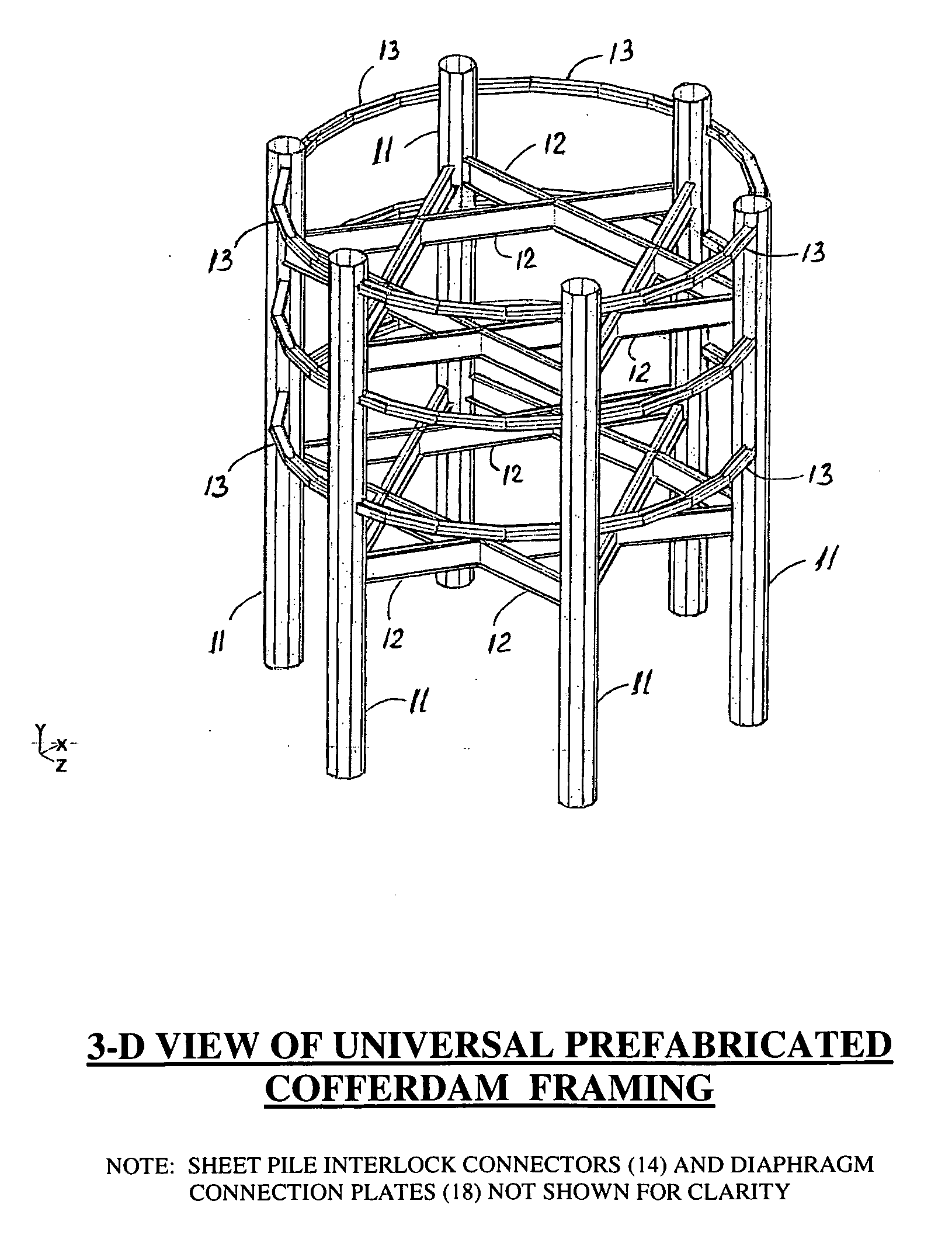

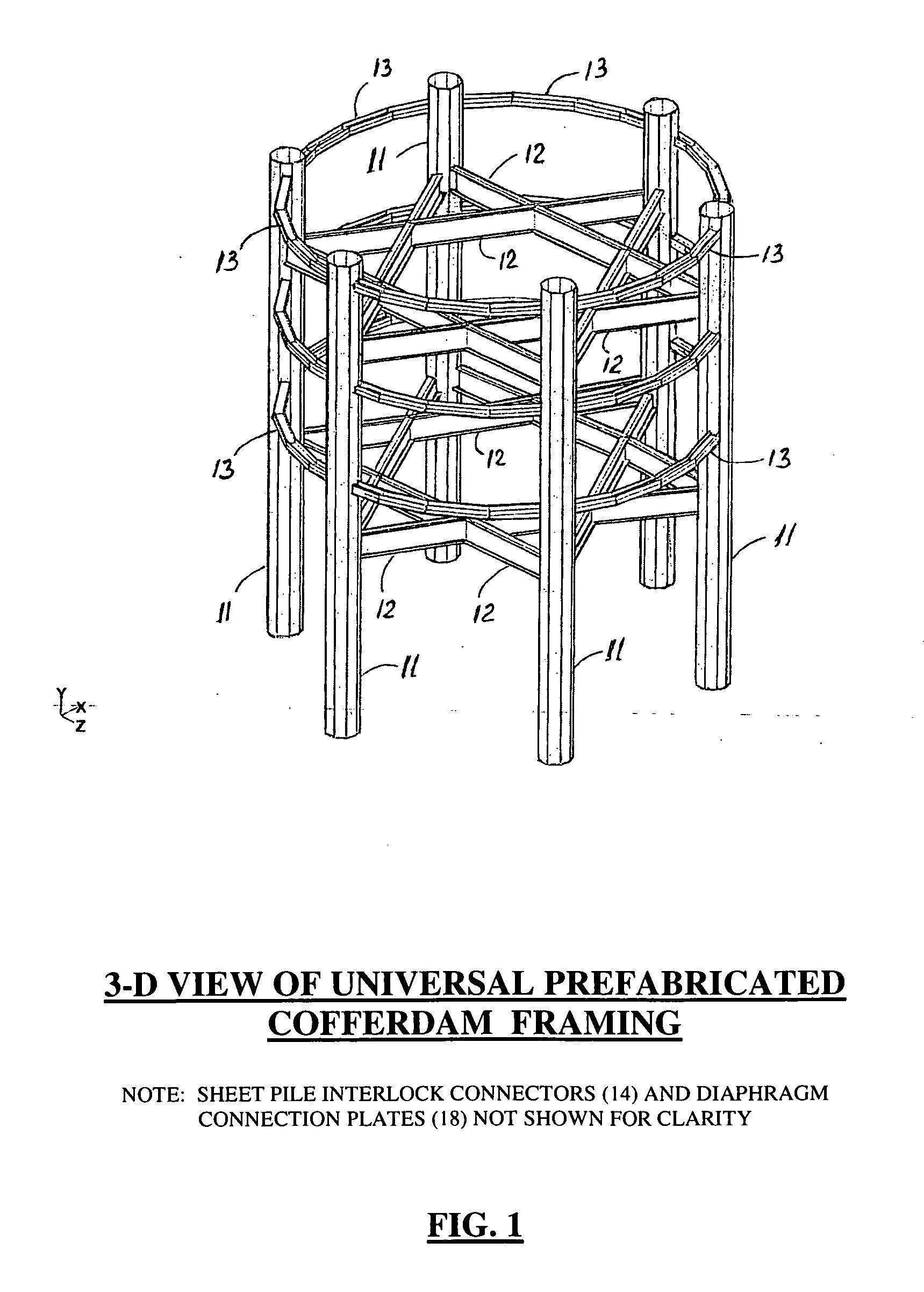

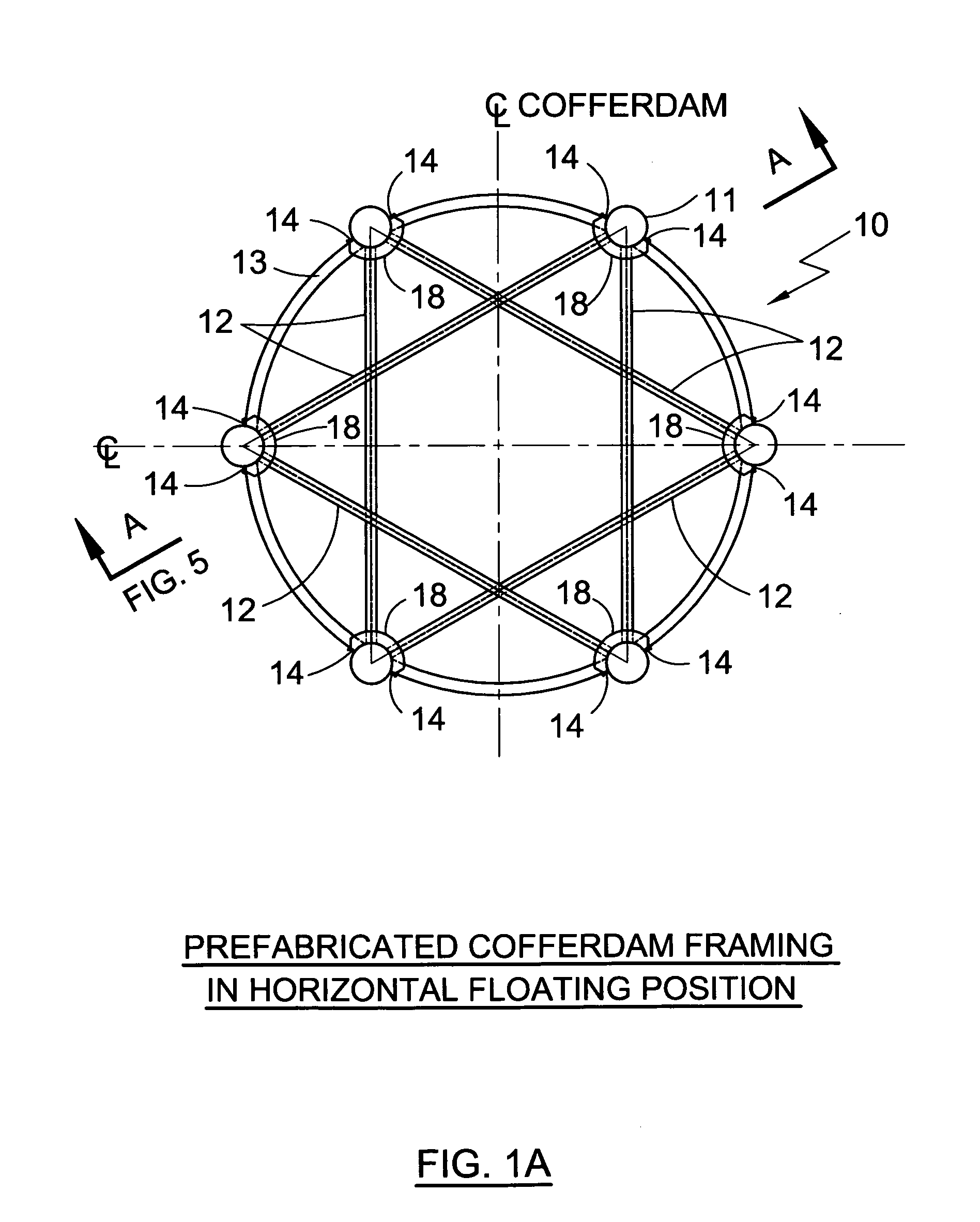

[0063]The present invention relates to an improved method of construction and installation of sheet pile Cellular Cofferdams. It also relates to improved design of Cofferdam structure itself, creating a new subclass that can be called Columnar Cofferdam structure. The following discussion describes in detail one embodiment of invention. This discussion, however, should not be construed, as limiting the invention to this particular embodiment. Practitioners skilled in the art will recognize other numerous embodiments as well. The drawings show similar elements of the invention denoted by the same numerical character in all views and sections shown in FIG. 1 through FIG. 9 where the present invention generally depicted by the numeral 10.

[0064]FIG. 1 is a 3-D View of Universal Prefabricated Cofferdam Framing.

[0065]FIG. 1A is an illustrative view of the prefabricated Cofferdam framing in a floating position. The prefabricated Cofferdam framing 10 includes six pipe columns 11 with liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com