Small-caliber plastic rib spiral tube without adhesive-bonded joint and production process for small-caliber plastic rib spiral tube without adhesive-bonded joint

A plastic-reinforced spiral and production process technology, which is applied in the direction of hoses, pipes, tubular objects, etc., can solve the problems of poor bonding of joints, increased waste rate, and inability to produce, so as to achieve no residue in transportation, improved product quality, smooth delivery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

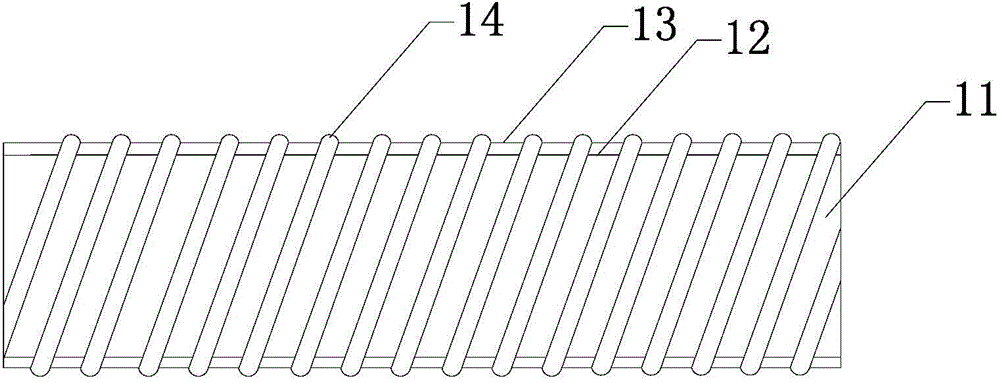

[0011] like figure 1 As shown, the plastic-reinforced spiral pipe with a small diameter and no bonding seam includes a plastic-reinforced pipe body 11, the inner diameter of the plastic-reinforced pipe body 11 is 6-16mm, and the inner wall of the plastic-reinforced pipe body 11 is integrally formed. The inner smooth surface 12 and the outer smooth surface 13 formed by the outer wall of the plastic rib tube body 11 are integrally formed. The outer wall of the plastic rib tube body 11 is provided with spiral plastic ribs 14 wound on the tube body.

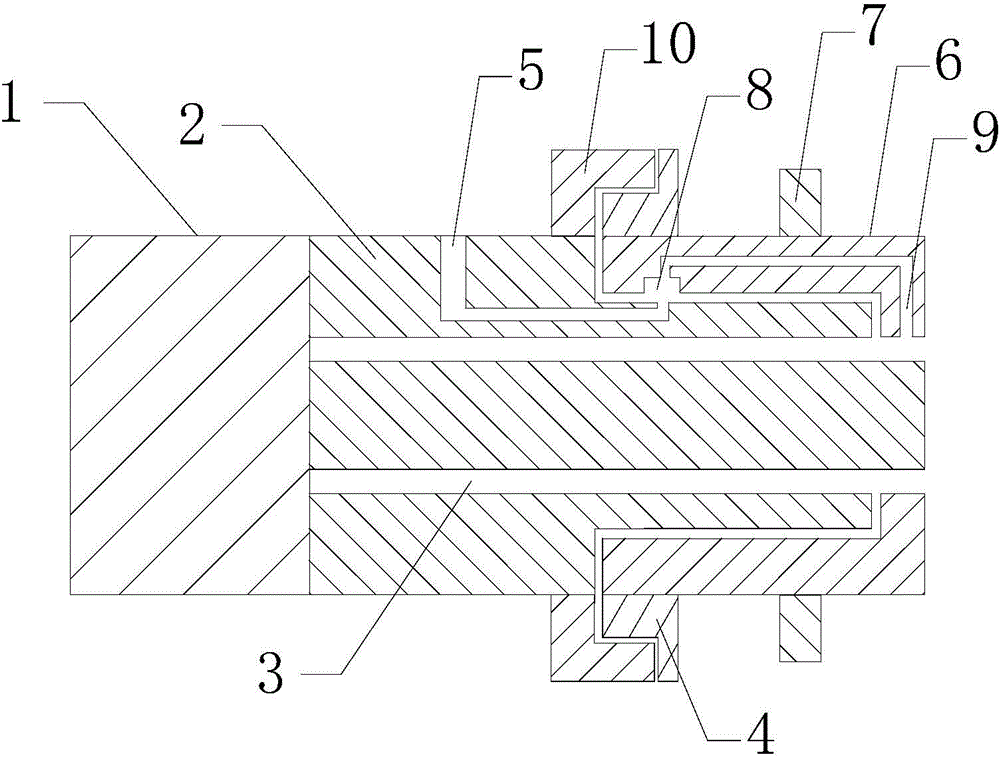

[0012] The production process of the plastic-reinforced spiral pipe with small diameter and no bonding seam includes the following steps. The plastic-reinforced pipe material is extruded from the extruder head, and the plastic-reinforced pipe body 11 is formed in the plastic-reinforced pipe forming channel. At...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com