Laterally-vertical type grinder of calcium carbonate

A calcium carbonate and grinding machine technology, applied in cocoa, grain processing, food science, etc., can solve the problems of easily damaged grinding discs, poor material flow, and low power, so as to increase the grinding area, prolong the service life, and avoid downtime. unexpected effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

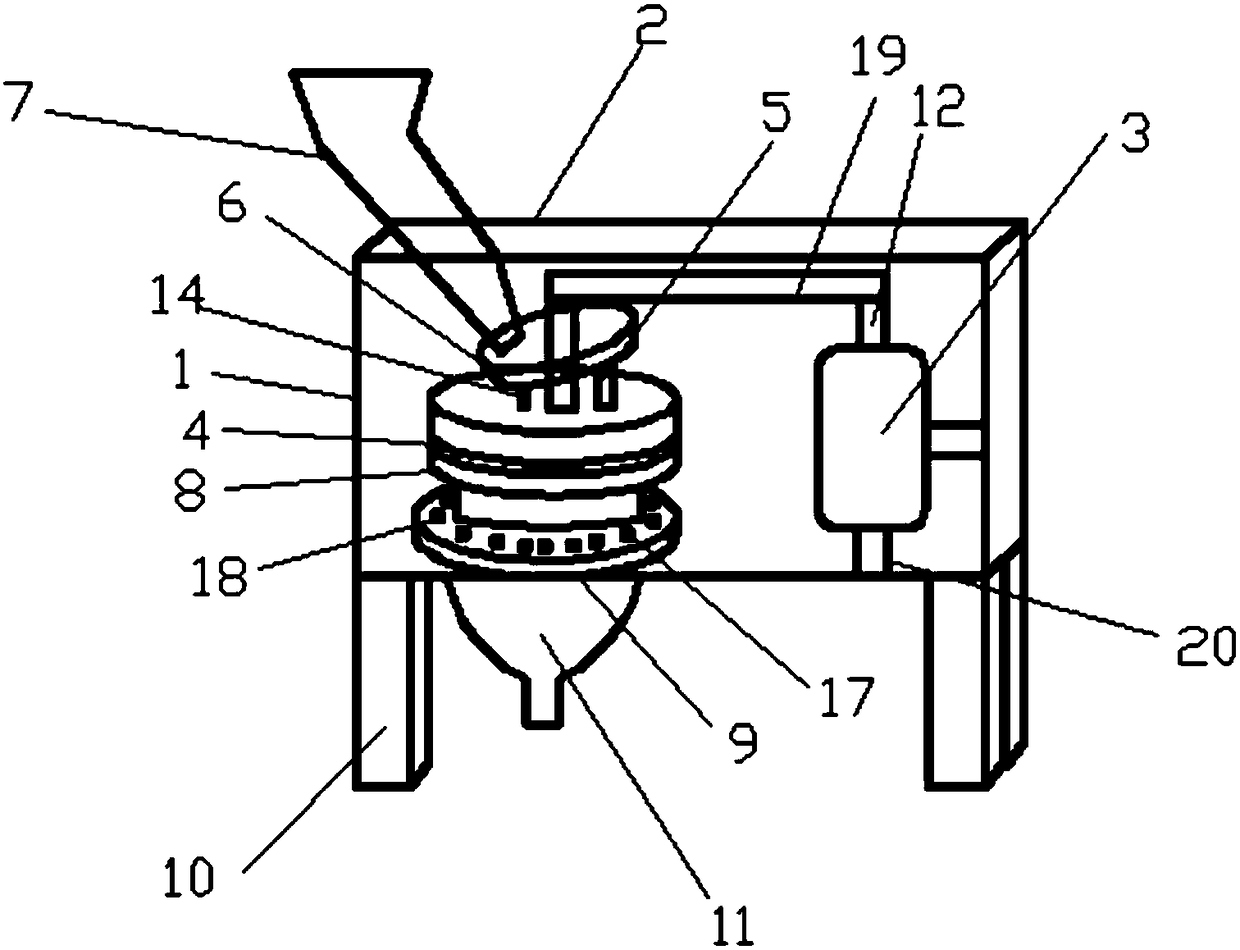

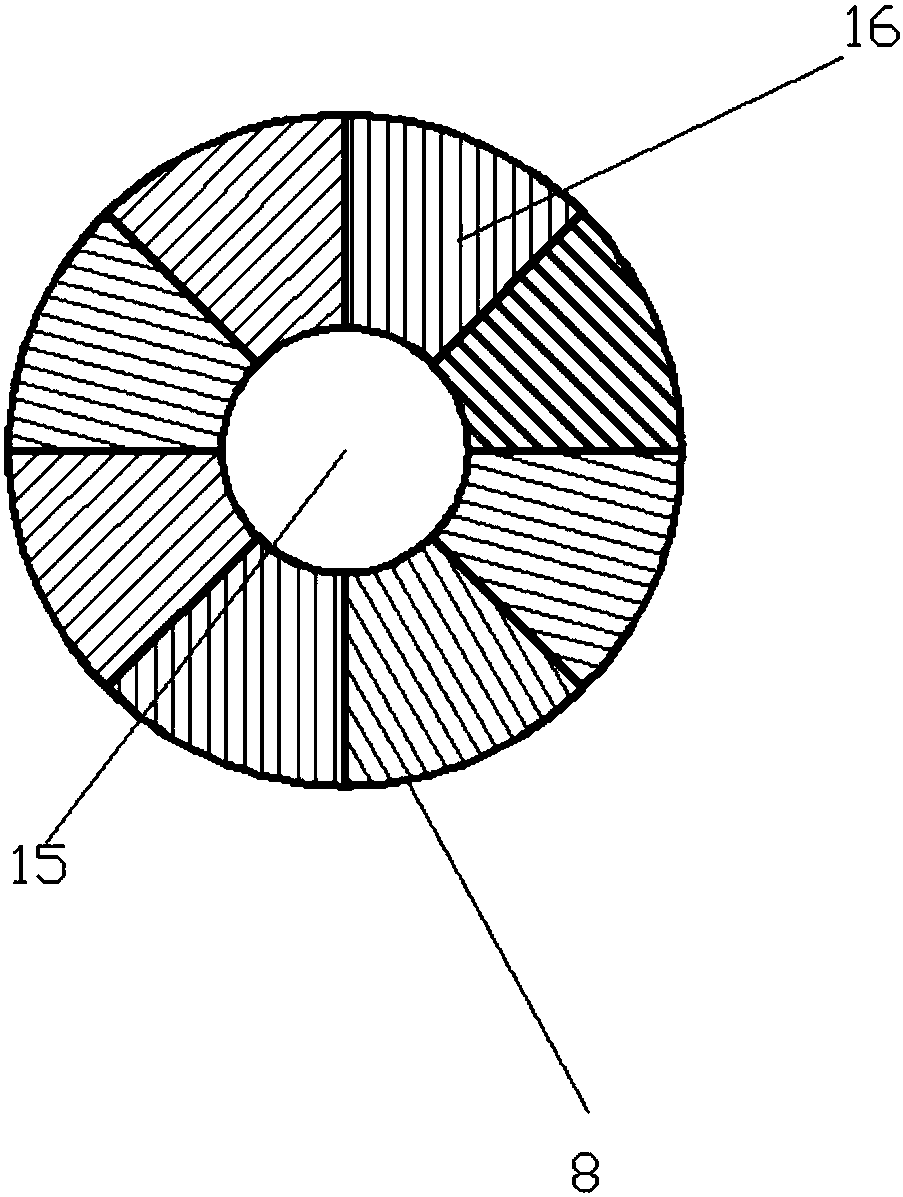

[0018] Specific implementation mode one: combine Figure 1-6 As shown, it includes a casing 1, and an organic cover 2 is installed on the top of the casing 1; a motor 3 is fixed at the right side of the casing 2; the motor 3 is connected with an upper grinding disc 4 through a rotating shaft 12; One end of the feed channel 5 is connected; the other end of the feed channel 5 is connected with an obliquely arranged annular material tray 6; the feed channel 5 is connected to the lowest point of the annular material tray 6; the annular material tray 6 passes through the upper grinding disc 4 The fixed rod 14 is connected; the cover 2 above the ring-shaped material tray 6 is provided with a feeding passage 7; the upper millstone 4 is engaged with the lower millstone 8; the center of the upper millstone 4 and the lower millstone 8 has a grinding chamber 15; The surface of the upper grinding disc 4 and the lower grinding disc 8 have eight oblique lines of grinding lines 16; the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com