Coal-derived ethylene glycol steam condensate heat recycling system and method

A coal-to-ethylene glycol and heat recovery technology, which is used in steam generation, preheating, feedwater heaters, etc., can solve problems such as energy waste, reduce resistance and energy waste, ensure smooth transportation, and increase temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

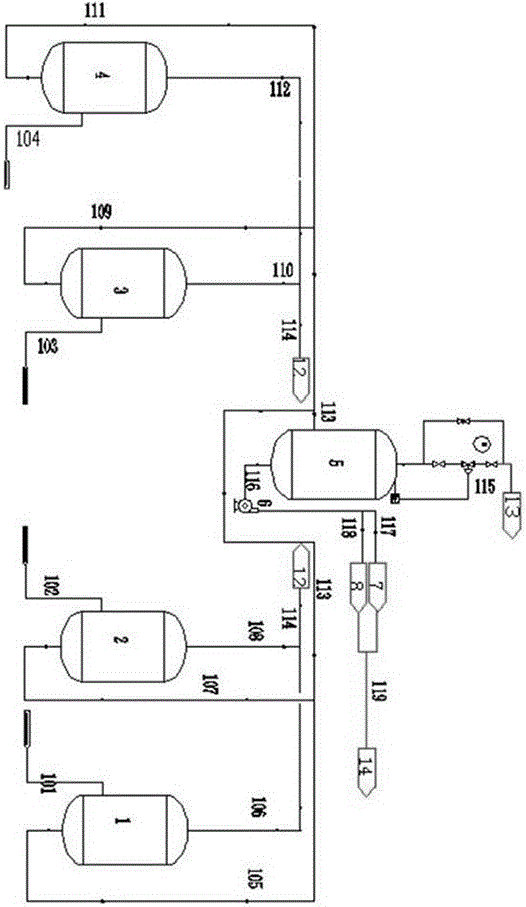

[0019] A coal-to-ethylene glycol steam condensate heat recovery system, such as figure 1 Shown, comprise high grade flash evaporation unit and low pressure flash tank 5, high grade flash evaporation unit comprises first flash evaporation unit, second flash evaporation unit, the 3rd flash evaporation unit and the 4th flash evaporation unit, the first flash evaporation unit The unit includes a first pipeline 101 leading to 0.8MPa condensate, a first flash tank 1 connected to the first pipeline at the inlet end, and a fifth pipeline 105 and the first flash tank provided at the outlet end of the first flash tank condensate The sixth pipeline 106 provided at the outlet end of the gas phase; the second flash unit includes a second pipeline 102 leading to the condensate of the rectification system at 1.5 MPa, a second flash tank 2 connected to the second pipeline at the inlet, and a second flash tank The seventh pipeline 107 arranged at the outlet end of the tank condensate and the e...

Embodiment 2

[0024] A method for recovering heat from coal-to-ethylene glycol steam condensate utilizes the coal-to-ethylene glycol steam condensate heat recovery system in Embodiment 1, and the recovery and utilization system will not be repeated here.

[0025] The recovery method is as follows: the high-grade steam condensate in the coal-to-ethylene glycol process production system enters the high-grade flash unit for flash evaporation, and the high-grade condensate: 1.0MPa steam passes through the heater to exchange heat with the material to form 0.8MPa The condensate enters the first flash tank 1 through the first pipeline 101 for flashing, and the 0.5MPa steam after the flashing is sent into the sixth pipeline 106 through the upper end gas phase outlet of the first flashing tank, and the obtained after flashing The 0.4MPa steam condensate enters the fifth pipeline 105; after the 1.7MPa steam of the rectification system exchanges heat with the material through the heater, the 1.5MPa ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com