Helical material transport machine

A conveyor and material technology, applied in the direction of transportation and packaging, loading/unloading, containers, etc., can solve the problems of equipment continuous feeding, increased warehouse pressure, material arching, etc., to achieve smooth material transportation, avoid arching, The effect of low drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

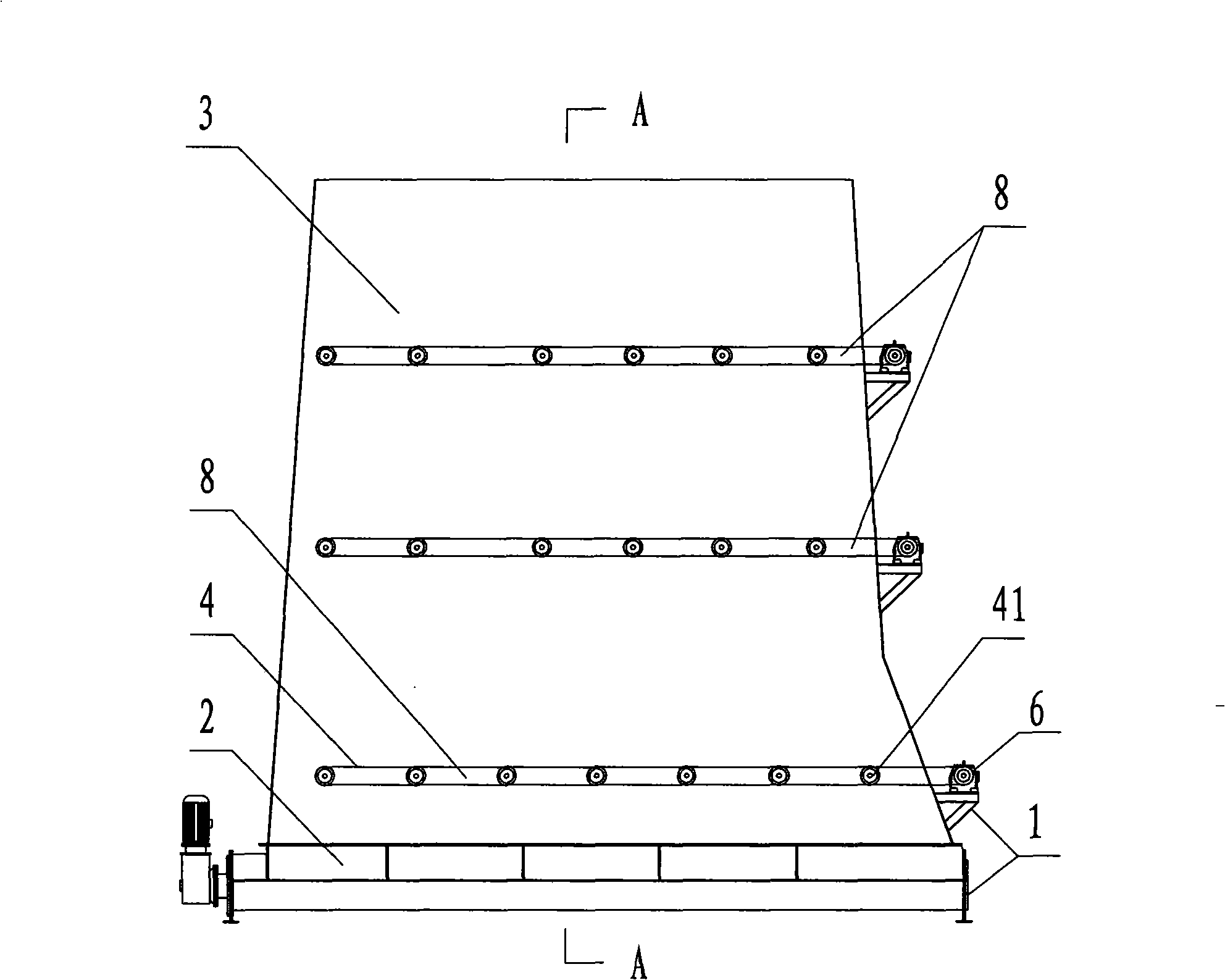

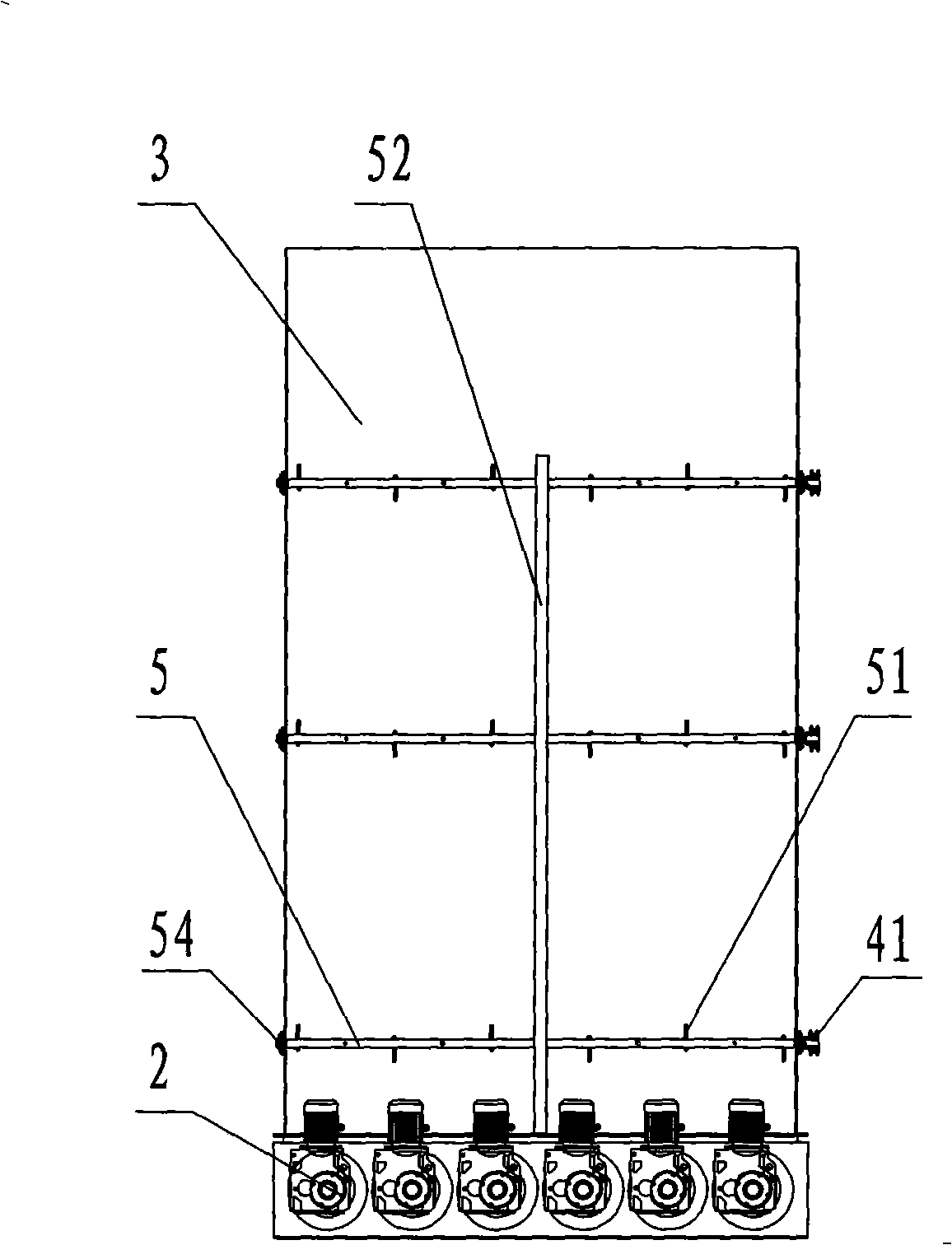

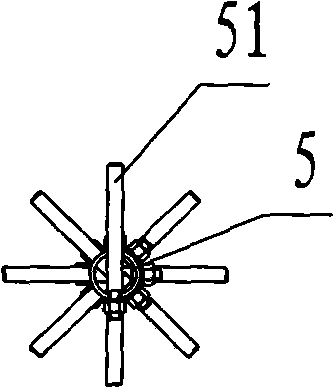

[0021] Such as figure 1 and figure 2 , is a kind of spiral material conveyor with loosening device of the present invention, comprises the screw material conveying unit 2 that is located on the frame 1, and the top of the screw material conveying unit 2 is provided with a silo 3, between the silo and the screw conveying unit 2 The junction is provided with a loosening device 8, and the middle and upper parts of the silo are also provided with a loosening device 8. The loosening device 8 includes a stirring shaft assembly flexibly installed on the feed bin 3, and the stirring shaft assembly includes a chain 4 linked A number of stirring shafts 5 and the motors 6 that are arranged on the frame 1 to drive the stirring shaft 5 to rotate, 54 in the figure are bearing seats, 41 are transmission sprockets, and the stirring shafts 5 pass through the bearing seats 54 arranged on the wall of the silo. It is flexibly installed at the junction of the silo and the screw conveyor unit 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com