Insert molded body and radiation structure

A technology of insert molding and bonding holes, applied in the direction of coating, etc., can solve the problem of low adhesion between resin parts and metal parts, and achieve the effect of smooth heat transfer and sufficient adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

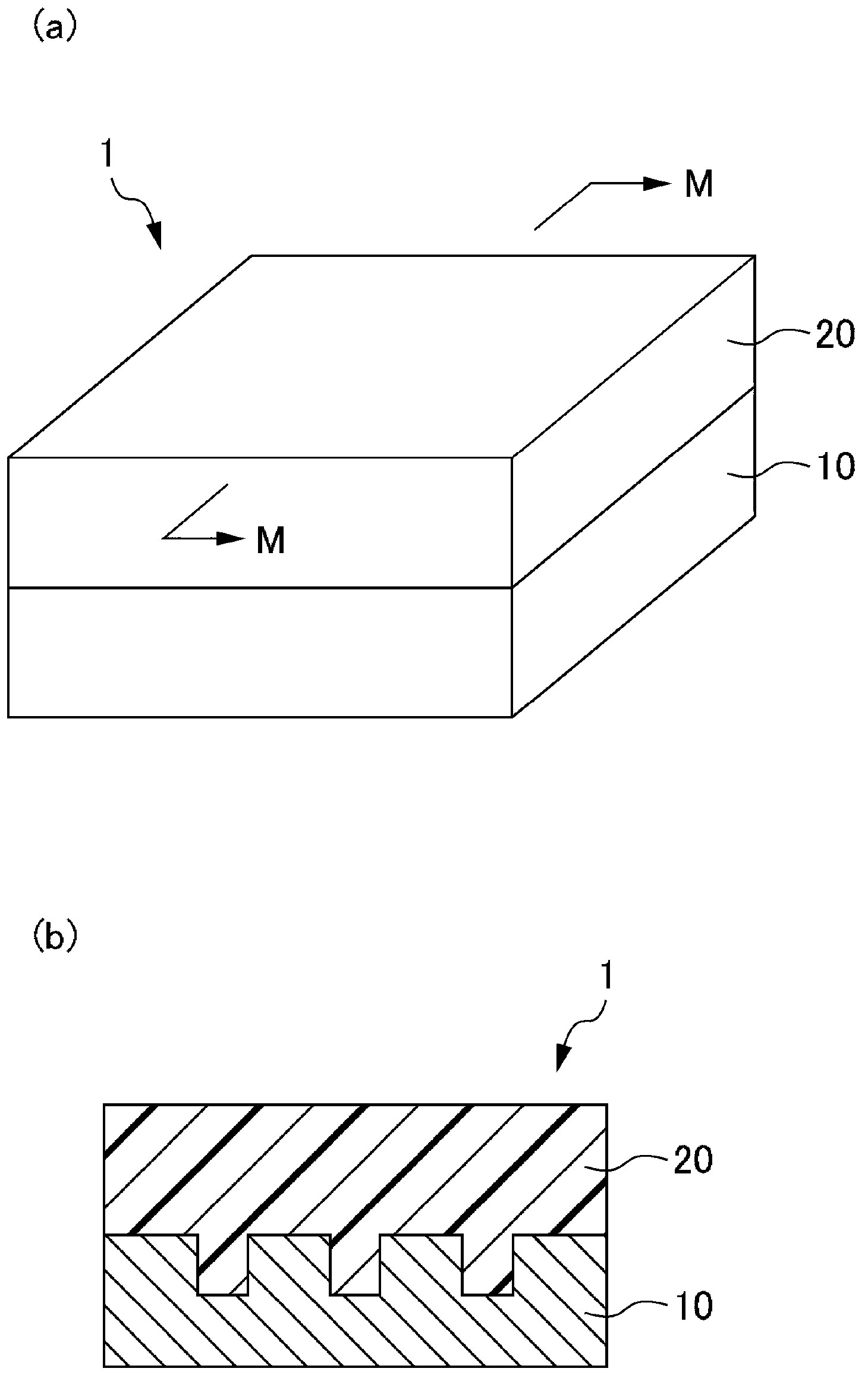

[0055] figure 1 It is a schematic diagram which shows the insert molding of 1st Embodiment, (a) is a perspective view, (b) is MM cross-sectional view.

[0056] like figure 1 As shown, the insert molded body 1 of this embodiment includes a metal member 10 and a resin member 20 . like figure 1 As shown, it is formed by laminating the resin component 20 on the metal component 10 . Additionally, if figure 1 As shown in (b), the resin member 20 enters into a hole (joint hole described later) formed in the metal member 10 .

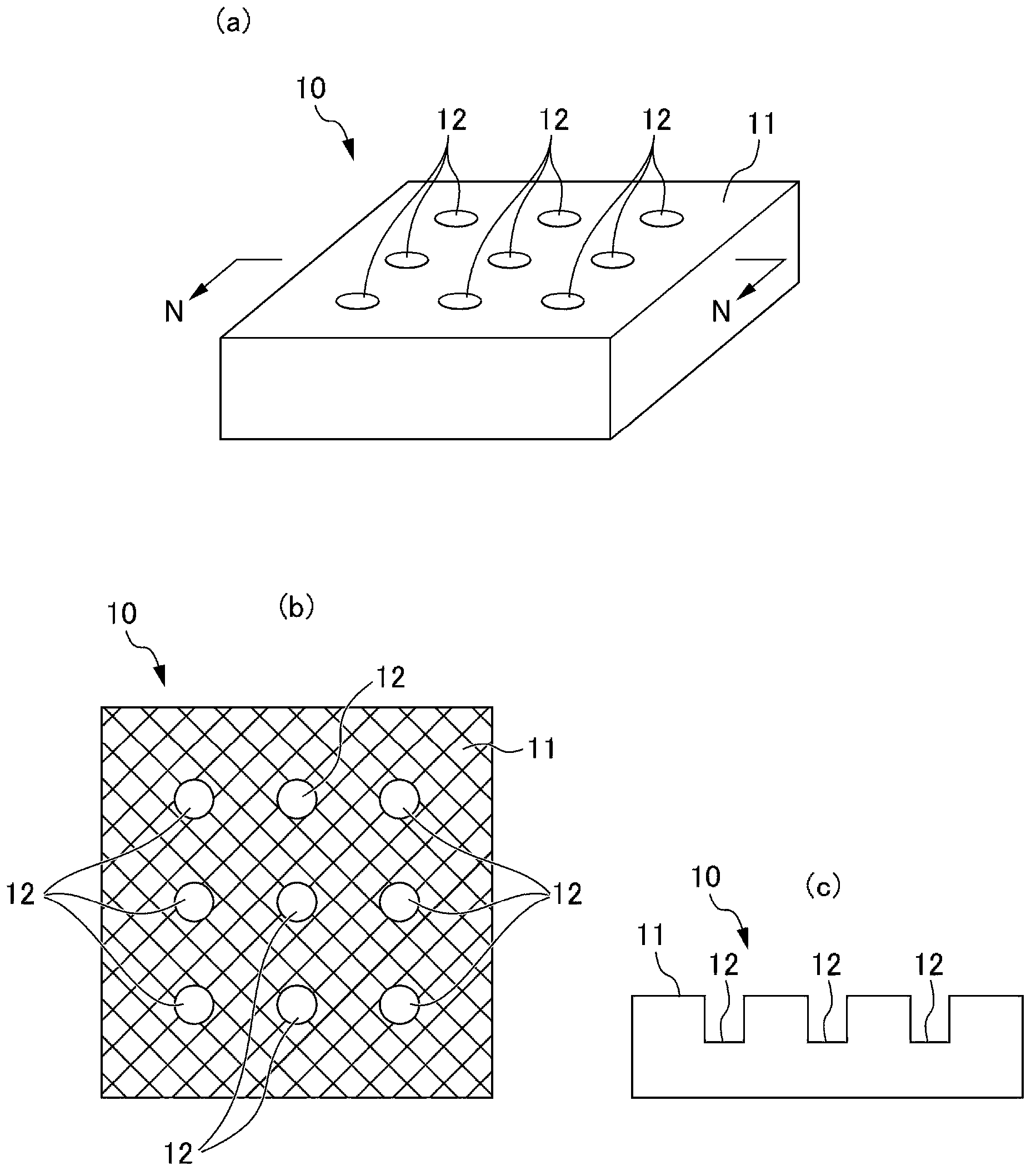

[0057] figure 2 It is a schematic diagram which shows the metal member 10, (a) is a perspective view, (b) is a top view, (c) is NN cross-sectional view.

[0058] like figure 2 As shown, the metal component 10 is a plate-shaped component. In addition, the metal part 10 has a joint surface 11 and two or more joint holes 12. The joint surface 11 is one surface constituting the metal part 10, which is in contact with a resin part 20 described later; ...

no. 2 approach

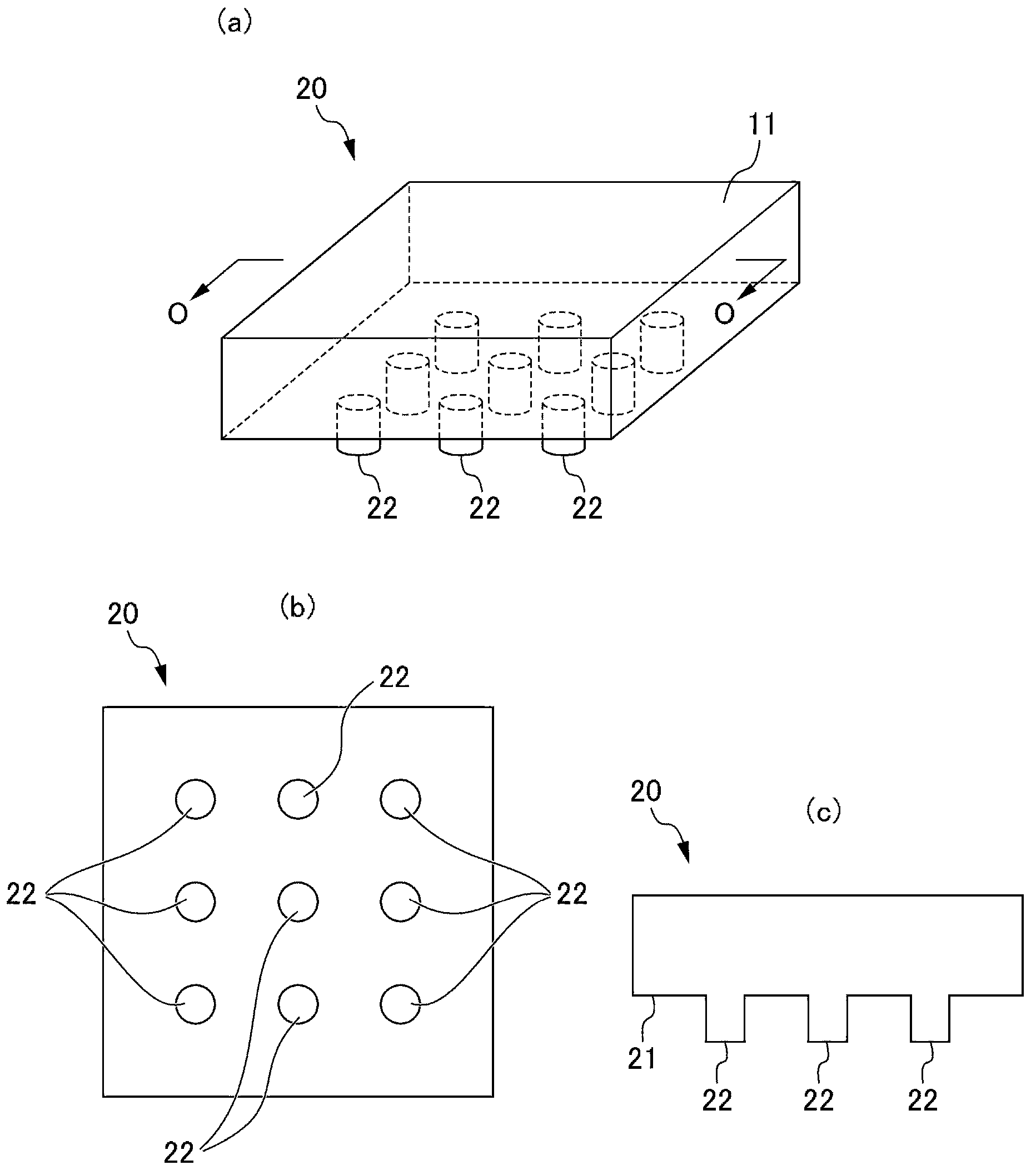

[0100] Next, edge reference Figure 4 A second embodiment of the insert molded article of the present invention will be described. The insert molded body 1A of the present embodiment is rectangular hexahedron like the insert molded body 1 of the first embodiment, Figure 4 It is a schematic diagram which shows the cross section of the insert molding 1A of 2nd Embodiment. It should be noted that in the description of the second embodiment and thereafter, the same reference numerals are assigned to the same constituent elements, and the description thereof will also be omitted.

[0101] The insert molded body 1A of the second embodiment is mainly different from the first embodiment in that the joint hole 12A formed on the joint surface 11A of the metal member 10A is a through hole penetrating the joint surface 11A and its rear surface.

[0102] In addition, since the bonding hole 12A penetrates the bonding surface 11A and its back side surface, the area S of the bonding surfac...

no. 3 approach

[0107] Next, edge reference Figure 5 A third embodiment of the insert molded article of the present invention will be described. The insert molded body 1B of the present embodiment is in the same rectangular hexahedron shape as the insert molded body 1 of the first embodiment and the insert molded body 1A of the second embodiment, Figure 5 It is a schematic diagram which shows the cross section of the insert molding 1B of 3rd Embodiment.

[0108] The insert molded body 1B of the third embodiment is different from the first embodiment in that the joint hole 12B formed on the joint surface 11B of the metal member 10B penetrates the joint surface 11B and the surface on the back side; at least a part of the joint hole 12B In the joint hole 12B, the cross-sectional area in the depth direction at a predetermined depth is smaller than the cross-sectional area in the depth direction at a position deeper than the predetermined depth.

[0109] The shape of the engaging hole 12B is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com