Bidirectional lateral washing method for filter cake of filter press

A washing method and filter press technology, which is applied in the field of filter press filtration, can solve the problems of small flow rate, slow washing process, waste of energy, etc., and achieve the effects of improving production efficiency, short washing time, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

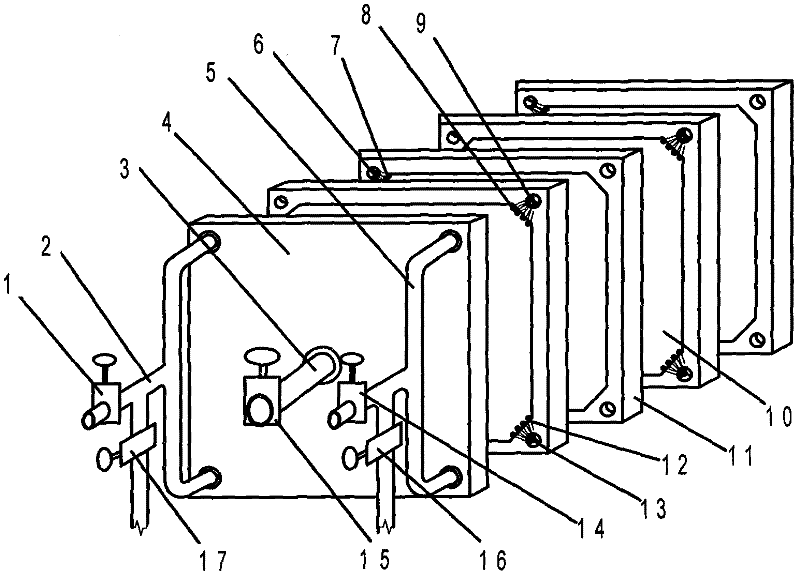

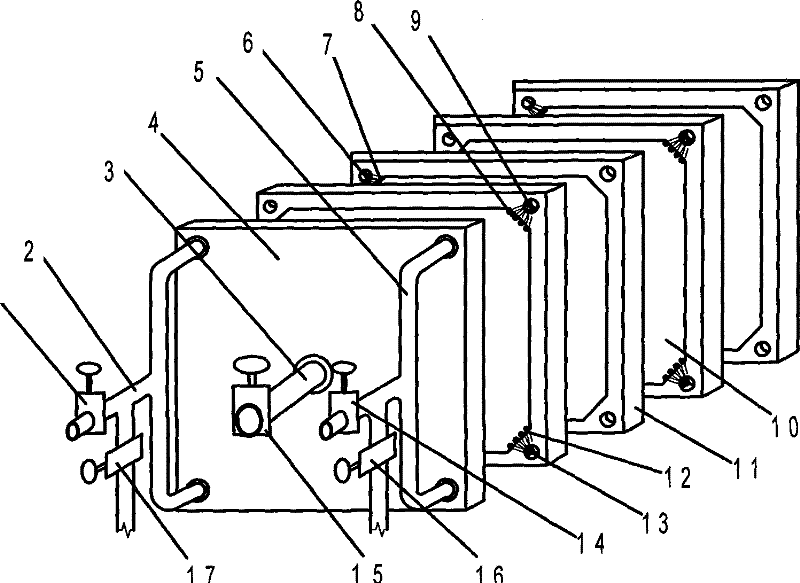

[0010] see figure 1 As shown, the present invention provides a two-way side-type washing method for filter cake of a filter press. The thrust plate 4 of the filter press is equipped with a feed pipeline 3, and a feed valve 15 is installed on the feed pipeline 3, and then the pipeline Connect the feed pump, install the tee left pipe 2 on the left side of the thrust plate 4, install the left valve 1 to connect the washing pump, and install the left drain valve 17 on the left pipe 2 of the tee to connect the drain pipe, and the right side of the thrust plate 4 The three-way right pipe 5 is installed on the top and the right valve 14 is connected to the washing pump, and the right drain valve 16 is installed on the top of the three-way right pipe 5 to connect the drain pipe. The material used for the pipe is seamless steel pipe, and the material is stainless steel or carbon structural steel , the valve selects a ball valve or a butterfly valve, and the box-type filter plate 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com