Washing and filtering device

A filter device and filter plate technology, applied in the field of medicine and fine chemical washing and filtration, can solve problems such as increasing the complexity of operations, and achieve the effects of good cleaning effect, less material transfer loss, and less turbid liquid residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

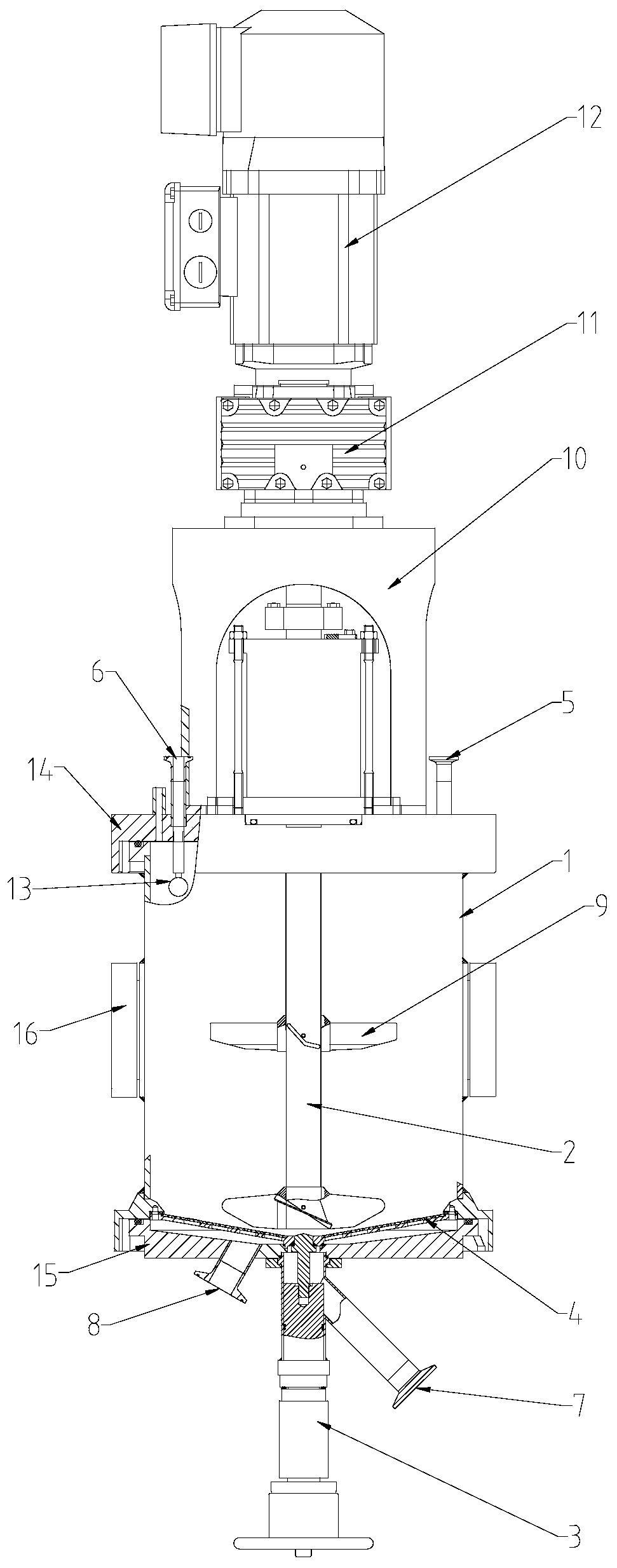

[0021] Such as figure 1 Shown, the present invention is a kind of washing and filtering device, comprises tank body 1, and tank body 1 top is provided with tank loam cake 14, and tank body 1 bottom is provided with tank lower cover 15, and tank body 1 is provided with stirring rod 2, stirs The rod 2 is provided with a stirring paddle 9, and the stirring paddle 9 has two, one is arranged on the end of the stirring rod 2 near the bottom of the tank body 1, and the other is arranged on the middle part of the stirring rod 2, and the two stirring paddles 9 are of different forms, so that The material and the washing liquid are fully mixed and contacted, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com