Smoke washing comprehensive utilization system equipment

A system equipment and flue gas technology, applied in the field of flue gas washing comprehensive utilization system equipment, can solve the problems of high operating costs, large changes in working conditions, complex pipelines, etc., and achieve short washing time, short residence time, and reduced volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A preferred embodiment of the present invention will be further described below in conjunction with the accompanying drawings, so as to help understand the content of the present invention.

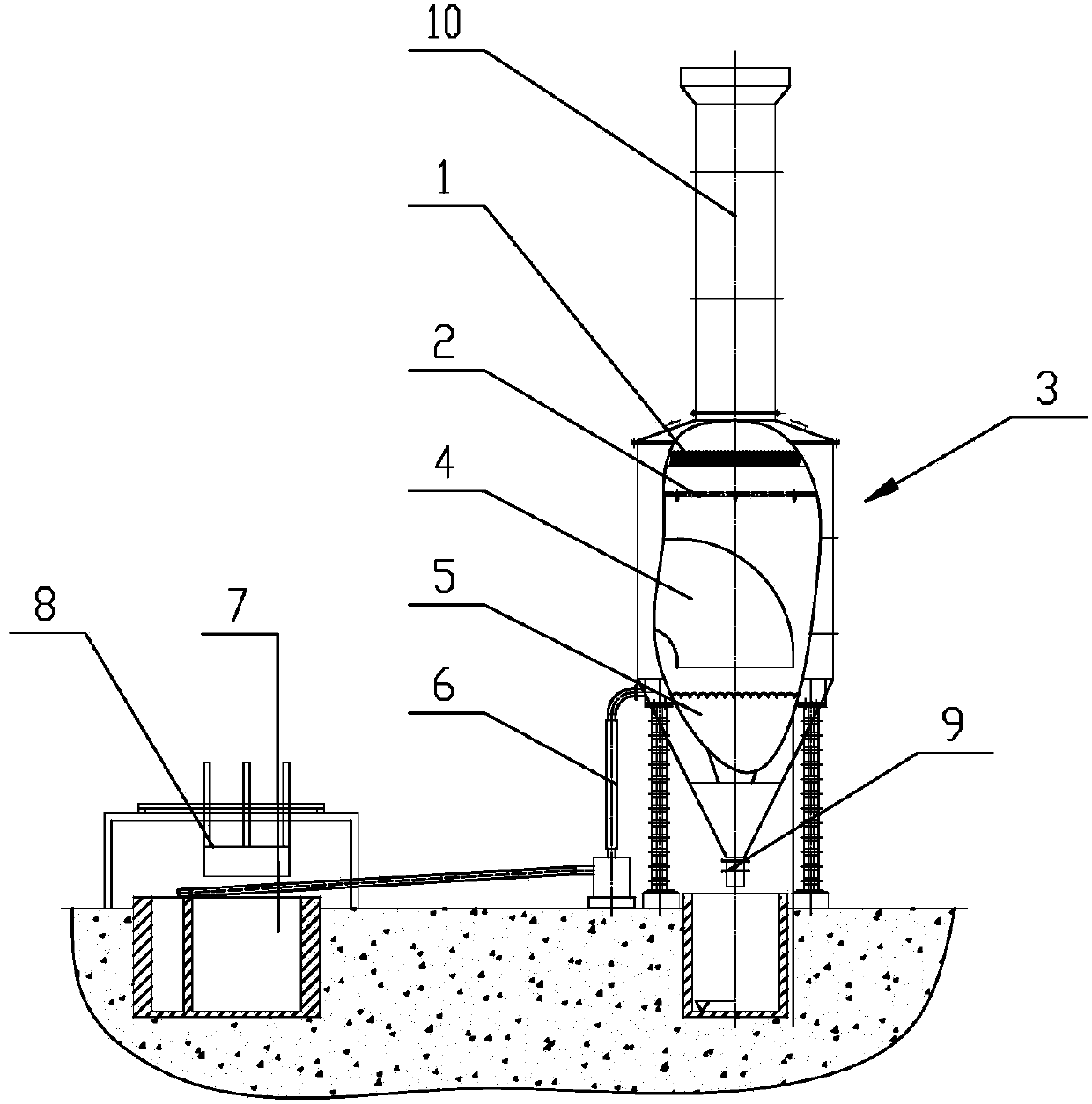

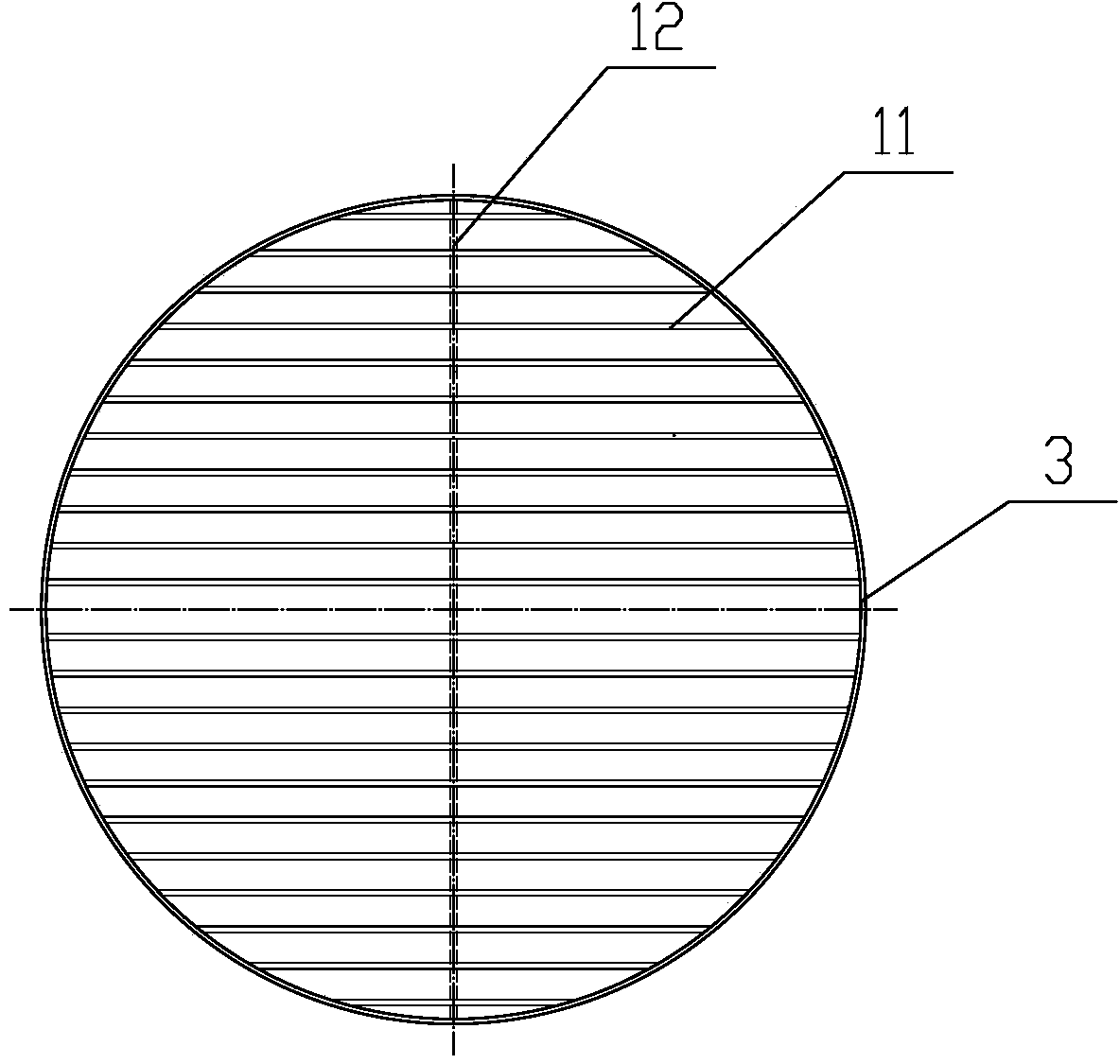

[0027] Such as Figure 1 to Figure 3 Shown, the present invention comprises washing tower 3, and the upper part of the tower body of washing tower 3 is a cylinder, and the bottom is a cone with a large upper part and a smaller lower part; the top of the cone is connected with one end of the overflow pipe 6, and the other end of the overflow pipe 6 Connected to the sedimentation tank 7, an automatic slag removal machine 8 is installed in the sedimentation tank 7; washing liquid is arranged in the cone, and the liquid level of the washing liquid is lower than the mouth of the overflow pipe 6; the bottom of the cone at the lower part of the tower body of the washing tower 3 is provided with a valve 9. The valve 9 is an anti-corrosion manual butterfly valve.

[0028] The air inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com