Method and device for controllable foam cleaning for washing, disinfection and sterilization

A foam and cleaning room technology, applied in three equipment fields, can solve the problems of high cost, low efficiency, large water consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

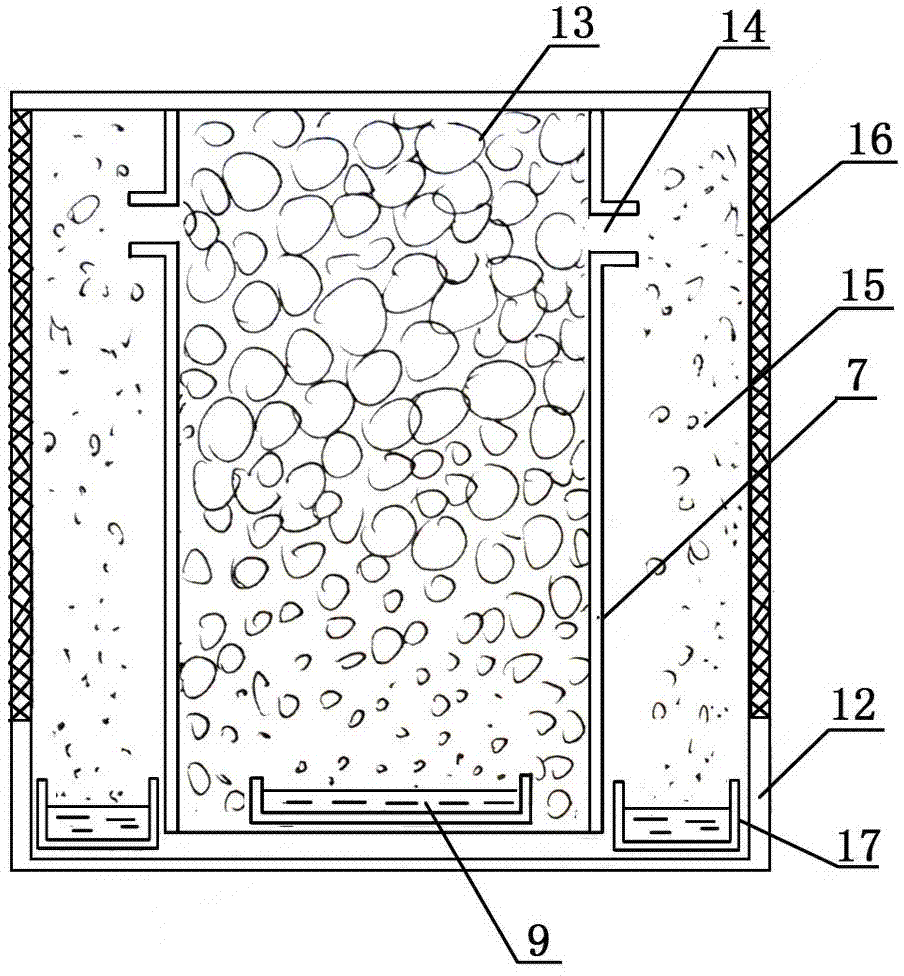

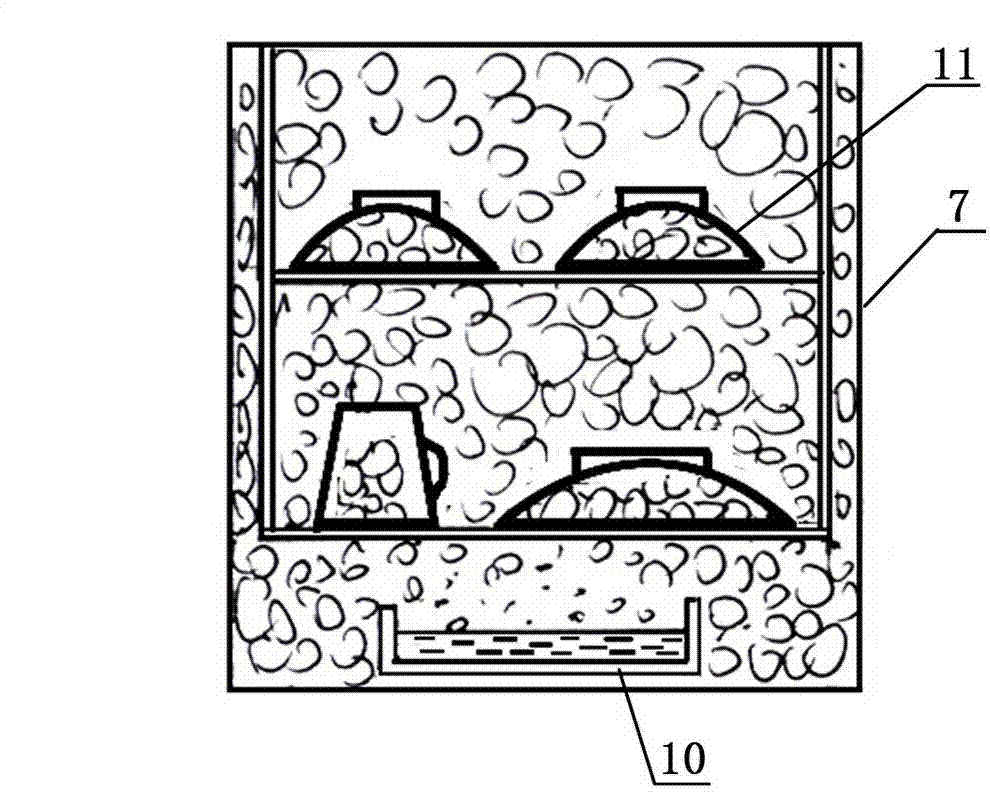

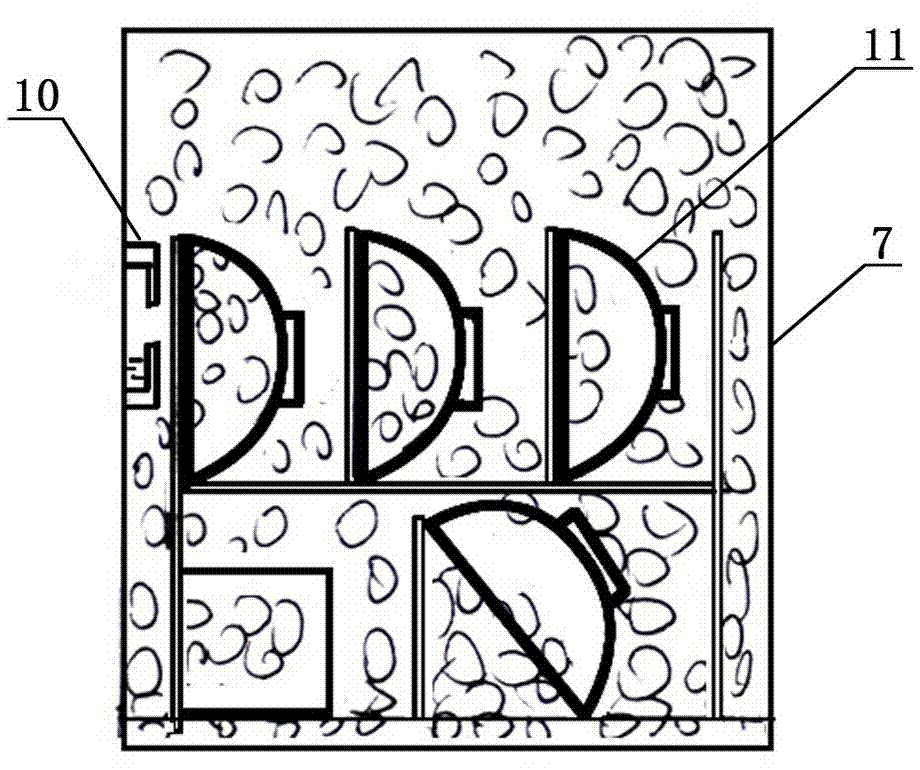

[0133] Examples see figure 1 As shown, this controllable foam cleaning method for washing, disinfection and sterilization uses heating components to heat the working fluid to generate foam, and a large amount of foam is directly formed in the cleaning room or introduced into the cleaning room from the outside; by effectively cleaning the foam Control, so that the dirt, harmful substances and microorganisms attached to the cleaning object placed in the cleaning room are fully in contact with the active ingredients on the foam surface at a temperature and pressure of 30-250 ° C and 1-5 standard atmospheric pressure in the cleaning room, Through a variety of mechanisms, it is separated, destroyed or killed, and as the pressure and temperature in the cleaning room decrease, it will separate from the surface of the object to be cleaned together with the foam, and the air with foam and pollutants in the cleaning room will be discharged from the cleaning room to complete the foam cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com