Combined piston type electronic vacuum pump for automobile

An electronic vacuum pump and combined piston technology, applied in piston pumps, variable displacement pump components, pumps, etc., can solve the problem of uneven sealing state and stress state of flexible sealing rings, complex structure and assembly, and reduced life and performance of vacuum pumps. problems, to improve assembly safety and flexibility, avoid positioning and press use, increase life and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with drawings and embodiments.

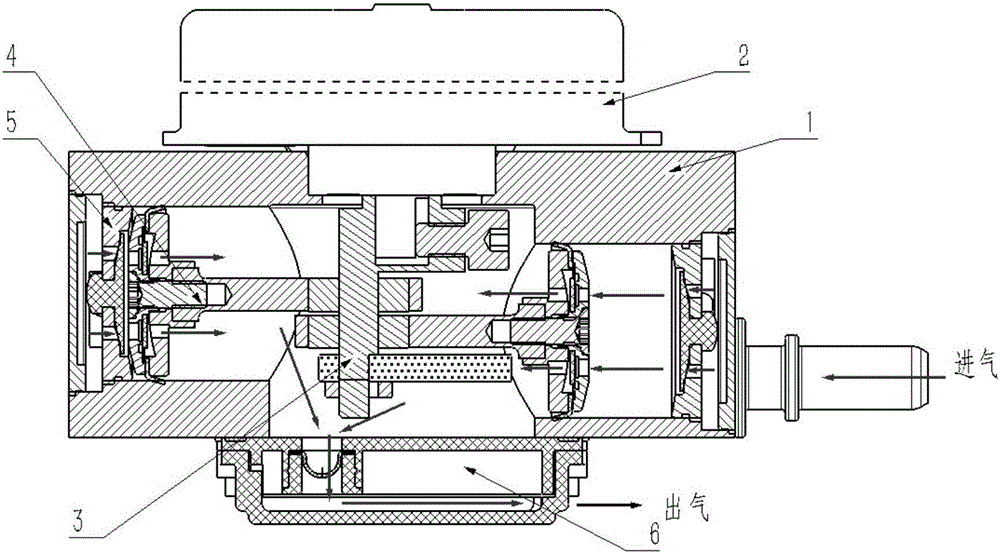

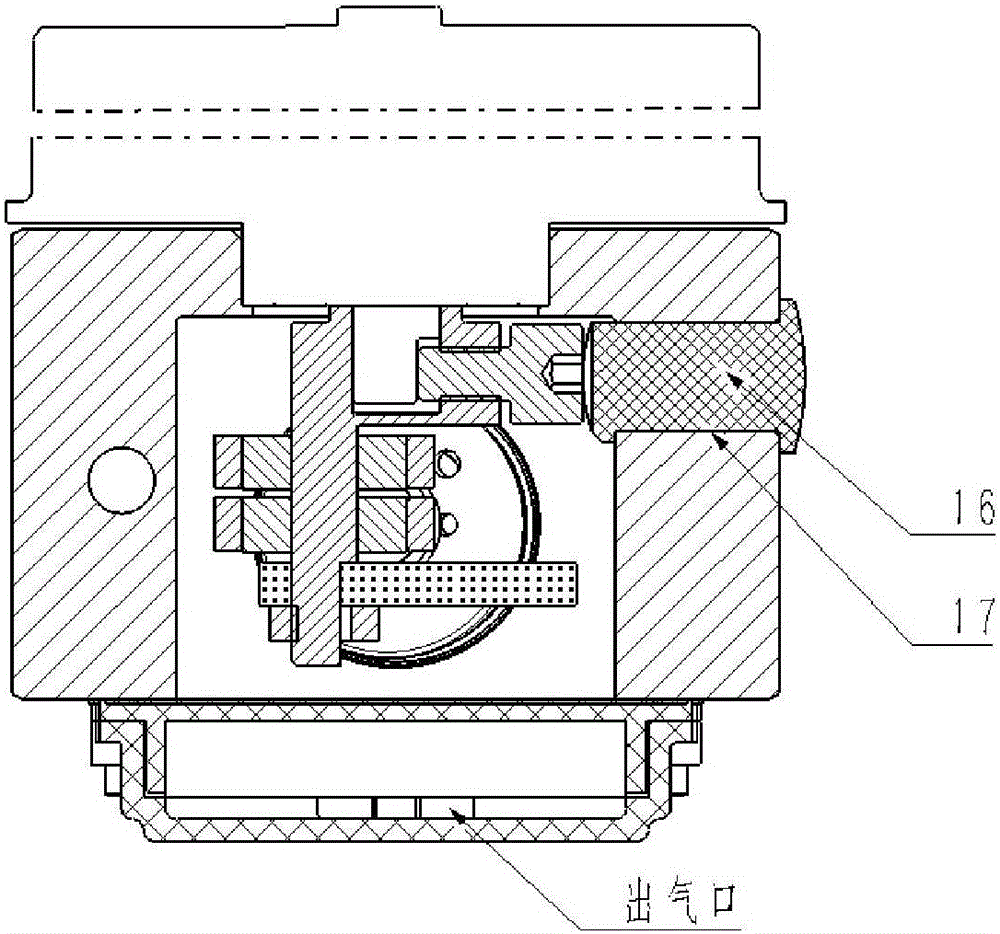

[0061] Such as figure 1 As shown, the present invention includes a valve body 1, a motor assembly installed on the top surface of the valve body 1, a sound-absorbing exhaust assembly 6 installed on the valve body 1, and a combined dynamic balance drive eccentric shaft assembly 3 built into the valve body 1 , two integrated one-way valve combined thin ball piston assembly 4 and two intake one-way valve 5.

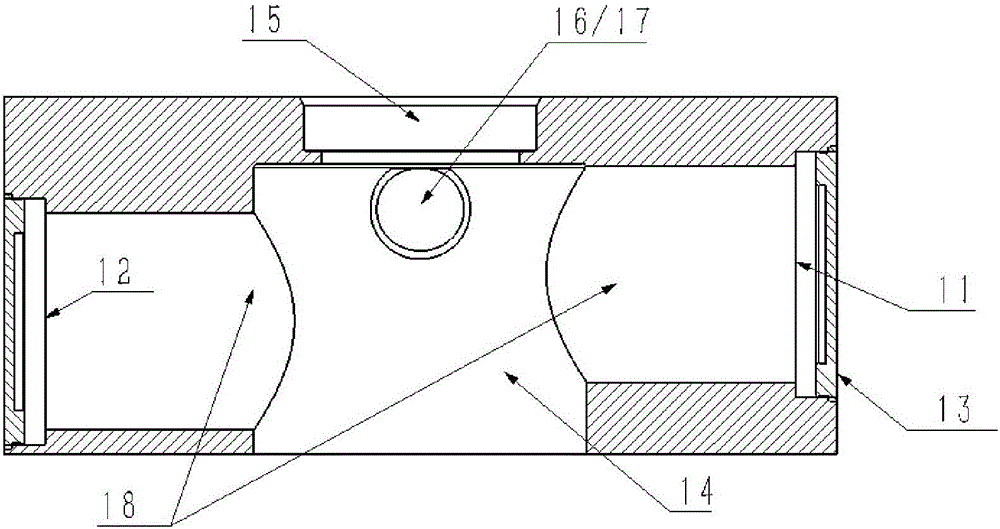

[0062] Such as image 3 As shown, the valve body 1 is machined from aluminum alloy, the valve body 1 is provided with a cylindrical central cavity 14 penetrating to the lower end surface, the upper end surface of the valve body 1 is provided with a motor mounting hole 15, and the left and right end surfaces of the valve body 1 are separated. There are left stepped hole 11 and right stepped hole 12 with the same structure, and the left stepped hole 11, right stepped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com