Rope pressing device of endless rope continuous-traction system

A technology of traction system and rope pressing device, which is applied in hoisting device, clockwork mechanism, locomotive, etc. It can solve the problems of large impact of traction plate, damage of pressing rope wheel, and adverse effects of endless rope system, etc., and achieves small impact , The effect of small opening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

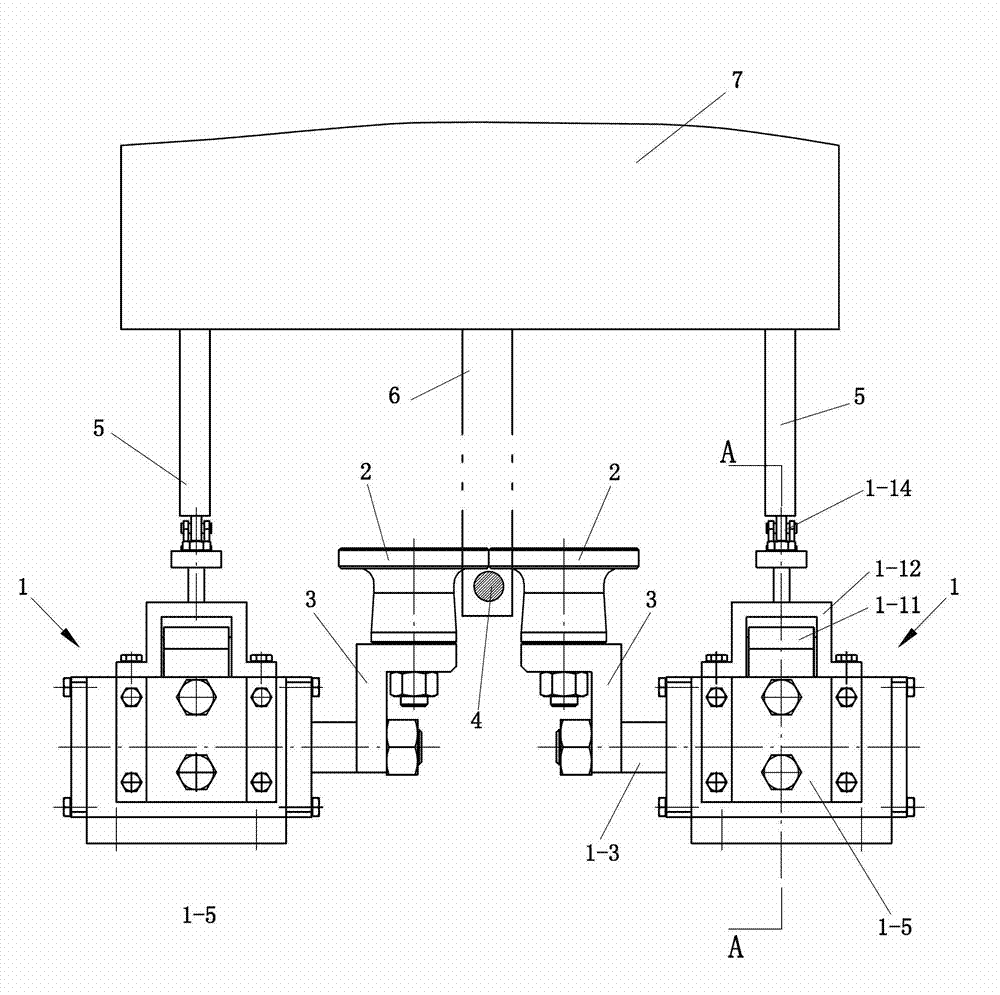

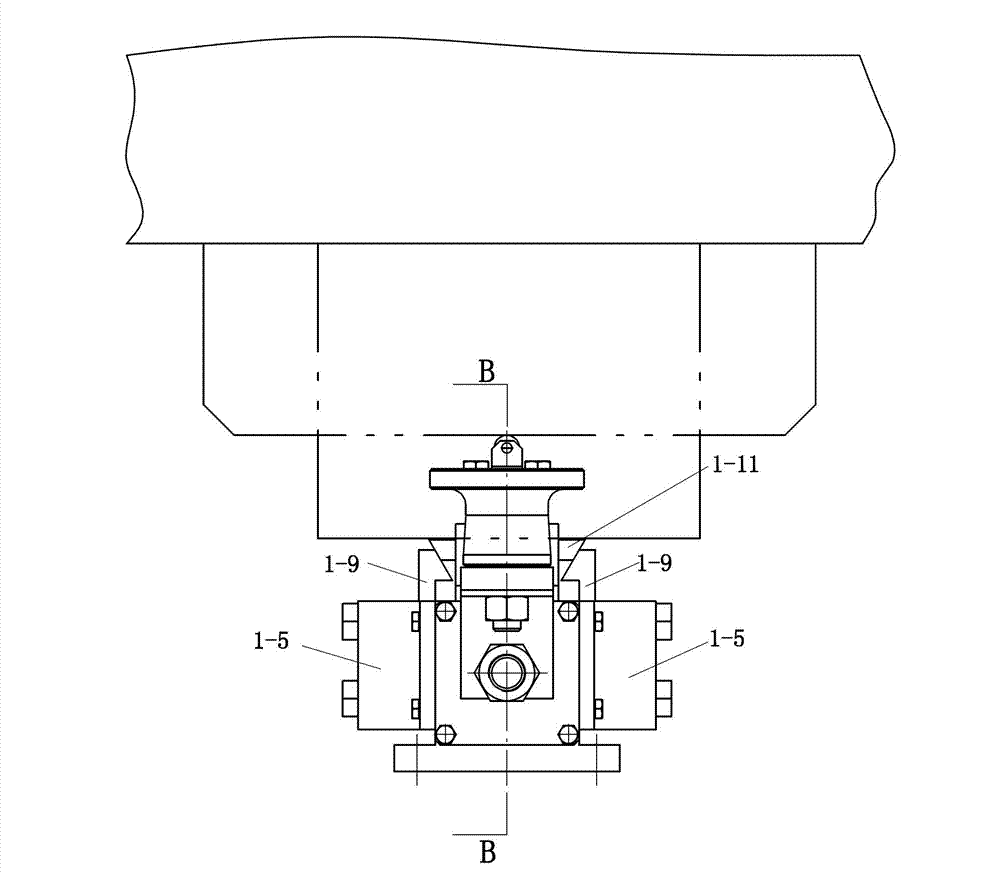

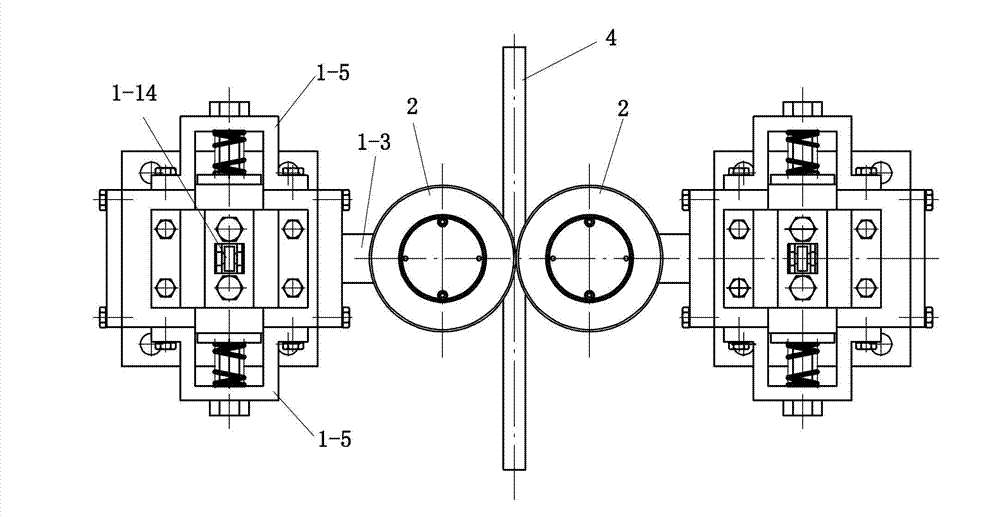

[0018] A rope-pressing device of an endless rope continuous traction system has two rope-pressing wheels 2, each of which is equipped with an opening and closing mechanism 1, and the opening and closing mechanism 1 is located on the rear side of the corresponding rope-pressing wheel 2.

[0019] The opening and closing mechanism 1 has a cylinder body 1-1, a piston 1-2 arranged in the cylinder body 1-1, a piston compression spring 1-4 on the rear side of the piston, a piston rod 1-3 connected to the front side of the piston, Two side frames 1-5 respectively connected to the left and right outer sides of the cylinder body, two translation blocks 1-9 with wedge-shaped heads in the two side frames 1-5 respectively, and two translation blocks 1-9 connected to the top surface of the cylinder body The top frame 1-12, the lifting block 1-11 in the top frame 1-12 and between the wedge-shaped heads of the two translation blocks, a pair of translation guide rods 1-6 and a pair of lifting g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com