Internally-arranged tapered rubber check valve

A check valve and rubber cone technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve the problems of poor sealing and residents' troubles, achieve small opening force, reliable sealing, and prevent the escape of odorous gases Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

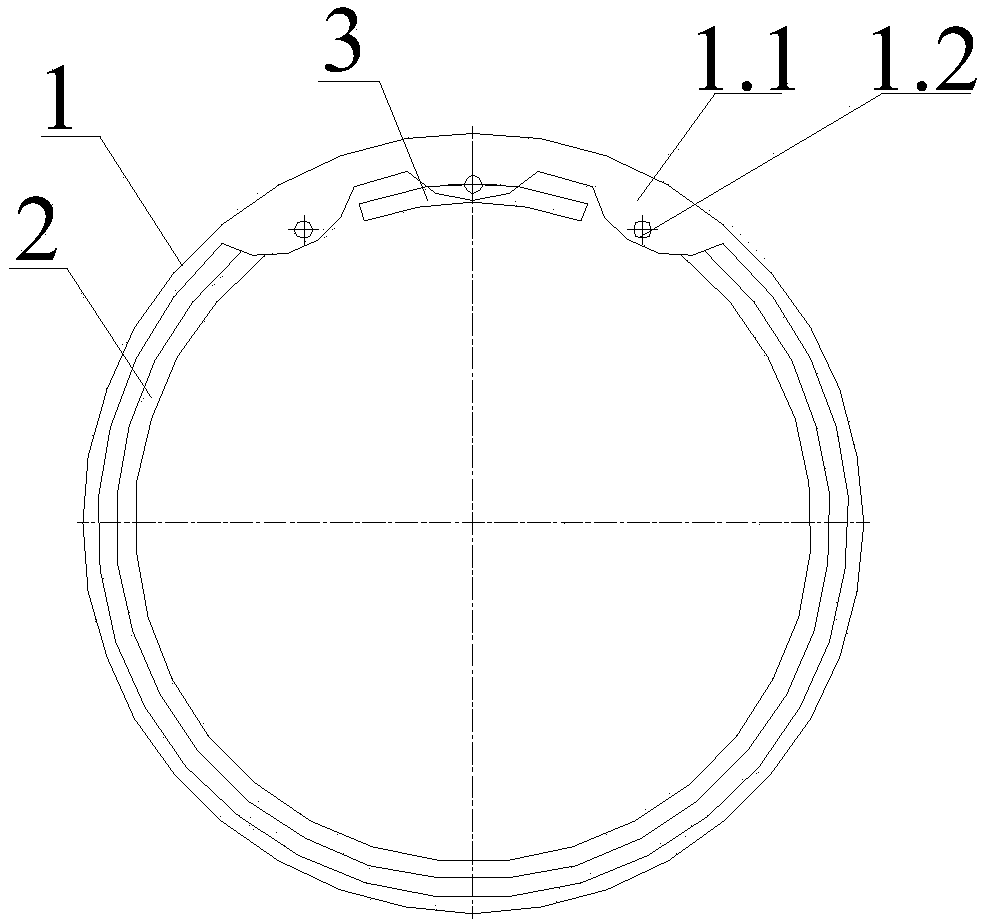

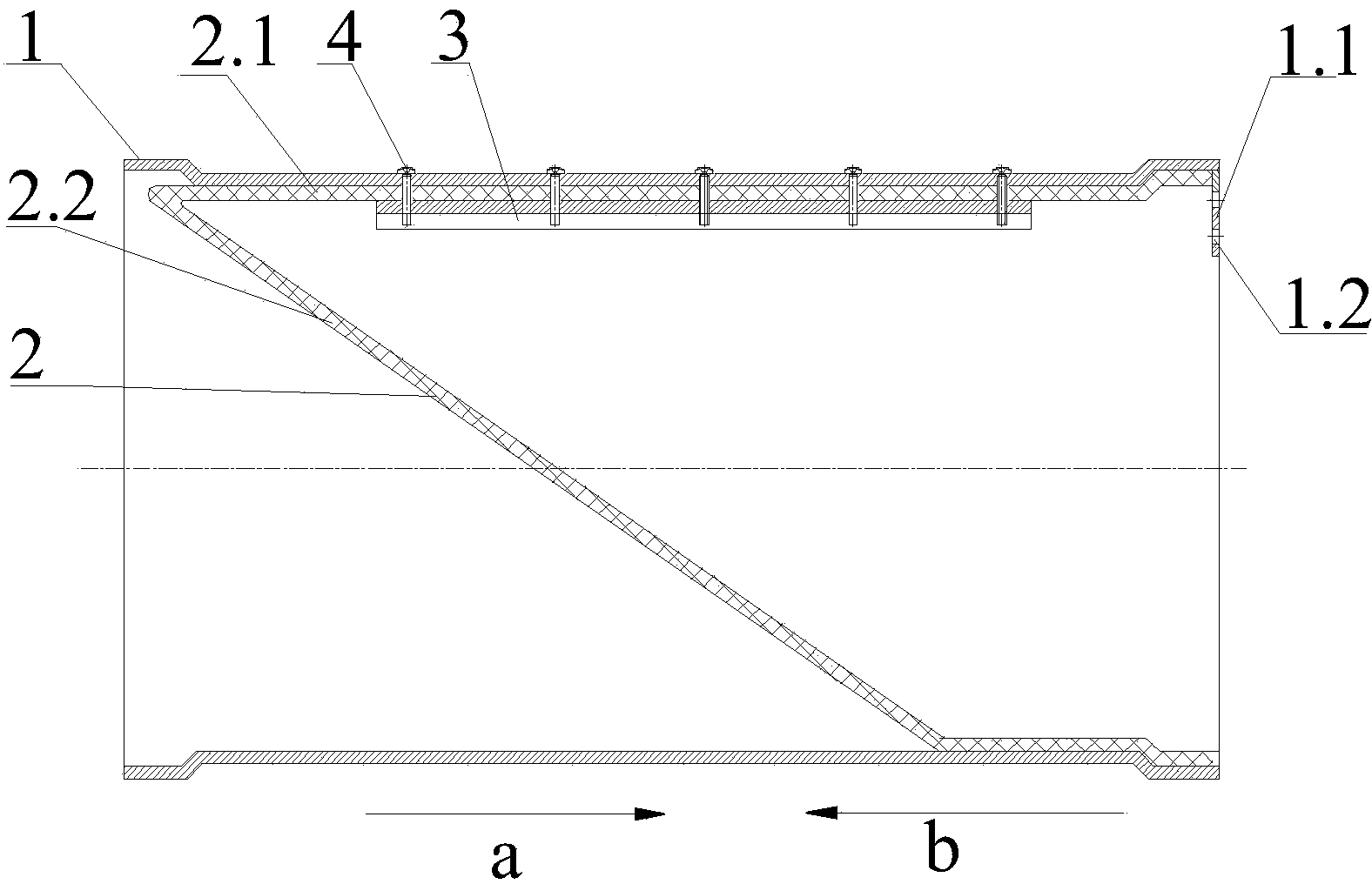

[0012] like figure 1 , figure 2 As shown, the present invention includes a pipe body 1, and a tapered rubber membrane 2 of the sealing and non-return pipe body 1 is fixed inside the pipe body 1 . The tapered rubber mold 2 includes a side wall 2.1 that fits the inner wall of the pipe body 1. The longitudinal center section of the side wall 2.1 is a trapezoidal structure with a long top and a short bottom. One end of the side wall 2.1 is sealed and connected with an inclined The water retaining surface 2.2, the other end of the side wall 2.1 is an open end, and the water retaining surface 2.2 is arranged facing the flow direction of the water flow in the pipe body 1 in a forward direction. The top of the side wall 2.1 of the tape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com