Tong-type automatic unhooking device

A technology of automatic decoupling and driving device, applied in the field of automatic decoupling device of pliers hook and lifting traction device, can solve the problems of low safety performance, violent swing of decoupling device, inaccurate position of drop point, etc. Accurate position, safe and reliable work, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

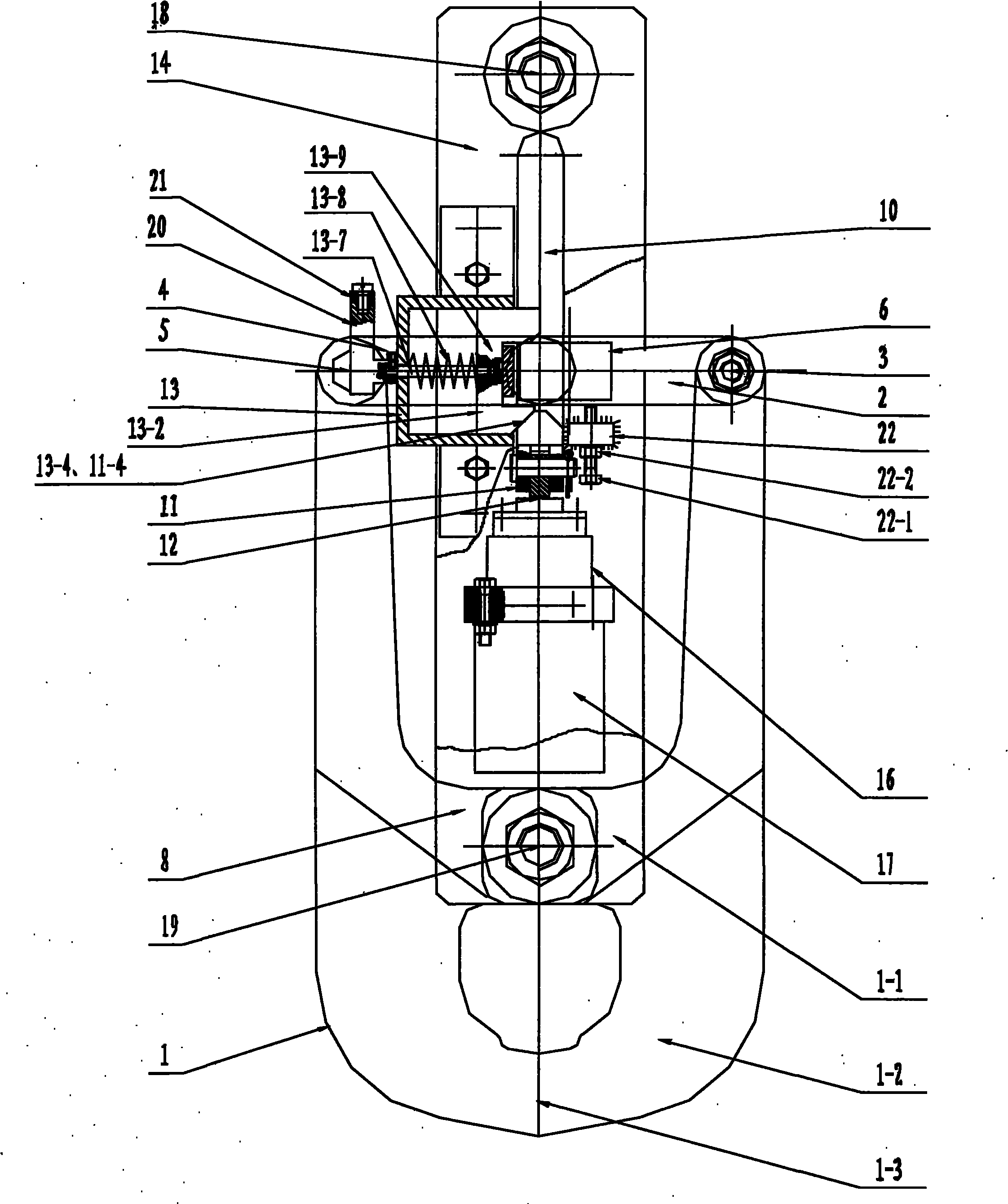

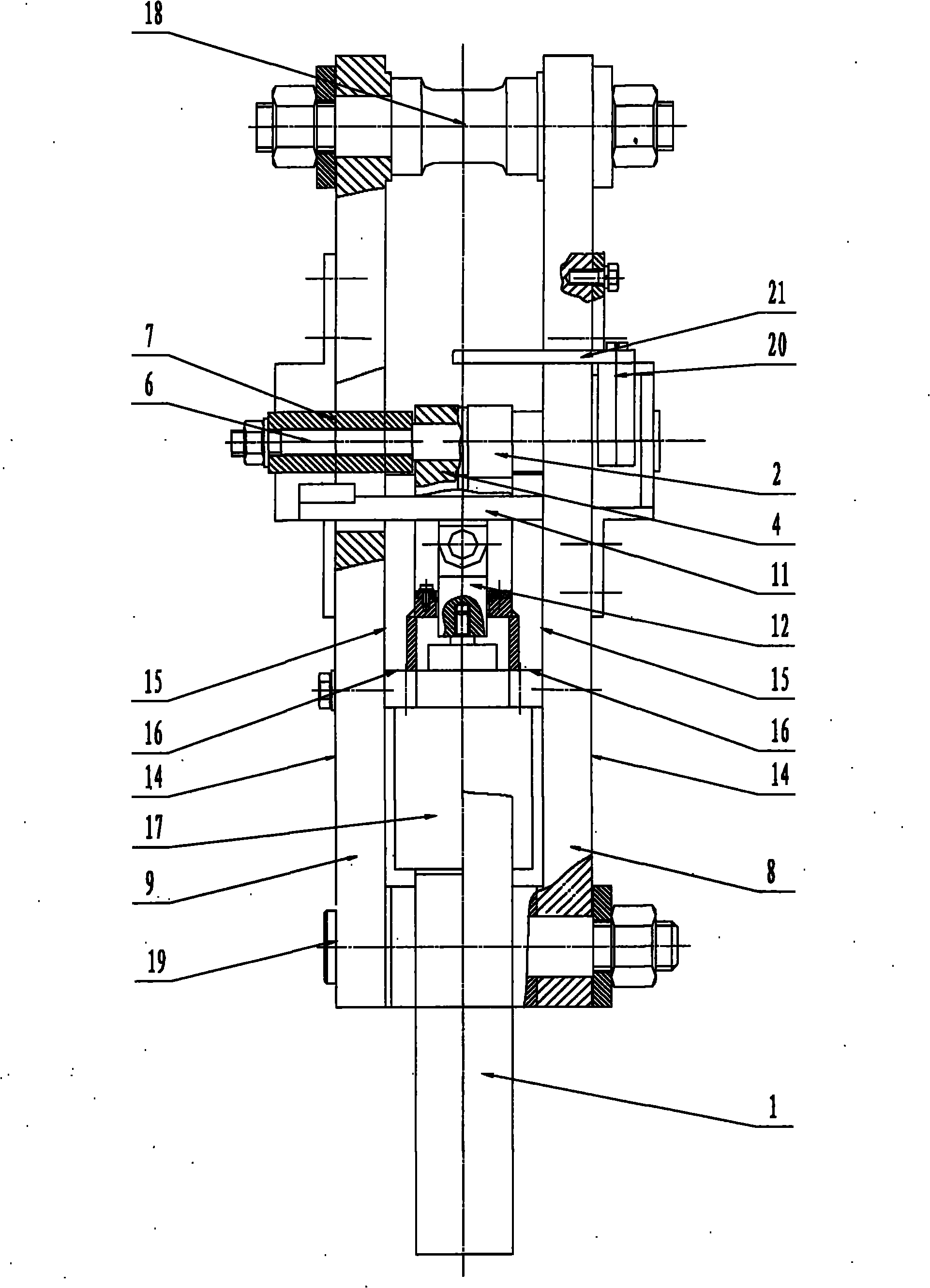

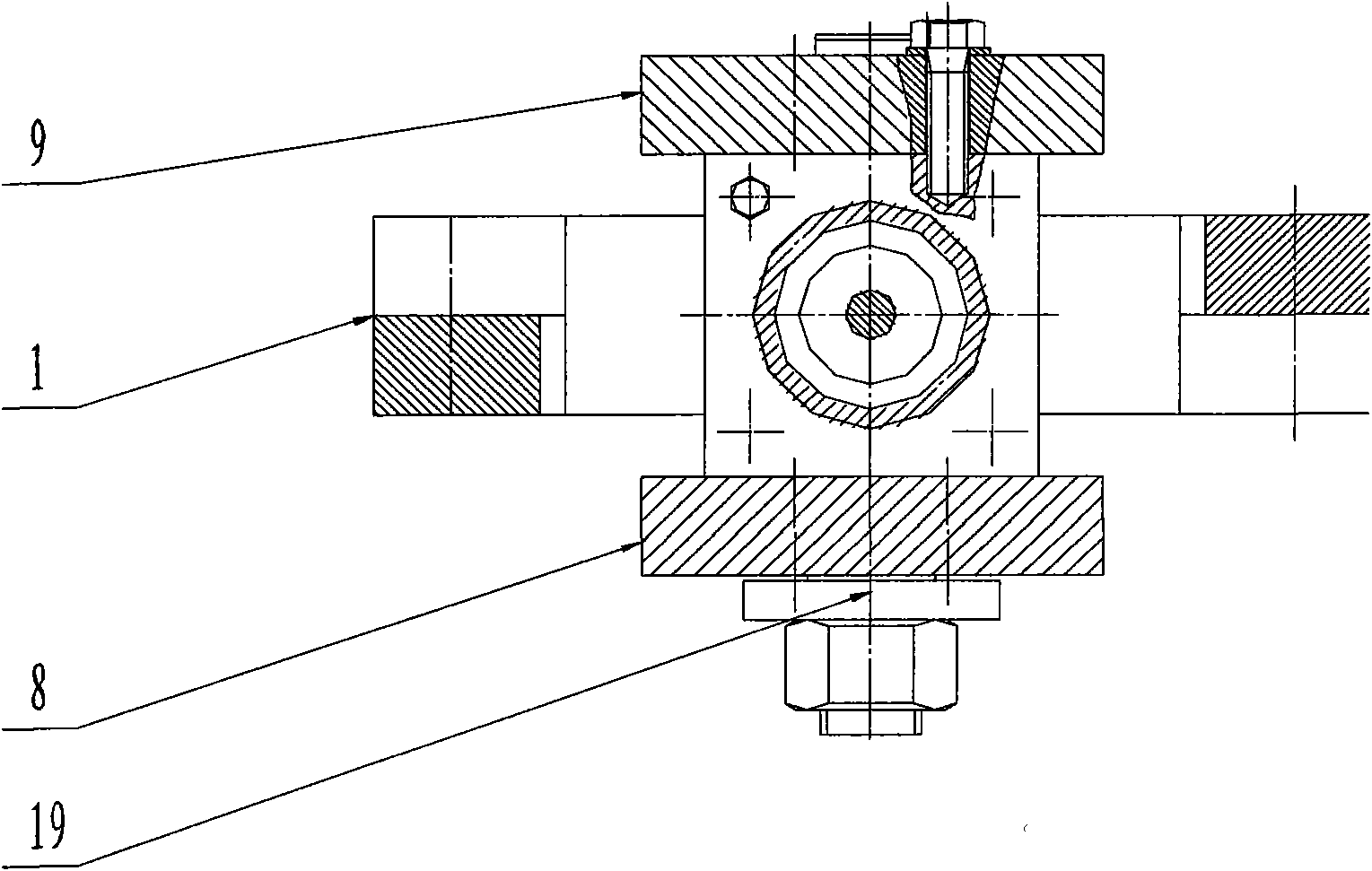

[0038] Such as figure 1 , figure 2 , image 3As shown, the pliers-type automatic decoupling device of the present invention comprises two symmetrically arranged tongs 1, wherein one end of one tongs 1 is hinged with the first connecting rod 2 through the first hinge 3, and one end of the other tongs 1 is connected to The second connecting rod 4 is hinged by the second hinge 5, and the other ends of the first connecting rod 2 and the second connecting rod 4 are all connected with the slider shaft 6, and one end of the slider shaft 6 is connected with the opening slider 7, and the slider shaft 6, The opening slide block 7 is placed in the chute 10 on the first pull plate 8 and the second pull plate 9, and a push rod 11 is also provided in the chute 10, on the side of the push rod 11 that is different from the slide block shaft 6 Connect the coupling shaft 12, the other end of the slider shaft 6 is locked in the self-locking device 13, the self-locking device 13 is arranged on...

Embodiment 2

[0040] On the basis of embodiment 1, the preferred embodiment of the present invention is, as figure 1 , Figure 4-Figure 7 As shown, the self-locking frame 13-1 of the self-locking device 13 is located on the outer surface 14 of the first pull plate 8, and the self-locking slider 13-2 is placed in the self-locking frame 13-1, and is connected with the self-locking frame 13-1. Sliding fit, self-locking slide block 13-2 is groove 13-3 shape, groove 13-3 one end boss is provided with an inclined-plane 13-4, and groove 13-3 is stuck in the inner baffle plate 13-5, automatically The groove bottom plate of lock slider 13-2 links to each other with pull bar 13-7, and pull bar 13-7 passes through outer baffle plate 13-6 and links to each other with handle 20, and the other end of handle 20 links to each other with handle linkage 21, and pull bar 13-7 overcoat has Spring 13-8, spring 13-8 is placed between self-locking slide block 13-2 and outer baffle plate 13-6, and all the other a...

Embodiment 3

[0042] On the basis of embodiment 2, the preferred embodiment of the present invention is, as figure 1 , Figure 8 As shown, the first pull plate 8 and the second pull plate 9 are oblate cuboids with the same structure, correspondingly arranged, the chute 10 is an oblong transparent groove, and the chute 10 is arranged at one end of the connecting pin shaft 18 of the pull plates 8 and 9 Between the connection bracket 16, the rest are exactly the same as the implementation 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com