Patents

Literature

51results about How to "Great opening force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

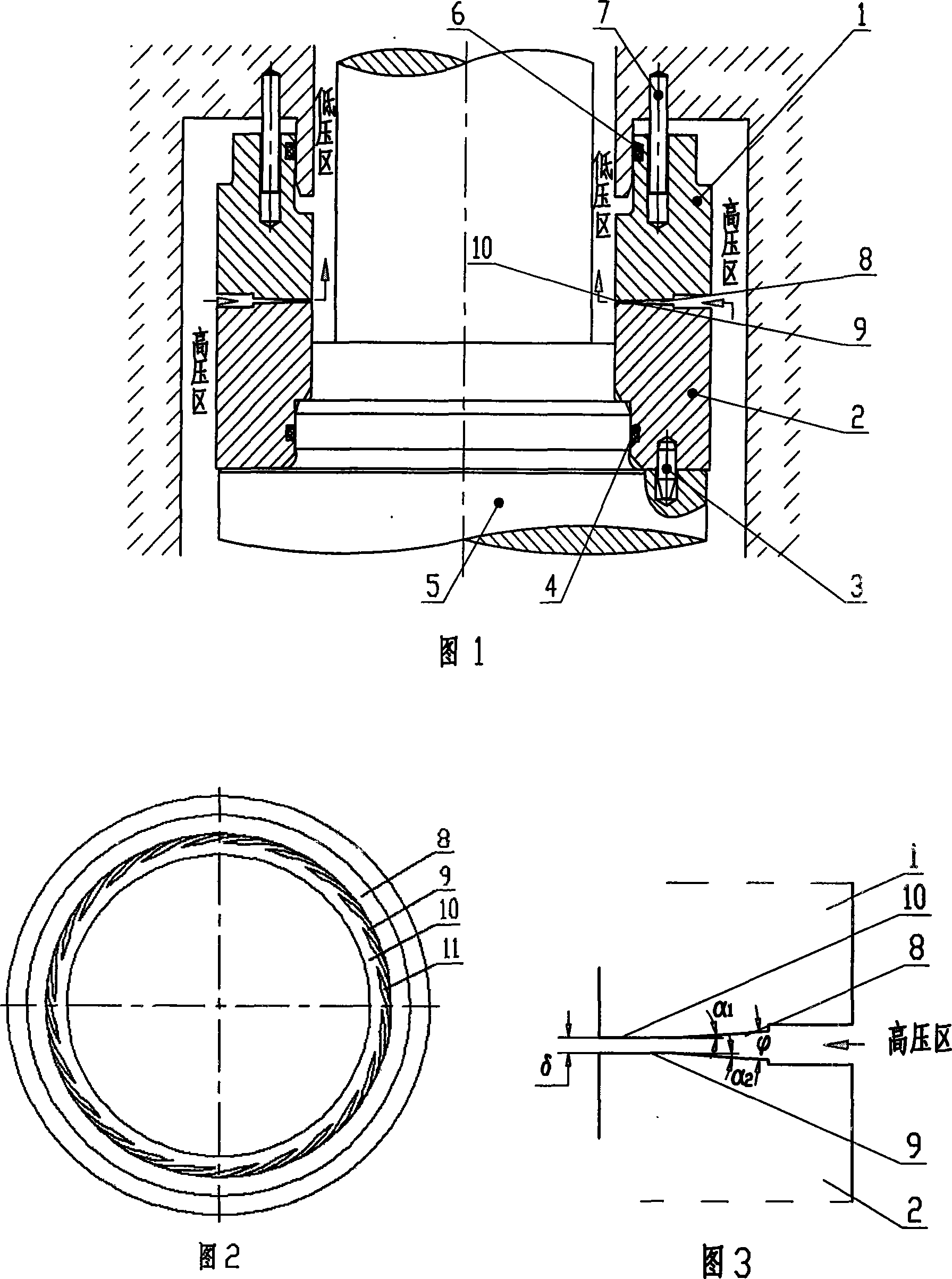

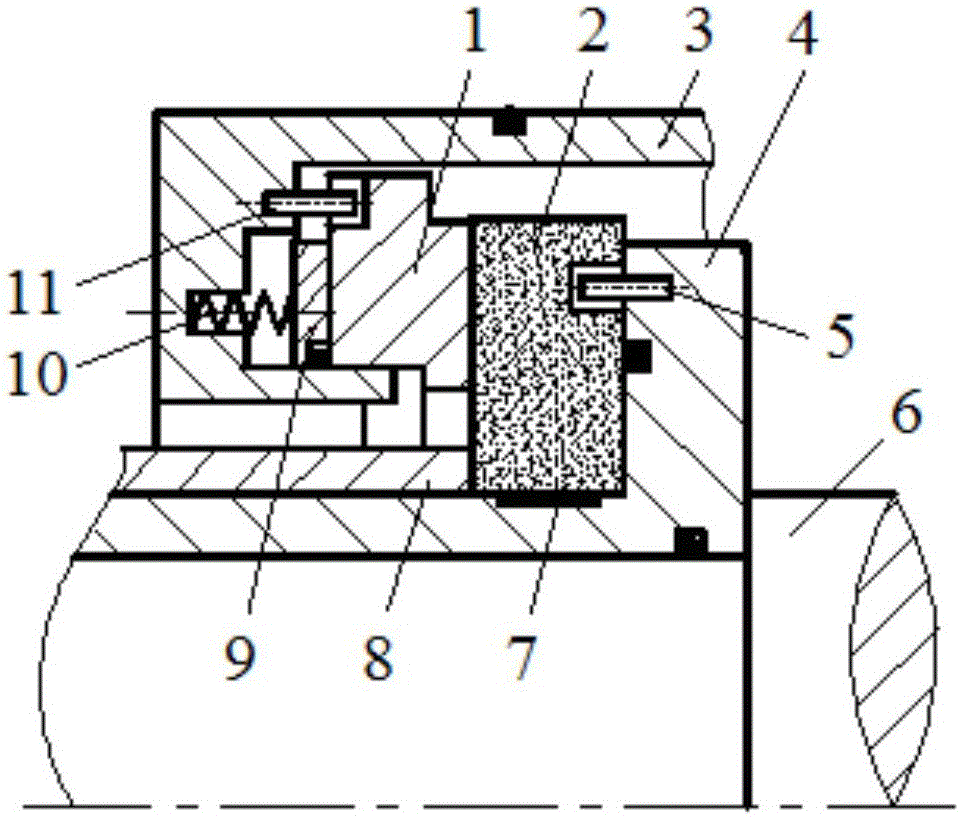

Pressure adaptive mechanical seal

The invention discloses a pressure self-adaptive mechanical seal device, which relates to the field of mechanical seal devices, and comprises a static ring assembly fixedly connected to the static part of the seal and a dynamic ring assembly that can rotate with the shaft. Discontinuous cavities uniformly distributed in the circumferential direction are processed on the radial side. There are through holes on the lower surface of each cavity. The through holes communicate with the low pressure area. The discontinuous cavities are sealed by sealing rings. According to different sealing conditions, the different The continuous cavity can adopt different structural forms to achieve the best sealing effect. This sealing device well solves the problem of seal end face wearing and tearing failure caused by sealing pressure fluctuations. Its notable feature is that it can adapt to sealing conditions with a wide pressure range. As the pressure of the sealed fluid increases, the bearing capacity of the seal will increase. The enhancement is adaptive.

Owner:BEIJING UNIV OF CHEM TECH

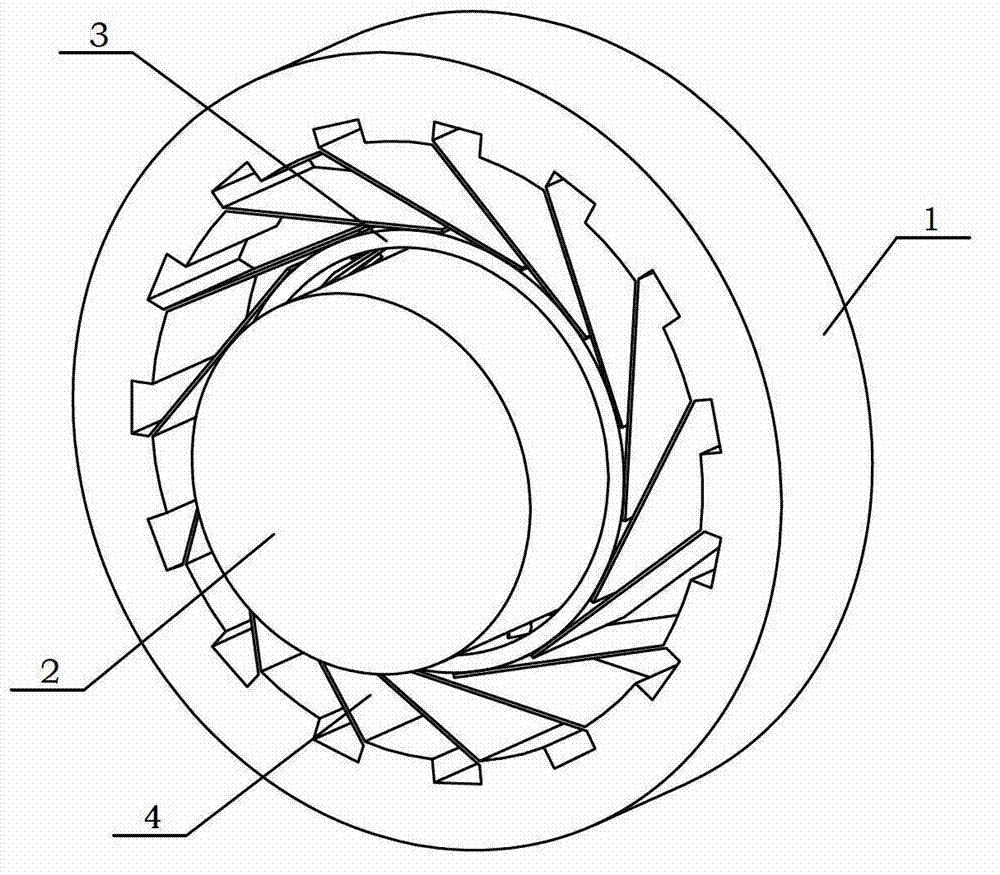

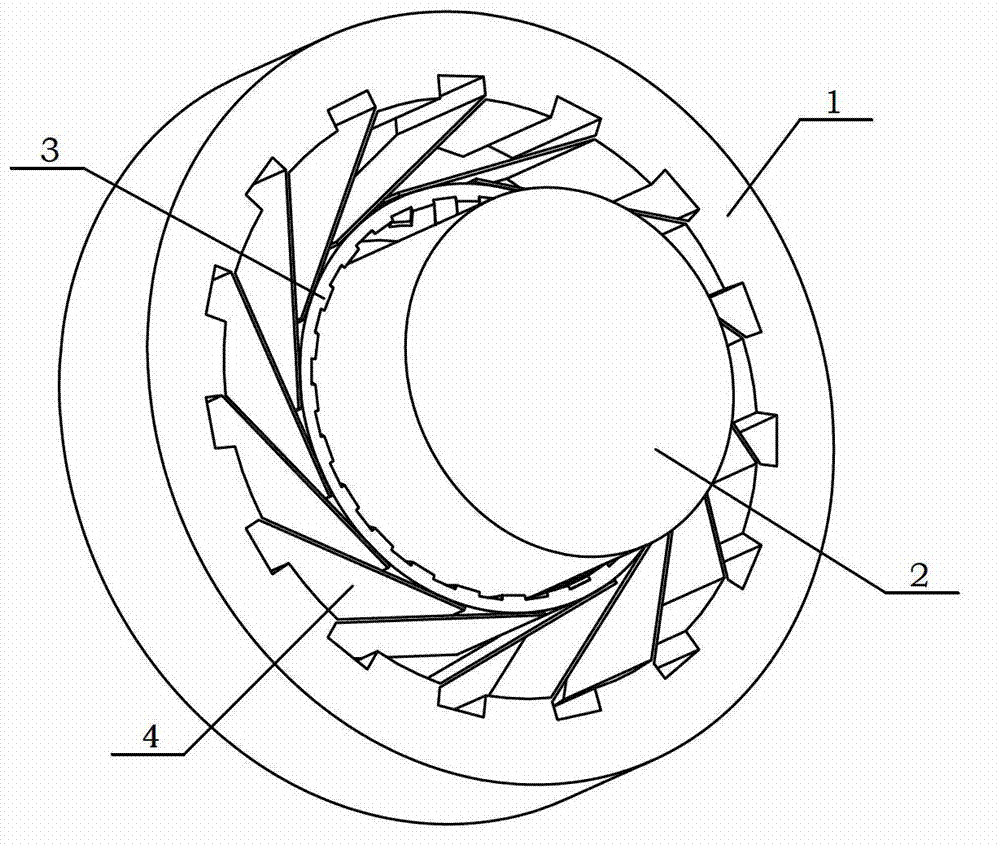

Gas cylinder surface sealing device with cantilever support and spiral chute

InactiveCN102758918AAchieving deformation adaptabilityAvoid or reduce contact wearEngine sealsHigh-pressure areaGas cylinder

The invention discloses a gas cylinder surface sealing device with a cantilever support and a spiral chute. The device comprises a sealing retainer, a rotor journal, a floating sealing ring and a cantilever supporting plate, wherein a dynamic pressure cylindrical sealing area is formed between the cylindrical sealing interface of the floating sealing ring and the cylindrical surface of the rotor journal, a high-pressure area and a low-pressure area are respectively arranged on two sides of the floating sealing ring, and the rotor journal and the floating sealing ring rotate relatively; and the floating sealing ring is supported by a plurality of cantilever sheets which are distributed circumferentially, and the cantilever sheets are fixed by the sealing retainer. The cylindrical surface gas film sealing device realizes non-contact and small-leakage sealing while adapting to the deformation in position sealing work process through the flexibility of the support and a dynamic pressure gas film, and is adaptive to the installation space requirement on non-shaft end position sealing through the cylindrical surface structure.

Owner:BEIHANG UNIV

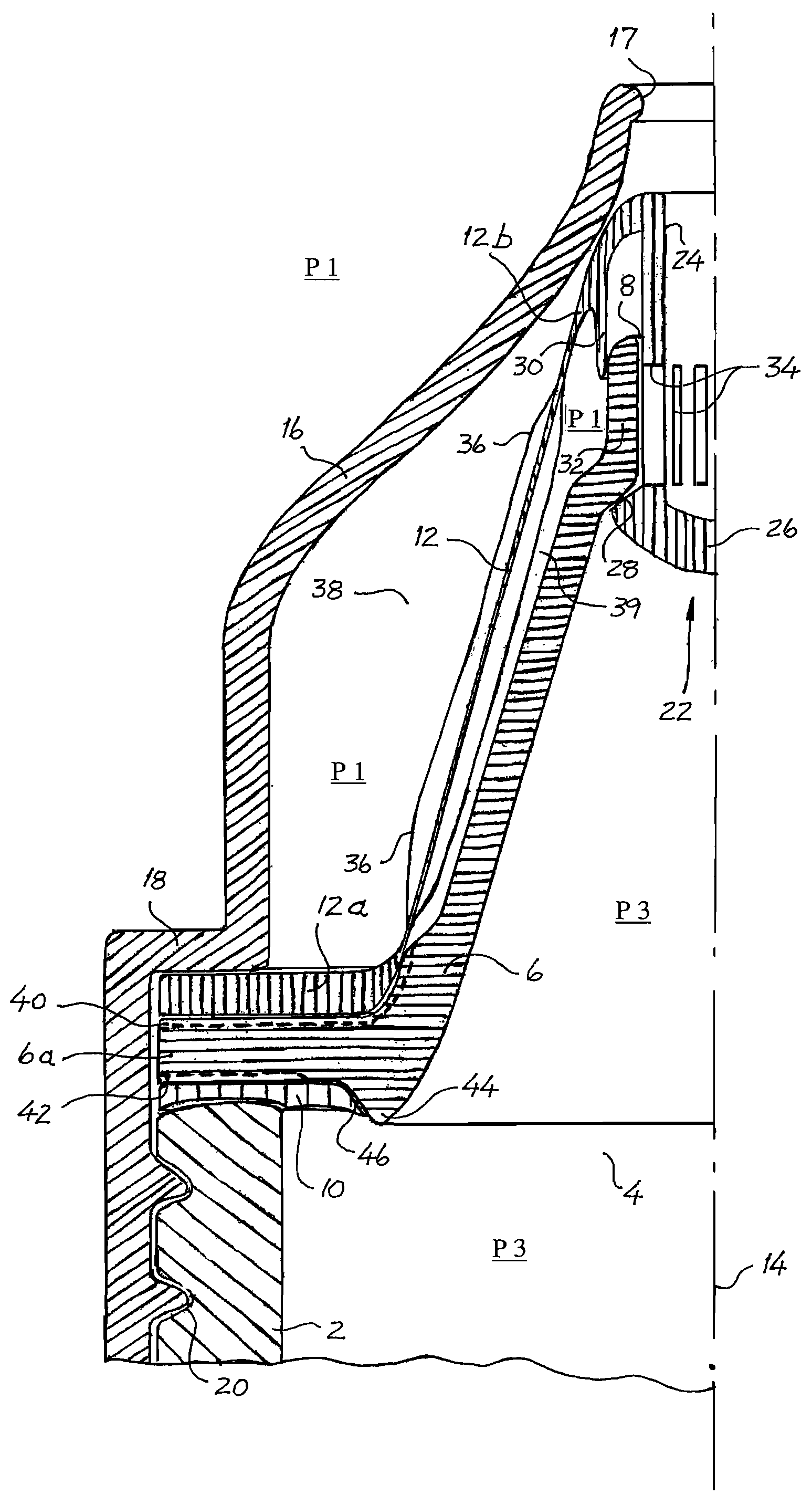

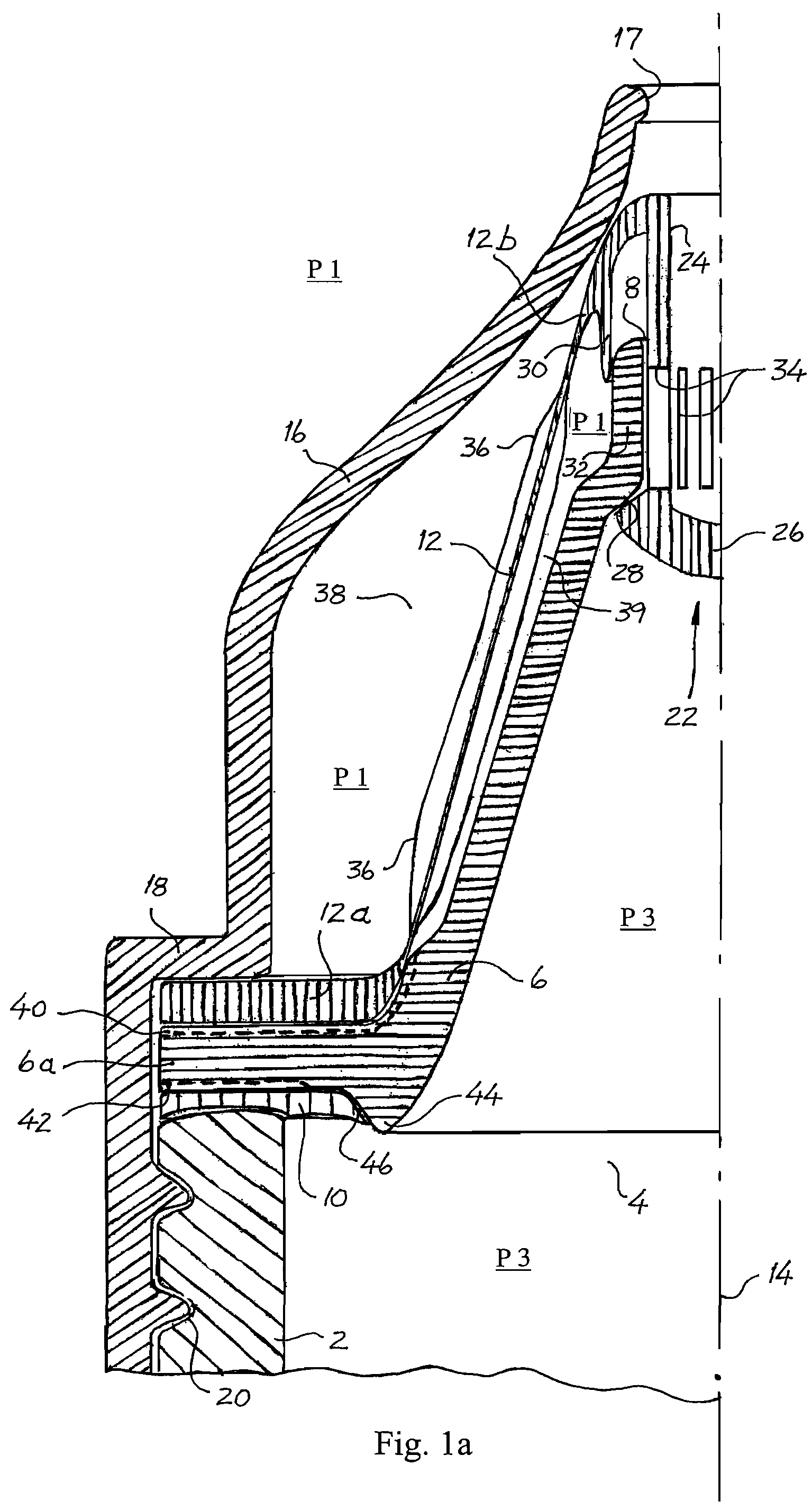

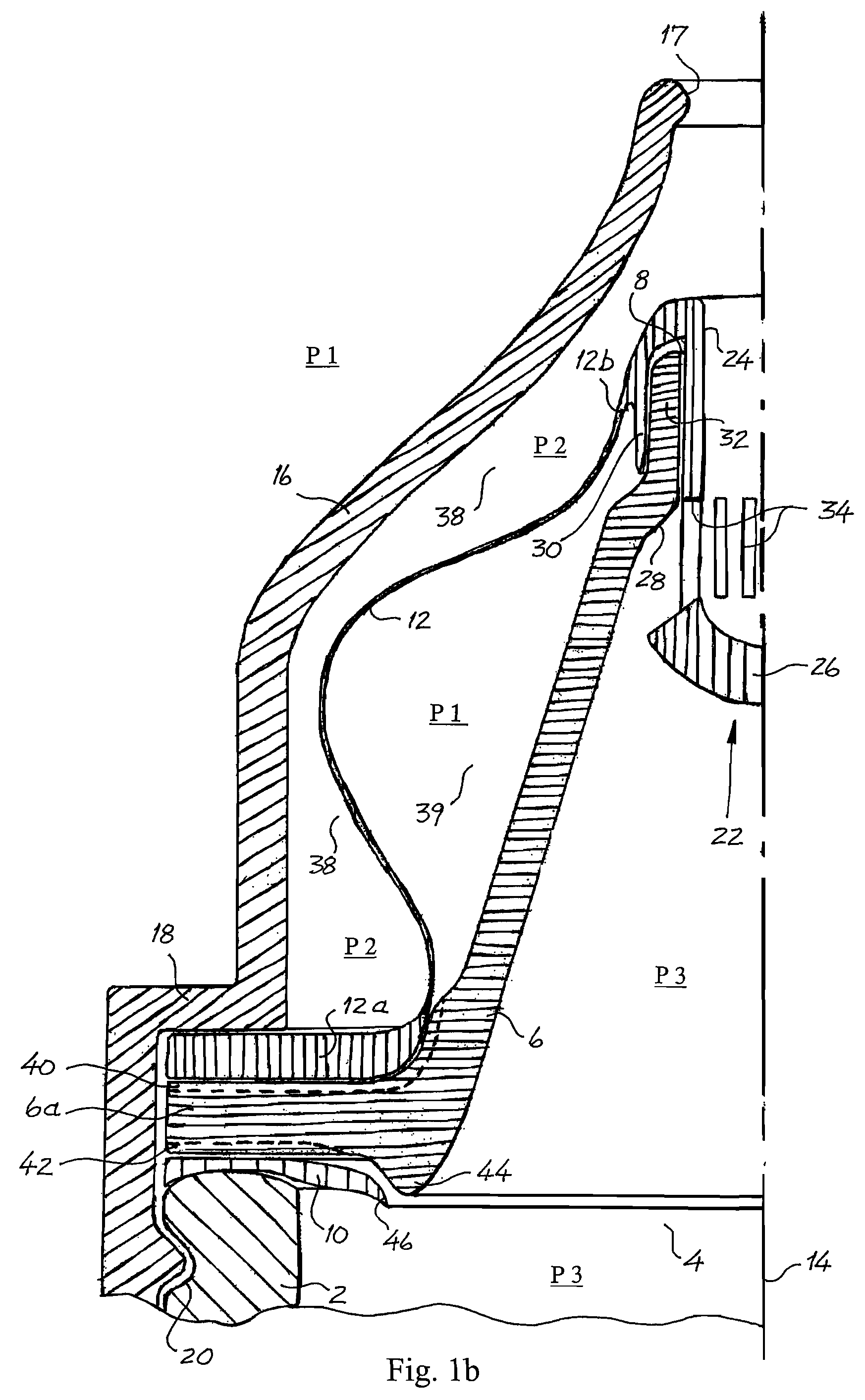

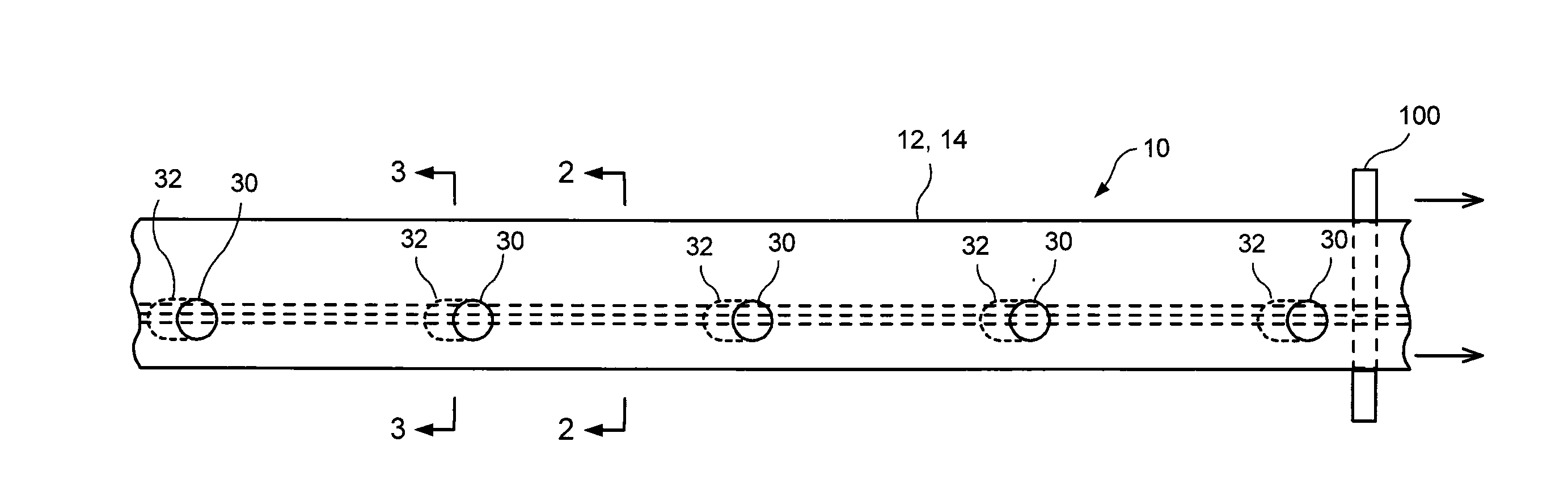

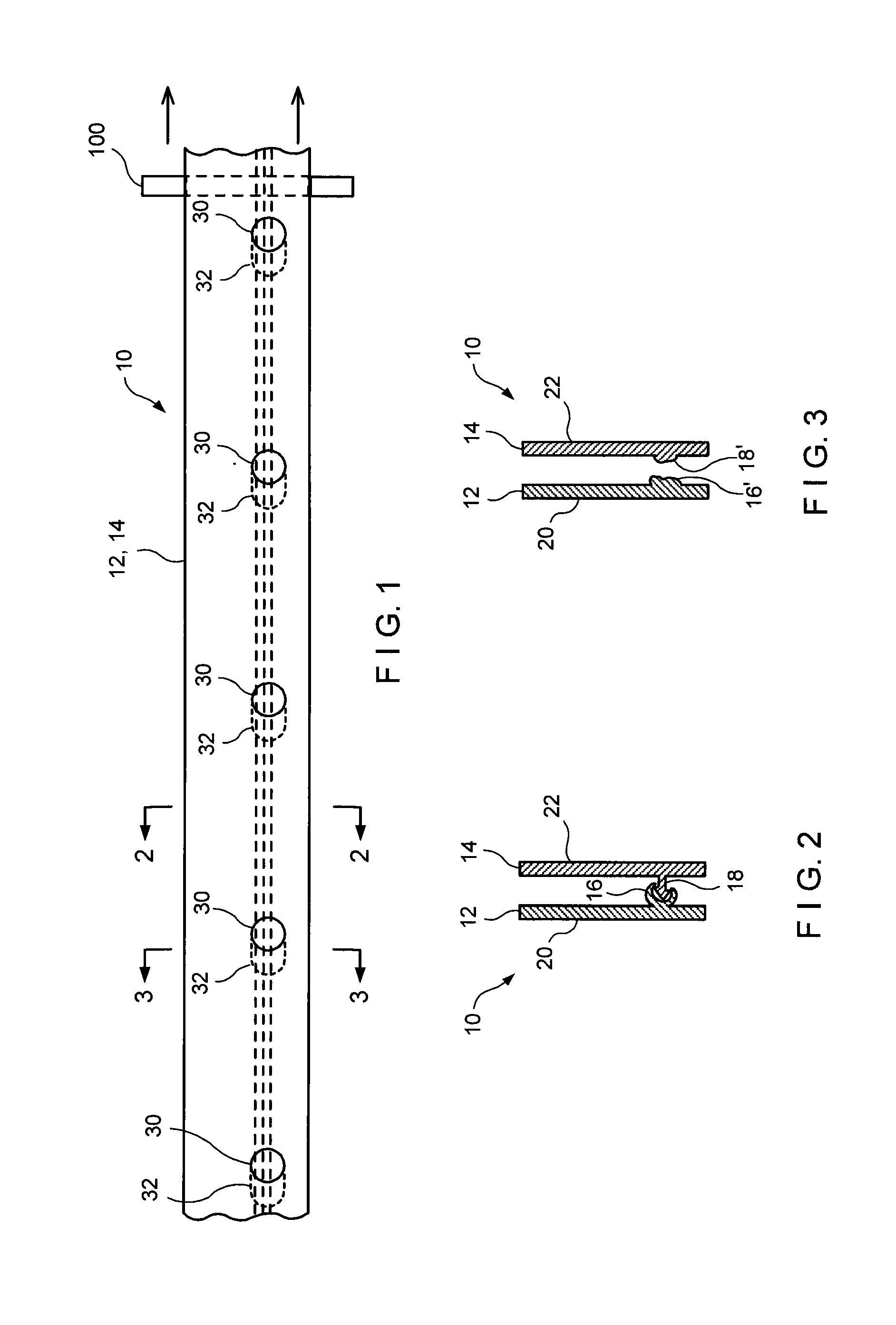

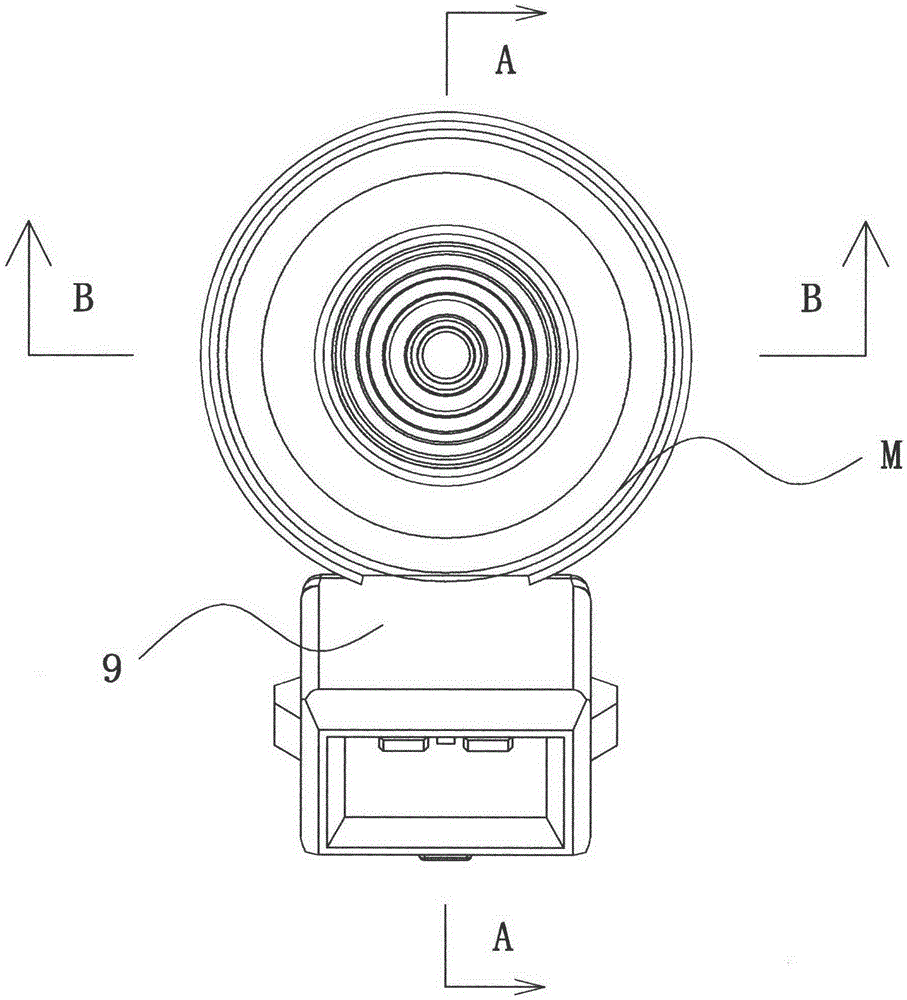

Opening-force-maximizing device of an underpressure-activated valve for a drinking container

ActiveUS7775394B2Sufficient energy storageCertain resistanceClosuresDispensing apparatusAxial distanceValve opening

An opening-force-maximizing device of an underpressure-activated valve for a drinking container (2). The device includes a partition wall (6, 106, 206) enclosing an outlet opening (4) and being provided with a wall opening (8, 108, 208) in pressure-sealing contact with an axially movable valve sealing member (22, 122, 222) being in position of rest. It also includes a continuous membrane (12, 112, 212) being arranged to the container (2) and about a valve axis (14) through the wall opening (8, 108, 208). The membrane (12, 112, 212) has an axial extent and consists of an attachment end (12a, 112a, 212a) fixedly connected to the partition wall (6, 106, 206), and a movable maneuvering end (12b, 112b, 212b) placed at an axial distance from the attachment end (12a, 112a, 212a). The maneuvering end (12b, 112b, 212b) is arranged in a tensile-force-transmitting manner to said sealing member (22, 122, 222). By arranging the membrane (12, 112, 212) with a maximum longitudinal extent when at rest in its inactive position, and by being arranged radially flexible and deflectable and also being arranged in a manner inhibiting axial stretching, a maximum valve opening force is achieved when underpressure-activated.

Owner:SMARTSEAL AS

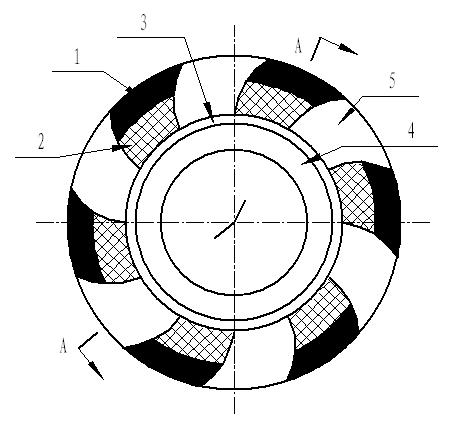

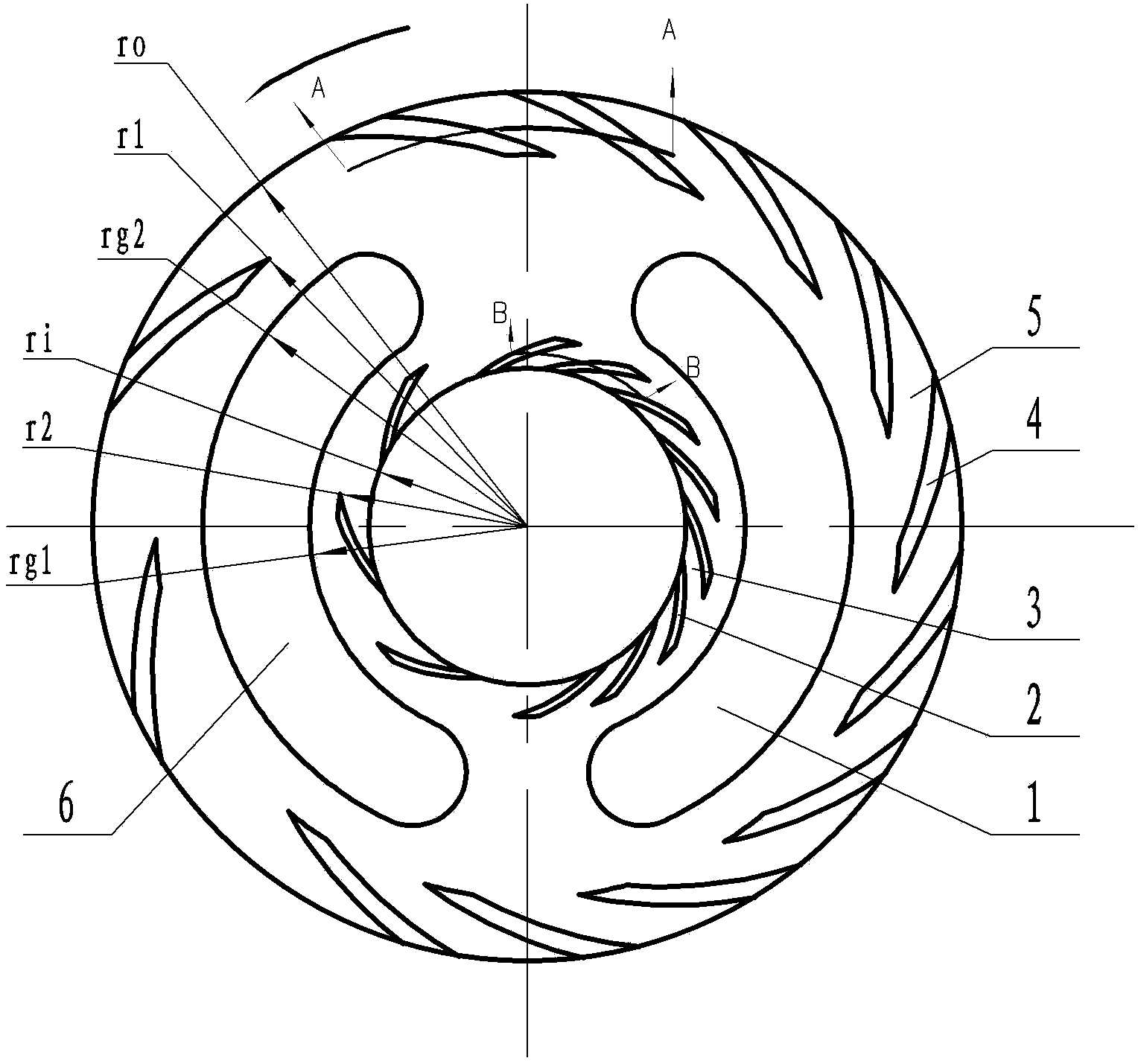

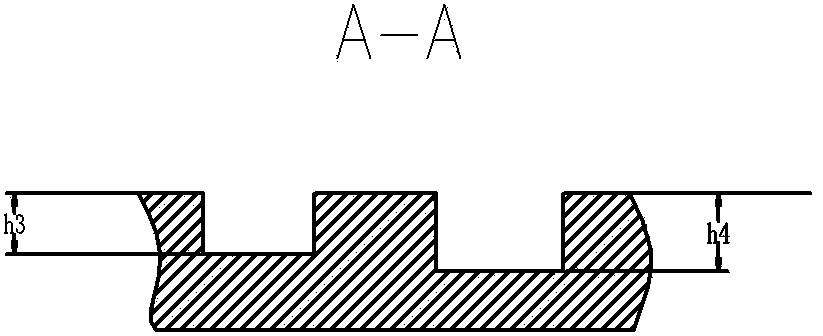

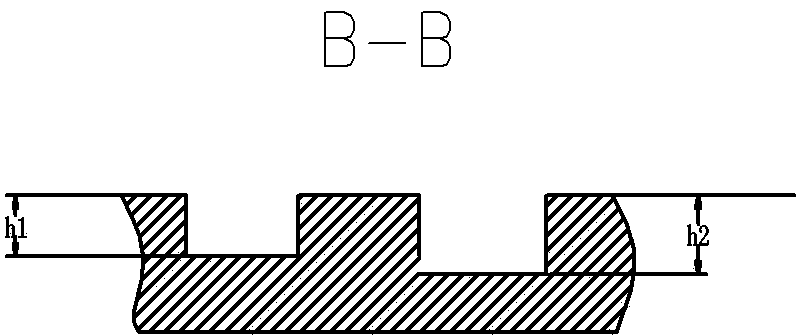

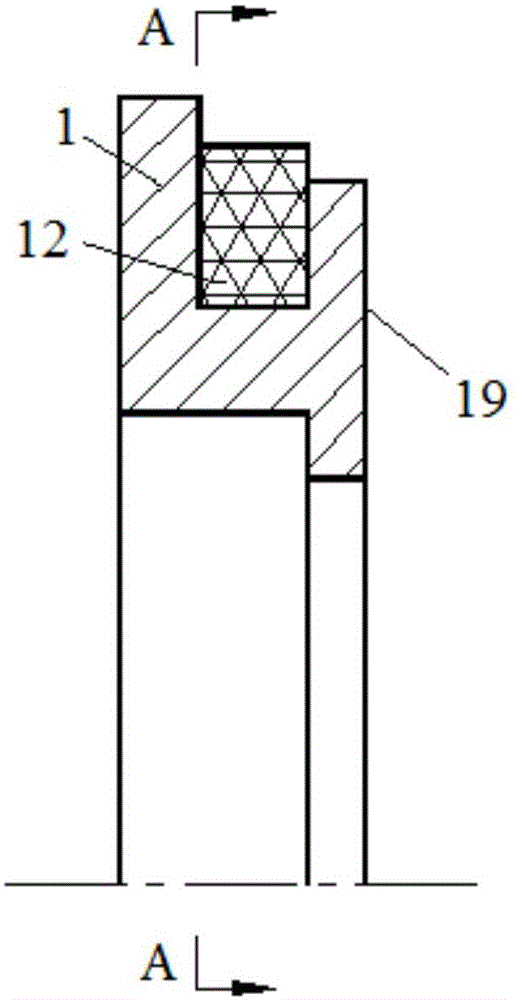

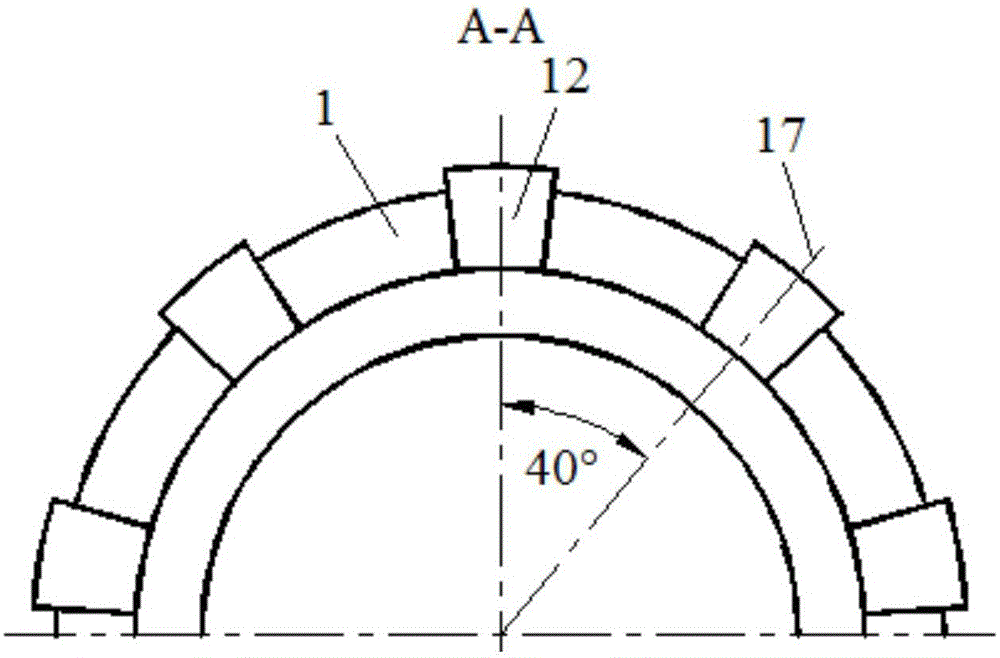

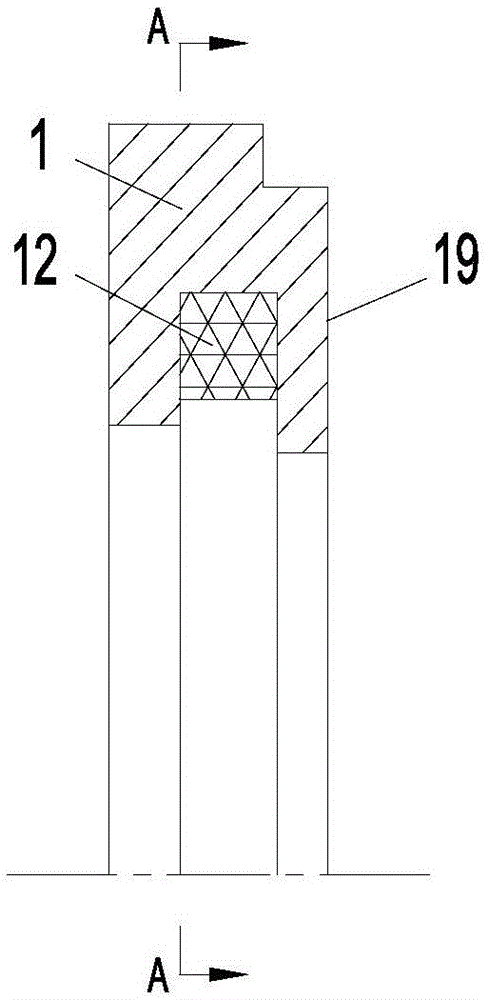

Solid particle suction preventive type fluid dynamic pressure mechanical sealing ring

ActiveCN102518809AImprove friction and lubricationAvoid wear and tearEngine sealsEngineeringSolid particle

The invention relates to a solid particle suction preventive type fluid dynamic pressure mechanical sealing ring, which is a mechanical sealing moving ring. A particle stopping groove with the micron-sized depth, a dynamic pressure groove with the micro-sized depth and a particle storage groove with the millimeter-sized depth are arranged on an end surface of the moving ring. The particle stopping groove can stop solid particles from being sucked in the sealing ring, the dynamic pressure groove has a fluid pumping effect and a dynamic pressure effect, and the particle storage groove has a solid particle storage function. Leakage of mechanical sealing can be reduced by the aid of the sealing ring, a lubricating effect of the sealing ring can be greatly improved, the solid particles are prevented from being sucked into a sealing end surface to cause abrasion of grinding particles, and processing is convenient.

Owner:JIANGSU UNIV

Leakproof dynamic pressure type valve plate

InactiveCN104019024AReduce leakageImprove volumetric efficiencyPositive displacement pump componentsLiquid fuel engine componentsPlunger pumpCylinder block

The invention discloses a leakproof dynamic pressure type valve plate, and relates to the technical field of engineering machines. The leakproof dynamic pressure type valve plate comprises a valve plate body with an oil suction opening and an oil pressing opening, a plurality of bending first micro type channels are arranged on the sealed end face of the valve plate body along the inner ring face of the inner side of the oil suction opening and the inner ring face of the inner side of the oil pressing opening, and a plurality of bending second micro type channels are arranged on the sealed end face of the valve plate body along the outer ring face of the outer side of the oil suction opening and the outer ring face of the outer side of the oil pressing opening. One ends of the first micro type channels are sealed, and the sealed ends extend towards the inner edge of the valve plate body to form openings. One ends of the second micro type channels are sealed, and the sealed ends extend towards the outer edge of the valve plate body to form openings. The rotating direction of the second micro type channels is the same as the counterrotating direction of the valve plate body, and the rotating direction of the first micro type channels is opposite to that of the second micro type channels. According to the valve plate, the problems that the amount of leakage between an existing dynamic pressure type valve plate and a plunger pump cylinder body is large, and the overturning moment of the cylinder body is large are solved, the volume efficiency of the valve plate is improved, and the service life is prolonged.

Owner:LIUZHOU LIUGONG HYDRAULIC COMPONENTS +1

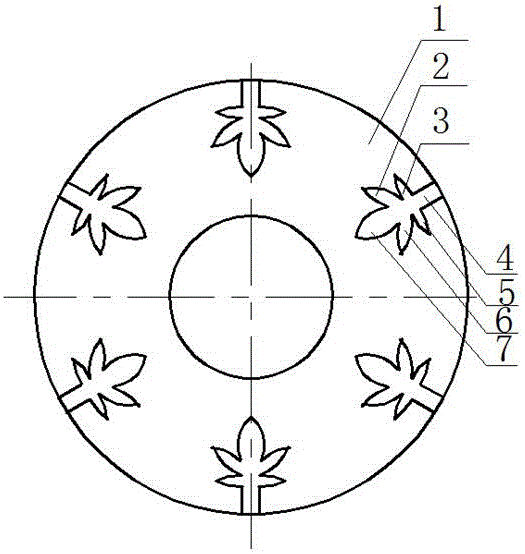

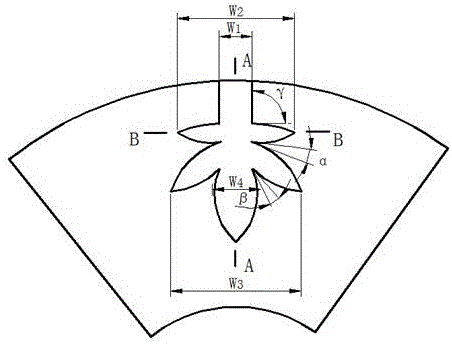

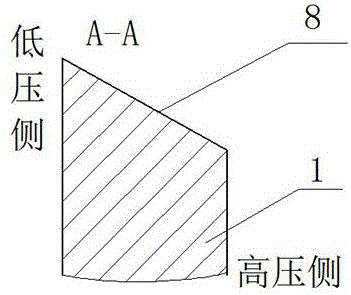

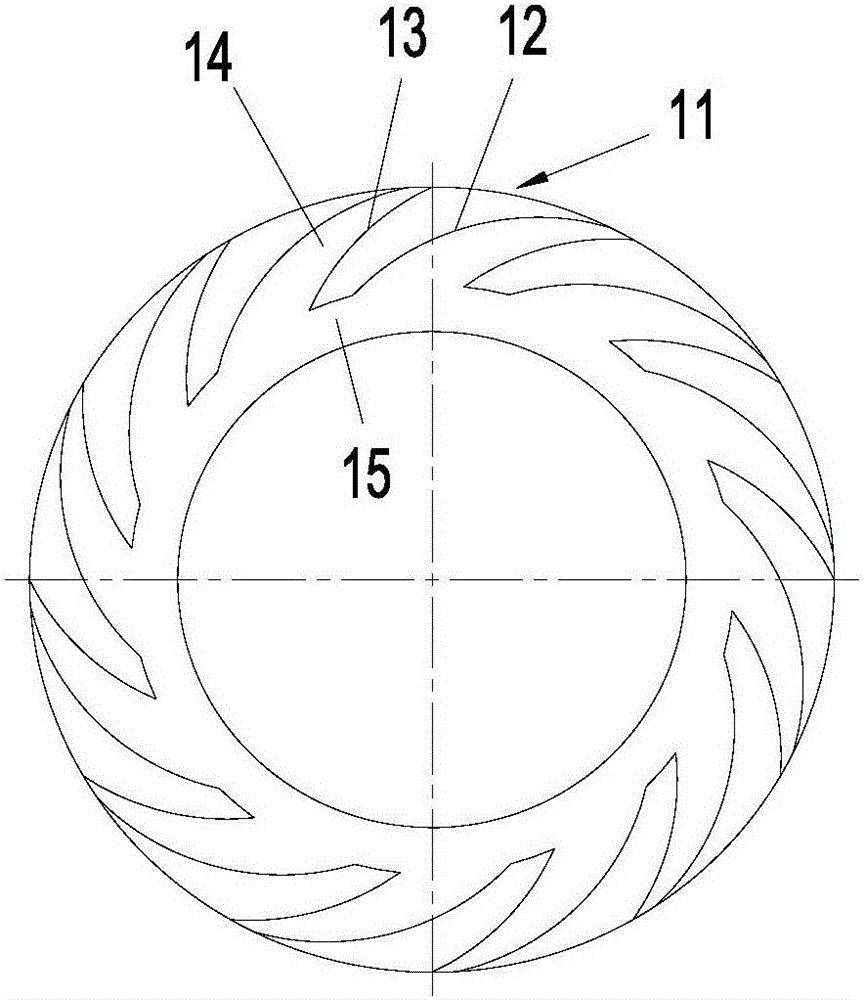

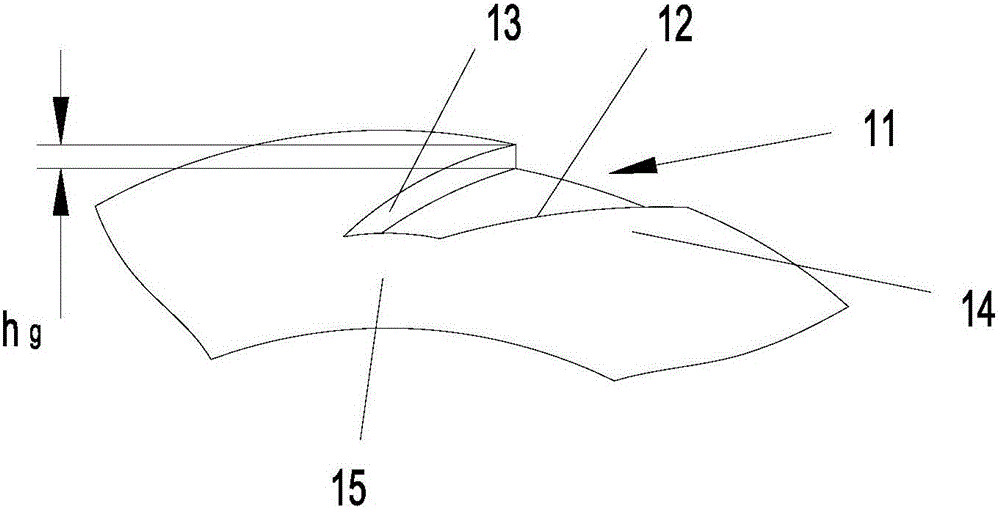

Mechanical seal ring with maple-leaf-like grooves

The invention relates to a mechanical seal ring with maple-leaf-like grooves. 2-50 maple-leaf-like grooves are circumferentially and evenly distributed in one end surface of the seal ring and are 1-100 mu m deep; each maple-leaf-like groove comprises a radial linear groove and five grooves, four of the five grooves are symmetrically distributed on two sides of the radial linear groove, another groove is connected with one end, close to the inner diameter of the seal ring, of the radial linear groove, and the radial linear groove is opened in the edge of the outer diameter of the seal ring; and the maple-leaf-like grooves are symmetric about the radial central axis. The seal ring is applicable to one-way rotation and two-way rotation machinery, is used for liquid sealing or dry gas sealing, can effectively reduce abrasions of seal end surfaces, has the relatively good flow guiding effect, the better opening force and the smaller leakage amount, has the better sealing effect and dynamic pressure performance, runs more stably and is wider in application range, and the cost is saved.

Owner:云南流体规划研究院有限公司

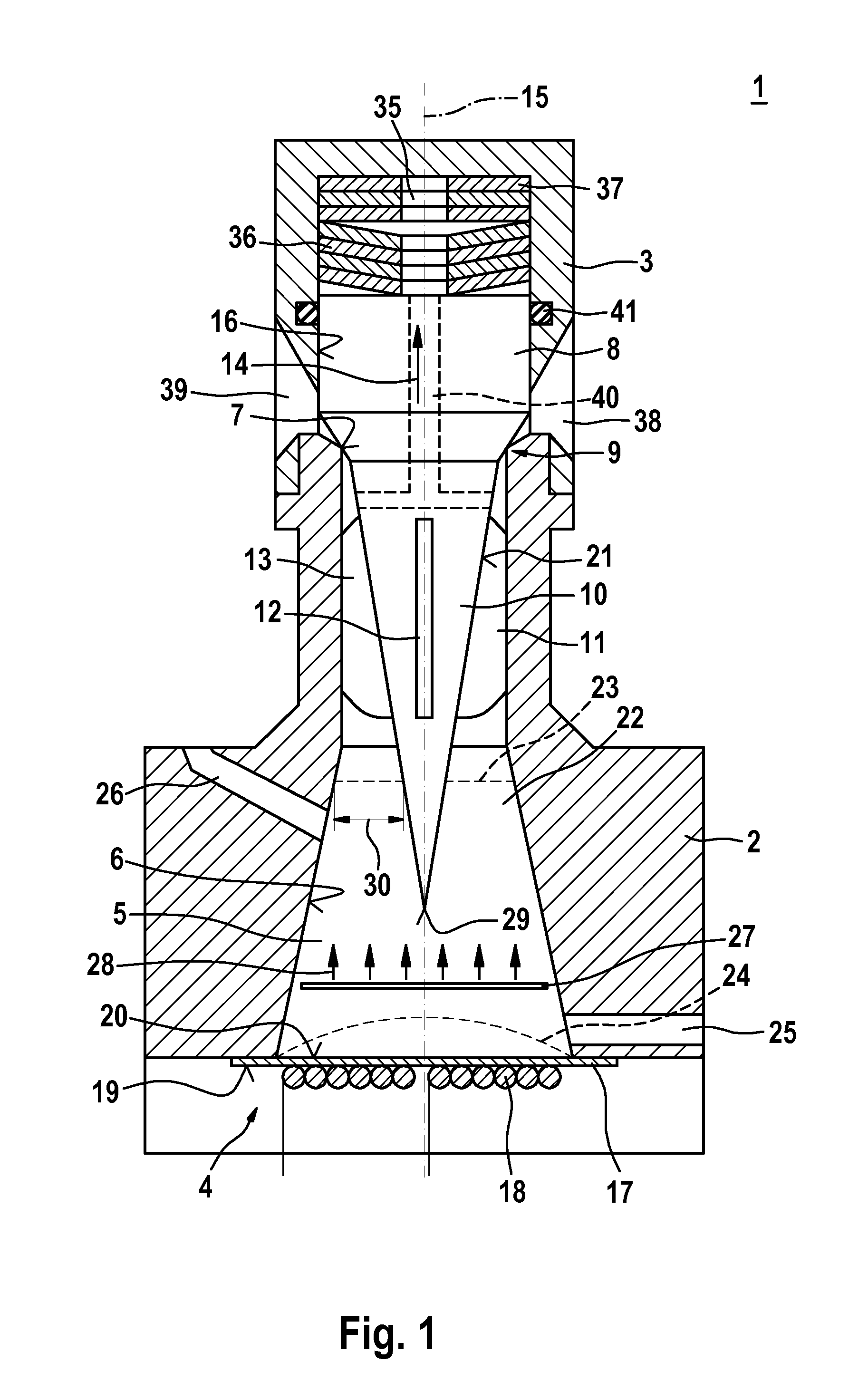

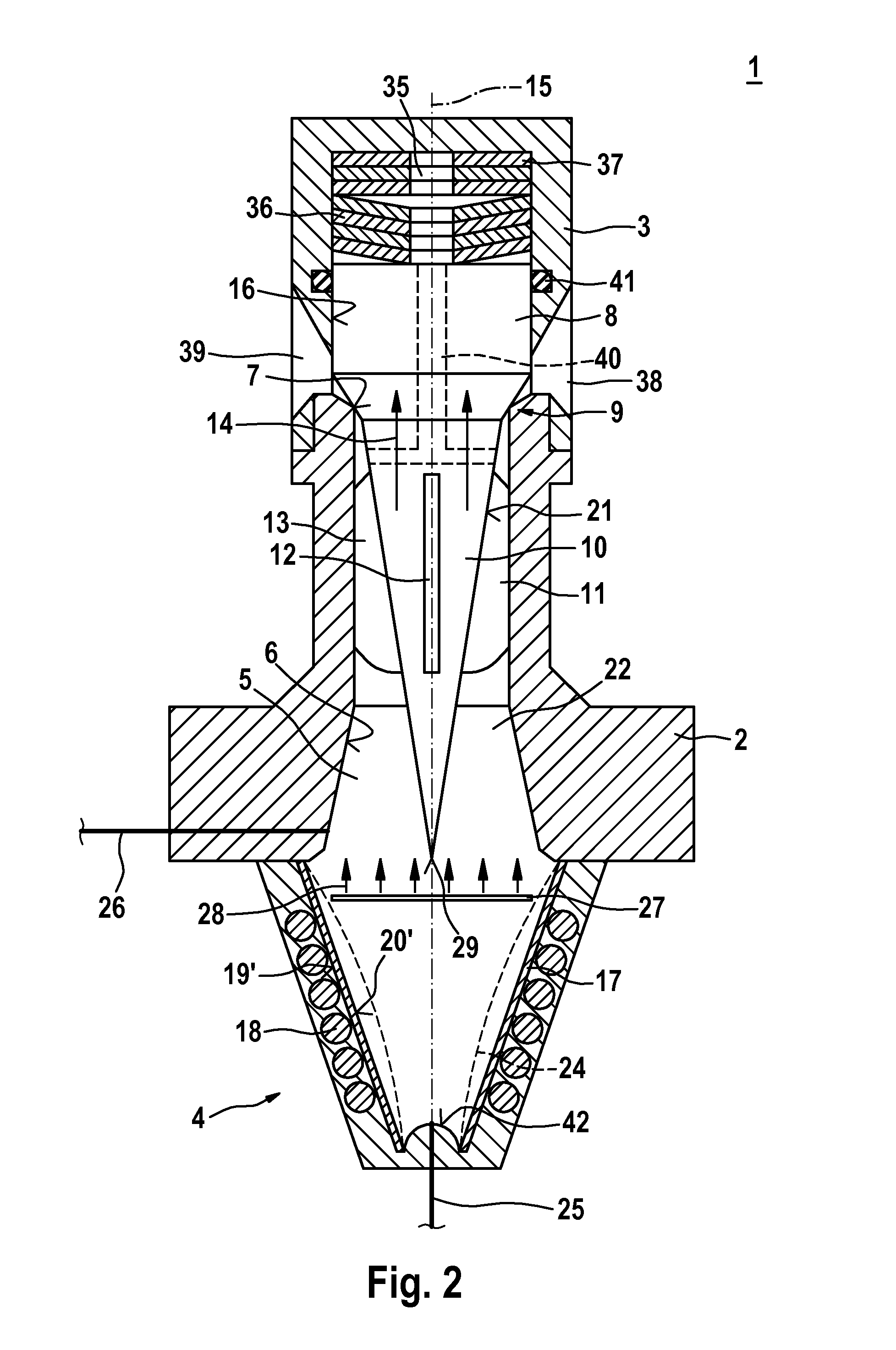

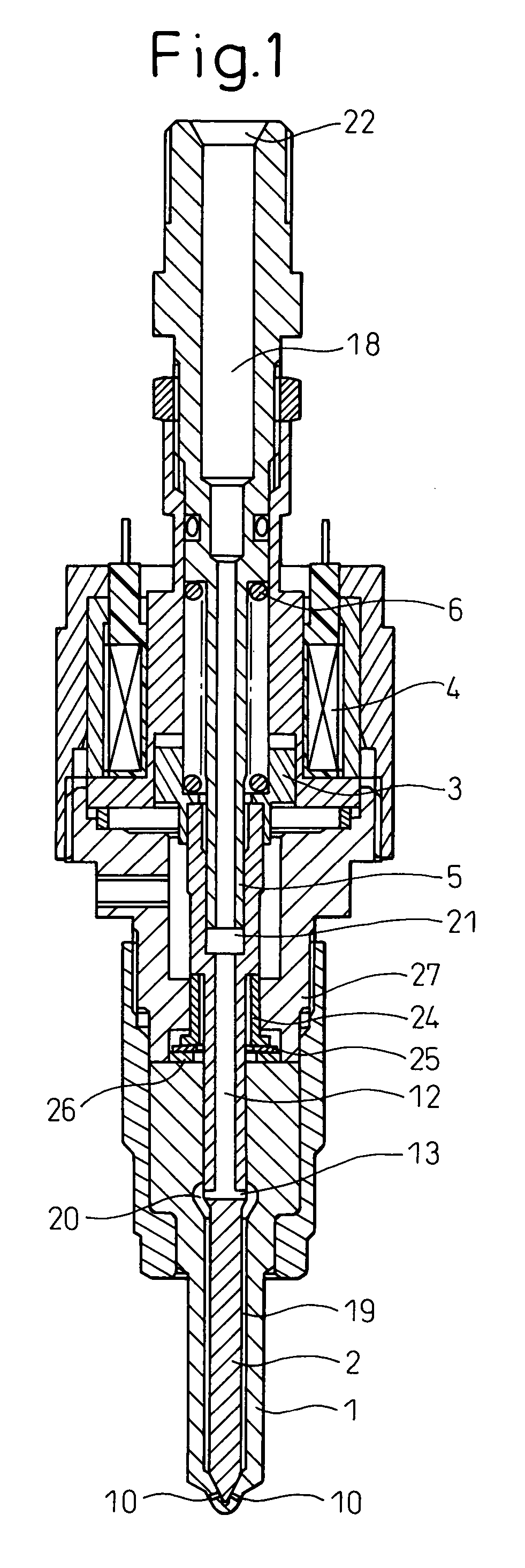

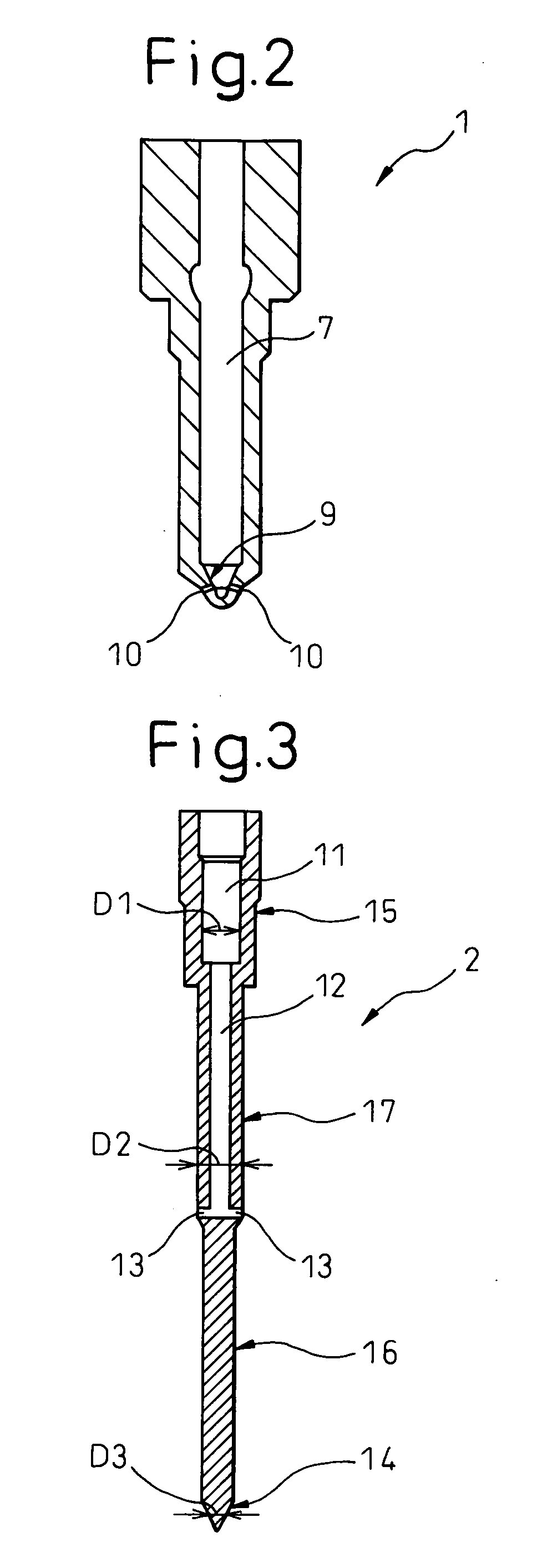

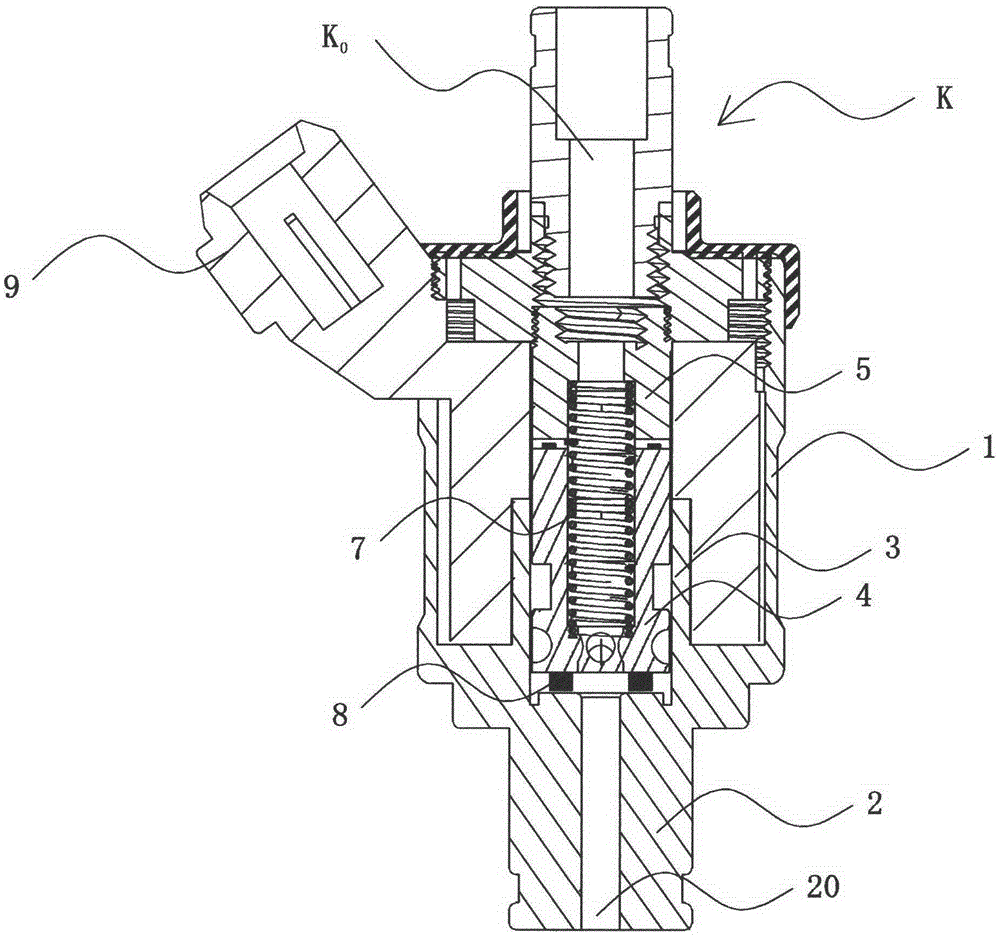

Injection valve

InactiveUS20120256013A1Injection behavior be improveImprove injectionMovable spraying apparatusSpray nozzlesExhaust gasInjector

The invention relates to an injection valve (1), which is used in particular as an injector for fuel injection systems or exhaust gas aftertreatment systems, comprising a shock wave actuator (4), a valve closing body (8) that interacts with a valve seat surface (7) to form a sealing seat (9), and a shock wave amplification channel (22). The shock wave amplification channel (22) is used to conduct shock waves (27) generated by the shock wave actuator (4) to the sealing seat (9) and to amplify said shock waves (27).

Owner:ROBERT BOSCH GMBH

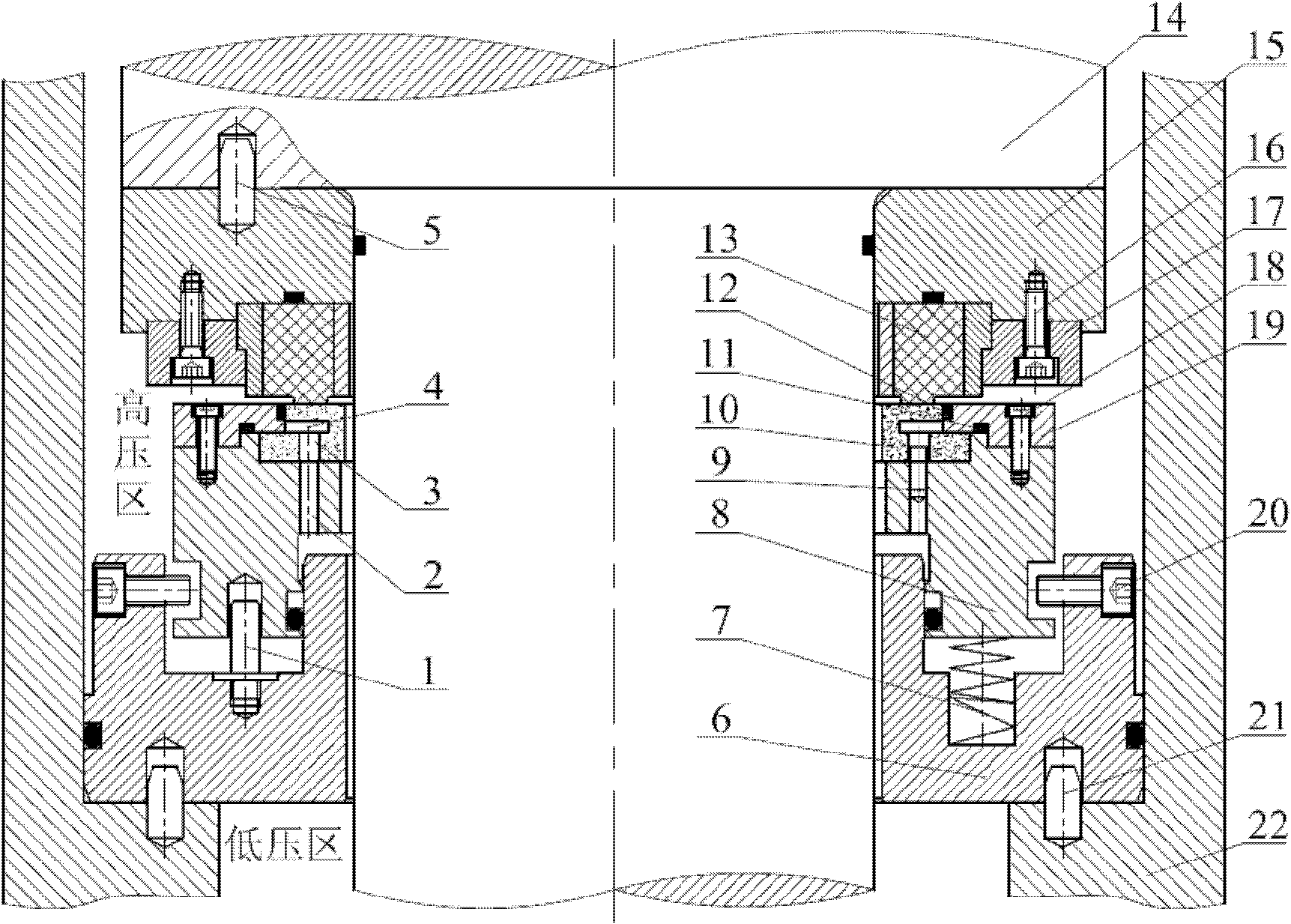

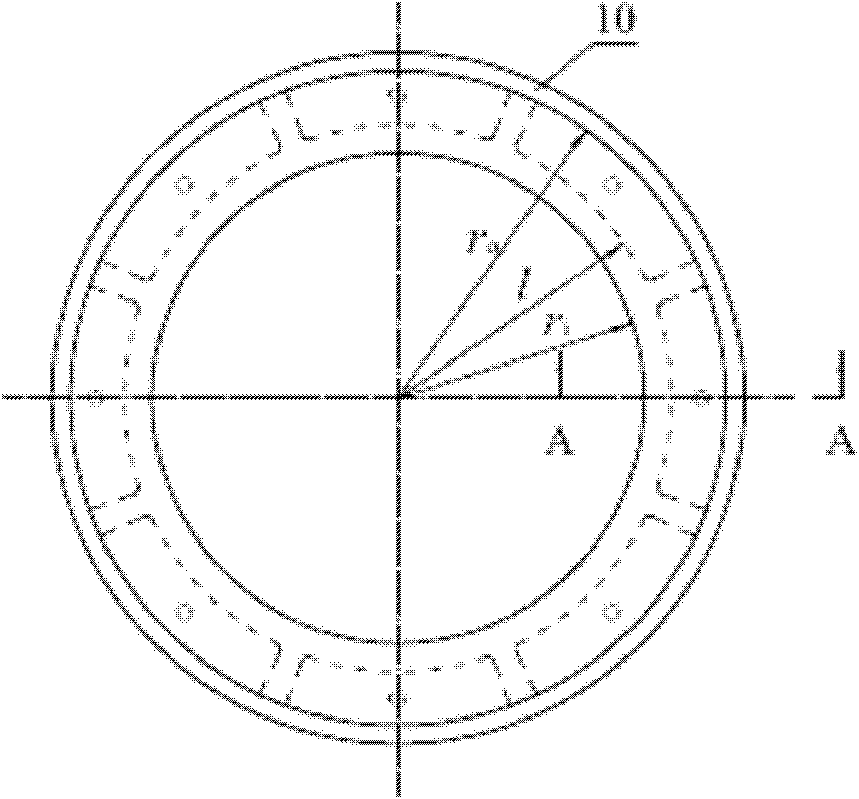

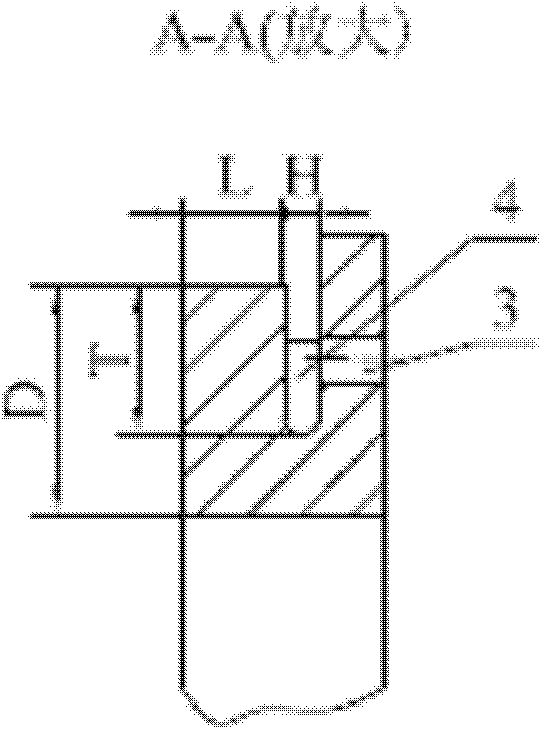

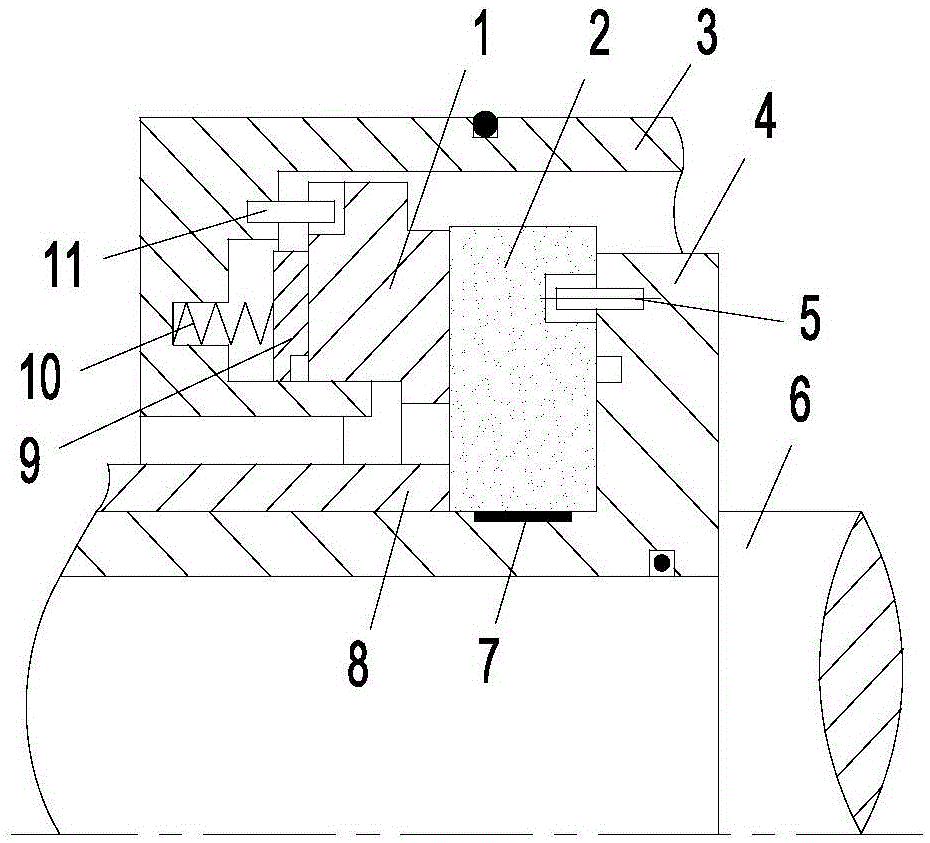

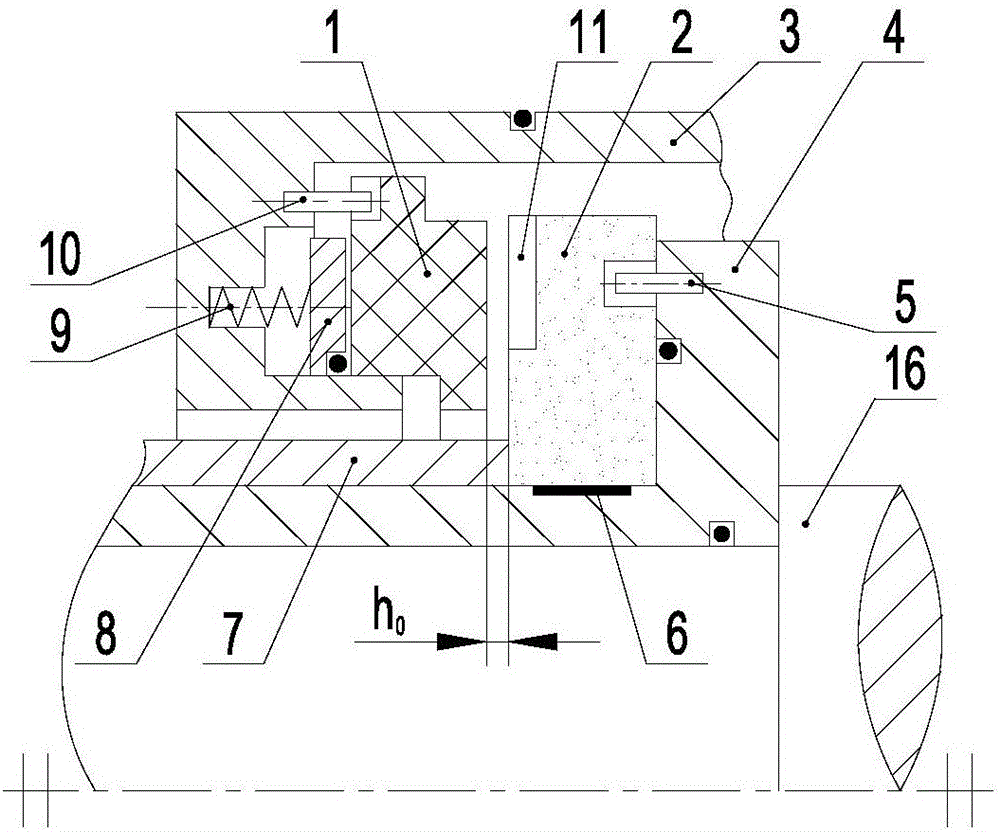

Hydrodynamic-hydrostatic pressure combined face seal device

ActiveCN101109447AReduce temperature riseIncrease the gapEngine sealsHydrostatic pressureEngineering

A hydrodynamic and hydrostatic combined end sealing arrangement is provided, which comprises a fixed ring that can be fixedly connected with the fixed part of a sealed part and a movable ring that can rotate with the rotator unit. Wherein, on the seal ends opposite to the fixed and movable ring, three adjacently arranged co-central circular end sealing areas are arranged respectively in sequence from outer to inner correspondingly. The outside in radial direction is a convergent clearance hydrostatic seal ring area that can form outside opening between the corresponding places at the two sides of the sealing arrangement, the middle is a hydrodynamic seal ring area for which a fluid hydrodynamic shallow groove on the end plane is provided, the inside is a circular area for the sealing dam with circular plane. The sealing arrangement combines hydrodynamic with hydrostatic end sealing, solves such problems as difficult to start a hydrostatic seal, end contacting due to high pressure fluctuation, and sealing failure, etc. by the action of hydrodynamic fluid, and can fully maintain the advantages with a fluid hydrostatic seal such as the high clearance and the control over the temperature rise of fluid, and realizes in a reasonable way the complementation of hydrodynamic and hydrostatic sealing and high reliability in controlling the fluid thickness at the end fluid film.

Owner:SICHUAN SUNNY SEAL

Zipper hole punch treatment

InactiveUS20100122440A1Little and no damageReduce breakageSnap fastenersEnvelopes/bags making machineryTrailing edgeInterlocking

The disclosure relates to a reclosable zipper for a package or bag wherein apertures are formed at periodic package-width intervals passing through the interlocking elements of the zipper profiles in order to minimize the mass of zipper material in areas where side seals of packages or bags will be subsequently formed. The otherwise interlocking elements upstream of, or at the trailing edge of, the apertures are deformed so as to prevent interlocking of the elements through a limited area. This allows a separator pin to pass through the area of the apertures and pass between the zipper profiles, eliminating or reducing the collision of the separator with the zipper profiles and subsequent potential damage to the zipper profiles.

Owner:ILLINOIS TOOL WORKS INC

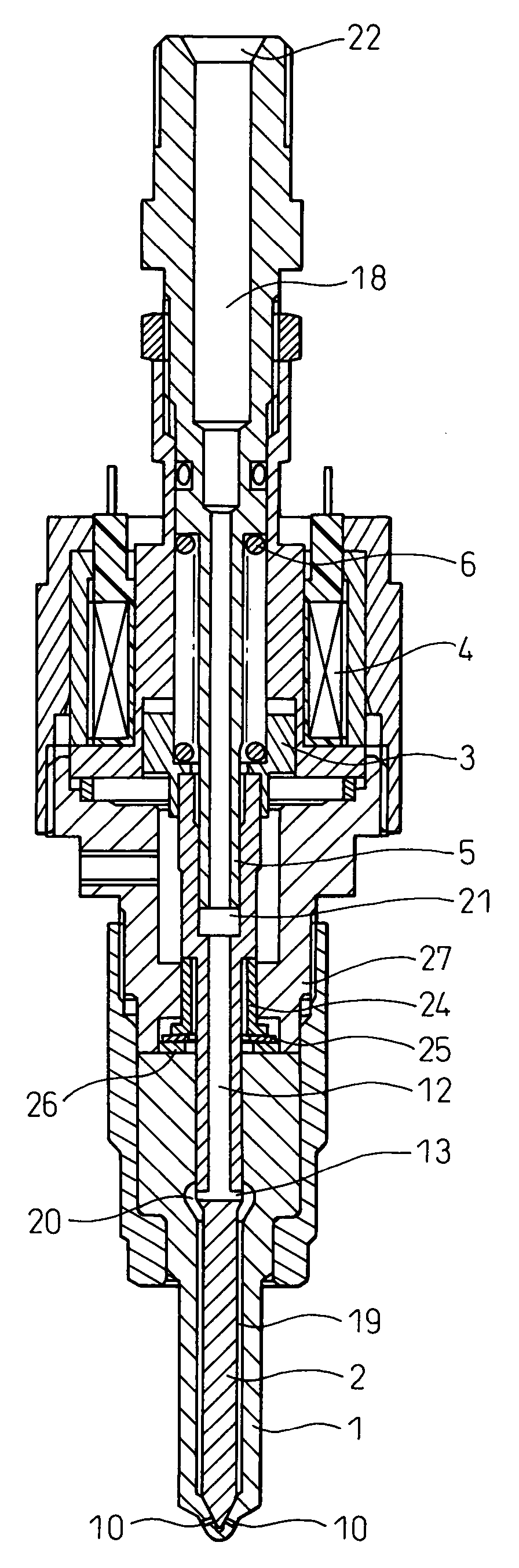

Fuel injection valve

InactiveUS20050072865A1Great opening forceImprove performanceOperating means/releasing devices for valvesSpray nozzlesThermodynamicsMechanics

A fuel injection valve includes a fuel injection port, a needle for cutting the fuel flow into the fuel injection port and a needle mover for moving the needle away from the fuel injection port and allowing the fuel to flow into the fuel injection port. When the needle is moved away from the fuel injection port by the needle mover, the force is applied by a force applicator to the needle away from the fuel injection port only during the period when the needle is moved away from the fuel injection port to less than a predetermined degree.

Owner:TOYOTA JIDOSHA KK +1

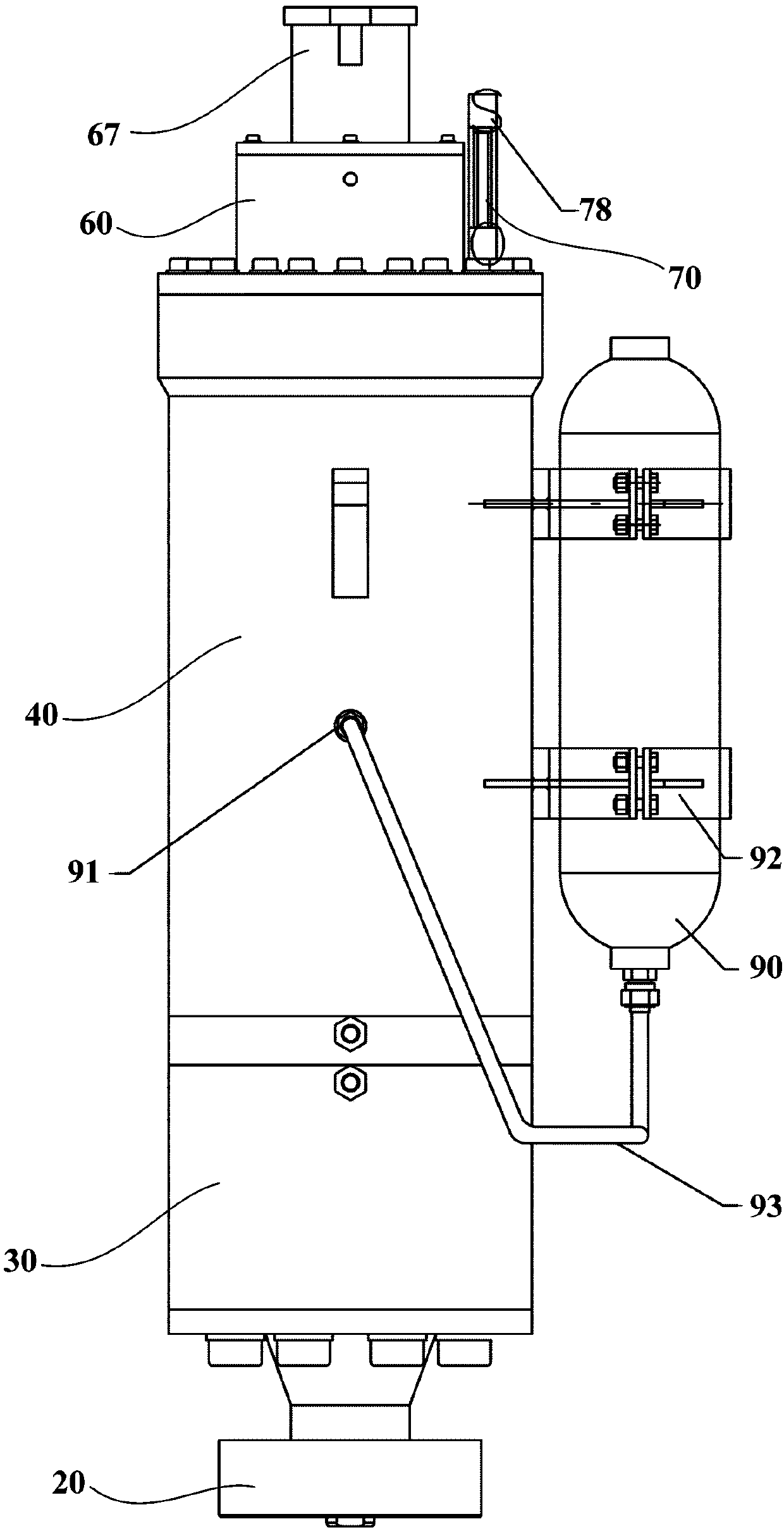

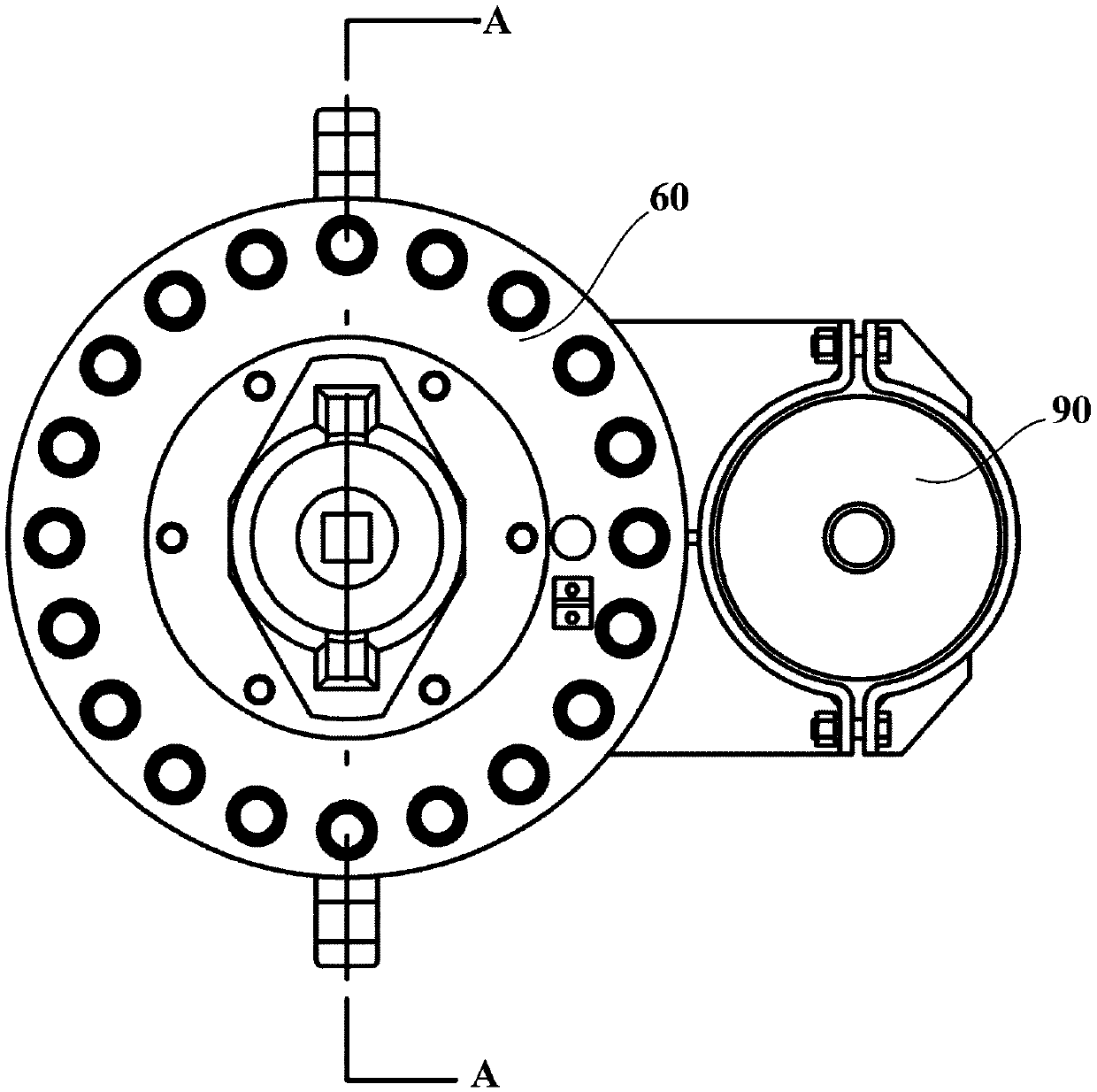

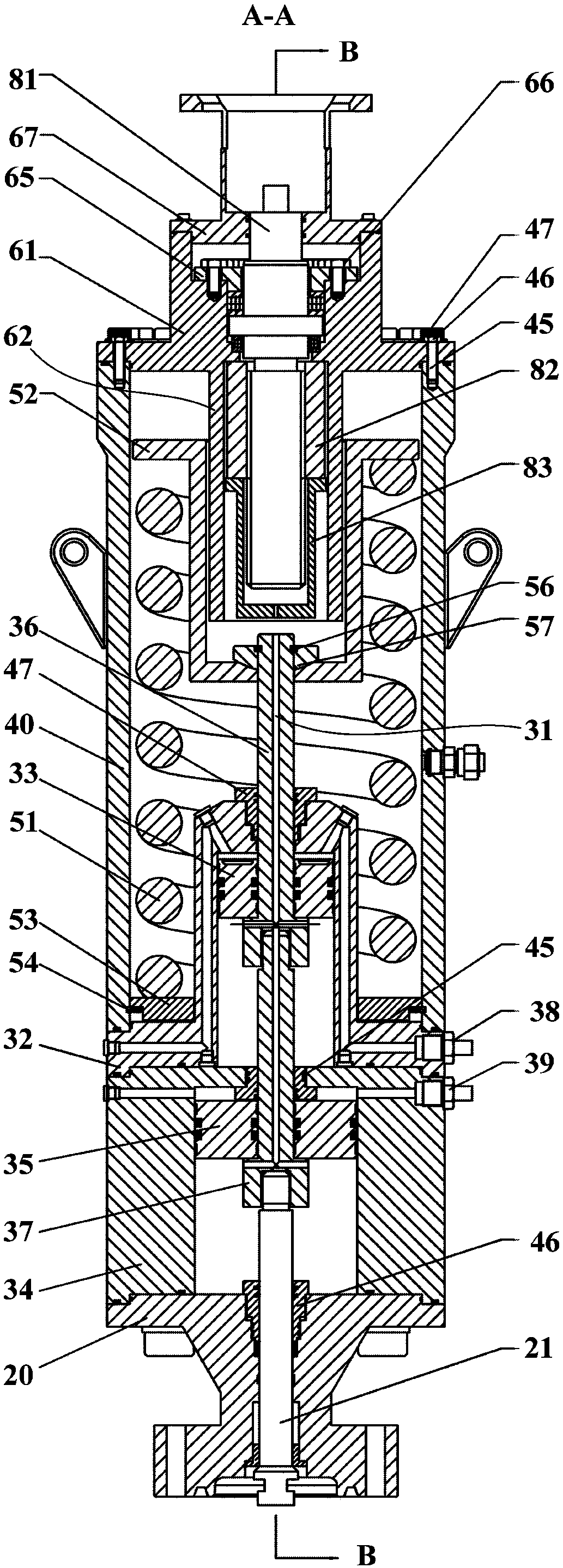

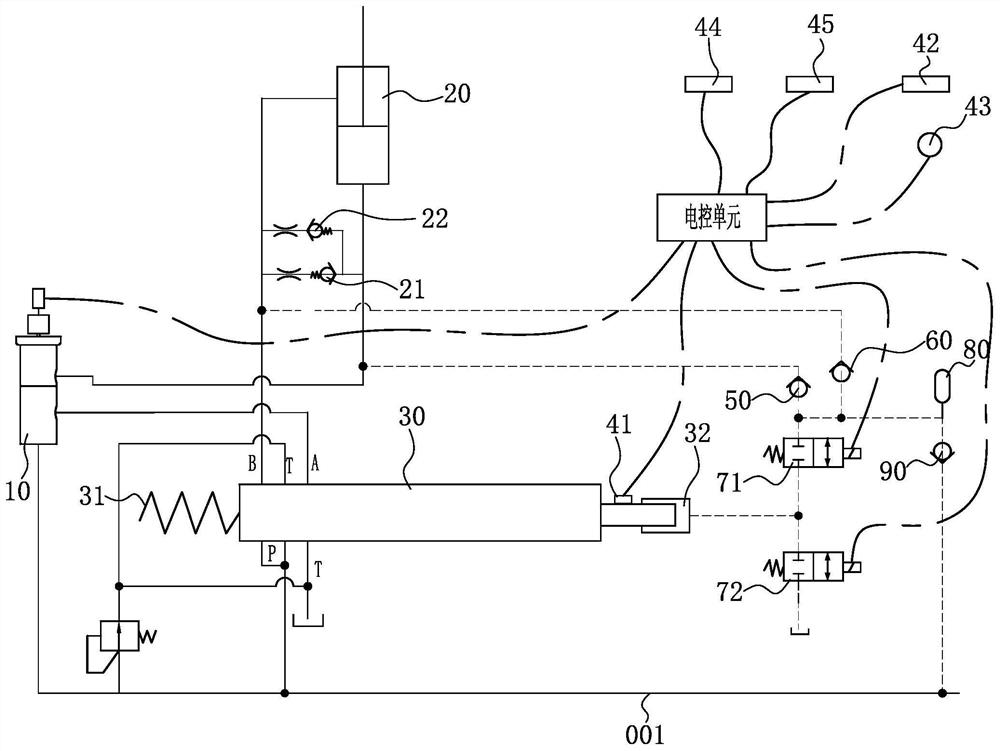

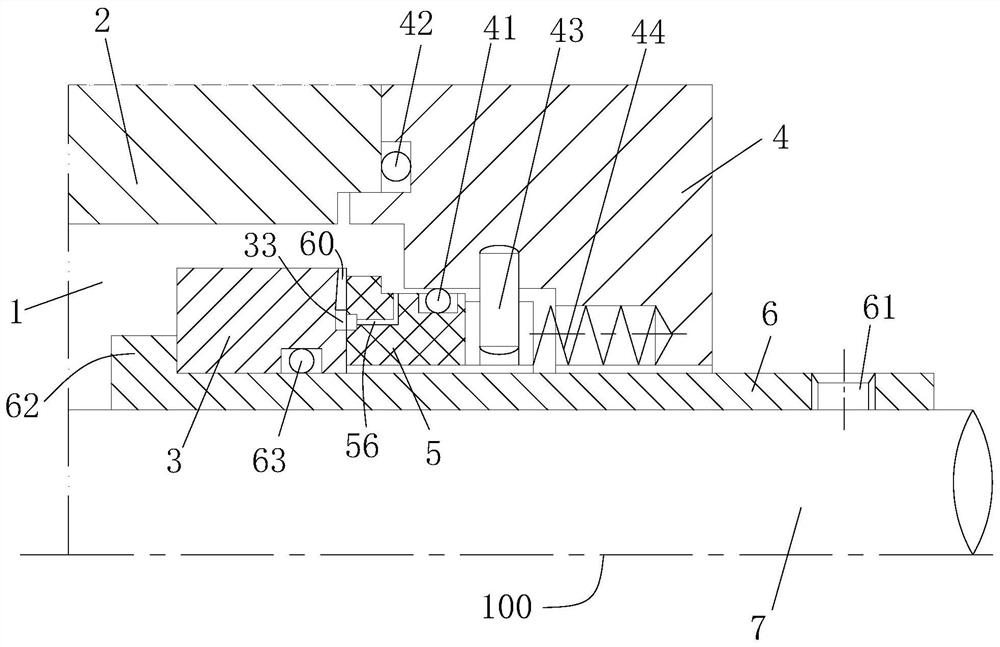

Redundant driving underwater gate valve executing mechanism

ActiveCN109538813AAchieve separation and independenceImprove reliabilityOperating means/releasing devices for valvesDynamic balanceEngineering

The invention provides a redundant driving underwater gate valve executing mechanism. The redundant driving underwater gate valve executing mechanism comprises a hydraulic driving device, wherein a piston and a piston rod are arranged to drive the piston rod to move downwards when the piston moves downwards, and the piston rod is separated from the piston when the piston rod moves downwards; a ROVdriving device is provided with a threaded shaft, a transmission nut and a sleeve; the transmission nut and the sleeve can move up and down in the sleeve, the sleeve is located on the lower side of the transmission nut, and the lower end of the sleeve is a contact plate for enabling the upper end of the piston rod to be in contact abutting against the upper end of the piston rod; the threaded shaft is rotationally arranged on the upper cover part and is matched with the transmission nut; and a pressure compensator is arranged on a mechanism shell through a support, and the pressure compensator is connected with a pressure compensation joint through a compensation oil pipe so as to communicate with the inner part of the mechanism shell. The two structures of hydraulic driving and ROV operation can be separated independently, and under the action of deep sea high pressure, the dynamic balance of the outer pressure inside the mechanism shell can be guaranteed.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

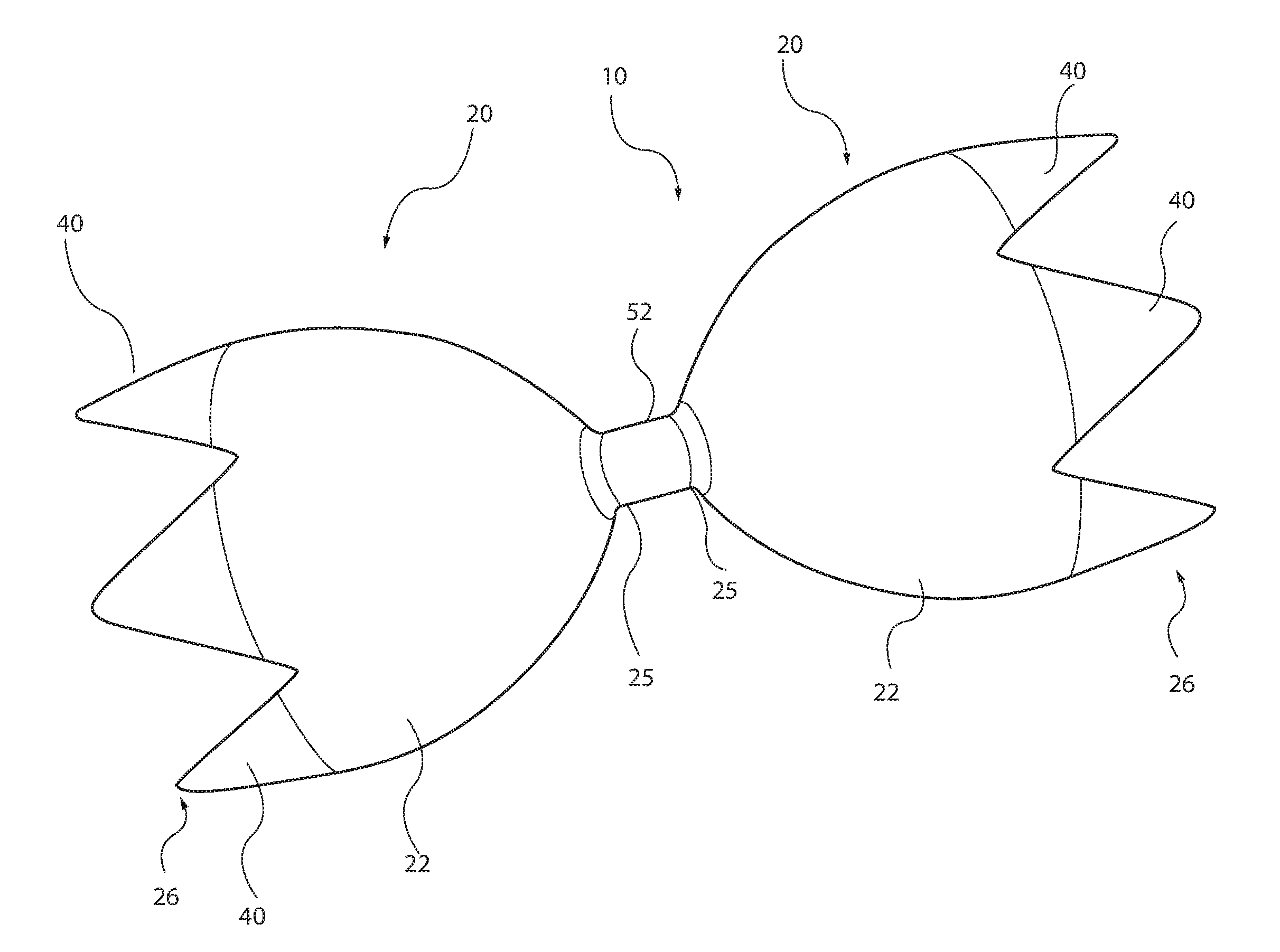

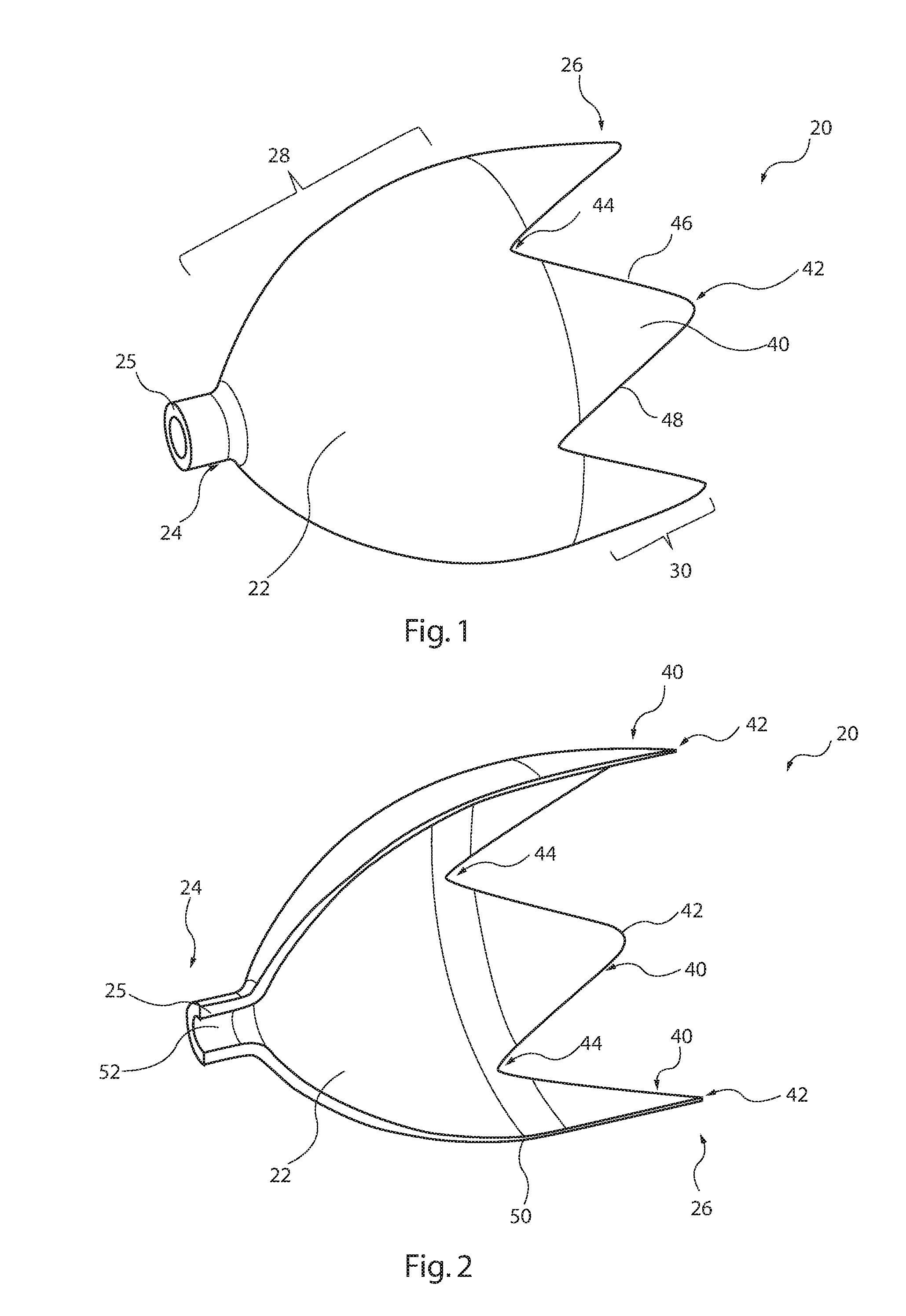

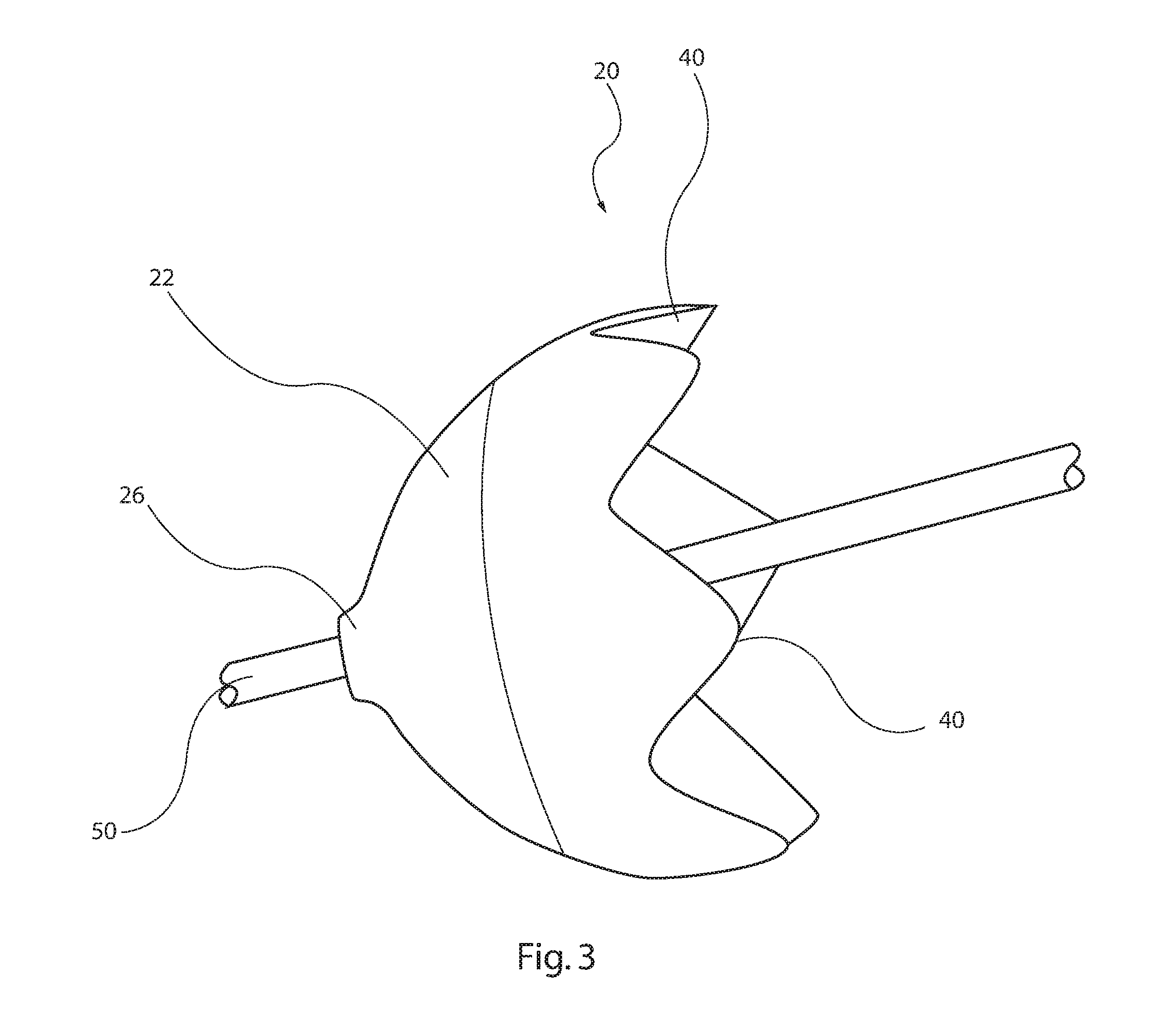

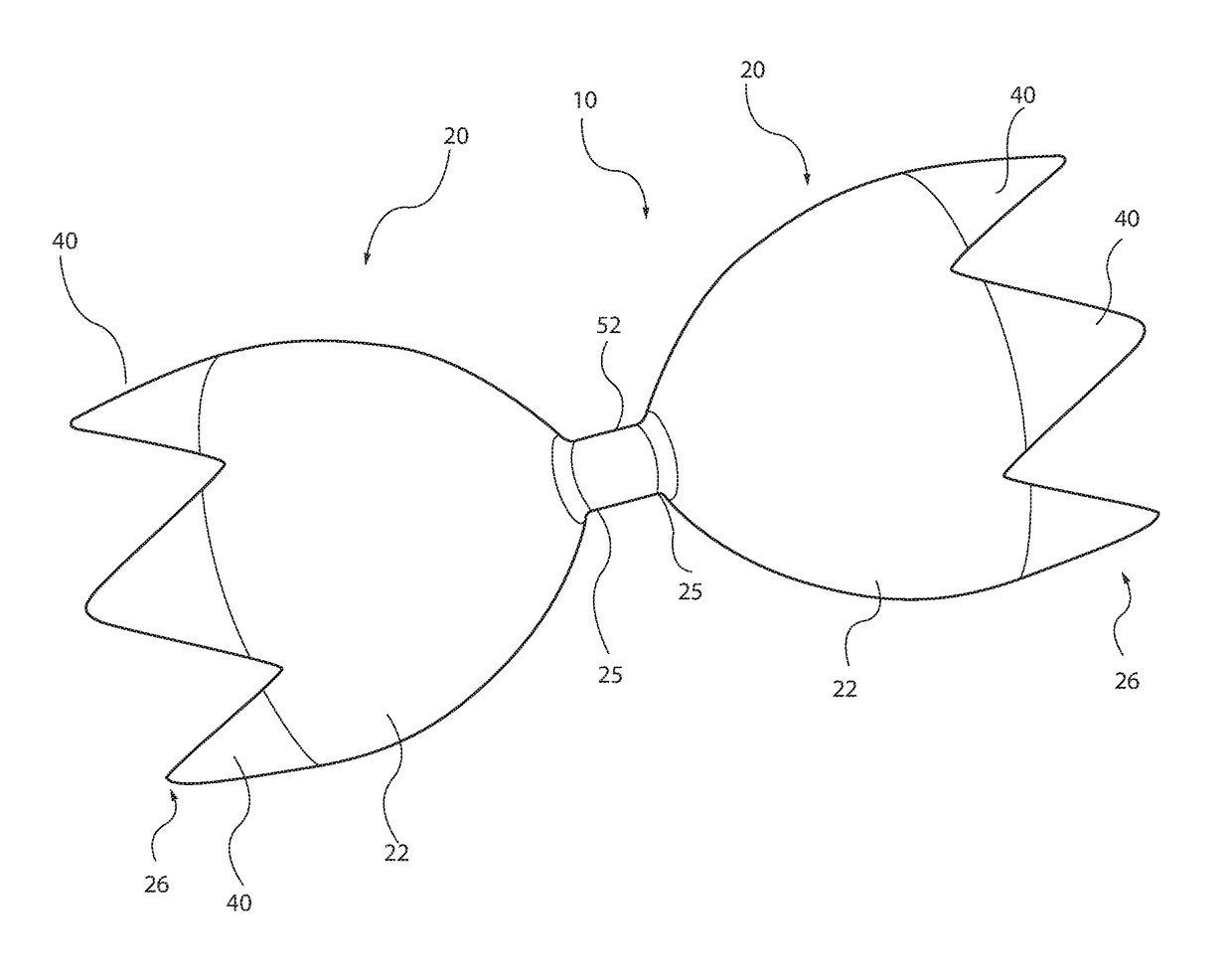

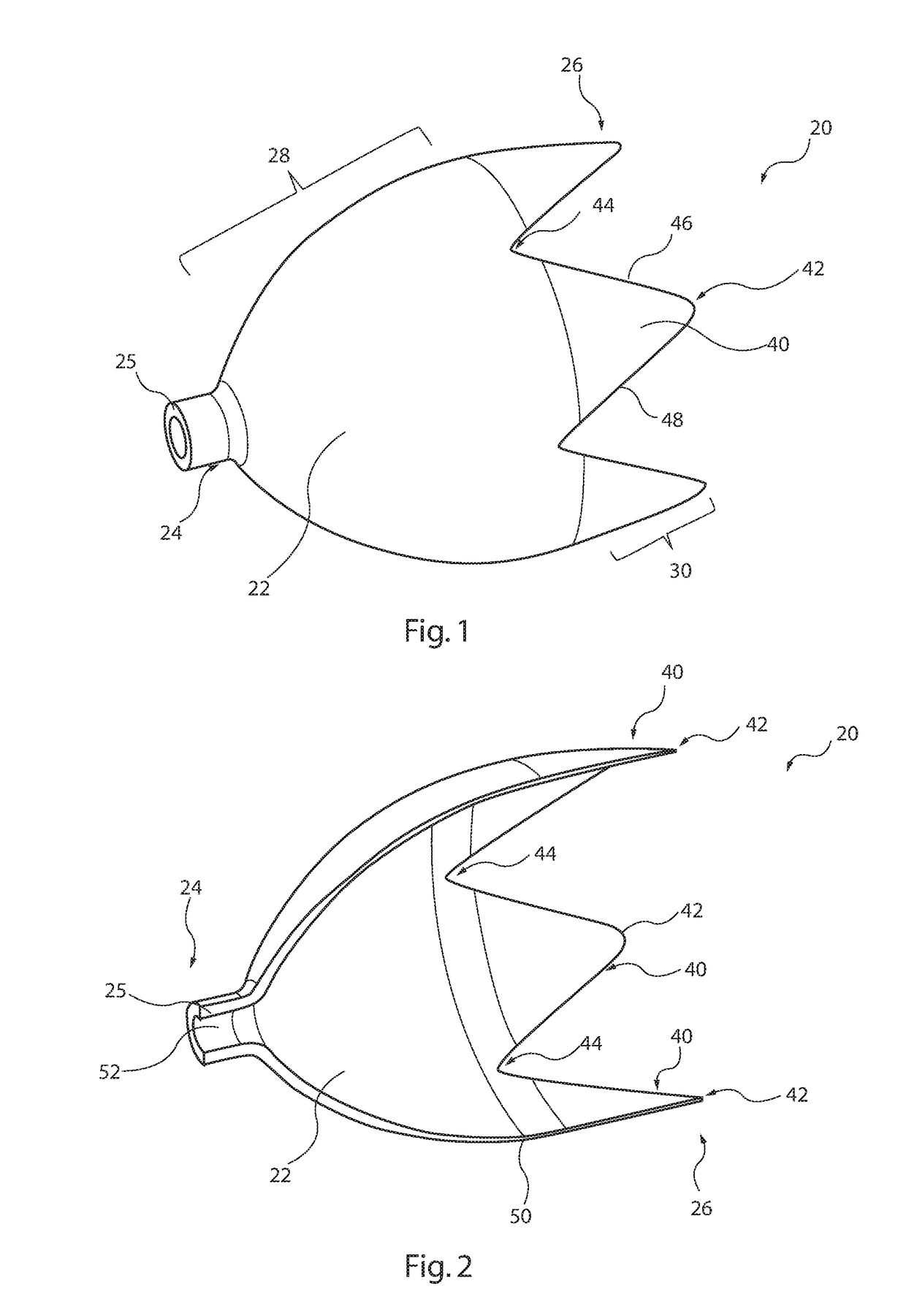

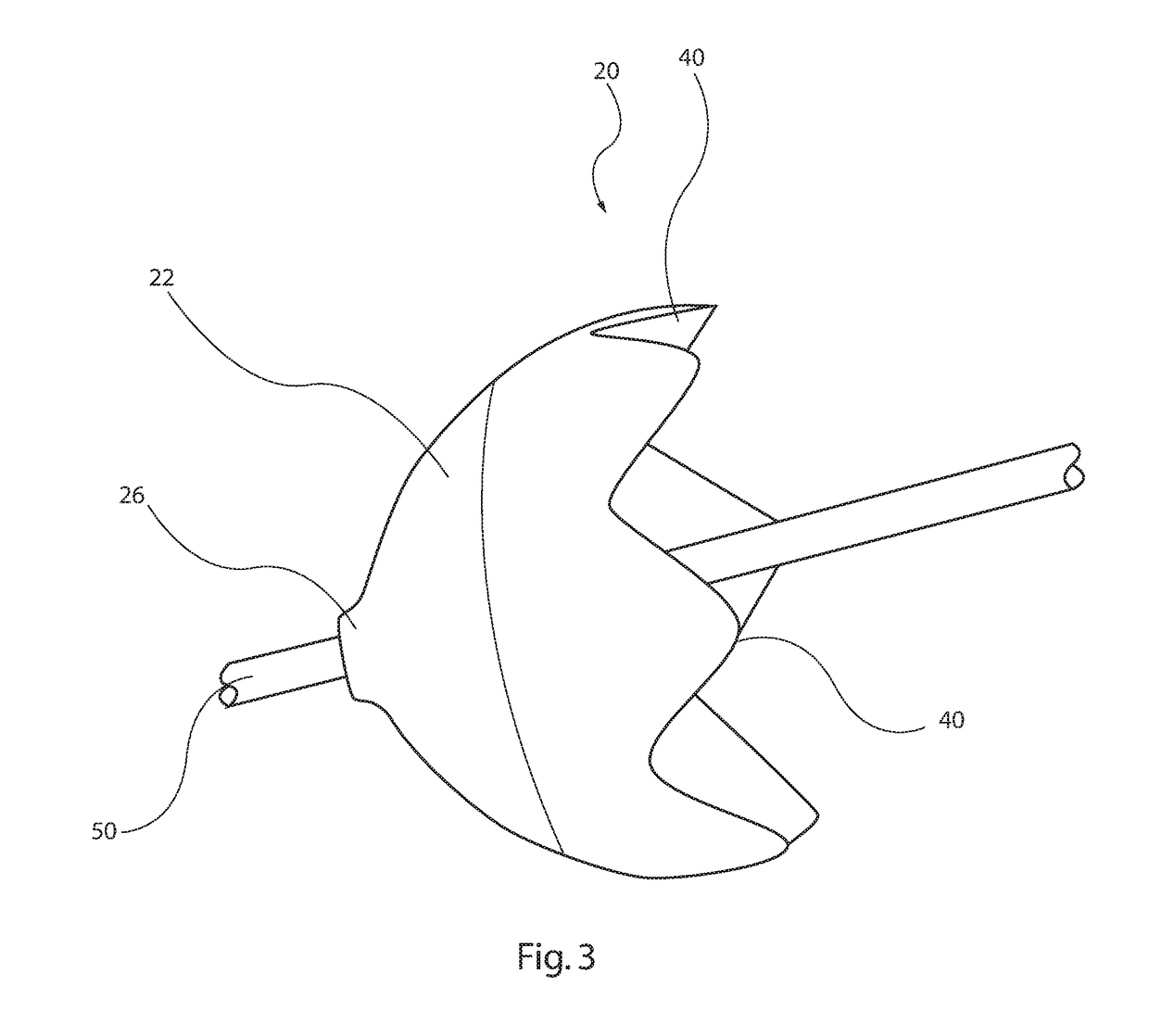

Cone expanding collapsible medical device

A vascular occluder includes first and second conical members disposed in opposing relation and which have tooth-shaped wide ends. The conical members are coupled to one another by a coupling element, which may be a cannula or rod. The conical members are formed of a membrane which has a thickness which increases towards the narrow ends and decreases towards the toothed elements. The toothed elements are preferably self-supporting within a vessel and avoid folds within the occluder membrane, which may otherwise result in leakage of blood around the device. The device may be provided with a supporting frame which may be at least partially embedded within the membrane. The membrane is preferably made of silicone.

Owner:COOK MEDICAL TECH LLC

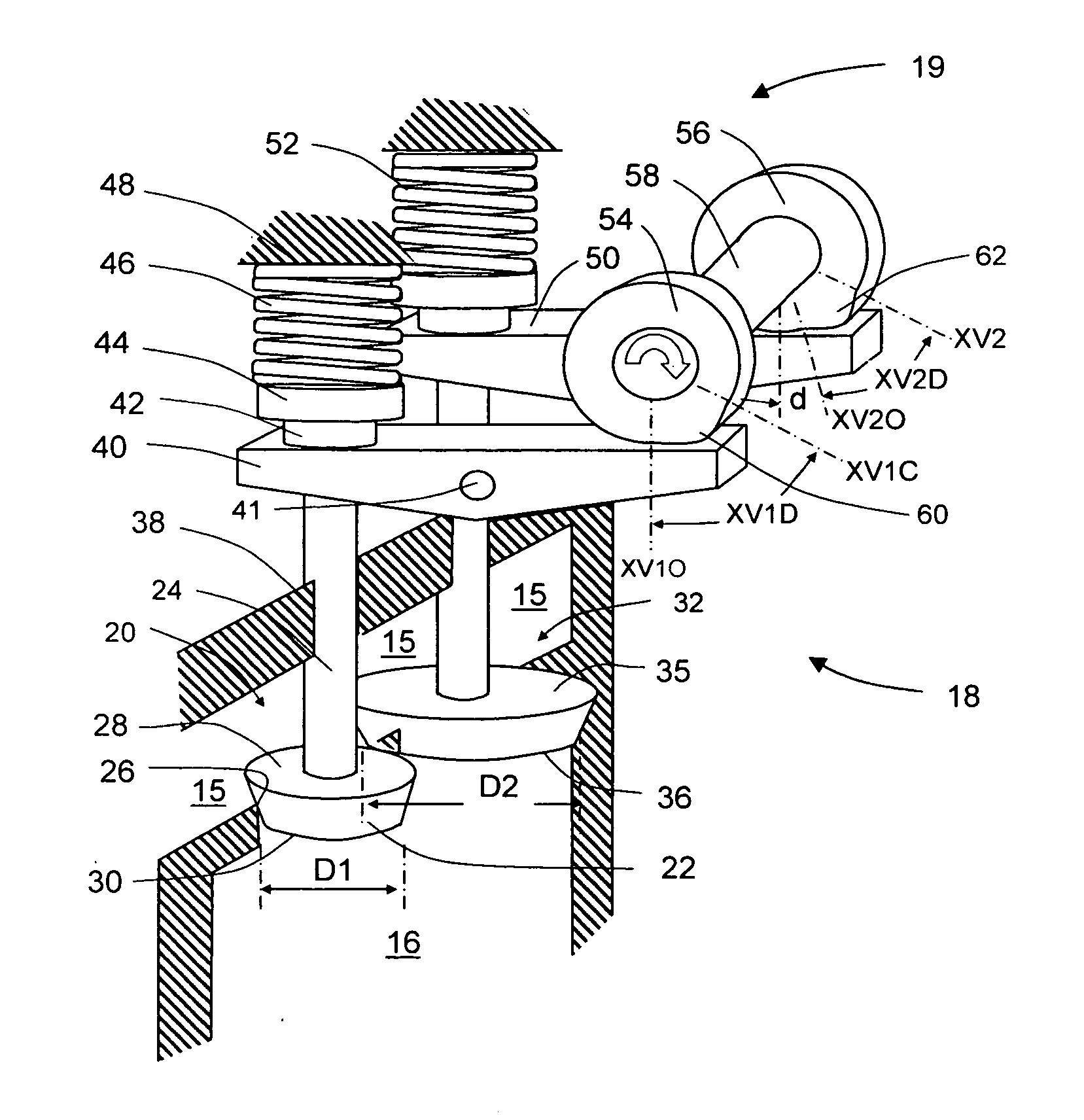

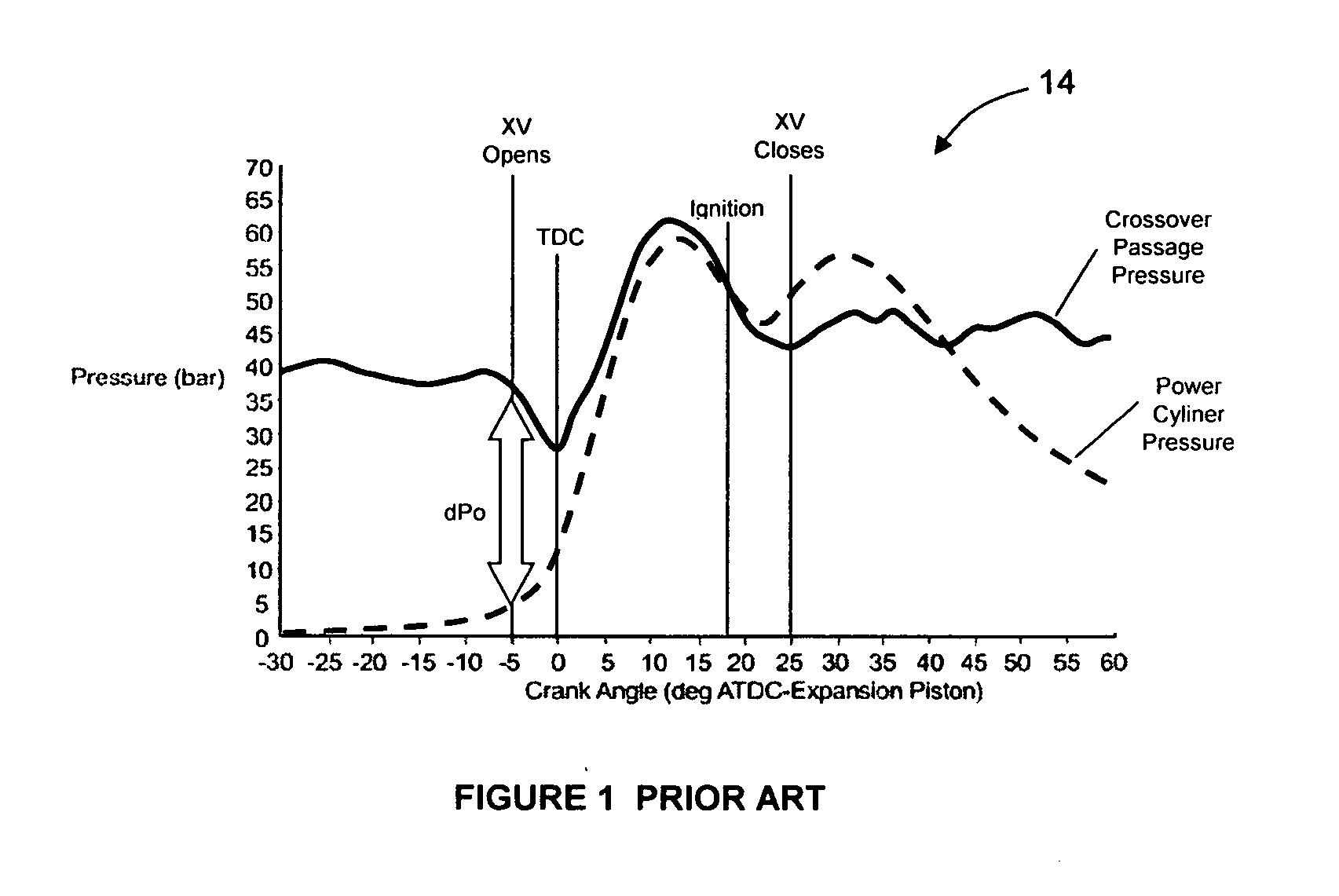

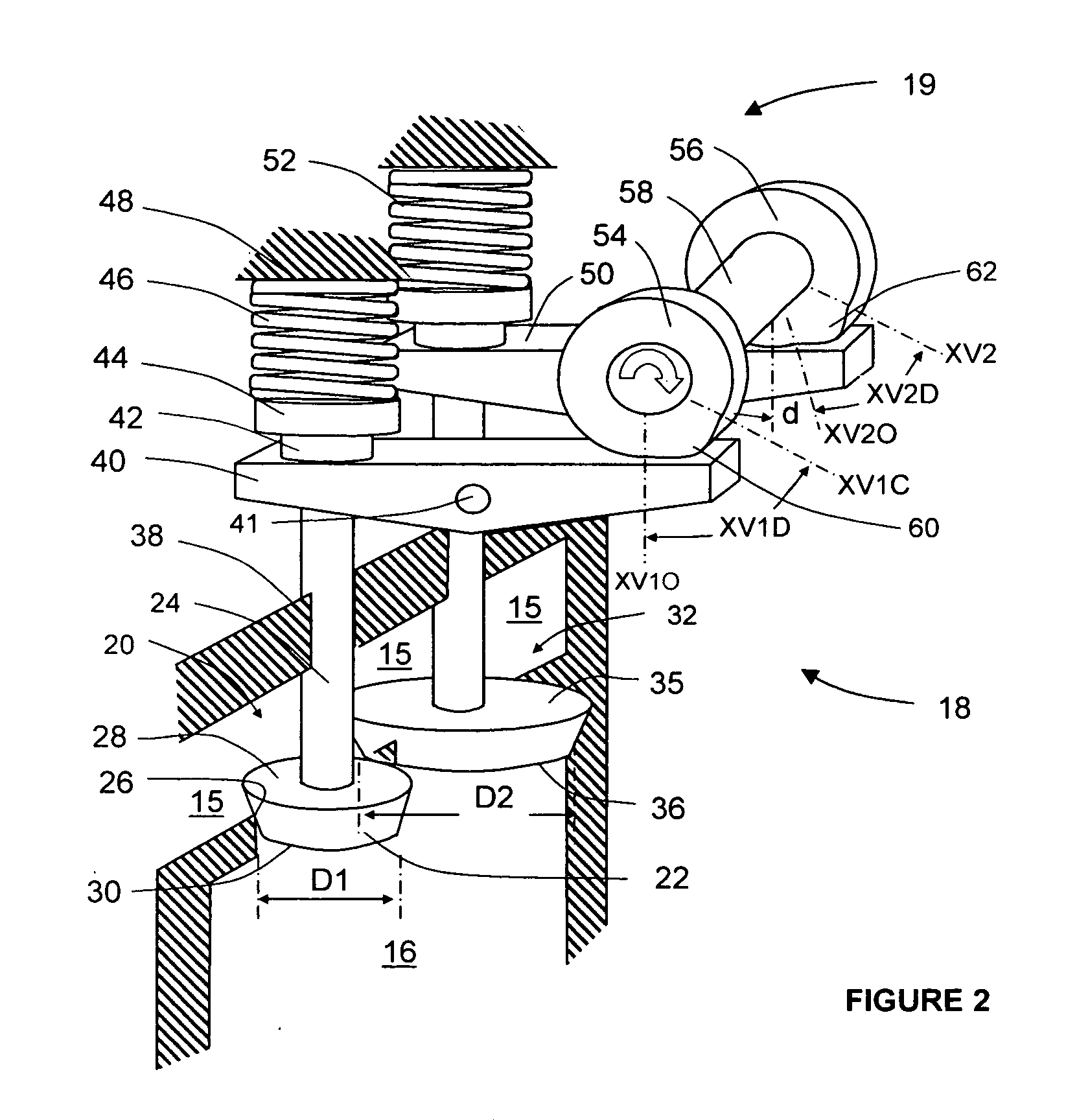

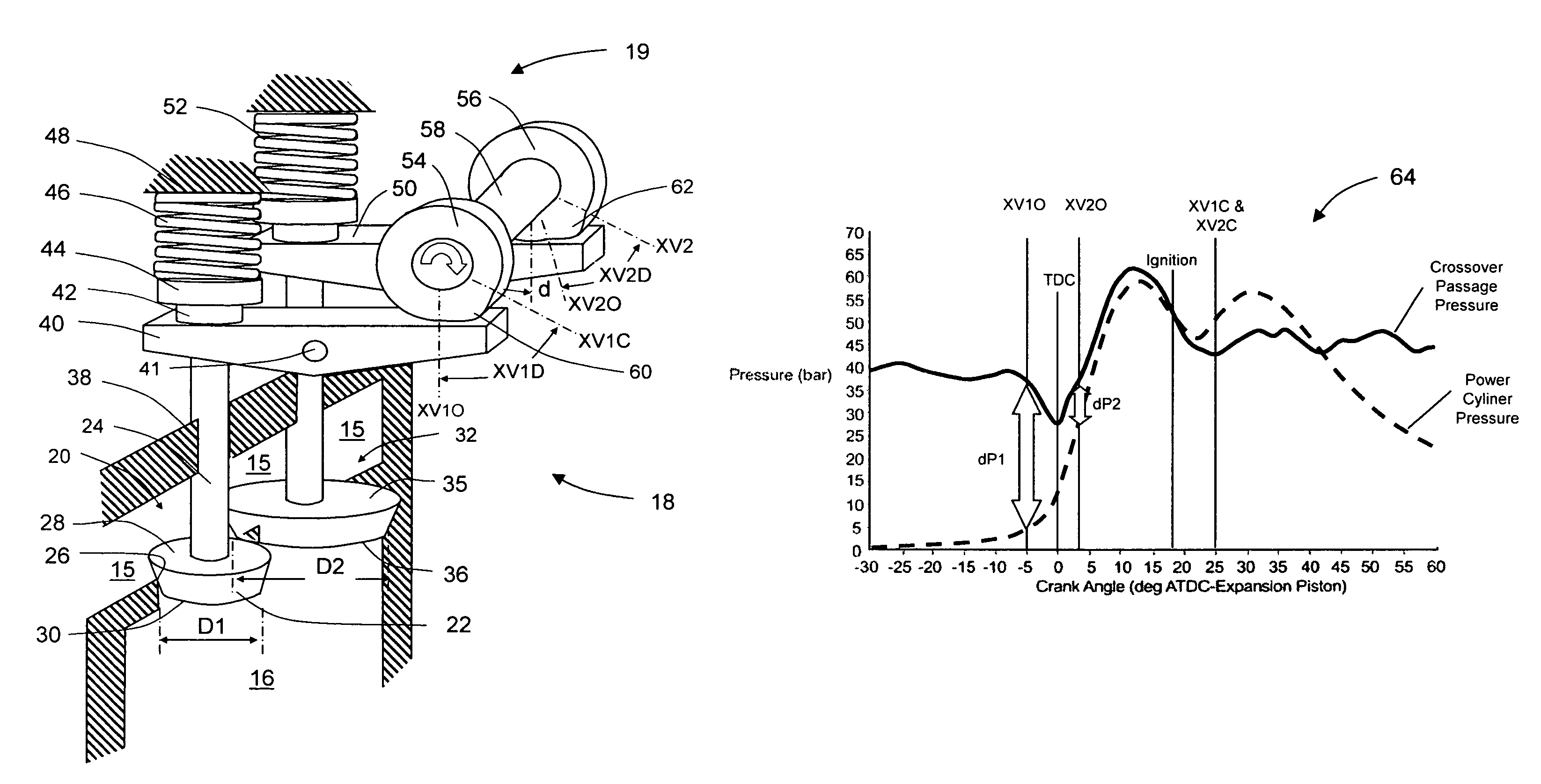

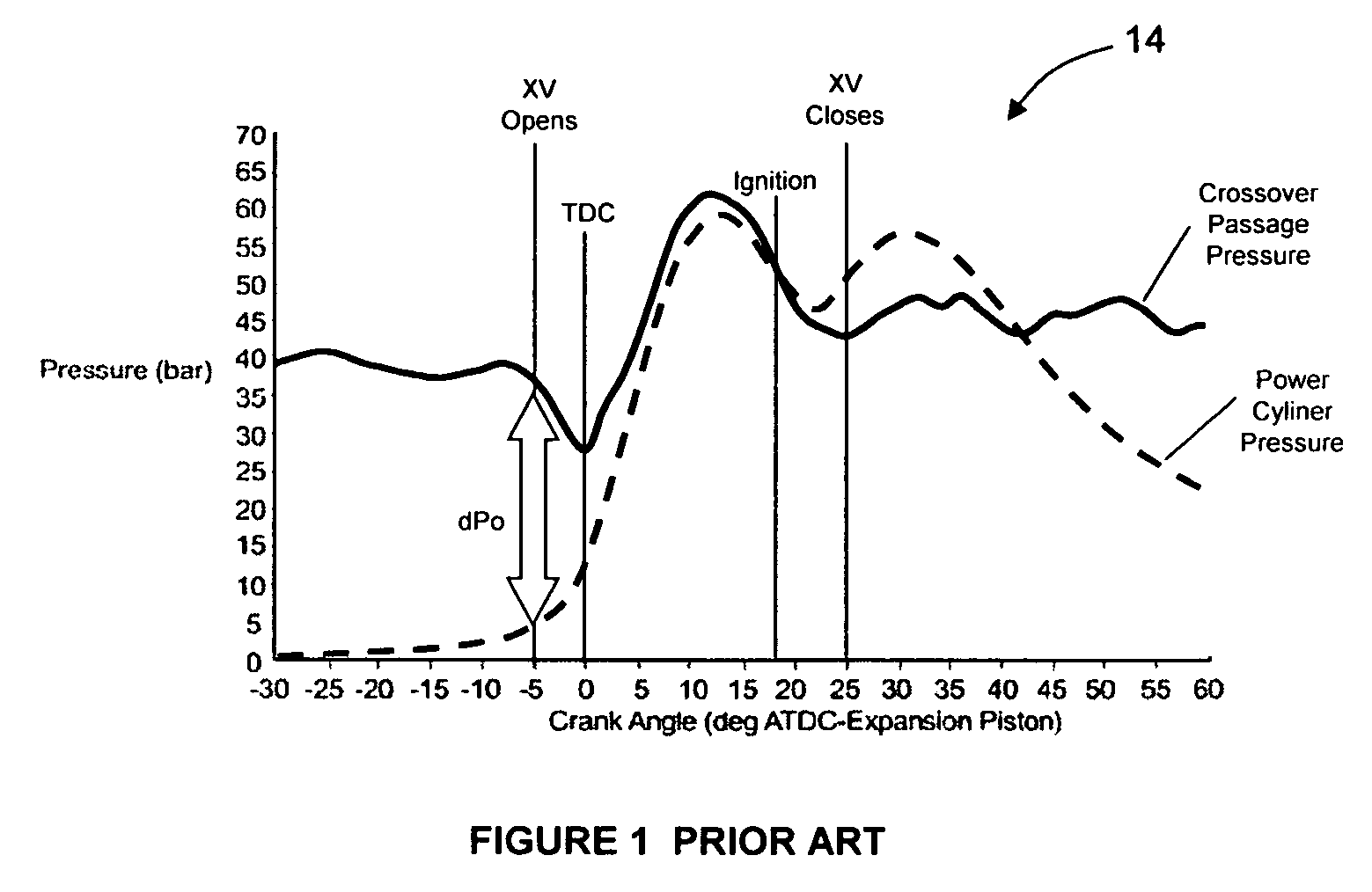

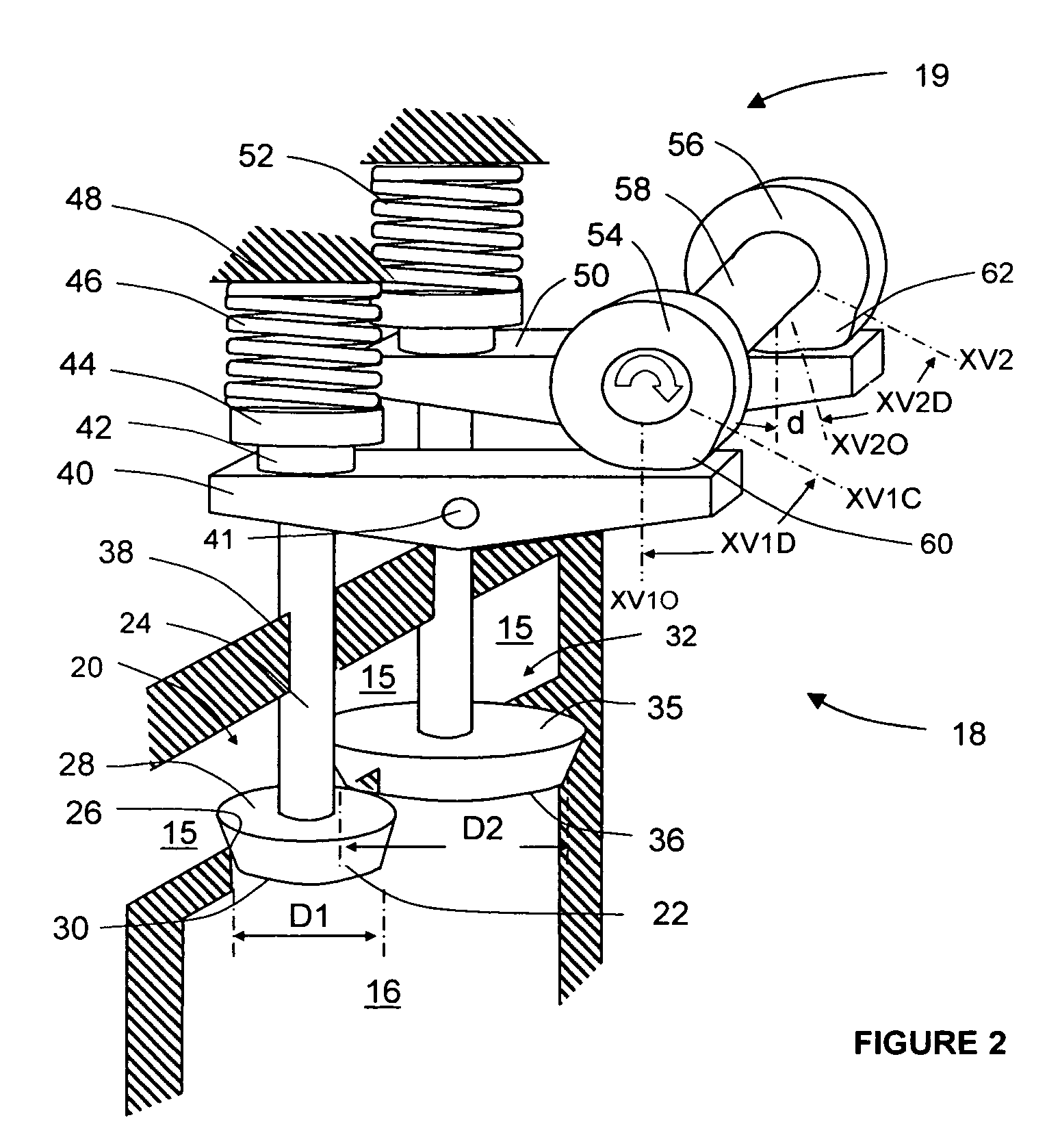

Crossover valve systems

InactiveUS20110017181A1Large initial opening forceReduction in flow areaOperating means/releasing devices for valvesCombustion enginesDifferential pressureValve opening

Crossover valve systems and corresponding methods offer an effective means to overcome large opening pressure force, or provide reasonable gas flow area, or both. In an exemplary embodiment, a crossover valve system for a split-cycle engine having a power cylinder and a crossover passage comprises first and second crossover valves, each valve opening outwardly away from the power cylinder and providing fluid communication between the power cylinder and the crossover passage, with the diameter of the second crossover valve being larger than the diameter of the first crossover valve; and an actuation mechanism operative to open the first crossover valve, then the second crossover valve after a predetermined delay to allow a certain rise in the pressure inside the power cylinder, resulting in much smaller differential pressure forces across the crossover valves, larger flow areas, or both.

Owner:LGD TECH LLC

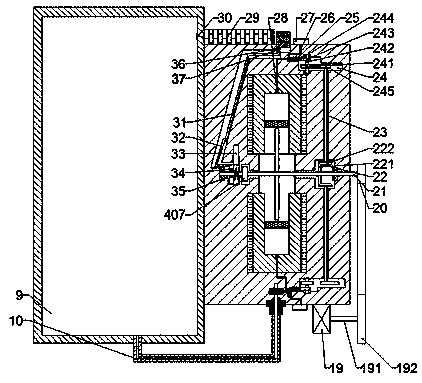

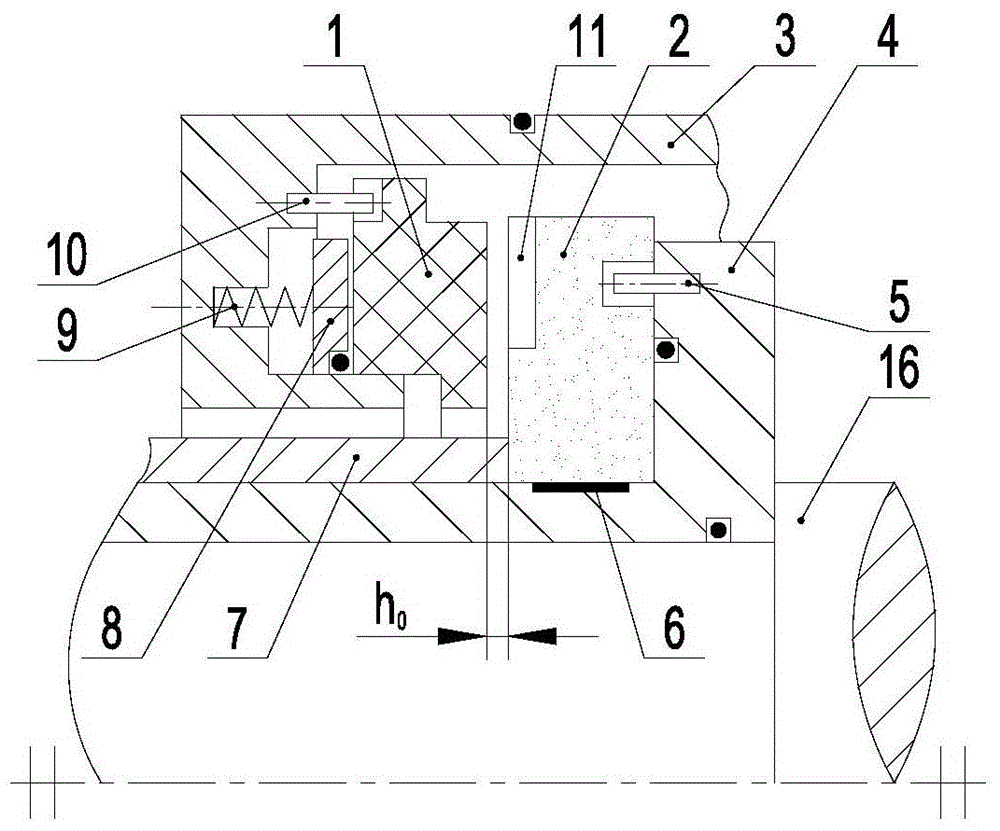

Mechanical seal device for end face seal ring with controllable bellows seal

ActiveCN105114626AImprove surface qualityEliminate or reduce the impactEngine sealsElectricityControl system

The invention relates to a mechanical seal device for an end face seal ring with controllable bellows seal. The mechanical seal device is provided with a moving ring and a non-rotating stationary ring, wherein the moving ring can synchronously rotate along with a rotating shaft, and the stationary ring is connected with a stationary ring base; the axial relative end faces of the moving ring and the stationary ring are the respective seal faces, and at least one seal face is in a plane structure. Electric heating structures keeping the distance with the seal faces are arranged in the circumferential direction of the stationary ring and / or the moving ring with the plane-structure seal surface at intervals, and the electric heating structures are connected with a control system. On the basis that the conventional end face bellows process is kept, the mechanical seal device can process the seal faces into high-precision planes and can obtain the high surface quality on the planes and the controllable bellows seal faces through heating control for the electric heating structures, therefore the influences on the seal effects caused by various factors can be effectively eliminated and avoided, the good hydrodynamic effect can be generated, and the ideal fluid film opening force and stiffness are obtained.

Owner:江苏光谷产业投资发展有限公司

Mechanical seal device with seal rings with controllable cone bevel seal end faces

The invention relates to a mechanical seal device with seal rings with controllable cone bevel seal end faces. The mechanical seal device is provided with a moving ring capable of synchronously rotating along with a rotary shaft and a non-rotating static ring connected with a static ring seat. Axially-opposite end faces between the moving ring and the static ring serve as respective seal faces. The seal face of at least one of the static ring and the moving ring is of a plane structure, and an annular electric heating structure concentric with the static ring and / or the moving ring is arranged at the position, spaced from the seal face, in the static ring and / or the moving ring and connected with a control system. On the basis of an existing end face processing technology, the seal faces can be processed into planes, the cone bevel structure seal faces with high surface quality and controllable cone angle sizes can be obtained on the planes through heating control over the annular electric heating structures, and therefore the influences of various factors on the seal effect can be effectively eliminated, a very good fluid hydrodynamic effect can be generated, and very ideal fluid film opening force and rigidity are obtained.

Owner:永嘉县环球机械密封件厂

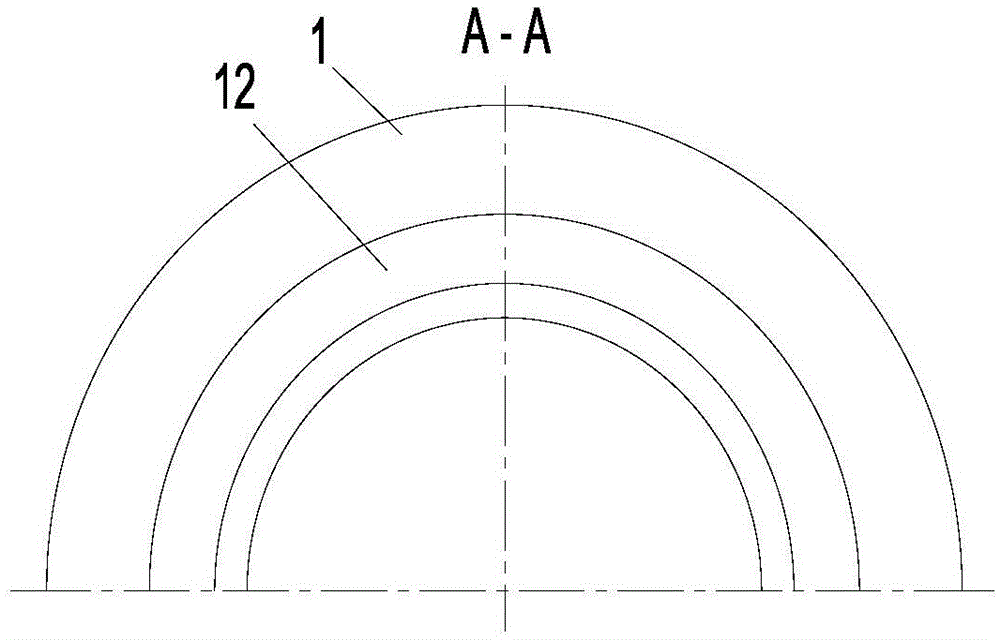

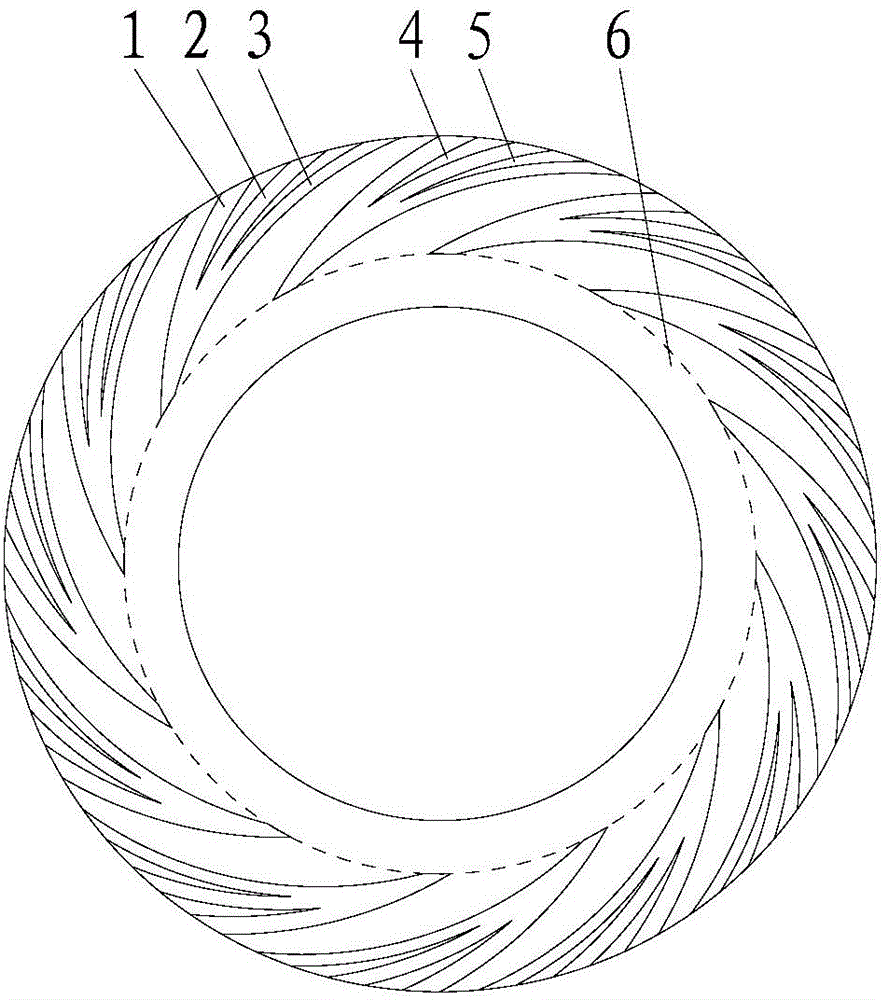

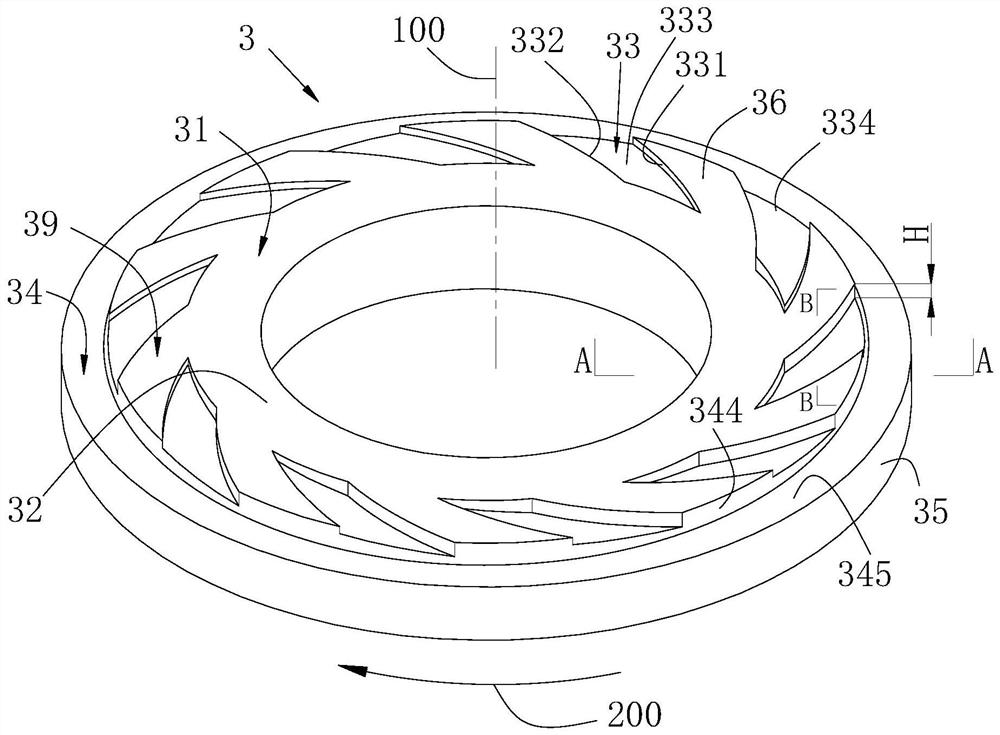

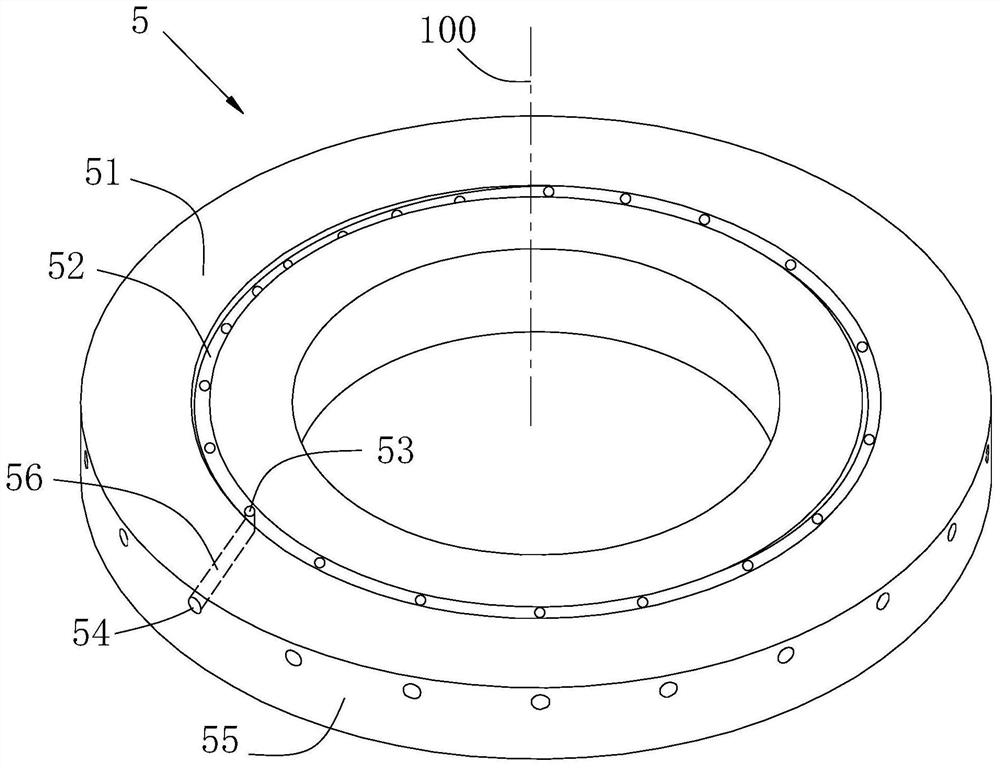

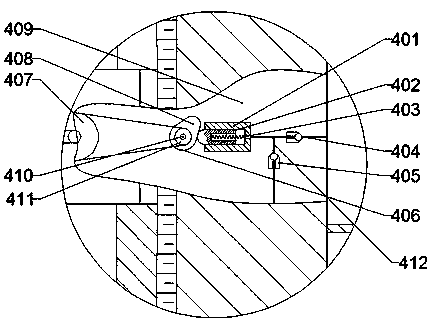

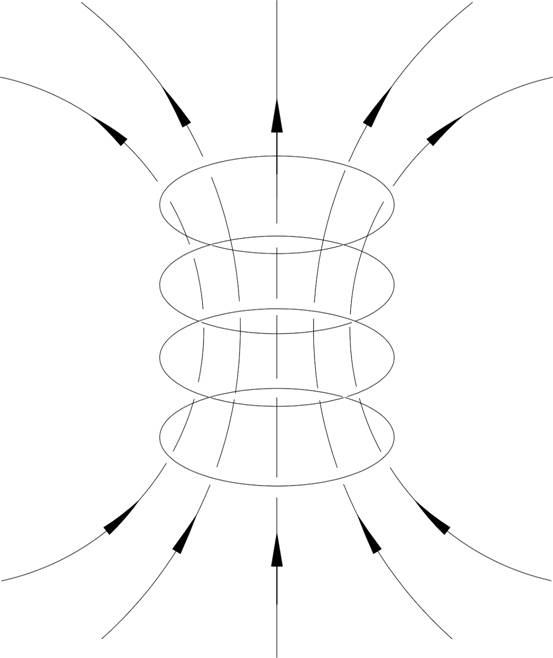

Gas lubrication cluster spiral groove end face mechanical sealing structure

InactiveCN104896099AStrong convergence propertiesImprove compression performanceEngine sealsLow speedGas lubrication

A gas lubrication cluster spiral groove end face mechanical sealing structure comprises a moving ring and a stationary ring of a mechanical seal. One side of the end face of the moving ring and one side of the end face of the stationary ring are high-pressure sides, namely, upper streams, and the other side of the end face of the moving ring and the other side of the end face of the stationary ring are low-pressure sides, namely, lower streams. A plurality of cluster spiral grooves symmetrically distributed along the circumference of the end face are formed in the end face of at least on sealing ring of the moving ring or the stationary ring, the cluster spiral grooves are formed by combining a plurality of micro spiral grooves with different spiral angles in the circumferential direction of the end face, the micro spiral grooves in the same cluster spiral groove are separated by a sealing weir free of grooves on the high-pressure side, the groove roots of the micro spiral grooves in the same cluster spiral groove are overlaid and communicated to a whole on the lower-pressure side, and sealing dams are arranged on the down streams of the cluster spiral grooves. Through the convergence configuration of bionic high-speed flyer wings and the alula structure of flyer wing front edges, the gas lubrication cluster spiral groove end face mechanical sealing structure has a high flow guide effect and compression function on fluid media, the low-speed start and stop characteristic, high-speed running stability and sealing performance of the seal can be improved, the high-speed disturbance rejection capacity of the seal is improved, and end face abrasion is avoided.

Owner:ZHEJIANG UNIV OF TECH

CNG/LPG (compressed natural gas/liquefied petroleum gas) fuel gas spray nozzle

ActiveCN103306857ALight in massStart fastInternal combustion piston enginesFuel supply apparatusSpray nozzleCompressed natural gas

The invention discloses a CNG / LPG (compressed natural gas / liquefied petroleum gas) fuel gas spray nozzle, which comprises a spray nozzle casing, a gas inlet joint, a casing sealing structure and an internal fuel passage part, wherein the spray nozzle casing comprises a fuel gas outlet nozzle part with a spraying hole, the gas inlet joint, the casing sealing structure and the internal fuel passage part are arranged on the spray nozzle casing, the tail end of the spraying hole is provided with a guide tube, a coil assembly is arranged outside the guide tube, an armature, a static iron core, a spring and sealing rubber are arranged in the guide tube, the fuel gas outlet nozzle part is provided with a nozzle core installing hole with internal screw threads and a gas outlet nozzle arranged at a nozzle core installing hole part, the tail end of the nozzle core installing hole is a guide tube assembly cavity which is arranged on the spray nozzle casing and is provided with internal screw threads, the guide tube assembly cavity is provided with a guide tube in threaded connection, and the armature in a flat round sheet type structure is arranged in the guide tube. The armature in the flat round sheet type structure has the advantages of light weight, high starting speed and high efficiency, the impact force on the guide tube and the static iron core is small, and the noise is low. The dismountable gas outlet nozzle brings convenience for the regulation and the dismounting maintenance on the fuel gas spray nozzle, the sealing rubber is fixed on the gas outlet nozzle, the load of the armature is reduced, and the damage to the surface coating of the armature caused by vulcanization adhesives is also avoided.

Owner:上海依相动力系统有限公司

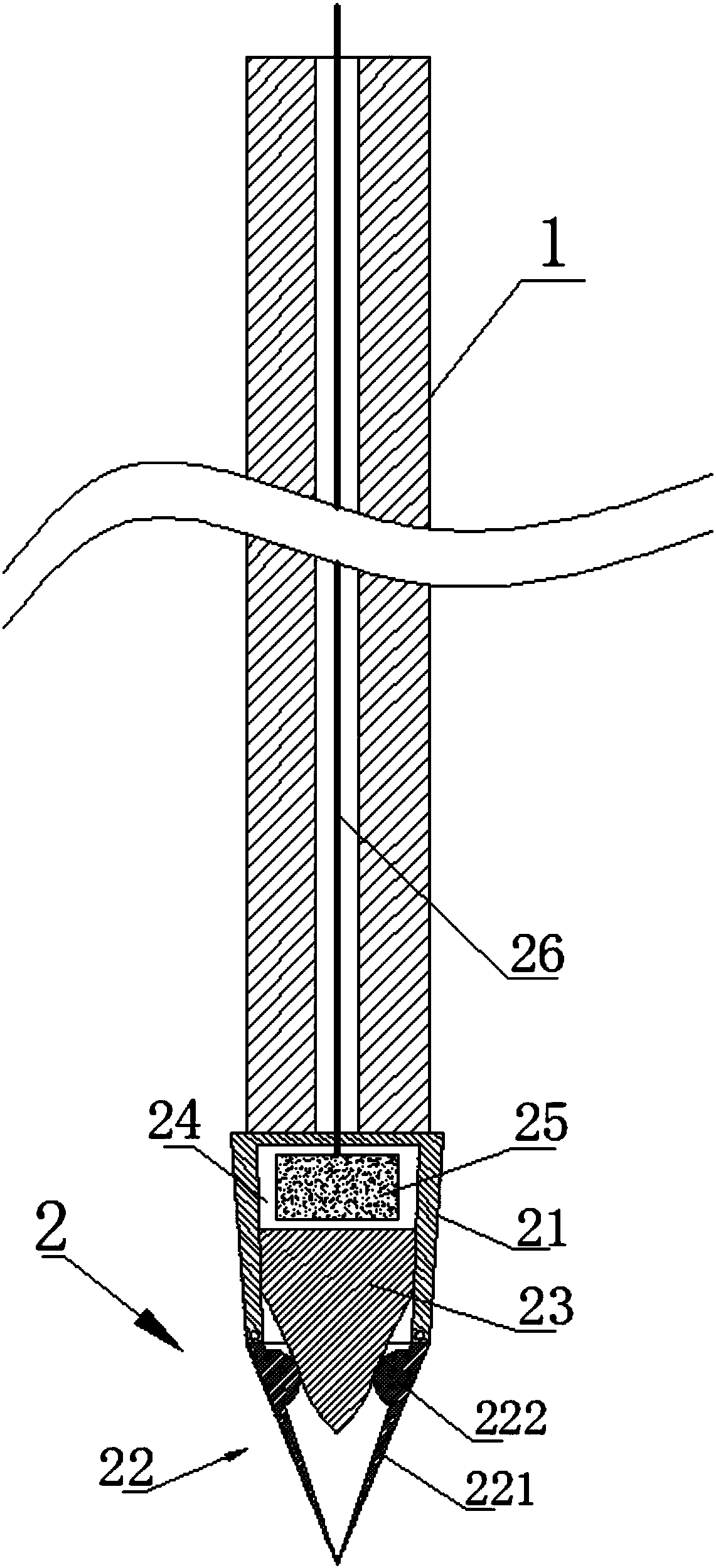

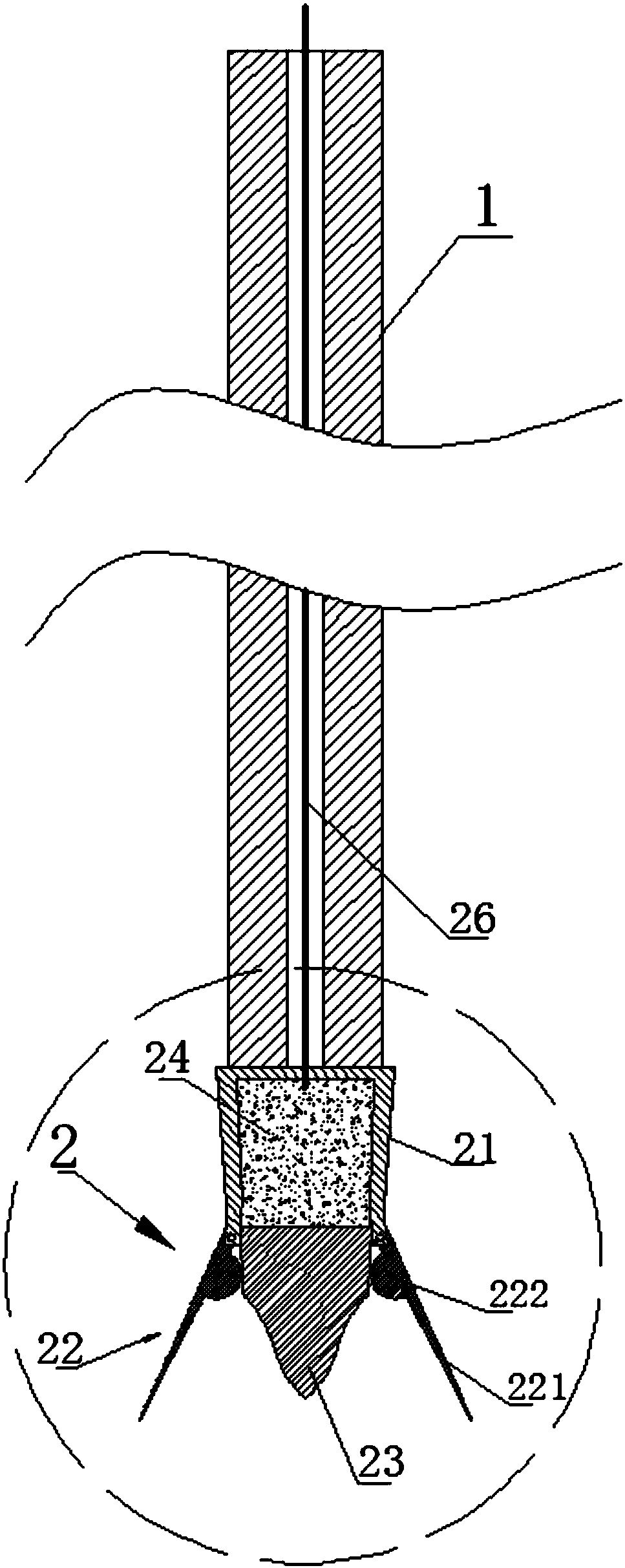

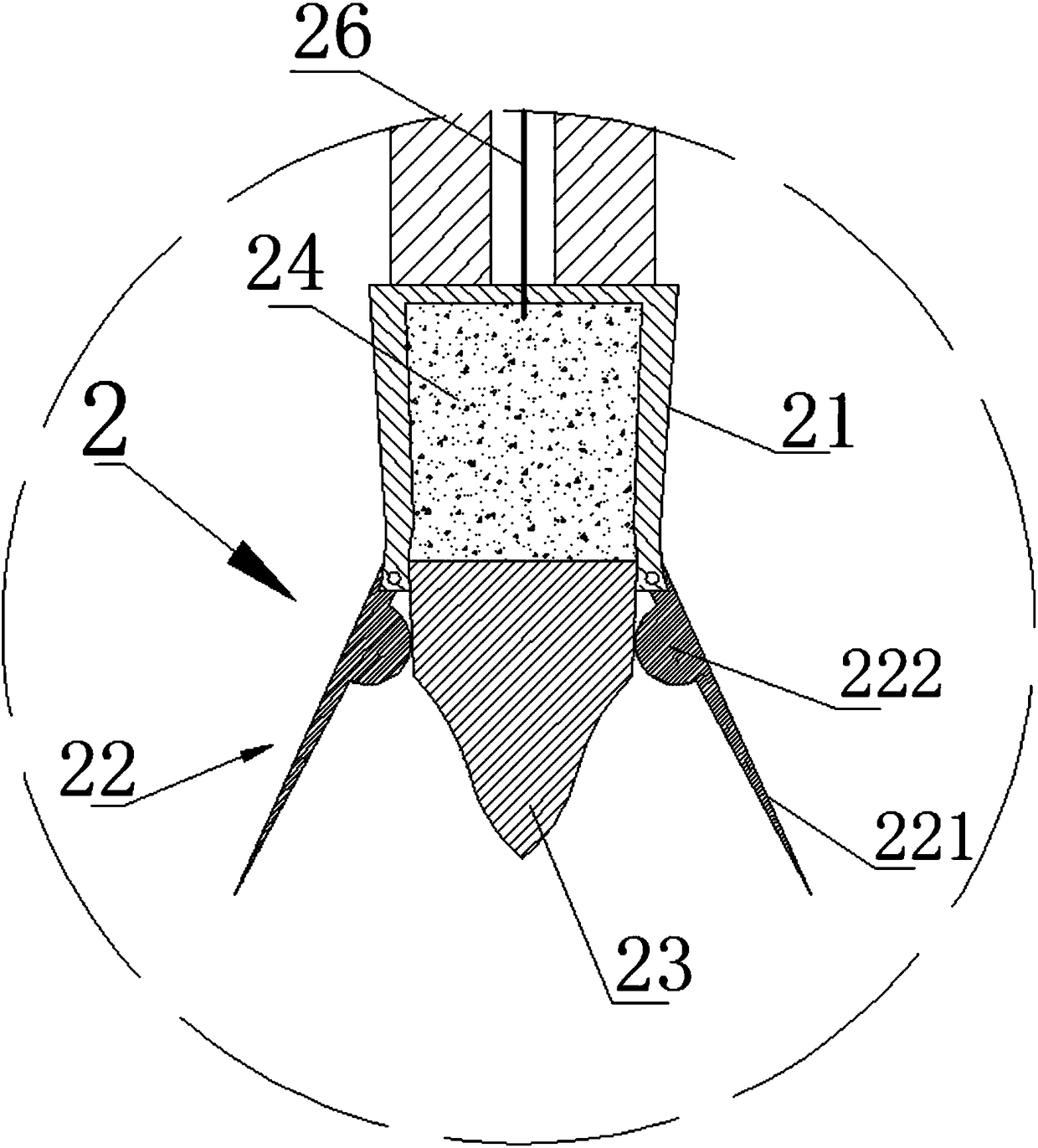

Expanding-type large head anchor rod

The invention relates to an expanding-type large head anchor rod. The expanding-type large head anchor rod comprises a rod body and a bullet-shaped hollow expanding portion arranged at the front end of the rod body; the expanding portion is composed of a cylindrical portion and a cone portion; one end of the cylindrical portion is fixedly connected with the front end of the rod body; and the coneportion is formed by enclosing a plurality of fan-shaped single pieces. The fan-shaped single pieces are rotatably connected with the other end of the cylindrical portion; a bullet-shaped pushing block is arranged in the cylindrical portion in a sealing and sliding sleeved model and an explosive cavity is formed by enclosing the pushing block and the cylindrical portion; and the explosive cavity is filled with gunpowder. The gunpowder is detonated by a lead which extends out of the rear end of the rod body; protrusions are arranged on the inner side faces of the fan-shaped single pieces; the cone portion is formed into a claw-like shape by external supporting and extruding of the protrusions by the pushing block after the gunpowder is detonated; and the cylindrical portion is progressivelyreduced in diameter from one end to the other end connected with the rod body.

Owner:郑敏

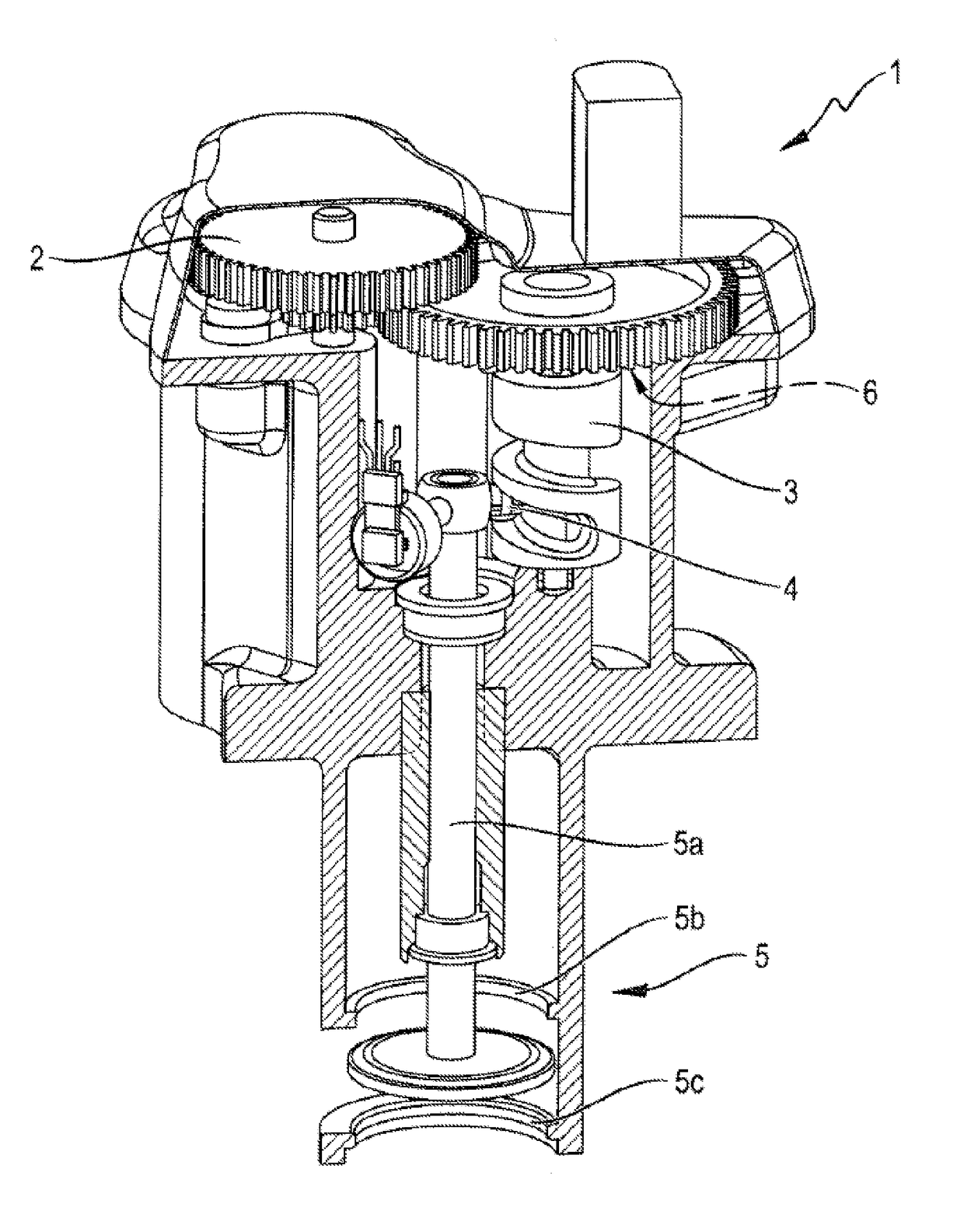

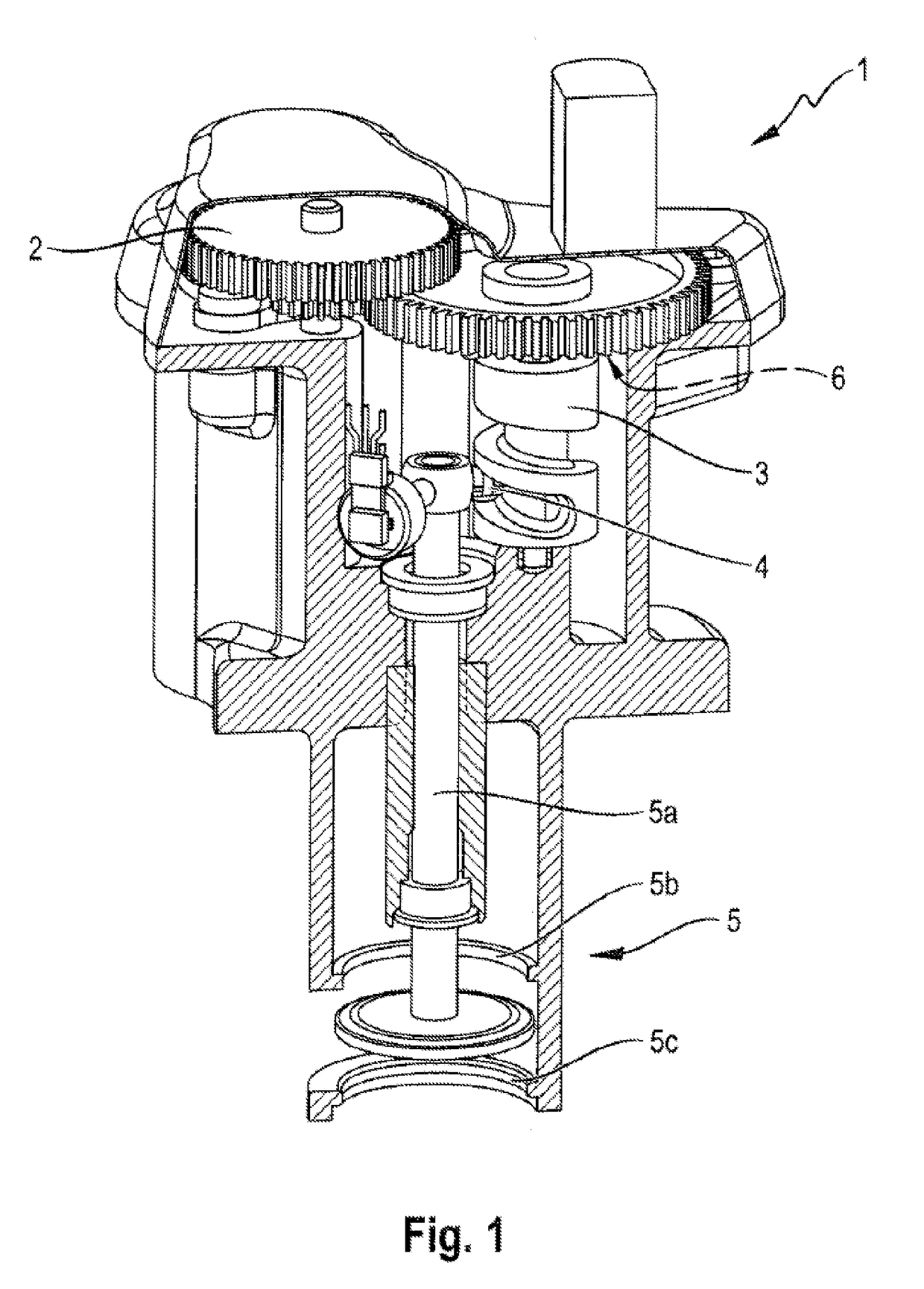

Actuator

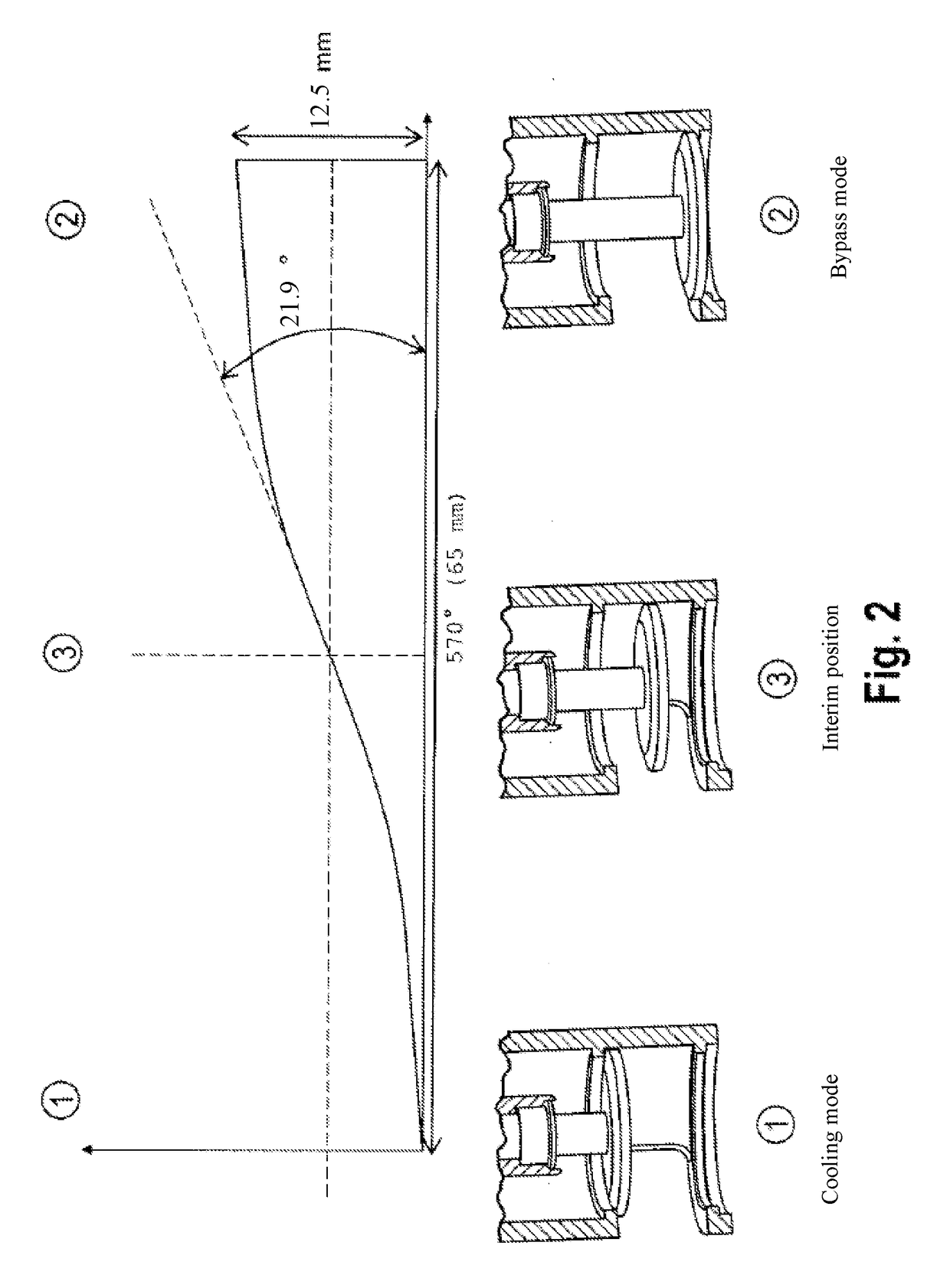

InactiveUS20180112593A1Adjust transmission capacityGreat opening forceOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringActuator

The invention pertains to an actuator for actuating a valve, the valve featuring a drive and at least one rotational threaded element with a first and a second threading segment and a third threading segment positioned between them. The actuator further features a drive element that is translationally driven by the threaded element. The actuator according to the invention is characterized in that the pitch angle in the third threading segment is greater than the pitch angle in the first and second threading segment.

Owner:HANON SYST

Crossover valve systems

InactiveUS8272357B2Reduction in overall flow area and capacityIncrease the cross-sectional areaCombustion enginesLift valveDifferential pressureValve opening

Crossover valve systems and corresponding methods offer an effective means to overcome large opening pressure force, or provide reasonable gas flow area, or both. In an exemplary embodiment, a crossover valve system for a split-cycle engine having a power cylinder and a crossover passage comprises first and second crossover valves, each valve opening outwardly away from the power cylinder and providing fluid communication between the power cylinder and the crossover passage, with the diameter of the second crossover valve being larger than the diameter of the first crossover valve; and an actuation mechanism operative to open the first crossover valve, then the second crossover valve after a predetermined delay to allow a certain rise in the pressure inside the power cylinder, resulting in much smaller differential pressure forces across the crossover valves, larger flow areas, or both.

Owner:LGD TECH LLC

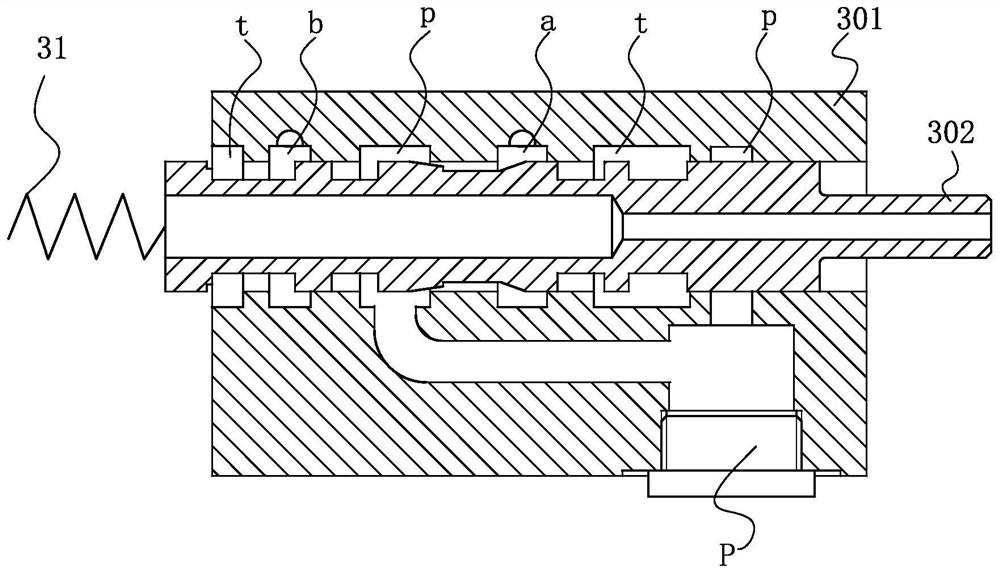

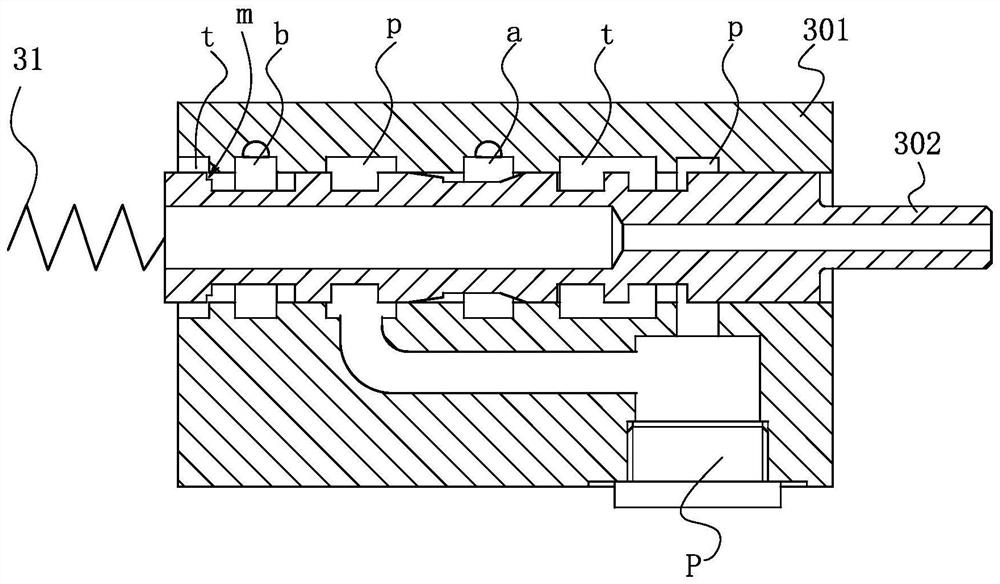

Stop valve of hydraulic suspension device

PendingCN111946688ANot affectedPrevent subsidenceAgricultural machinesServomotor componentsThermodynamicsCap device

The invention discloses a stop valve of a hydraulic suspension device. The stop valve is arranged between a rodless cavity of a lifting oil cylinder and a first working oil port of a hydraulic distributor. The stop valve comprises a valve bush, a valve element, a return spring and a gland device. The valve element comprises a first valve element section and a second valve element section which arethe same in outer diameter. The second valve element section is provided with a flange. The flange is provided with a valve element sealing conical surface. A valve bush sealing conical surface is arranged at an end of the first valve bush. The taper of the valve element sealing conical surface is different from that of the valve bush sealing conical surface. Under the action of the return spring, when the valve element sealing conical surface abuts against the inner side edge of the valve bush sealing conical surface, a first cavity and a second cavity are disconnected. In a neutral state, the stop valve is closed, connection between the rodless cavity of the lifting oil cylinder and the hydraulic distributor is cut off, and farm tool sedimentation caused by leakage of the hydraulic distributor is avoided; and in addition, when the valve is opened, only the elastic force of the return spring needs to be overcome, the valve is completely not affected by hydraulic oil flowing through the valve, and the stop valve is more sensitive in operation and more reliable to use.

Owner:WEIFANG LICHUANG ELECTRONICS TECH

Diffusion-type self-pumped fluid dynamic and static pressure mechanical seal

ActiveCN112963543ADoes not dilute quicklyLarge flow cross sectionEngine sealsMechanical engineeringMechanics

The invention discloses a diffusion-type self-pumped fluid dynamic and static pressure mechanical seal. The mechanical seal comprises a movable ring and a static ring which are coaxially arranged, wherein a first sealing face of the movable ring comprises a diffusion ring groove, a spiral groove area and a sealing dam from outside to inside, and a backwardly-bent spiral groove is formed in the spiral groove area; the orientation of a fluid outlet of the backwardly-bent spiral groove is opposite to the rotating direction of the movable ring; a current collecting ring groove is formed in a second sealing face of the static ring, a drainage hole channel communicating with a sealing cavity is formed in a ring body of the static ring, an inlet of the drainage hole channel is located in the peripheral face of the static ring, and an outlet of the drainage hole channel is located in the current collecting ring groove; a gap between the second sealing face and the diffusion ring groove forms an annular diffusion cavity with a radial opening; and a first bottom face of the diffusion ring groove is arranged to be a slope face or a curved face from outside to inside in the radial direction, and the slope face or the curved face is gradually close to the second sealing face from inside to outside in the radial direction. By means of the mechanical seal, large sealing end face opening force can be provided, and the requirement for zero-leakage long-period operation of a non-contact mechanical seal is met.

Owner:NANJING FORESTRY UNIV

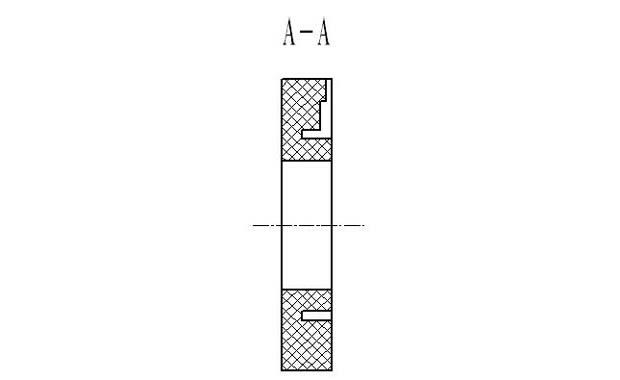

Dry air-sealed end face groove profile rotating bilaterally

InactiveCN103216626ASimplify processing difficultyAchieve serializationEngine sealsDry gas sealEngineering

The invention discloses a dry air-sealed end face groove profile rotating bilaterally. The dry air-sealed end face groove profile is provided with a movable ring end face, wherein 8-12 dynamic pressure grooves are uniformly distributed on the dynamic ring end face along a circumferential direction; each dynamic pressure groove is concave; the depth of each dynamic pressure groove is 5-15 mum; and each dynamic pressure groove has a concave structure constructed by an inlet arc line which is formed on the outer circumference of a dynamic ring, a left outer-side arc edge and a right outer-side arc edge which are connected to the two ends of the inlet arc line symmetrically, a left outer side straight edge and a right outer side straight edge which are correspondingly connected to the other ends of the left outer side arc edge and the right outer side arc edge respectively and of which the extension lines are vertical to the inner circumference of the dynamic ring, a left groove root and a right groove root which are correspondingly connected to the other ends of the left outer side straight edge and the right outer side straight edge respectively and are parallel to the outer circumference of the dynamic ring and the inner circumference of the dynamic ring, and a middle isolating block of which the periphery is connected with the other ends of the left groove root and the right groove root. Due to the adoption of the dry air-sealed end face groove profile, the sealing pneumatic performance can be improved, the groove profile processing difficulty is lowered, the matching property of a sealed groove profile and the practical requirement is improved, and the higher requirement of modern industry on sealing is met.

Owner:TIANJIN UNIV

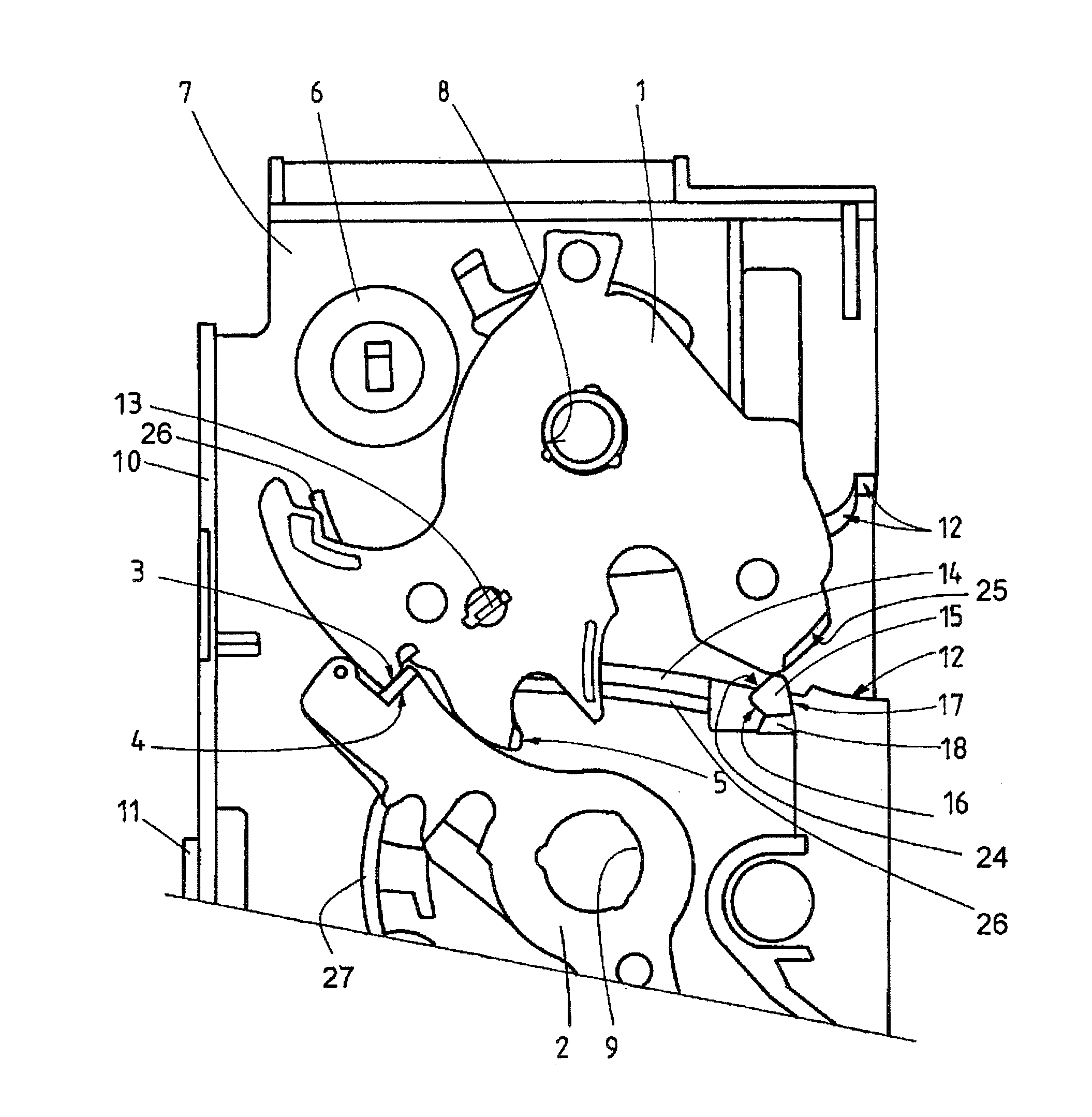

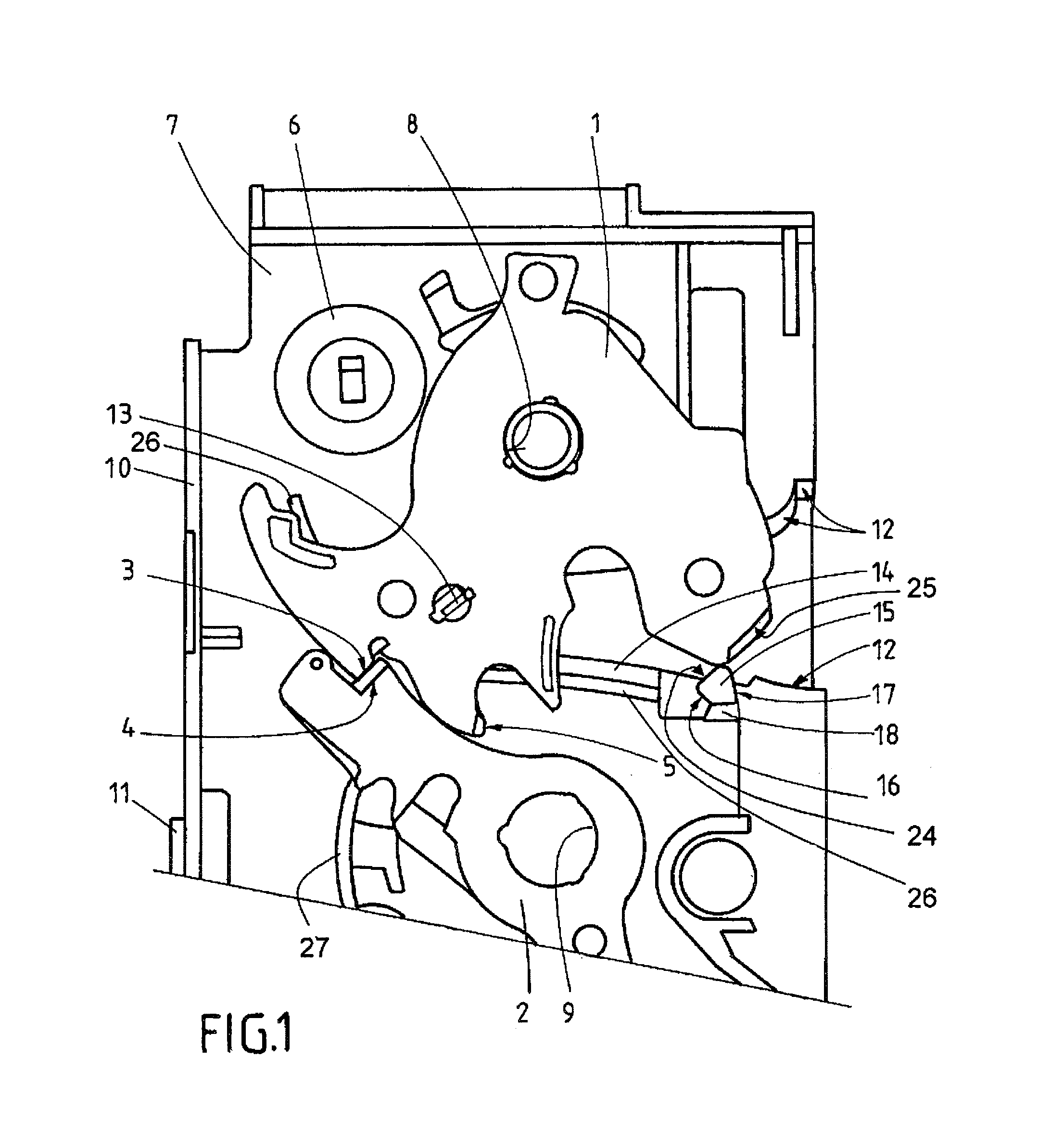

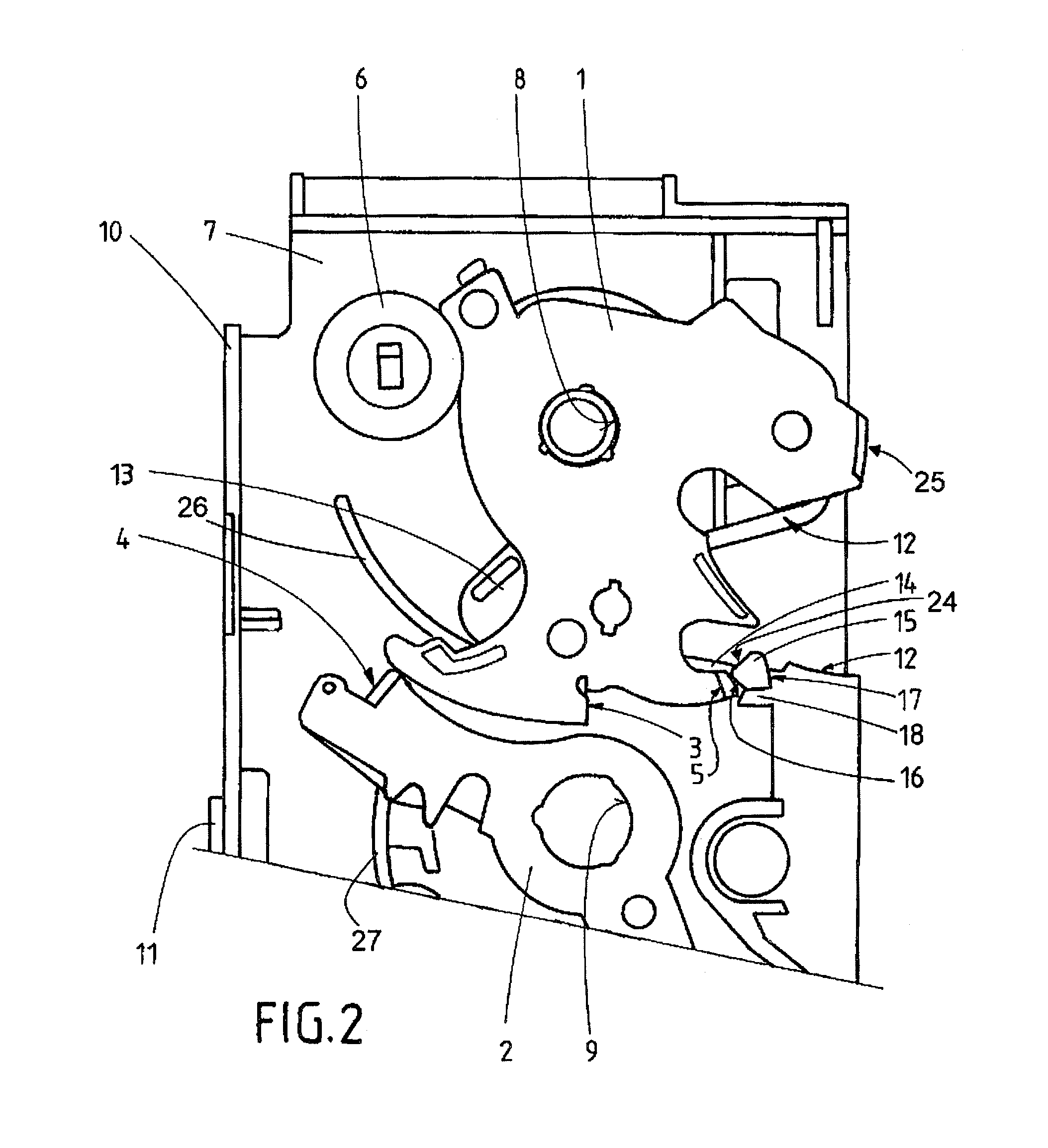

Motor vehicle door lock

ActiveUS20140292002A1Increase forceMechanism can be difficultNoise-prevention/anti-rattling lockingConstruction fastening devicesEngineeringAbutment

A lock including a catch mechanism made up of a rotary latch and catch for latching the rotary latch. The rotary latch and catch have blocking surfaces for latching purposes. In the latched state, the blocking surface of the rotary latch rests on the blocking surface of the catch, and this prevents the rotary latch from being able to rotate in the direction of the open position. The lock also includes a component with an abutment surface, against which the blocking surface of the rotary latch butts in the open position of the catch mechanism. This abutment prevents the situation where, in the open position, dust can pass onto the blocking surface of the rotary latch. In addition, the abutment reduces the penetration of dust into the catch mechanism. An increase in the opening forces as service life increases is thus avoided.

Owner:KIEKERT AG

Equipment for compressing air

InactiveCN109268231AImprove compression efficiencyExtended service lifePump testingPositive displacement pump componentsAir compressionExhaust valve

The invention discloses equipment for compressing air. The equipment comprises an air compression device, a primary compression air cylinder which is arranged in the air compression device and provided with a downward opening and a cooling water cavity surrounding the primary compression air cylinder; a cooling water nozzle is fixedly arranged at the right side of the air compression device, the cooling water cavity is communicated with the cooling water nozzle, an air inlet valve is arranged in the upper wall of the primary compression air cylinder, an air inlet channel is arranged in the airinlet valve, and an air inlet valve flap with a downward opening is slidably arranged in the air inlet channel; the air inlet flap is fixedly connected with the air inlet channel through an air inletcompression spring, an air exhaust valve which is located at the left side of the air inlet valve is arranged in the upper wall of the primary compression air cylinder, an air exhaust channel runs through the air exhaust valve, and an air exhaust valve flap which is slidably connected with the air exhaust channel and provided with an upward opening is arranged in the air exhaust valve, and fixedly connected with the air exhaust channel through an air exhaust compression spring.

Owner:斯丹红

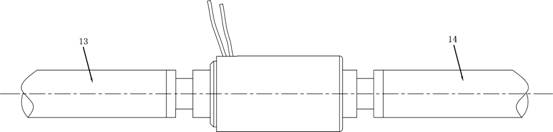

cng/lpg gas nozzle

ActiveCN103306857BLight in massStart fastInternal combustion piston enginesFuel supply apparatusVulcanizationCompressed natural gas

The invention discloses a CNG / LPG (compressed natural gas / liquefied petroleum gas) fuel gas spray nozzle, which comprises a spray nozzle casing, a gas inlet joint, a casing sealing structure and an internal fuel passage part, wherein the spray nozzle casing comprises a fuel gas outlet nozzle part with a spraying hole, the gas inlet joint, the casing sealing structure and the internal fuel passage part are arranged on the spray nozzle casing, the tail end of the spraying hole is provided with a guide tube, a coil assembly is arranged outside the guide tube, an armature, a static iron core, a spring and sealing rubber are arranged in the guide tube, the fuel gas outlet nozzle part is provided with a nozzle core installing hole with internal screw threads and a gas outlet nozzle arranged at a nozzle core installing hole part, the tail end of the nozzle core installing hole is a guide tube assembly cavity which is arranged on the spray nozzle casing and is provided with internal screw threads, the guide tube assembly cavity is provided with a guide tube in threaded connection, and the armature in a flat round sheet type structure is arranged in the guide tube. The armature in the flat round sheet type structure has the advantages of light weight, high starting speed and high efficiency, the impact force on the guide tube and the static iron core is small, and the noise is low. The dismountable gas outlet nozzle brings convenience for the regulation and the dismounting maintenance on the fuel gas spray nozzle, the sealing rubber is fixed on the gas outlet nozzle, the load of the armature is reduced, and the damage to the surface coating of the armature caused by vulcanization adhesives is also avoided.

Owner:上海依相动力系统有限公司

Cone expanding collapsible medical device

A vascular occluder includes first and second conical members disposed in opposing relation and which have tooth-shaped wide ends. The conical members are coupled to one another by a coupling element, which may be a cannula or rod. The conical members are formed of a membrane which has a thickness which increases towards the narrow ends and decreases towards the toothed elements. The toothed elements are preferably self-supporting within a vessel and avoid folds within the occluder membrane, which may otherwise result in leakage of blood around the device. The device may be provided with a supporting frame which may be at least partially embedded within the membrane. The membrane is preferably made of silicone.

Owner:COOK MEDICAL TECH LLC

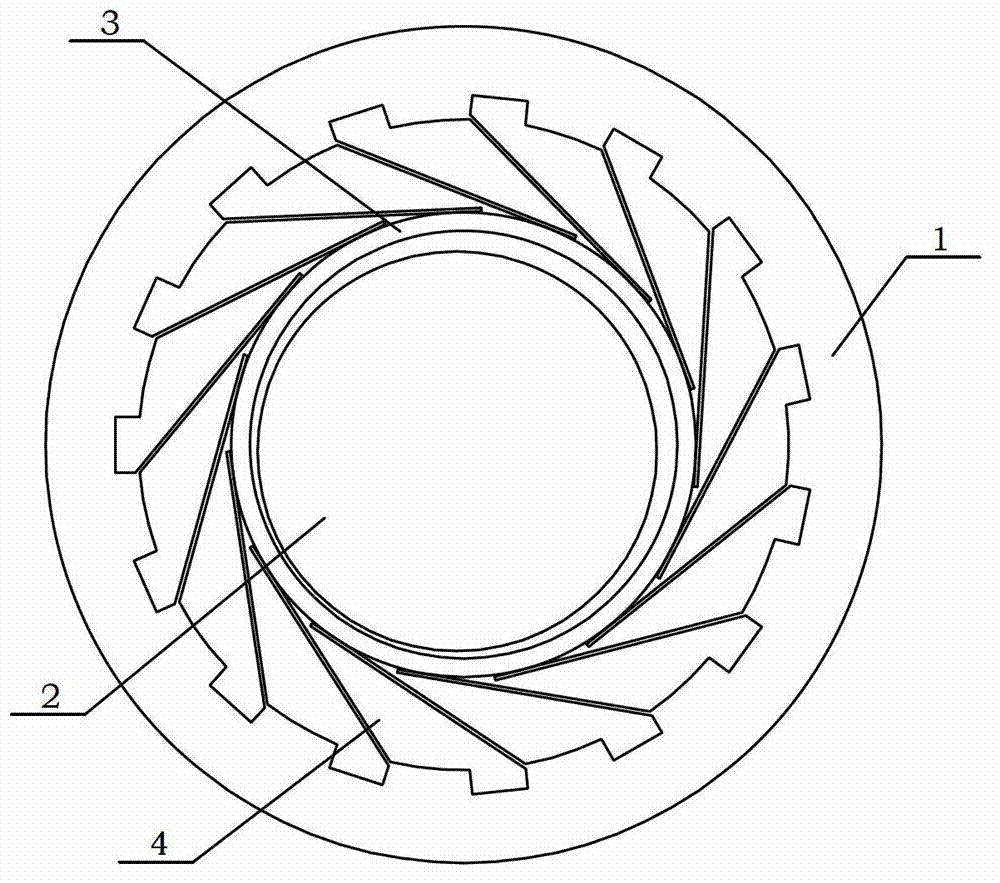

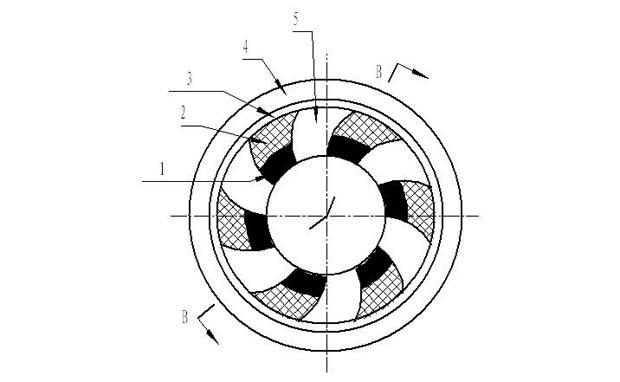

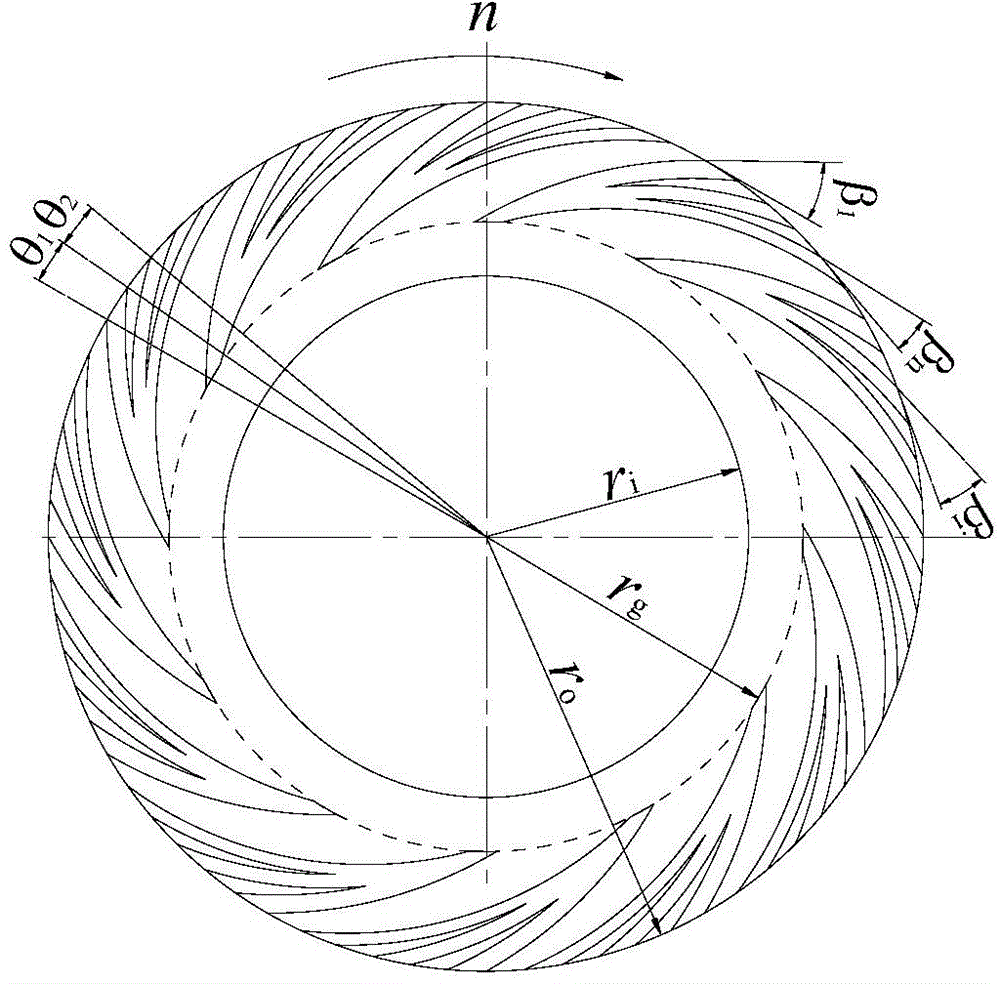

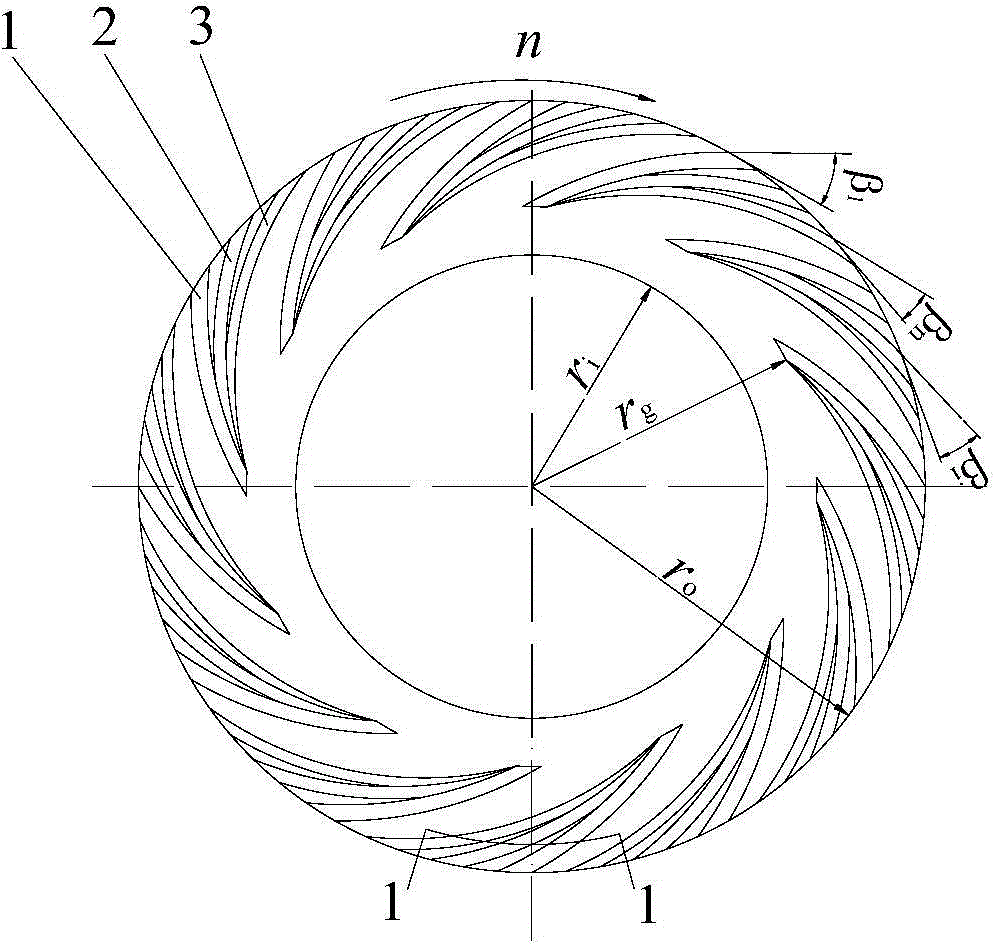

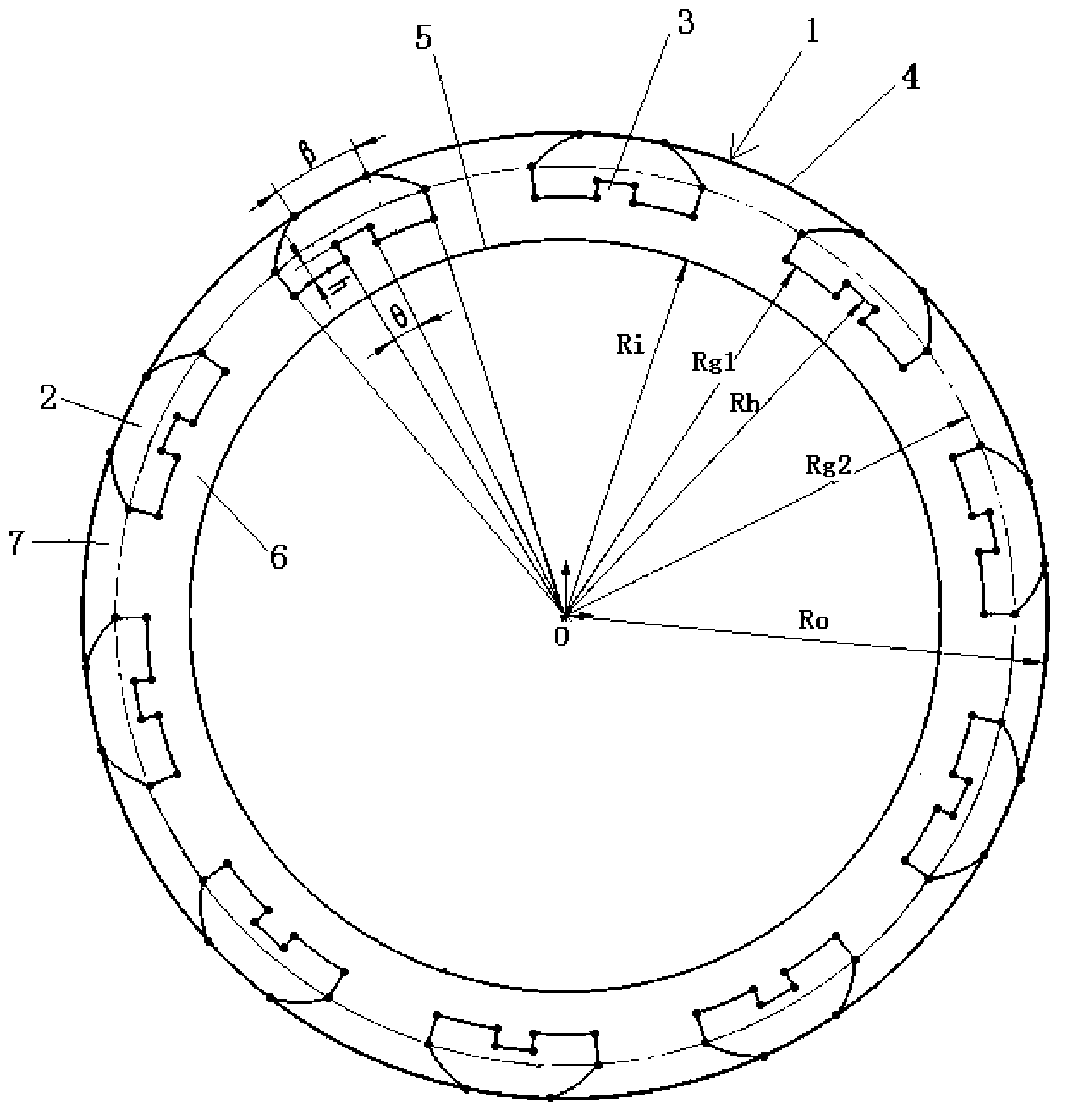

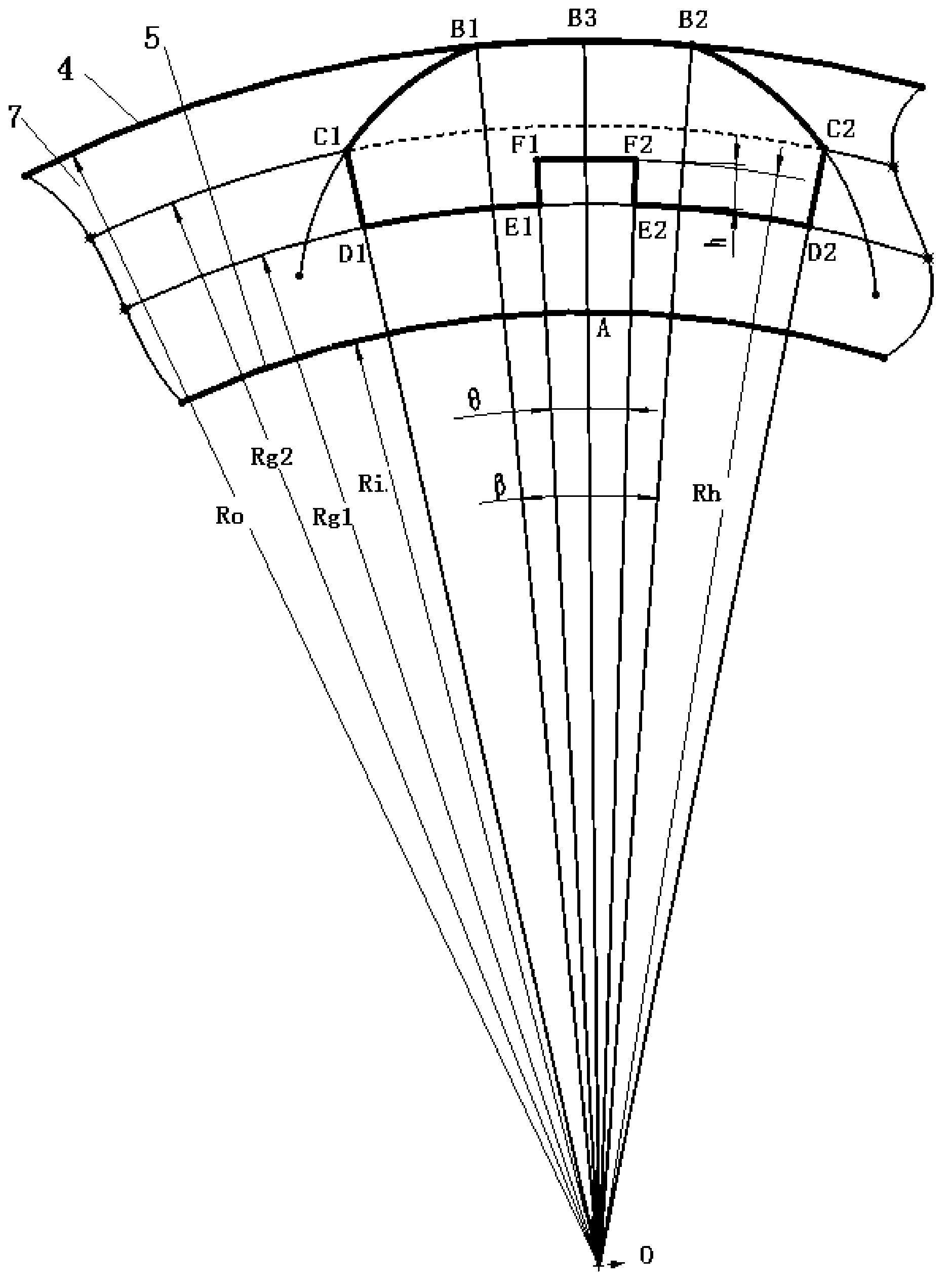

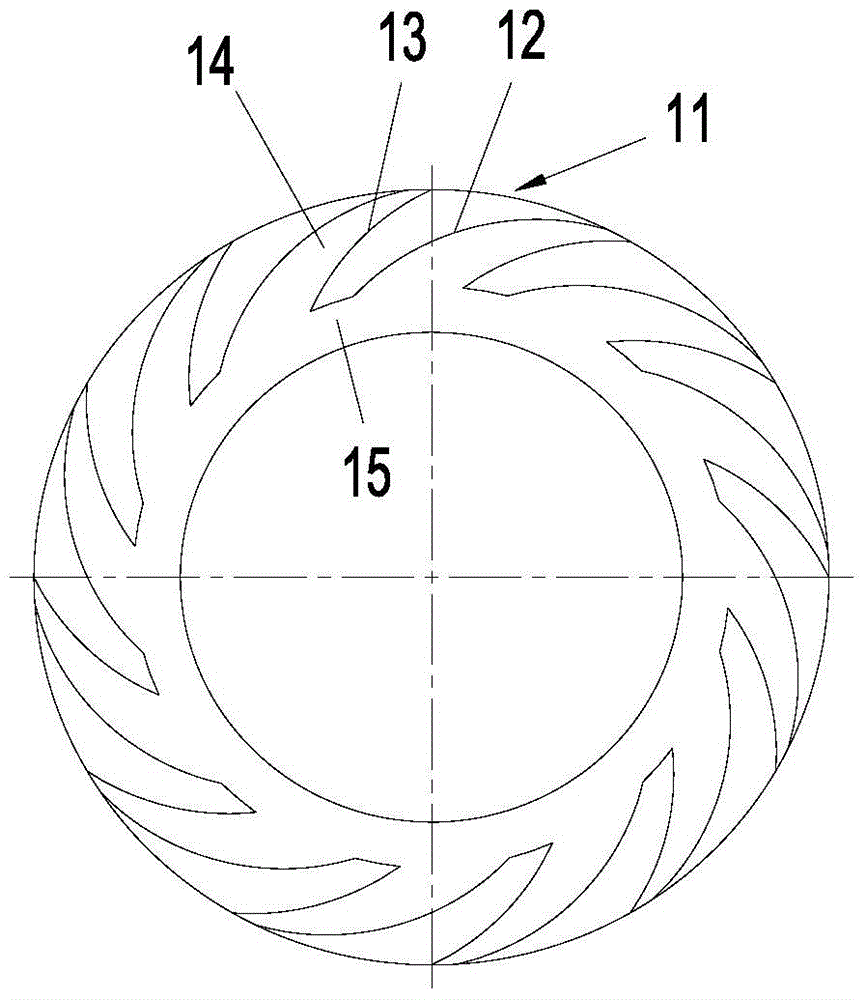

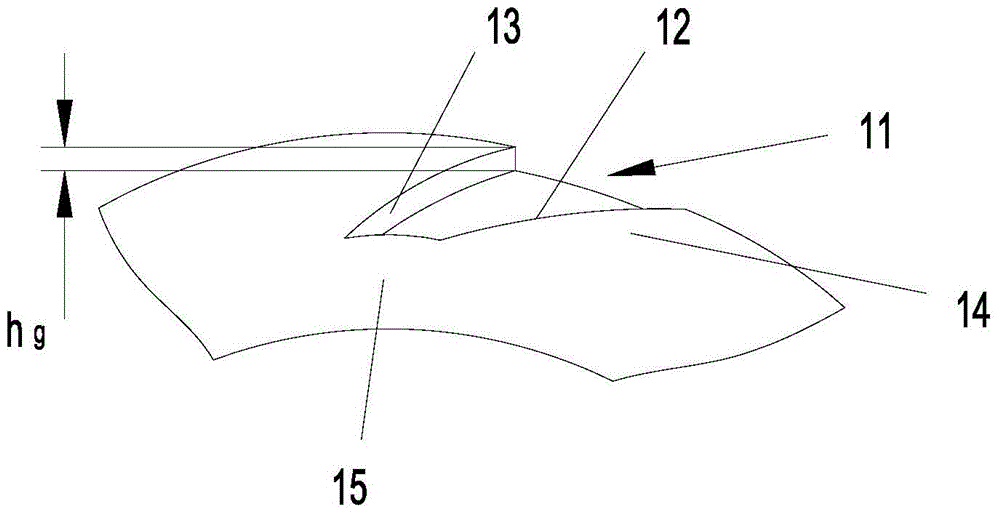

Seal ring with streamline groove end face and mechanical seal device

ActiveCN105065675AGreat opening forceGood fluid dynamic pressure effect on the end surfaceEngine sealsCarrying capacityMachining

The invention provides a seal ring with a streamline groove end face. The end face is provided with shaped grooves which are arranged evenly and divided by isolation components with the height of the end plane and in the same form. The shaped grooves are grooves with the center lines arranged along the streamline tracks for seal fluid particles flowing inwards from the periphery of the seal ring. The ratio range of the opening arc length, along the periphery of the seal ring, of each of the shaped grooves to the arc length of the same radial direction side of the neighboring isolation component is 0.2-5, and the preferred ratio range is 0.8-1.2. According to the seal ring with the streamline groove end face and the mechanical seal device, on the basis of the existing machining technology, the opening force, rigidity and carrying capacity of an end face fluid film on the seal end face are improved by an extremely large margin; the seal ring with the streamline groove end face and the mechanical seal device have better end face fluid hydrodynamic effect compared with traditional seal end face obviously.

Owner:内江金鸿曲轴有限公司 +1

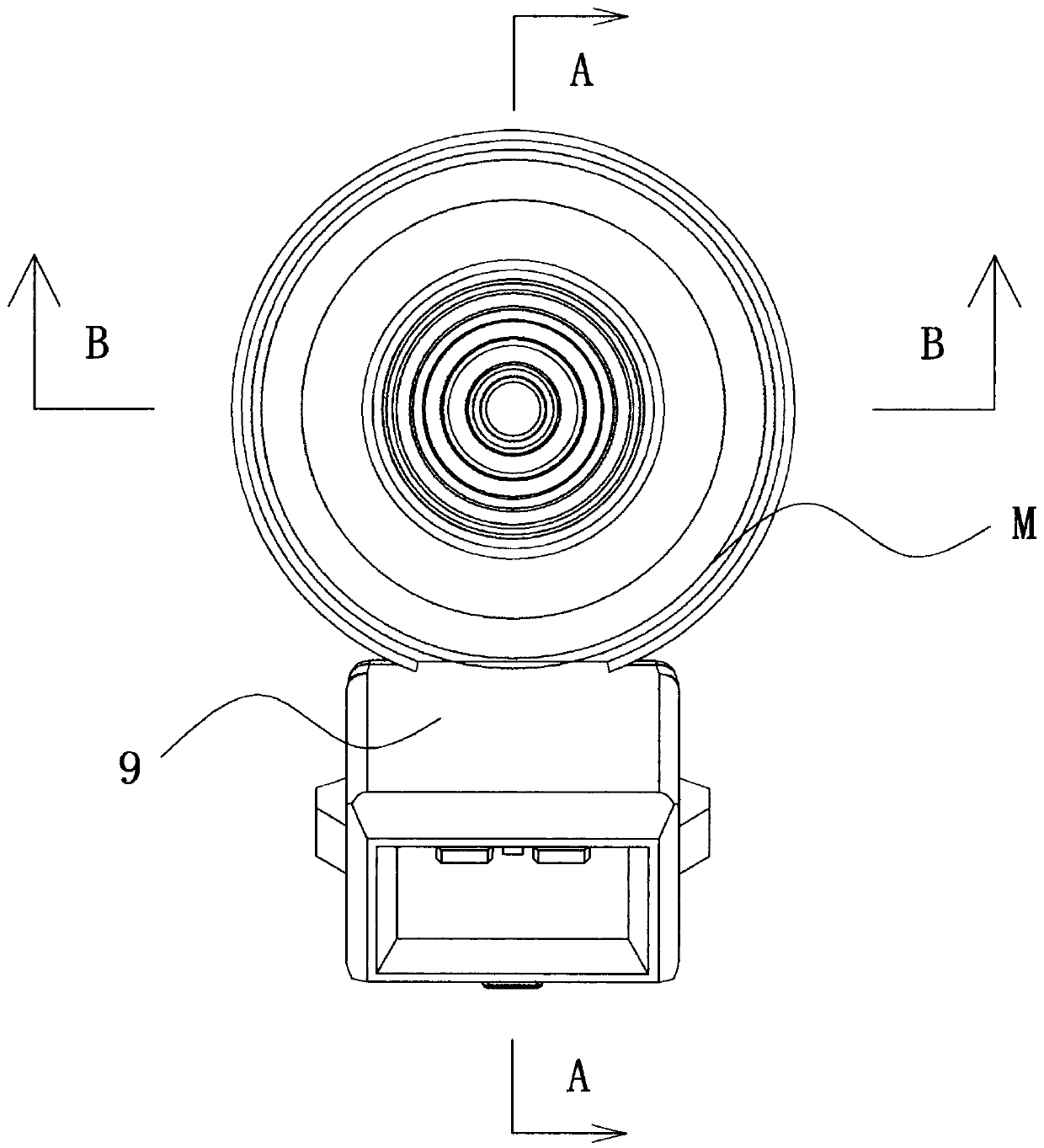

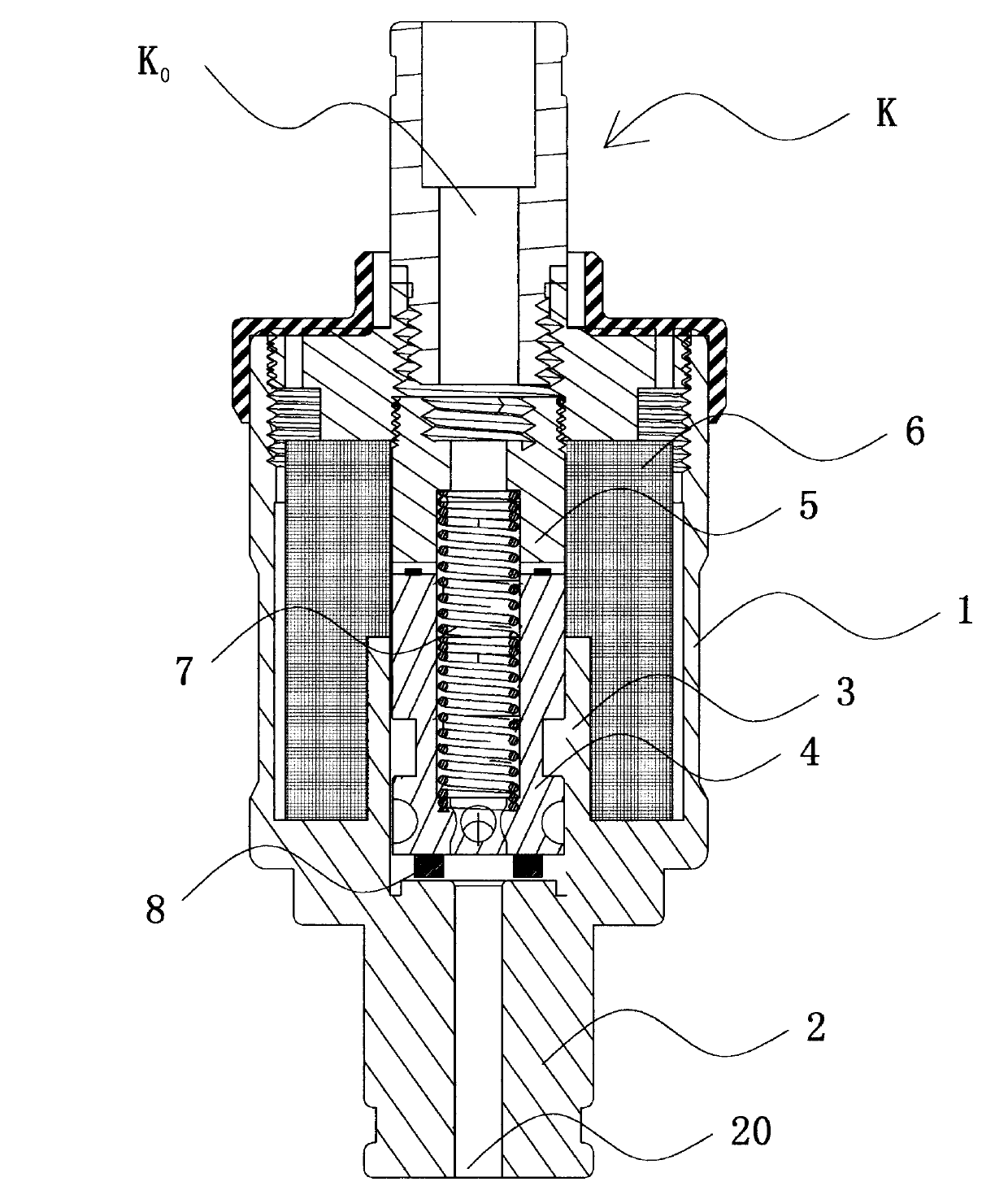

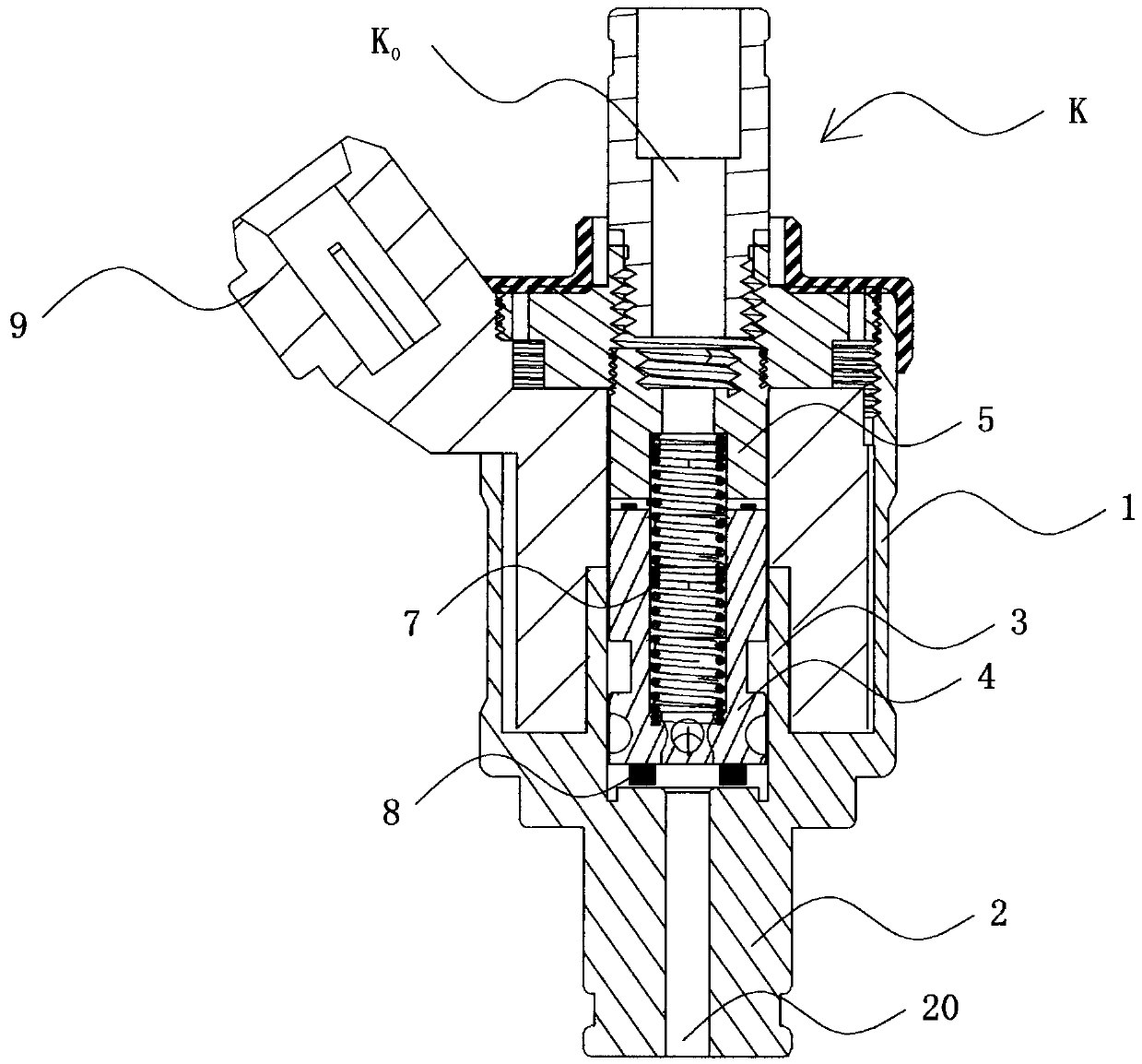

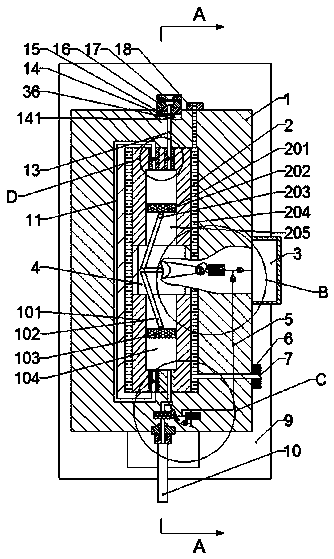

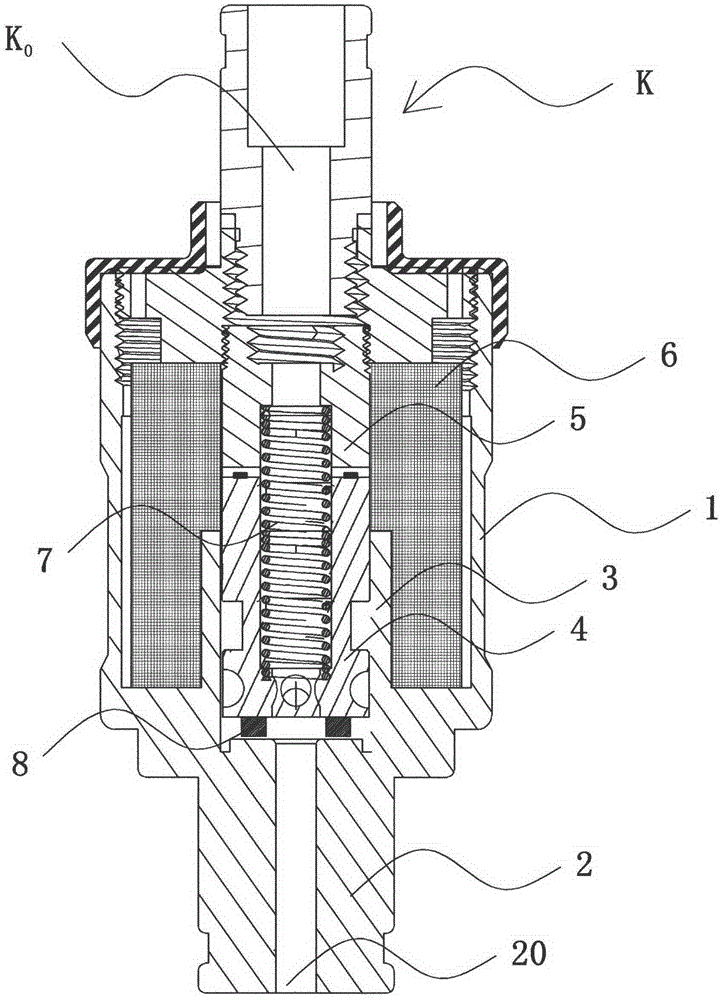

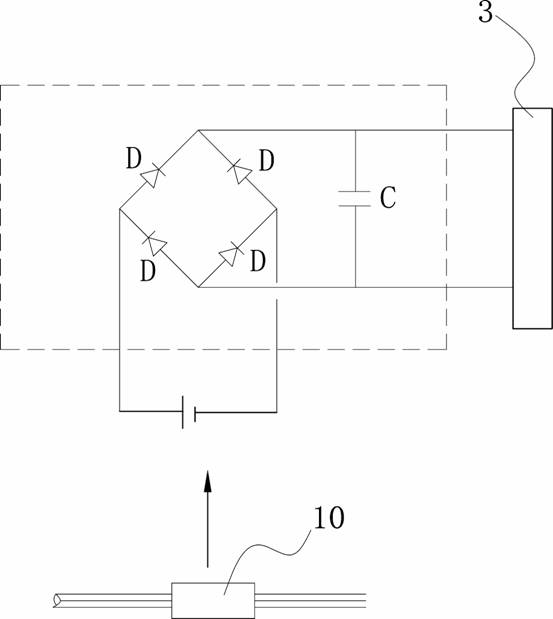

Miniature high-pressure electromagnetic valve

ActiveCN114396504AGreat opening forceEnhanced magnetic forceOperating means/releasing devices for valvesLift valveEngineeringScrew thread

The invention provides a miniature high-pressure electromagnetic valve which comprises a metal coil framework, a fixed iron core fixed to one end of the coil framework and a coil winding installed on the coil framework, and a screw joint part is arranged at the end, facing the coil framework, of the fixed iron core. The screw joint part extends into the coil framework and is in threaded connection with the coil framework, and the ratio of the length of the part, extending into the coil winding, of the screw joint part to the axial length of the coil winding is 1 / 5-1 / 3: 1; a first magnetizer is arranged at one end, far away from the screw joint part, of the fixed iron core, a second magnetizer is sleeved at the other end of the coil framework, and the thickness of the first magnetizer and the thickness of the second magnetizer are 1-3mm; the miniature high-pressure electromagnetic valve overcomes the defects that an existing electromagnetic valve is complex in structure, large in size, poor in strength, small in magnetic field force and short in service life.

Owner:YUYAO SANLIXIN SOLENOID VALVE CO LTD

Seal ring and mechanical seal device with streamlined groove end face

ActiveCN105065675BGreat opening forceGood fluid dynamic pressure effect on the end surfaceEngine sealsCarrying capacityMachining

The invention provides a seal ring with a streamline groove end face. The end face is provided with shaped grooves which are arranged evenly and divided by isolation components with the height of the end plane and in the same form. The shaped grooves are grooves with the center lines arranged along the streamline tracks for seal fluid particles flowing inwards from the periphery of the seal ring. The ratio range of the opening arc length, along the periphery of the seal ring, of each of the shaped grooves to the arc length of the same radial direction side of the neighboring isolation component is 0.2-5, and the preferred ratio range is 0.8-1.2. According to the seal ring with the streamline groove end face and the mechanical seal device, on the basis of the existing machining technology, the opening force, rigidity and carrying capacity of an end face fluid film on the seal end face are improved by an extremely large margin; the seal ring with the streamline groove end face and the mechanical seal device have better end face fluid hydrodynamic effect compared with traditional seal end face obviously.

Owner:内江金鸿曲轴有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com