Diffusion-type self-pumped fluid dynamic and static pressure mechanical seal

A mechanical seal, dynamic and static pressure technology, applied to the sealing of the engine, mechanical equipment, engine components, etc., can solve the problems of low pressure bearing capacity, small rigidity, affecting safety, etc., and achieve the effect of increasing the opening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

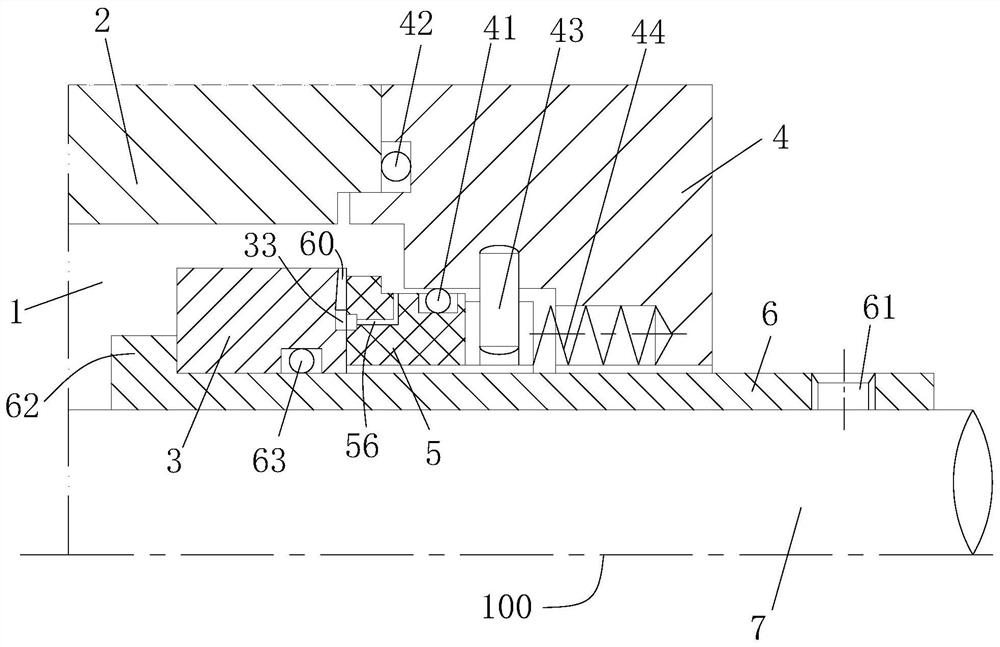

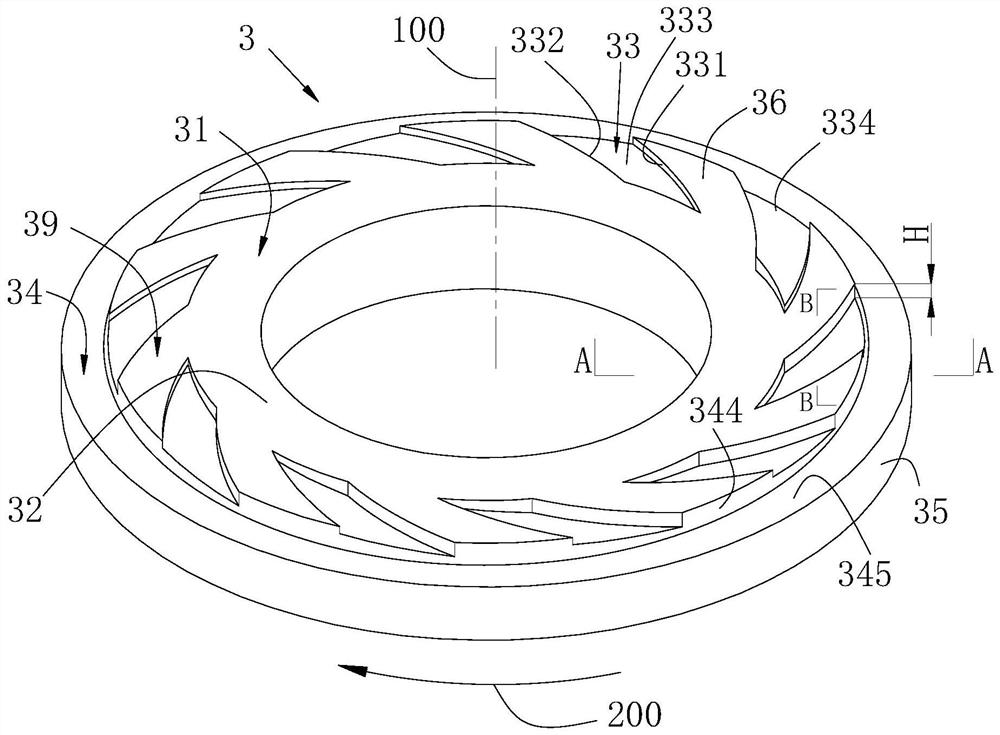

[0031] refer to figure 1 , figure 2 and image 3 , a diffuser type self-pumping fluid dynamic and static pressure mechanical seal, which is arranged between the casing 2 and the rotating shaft 7 of the rotating equipment, and includes a moving ring 3 and a static ring 5 that cooperate with each other, and the moving ring 3 and the static ring 5 is arranged coaxially along the axis 100, and a sealed chamber 1 is formed between the casing, the moving ring and the static ring.

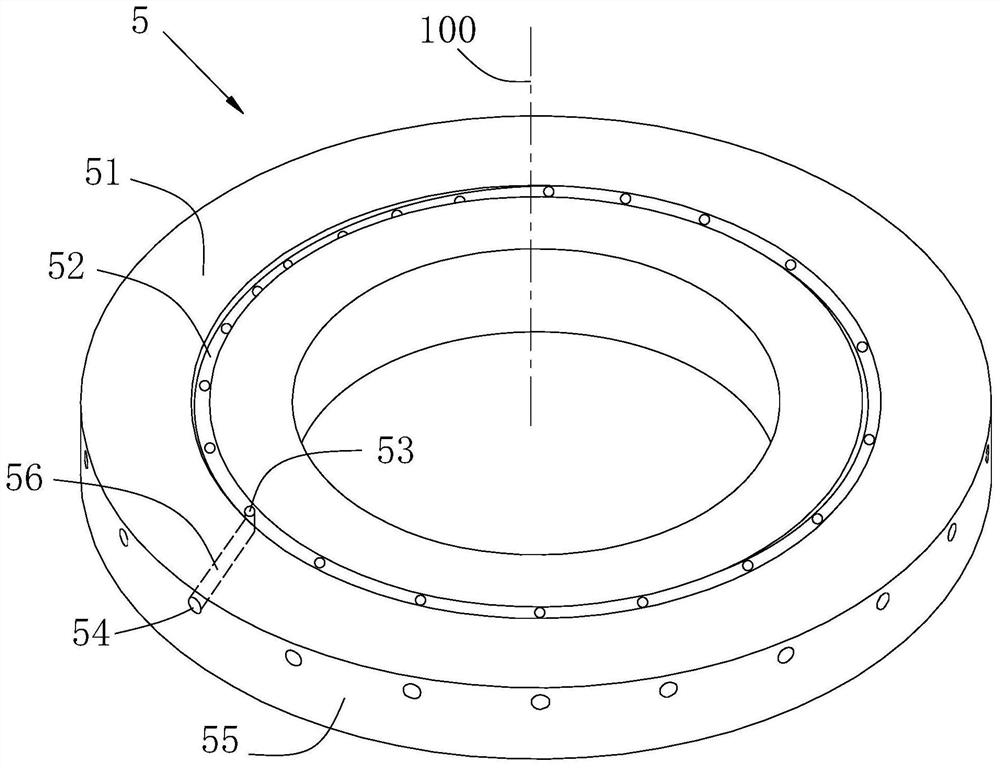

[0032]A shaft sleeve 6 is sleeved on the rotating shaft 7 , and the shaft sleeve 6 is fixed on the rotating shaft 7 through the screw hole 61 with a set screw, and the moving ring and the static ring are both sleeved on the rotating shaft 7 . The moving ring 3 leans against the step portion 62 of the bushing 6, the static ring 5 is located outside the moving ring, the static pressure seat 4 presses the static ring 5 against the moving ring through the spring 44, and the pin 43 fixes the static ring to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com