Patents

Literature

109 results about "Pressure dependent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure Dependent. Stability is compromised because the system is pressure dependent. Changes and fluctuations create improper flow rates and pressurization problems. Rebalancing is required at every damper location when changes are made or fan system performance degrades.

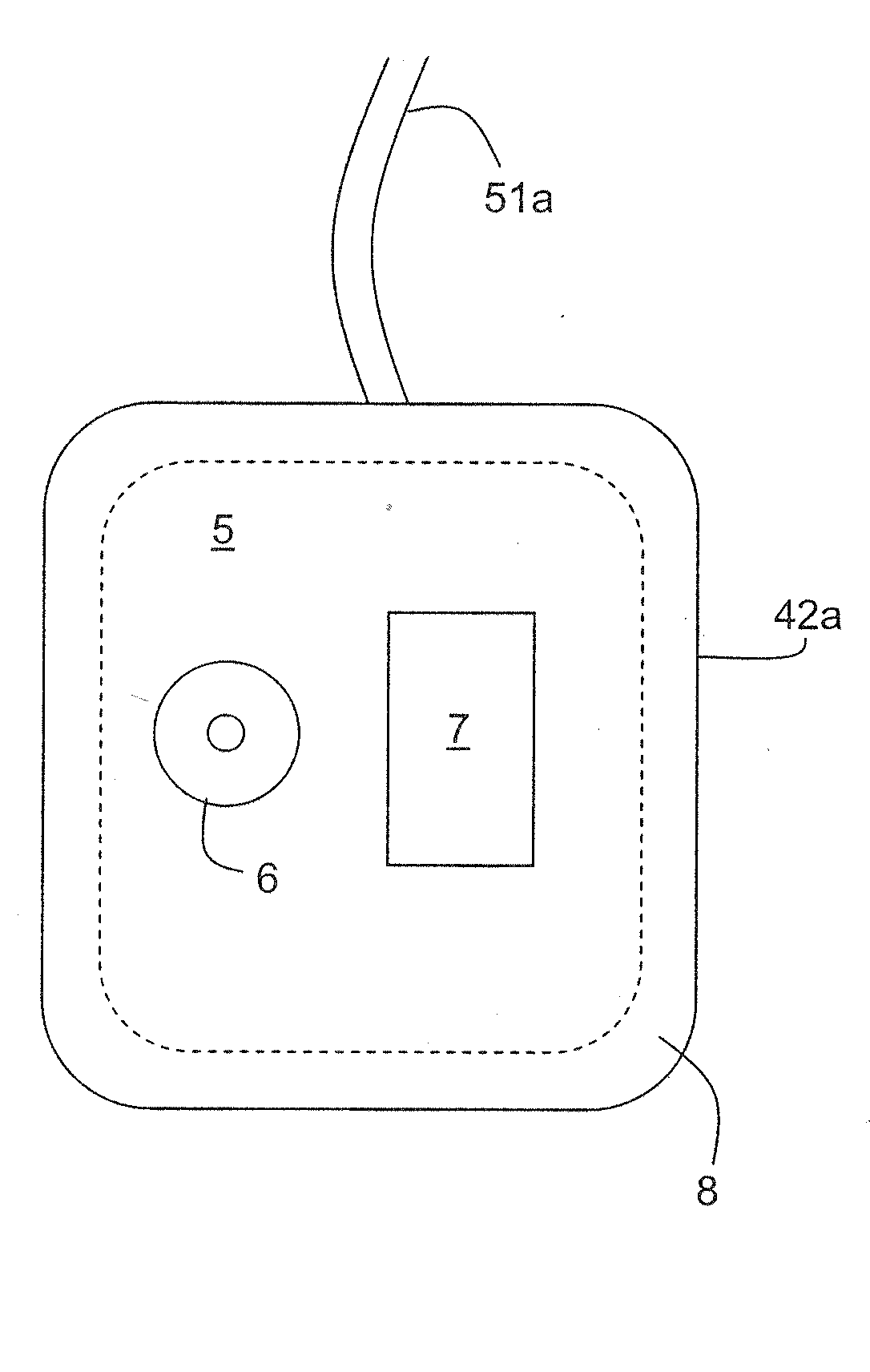

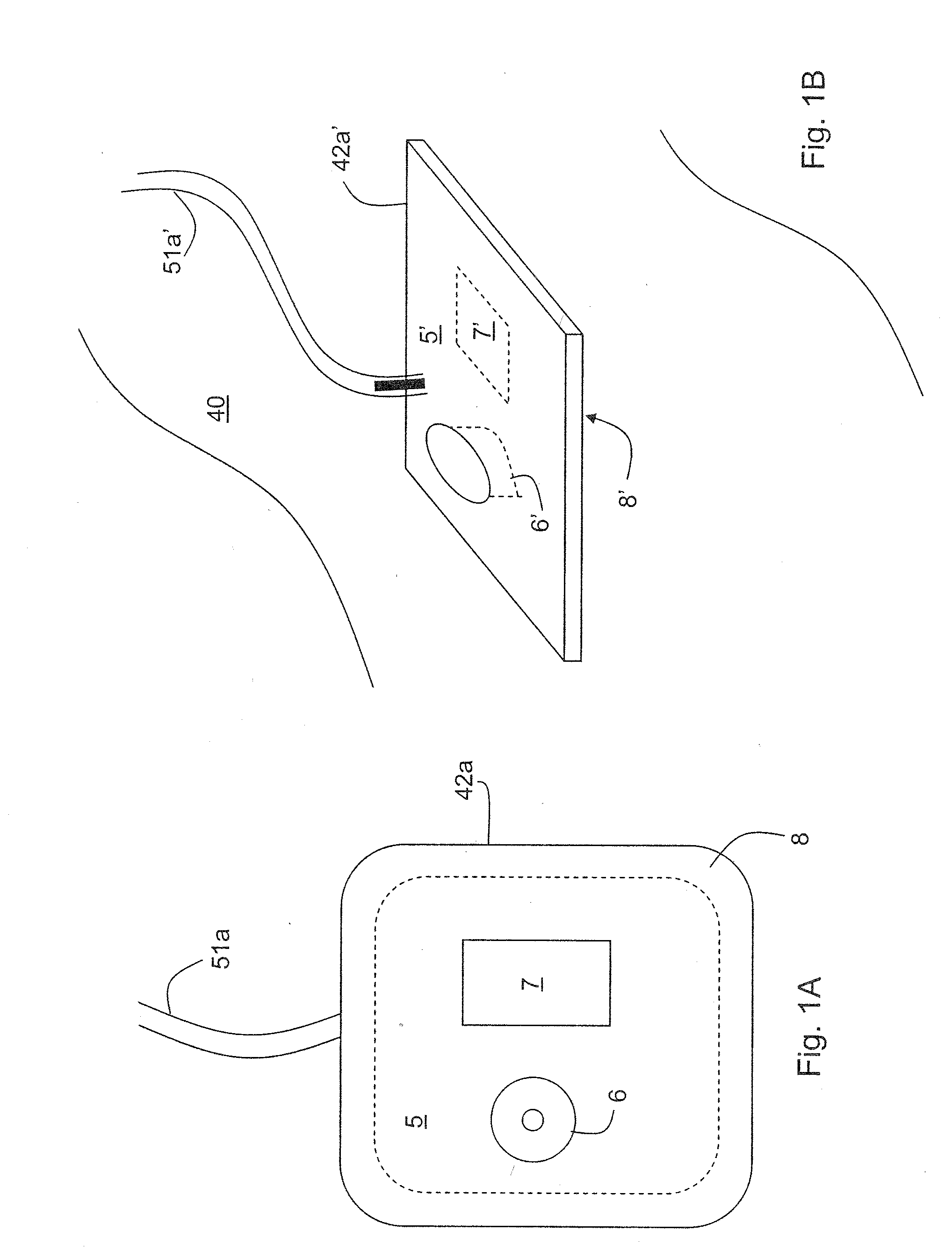

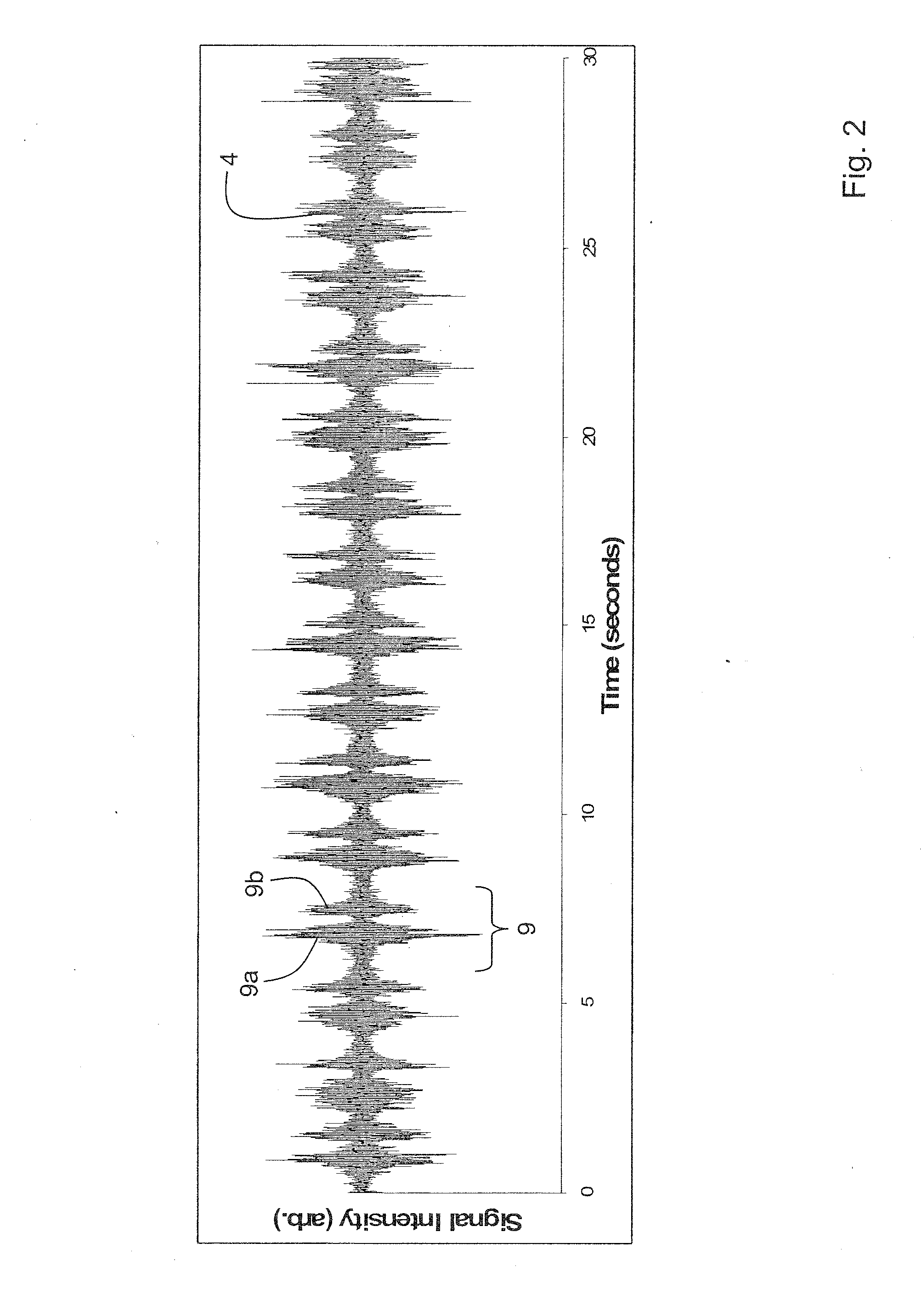

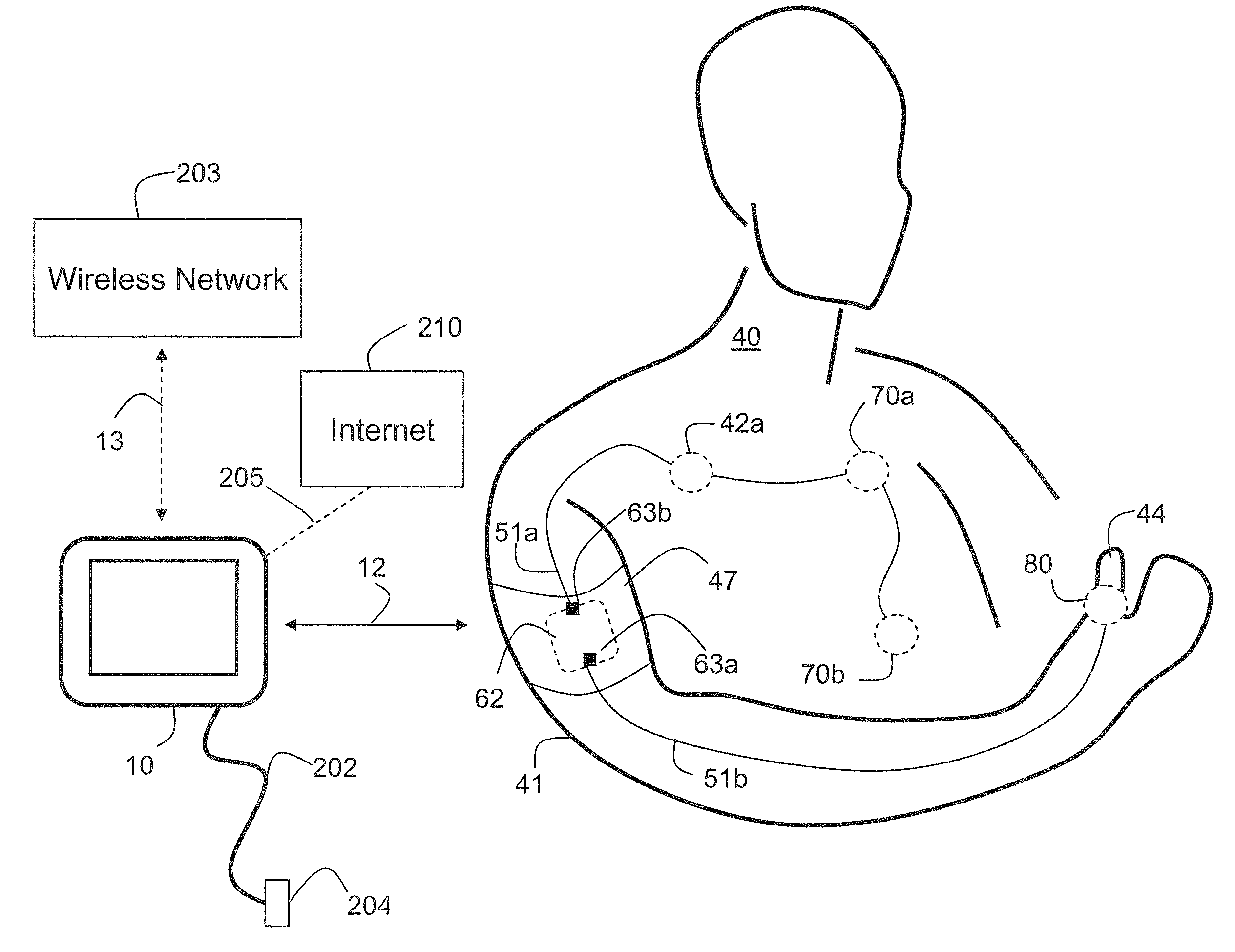

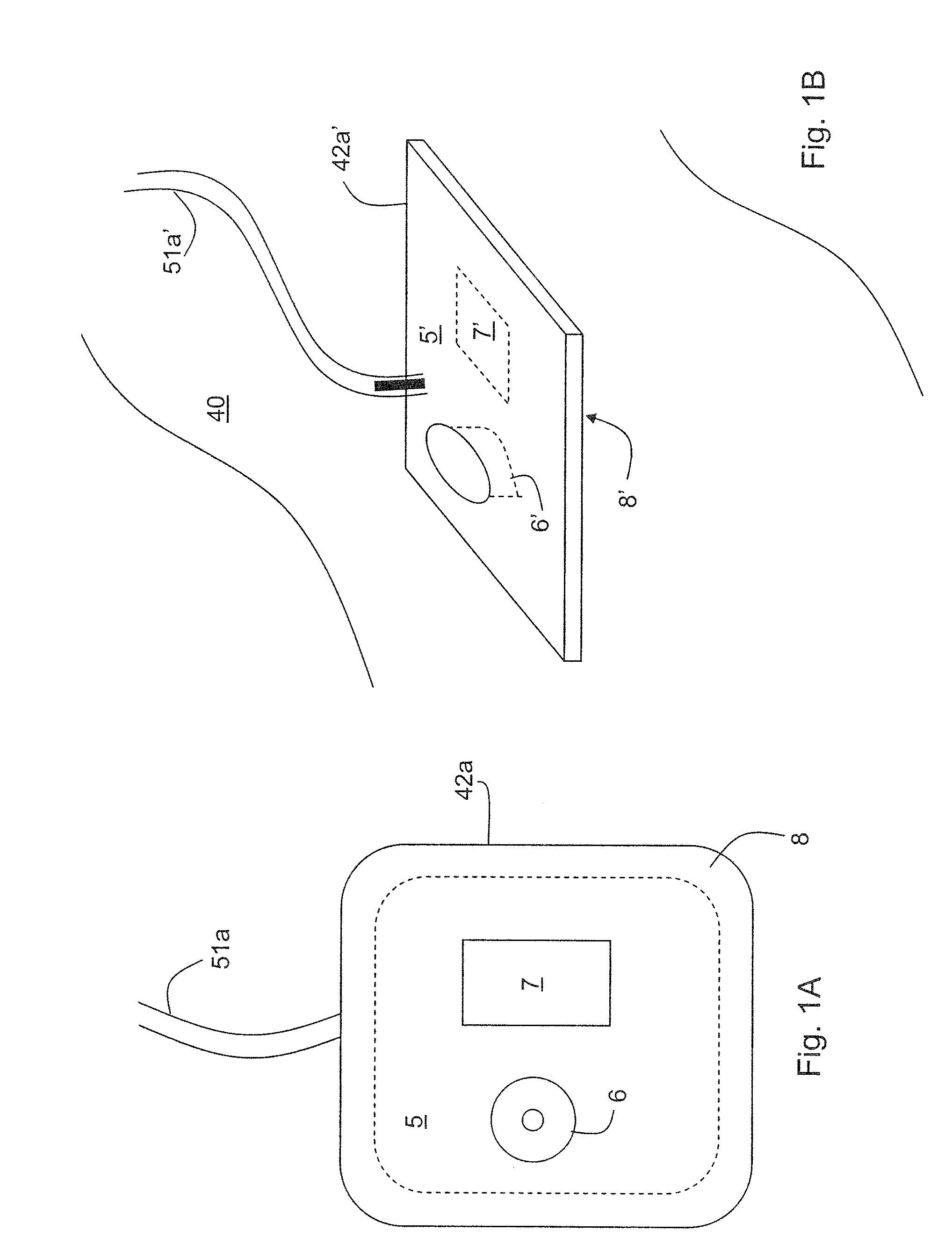

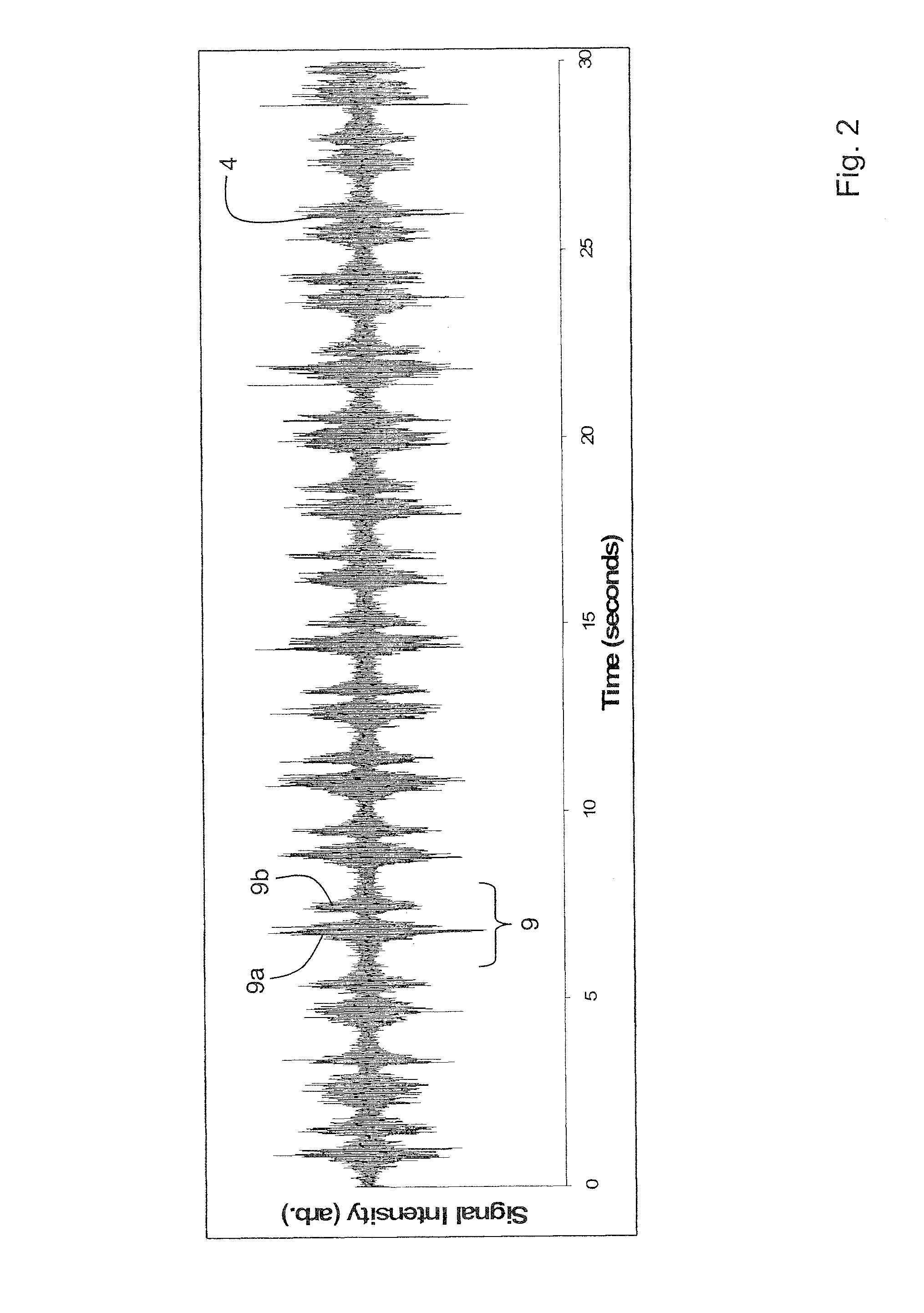

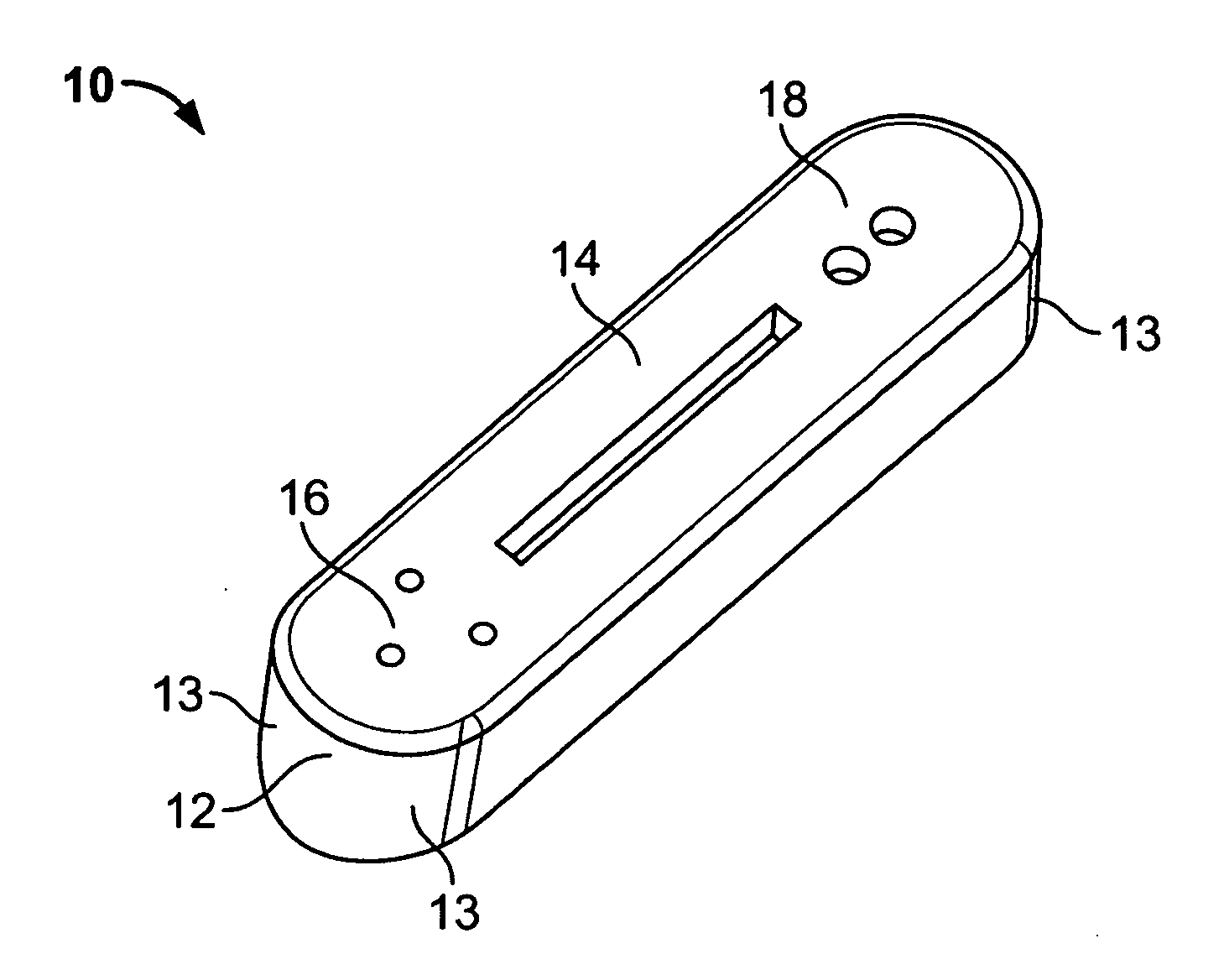

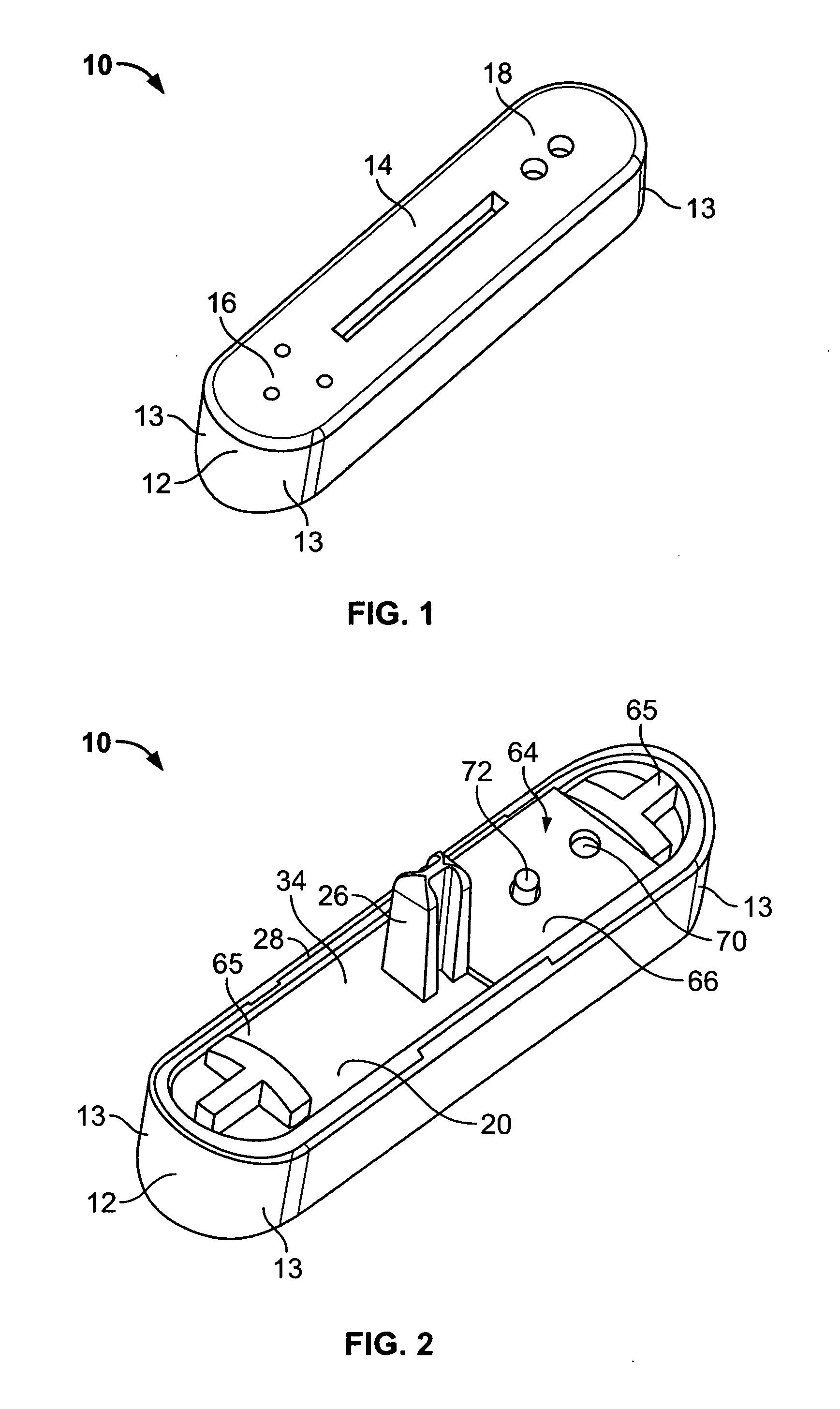

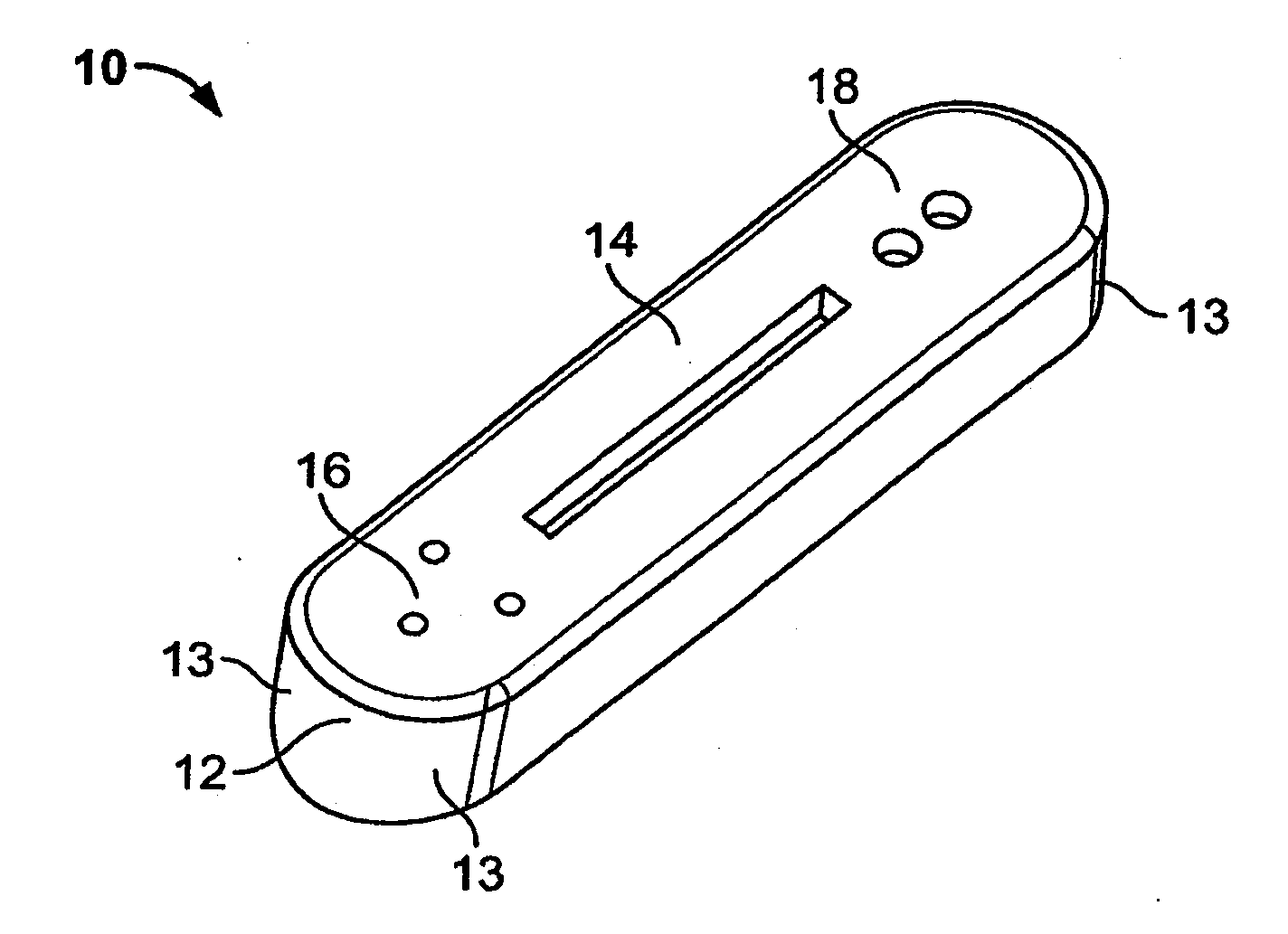

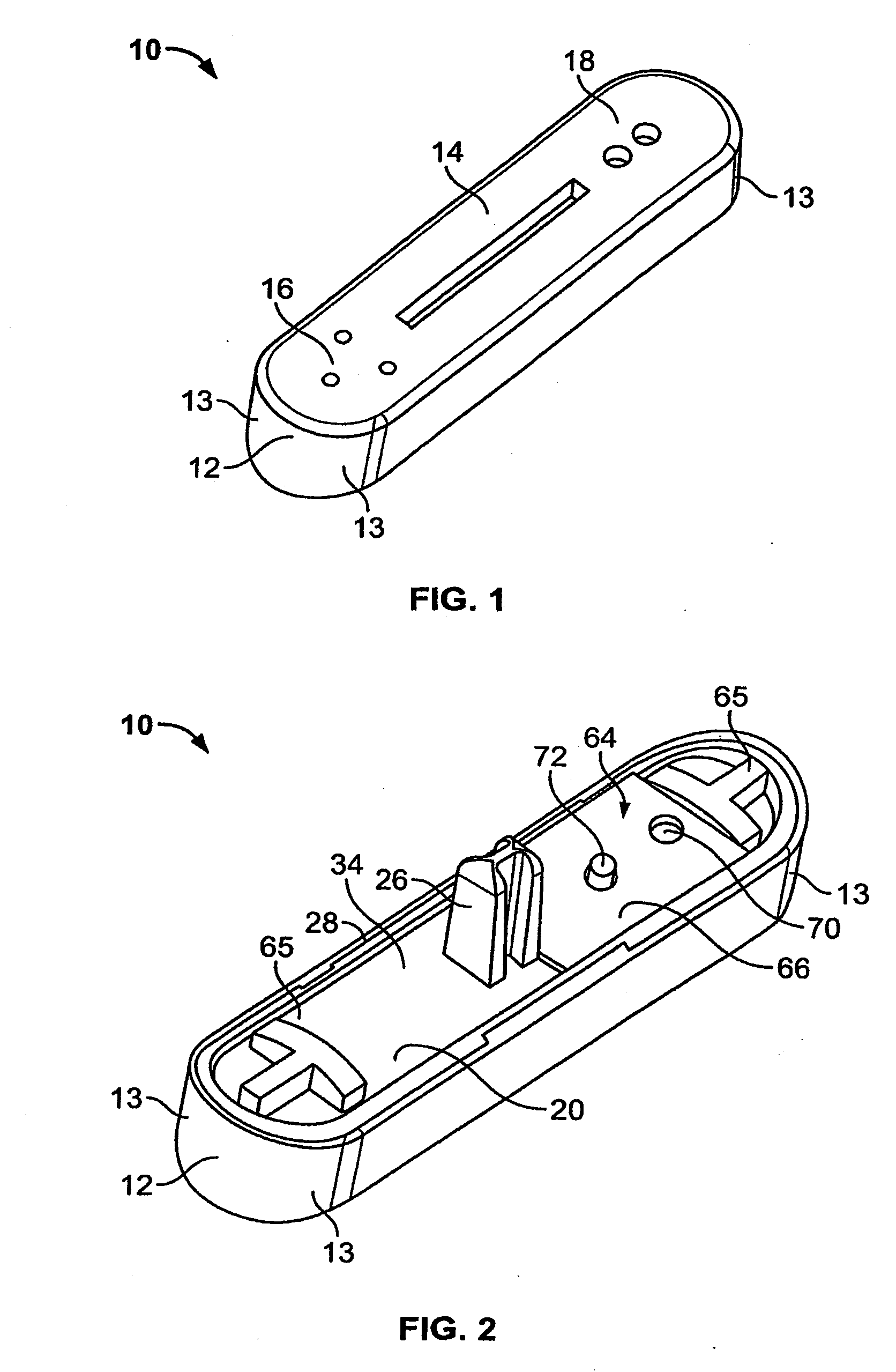

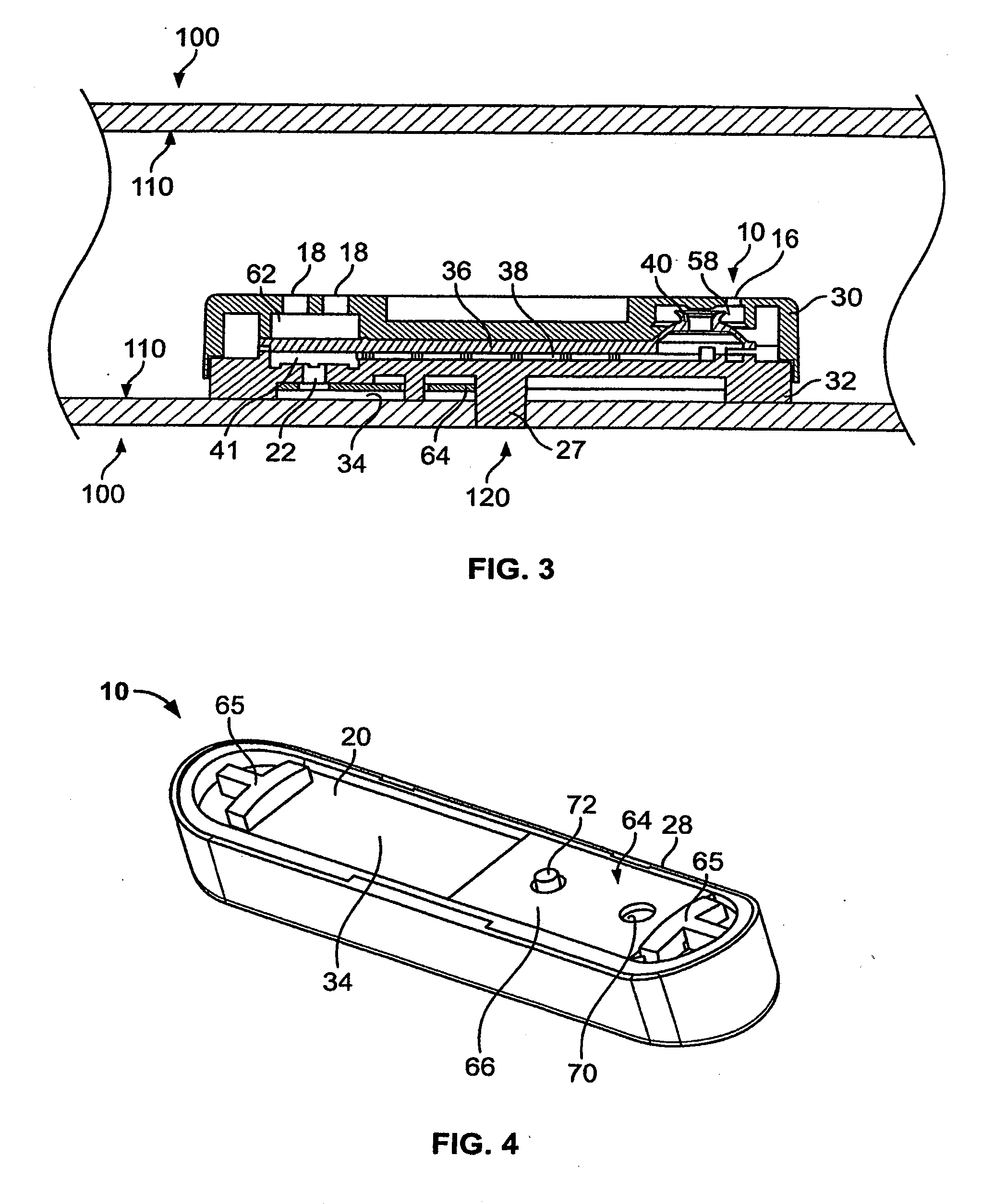

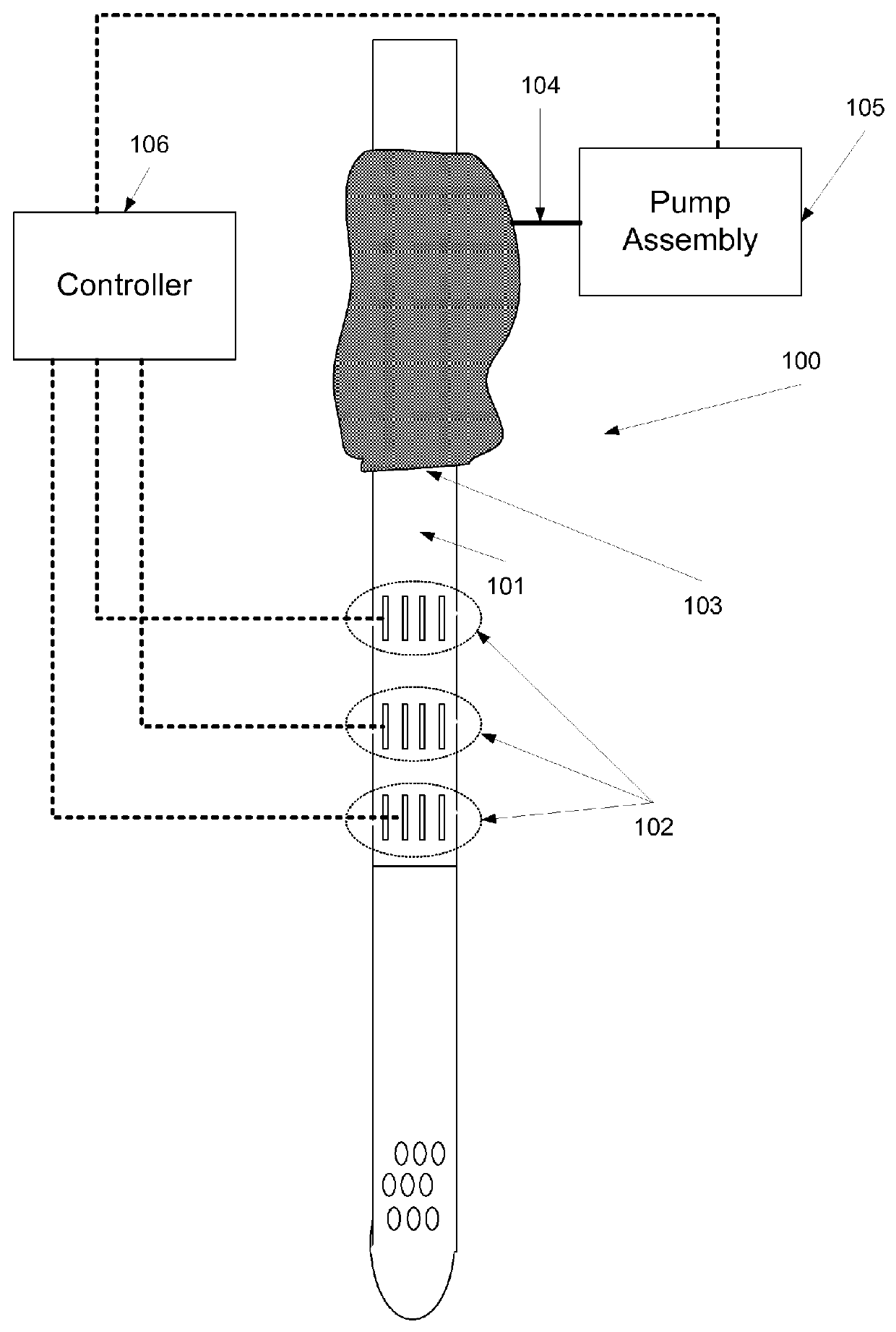

Device for determining respiratory rate and other vital signs

A body-worn sensor that measures respiratory rate and other vital signs using an acoustic sensor (e.g., a small-scale sensor). The body-worn sensor features a chest-worn patch sensor that combines both the acoustic sensor and an ECG electrode into a single adhesive patch. To measure blood pressure, the device additionally performs a ‘composite’ PTT-based measurement that features both pressure-dependent and pressure-free measurements. The acoustic sensor measures respiration rate by recording sounds related to the patient's inspiration and expiration. The acoustic sensor is typically placed near the patient's trachea, but can also be placed on the middle right and left side of the chest, and the middle right and left side of the back.

Owner:SOTERA WIRELESS

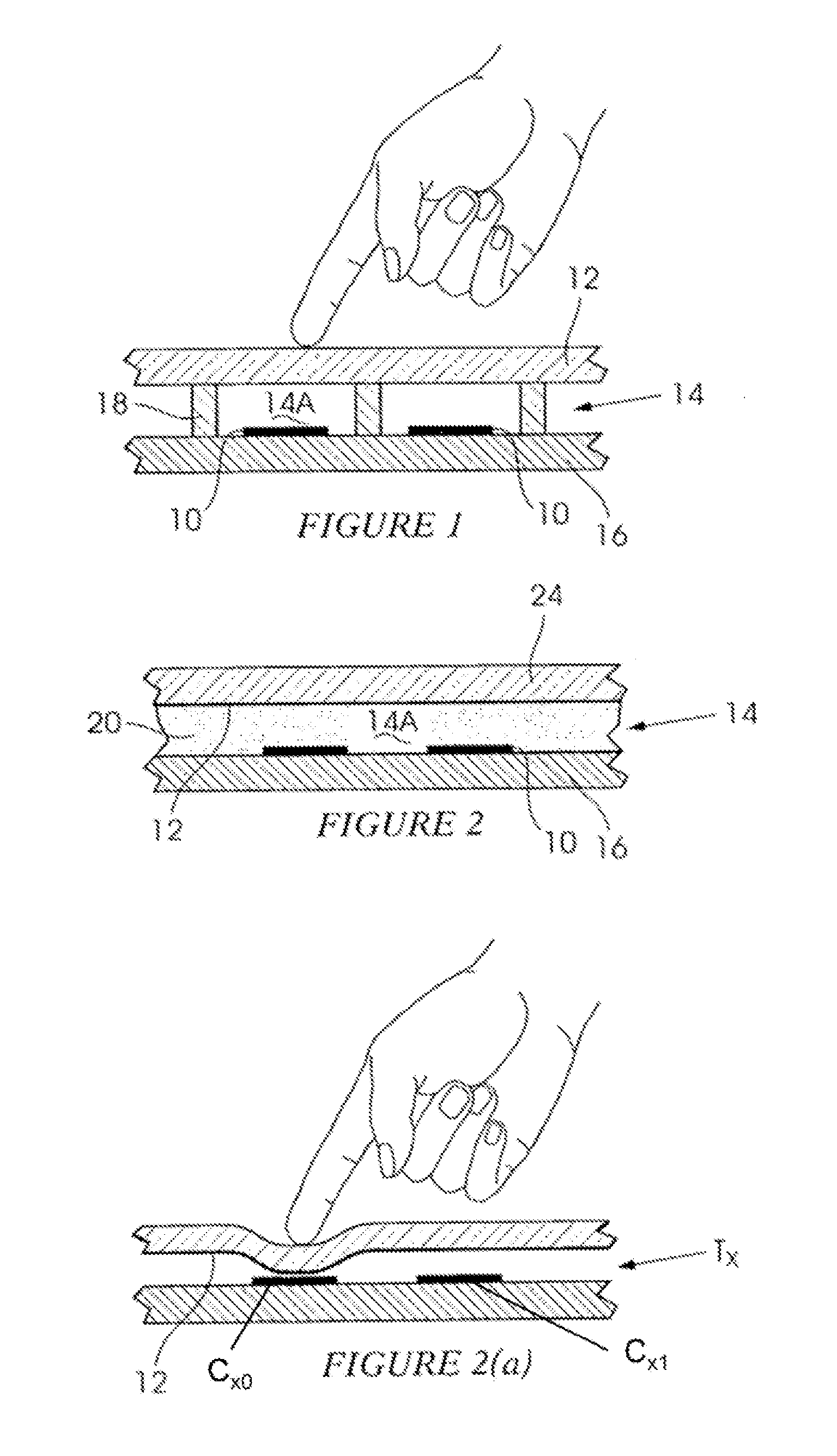

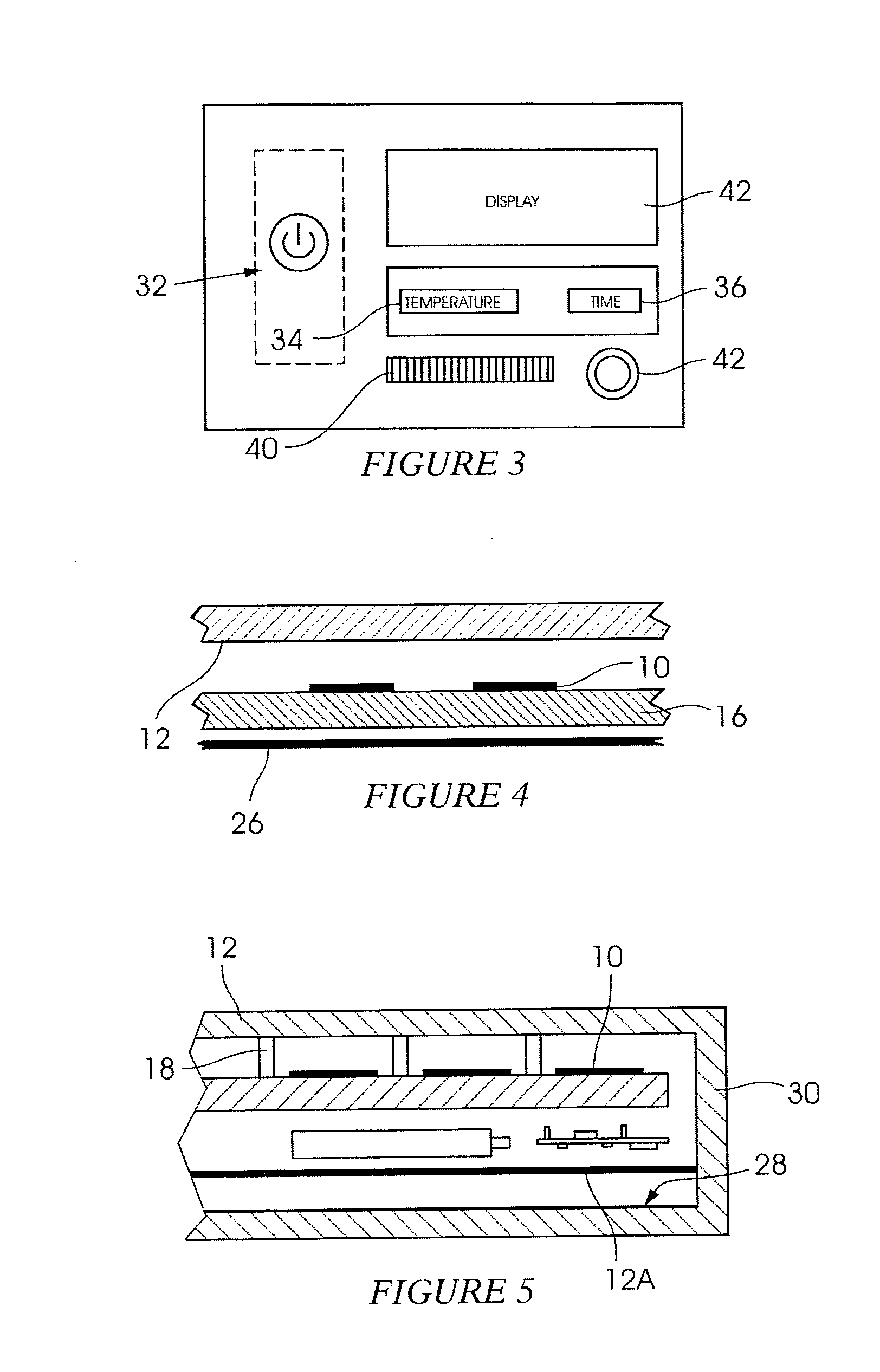

Pressure dependent capacitive sensing circuit switch construction

ActiveUS20130093500A1Easy constructionElectronic switchingInput/output processes for data processingEvent typeEngineering

A user interface which includes a capacitive measurement circuit with a sense plate covered by an electrically conductive cover member, and wherein said circuit may sense two types of events, said types distinguished by an inverse change in measured capacitance, and wherein user proximity and touches with less than a minimum required force constitute one event type, and touches with more than said minimum force constitute the other event type.

Owner:AZOTEQ HLDG LTD

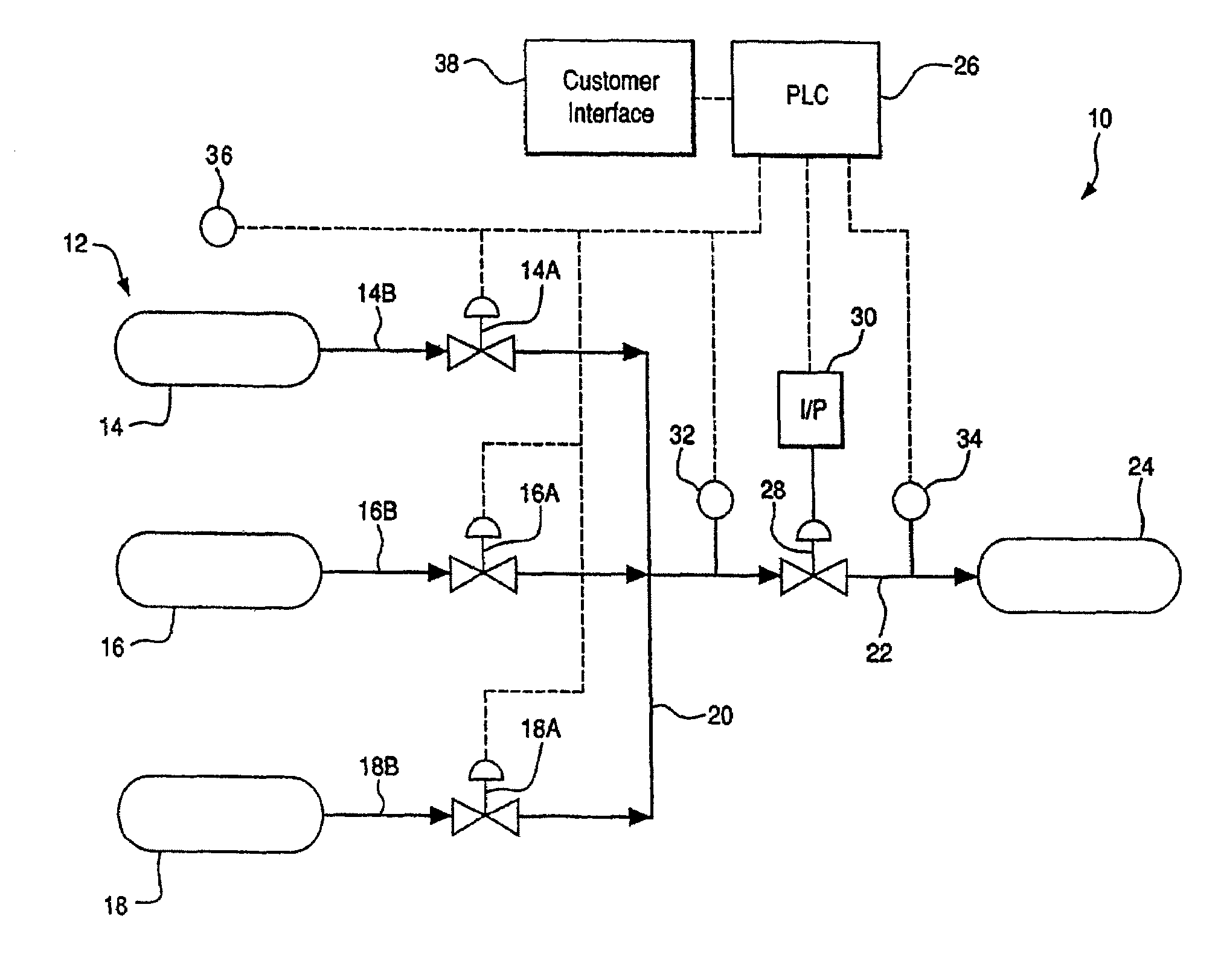

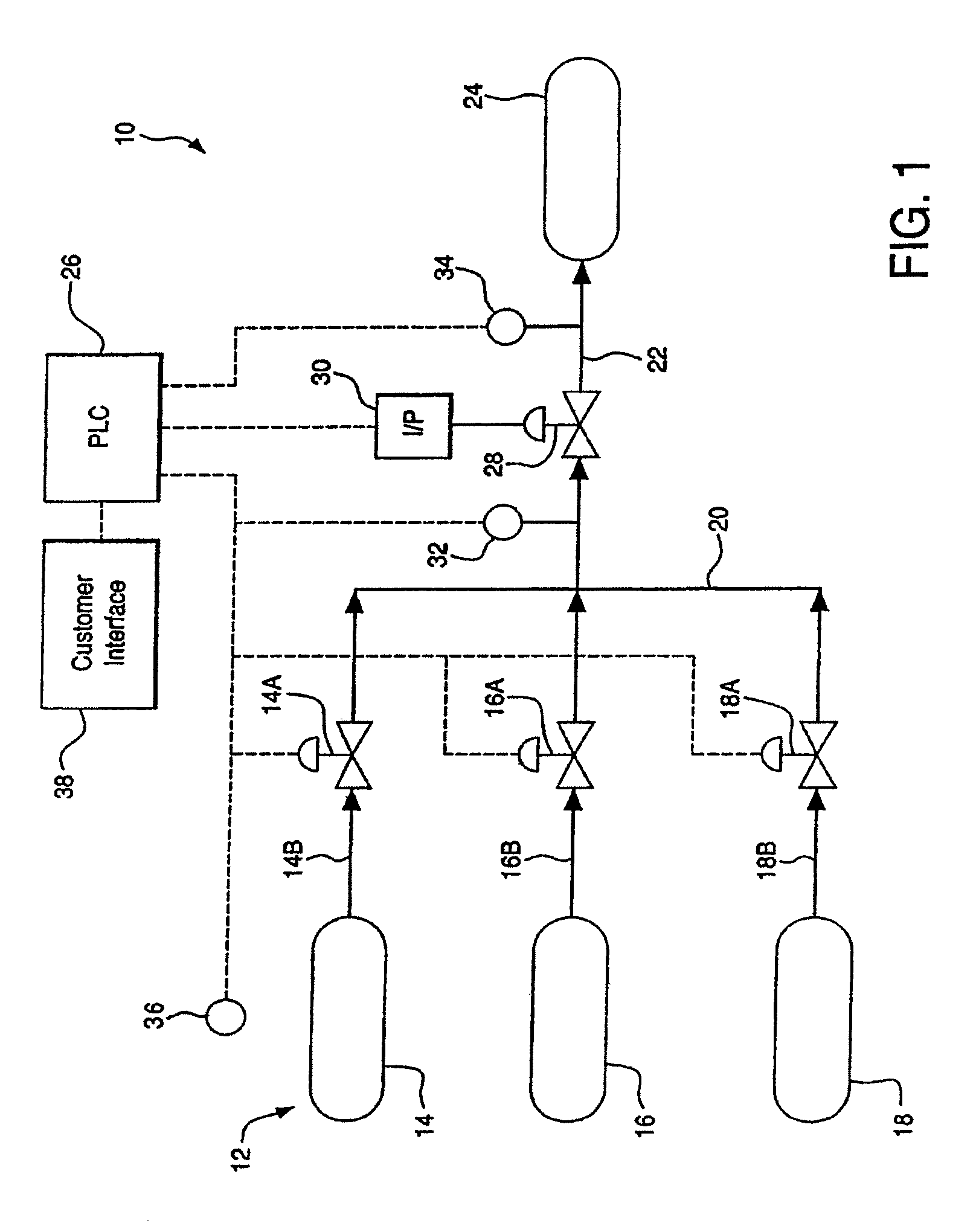

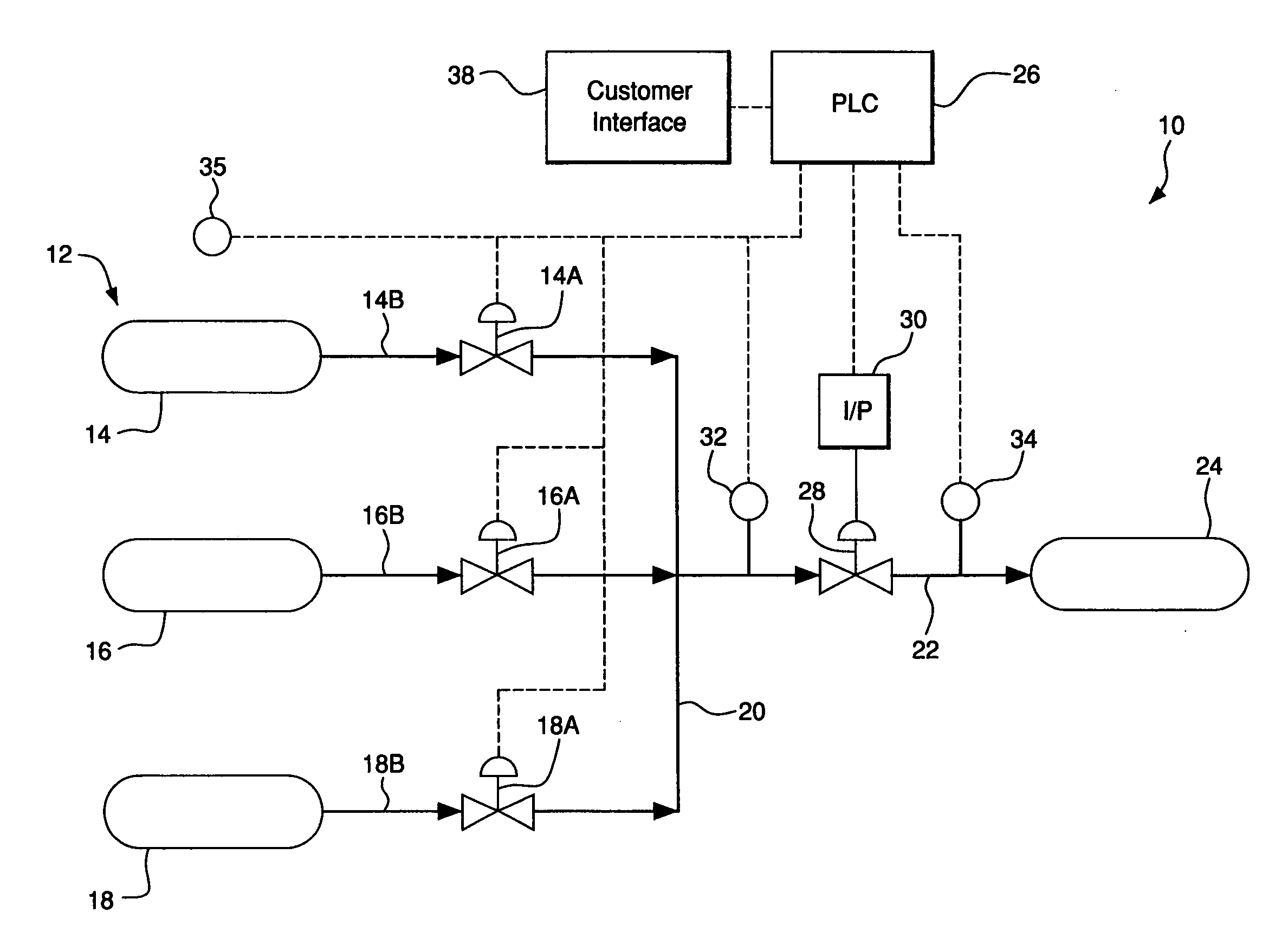

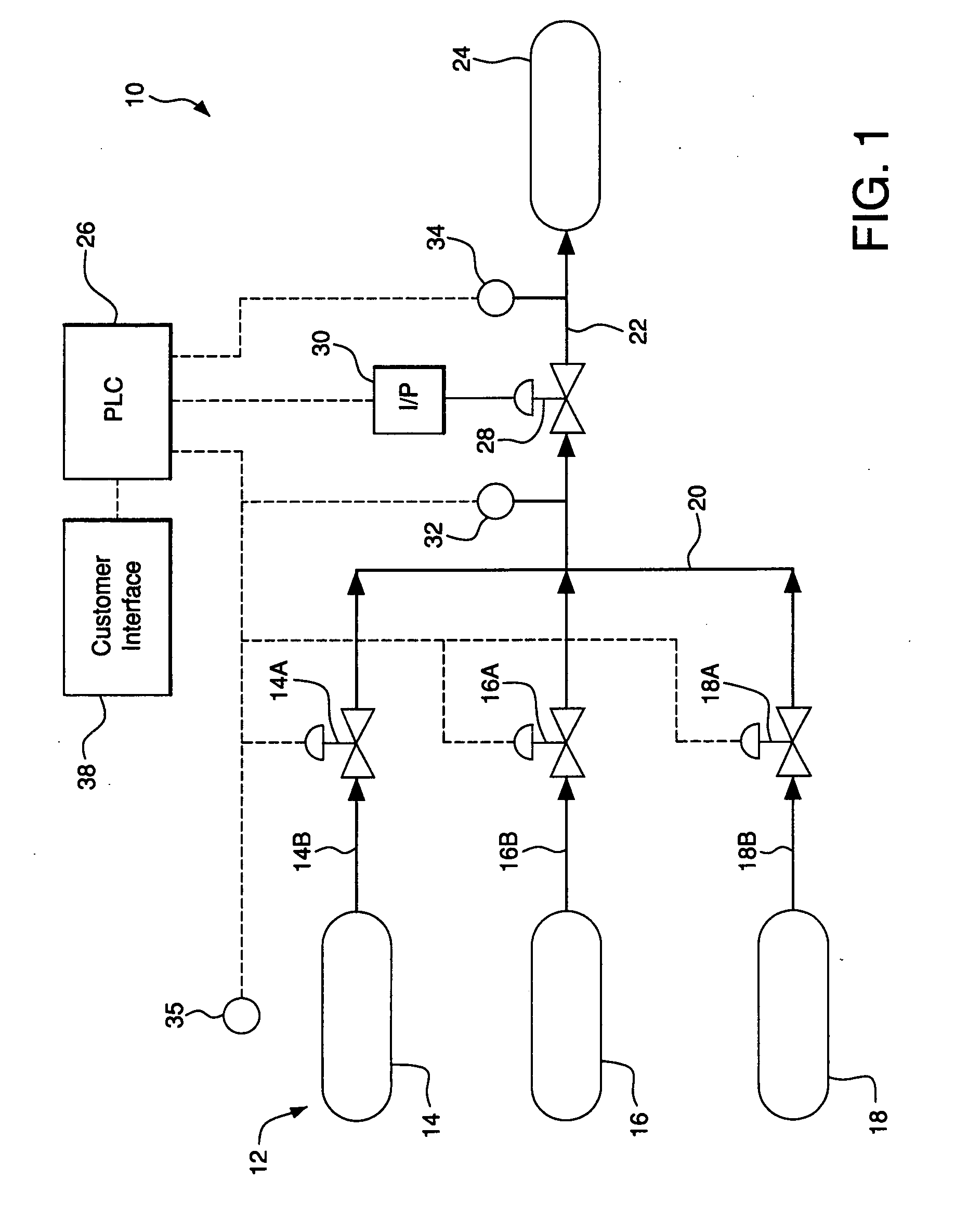

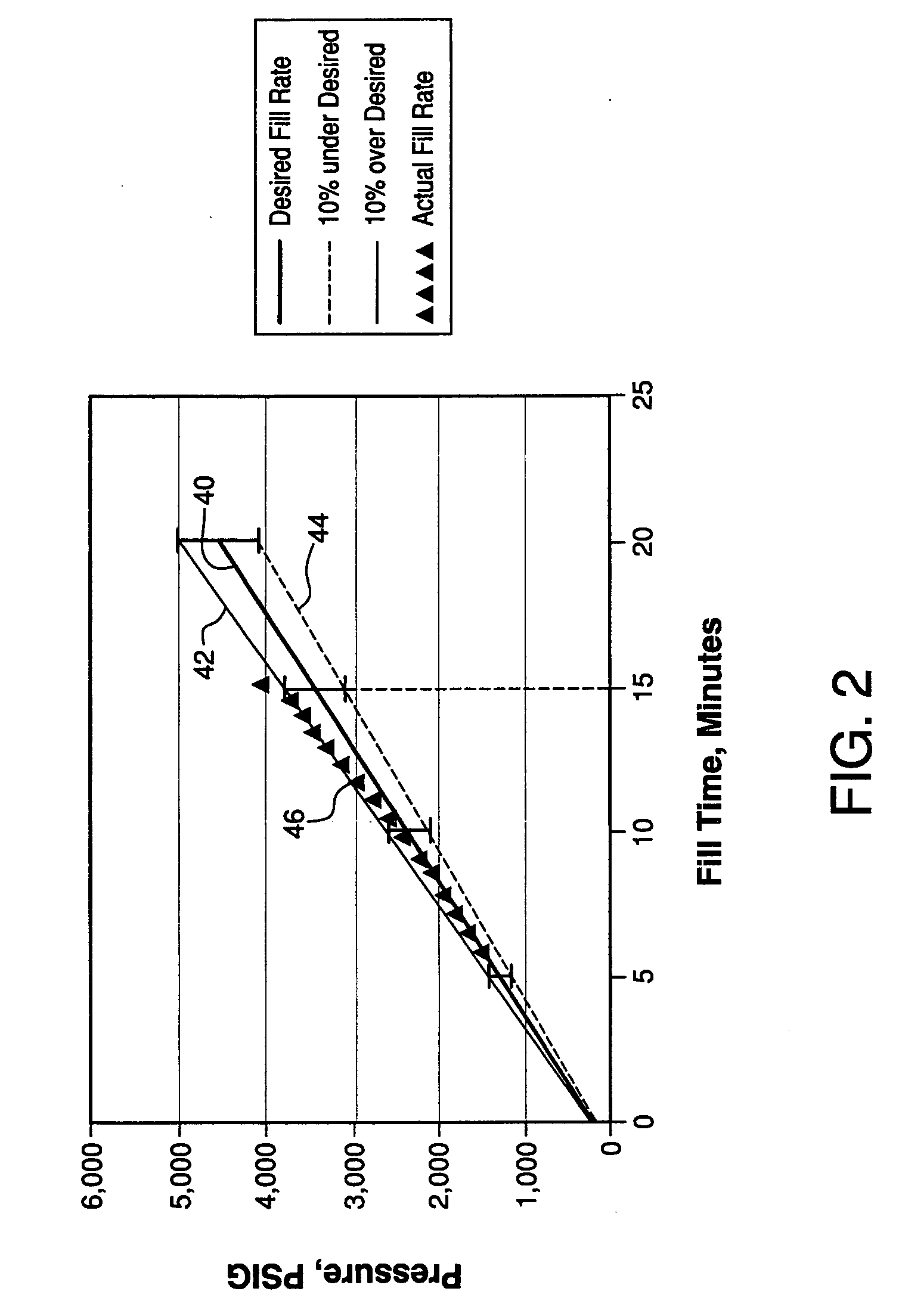

Diagnostic method and apparatus for a pressurized gas supply system

ActiveUS7568507B2Prevent excessive pressure risePreventing a potentially dangerous overheating problemLiquid fillingGas handling applicationsLine tubingEngineering

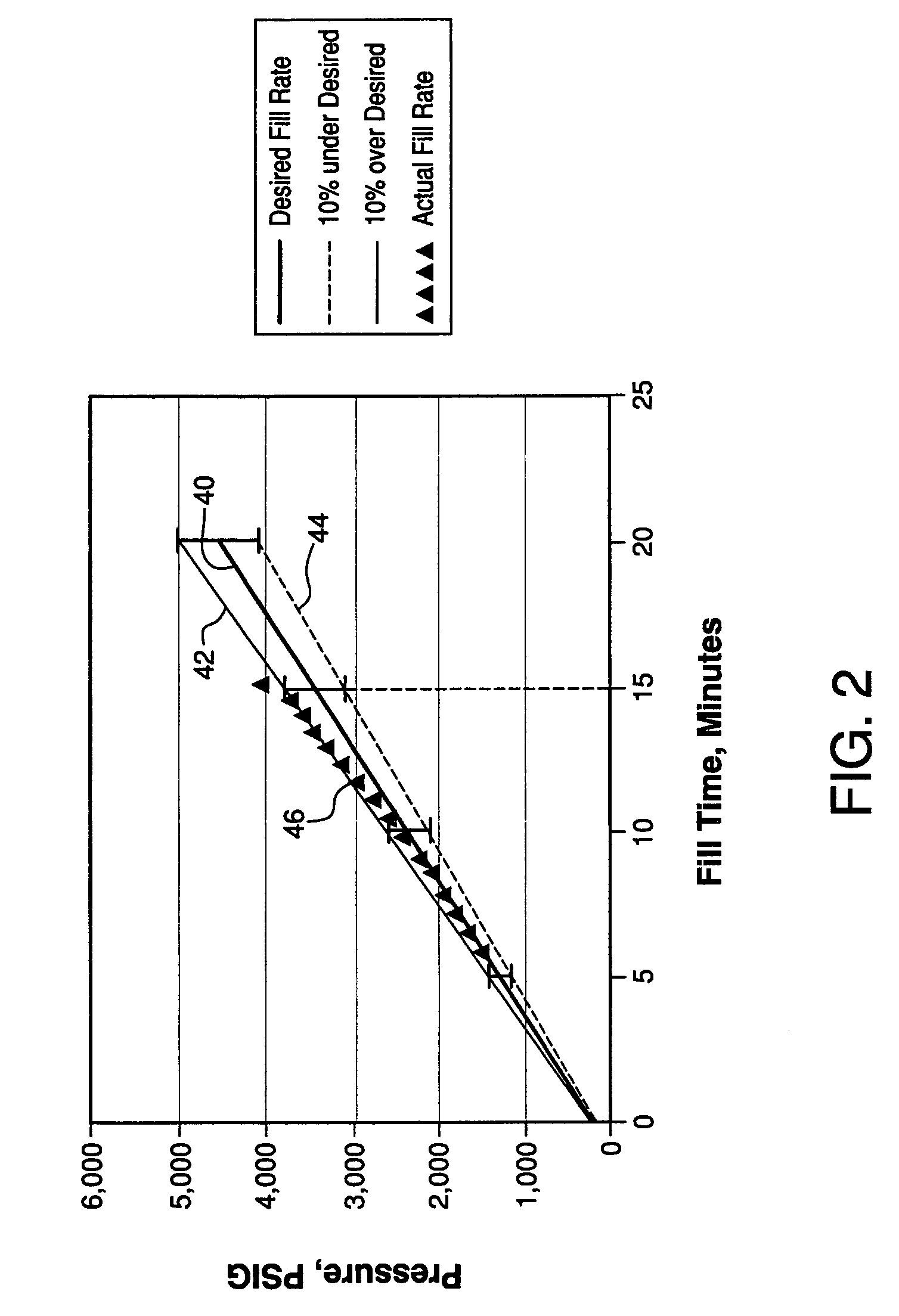

A diagnostic method for a gas supply system includes: determining a desired ramp rate for filling a vessel from a supply of compressed gas; monitoring the actual pressure of gas entering the vessel; and discontinuing the flow of gas into the vessel when the actual pressure deviates from the intended pressure at the desired ramp rate by an undesired amount. A system for carrying out the method includes a flow controller for controlling operation of the supply system to deliver compressed gas from a source to a vessel through a supply line at a desired ramp rate. The system employs a pressure monitor downstream of a control valve for measuring the pressure of gas directed into the vessel and transmitting pressure-related data to the flow controller, which closes the control valve to discontinue filling of the vessel if the actual pressure exceeds a permissible deviation from the intended pressure.

Owner:AIR PROD & CHEM INC

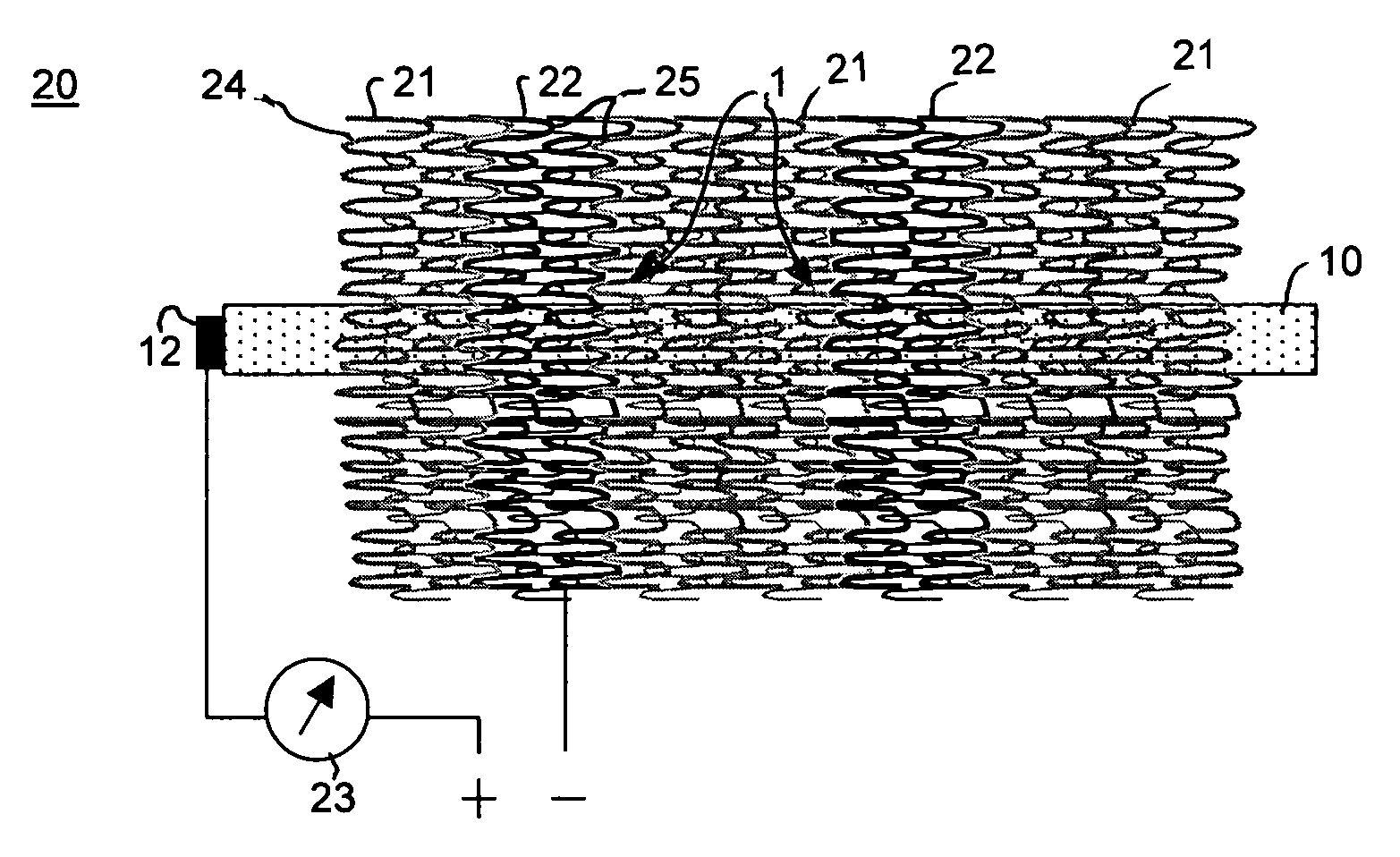

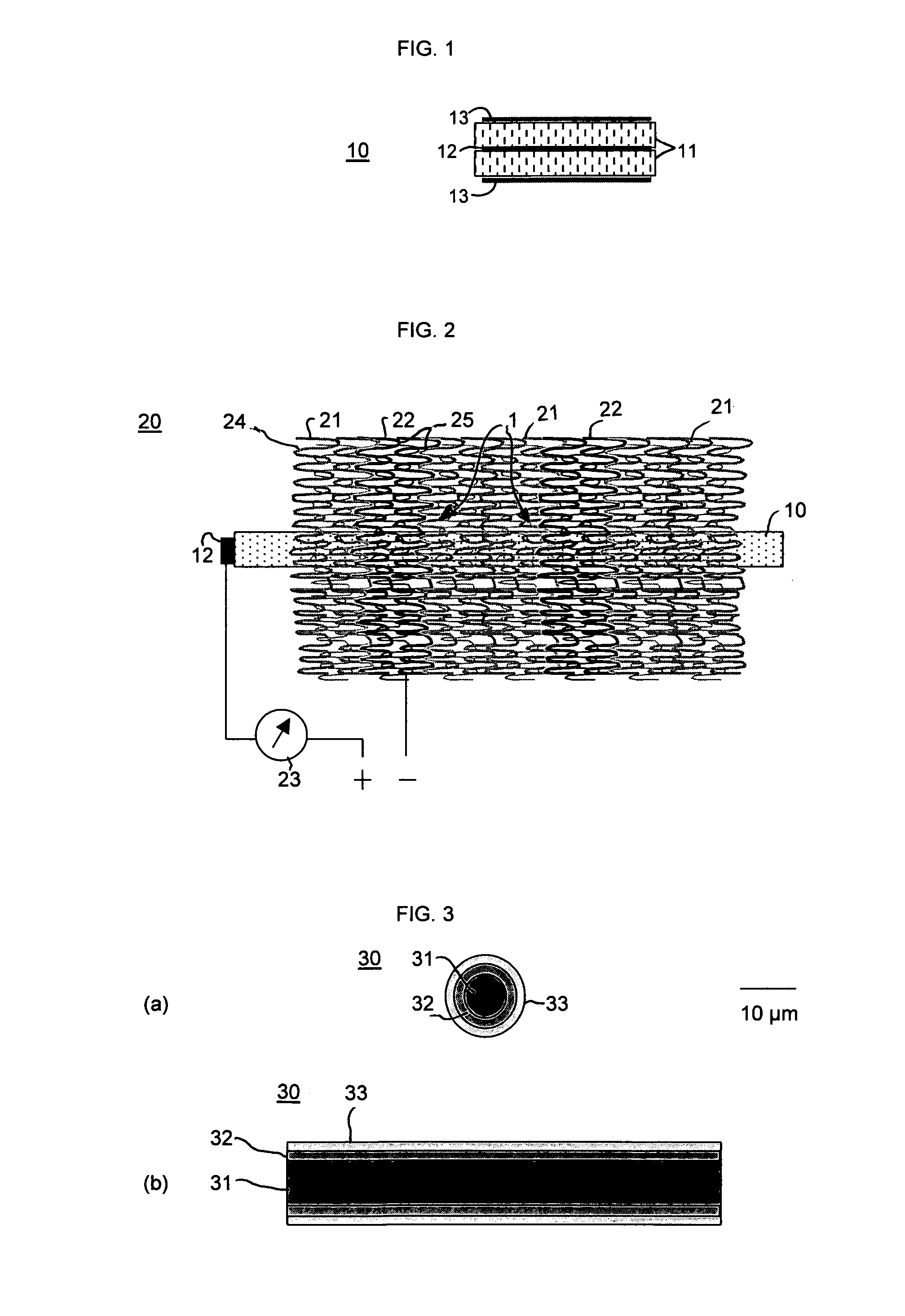

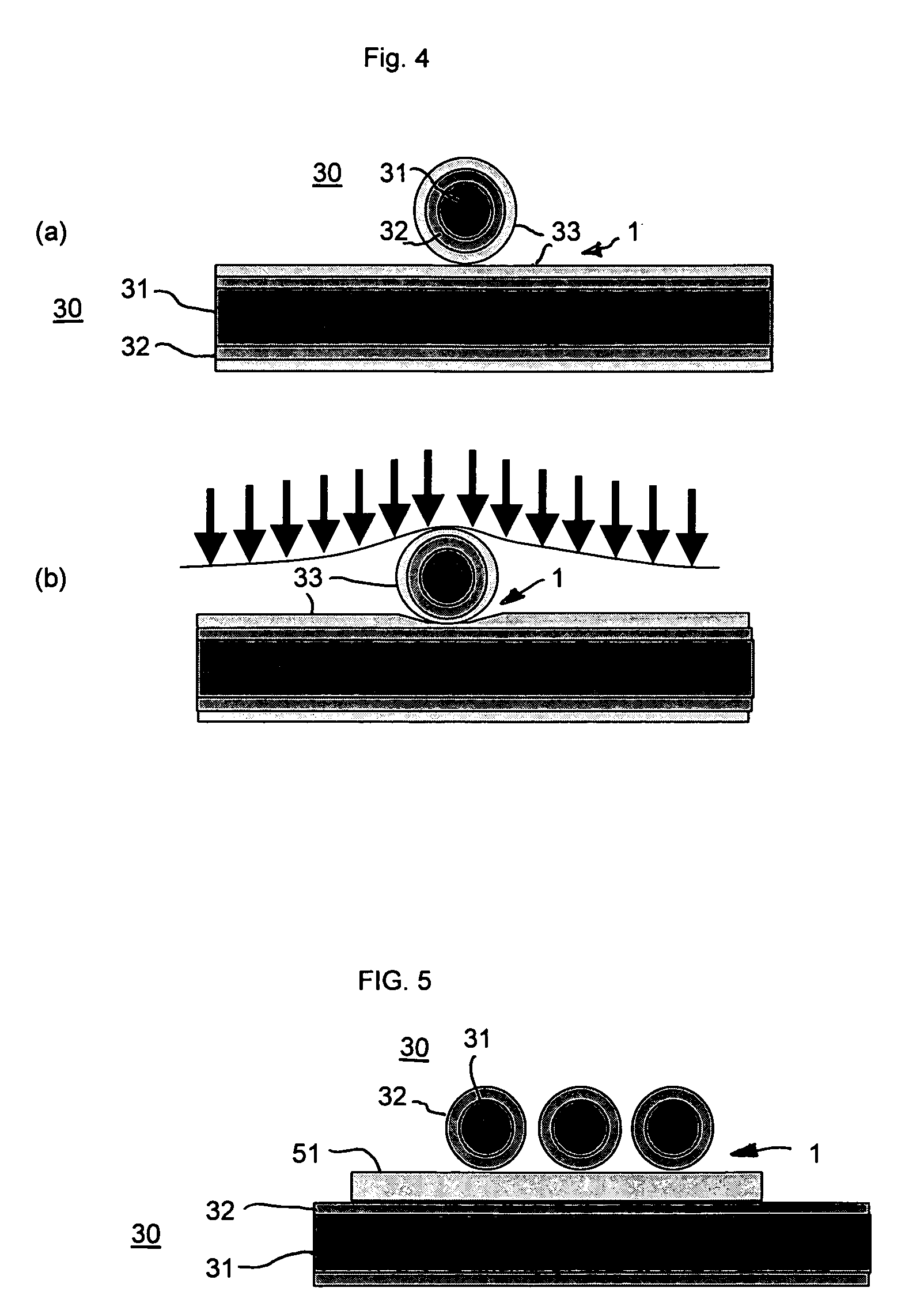

Pressure Sensor

InactiveUS20080307899A1Precise and reliable pressurePrecise and reliable resultsWeft knittingOrnamental textile articlesElectrical resistance and conductancePressure sensor

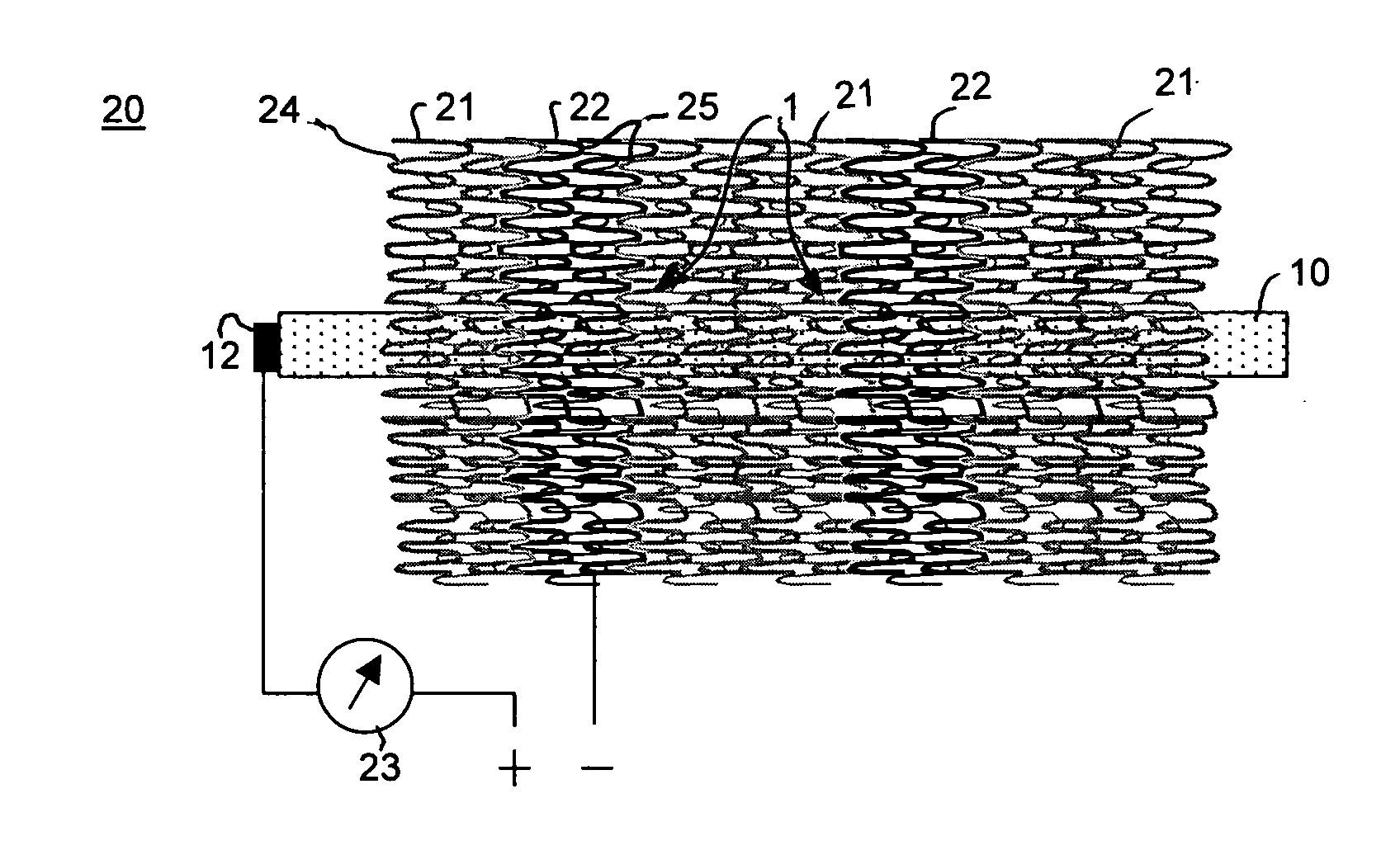

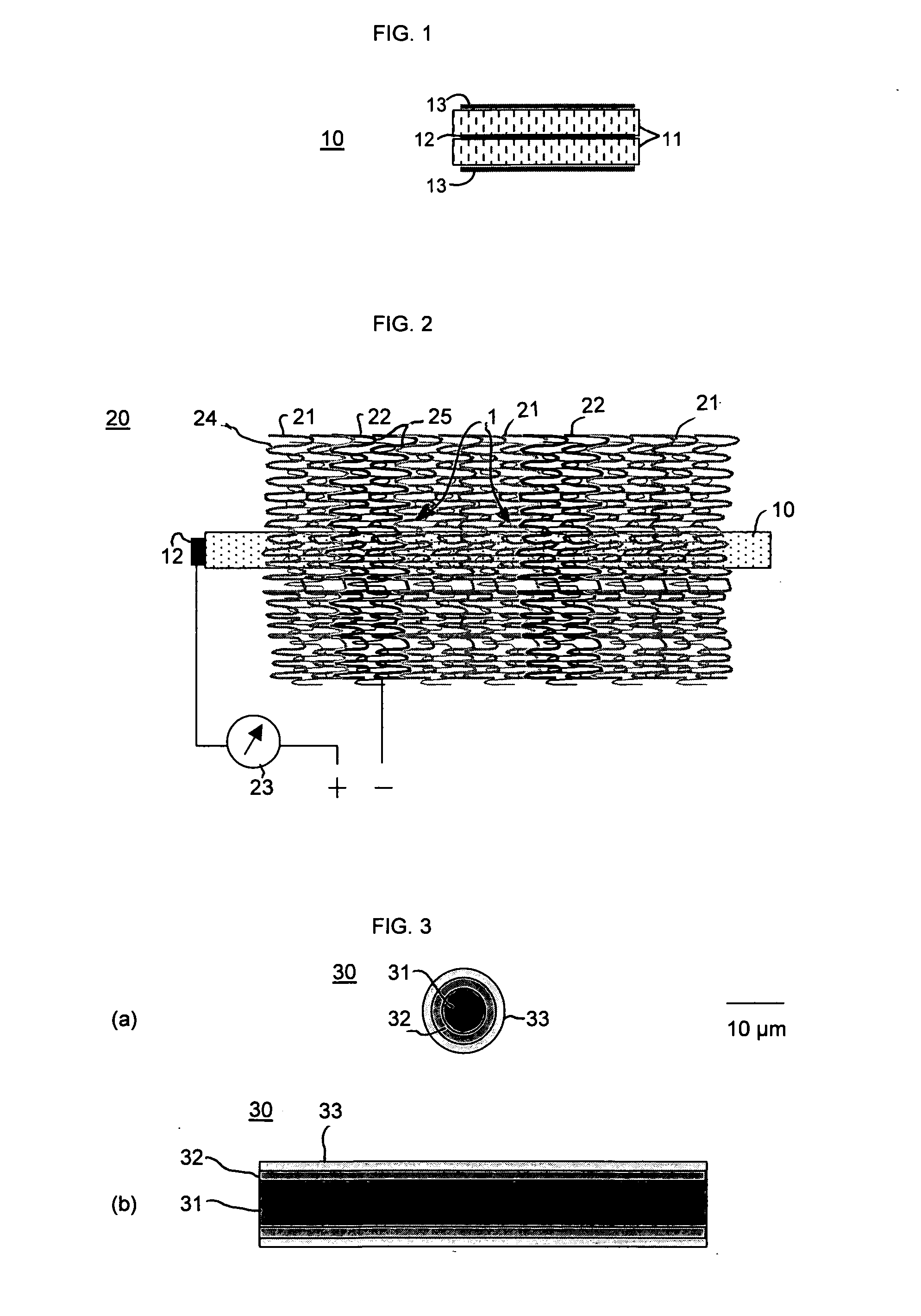

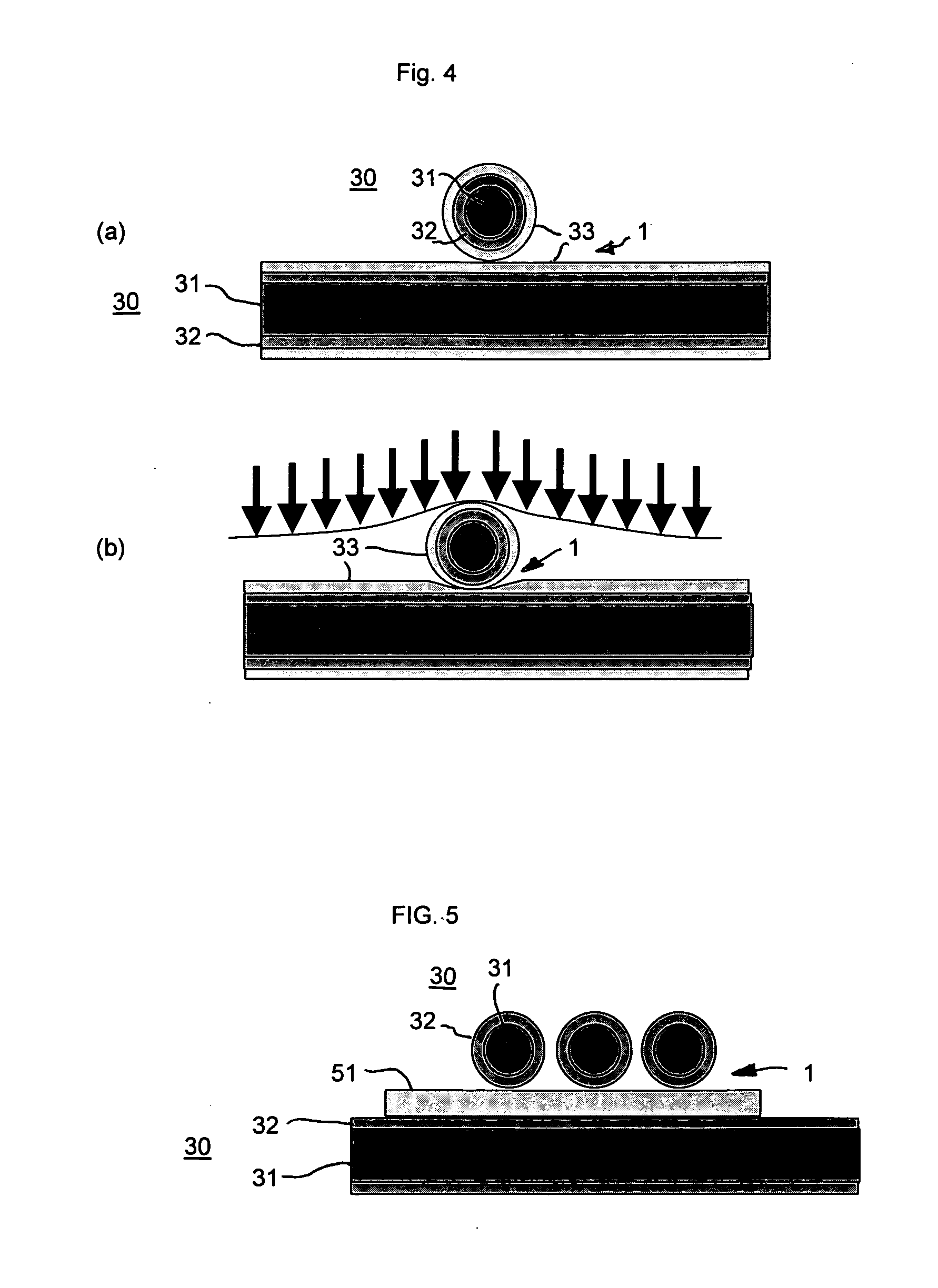

The invention relates to a pressure sensor which can be incorporated into textile products. The pressure sensor includes a multilayer thread having a pressure sensitive layer exhibiting a pressure-dependent electrical resistance, and a conductive layer in contact with the pressure sensitive layer. Further, the sensor includes conductive threads in contact with the multilayer thread.

Owner:INGO MAYER GMBH & CO KG

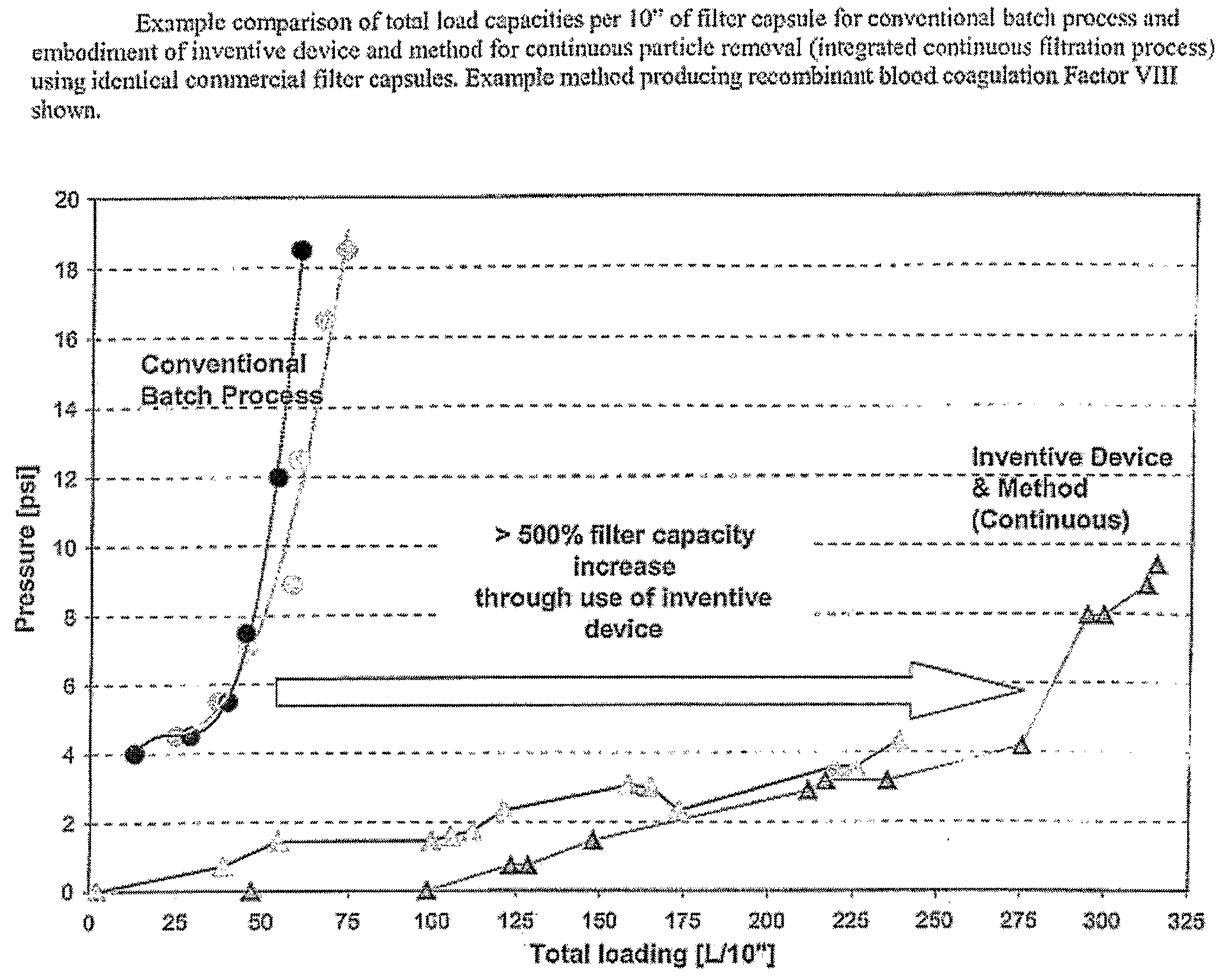

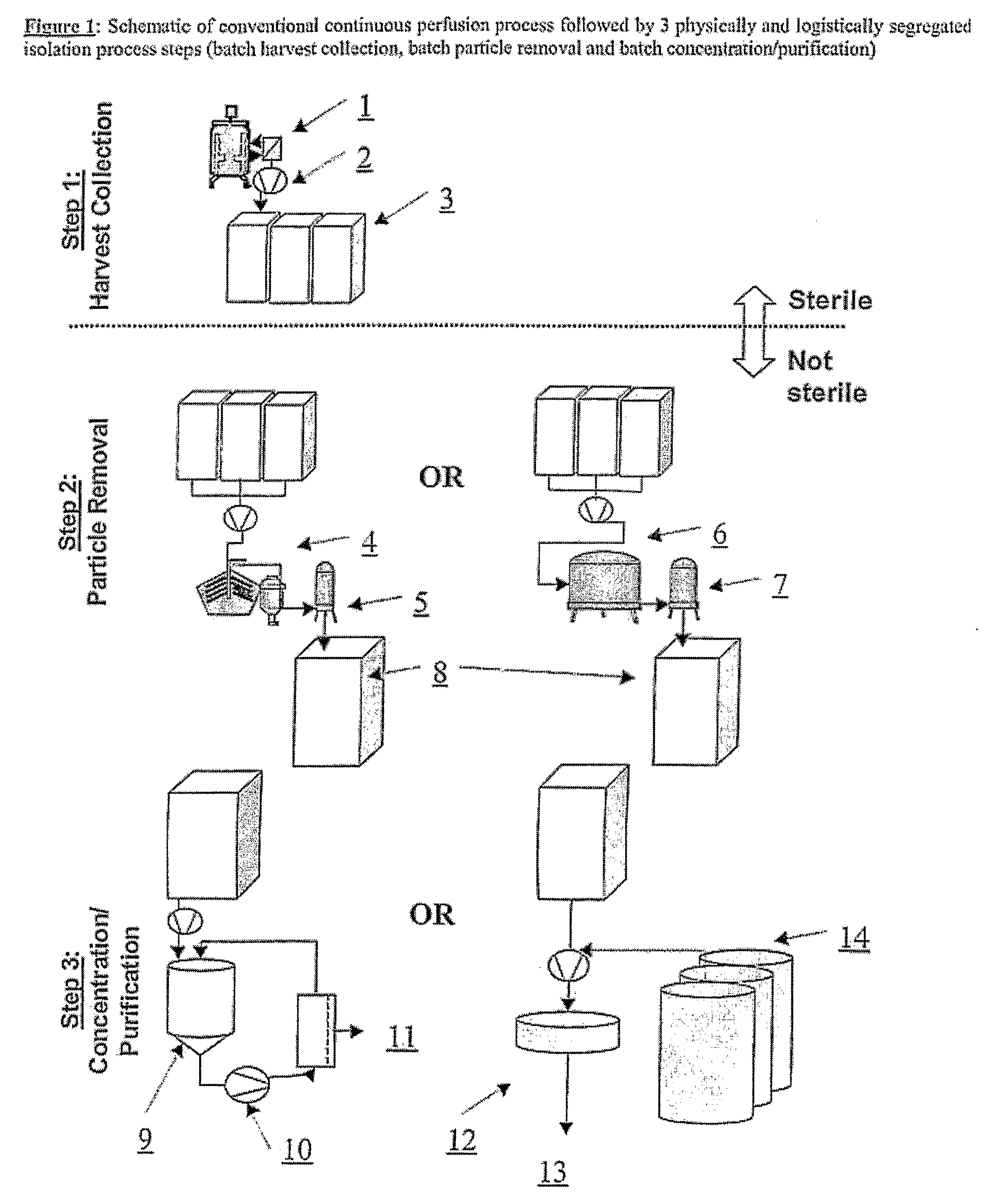

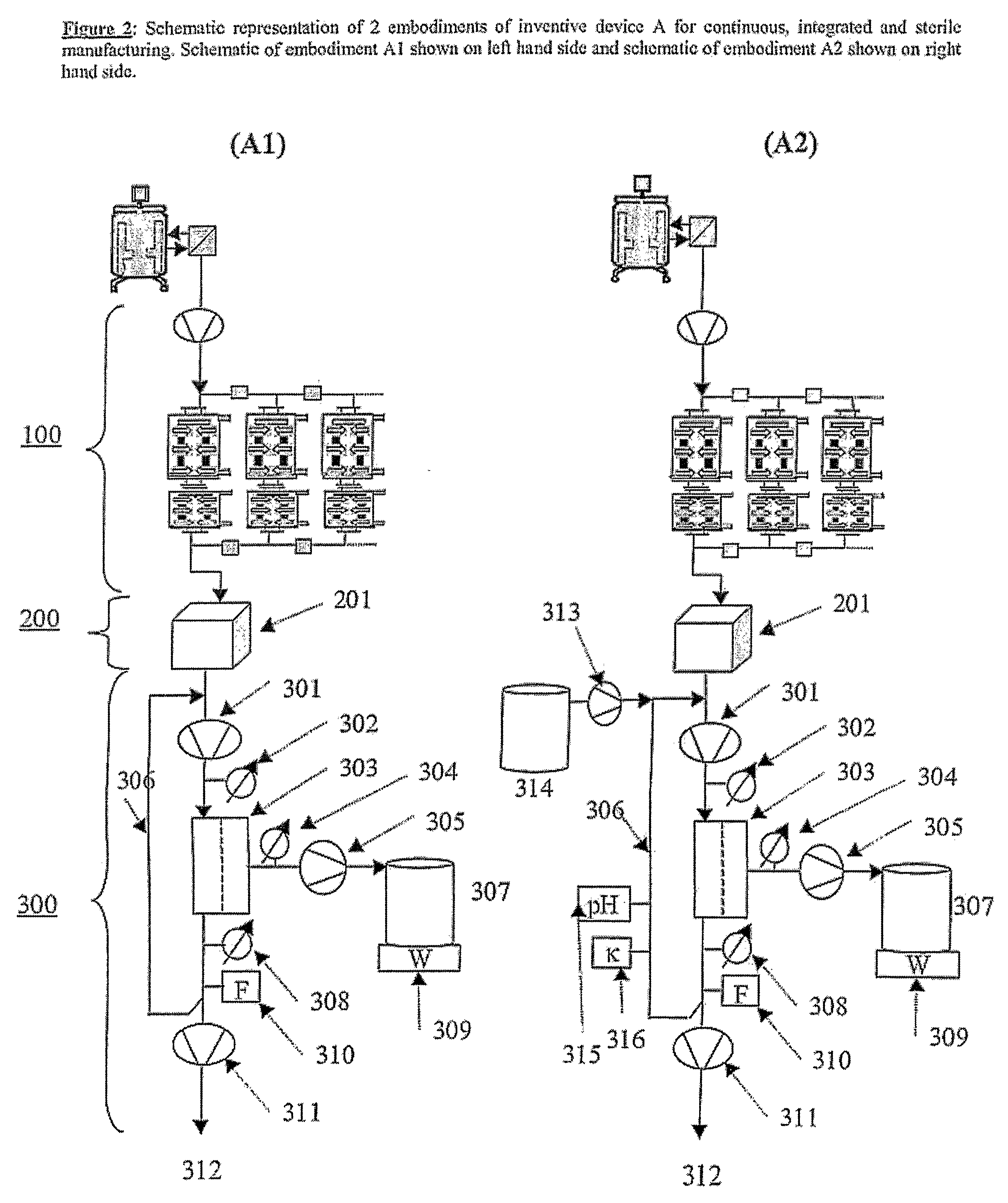

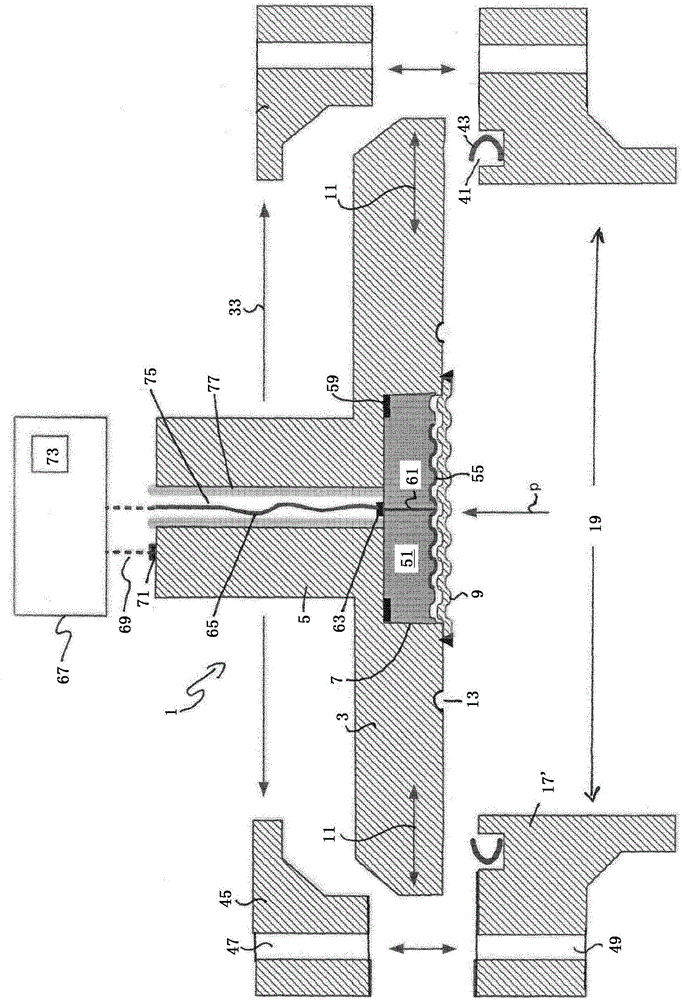

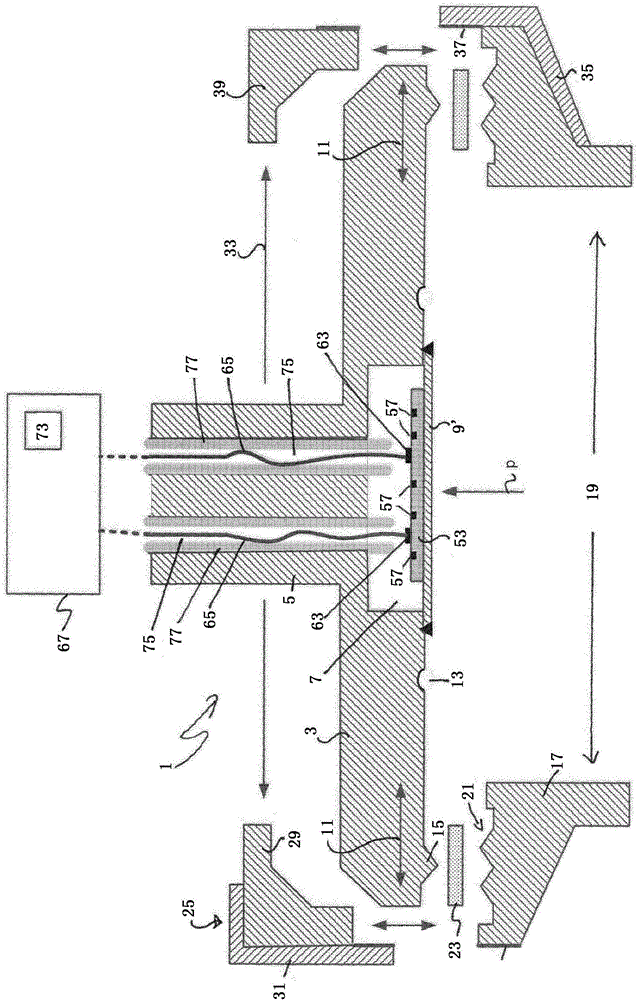

Devices and Methods for Integrated Continuous Manufacturing of Biological Molecules

ActiveUS20080269468A1Bioreactor/fermenter combinationsFactor VIIContinuous perfusionChemical physics

The present invention relates to a process and apparatus for purifying a molecule of interest from a heterogeneous clarified fluid mixture. The apparatus of the invention generally comprises a continuous perfusion fermentation system, a continuous particle removal system integrated with the perfusion fermentation system; and a continuous purification system integrated with the particle removal system, which is maintained under sterile conditions. The process comprises filtering a heterogeneous clarified fluid mixture by continuous ultrafiltration at a specific flow rate below the transition point of the molecule of interest in the pressure-dependent region of the flux versus TMP curve, wherein the specific flow rate is maintained substantially constant throughout the continuous ultrafiltration.

Owner:BAYER HEALTHCARE LLC

Device for determining respiratory rate and other vital signs

A body-worn sensor that measures respiratory rate and other vital signs using an acoustic sensor (e.g., a small-scale sensor). The body-worn sensor features a chest-worn patch sensor that combines both the acoustic sensor and an ECG electrode into a single adhesive patch. To measure blood pressure, the device additionally performs a ‘composite’ PTT-based measurement that features both pressure-dependent and pressure-free measurements. The acoustic sensor measures respiration rate by recording sounds related to the patient's inspiration and expiration. The acoustic sensor is typically placed near the patient's trachea, but can also be placed on the middle right and left side of the chest, and the middle right and left side of the back.

Owner:SOTERA WIRELESS

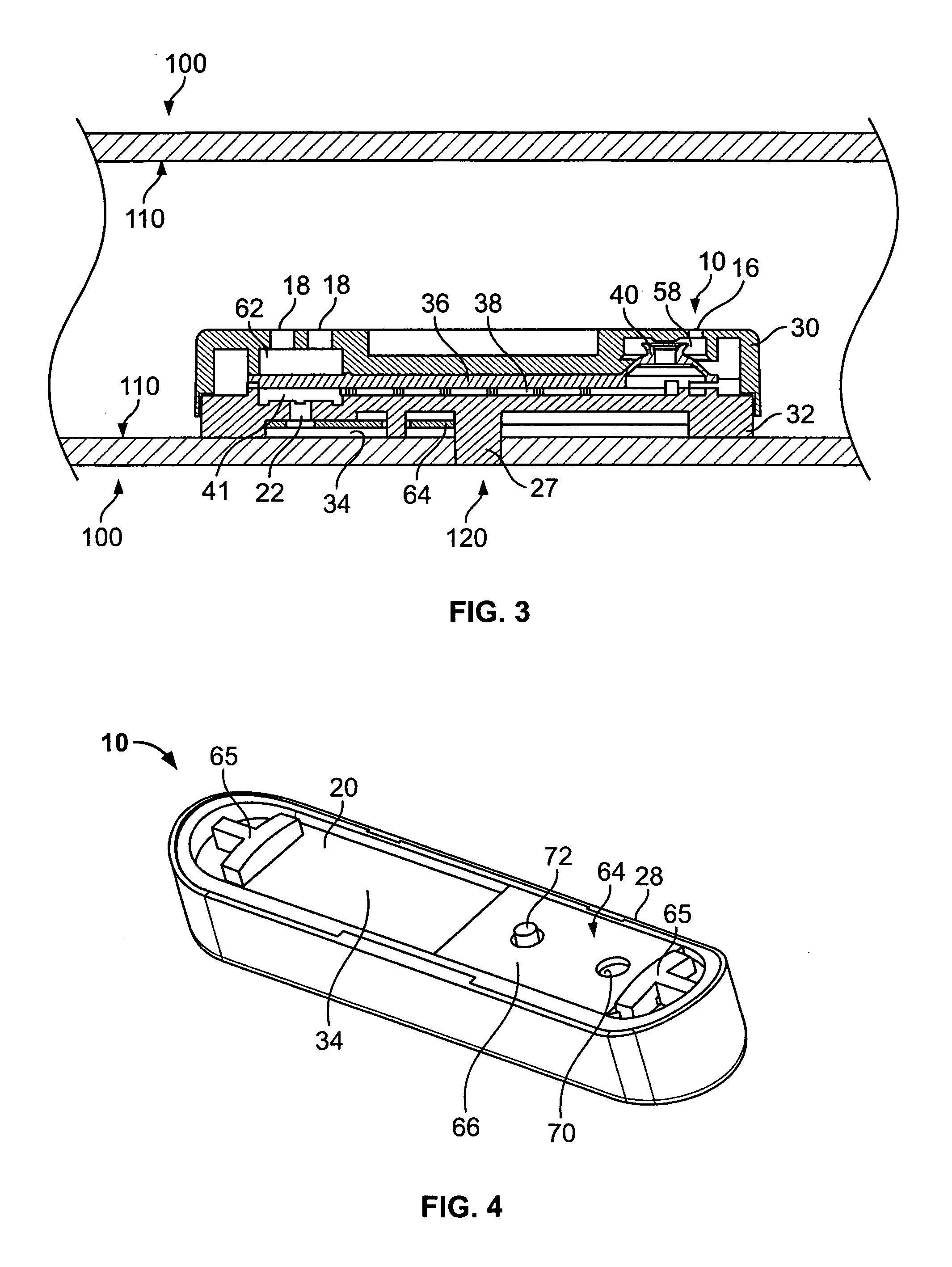

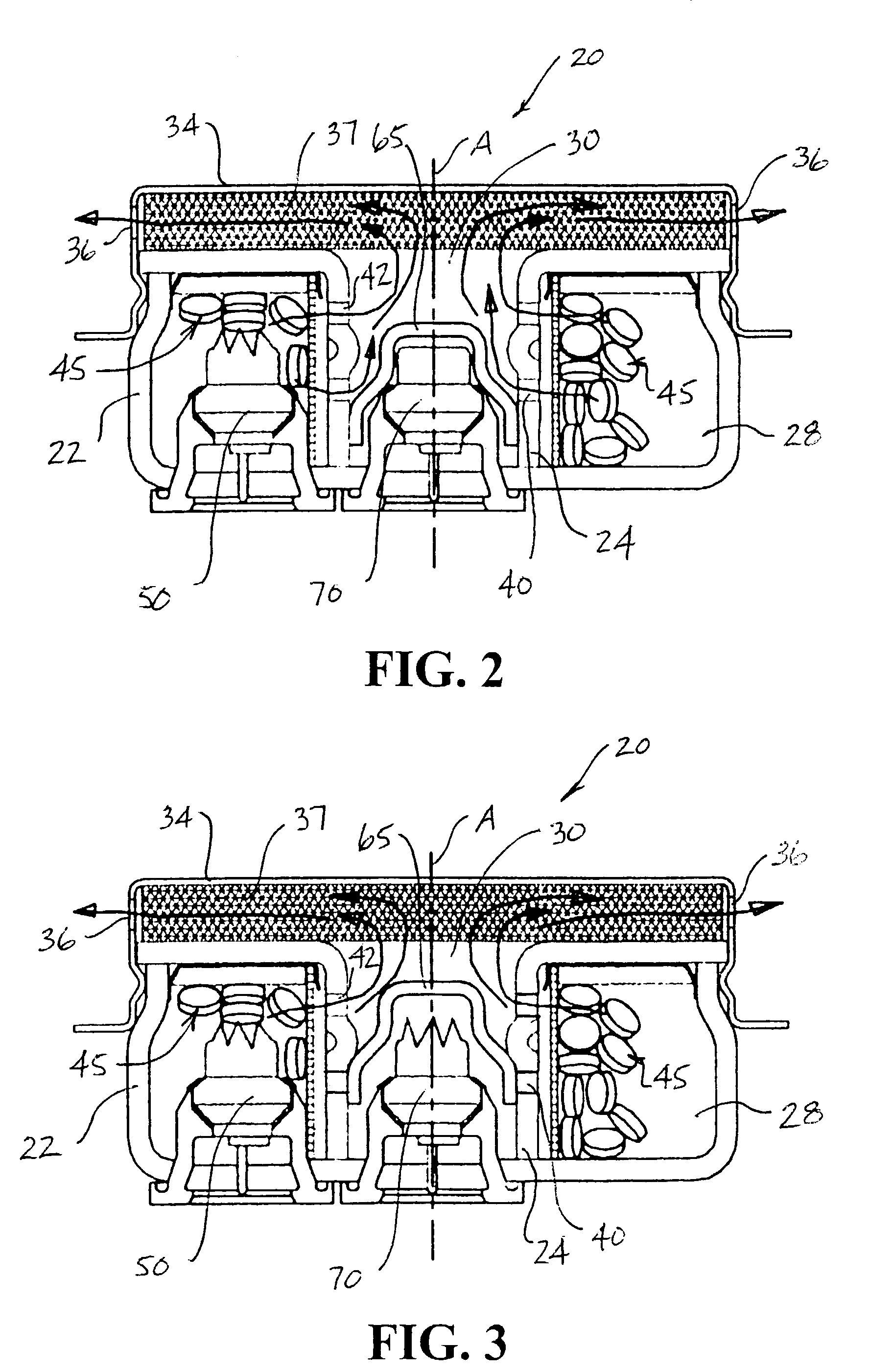

Drip emitter

A drip emitter is provided for delivering irrigation water from a supply tube to an emitter outlet at a reduced and relatively constant flow rate. Water enters the emitter through a first inlet and proceeds into a first chamber. When the water pressure is above a predetermined level, a one-directional valve opens to allow fluid flow past the first chamber, through a tortuous path flow channel, and through an emitter outlet. A second inlet is used to compensate for water pressure fluctuations in the supply tube to maintain output flow at a relatively constant rate. Water enters the second inlet and presses a flexible diaphragm toward a water metering surface to provide pressure-dependent control of the output flow. A copper member is mounted to the emitter over the emitter outlet to prevent plant root intrusion into the emitter outlet.

Owner:RAIN BIRD CORP

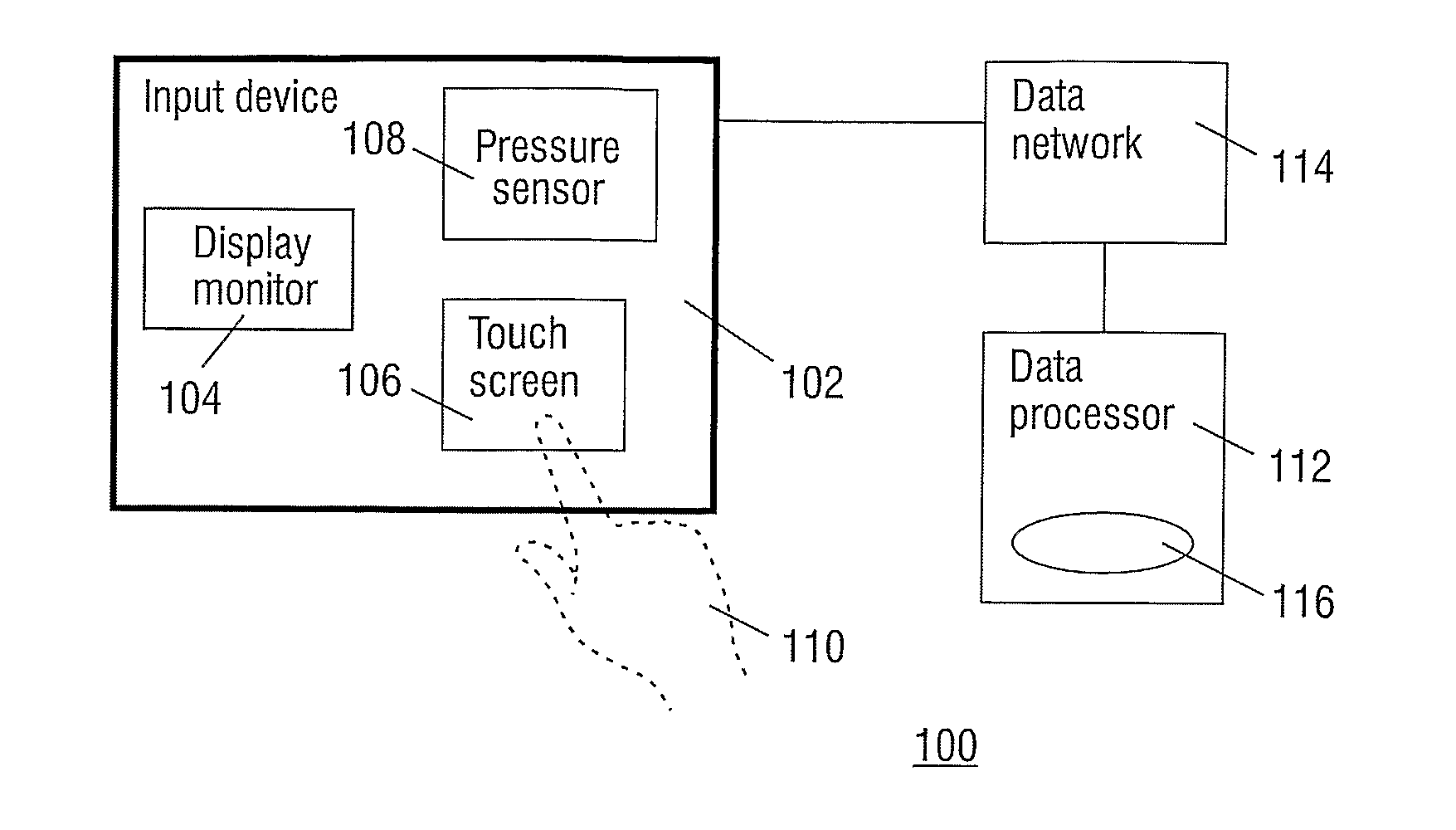

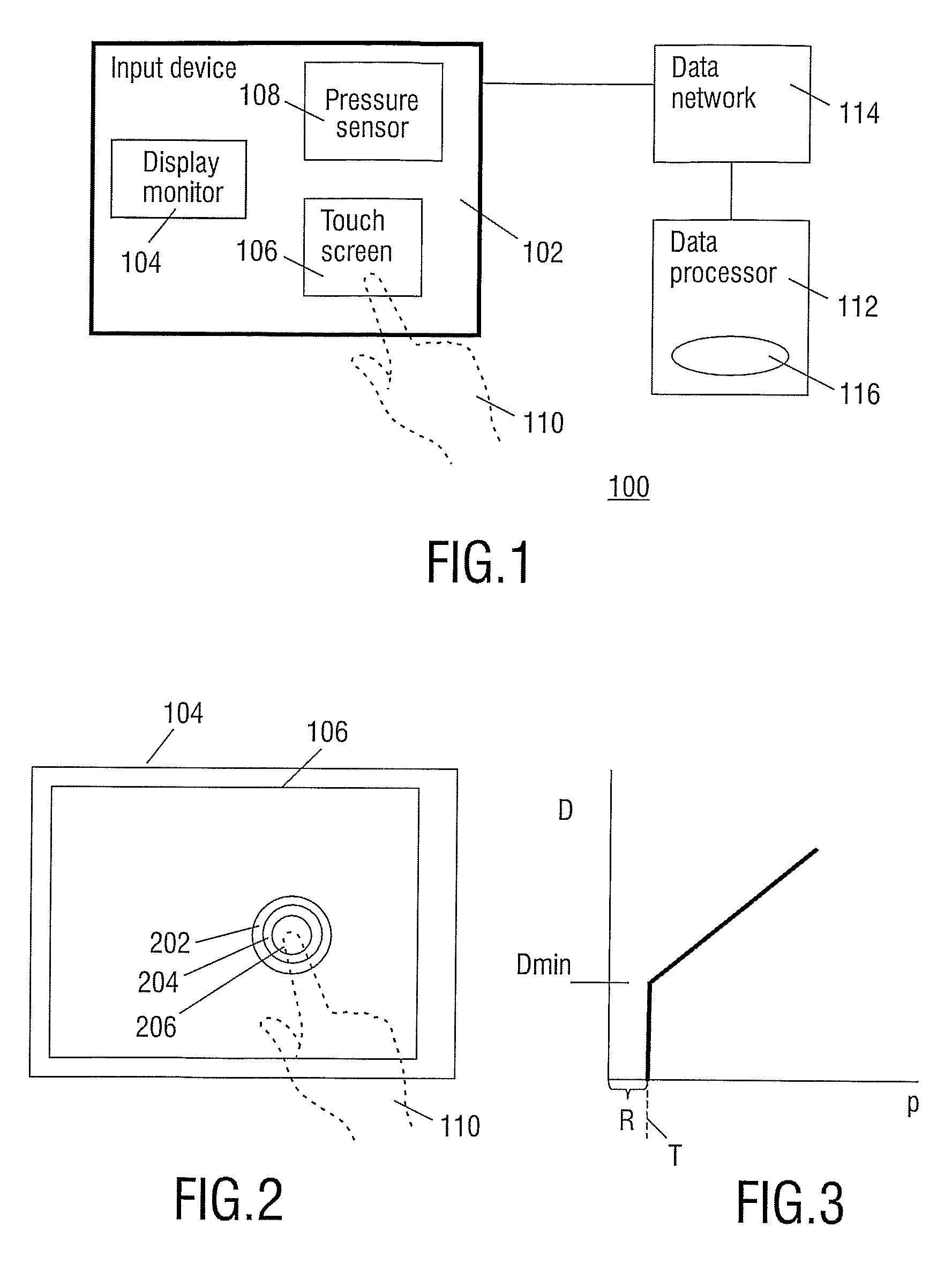

Touch screen with pressure-dependent visual feedback

A data processing system, e.g., a remote control device, has a pressure-sensitive touch screen arranged over a display monitor. The monitor provides a visual indication depending on a magnitude of a pressure registered by the touch screen. The indication is rendered as centered on the touch area and has an attribute that depends on the pressure exerted.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Pressure sensor

InactiveUS7770473B2Precise and reliable pressurePrecise and reliable resultsWeft knittingOrnamental textile articlesElectrical resistance and conductanceEngineering

The invention relates to a pressure sensor which can be incorporated into textile products. The pressure sensor includes a multilayer thread having a pressure sensitive layer exhibiting a pressure-dependent electrical resistance, and a conductive layer in contact with the pressure sensitive layer. Further, the sensor includes conductive threads in contact with the multilayer thread.

Owner:INGO MAYER GMBH & CO KG

Diagnostic method and apparatus for a pressurized gas supply system

ActiveUS20070125441A1Prevent fast fill ratePrevent excessive pressure riseLiquid fillingGas handling applicationsProduct gasEngineering

A diagnostic method for a gas supply system includes: determining a desired ramp rate for filling a vessel from a supply of compressed gas; monitoring the actual pressure of gas entering the vessel; and discontinuing the flow of gas into the vessel when the actual pressure deviates from the intended pressure at the desired ramp rate by an undesired amount. A system for carrying out the method includes a flow controller for controlling operation of the supply system to deliver compressed gas from a source to a vessel through a supply line at a desired ramp rate. The system employs a pressure monitor downstream of a control valve for measuring the pressure of gas directed into the vessel and transmitting pressure-related data to the flow controller, which closes the control valve to discontinue filling of the vessel if the actual pressure exceeds a permissible deviation from the intended pressure.

Owner:AIR PROD & CHEM INC

Drip emitter

A drip emitter is provided for delivering irrigation water from a supply tube to an emitter outlet at a reduced and relatively constant flow rate. Water enters the emitter through a first inlet and proceeds into a first chamber. When the water pressure is above a predetermined level, a one-directional valve opens to allow fluid flow past the first chamber, through a tortuous path flow channel, and through an emitter outlet. A second inlet is used to compensate for water pressure fluctuations in the supply tube to maintain output flow at a relatively constant rate. Water enters the second inlet and presses a flexible diaphragm toward a water metering surface to provide pressure-dependent control of the output flow. A copper member is mounted to the emitter over the emitter outlet to prevent plant root intrusion into the emitter outlet.

Owner:RAIN BIRD CORP

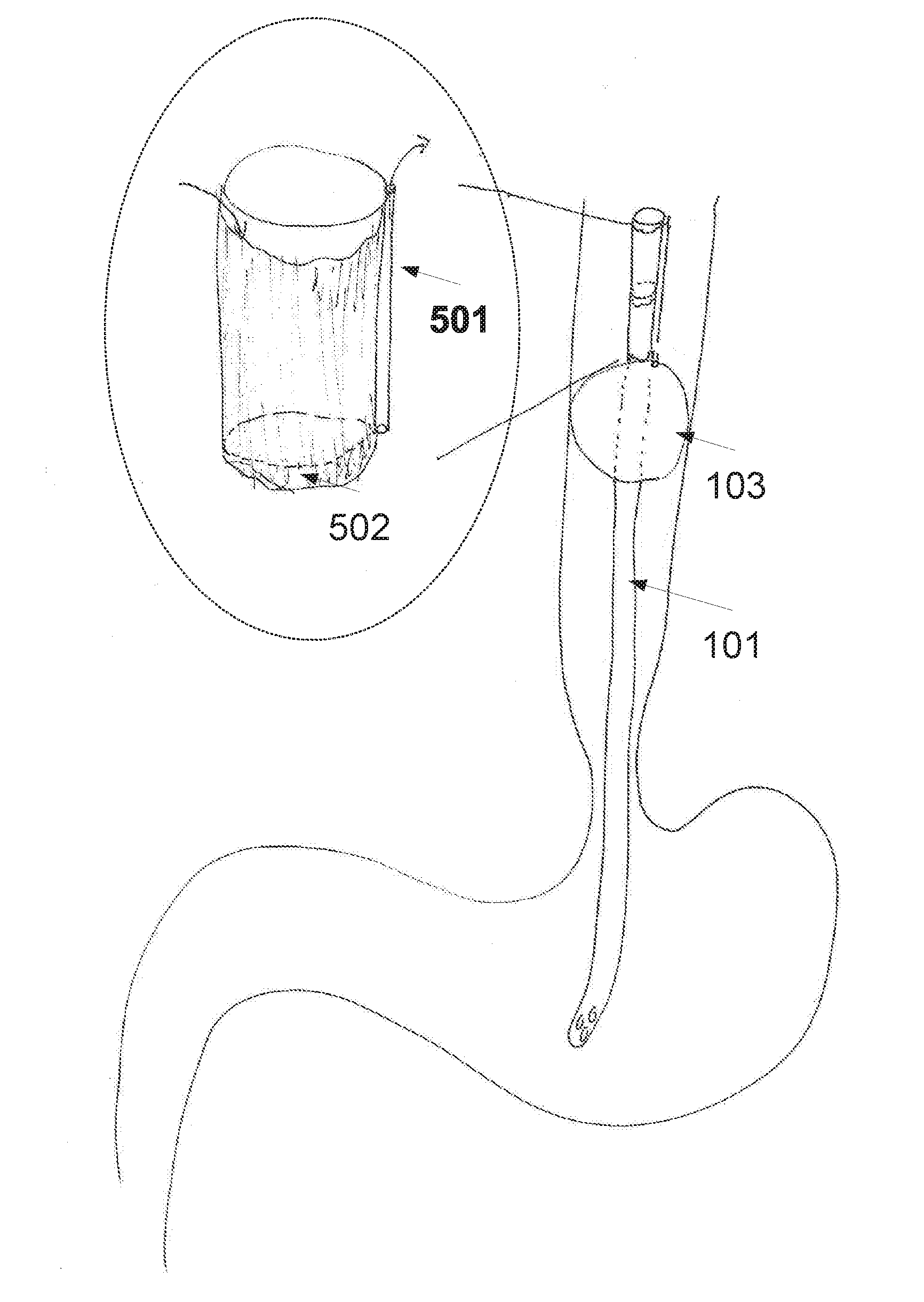

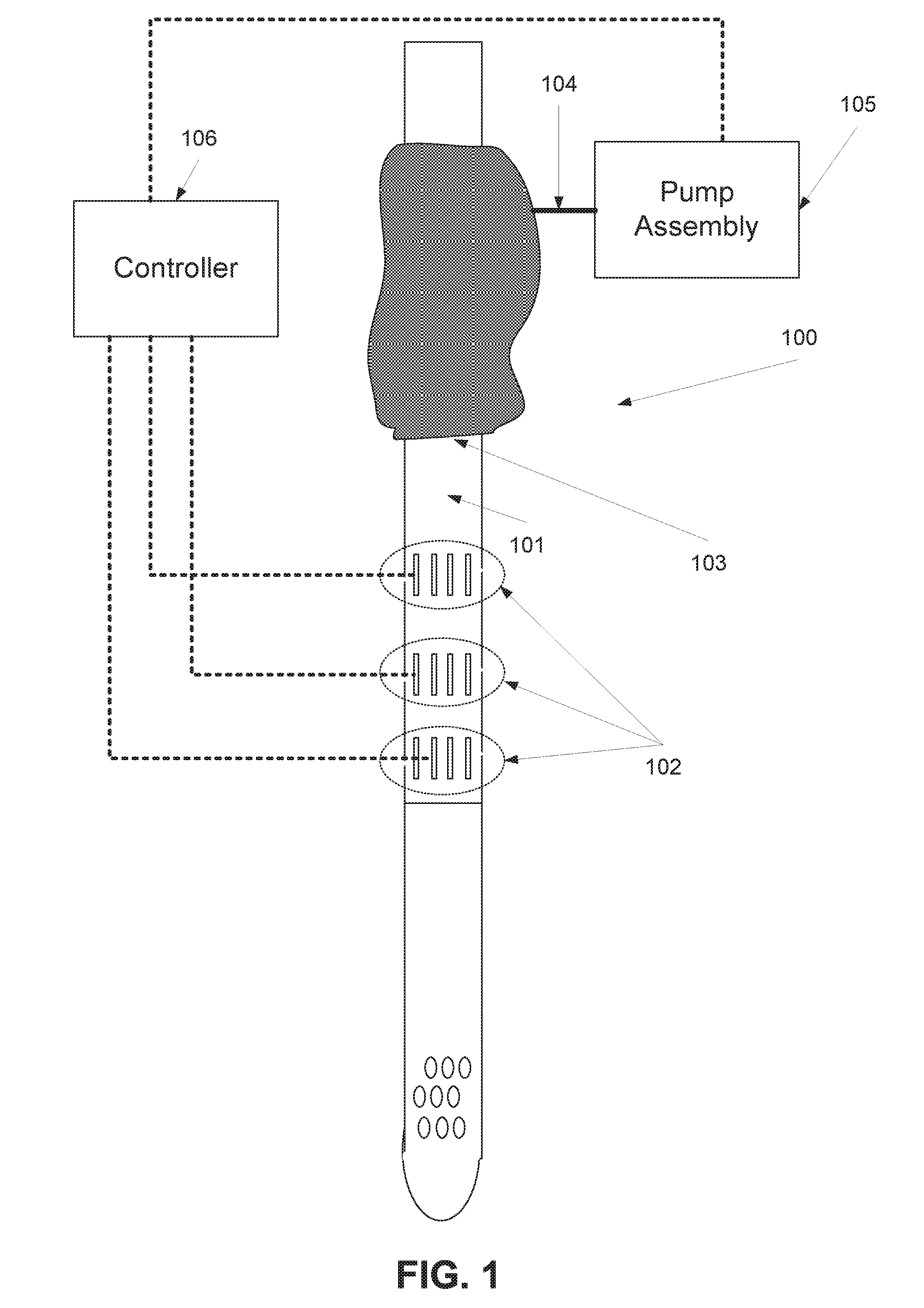

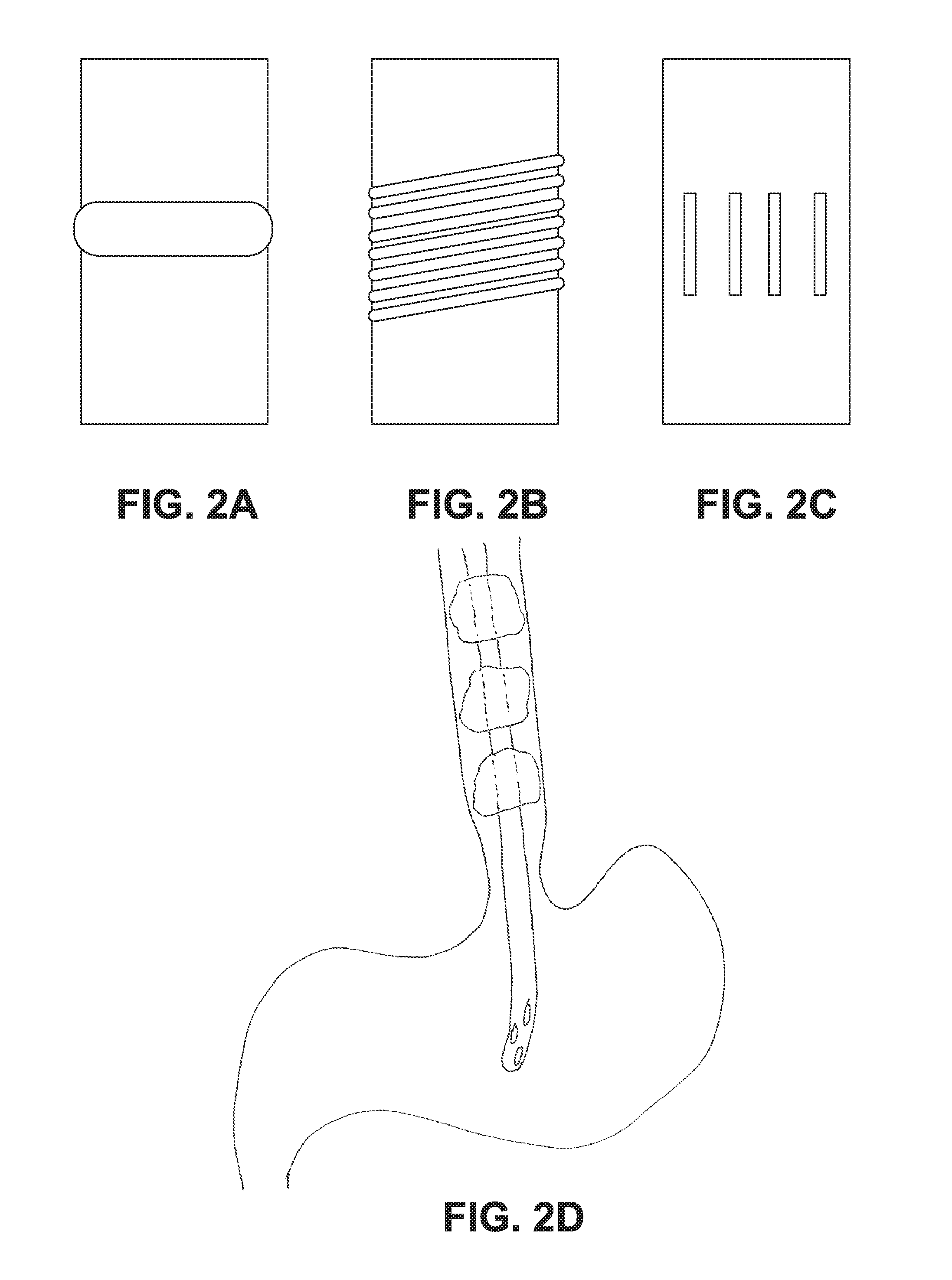

Method and device of detecting and/or blocking reflux

ActiveUS20160113843A1Increase air pressureImprove inflationMedical devicesDiagnostic recording/measuringRefluxOrogastric tube

A naso / orogastric device having backflow blocking means and comprises a naso / orogastric tube sized and shaped for being disposed within the esophagus so that at least a distal end thereof being placed in the stomach lumen of a patient, at least one elastic esophageal body, positioned along the naso / orogastric tube, having a pressure dependent volume, at least one esophageal sensor that detects fluid around at least one segment of the naso / orogastric tube, and a pressure regulator that regulates a pressure within the elastic esophageal body according to the detection.

Owner:ART HEALTHCARE

Pharmaceutical composition for the treatment of itch

Disclosed is a topical preparation for the treatment of topical itch in humans and animals. The said composition consists of Opuntia, Propolis, Stearic Acid, Beeswax, Vegetable Oil and β-sitosterol. Itch includes scratch reaction itch, anal itch, or irritant itch due to plants (e.g., poison ivy), insect bite, sunburn, chemical itch, eczema, pruritis dermatitis, diabetic skin itch, aging skin itch, foot-itch, chickenpox, jock itch, hives, itch of healing burns and wounds, dry winter skin itch, and stress-related scalp itch, etc

Owner:PBN PHARMA

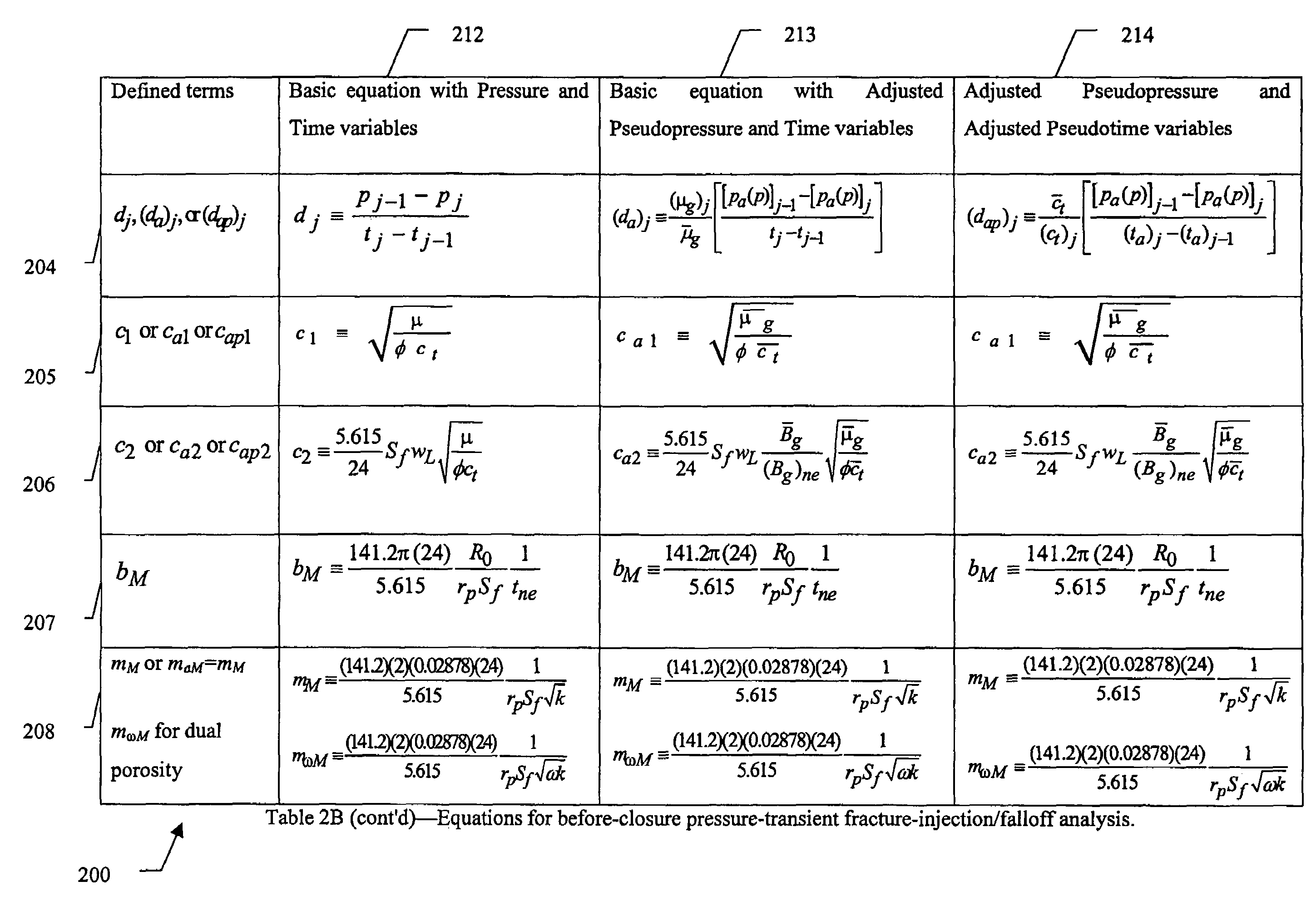

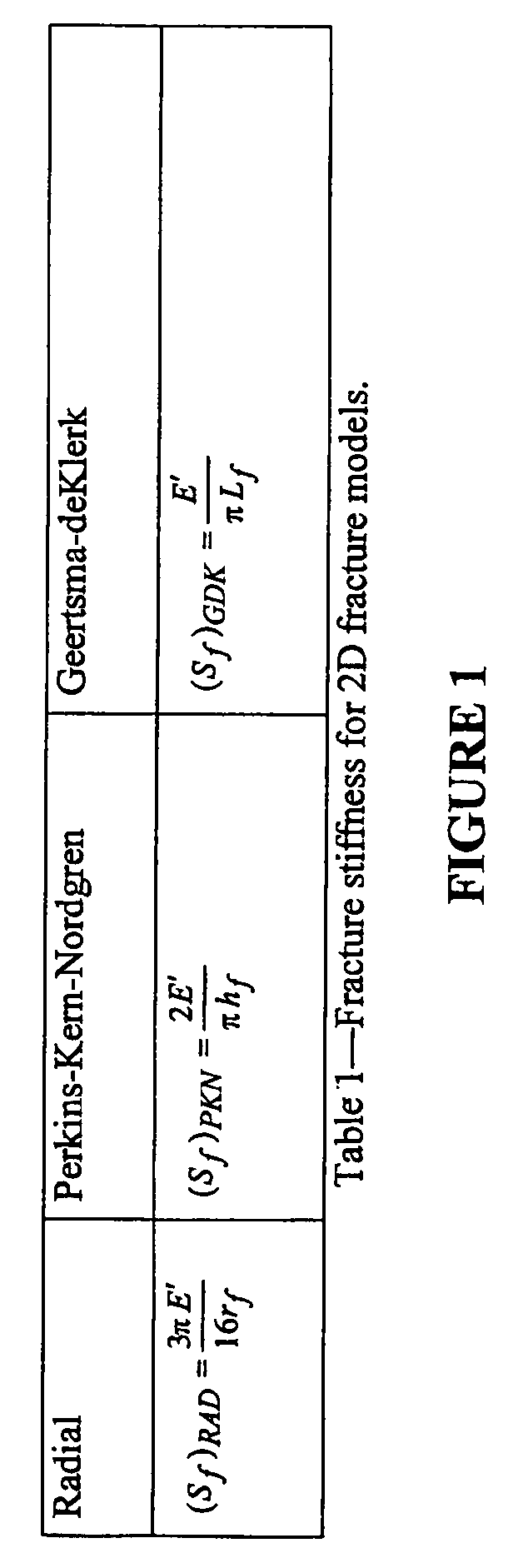

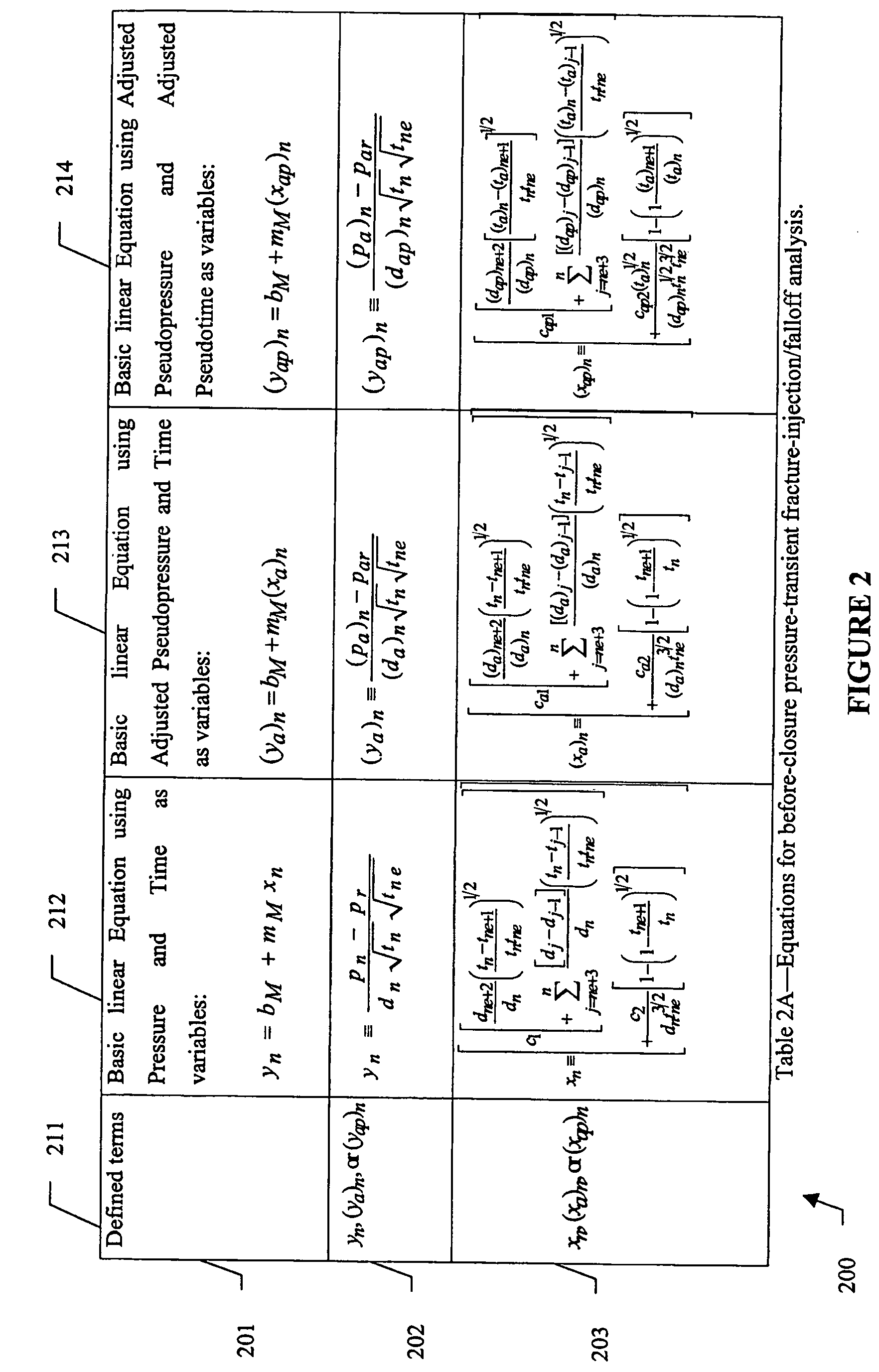

Methods and apparatus for estimating physical parameters of reservoirs using pressure transient fracture injection/falloff test analysis

ActiveUS7054751B2Reduce adverse effectsError minimizationElectric/magnetic detection for well-loggingPermeability/surface area analysisInjection pressureEmulsion

A before-closure pressure-transient leakoff analysis for a fracture-injection / falloff test is used to mitigate the detrimental effects of pressure-dependent fluid properties on the evaluation of physical parameters of a reservoir. A fracture-injection / falloff test consists of an injection of liquid, gas, or a combination (foam, emulsion, etc.) containing desirable additives for compatibility with the formation at an injection pressure exceeding the formation fracture pressure followed by a shut-in period. The pressure falloff during the shut-in period is measured and analyzed to determine permeability and fracture-face resistance by preparing a specialized Cartesian graph from the shut-in data using adjusted pseudodata such as adjusted pseudopressure data and time as variables in a first method, and adjusted pseudopressure and adjusted pseudotime data as variables in a second method.

Owner:HALLIBURTON ENERGY SERVICES INC

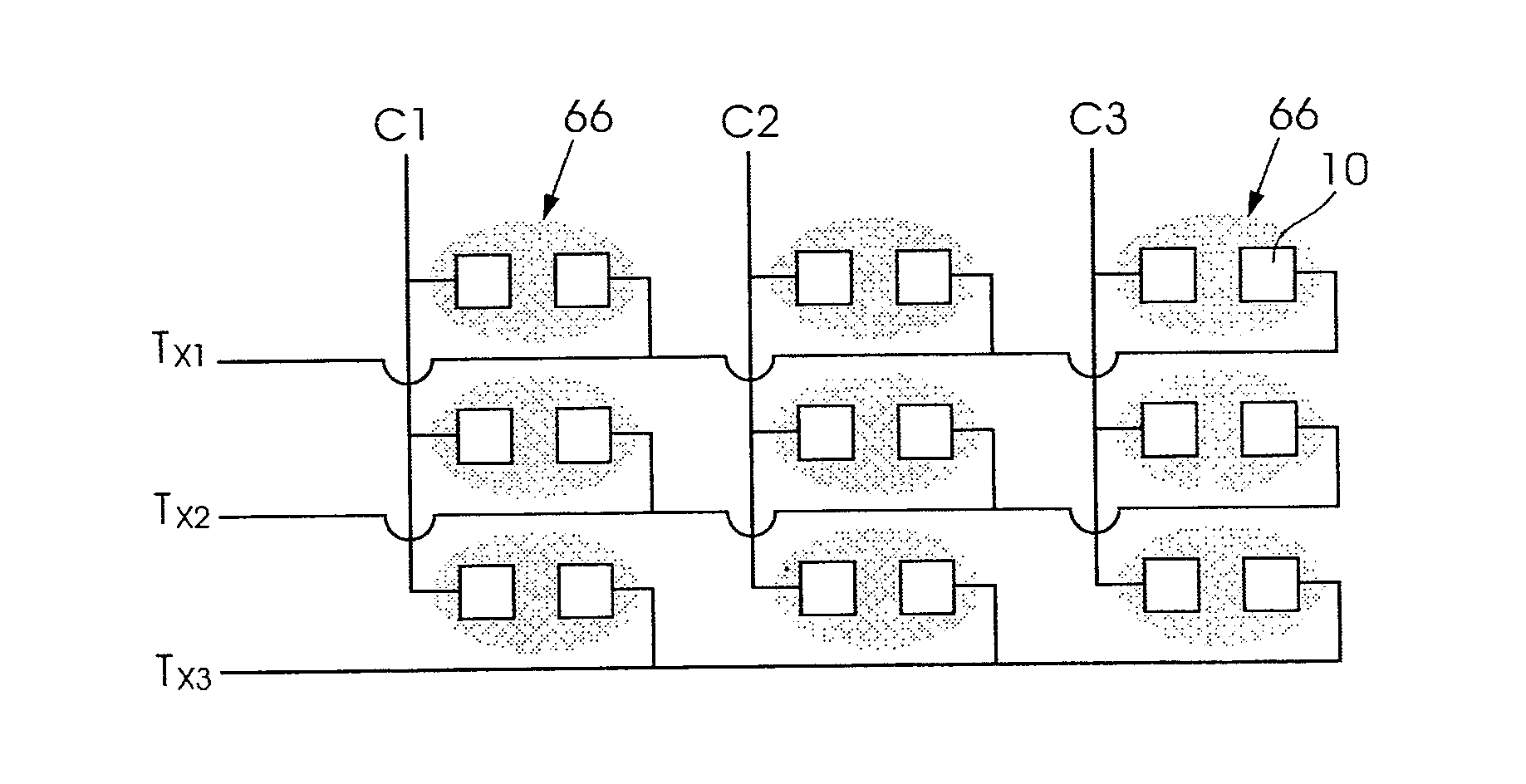

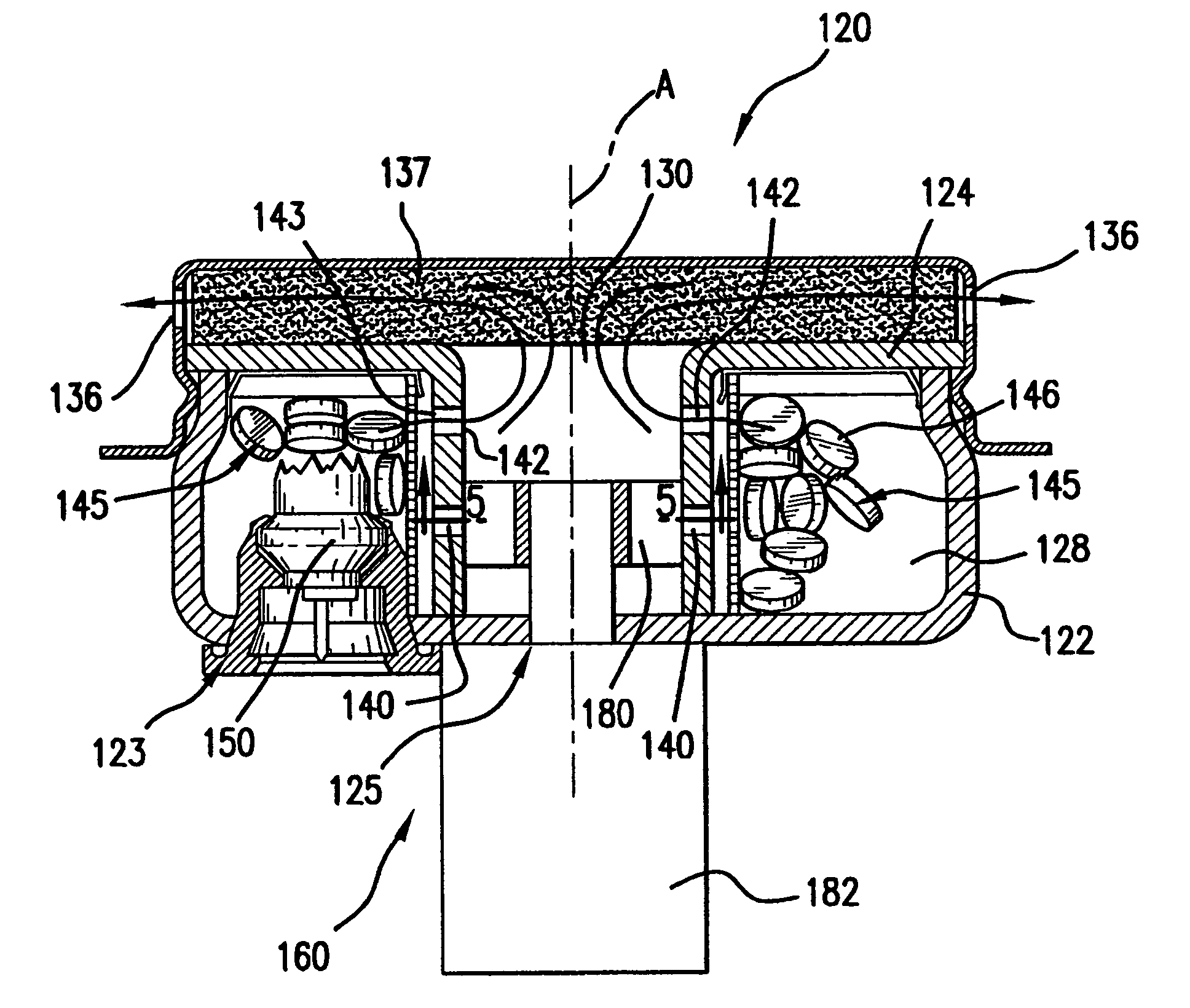

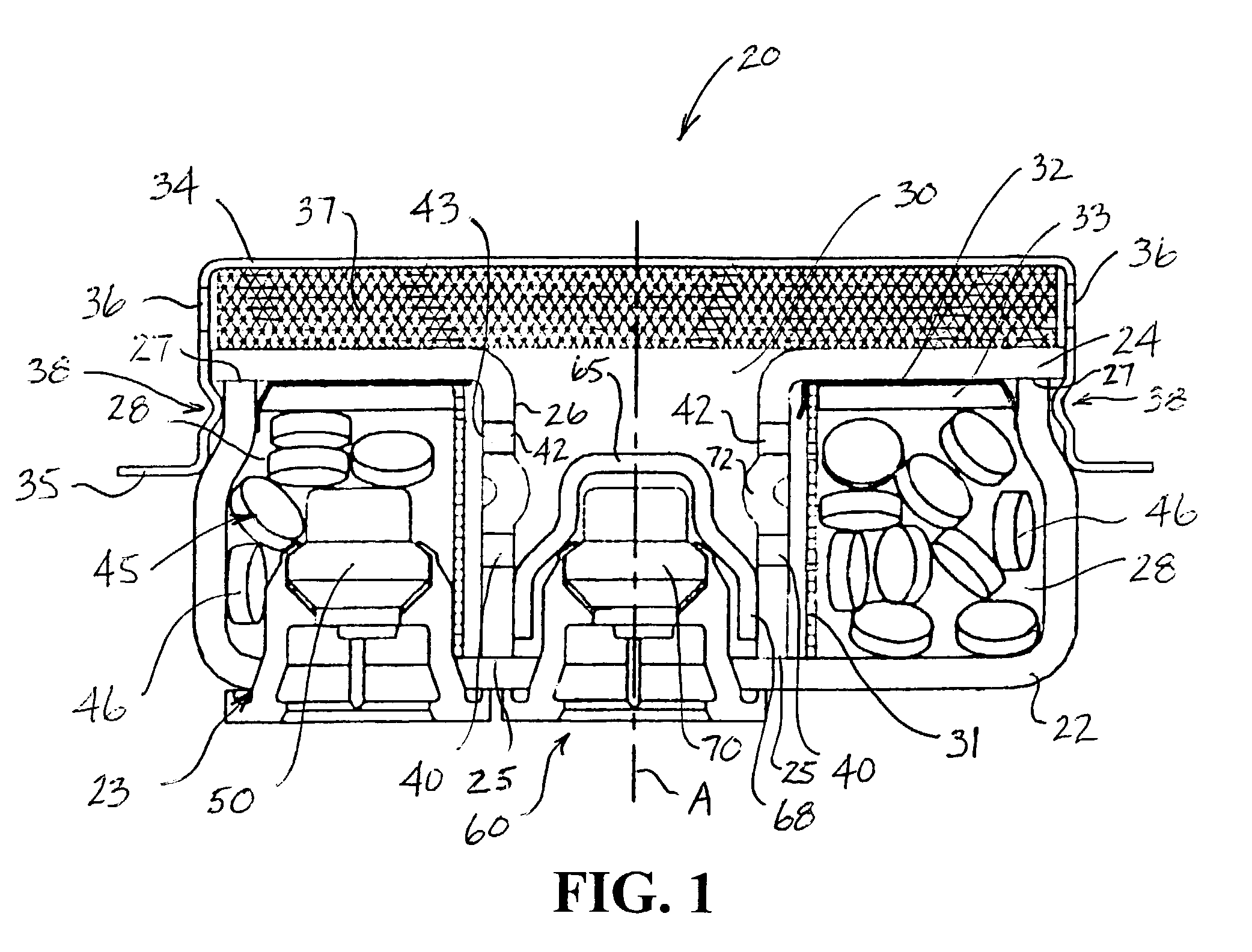

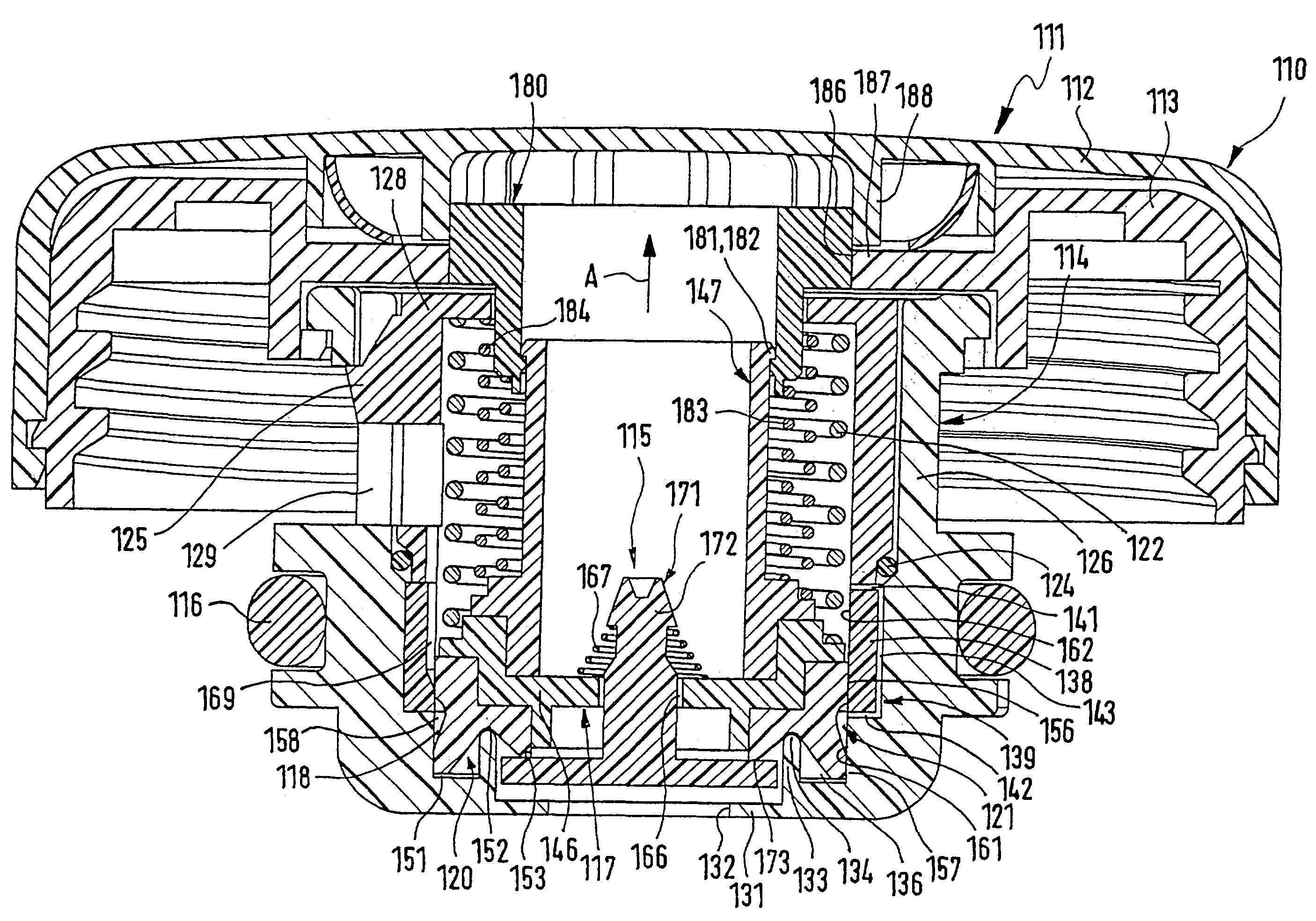

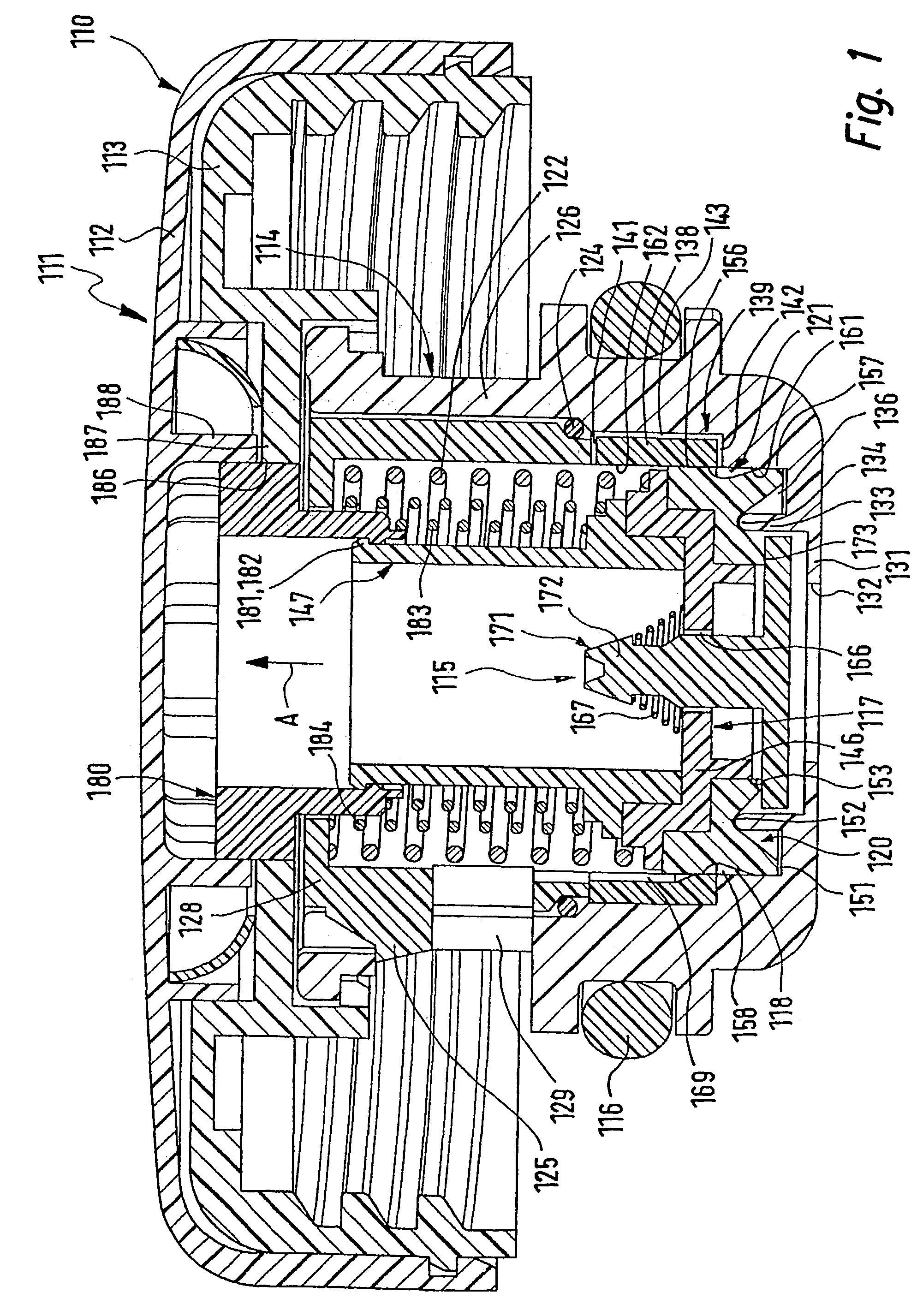

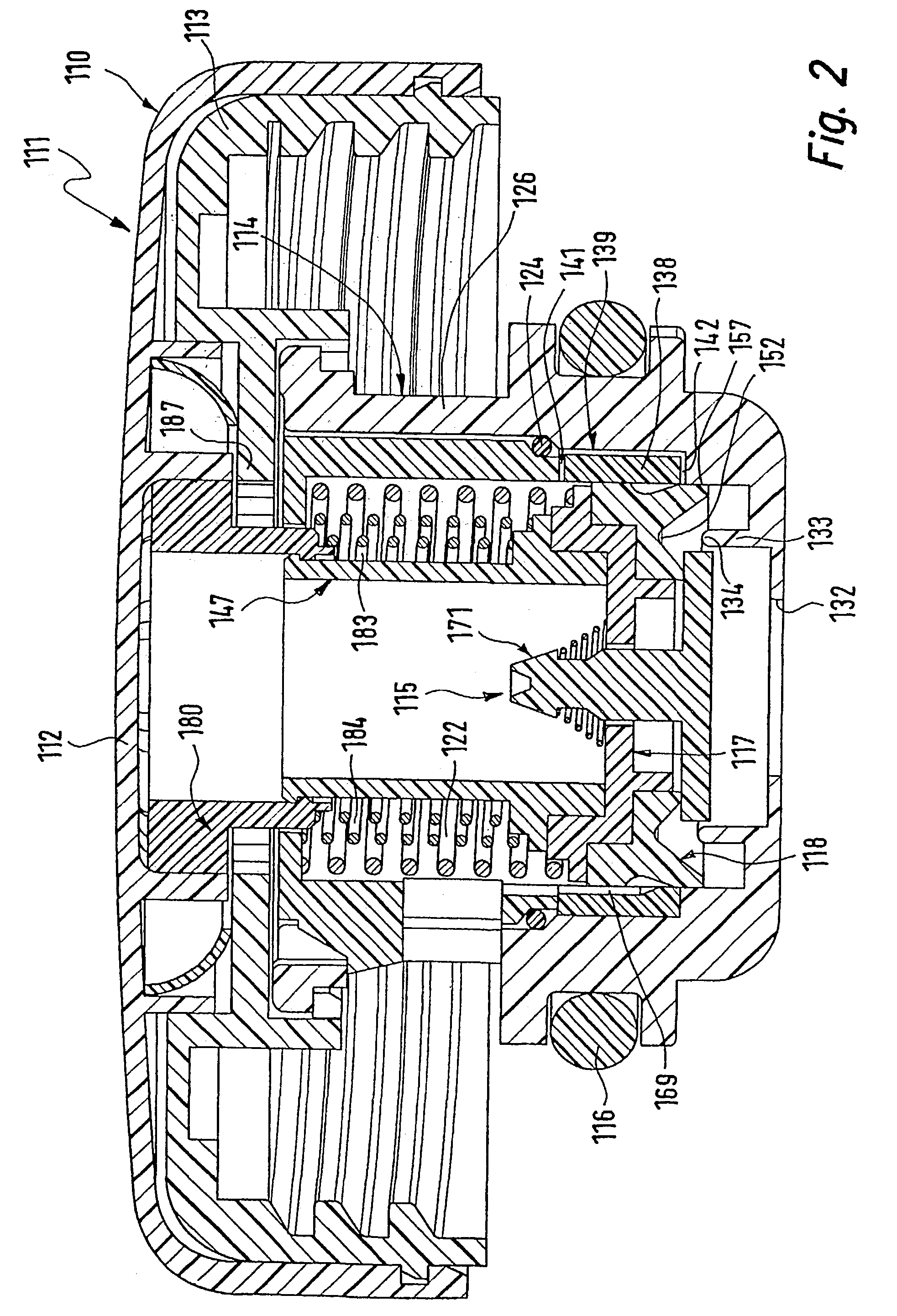

Adaptive output, toroidal-shaped pyrotechnic inflator

A toroidal-shaped adaptive output inflator is provided wherein the inflator includes an outer housing and an inner housing together defining an outer chamber and an inner chamber. A supply of gas-generating pyrotechnic material having a burn rate that is pressure dependent is contained within the outer chamber and at least a portion of the supply of gas-generating pyrotechnic material is reactable to generate a product gas. The inflator also includes a first plurality of apertures and a second plurality of apertures each formed in the inner housing, and each providing independent fluidic communication between the outer chamber and the inner chamber wherethrough at least a portion of the product gas can exit the outer chamber into the inner chamber. An output control device positioned within the inner chamber is movable or rotatable between a first or open position allowing fluidic communication between the outer chamber and the inner chamber through the first plurality of apertures and the second plurality of apertures, and a second or closed position at least partially obstructing fluidic communication between the outer chamber and the inner chamber through at least one of the first plurality of apertures. Also provided is a control assembly in operational control communication with the inflator and associated or related methods for adjusting inflation gas output from the inflator.

Owner:AUTOLIV ASP INC

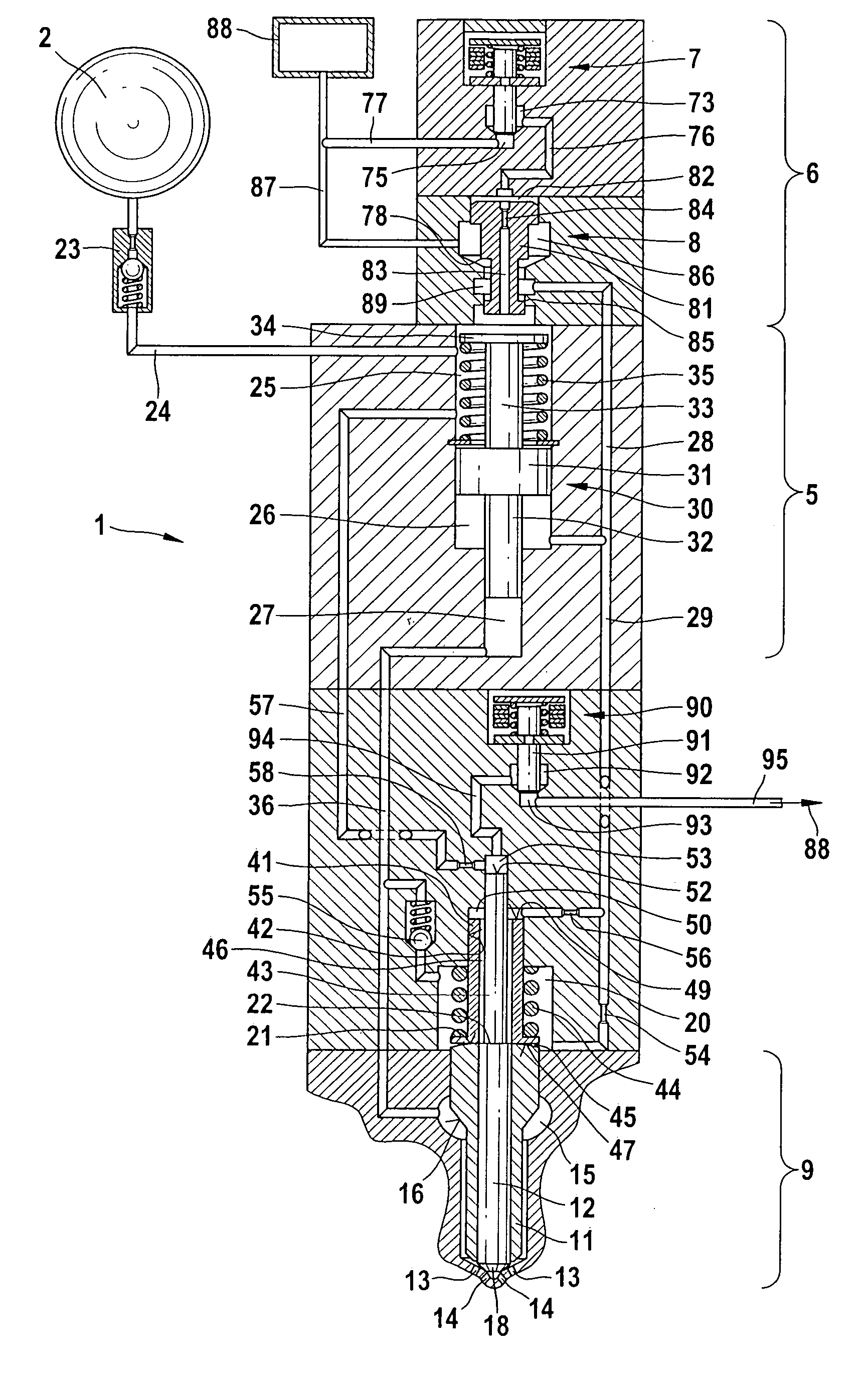

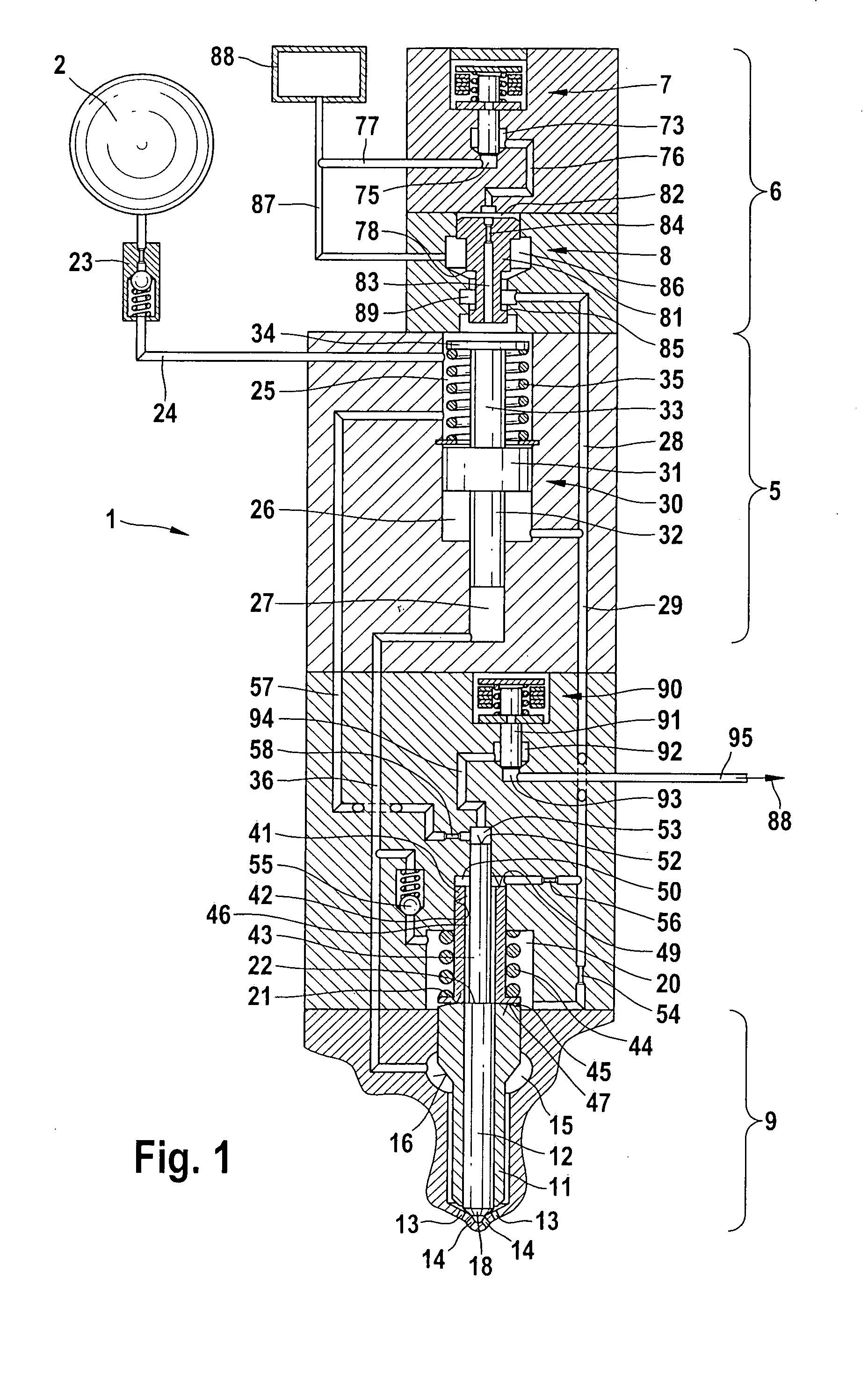

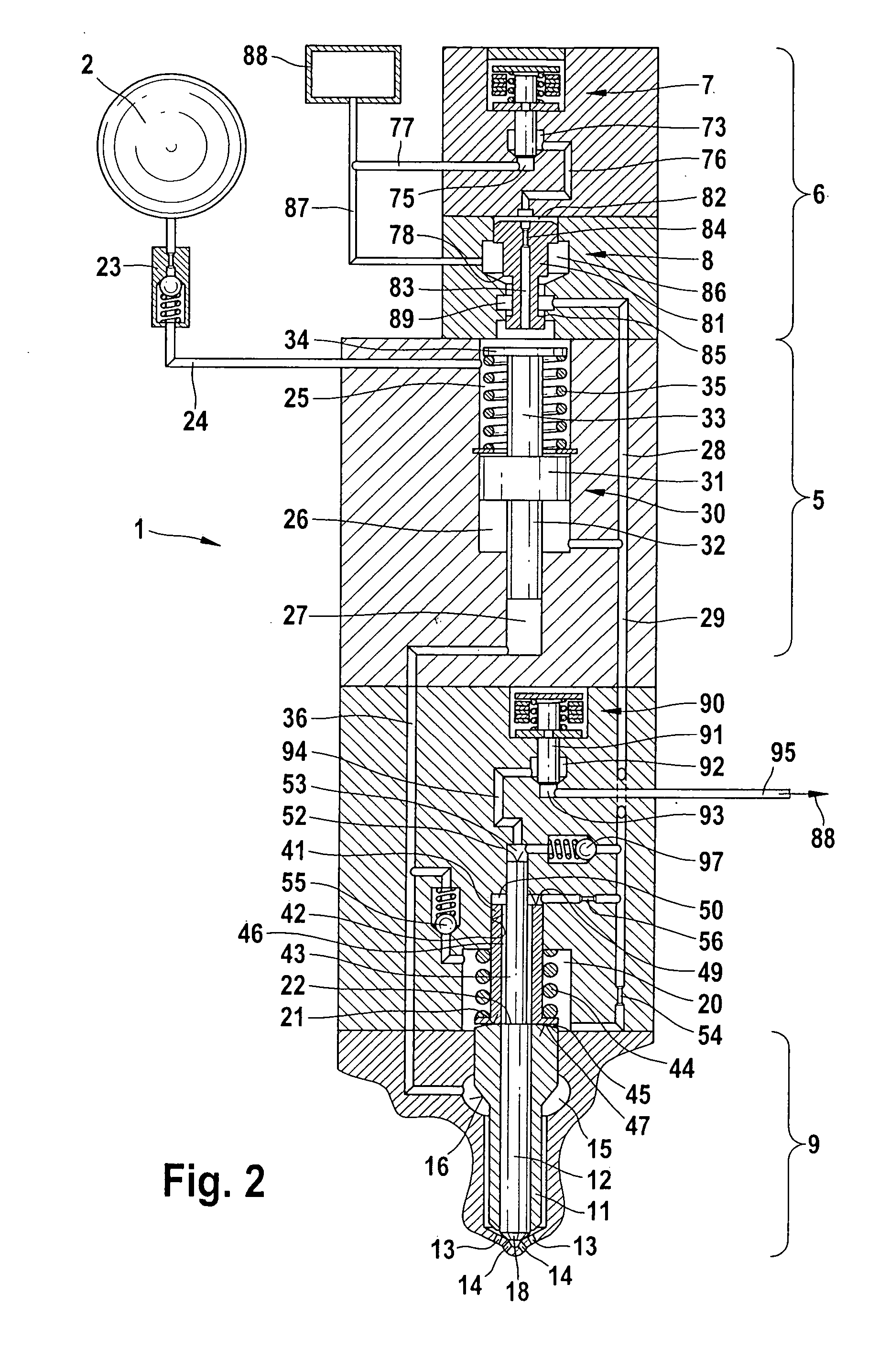

Fuel injection apparatus for internal combustion engines, with nozzle needles that can be actuated directly

InactiveUS20050224600A1Improve adaptabilityMeet demandMachines/enginesFuel injecting pumpsCombustionControl room

A fuel injection apparatus having a fuel injector fed by a high-pressure fuel source and having an injection valve with injection nozzles associated with coaxial inner and outer nozzle needles can be actuated in a pressure-dependent manner to open and close various injection cross sections at the injection nozzles. A pressure surface of the outer nozzle needle is associated with a closing chamber. To actuate the outer nozzle needle, a first on / off valve can connect the closing chamber to a low-pressure / return system. The inner nozzle needle has a control piston whose pressure surface protrudes into a second control chamber, and a second on / off valve is can connect the control chamber to the low-pressure / return system so that when the second on / off valve is actuated, the pressure is relieved in the second control chamber. This permits a separate actuation of the outer nozzle needle and inner nozzle needle.

Owner:ROBERT BOSCH GMBH

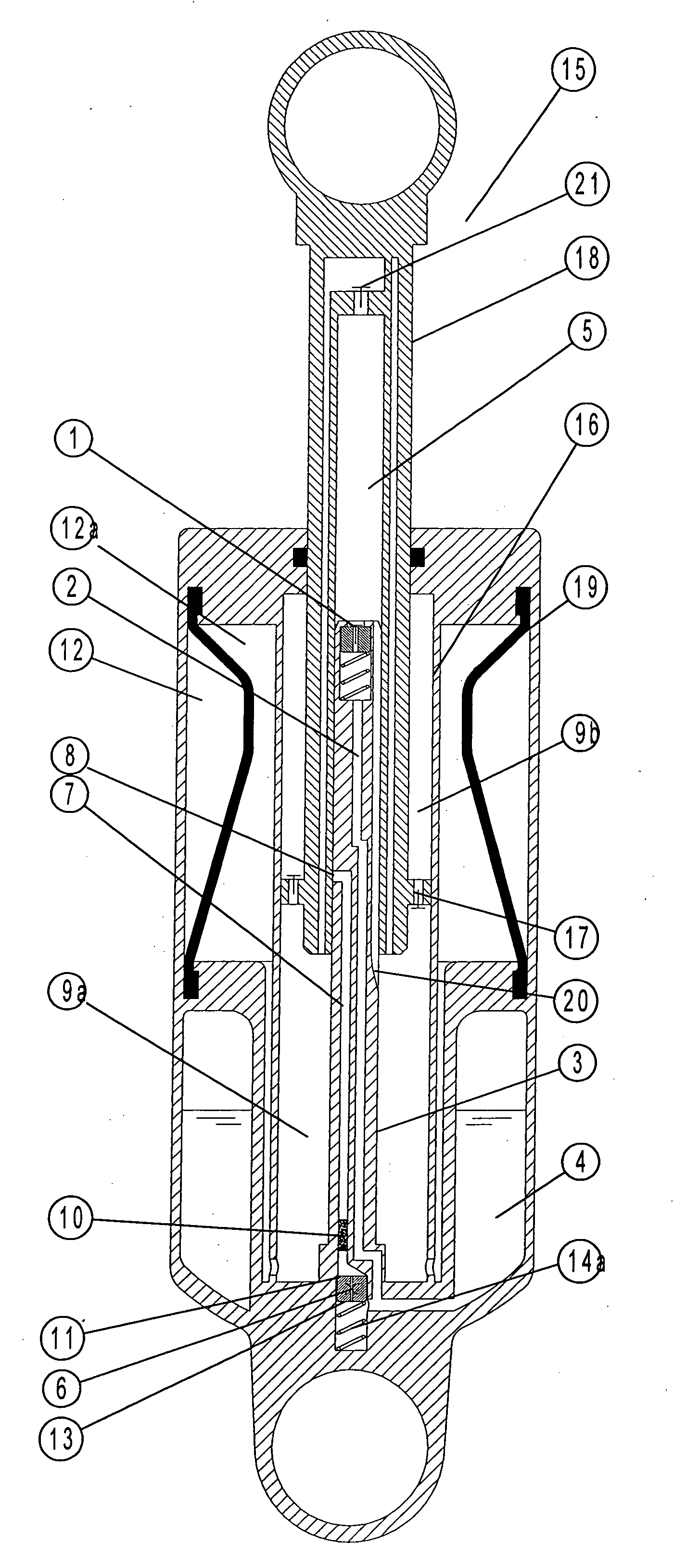

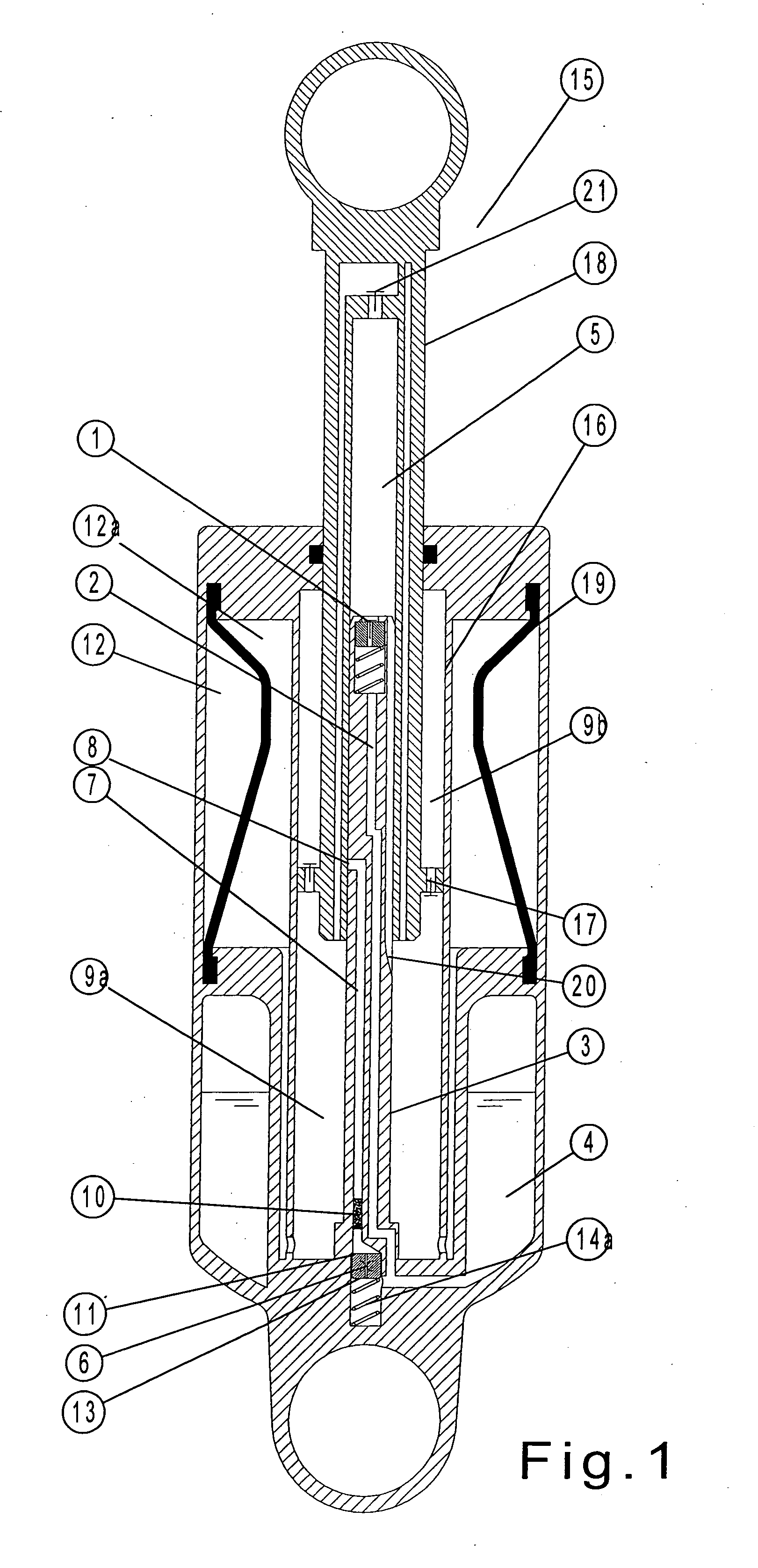

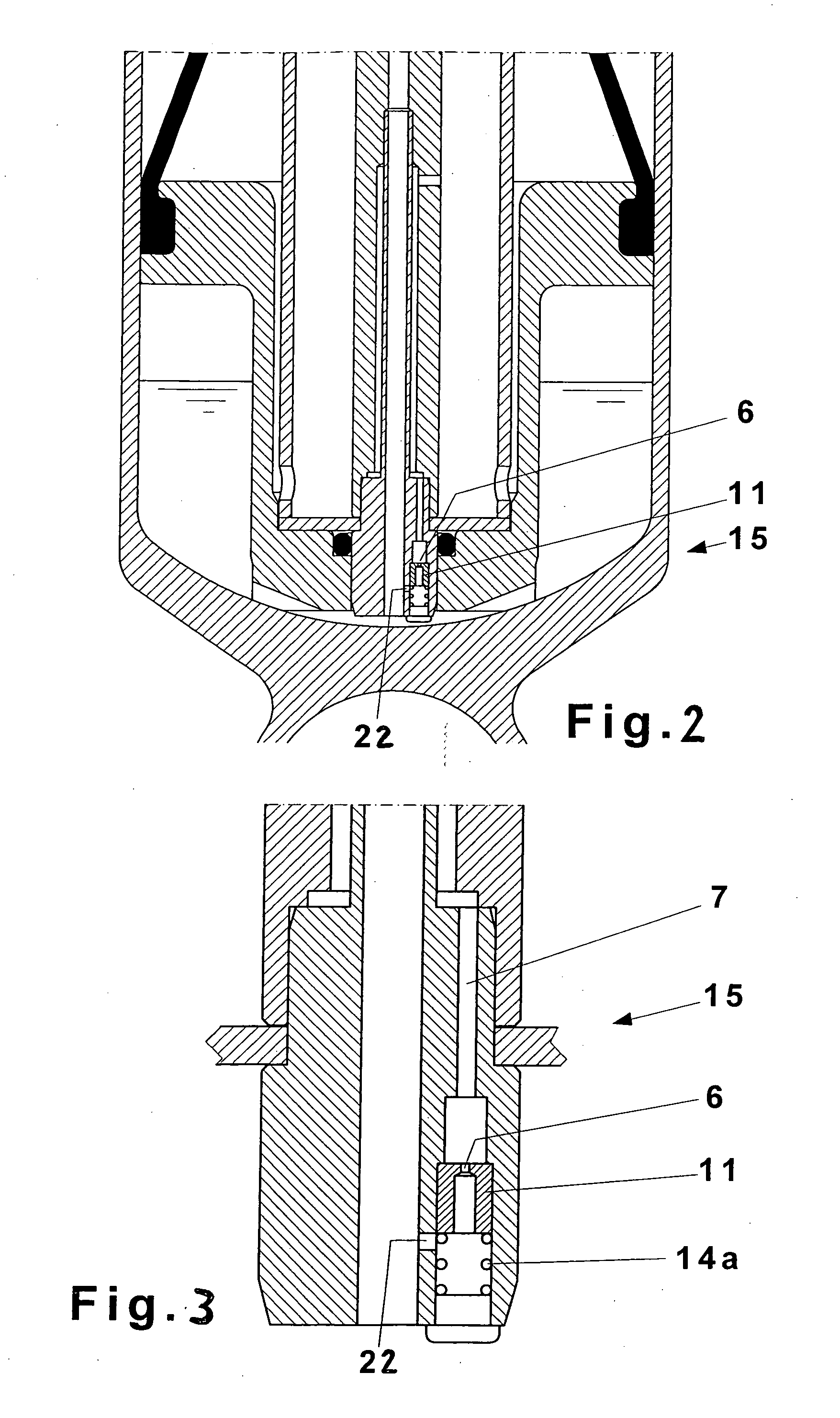

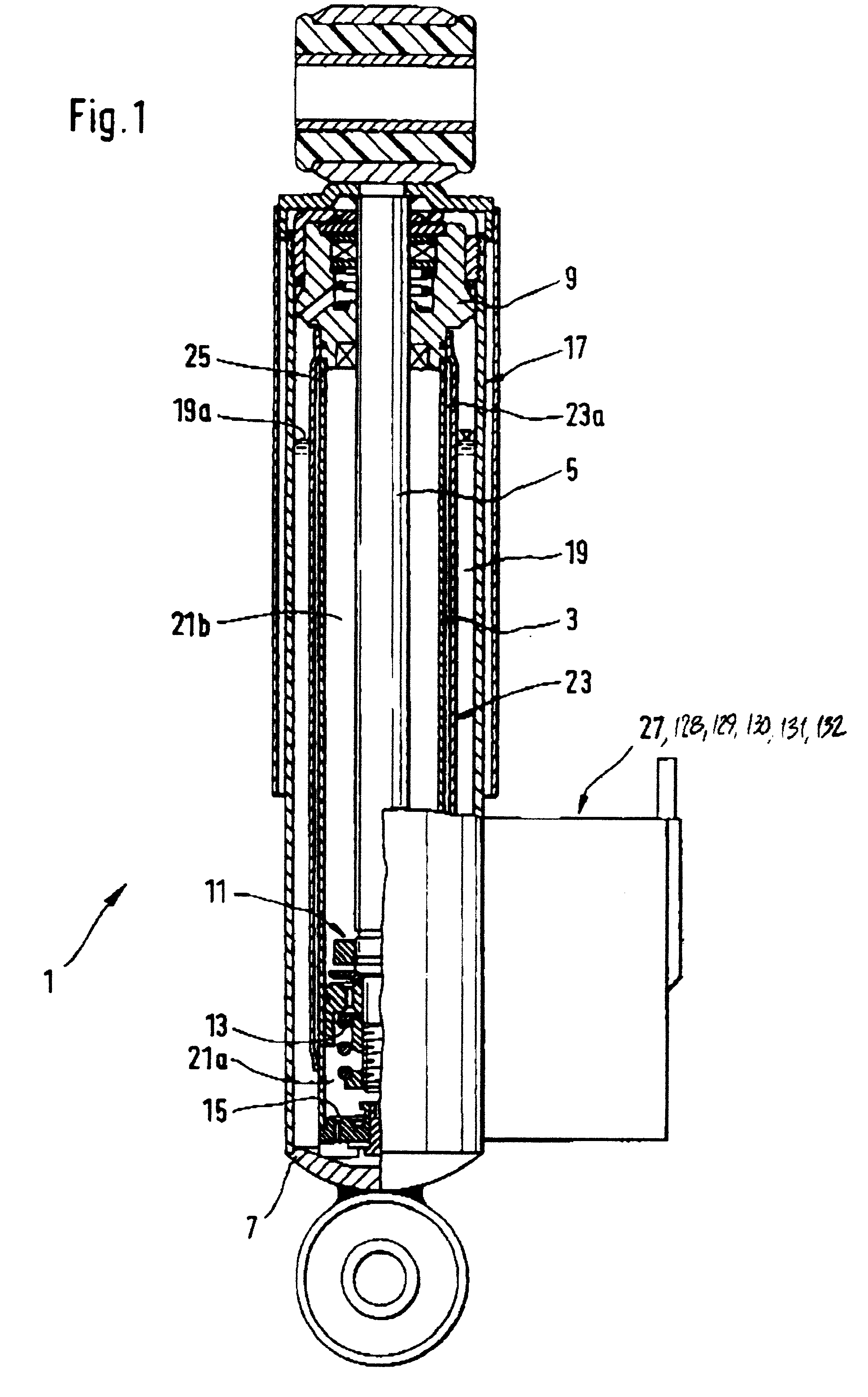

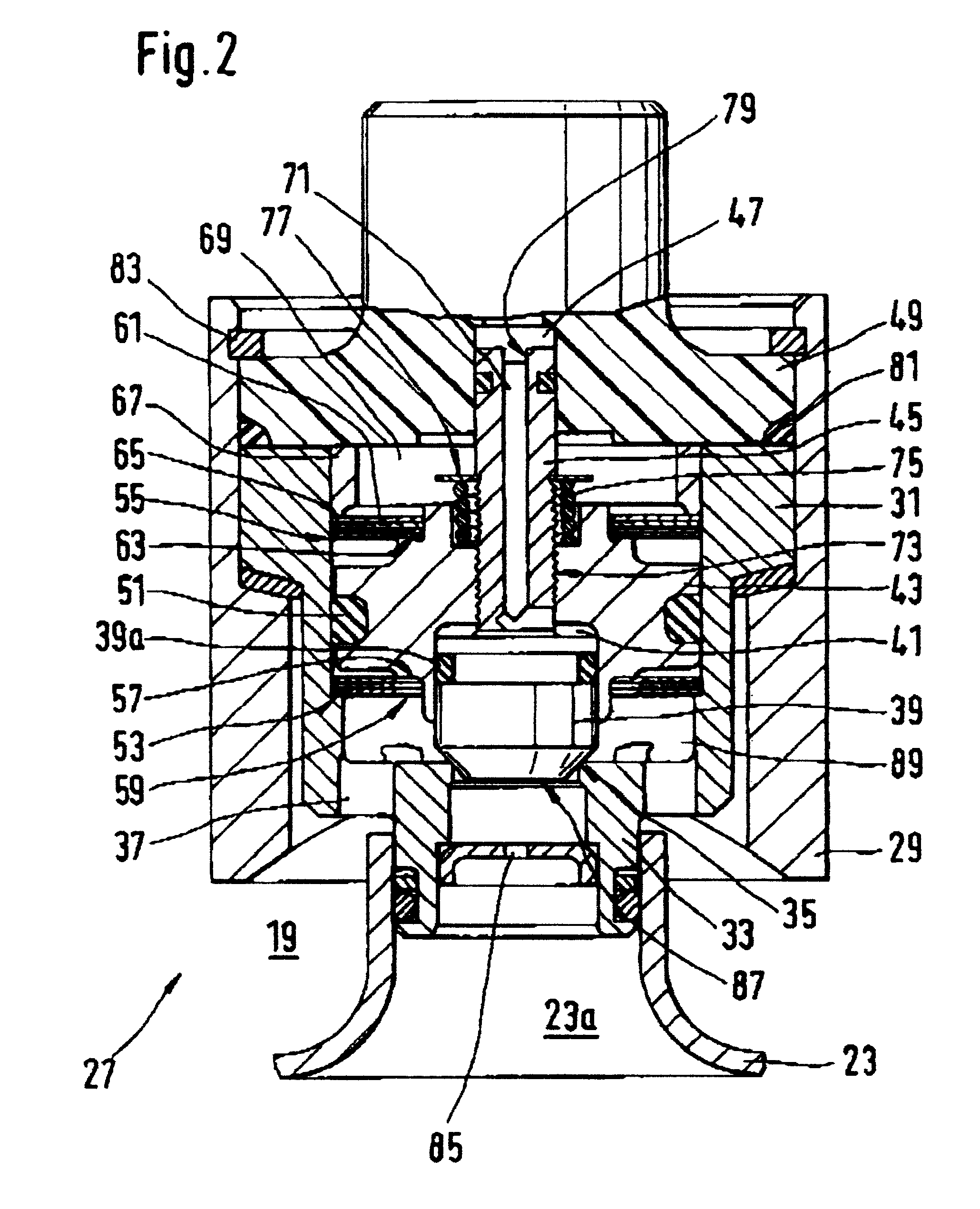

Self-pumping hydropneumatic spring-damper unit

A self-pumping hydropneumatic spring-damper unit with internal leveling control is provided. The spring-damper unit has an oil-filled work cylinder under pressure by gas cushions. A damping piston is displaceable in the work cylinder and arranged at the end of a hollow piston rod whose hollow space serves to receive a pump by means of a pump rod fastened to the work cylinder. Damping medium is sucked out of a reservoir space when the piston rod moves outward and is conveyed into the work space when the piston rod moves inward. The pump rod has a control opening and, at a distance therefrom, an outlet bore for pressure equilibrium between work spaces in the work cylinder. At least one pressure-dependent throttle point is provided in the pump space between the high-pressure and low-pressure gas cushions. A first flow connection in the pump rod provided with at least one check valve connects the low-pressure gas cushion to the pump space. A second flow connection having the throttle point is connected to the work space by the outlet bore.

Owner:ZF FRIEDRICHSHAFEN AG

Method and device of detecting and/or blocking reflux

ActiveUS9226878B2Increase air pressureImprove inflationDiagnostic recording/measuringSensorsRefluxOrogastric tube

Owner:ART HEALTHCARE

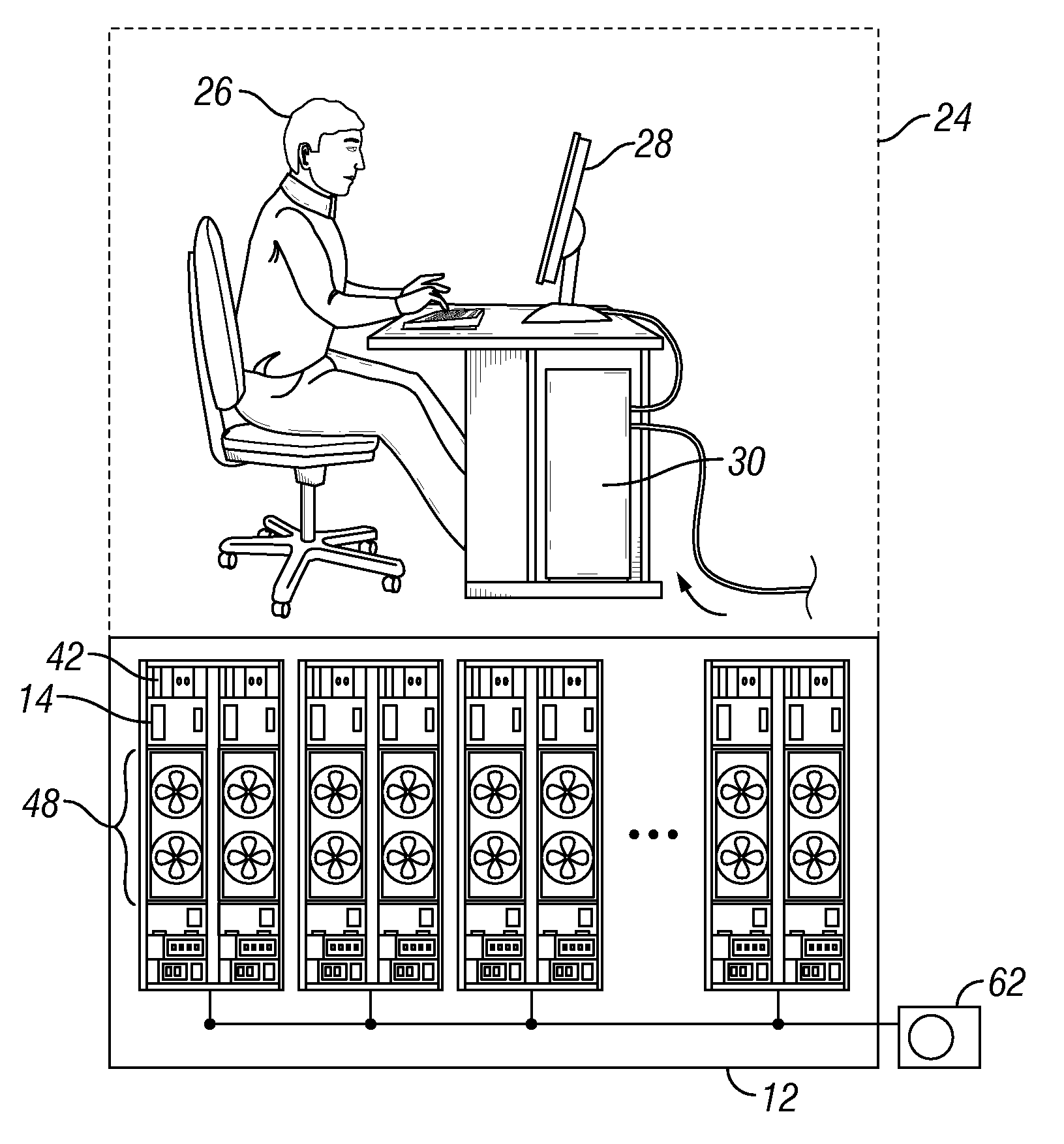

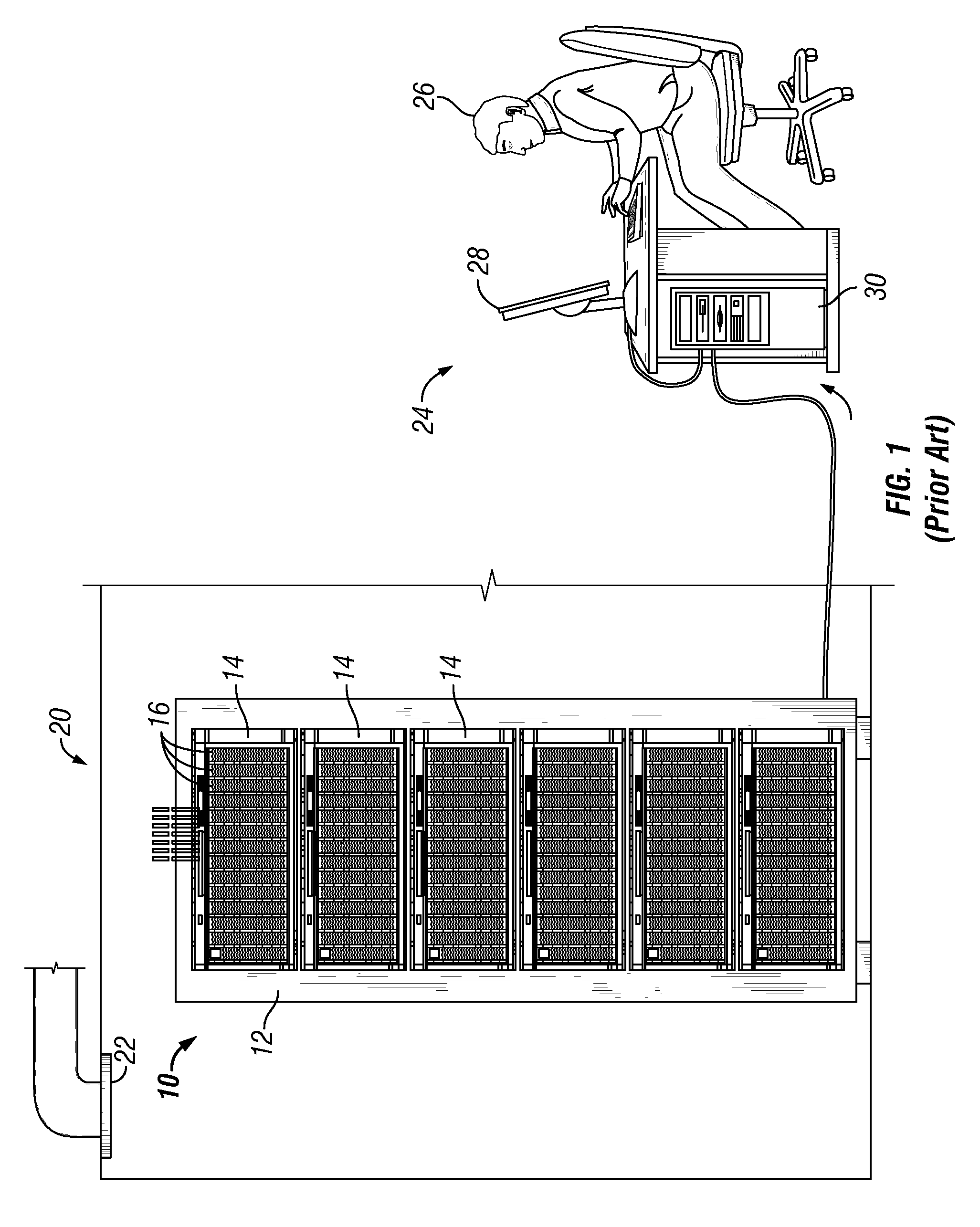

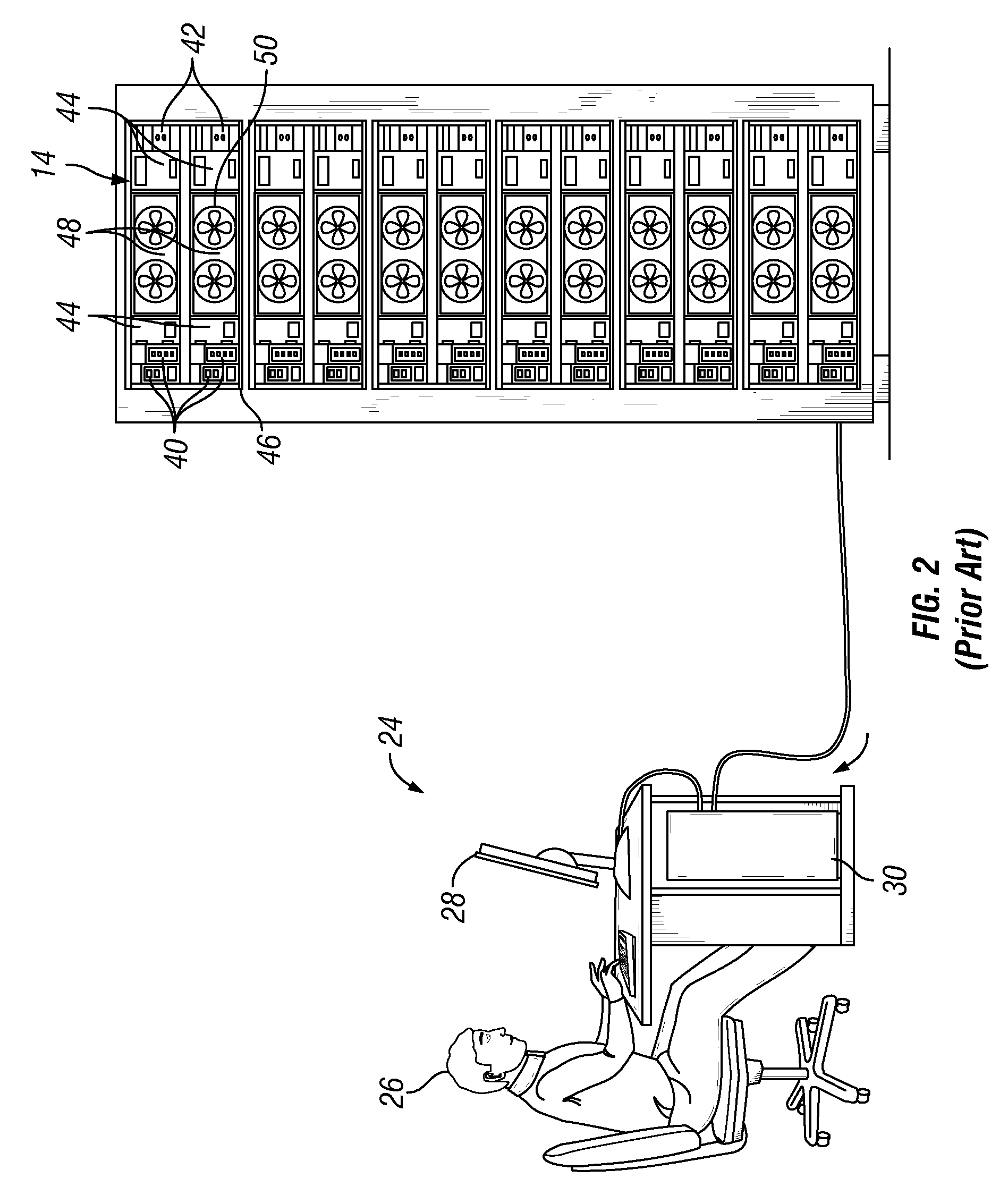

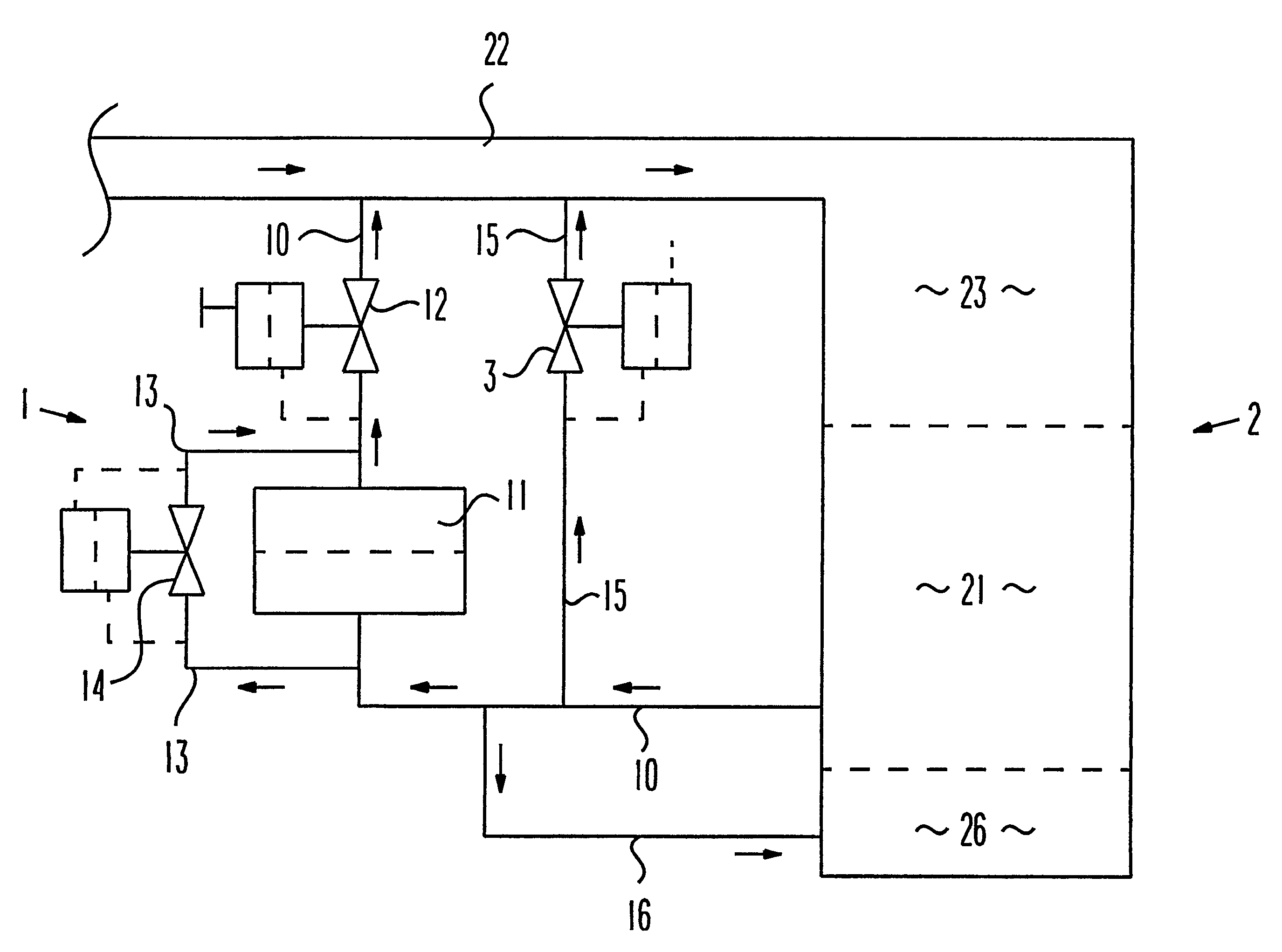

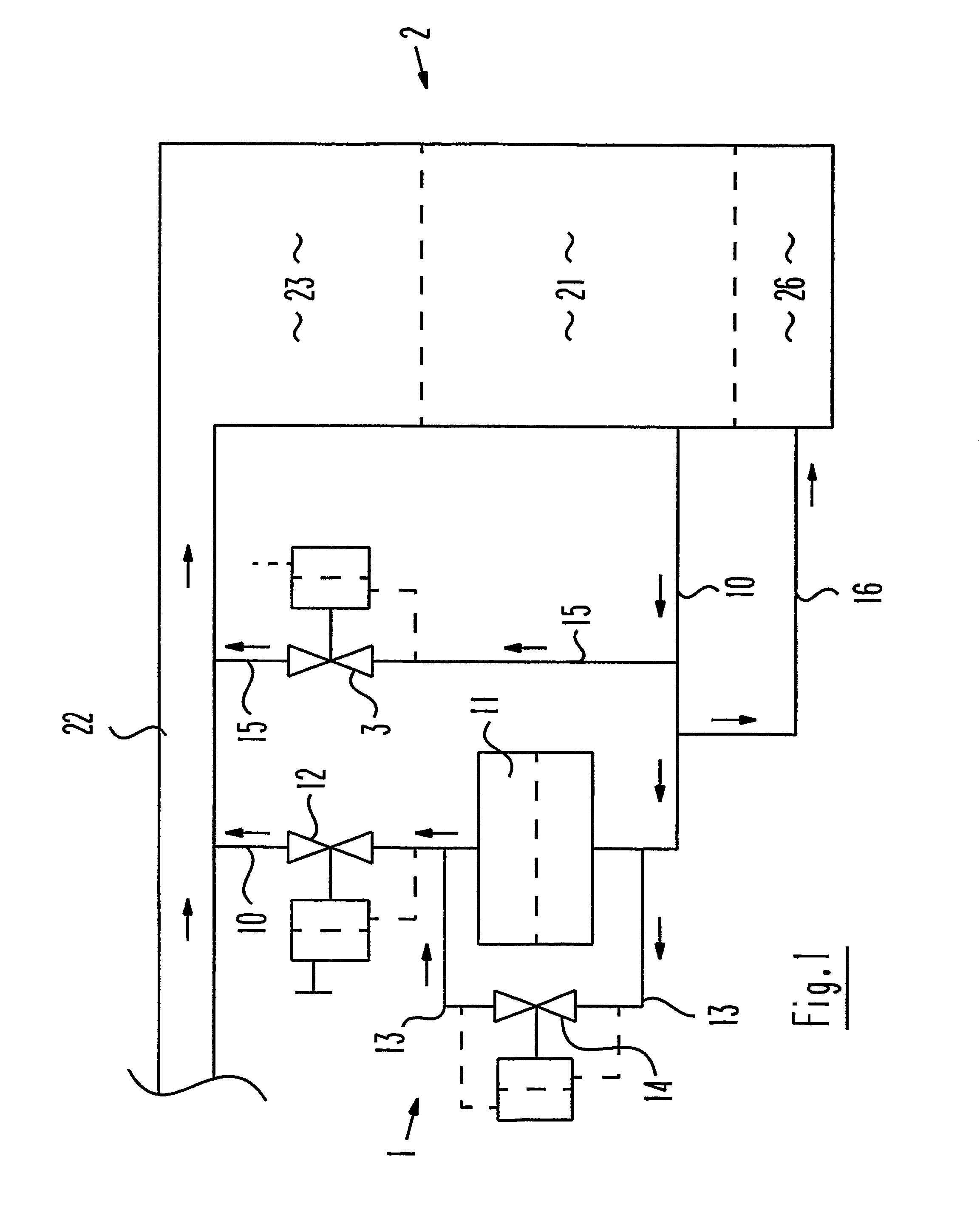

Air-pressure-dependent control of cooling systems using a shared air pressure sensor

InactiveUS20080304229A1Digital data processing detailsCooling/ventilation/heating modificationsComputer moduleWorkload

Systems and methods provide altitude-dependent fan control for a plurality of electronic subsystems using a shared air pressure sensor. Each server or multi-server chassis of a rack system is a subsystem of the rack system. Each subsystem receives its own on-board fan or blower module. The shared air pressure sensor senses air pressure and outputs a signal to all of the subsystems. Each subsystem then independently regulates its own fan speed according to the signal output by the shared air pressure sensor. Other fan operational parameters, such as the number of fans recruited, may also be controlled according to altitude according to the invention. A variety of other performance parameters, such as internal air or component temperature, ambient air temperature, server workload, and processor activity level, may also be factored into control of these fan operational parameters.

Owner:IBM CORP

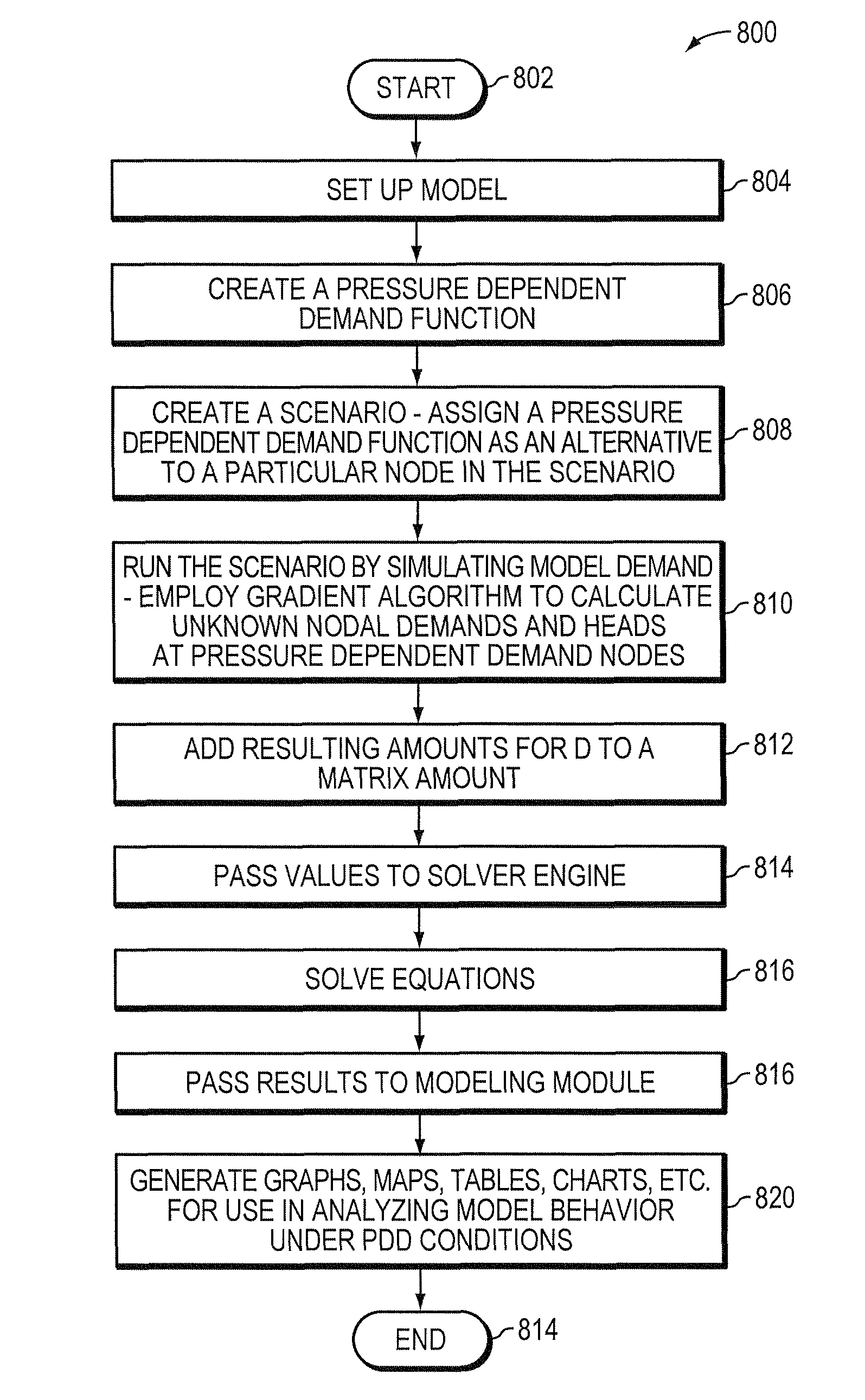

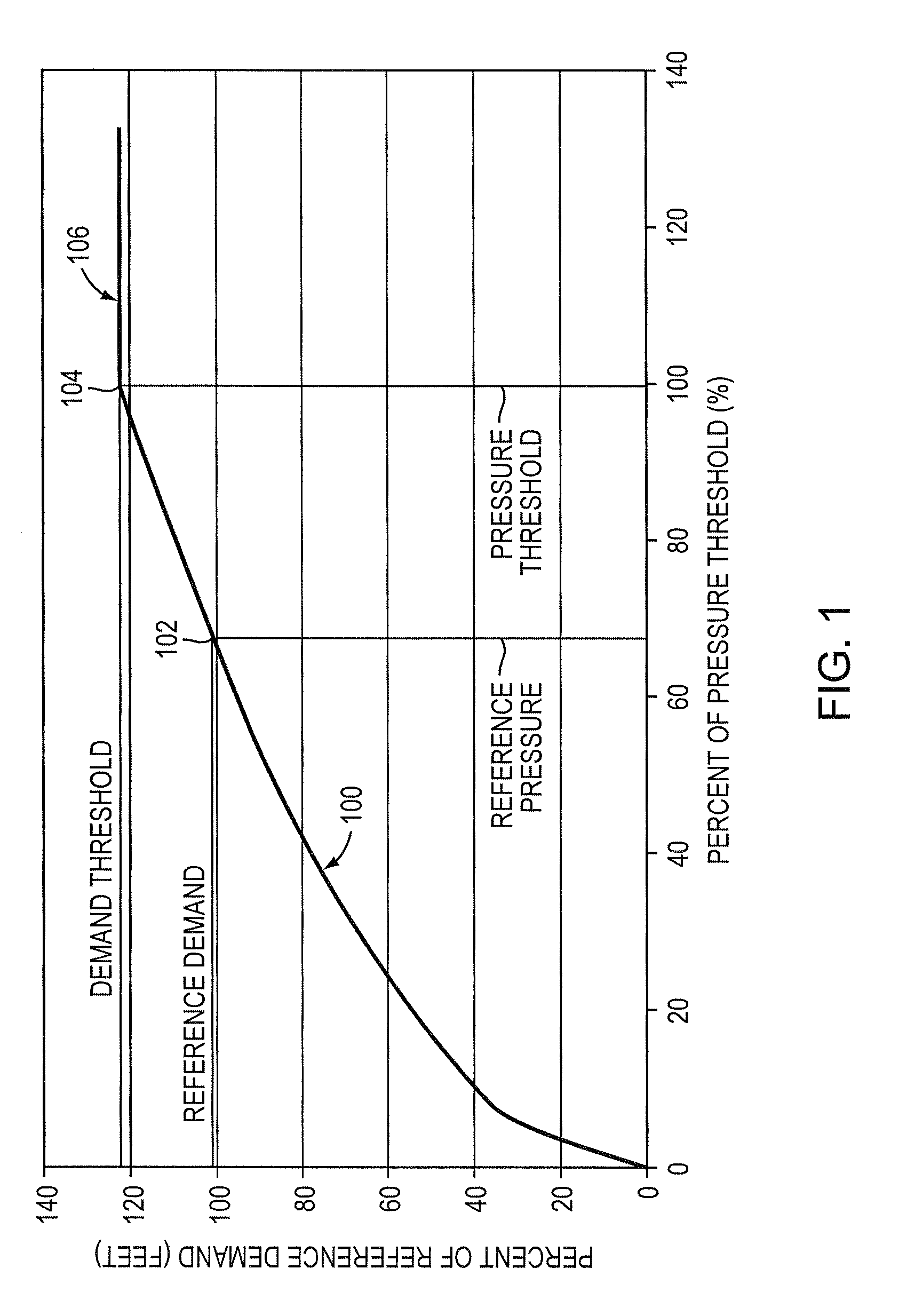

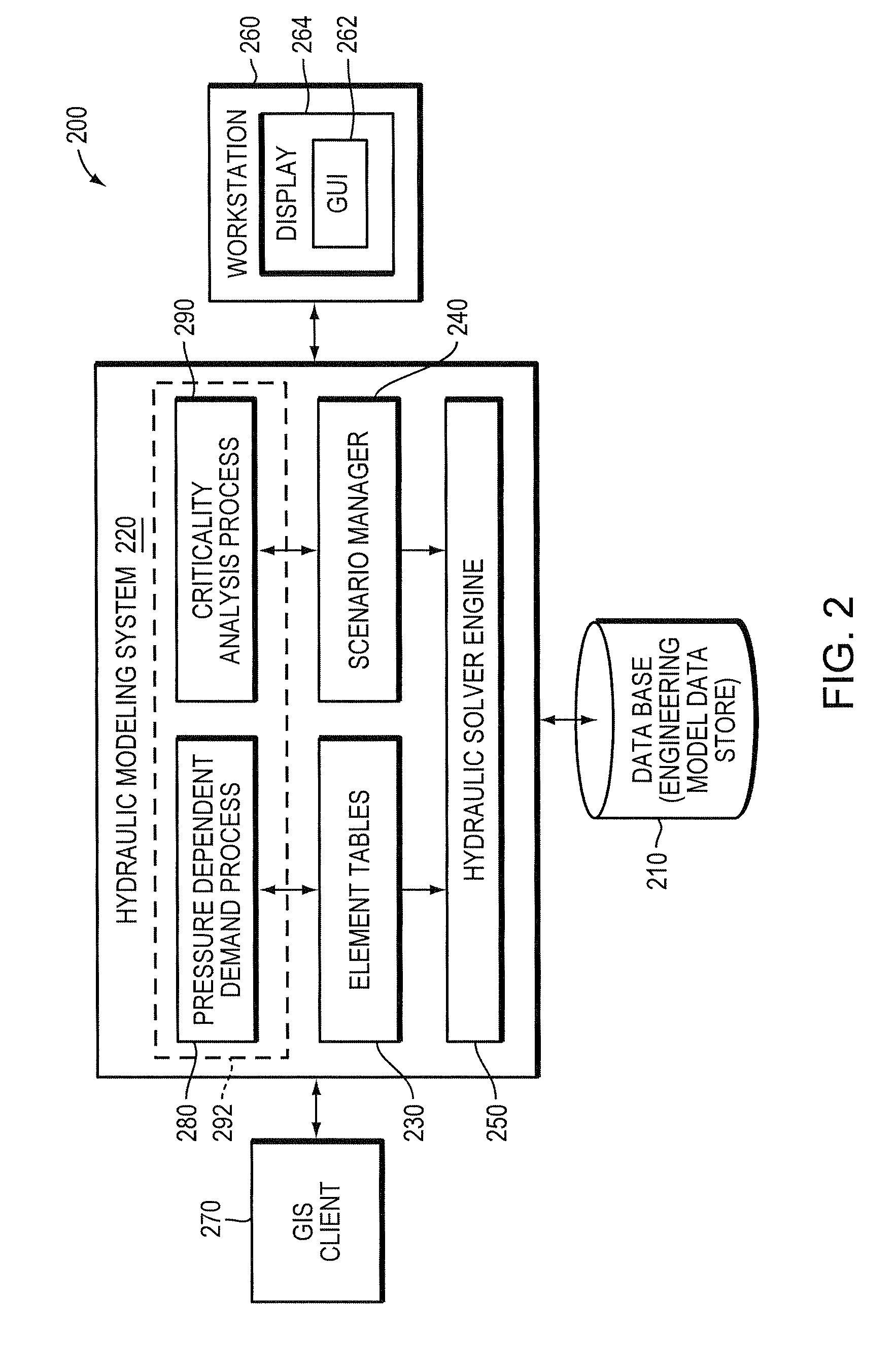

Efficient method for pressure dependent water distribution analysis

A computer software program provides an algorithm that solves for unknown demands (and junction pressures) within a modeling system that uses a generalized, unified loop-node formulation. The program can be used to calculate the available demand (i.e., the amount of water that is to be supplied) according to the nodal pressure. Both nodal heads and flows are simultaneously solved using a gradient algorithm, which allows, in accordance with the present invention, the model to simulate situations where a change in pressure affects the quantity of water used. Criticality analyses for segments of a system in such pressure dependent scenarios can also be performed using the software program of the present invention.

Owner:BENTLEY SYST INC

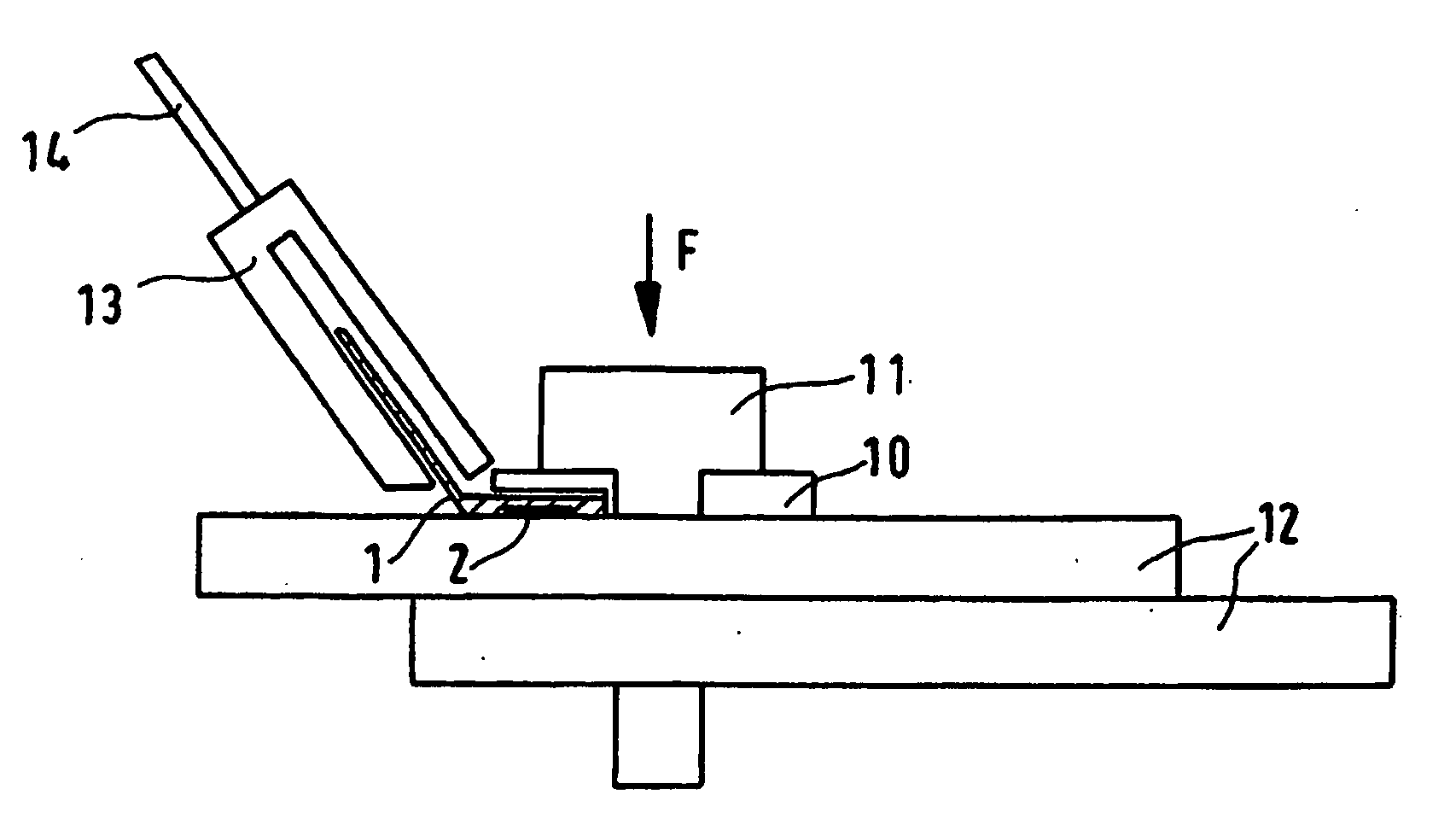

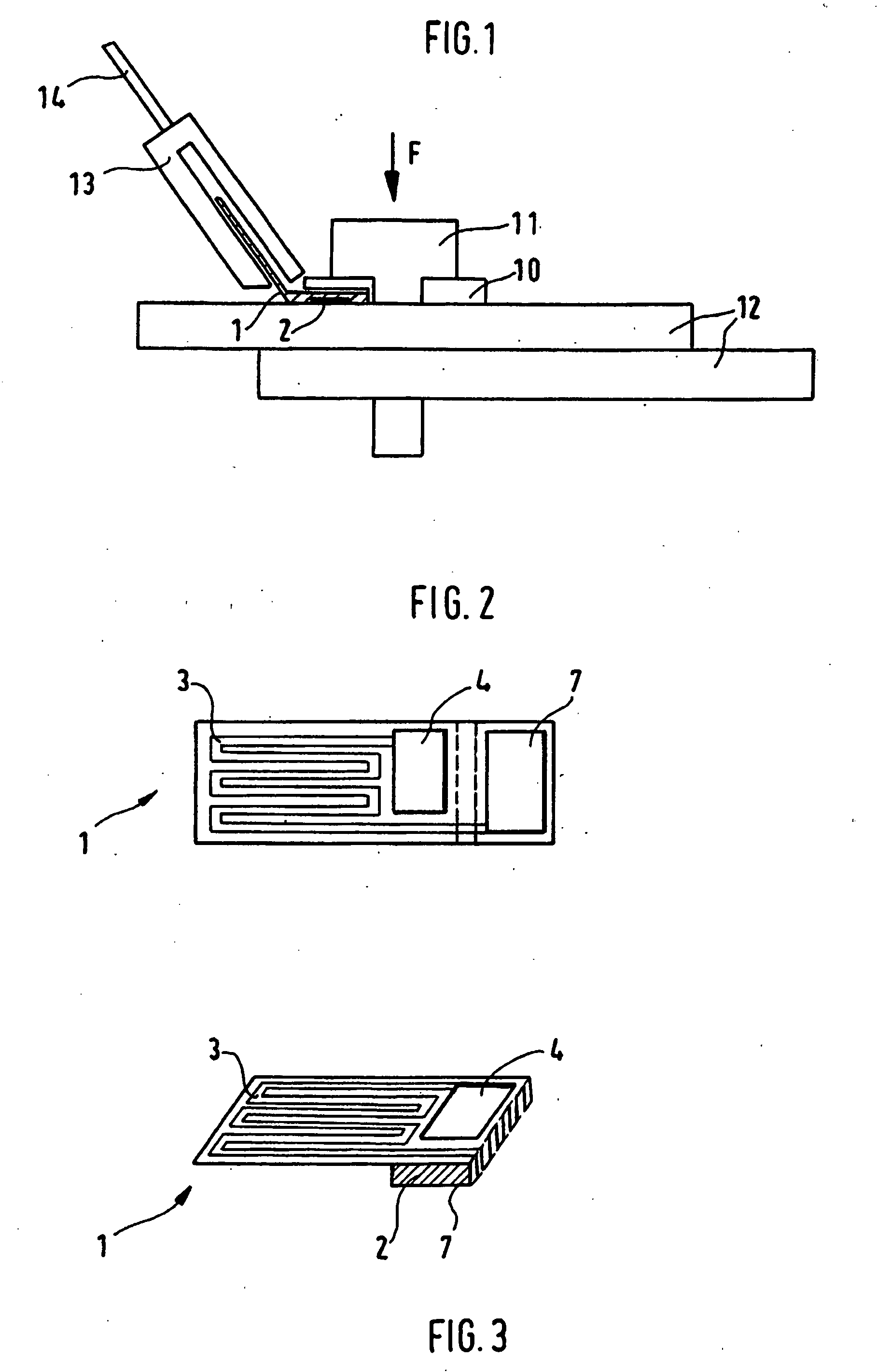

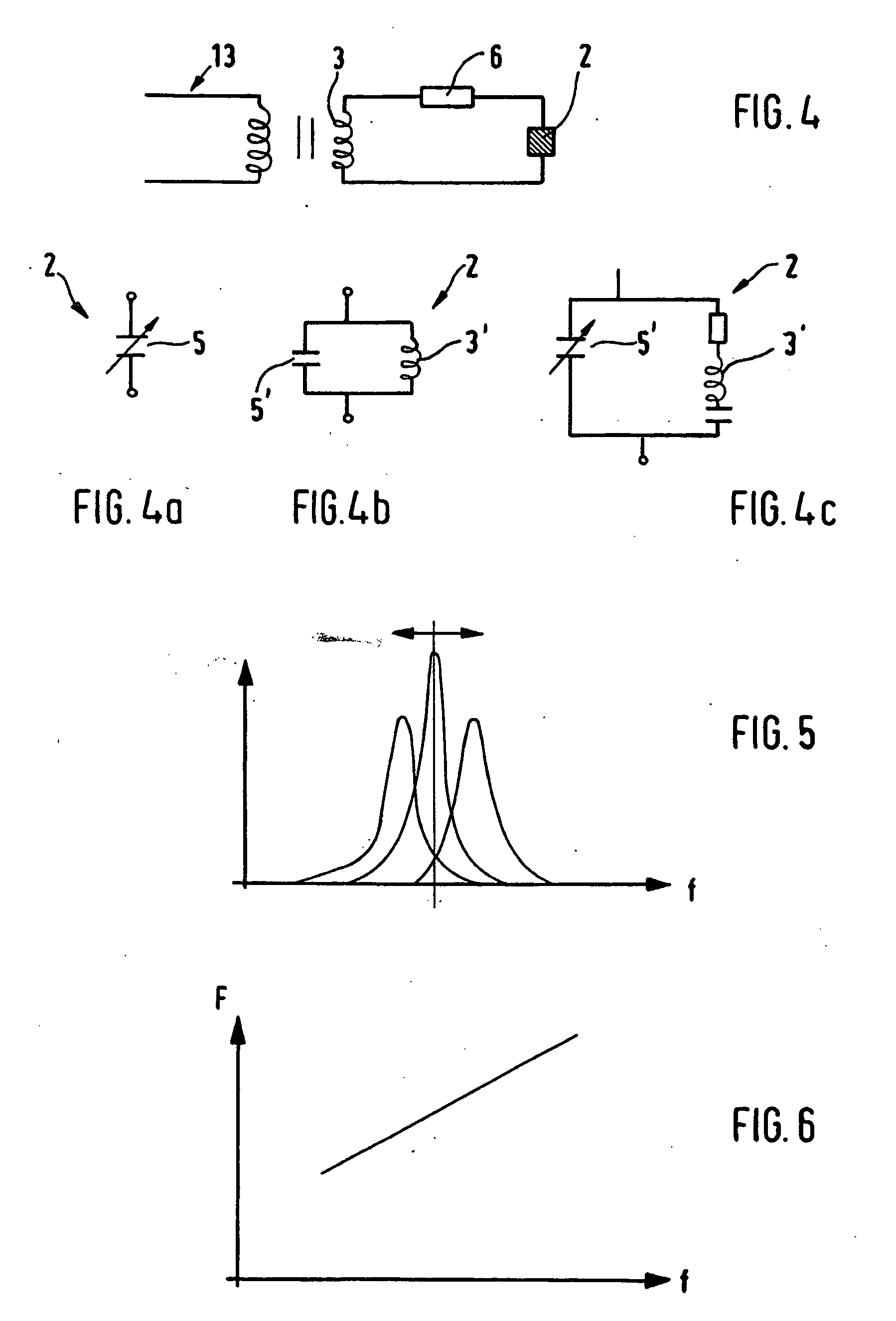

Stress/extension-measuring sensor and method for measuring stress/expansion

InactiveUS20050284231A1Easy to adjustEasy to monitorMeasurement of torque/twisting force while tighteningLoad modified fastenersEngineeringInductor

A stress / strain measuring sensor for the continuous monitoring of stress / strain conditions, especially in screwed bolts, along with a corresponding measuring process is disclosed. An arrangement, and a corresponding method, are provided that are uncomplicated and easy to implement, and enable a continuous monitoring of stress / strain conditions. This is attained using a sensor (1) that comprises a first inductor (3) and at least one additional element (2), which comprises at least one pressure-dependent first impedance (5) or a second impedance (5′) and a second inductor (3′), wherein the second impedance (5′) and / or the second inductor (3′) are pressure-dependent, so that when the amount of pressure applied to the element (2) changes, the resonant frequency of an electromagnetic resonating circuit (3, 5; 3′, 5′) that is formed by impedance (5, 5′) and inductor (3, 3′) changes.

Owner:AIRBUS OPERATIONS GMBH

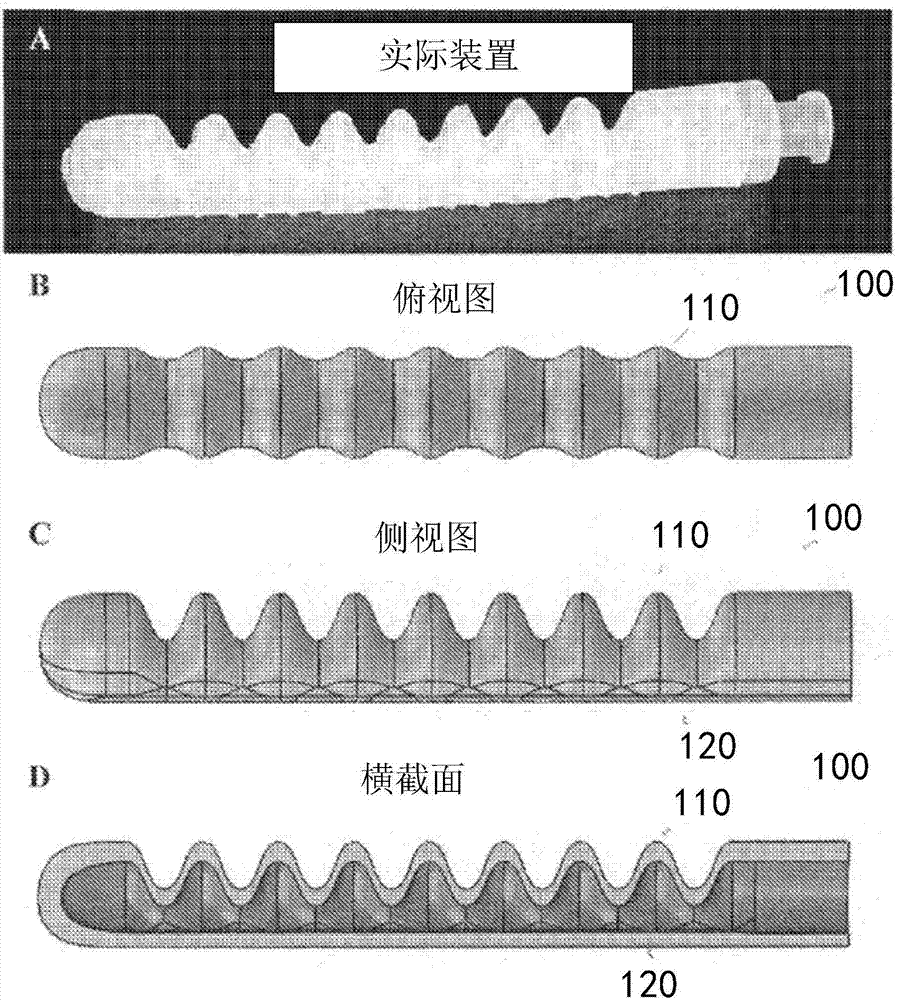

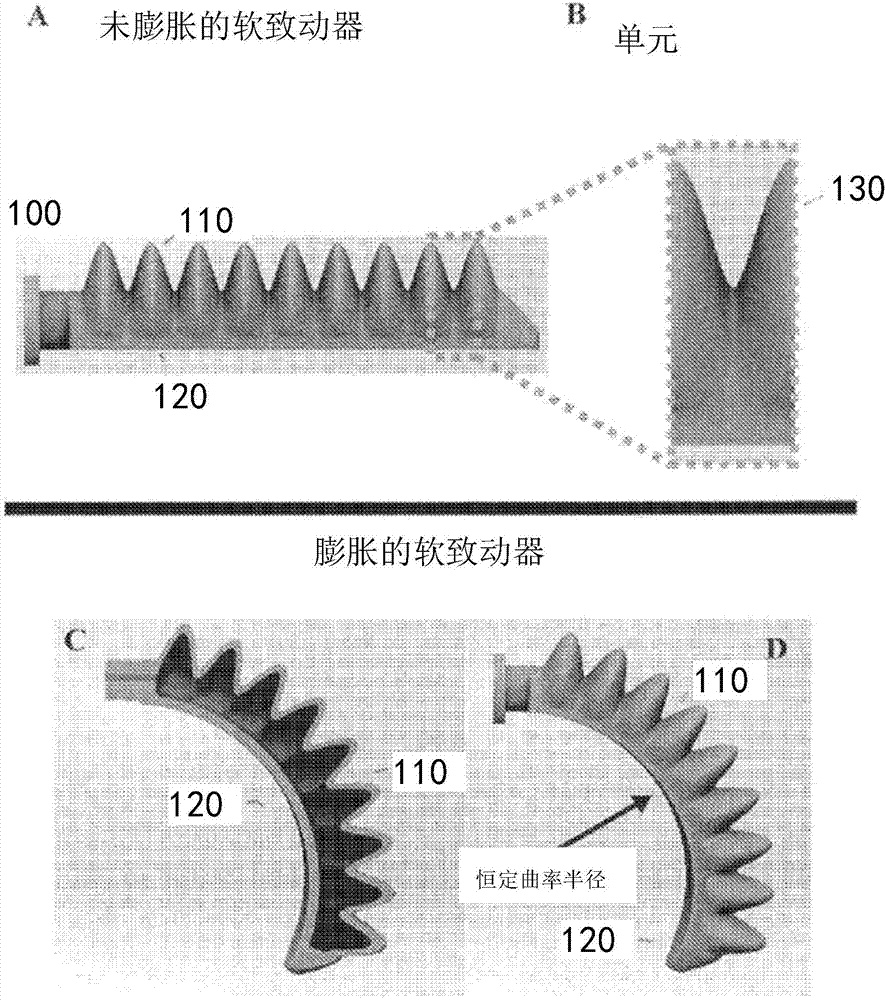

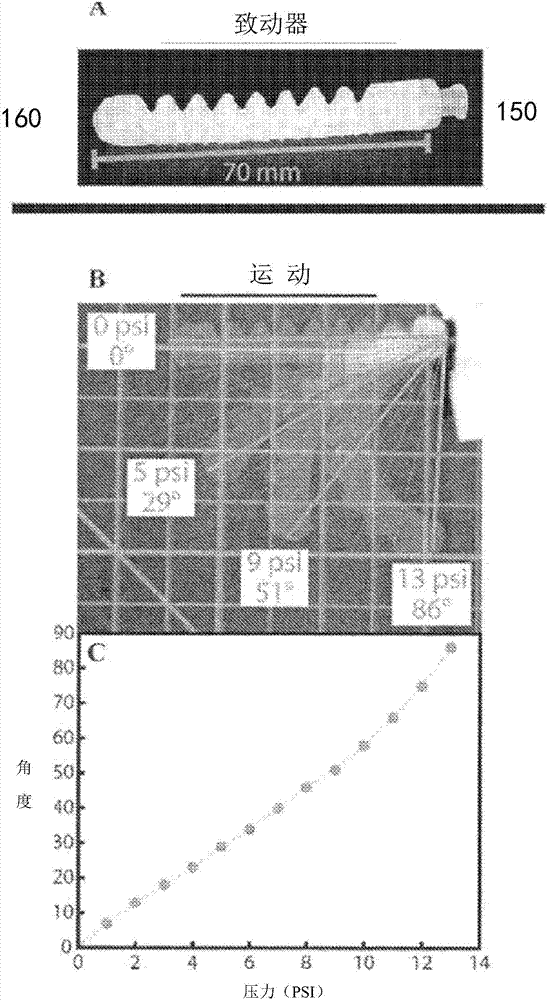

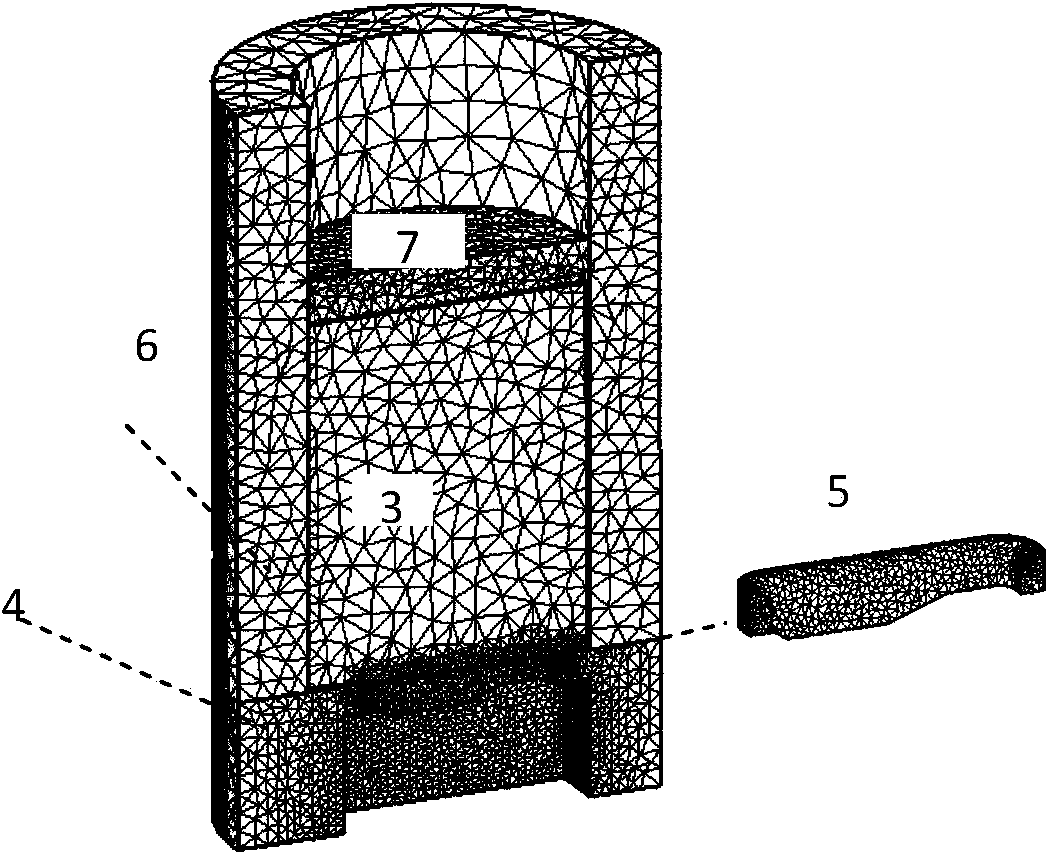

Soft robotic actuators utilizing asymmetric surfaces

InactiveCN107002721ASimplify the modeling processSimplify the design processProgramme-controlled manipulatorGripping headsInternal pressureControl theory

A soft robotic actuator is disclosed. The actuator includes a first portion with a substantially constant profile and a second portion with a regularly varying profile, and bends in a pressure-dependent fashion as the internal pressure within the actuator is increased or decreased. The present invention addresses the needs described above by providing actuators that are configured to perform new fundamental motions through the inclusion of design elements which can be configured, through the manipulation of a relatively short list of parameters, to undergo specific pressure-actuated changes which can be designed using quantitative modeling techniques.

Owner:SOFT ROBOTICS

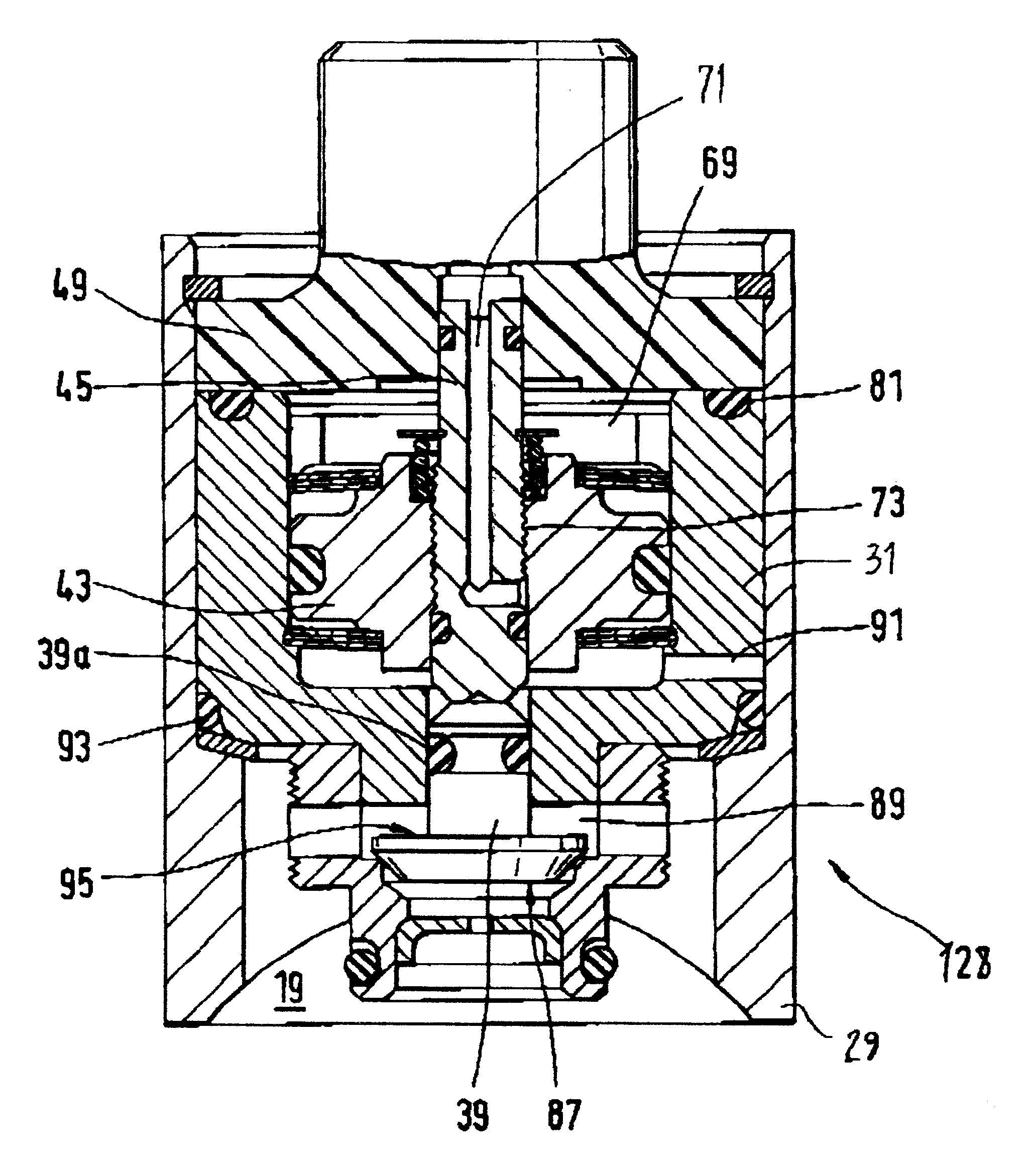

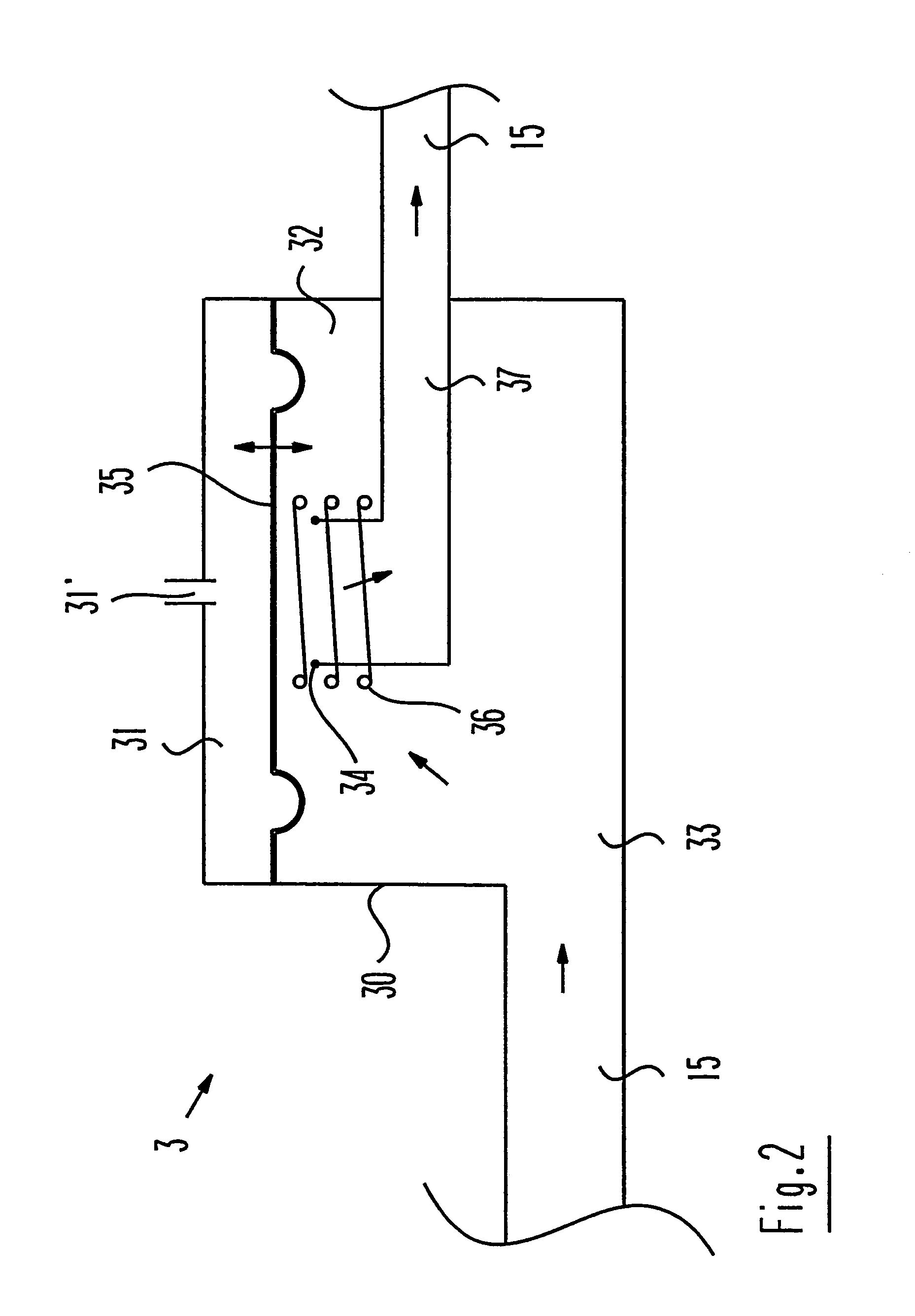

Pressure-dependent valve for a vibration damper

A pressure-dependent valve, for use with an adjustable vibration damper comprising a piston rod arranged in an axially movable fashion in a cylindrical tube filled with damping fluid, is controlled by a pressure transducer pressurized via a pressure connection opening. The pressure-dependent valve includes a valve body axially movable relative to a valve surface. The valve body and valve surface together determine a valve passage cross-section. The pressure transducer is float-mounted in a pressure space and supported by at least one spring. One of the valve parts determining the valve passage cross-section is movable relative to the current position of the pressure transducer by an adjustment device.

Owner:ZF FRIEDRICHSHAFEN AG

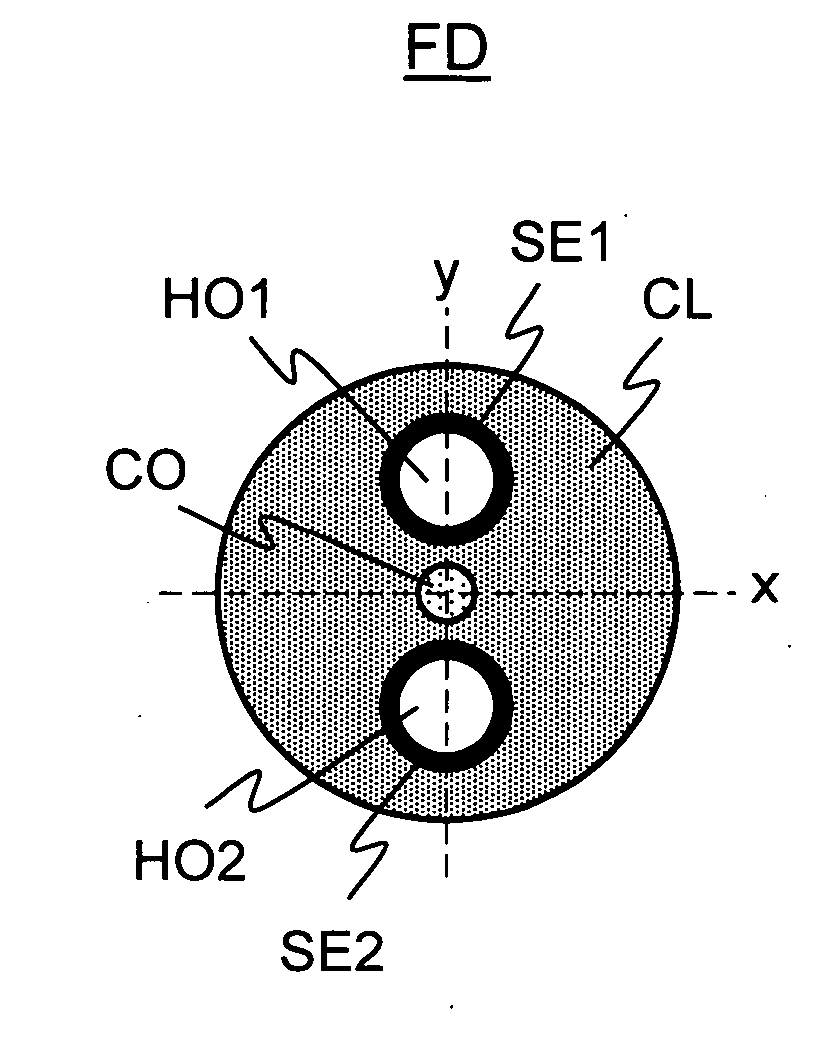

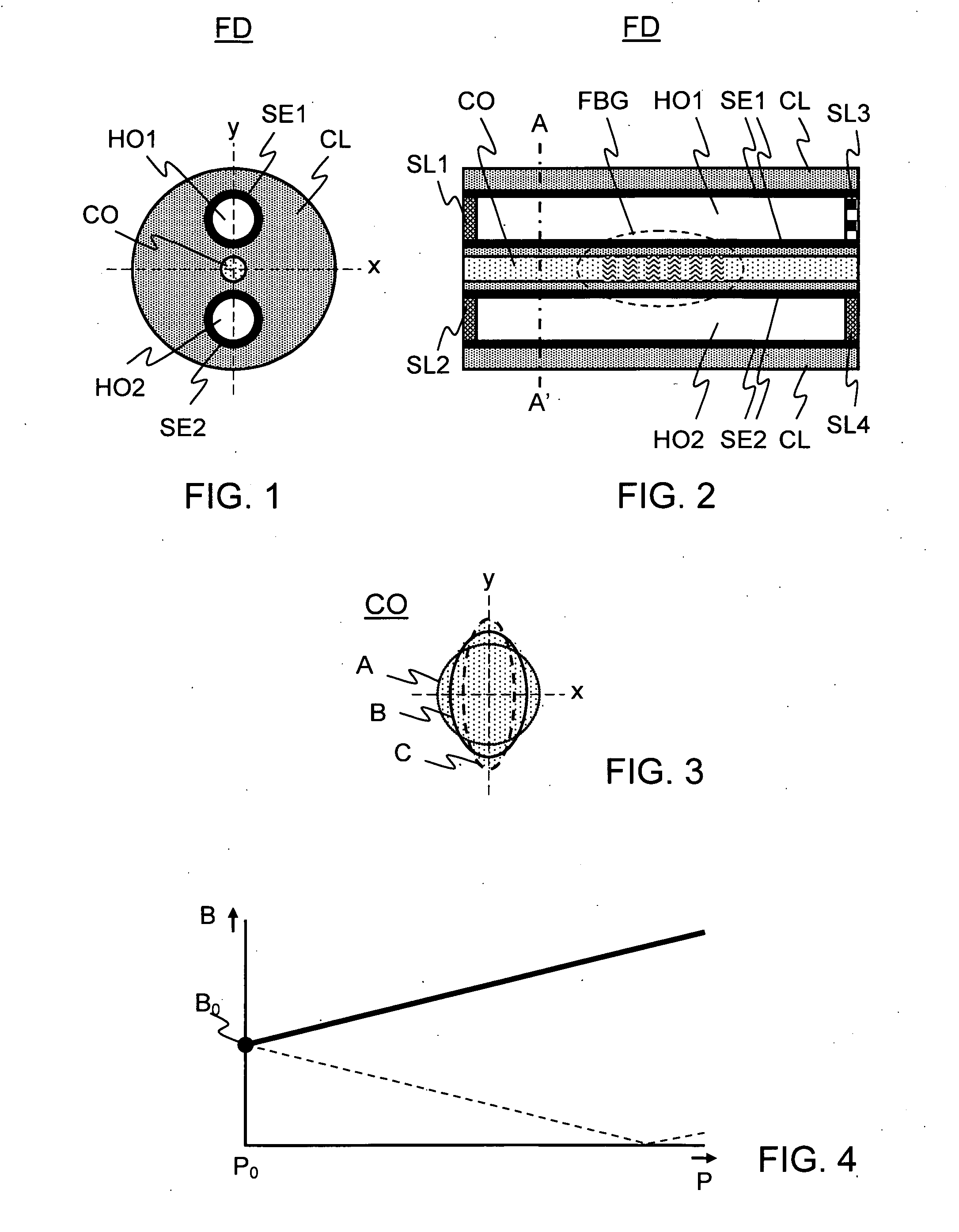

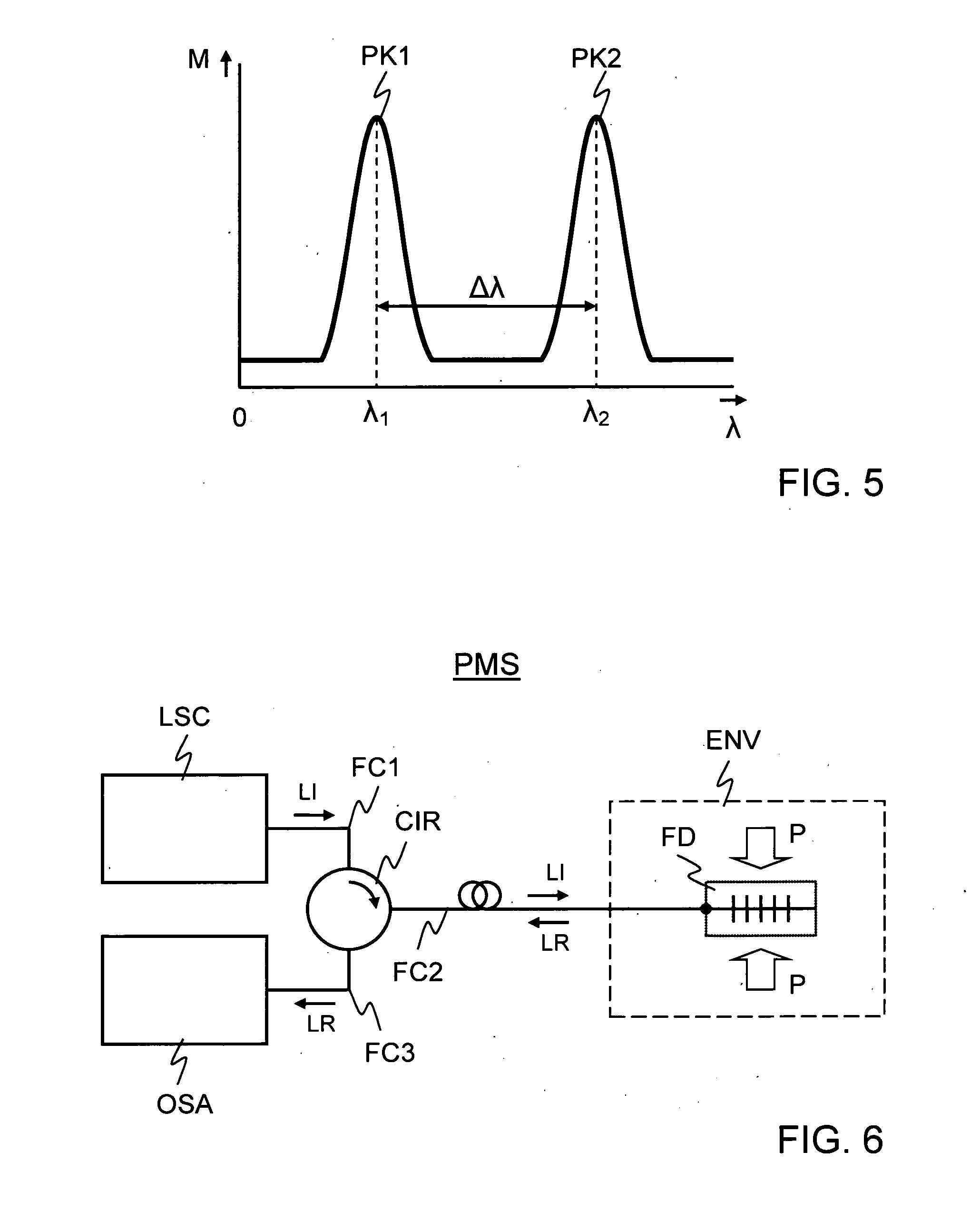

Pressure and Measurement by Means of An Optical Fiber

InactiveUS20120234101A1Accurate pressure measurementLow costCladded optical fibreForce measurement by measuring optical property variationAnisotropic stressExternal pressure

Owner:SCHLUMBERGER TECH CORP

Apparatus for ventilating the crankcase of a combustion engine

InactiveUS7025049B2Reliably preventedIncrease pressureCombustion enginesCrankcase ventillationCombustionEngineering

The invention relates to a device for crankcase ventilation of an internal combustion engine, comprising a ventilation duct extending from the crankcase to an induction tract of the internal combustion engine, whereby at least one oil vapor separator causing a drop in pressure is arranged in said duct and a crankcase vacuum control valve is arranged upstream or downstream therefrom and can be adjusted according to the pressure in the crankcase such that a lower pressure threshold valve in the crankcase is respected. The novel device is characterized in that a discharge duct extending from the crankcase to the induction tract of the internal combustion engine is also provided, whereby a crankcase overpressure limiting valve is disposed inside said duct and can be adjusted in a pressure-dependent manner to ensure that an upper pressure threshold in the crankcase is not exceeded.

Owner:HENGST WALTER

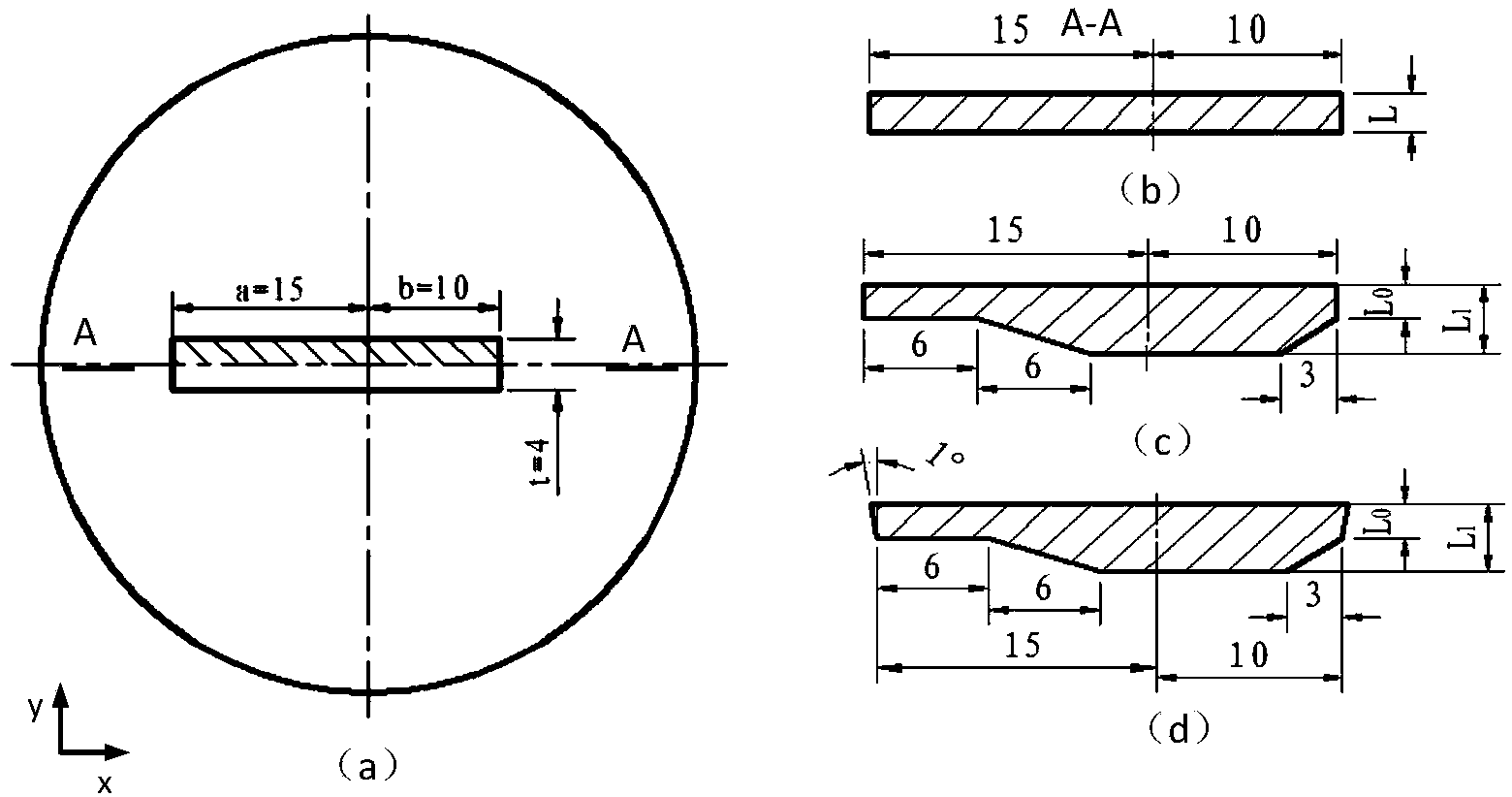

Numerical simulation method for analyzing structure dimensions of unequal-length working tape of extrusion die

Provided is a numerical simulation method for analyzing structure dimensions of an unequal-length working tape of an extrusion die. Simulation is carried out on the sectional material extrusion process, a die surface and the working tape are arranged to be two independent entities, a slope working tape is arranged, the inclination angle between the surface of the working tape and the extrusion direction ranges from 1 degree to 2 degrees, after three-dimensional model assembly is carried out, meshing is carried out, split friction boundary conditions are set, and a common friction model is selected for a deformation body, the inner wall of an extrusion barrel and the die surface, namely, a cutting friction model with a constant friction factor is adopted; a Coulomb friction model related to pressure is adopted for the deformation body and the surface of the working tape; extrusion technological parameters are applied to finite element software, data files are generated, and simulation analysis is carried out. According to the numerical simulation method for analyzing the structure dimensions of the unequal-length working tape of the extrusion die, due to the fact that the method of split modeling, the method of the slope working tape, the method of the split friction boundary conditions and the like are integrated, the problem that the deformation body is separated from the surface of the unequal-length working tape, or makes local contact with the surface of the unequal-length working tape is solved.

Owner:INNER MONGOLIA UNIV OF TECH

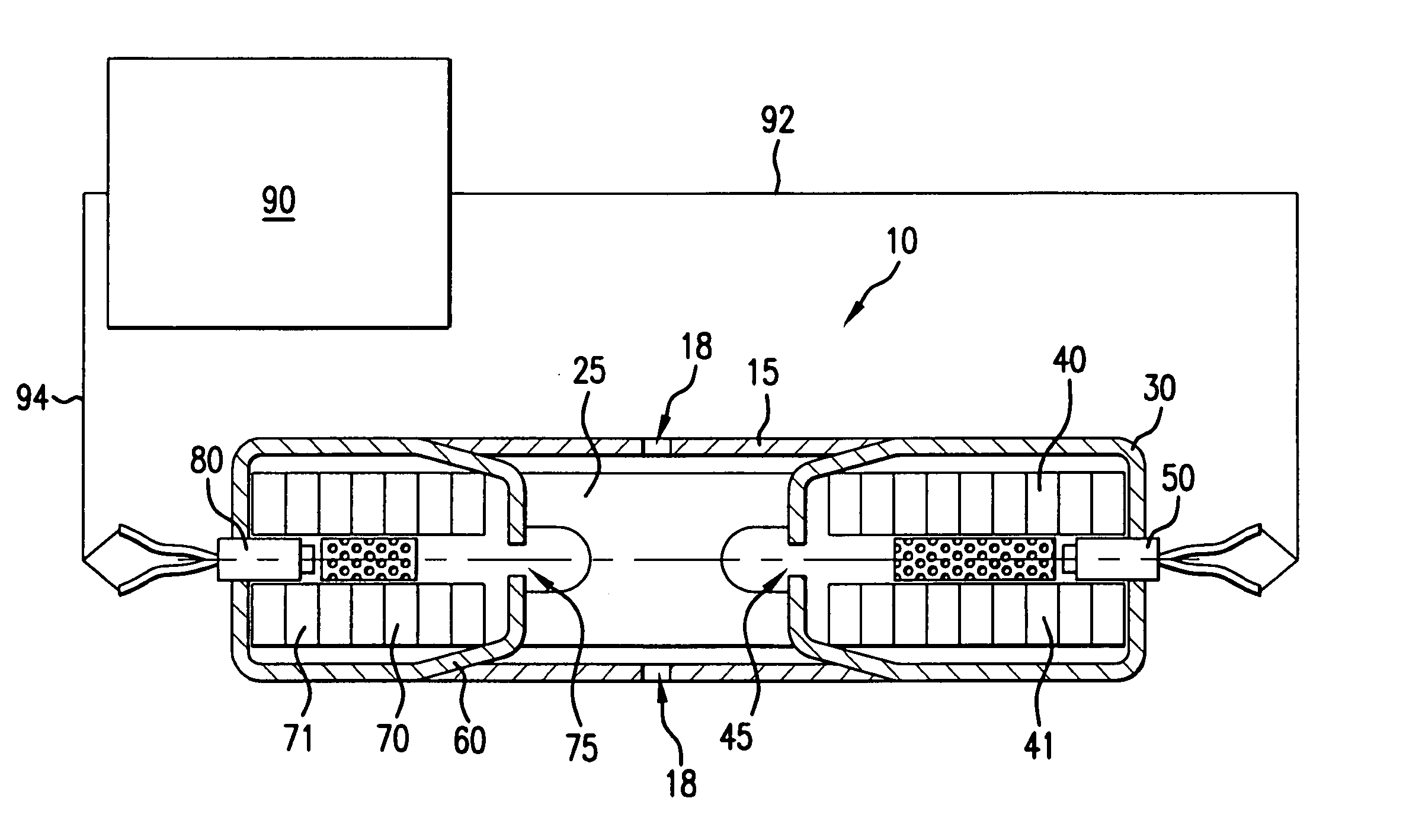

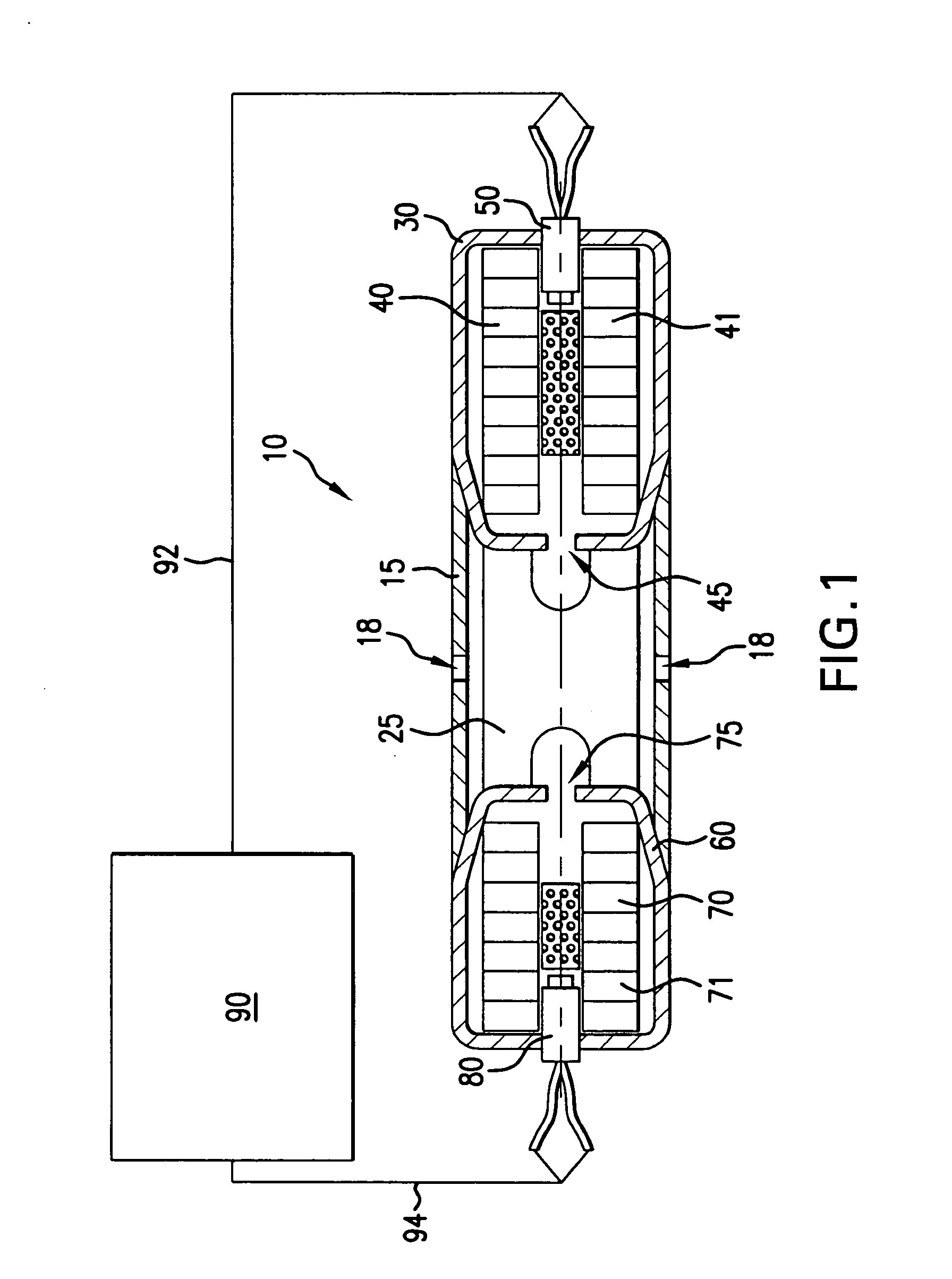

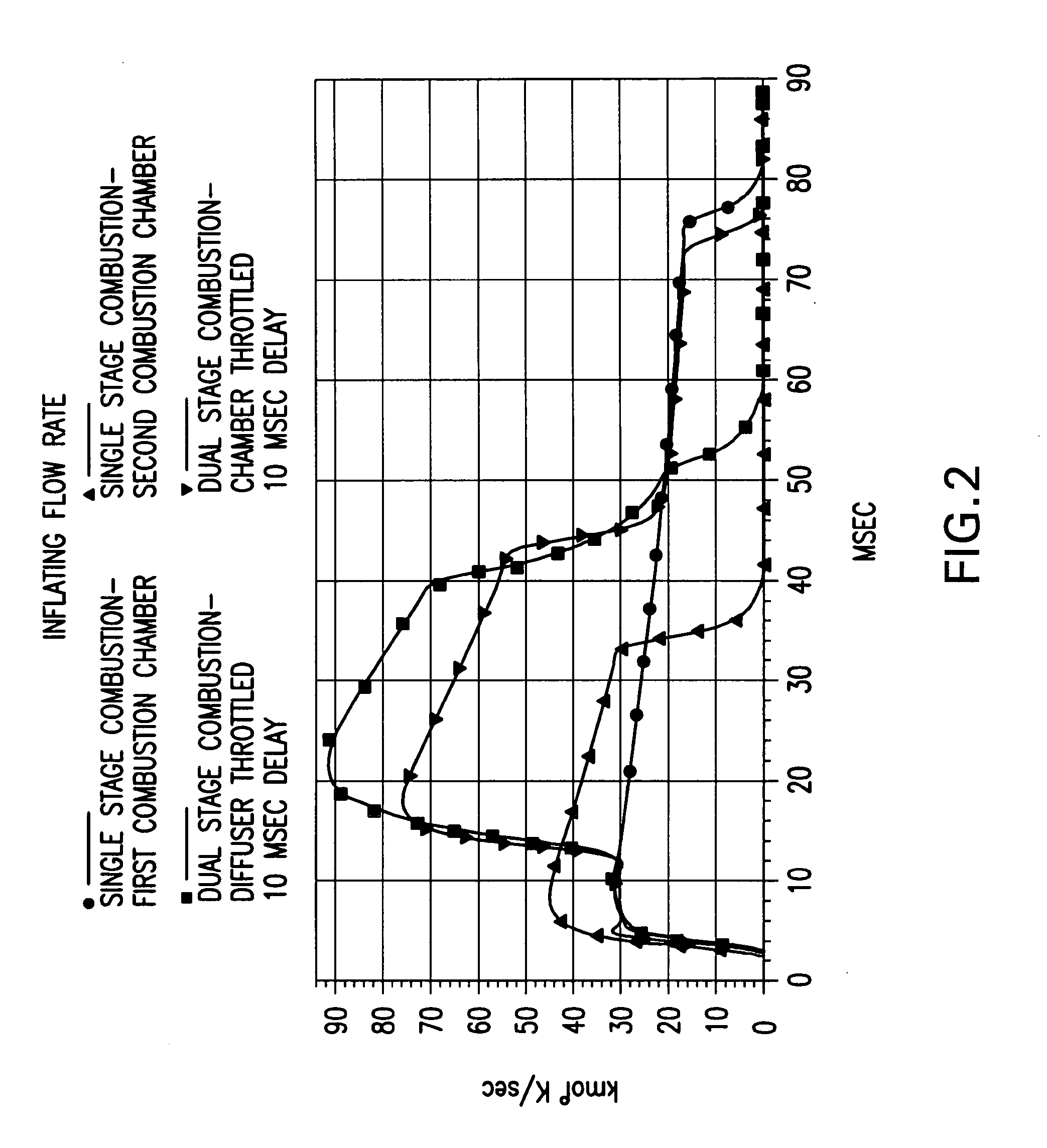

Pressure-enhanced, adaptive inflator device

InactiveUS20050098988A1Increase operating pressureImprove pressure resistancePedestrian/occupant safety arrangementPressure gas generationCombustion chamberSingle stage

An inflator device that includes a diffuser chamber with a first combustion chamber and a second combustion chamber each connected to the diffuser chamber. A supply of a first gas-generating pyrotechnic material having a burn rate that is pressure dependent is contained within the first combustion chamber. The first combustion chamber forms or includes an orifice providing independent fluidic communication between the first combustion chamber and the diffuser chamber. This orifice throttles a single stage combustion wherein the supply of the first gas-generating pyrotechnic material is selectively reactable to produce a first combustion chamber single stage combustion product gas. A supply of a second gas-generating pyrotechnic material is contained within the second combustion chamber. The second combustion chamber forms or includes an orifice that provides independent fluidic communication between the second combustion chamber and the diffuser chamber. This orifice throttles a single stage combustion wherein the supply of the second gas-generating pyrotechnic material is selectively reactable to produce a second combustion chamber single stage combustion product gas. The diffuser chamber forms or includes at least one exit orifice. This diffuser exit orifice throttles a dual stage combustion wherein the supply of the first gas-generating pyrotechnic material is reactable to produce a first combustion chamber dual stage combustion product gas and the supply of the second gas-generating pyrotechnic material is reactable to produce a second combustion chamber dual stage combustion product gas.

Owner:AUTOLIV ASP INC

Closure cap provided with anti-twisting

A pressure cap for openings in tanks, in particular in automobile radiators, has an outer cap component which is provided with a locking element that can be connected to the tank's neck, and provided with a handling element rotatably mounted in relation to said locking element, and furthermore provided with a coupling insert which is anti-rotationally mounted in the handling element and which can be axially engaged in and disengaged from the locking element to allow a releasably non-rotational connection between the locking element and the handling element. The pressure cap is furthermore provided with a valve assembly containing a valve body that can be axially moved back and forth, for releasing and blocking flow connections between the inside and the, outside of the tank depending on the pressure prevailing inside the tank. To create an anti-rotation means directly governed by and in time and sequence with the conditions prevailing inside the tank, it is provided that the engaging and disengaging movement of the coupling insert is derived from the pressure-dependent axial movement of the valve body of the valve assembly.

Owner:REUTTER HEINRICH

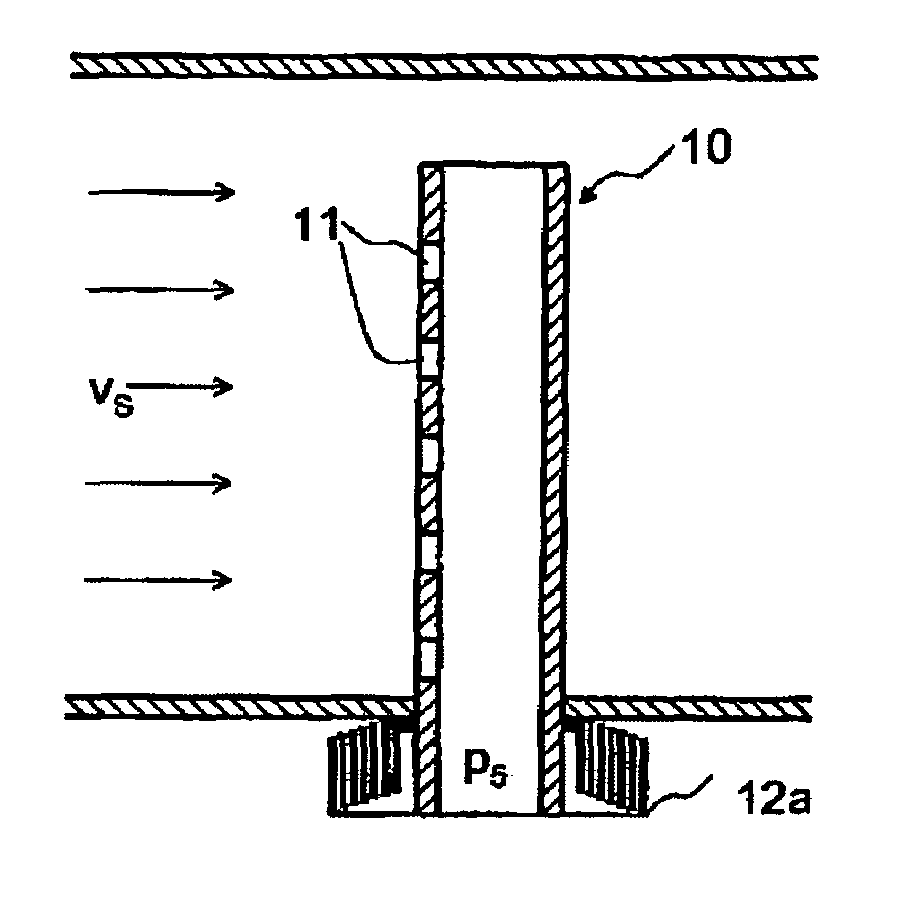

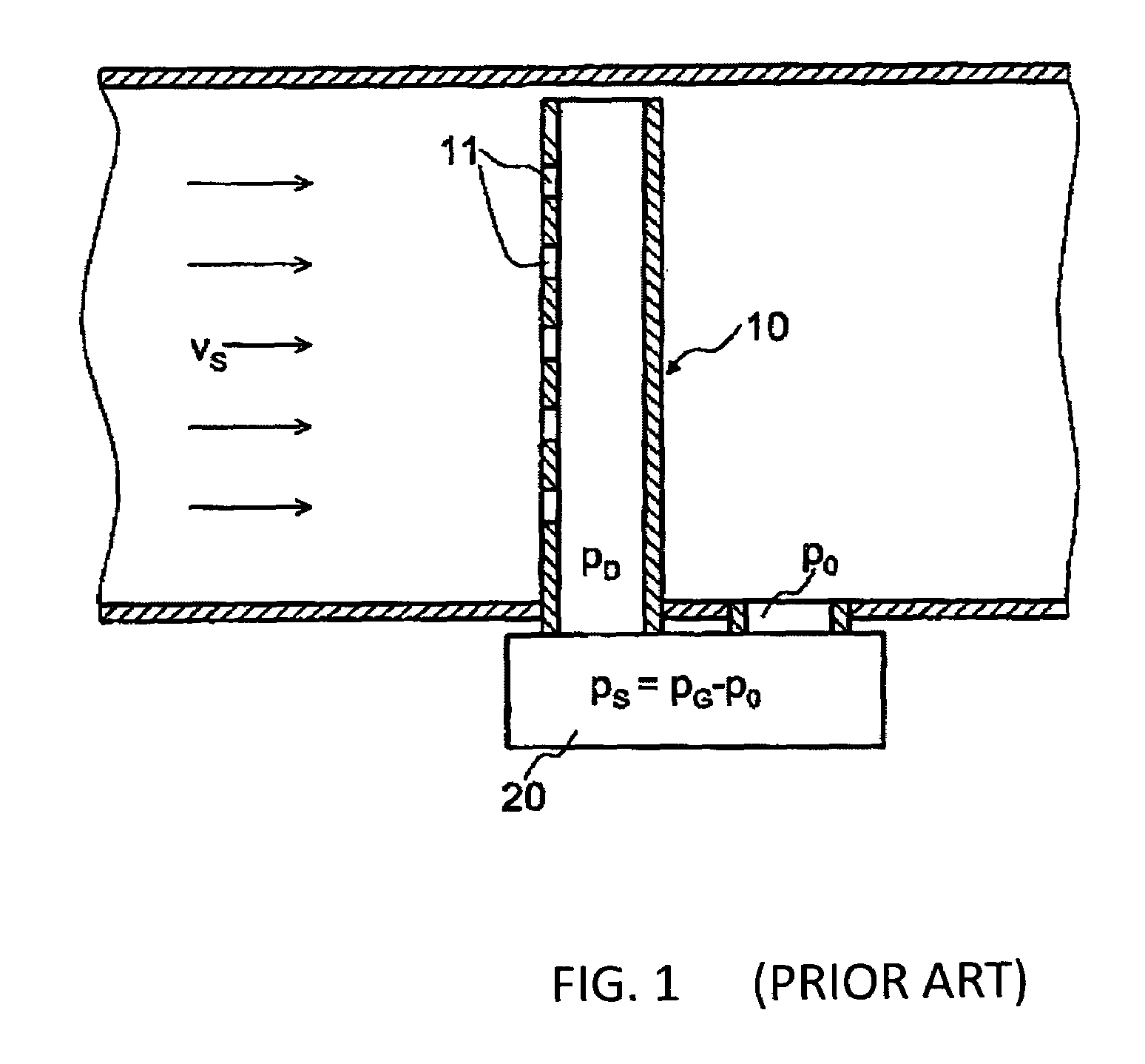

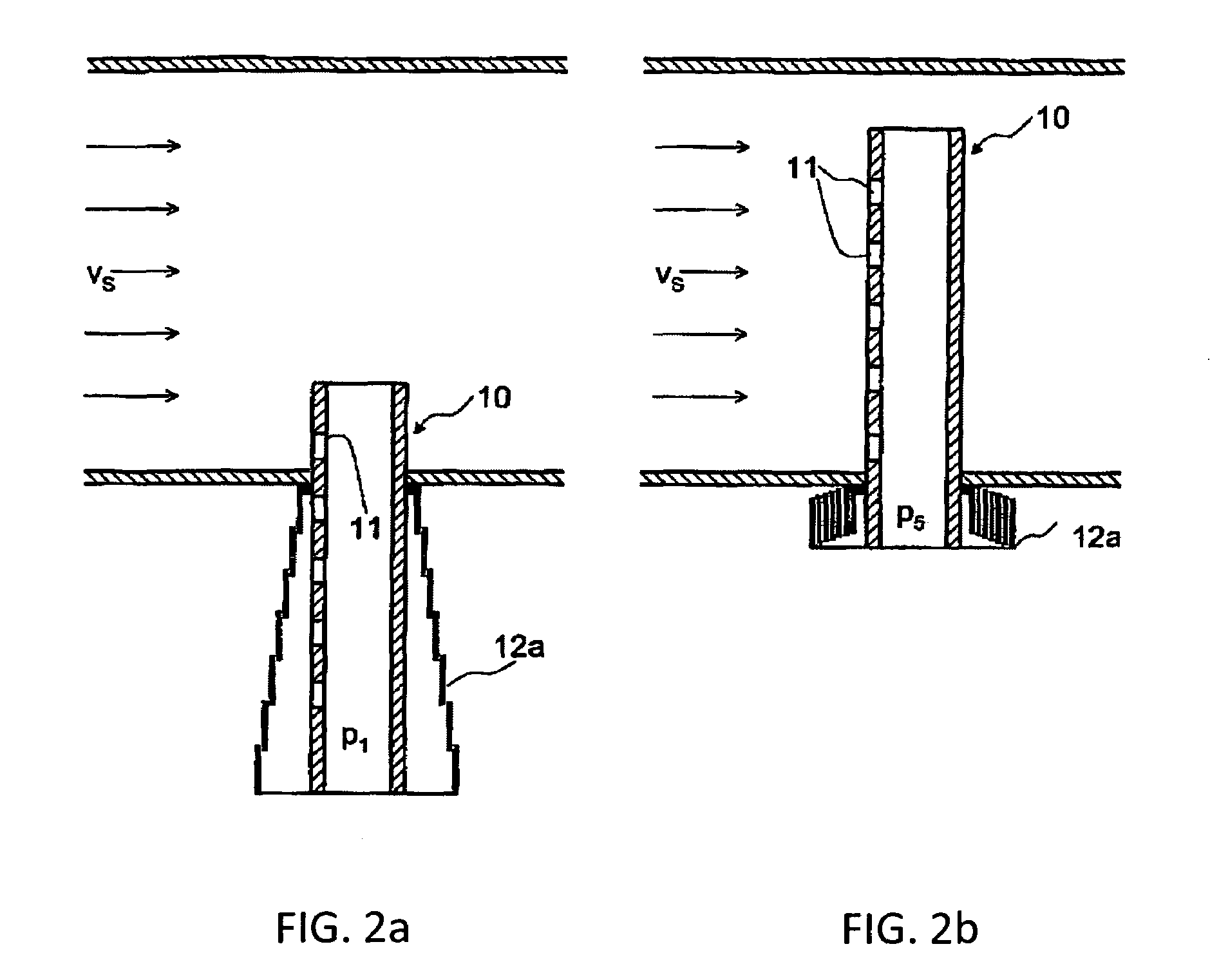

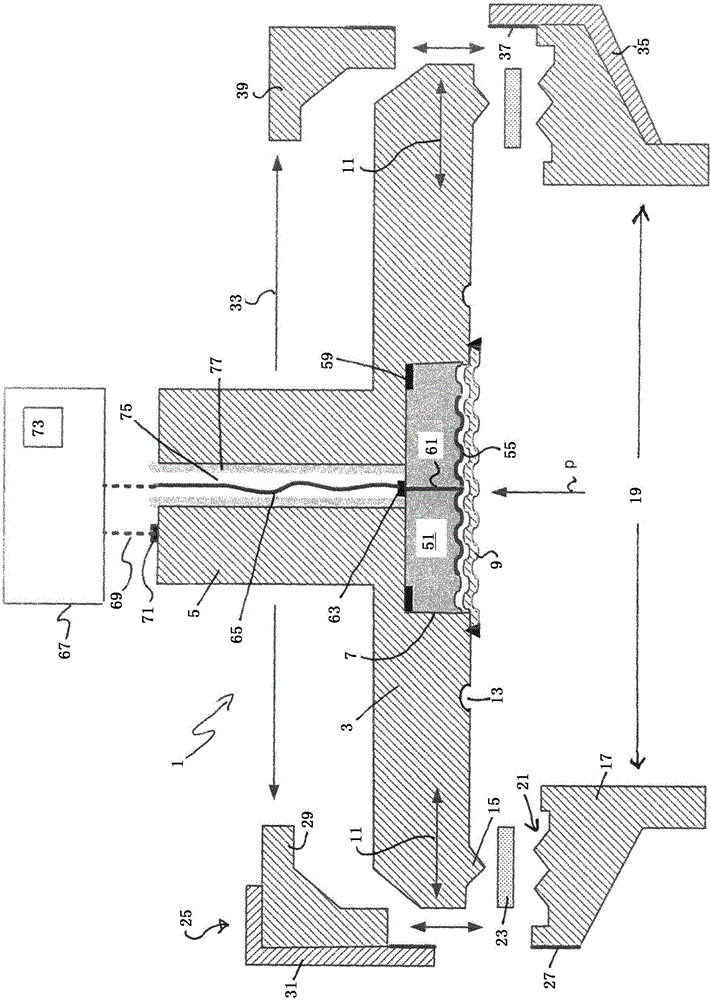

Measuring arrangement for flow measurement in a channel

A measuring arrangement for determining flow speeds in a flow channel includes a probe tube which is introduced via a first opening into the flow channel. The probe tube is exposed to a flow with a flow speed, the side of the probe tube facing the flow comprising a plurality of openings which are interconnected inside the probe tube such that a total pressure dependent on the flow speed prevails inside the probe tube. The measuring arrangement also comprises a static pressure opening in the flow channel, and a differential pressure sensor that determines the differential pressure between the total pressure inside the probe and the static pressure in the flow channel. The probe tube may be partially surrounded by a shield which is mobile and / or length-adjustable and that, according to its position and / or length along the probe tube, may close one, several or none of the openings.

Owner:TESTO AG

Pressure sensor

ActiveCN105829853ANo measurement impairmentFluid pressure measurement by electric/magnetic elementsTransducerEngineering

Owner:EHNDRESS KHAUZER GMBKH KO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com