Ventilation unit for a die casting device

A kind of exhaust device and equipment technology, which is applied in the direction of casting molding equipment, metal processing equipment, casting mold, etc., and can solve the problem of insufficient molding cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

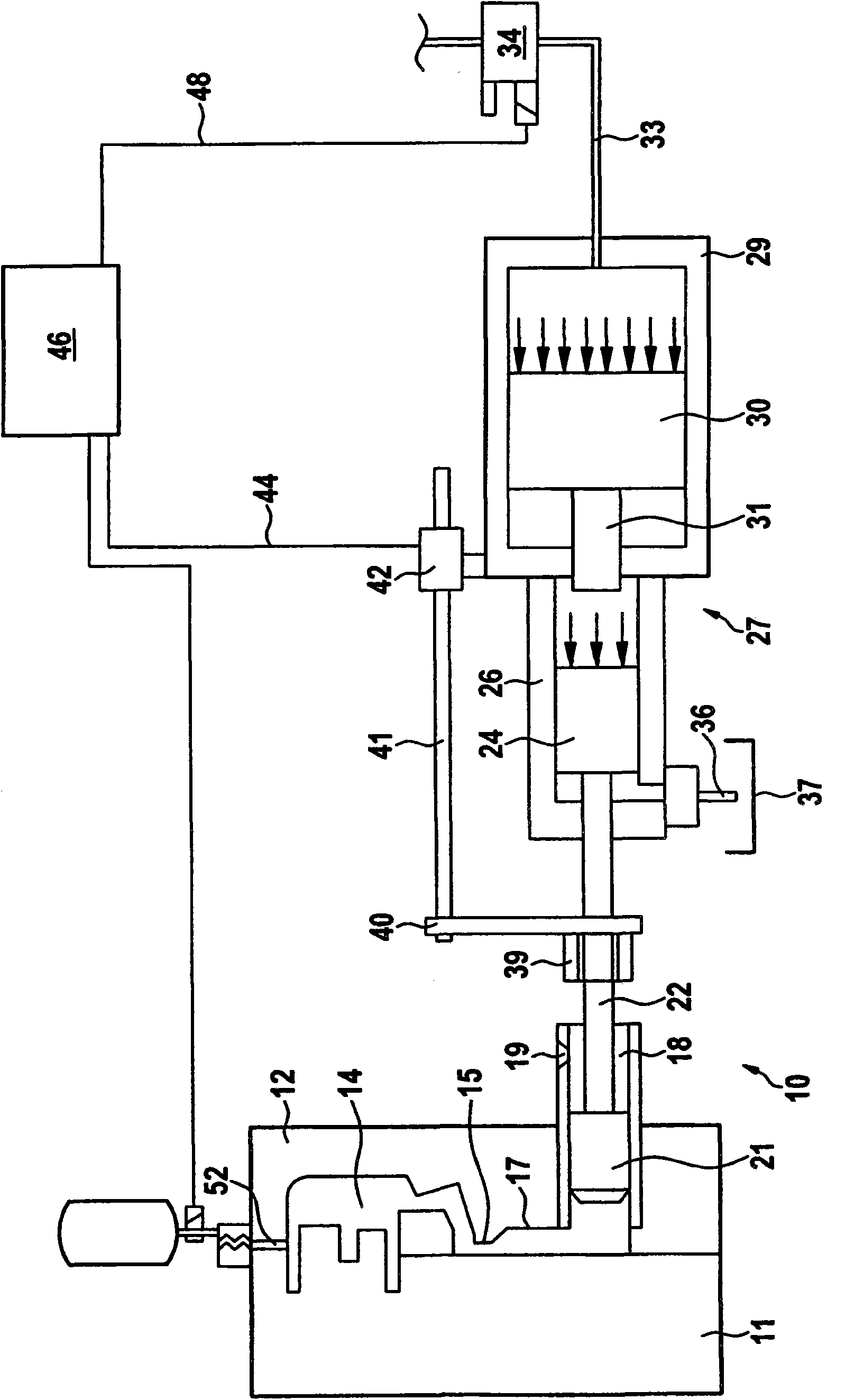

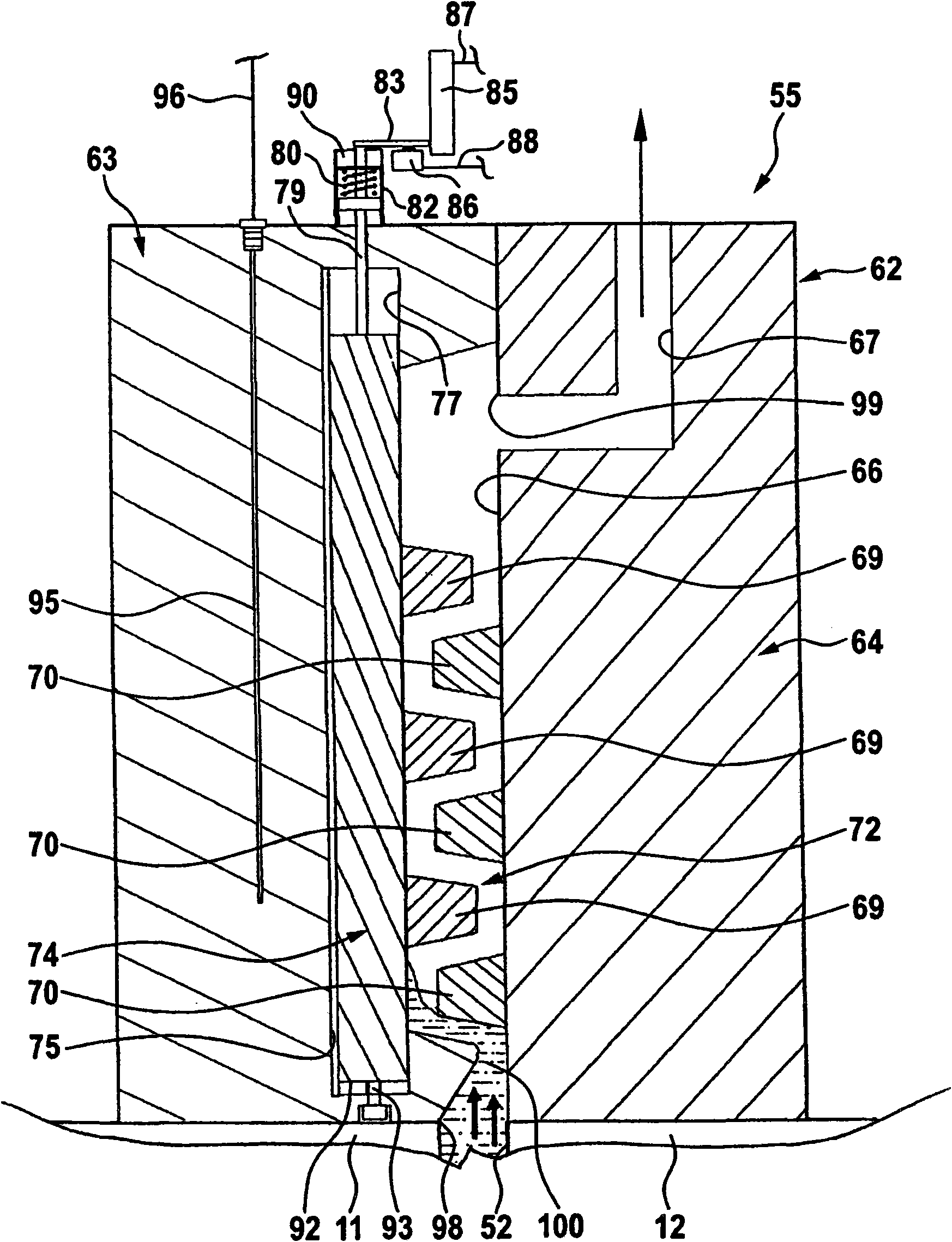

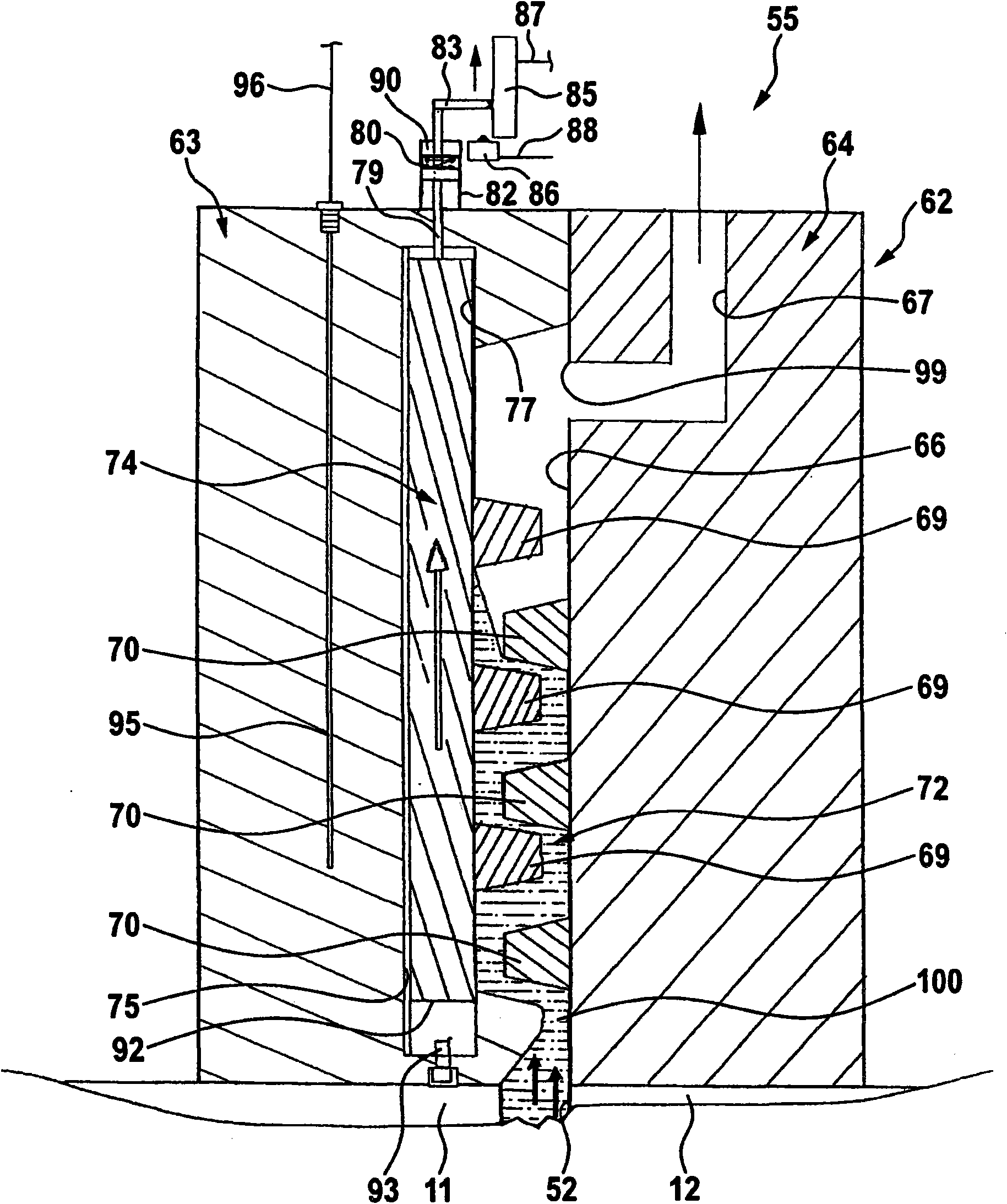

[0028] exist figure 1 A die-casting device 10 according to the invention is schematically shown in FIG. A mold closing unit not shown in the figures cooperates. The mold closing unit comprises movable jaws and fixed jaws, which are not shown in the figures for a better overview, and one of the two mold halves 11 , 12 is advantageously held in each case on these splints. With the aid of this mold closing unit, a predetermined clamping force can be applied to the two mold halves 11 , 12 . The two mold halves 11, 12 form between each other a forming cavity 14 which has the shape of the casting to be cast, into which the casting material (such as a metal melt, preferably liquid aluminum or Magnesium material) is pressed into the molding cavity 14. For this purpose, the forming cavity 14 has an access opening, which is commonly referred to as a "cutting surface (Anschnitt)" and is located at figure 1 are marked with reference numeral 15. The cut surface 15 is connected via an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com