Redundant driving underwater gate valve executing mechanism

An actuator, driving water technology, applied in the direction of engine components, valve details, valve devices, etc., can solve problems such as maintenance difficulties, affecting the normal production of underwater oil and gas fields, etc., to ensure sealing performance, reduce the risk of sticking, and avoid pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

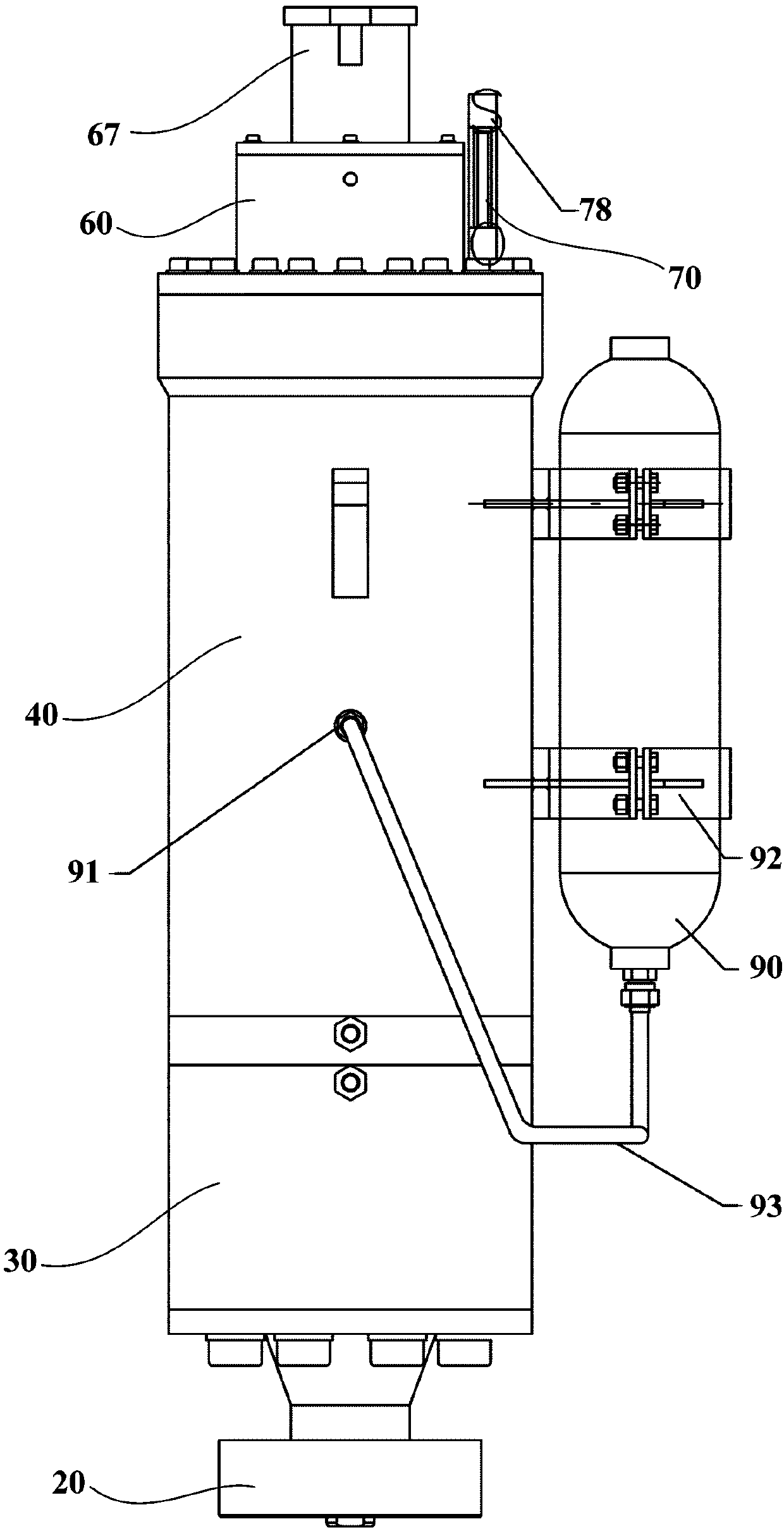

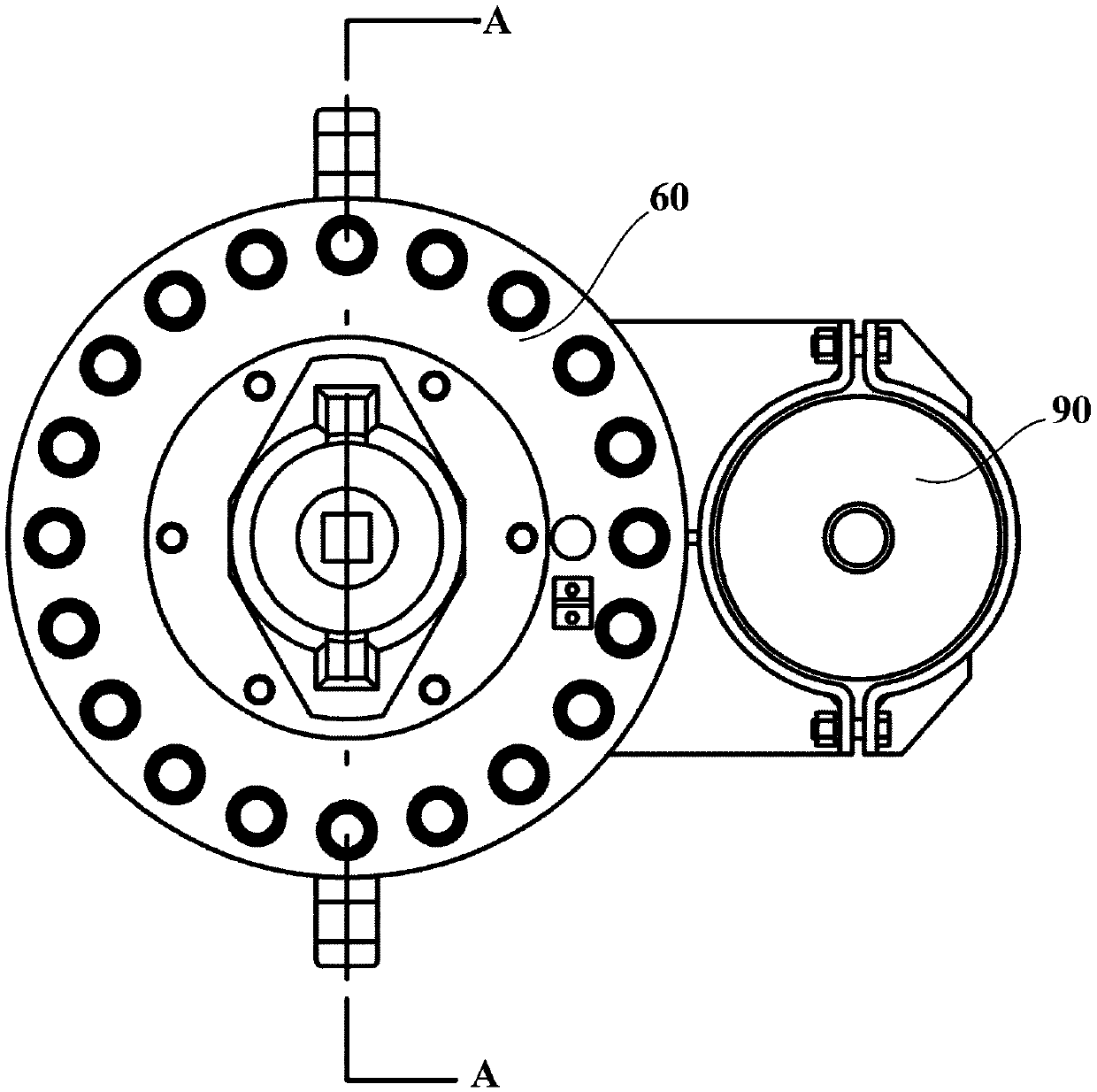

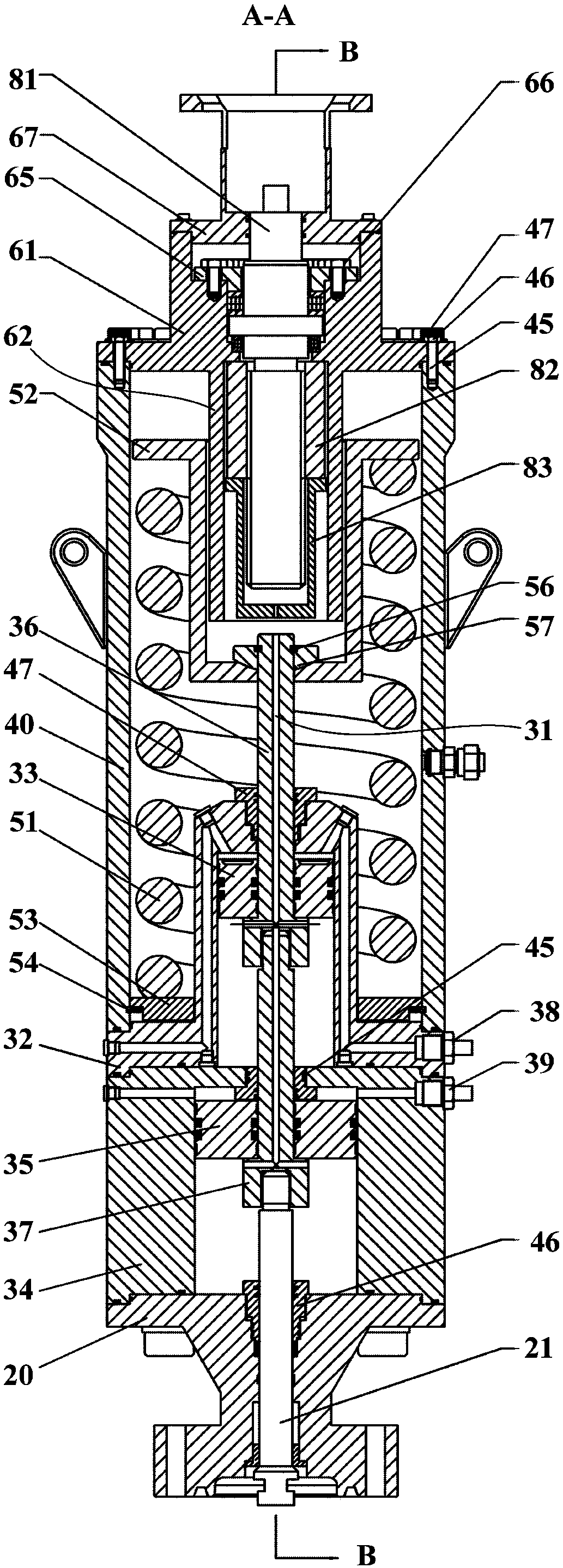

[0043] figure 1 It is a schematic front view of a redundantly driven underwater gate valve actuator according to an embodiment of the present invention. Such as figure 1 shown, and refer to Figure 2 to Figure 4 , the embodiment of the present invention provides a redundantly driven underwater gate valve actuator. The redundantly driven underwater gate valve actuator includes a valve body end cover 20, a valve stem 21 that can move up and down through the valve body end cover 20 and is sealingly connected with the valve body end cover 20, a hydraulic drive device 30, and a mechanism housing. Body 40 , reset assembly 50 , upper end cover 60 , valve stem position indicating assembly 70 , ROV driving device 80 and pressure compensator 90 .

[0044] The hydraulic drive device 30 is connected to the valve body cover 20 and has a piston rod, at least one cylinder and at least one piston. Each piston is located within a cylinder. The lower end of the piston rod is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com