Patents

Literature

70results about How to "Reduced risk of getting stuck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

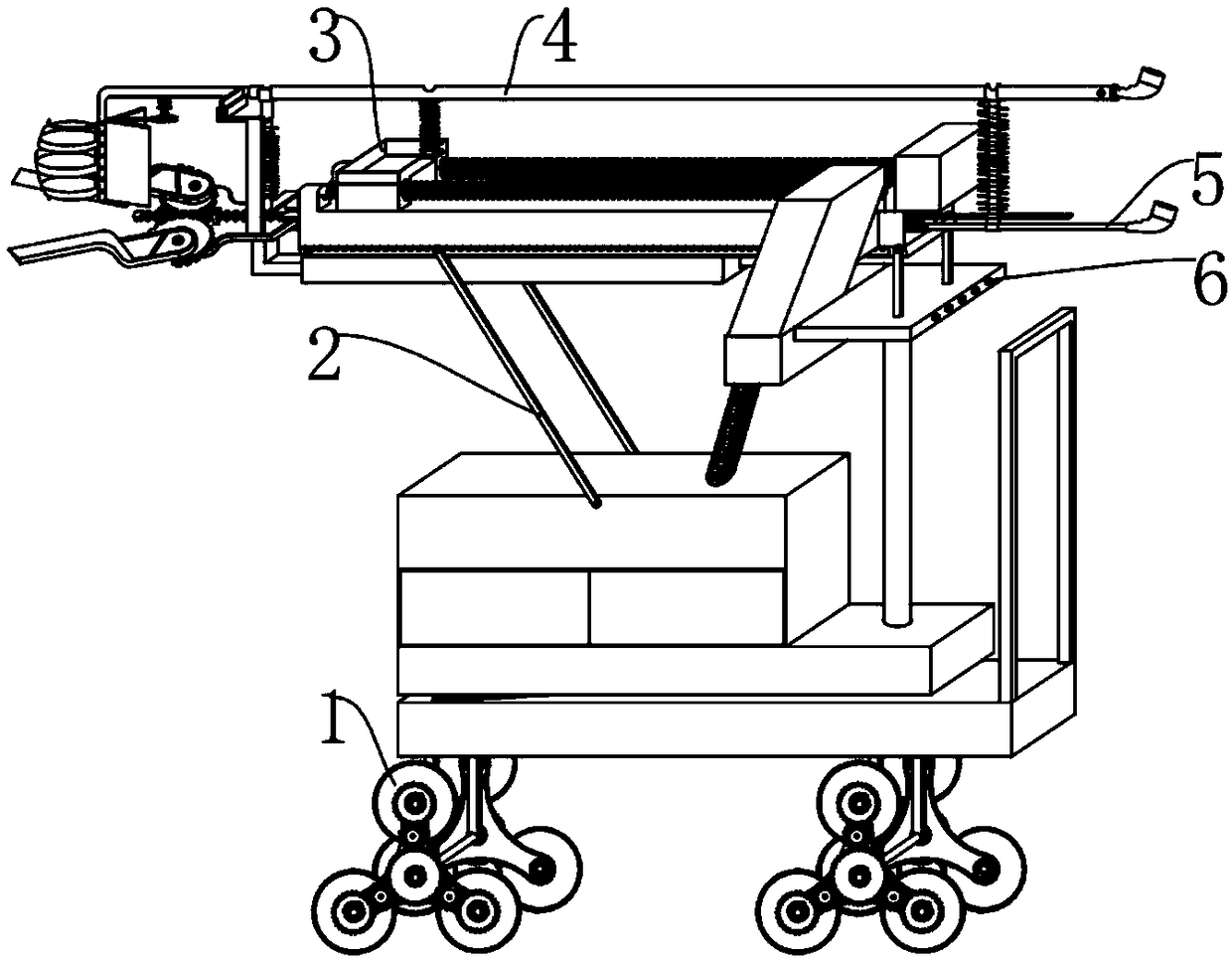

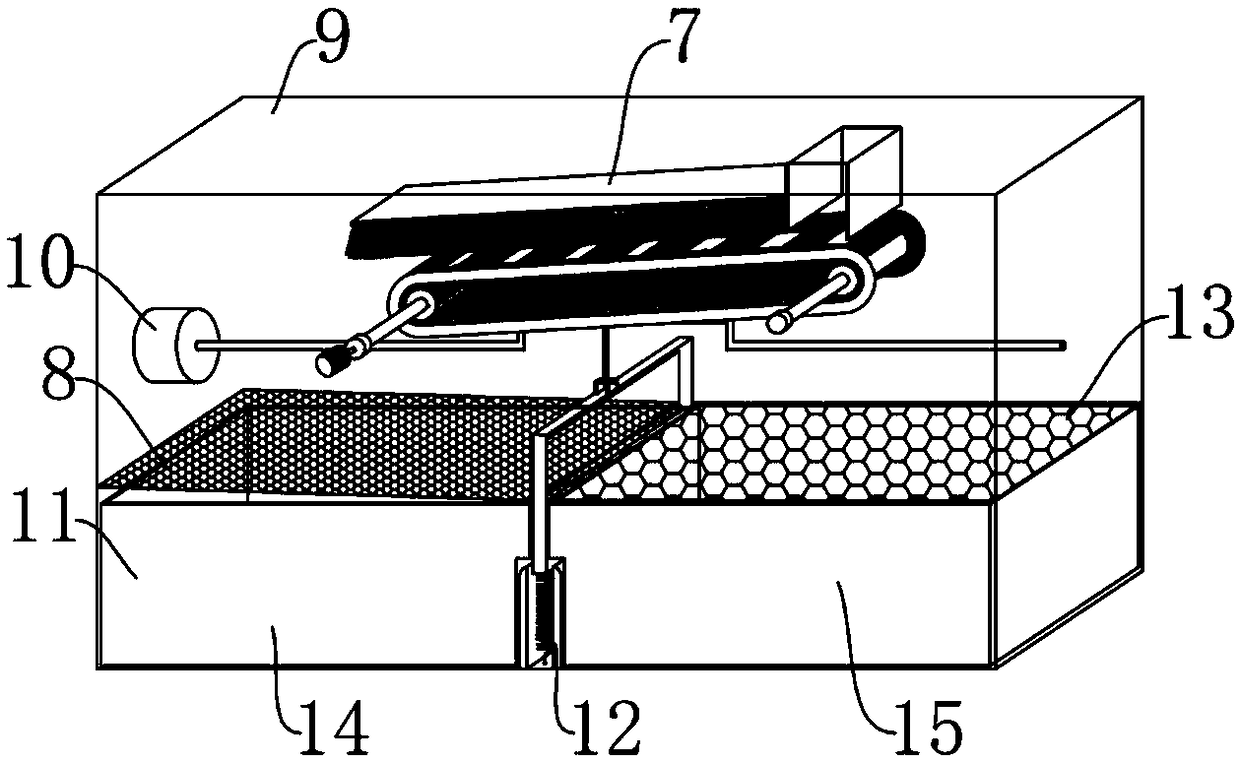

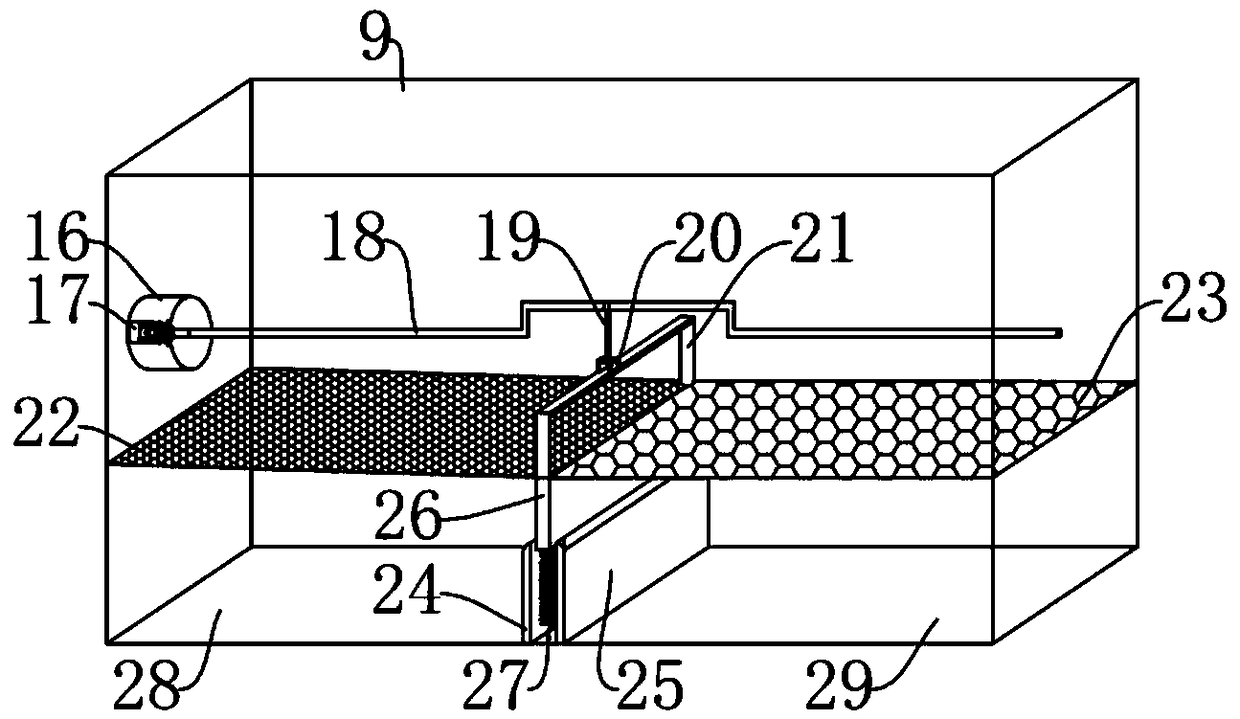

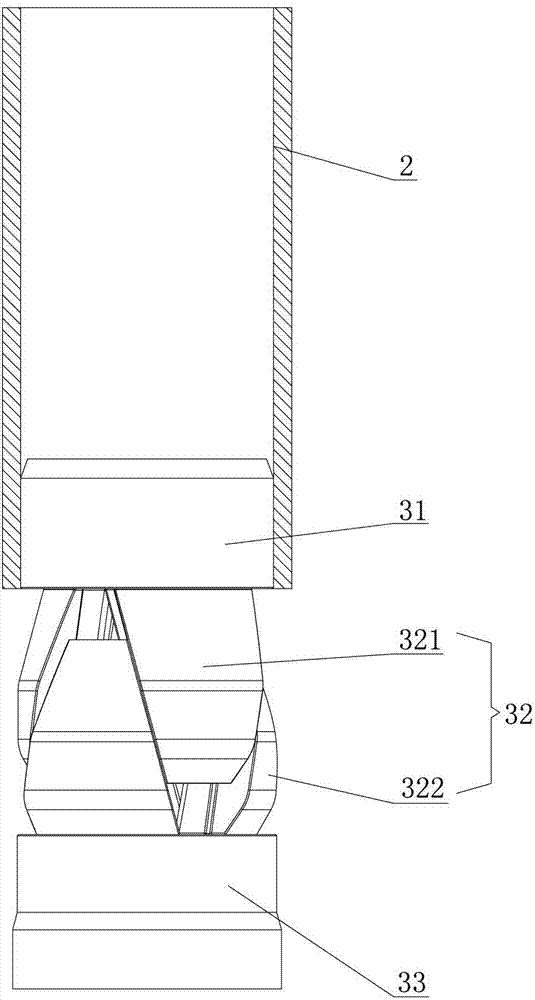

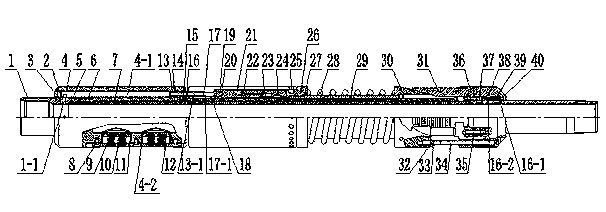

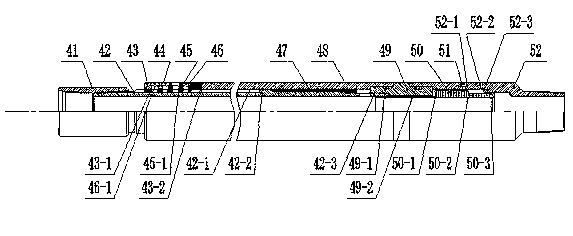

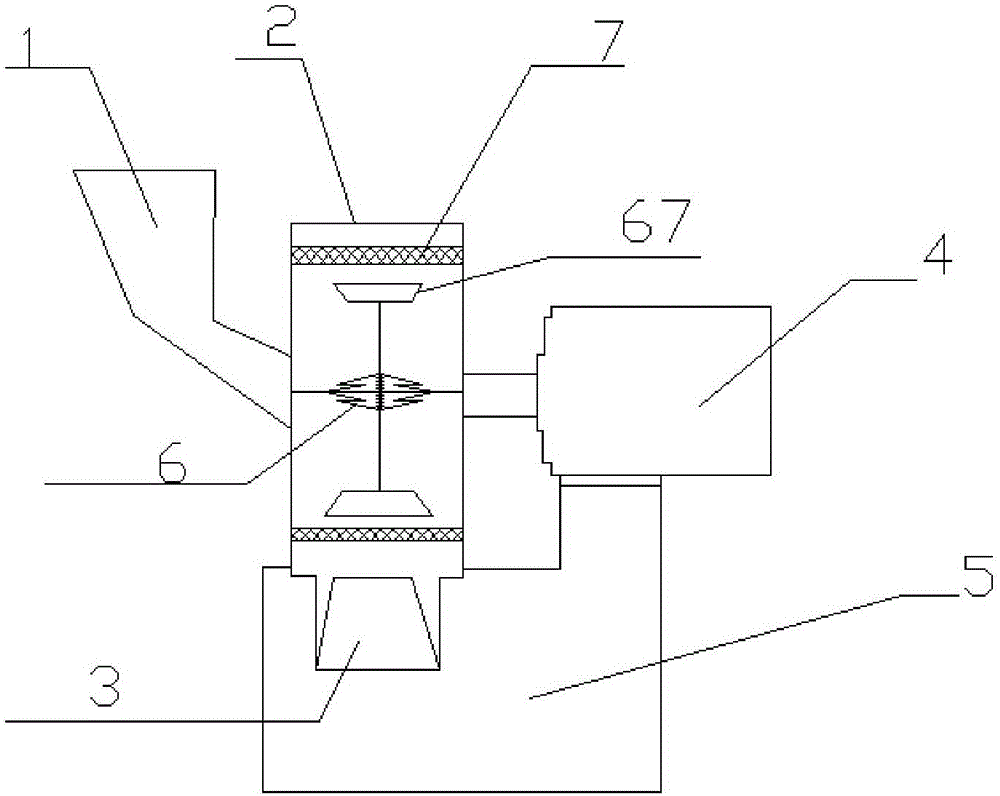

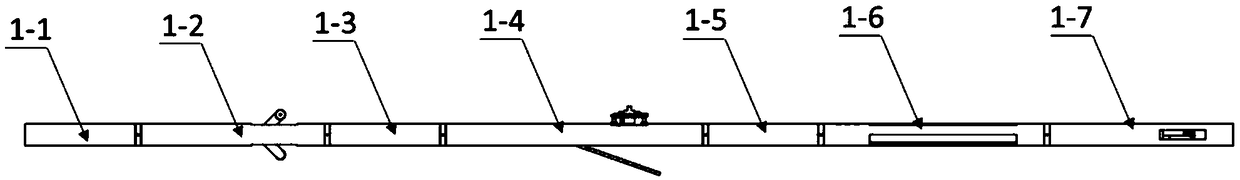

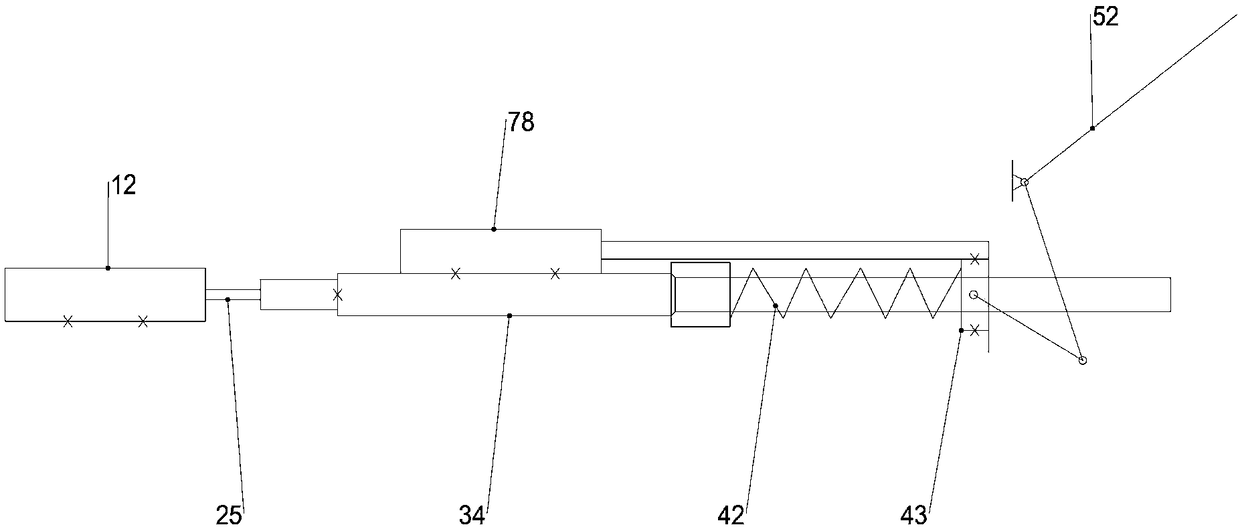

Picking cart for prickly pear

ActiveCN109287270ASimple structureImprove picking safetySievingScreeningPEARAgricultural engineering

The invention discloses a picking cart for prickly pear. The cart comprises a mobile mechanism, a cutting mechanism, a tightening mechanism, a conveying mechanism, a thorn removal mechanism, a screening mechanism, a supporting mechanism and a key module. The supporting mechanism is arranged on the mobile mechanism, the screening mechanism is arranged on the mobile mechanism, and the thorn removalmechanism is arranged on the screening mechanism; the cutting mechanism is arranged on the supporting mechanism, the conveying mechanism is arranged on the cutting mechanism and the mobile mechanism,the tightening mechanism is arranged on the cutting mechanism, and the key module is arranged on the supporting mechanism and the tightening mechanism. The invention belongs to the technical field ofagricultural machinery and particularly provides the picking cart for the prickly pear. The picking cart for the prickly pear is easy to operate, convenient to move, high in safety and picking efficiency and capable of cutting the prickly pear without damage, guaranteeing that the prickly pear without damage is conveyed to a loading box and achieving real-time thorn removal and screening.

Owner:济宁理工思源物业服务有限公司

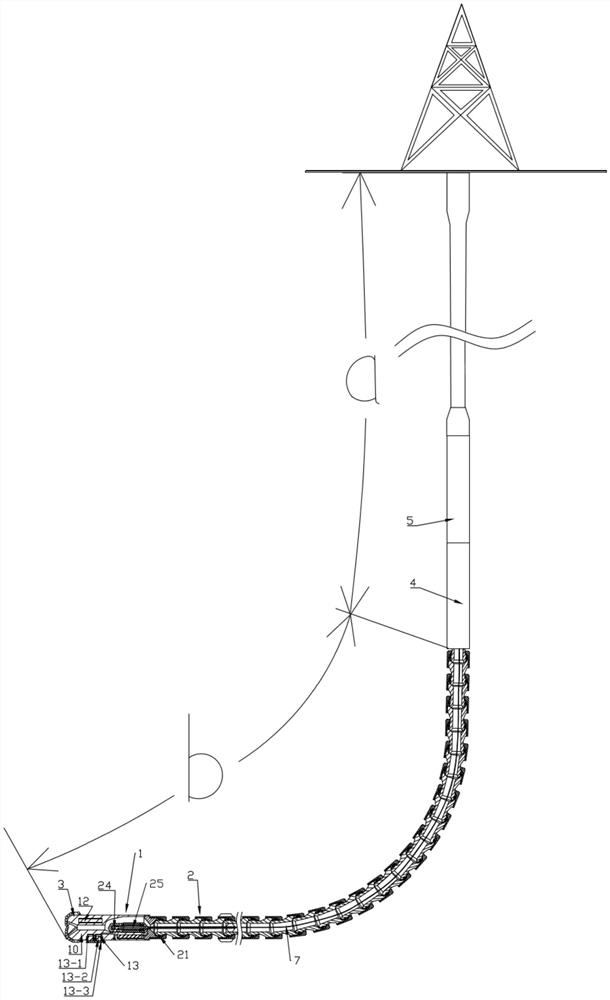

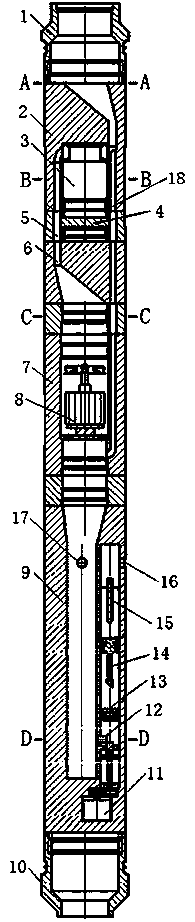

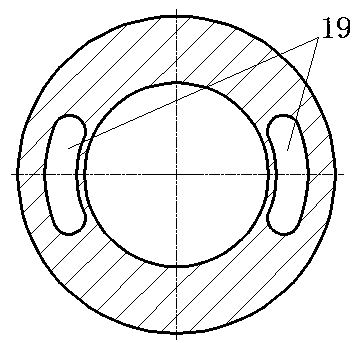

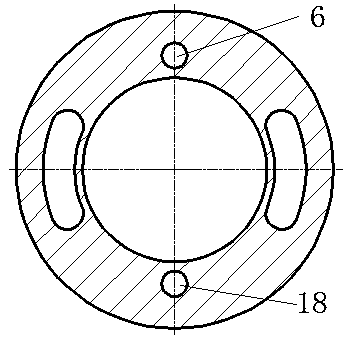

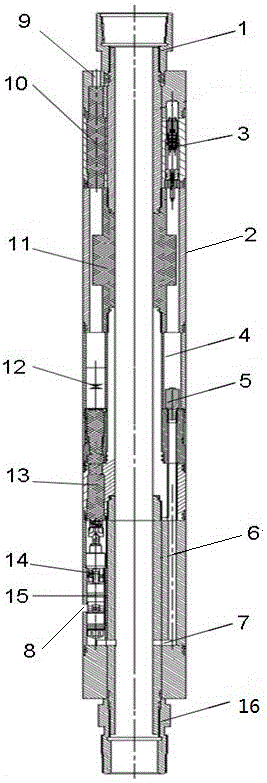

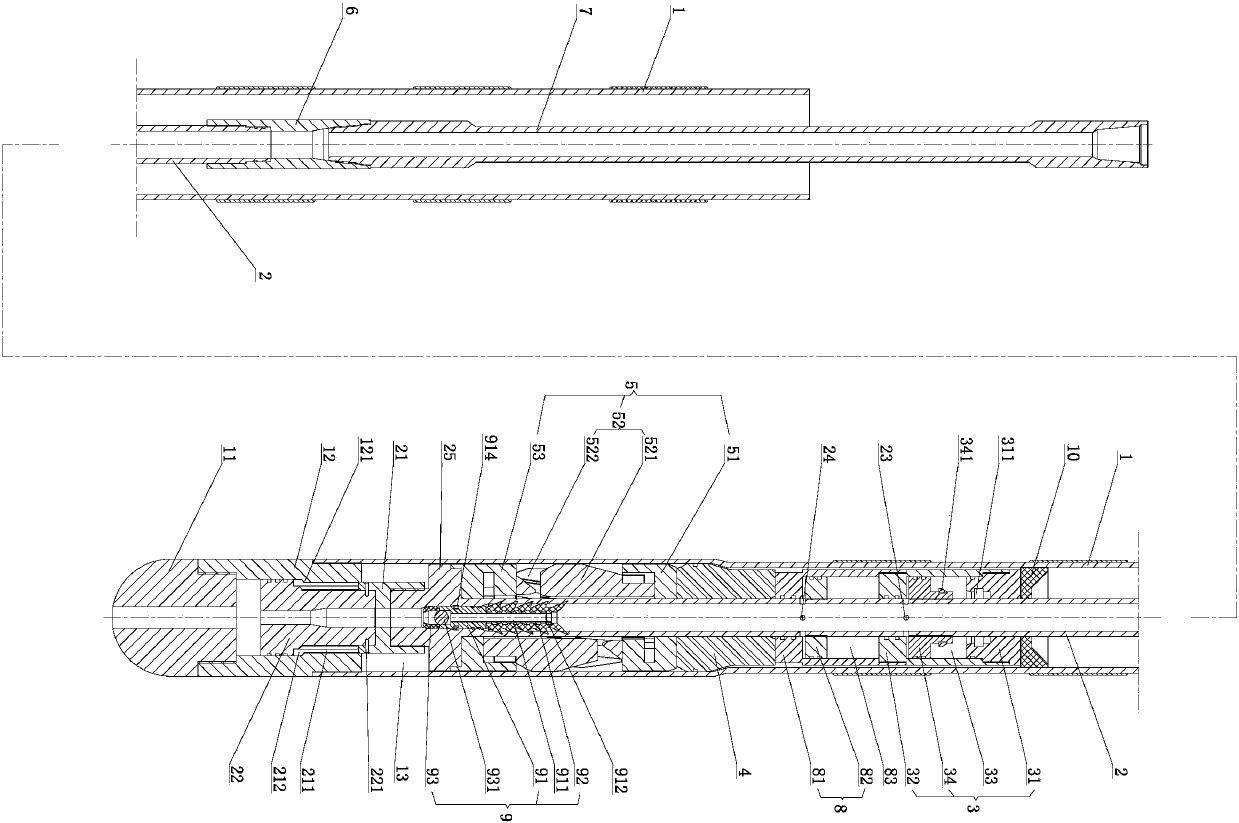

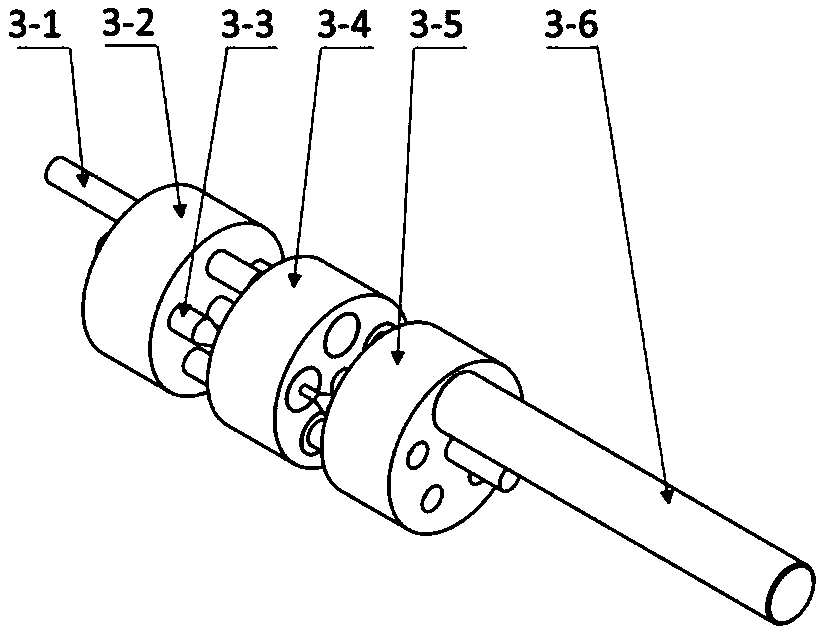

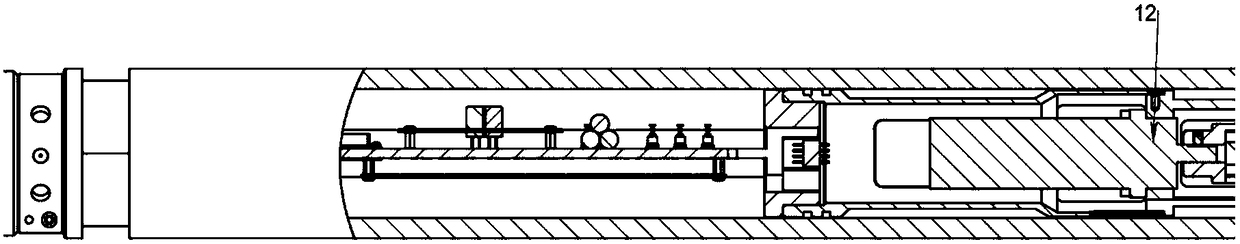

Controllable track lateral drilling tool and method

ActiveCN112832681ASolve the extension problemPracticalSurveyDrilling rodsMining engineeringWell drilling

The invention discloses a controllable track lateral drilling tool and method. The controllable track lateral drilling tool comprises a high-passing-ability lateral drilling section and a drilling power transmission section, wherein the high-passing-ability lateral drilling section can achieve drilling of an extending well section of a short-extremely-short-radius well section through the short-extremely-short-radius well section extending from the lateral direction of a main borehole. According to the designed controllable track lateral drilling tool, the borehole can be obliquely drilled at the tail end or any position in the middle of an original borehole track in a short-extremely-radius mode and then extends and is drilled in the lateral direction; and meanwhile, the controllable track lateral drilling tool has engineering feasibility and practical value on thin reservoir development, remaining oil potential tapping, under-salt reservoir horizontal well development, multi-layer system merging development, coal bed gas development, coal mine underground gasification development, unconventional oil and gas development, shallow horizontal well drilling, seabed shallow horizontal well drilling and development of other kinds of minerals.

Owner:万晓跃

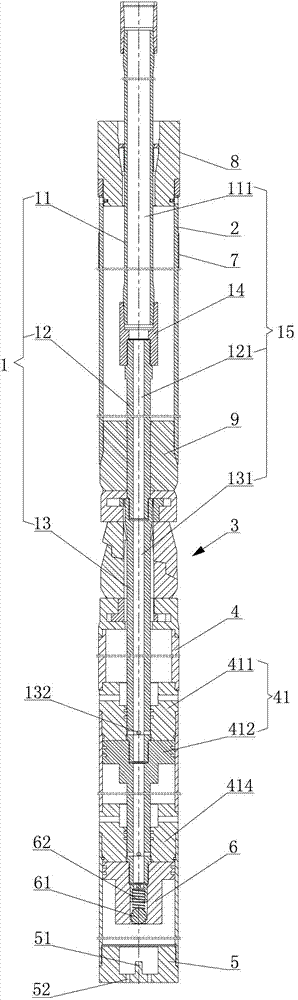

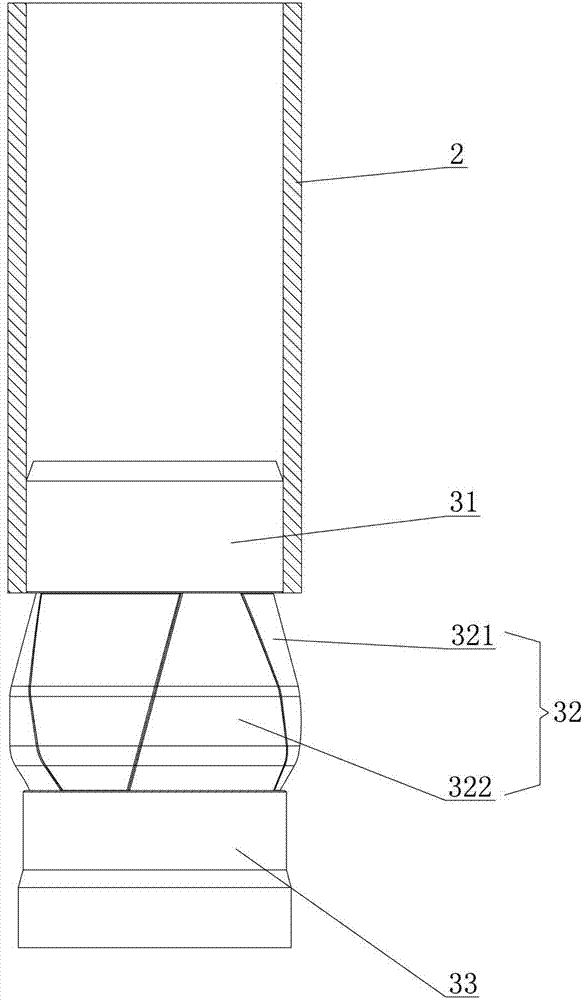

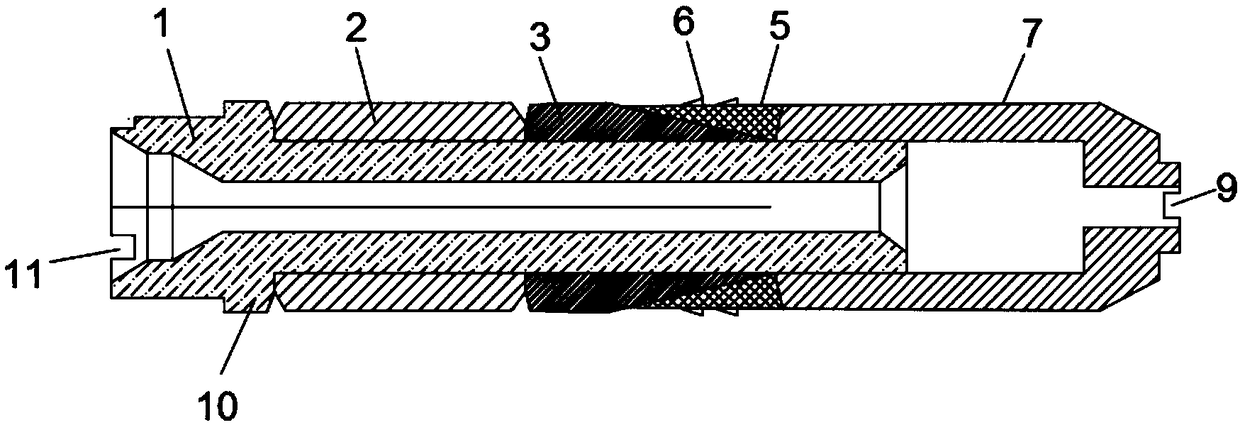

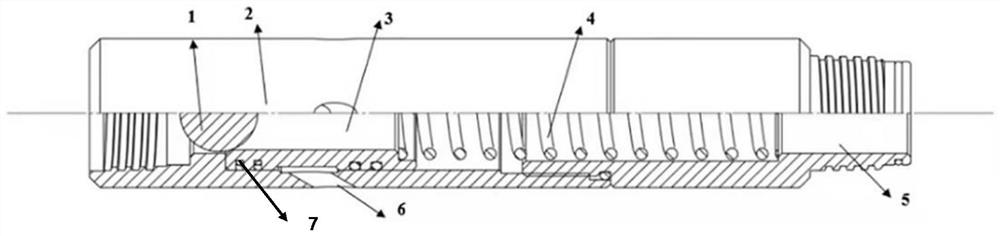

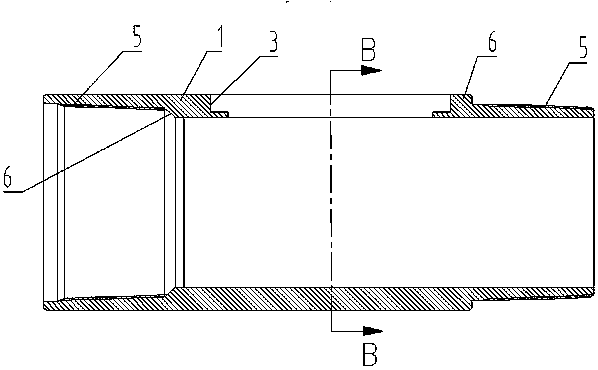

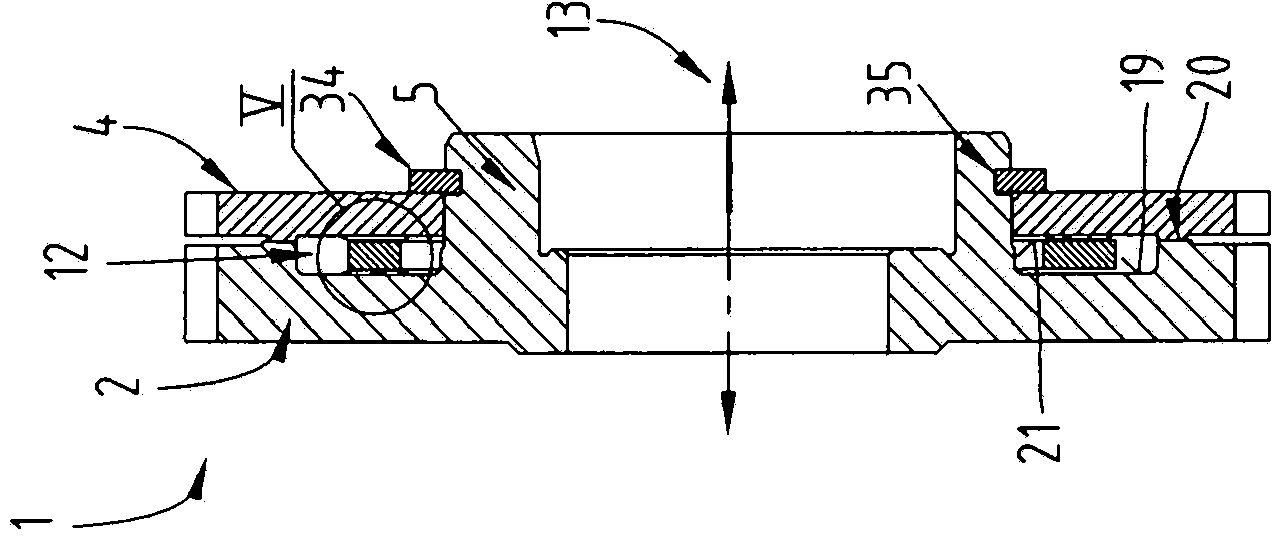

Expansion pipe

ActiveCN102966327AMaximize the expansion rateNo loss of sizeSealing/packingHydraulic cylinderEngineering

The invention discloses an expansion pipe which comprises a pressure pipe column, an expansion pipe body, a combined reducing expansion cone, a hydraulic cylinder and a bull nose, wherein the pressure pipe column is provided with an oil pipe, a connecting pipe and a center pipe which are sequentially connected; the oil pipe is sleeved with the expansion pipe body; the combined reducing expansion cone is positioned at the lower end of the expansion pipe body; the center pipe is sleeved with the combined reducing expansion cone; the hydraulic cylinder is positioned at the lower end of the combined reducing expansion cone; a plurality of pressurizing devices which are connected in series are arranged in the hydraulic cylinder; the lower ends of the pressurizing devices are connected with a ball valve seat; and the bull nose is connected to the lower end of the hydraulic cylinder. According to the expansion pipe disclosed by the invention, the combined reducing expansion cone is arranged outside the expansion pipe body of the expansion pipe, so that the diameter of the pipe column is minimized in the process that the pipe column extends into a barefoot well, and the risk that the pipe column is blocked in the extending process is reduced; and moreover, the reducing expansion can be implemented by the combined reducing expansion cone, the expansion ratio of the expansion pipe can be maximized, the expansion pipe blocks off a layer section of a troublesome stratum of the barefoot well after being expanded, and the effect of no loss of the size of a borehole can be implemented.

Owner:PETROCHINA CO LTD

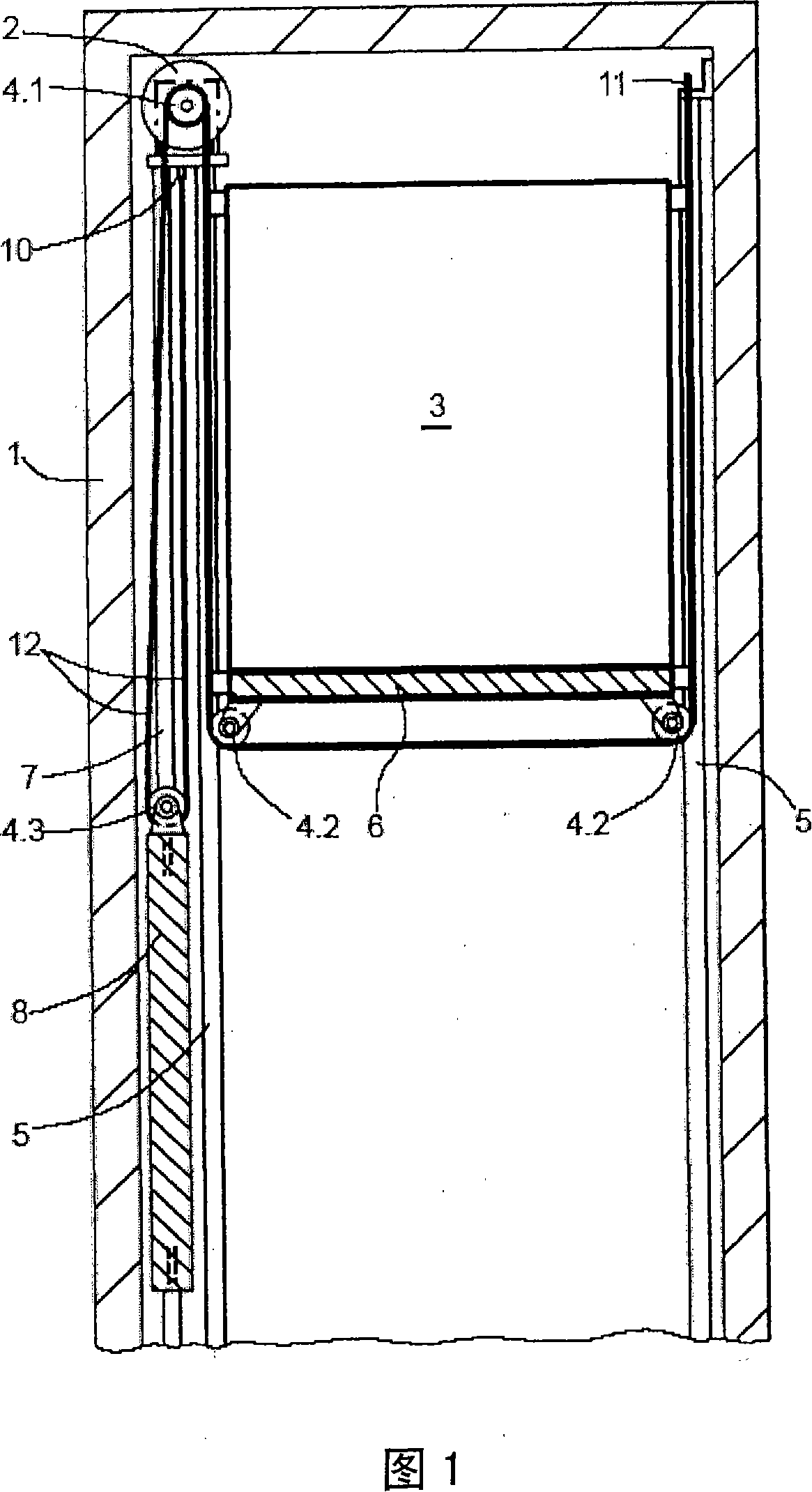

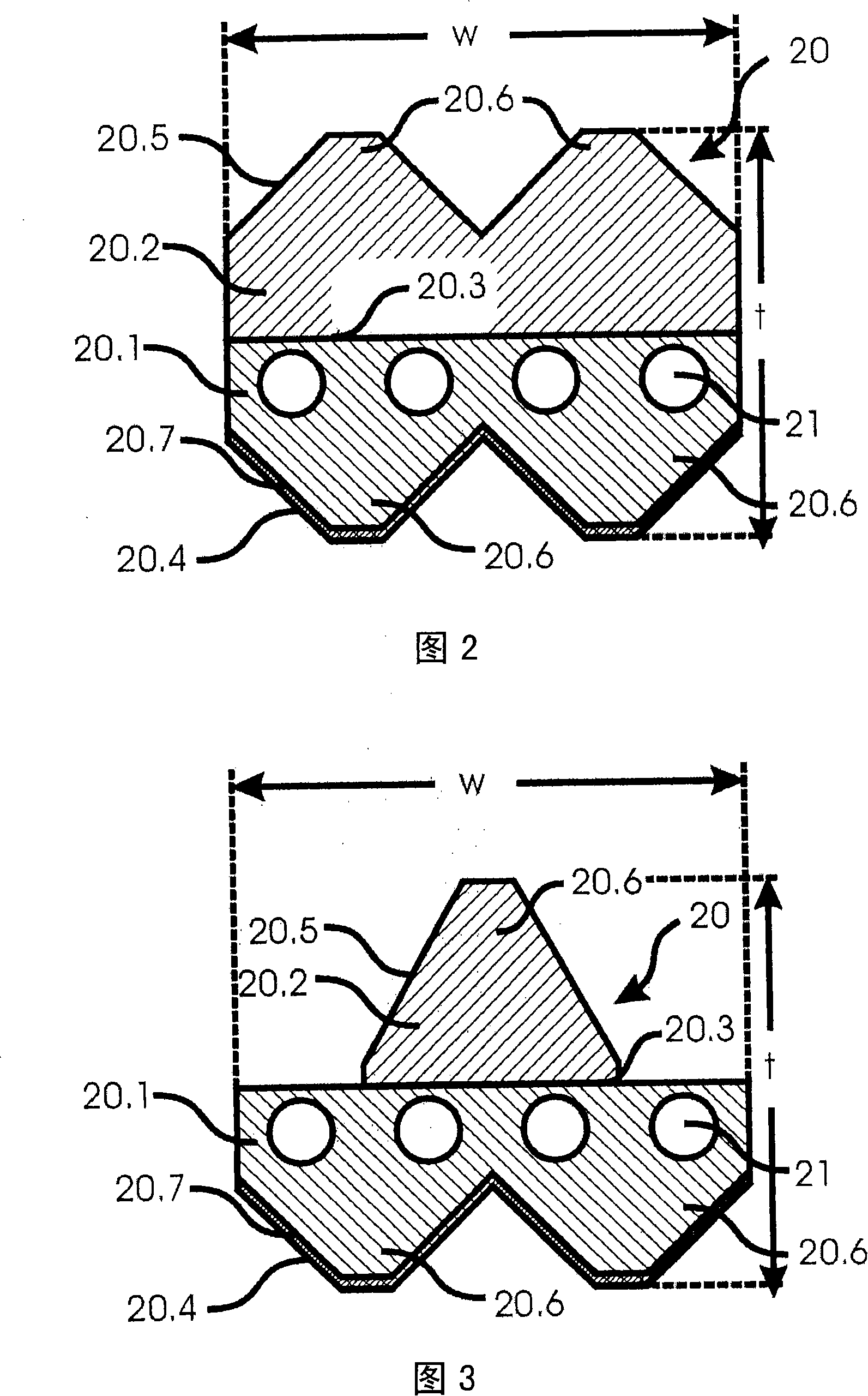

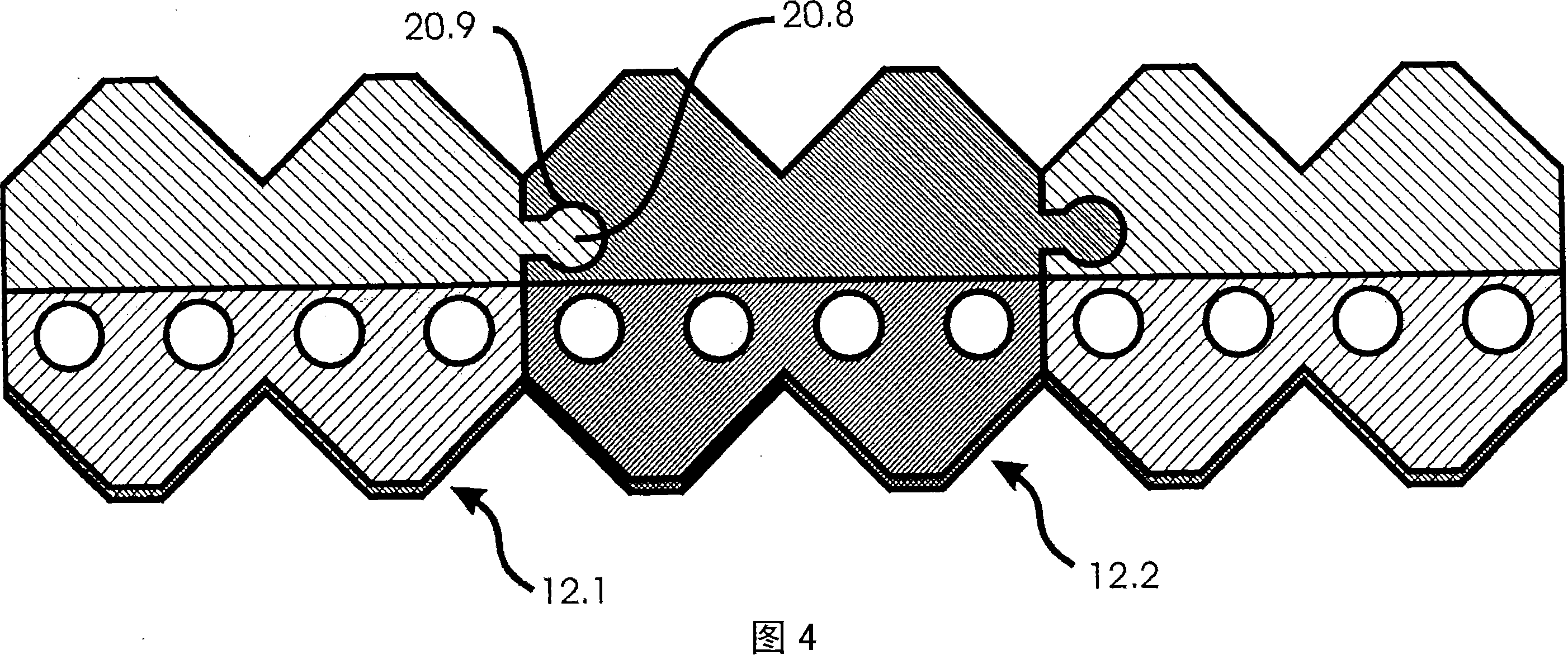

Lift facility, belt for such a lift facility, method for manufacturing such a belt, combination of such a belt and method for assembling such a combination in a lift facility

InactiveCN101121487AReduced risk of getting stuckLarge geometric moment of inertiaElevatorsBeltsEngineeringMechanical engineering

Owner:INVENTIO AG

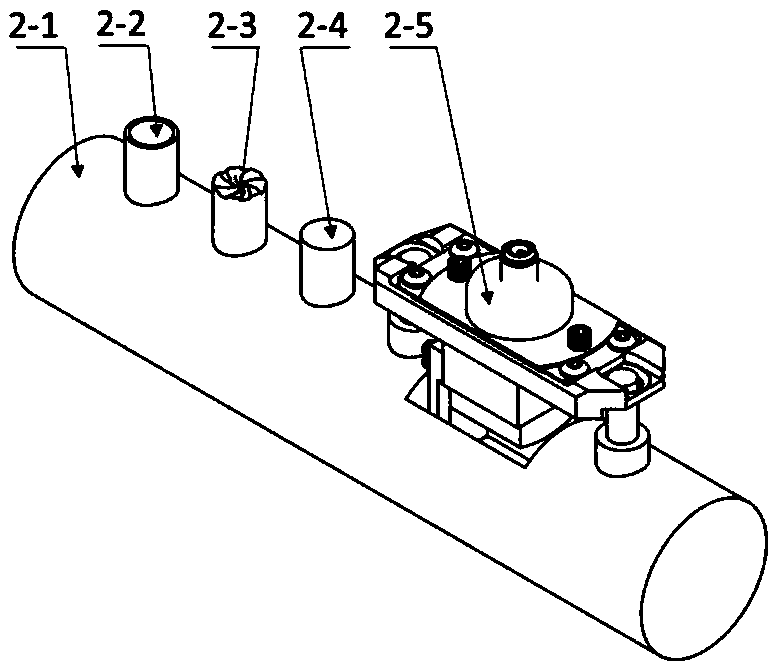

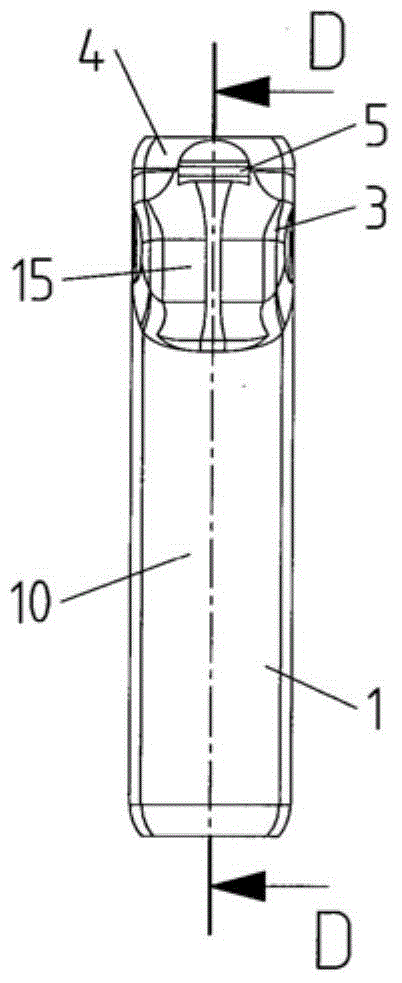

Jet dredging pipe cleaner

InactiveCN103551351AEasy to operatePracticalHollow article cleaningPressure controlled ventilationPressure control

The invention discloses a jet dredging pipe cleaner which comprises a pipe cleaner body (1) with the outline in a cylinder shape, an annular pipe cleaner scraping plate (2) is arranged on the periphery of the pipe cleaner body (1), a fluid channel (3) penetrates the pipe cleaner body (1), a jet port (4) is formed in the fluid channel (3) at the position of the tail end of the pipe cleaner body (1), a pressure control valve (5) for controlling on-off of the fluid channel (3) is arranged on the pipe cleaner body (1), is opened when the head end fluid pressure of the pipe cleaner body (1) is higher than a preset value and is closed when the head end fluid pressure of the pipe cleaner body (1) is lower than the preset value. By using the jet dredging pipe cleaner to conduct pipe cleaning operation, risks of subsea pipe blocking in subsea pipe cleaning operation are greatly reduced, and subsea pipe blocking removing cost and blocking removing uncertainties are reduced. The pipe cleaner is simple, easy to operate and practical.

Owner:CHINA NAT OFFSHORE OIL CORP +1

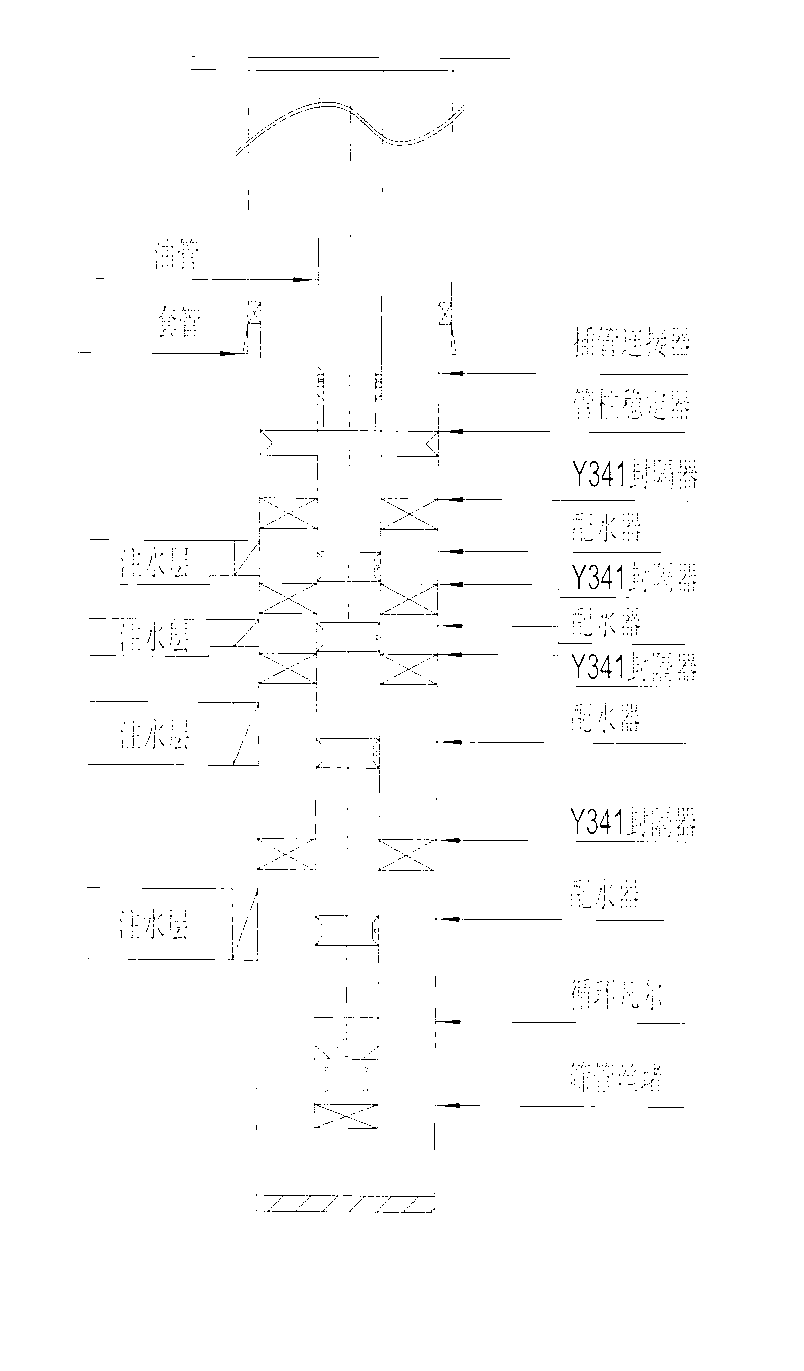

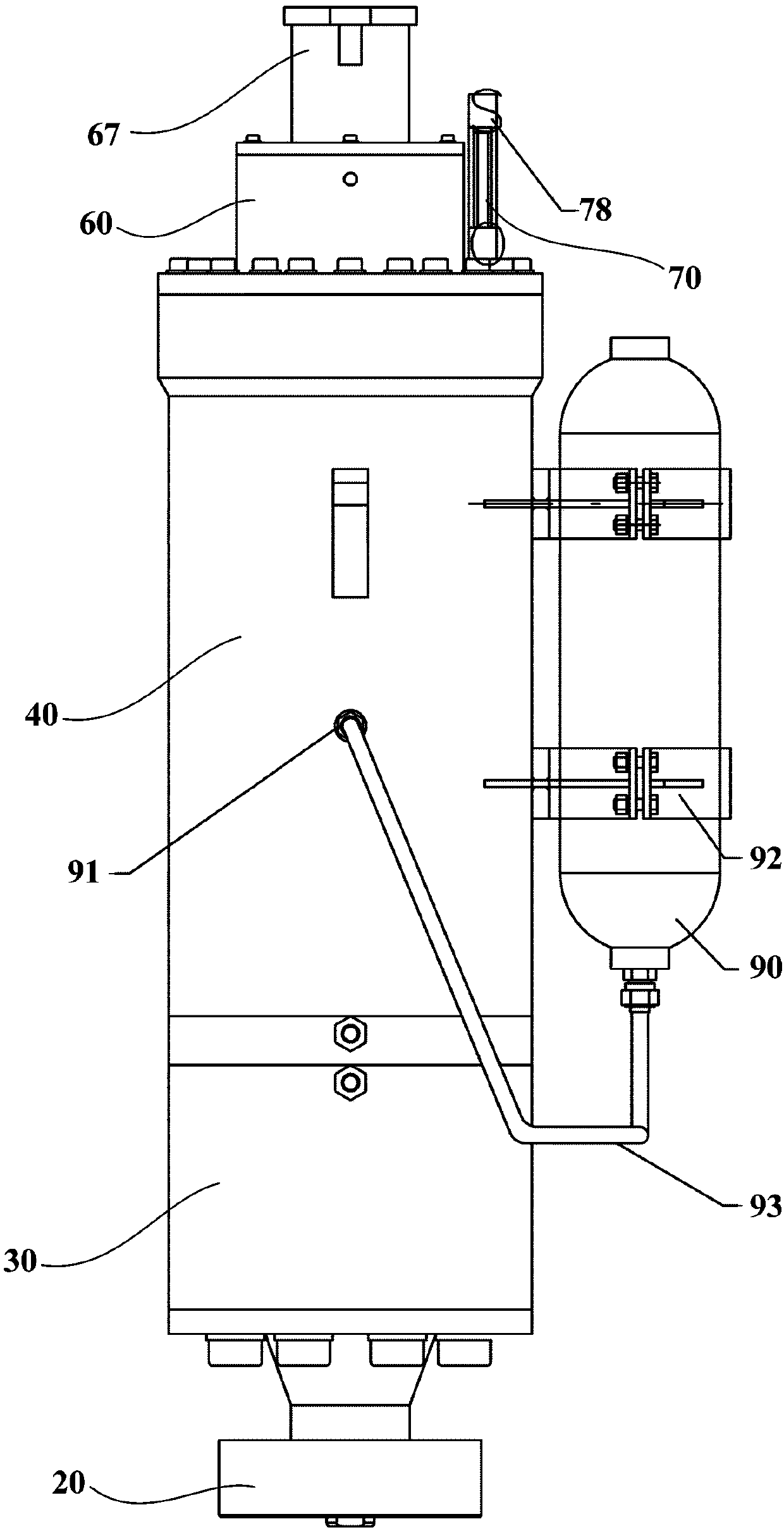

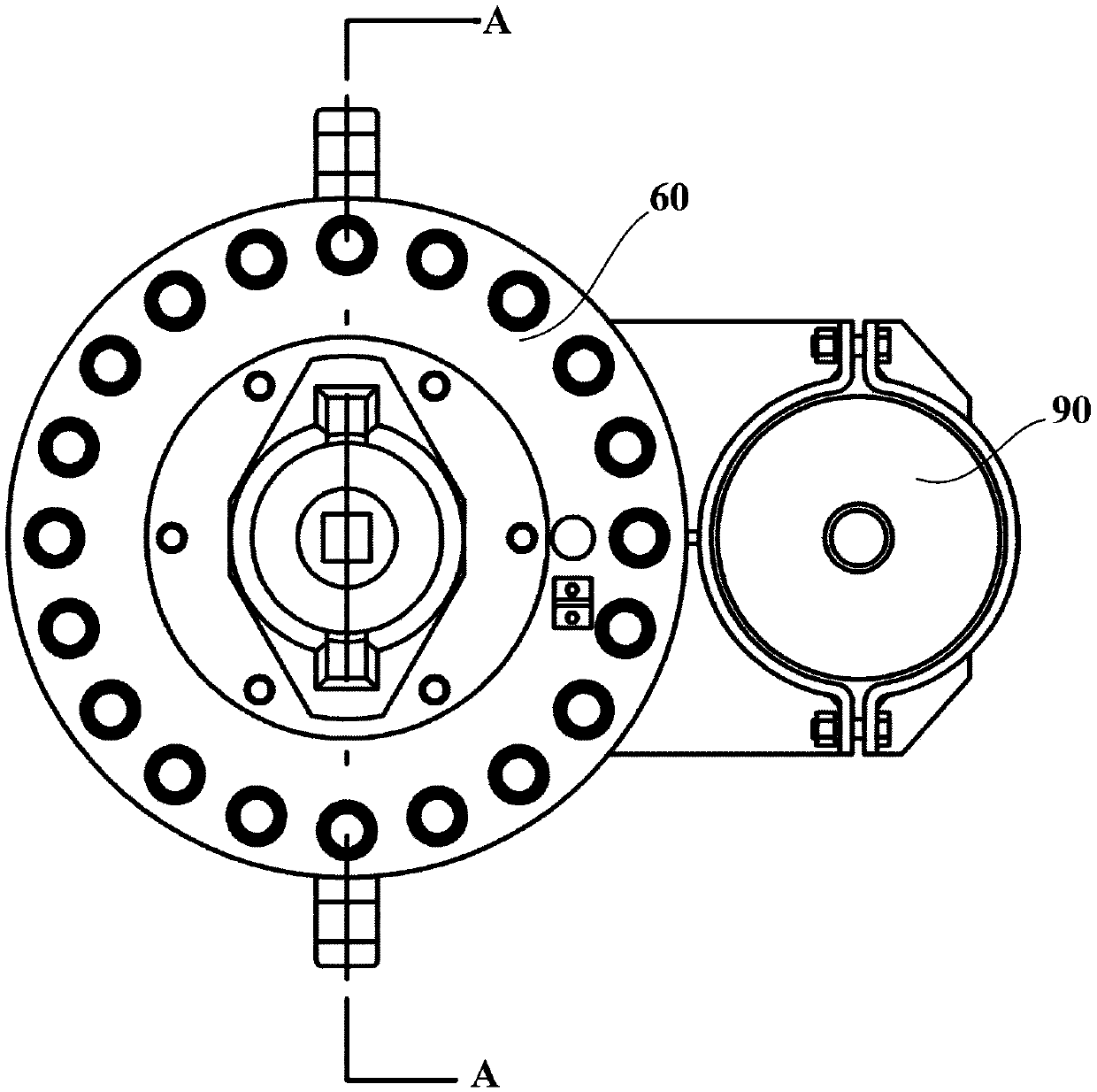

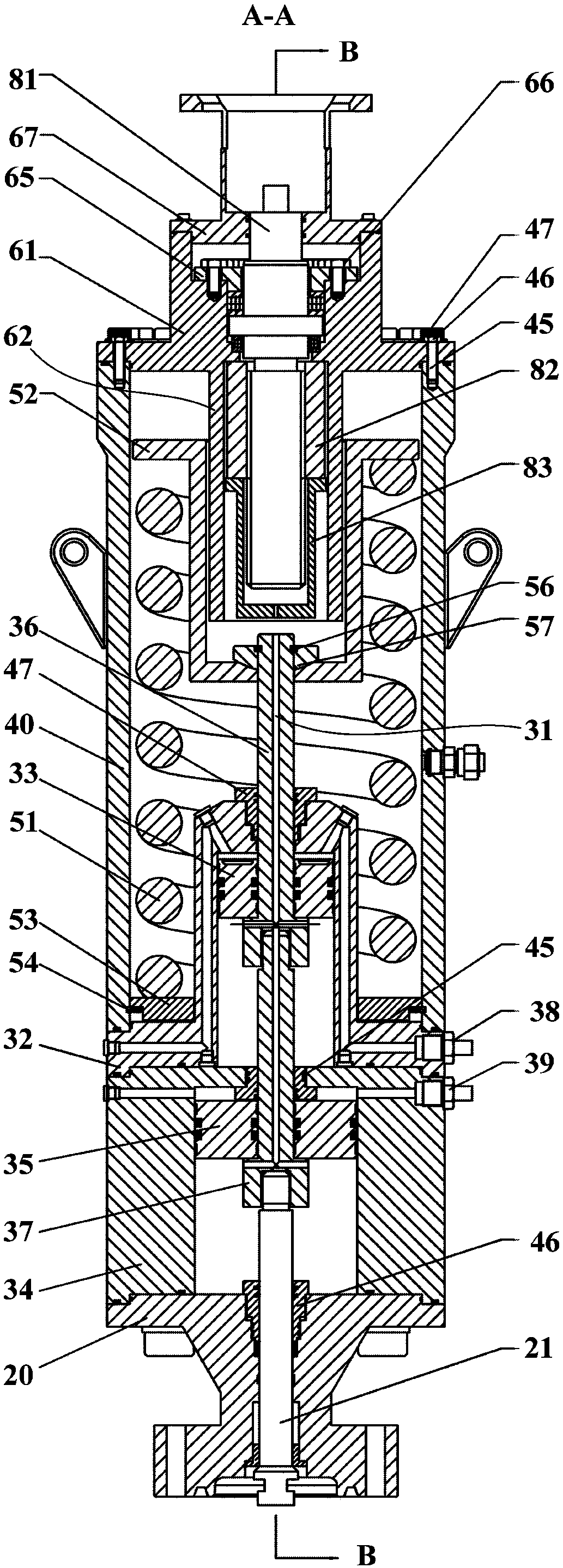

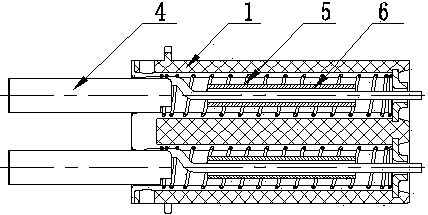

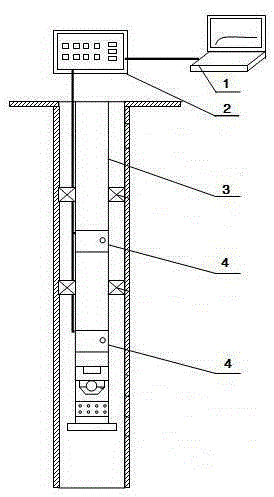

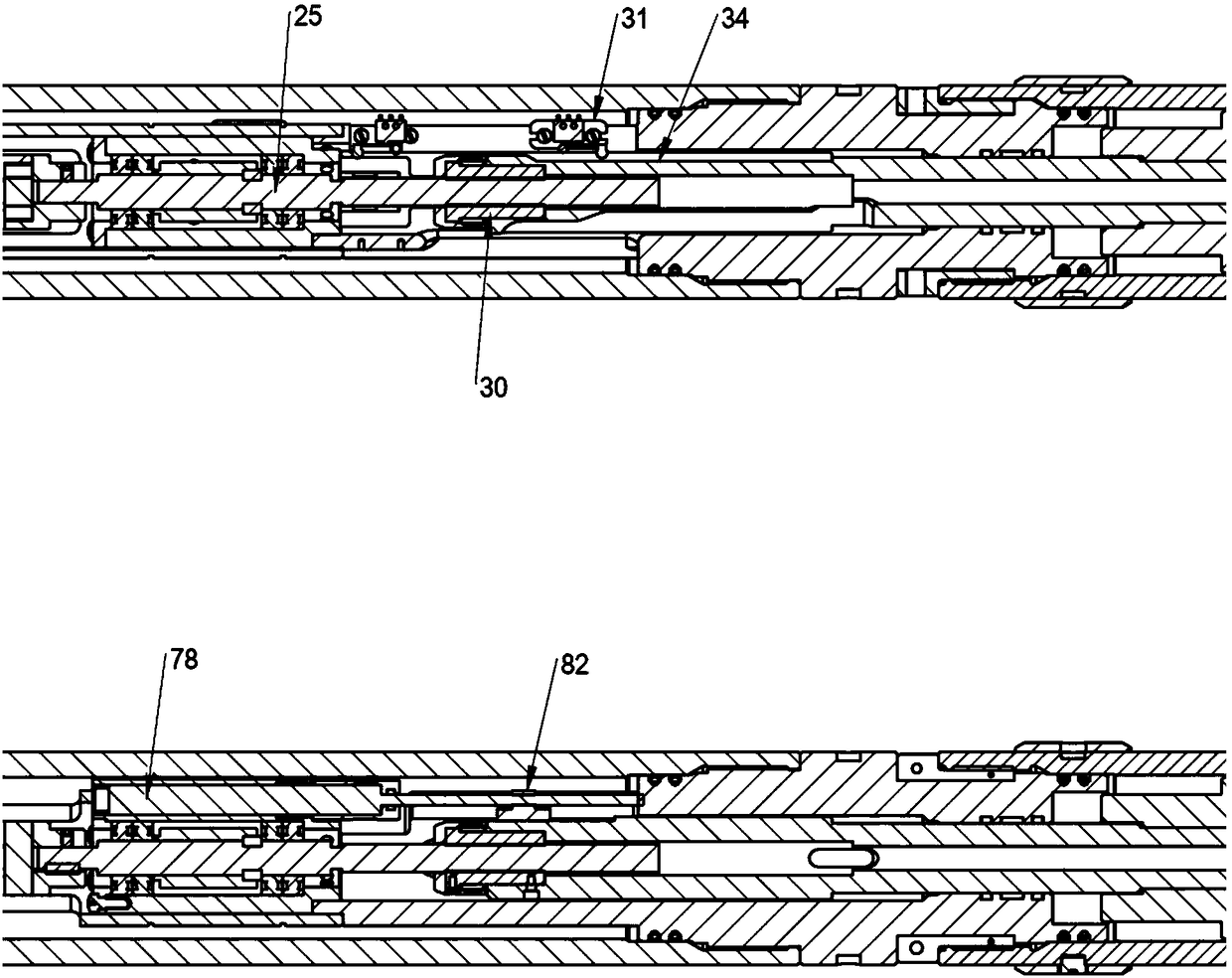

Layering water injection flow intelligent adjusting system under pit

ActiveCN109083623AReduce labor intensityReduced risk of getting stuckFluid removalWell/borehole valve arrangementsResistance thermometerThermistor

The invention relates to a layering water injection flow intelligent adjusting system under a pit. The layering water injection flow intelligent adjusting system under the pit comprises a PLC controlunit, an upper joint, a cone-hole flow passage converting pipe, a power generation unit, an intelligent water dispenser and a lower joint, wherein the upper joint, the cone-hole flow passage converting pipe, the power generation unit, the intelligent water dispenser and the lower joint are successively connected from top to bottom, two deflected holes are formed in both sides of the cone-hole flowpassage converter pipe, and an upper round taper hole is located between the two deflected holes; the tail end of the upper round taper hole is communicated with a power generation branch and a waterinjection branch, an electromagnetic valve is installed on the cone-hole flow passage converter pipe, and the tail end of the power generation branch is connected with a lower round taper hole; the lower round taper hole is communicated with the power generation unit, and an impeller power generator under the pit is arranged in the power generation unit; the lower end of the power generation unitand the water injection branch are connected with the intelligent water dispenser, a water dispensing cavity of the intelligent water dispenser is communicated with a water outlet cavity through an adjustable water nozzle, a platinum thermistor thermometer, a lever flowmeter and a silicon piezoresistive pressure meter are arranged in the water outlet cavity, and the adjustable water nozzle is connected with a gear motor. Repeated throwing and catching operations are not needed, and the water injection amount can be adjusted in real time.

Owner:华运隆腾机械制造有限公司

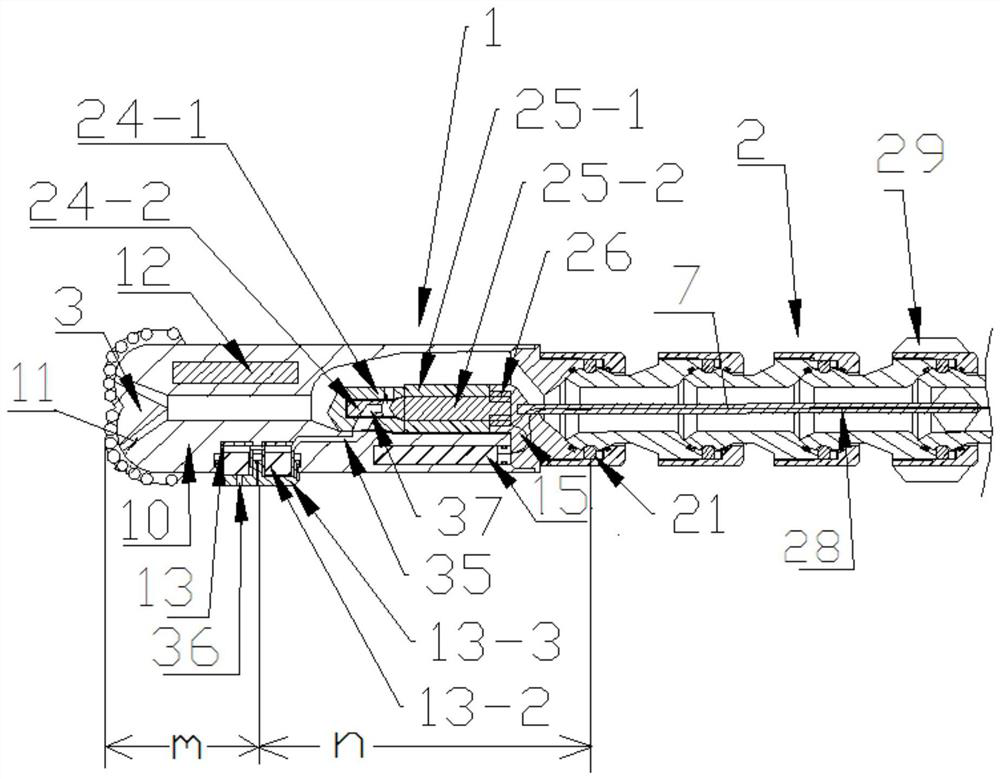

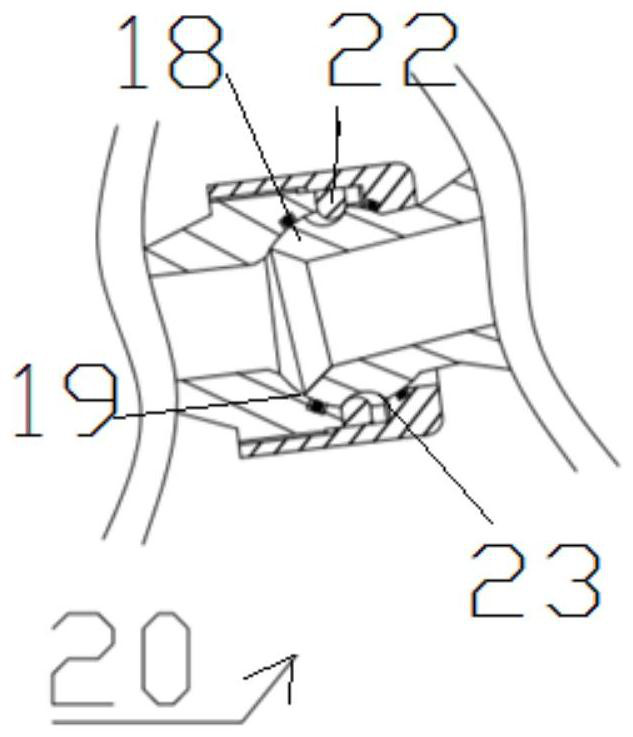

Insertion pipe type release separate-layer water injection string and operation process thereof

The invention relates to an oil field separate-layer water injection process and a matched tool, in particular to an insertion pipe type release separate-layer water injection string and an operation process thereof. The insertion pipe type release separate-layer water injection string is formed by a conventional separate injection tool string, an intubation tube connector and a string stabilizer; and the intubation tube connector and the string stabilizer are sequentially arranged at the upper part of the conventional separate injection tool string. According to the invention, by anchoring of a release and sealed water injection of an intubation tube, the force condition of the separate injection string is changed; a separated upper blank tubing is suspended at a wellhead; the separated separate injection tool string is anchored and suspended on the string stabilizer; the blank tubing at the upper part is in intubation tube seal fit with the string stabilizer and the separate injection tool string at the lower part without being in screwed connection with the string stabilizer and the separate injection tool string at the lower part; the hazard to a packer rubber sleeve at the lower part, which is caused by vermiculation of the string at the upper part when water injection pressure and temperature fluctuate, is fundamentally eliminated; the string stabilizer is released step by step; and the difficult problem that the release string cannot be pulled out is solved. The water injection tool is simply manufactured, is convenient to operate and has high universality.

Owner:李运柱

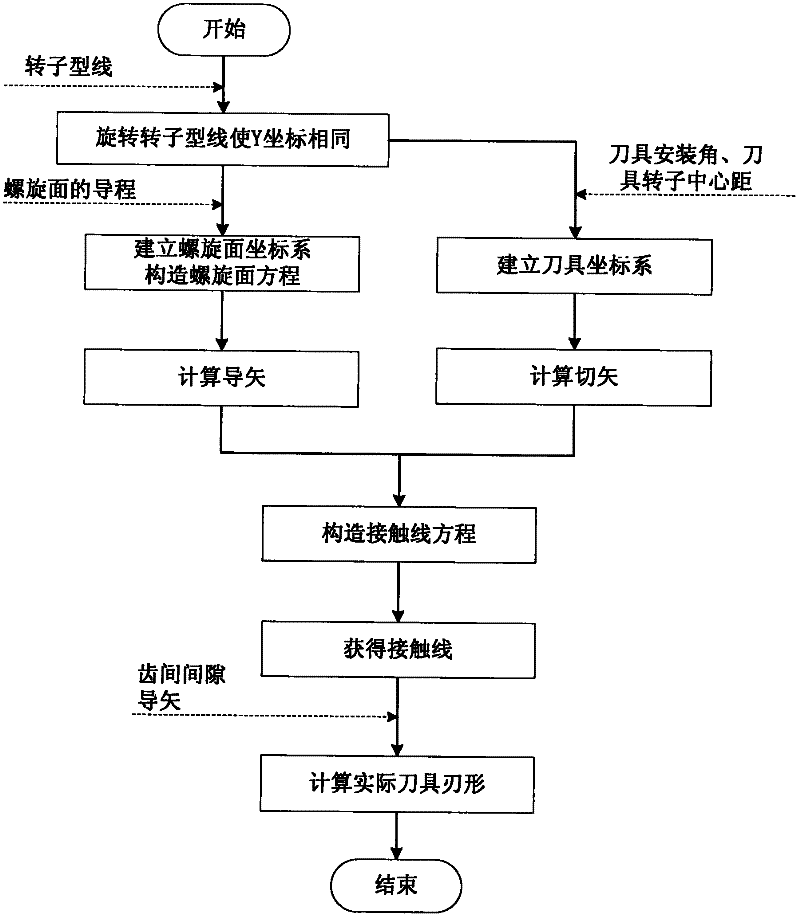

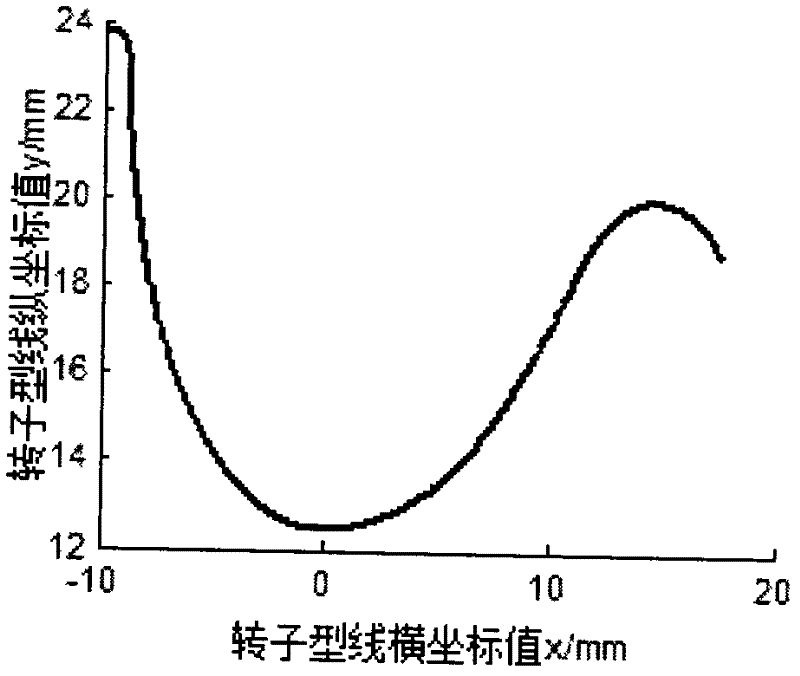

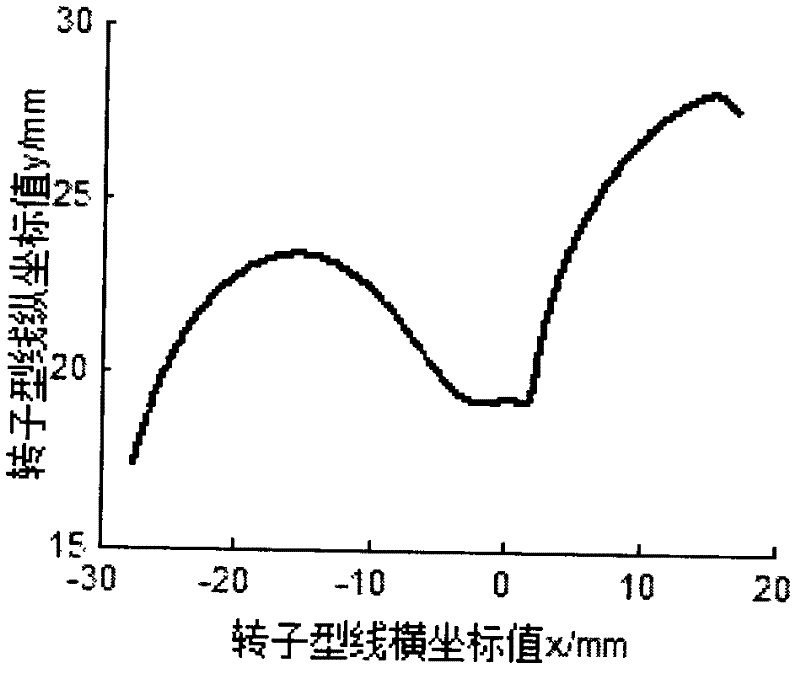

Cutter edge modification method for processing helicoid of screw rotor

ActiveCN102508956AReduced risk of getting stuckGuaranteed safe operationSpecial data processing applicationsEngineeringMechanical engineering

The invention provides a cutter edge modification method for processing the helicoid of a screw rotor. The method has the following beneficial effects: the equidistant tooth surfaces of tooth surfaces of a theoretical rotor processed by a grinding wheel or a cutter are obtained through analysis and computation; the equidistant tooth surfaces are not equal in normal gaps of lines of contact; profile gaps are not equal on the end face of the theoretical rotor and the end face of a practical rotor, namely, when the meshing point is farther from the rotor axis, the profile gaps can be enlarged asthe helical angle is enlarged; and such gap distribution ensures that the tooth surfaces of the rotor are insensitive to change of the side gaps of a synchronous rotor or gear, thus reducing the danger that tooth surfaces of the rotor are stuck and being very beneficial to safe operation of machinery.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Redundant driving underwater gate valve executing mechanism

ActiveCN109538813AAchieve separation and independenceImprove reliabilityOperating means/releasing devices for valvesDynamic balanceEngineering

The invention provides a redundant driving underwater gate valve executing mechanism. The redundant driving underwater gate valve executing mechanism comprises a hydraulic driving device, wherein a piston and a piston rod are arranged to drive the piston rod to move downwards when the piston moves downwards, and the piston rod is separated from the piston when the piston rod moves downwards; a ROVdriving device is provided with a threaded shaft, a transmission nut and a sleeve; the transmission nut and the sleeve can move up and down in the sleeve, the sleeve is located on the lower side of the transmission nut, and the lower end of the sleeve is a contact plate for enabling the upper end of the piston rod to be in contact abutting against the upper end of the piston rod; the threaded shaft is rotationally arranged on the upper cover part and is matched with the transmission nut; and a pressure compensator is arranged on a mechanism shell through a support, and the pressure compensator is connected with a pressure compensation joint through a compensation oil pipe so as to communicate with the inner part of the mechanism shell. The two structures of hydraulic driving and ROV operation can be separated independently, and under the action of deep sea high pressure, the dynamic balance of the outer pressure inside the mechanism shell can be guaranteed.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Method for solving sticking in plug drilling of shale gas long horizontal well coiled tubing

InactiveCN107620580AEffective guidance and standard operationReduced risk of getting stuckBorehole/well accessoriesCoiled tubingShale gas

The invention discloses a method for solving sticking in plug drilling of a shale gas long horizontal well coiled tubing. The method comprises the following steps that 1, an unobstructed condition ofa circulation channel is judged according to wellhead pressure and a condition of reversing out debris; 2, a corresponding combined sticking solving method is adopted according to the type of sticking; and 3, if the sticking solving method in the step 2 is still unable to solve sticking, salvage sticking solving is adopted. In the initial stage of gas field development, situations such as stickingin coiled tubing plug drilling are caused by the facts that personnel risk consciousness is not enough and methods adopted are unreasonable, huge well control safety risks are brought to plug drilling operation, meanwhile, the situation that the gas well can not produce normally is caused, and in severe case, gas well scrap is even caused. By means of the method for solving sticking in plug drilling of the shale gas long horizontal well coiled tubing, the plug drilling construction personnel can be effectively instructed to operate according to requirement specification, the risk of stickingis reduced to be no more than 15, and the success rate of sticking solving is improved to be equal to or greater than 35%.

Owner:CHINA PETROLEUM & CHEM CORP +1

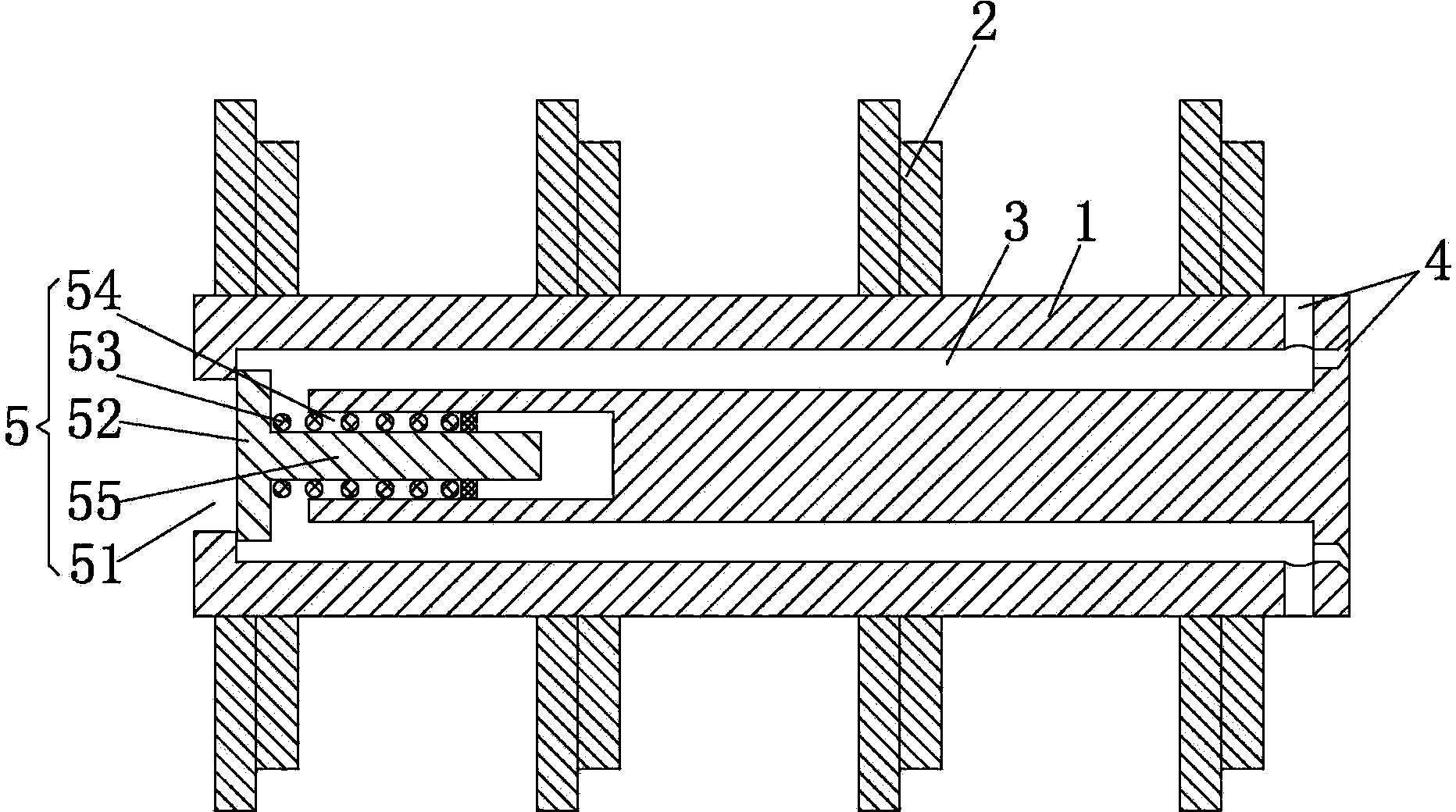

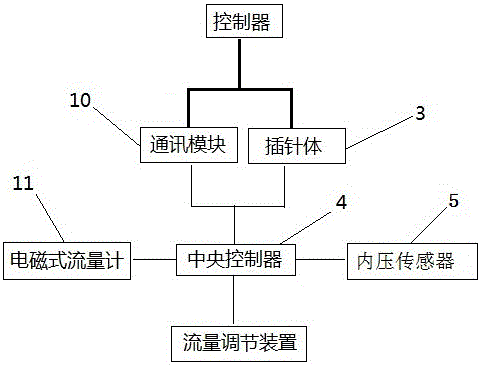

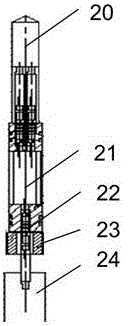

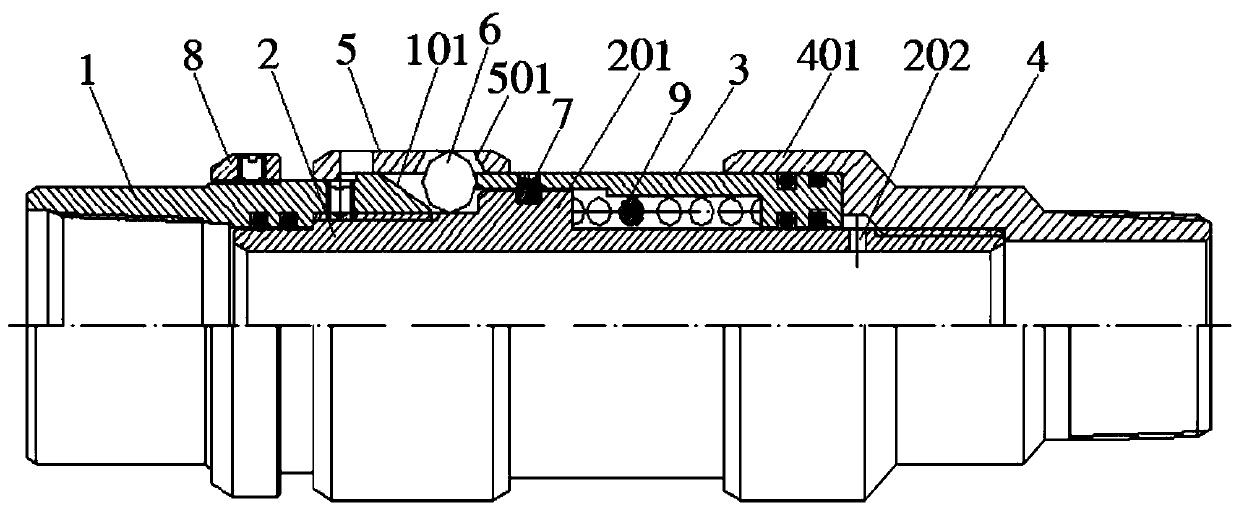

Intelligent injection allocation device of integrated electromagnetic flowmeter

ActiveCN106499372AReduce labor intensityImprove the level of intelligenceSurveyFluid removalElectricityInternal pressure

The invention relates to an intelligent injection allocation device of an integrated electromagnetic flowmeter. The intelligent injection allocation device comprises an upper connector, a housing and a lower connector which are sequentially connected from top to bottom, wherein a central controller is installed in the middle of an annulus cavity of the housing, the electromagnetic flowmeter is installed in the annulus cavity of the upper portion of the central controller, a communicating module and a pin body are installed in the annulus cavity of the upper portion of the electromagnetic flowmeter, a flow adjusting device and an inner pressure sensor are installed in the annulus cavity of the lower portion of the central controller, the central controller is electrically connected with the pin body, the communicating module, the electromagnetic flowmeter, the flow adjusting device and the inner pressure sensor, and the pin body and the communicating module are connected to a ground controller through cables. The intelligent injection allocation device transmits data and performs power supply through cables and can automatically adjust layered water injection amount, and the problems of low layered water injection pass percent, large manual operating amount and unachieved underground real-time monitoring are solved.

Owner:PETROCHINA CO LTD

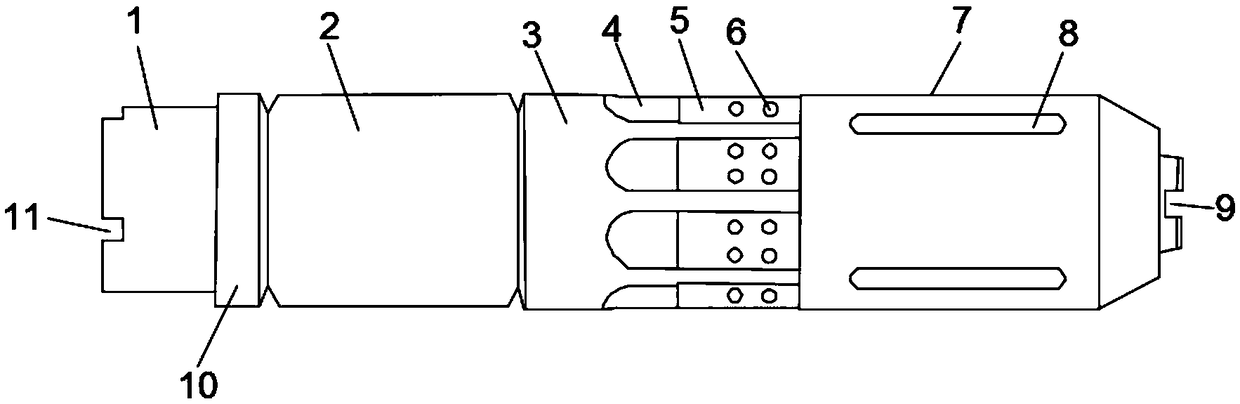

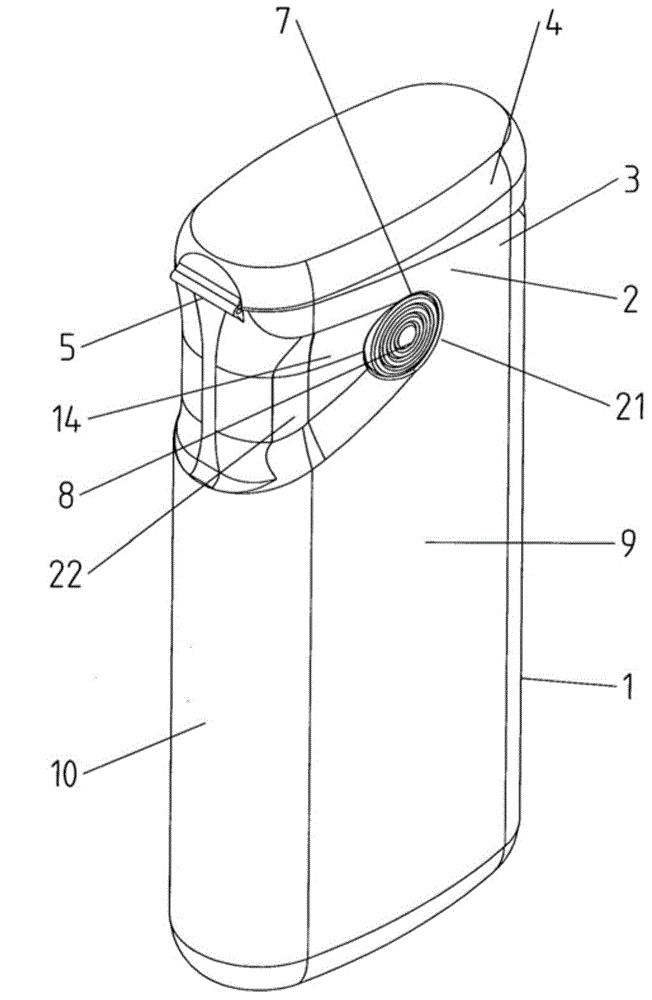

Soluble bridge plug

InactiveCN109505559AAvoid damageExtended service lifeSealing/packingPetroleum engineeringSet packing

The invention discloses a soluble bridge plug and relates to the technical field of downhole tools of oil and gas wells. The problem is solved that the slip tooth direction is simple in the setting-packing process of an existing bridge plug and accordingly the underground resistance risk is high. The soluble bridge plug comprises a mandrel, a rubber cylinder, a cone sleeve, multiple slips and a lower joint short section, wherein the mandrel is of a hollow structure and is provided with a limiting boss, the rubber cylinder and the cone sleeve sequentially and slidingly sleeve the outer surfaceof the mandrel on one side of a limiting boss, the multiple slips are located on the conical face of the cone sleeve through a radial limiting structure, one end of the lower joint short section slidingly sleeves the other end of the mandrel and abuts against the slips, each slip is provided with multiple slip teeth, the slip teeth are oblique truncated cylinders and include lower slip teeth downward inclining in the oblique cross section direction as the conical surface directions of the cone sleeve and upper slip teeth upward inclining in the oblique cross section direction as the conical surface directions of the cone sleeve. The downhole resistance risk is reduced, and the potential safety hazards of oil and gas well operation are reduced.

Owner:成都铭鉴知源油田工程科技有限公司 +1

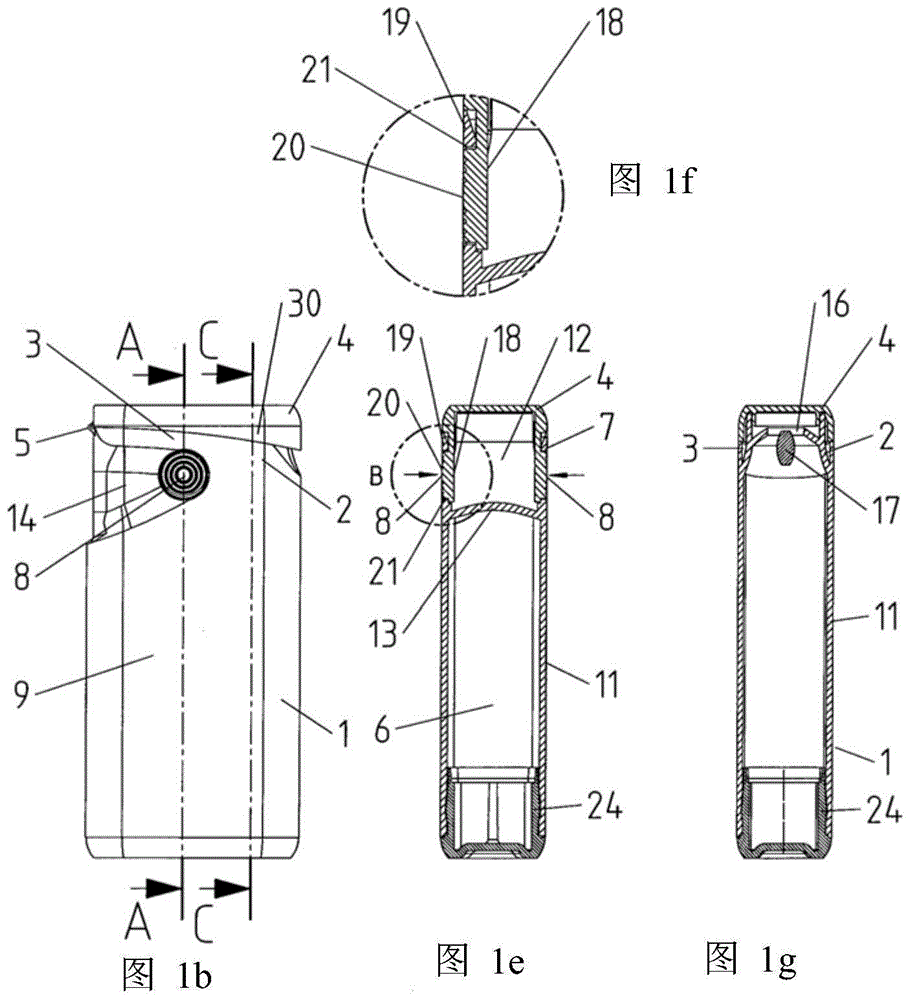

Expansion pipe completing tool

InactiveCN103742092ADoes not affect sequencePrecise positioningSealing/packingHydraulic cylinderExpansion joint

The invention provides an expansion pipe completing tool. The expansion pipe completing tool comprises an expansion pipe, a central pipe, a first level hydraulic cylinder and a first level expansion cone; the lower end of the expansion pipe is connected with a float shoe; the central pipe is arranged inside the expansion pipe in a penetration mode; the lower end of the central pipe is sequentially connected with an expansion cone locking splitting claw and an expansion cone locking mandrill; the upper end of the central pipe is provided with a first penetration hole; the first level hydraulic cylinder is sleeved to the central pipe position which is provided with the first penetration hole; the first level expansion cone which is sleeved to the central pipe is arranged at the lower end of the first level hydraulic cylinder; the lower end of the first level expansion cone is provided with a reducing expansion cone which is sleeved to the central pipe. According to the expansion pipe completing tool, the reducing expansion cone which is in a combined type reducing structure enables the diameter of a pipe column to be minimum and lowering resistance risks to be reduced when the pipe column lowers to an open hole well, the reducing cone can provide a large expansion rate after being assembled, and the well hole size is not loosed or loosed as little as possible during expansion pipe completing.

Owner:PETROCHINA CO LTD

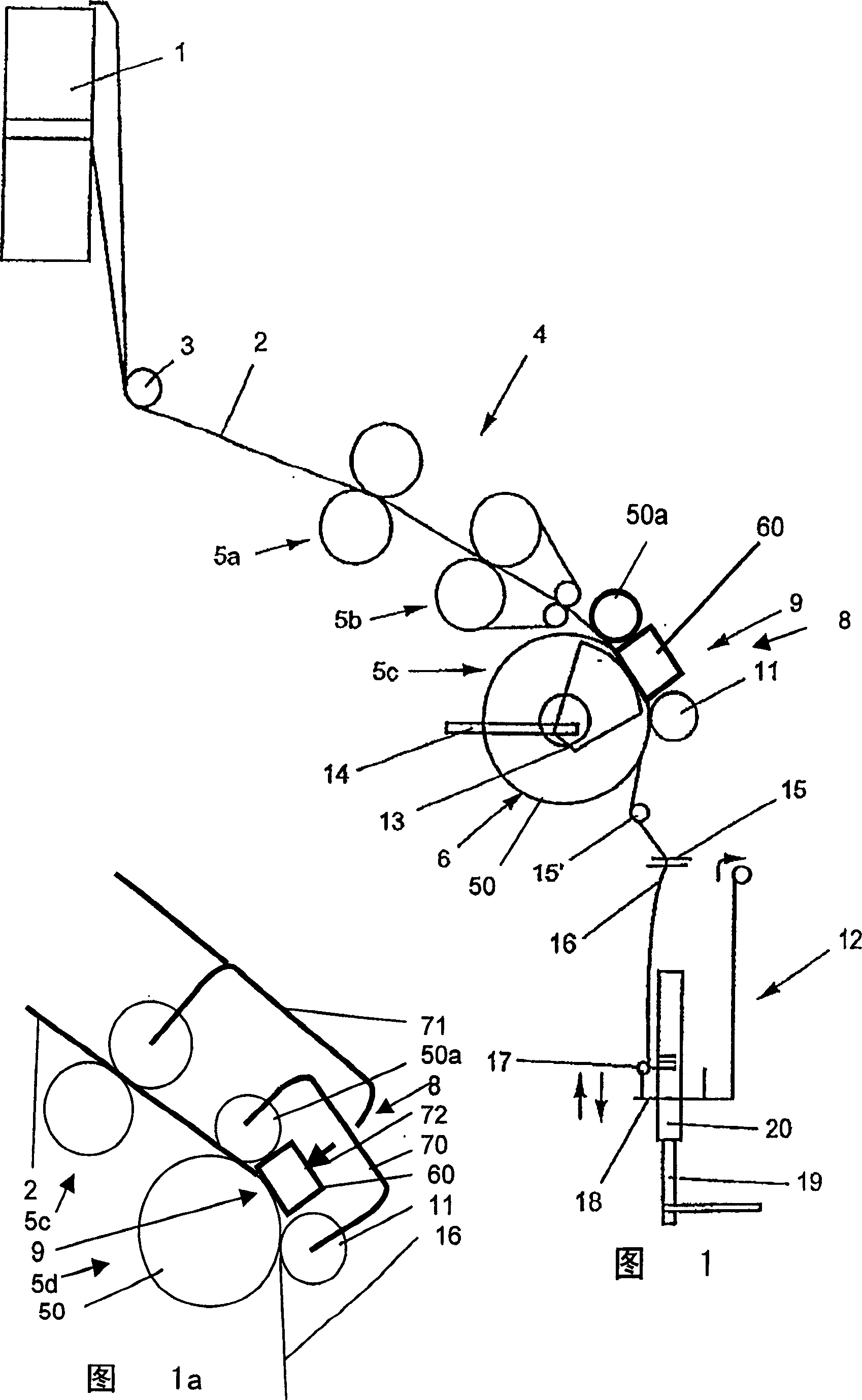

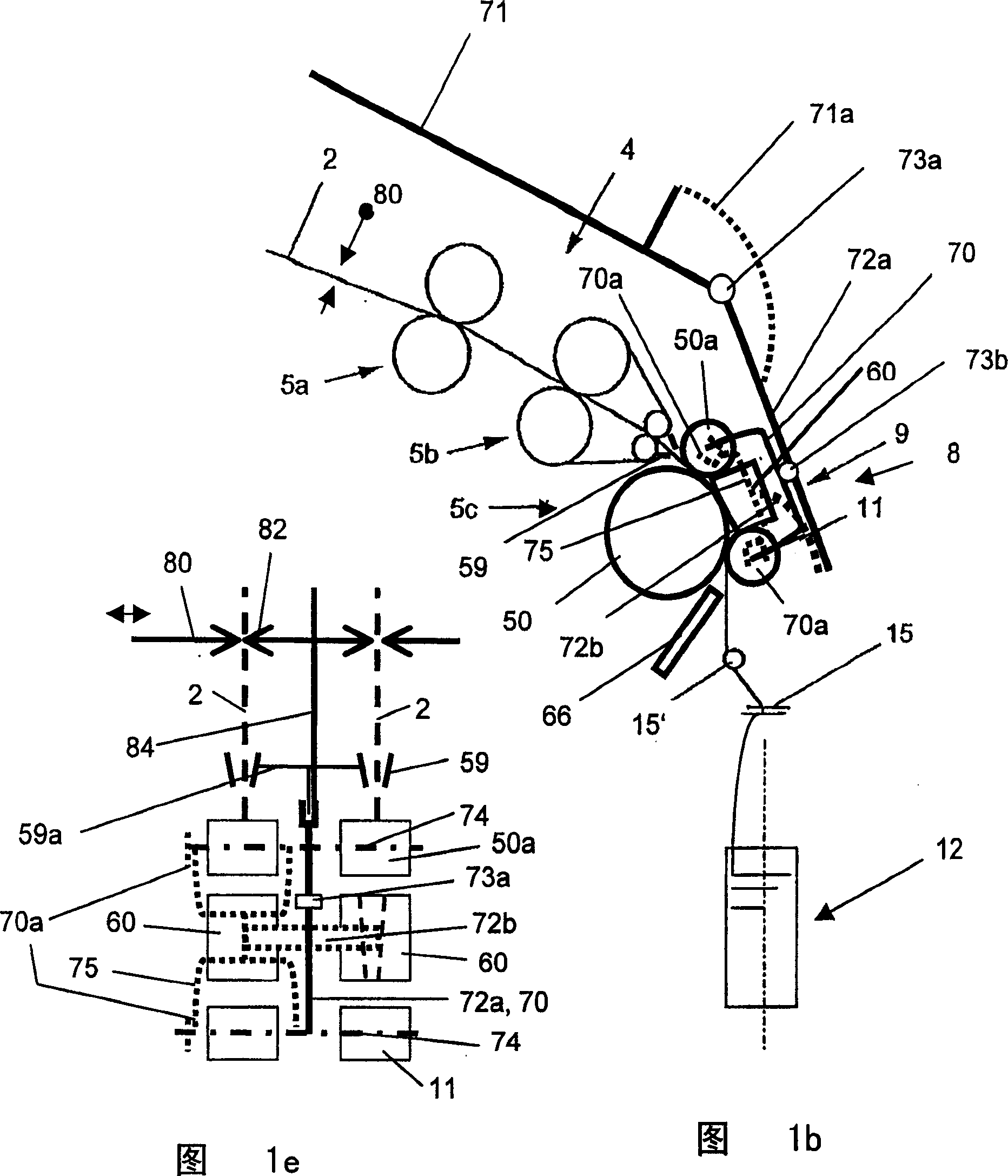

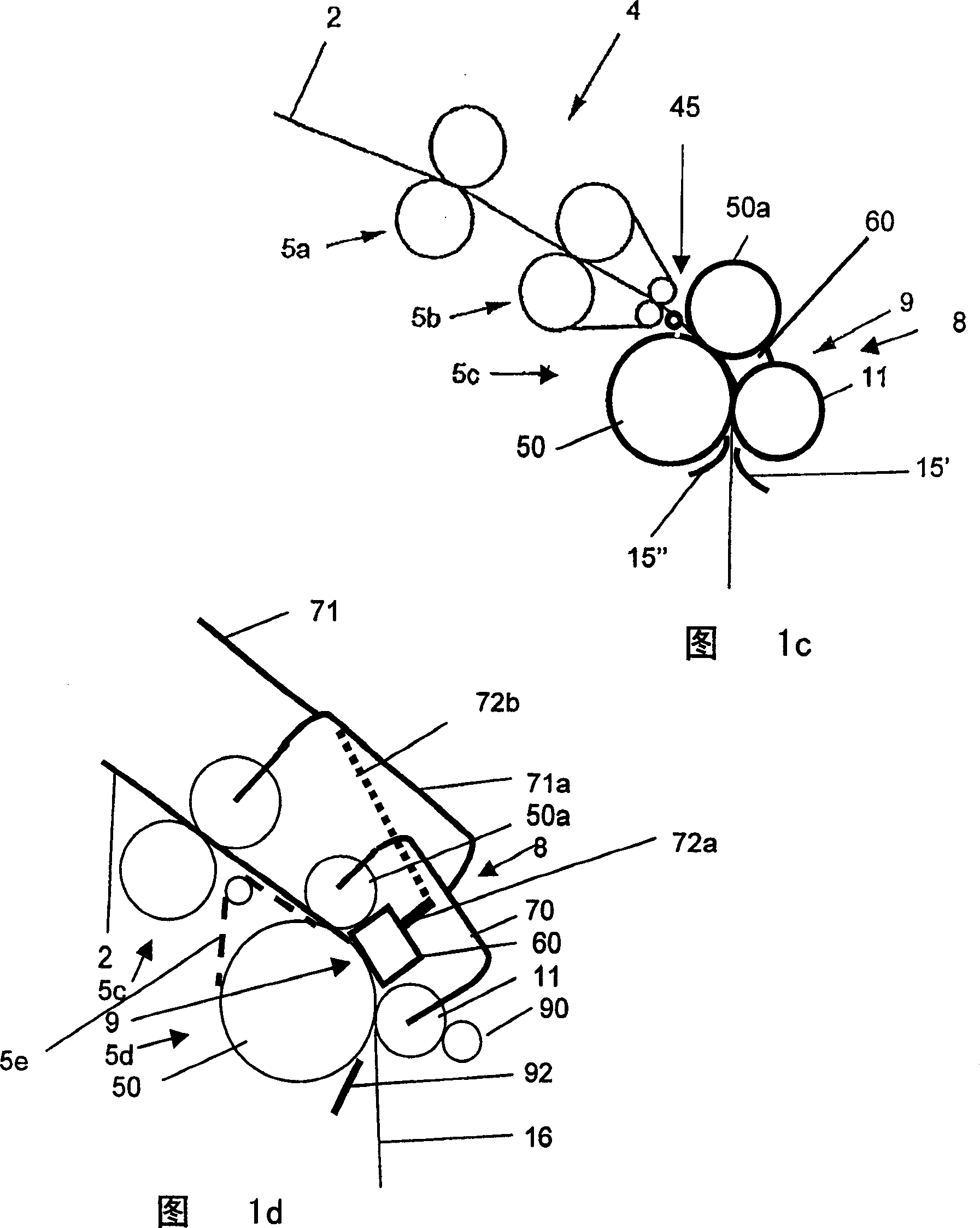

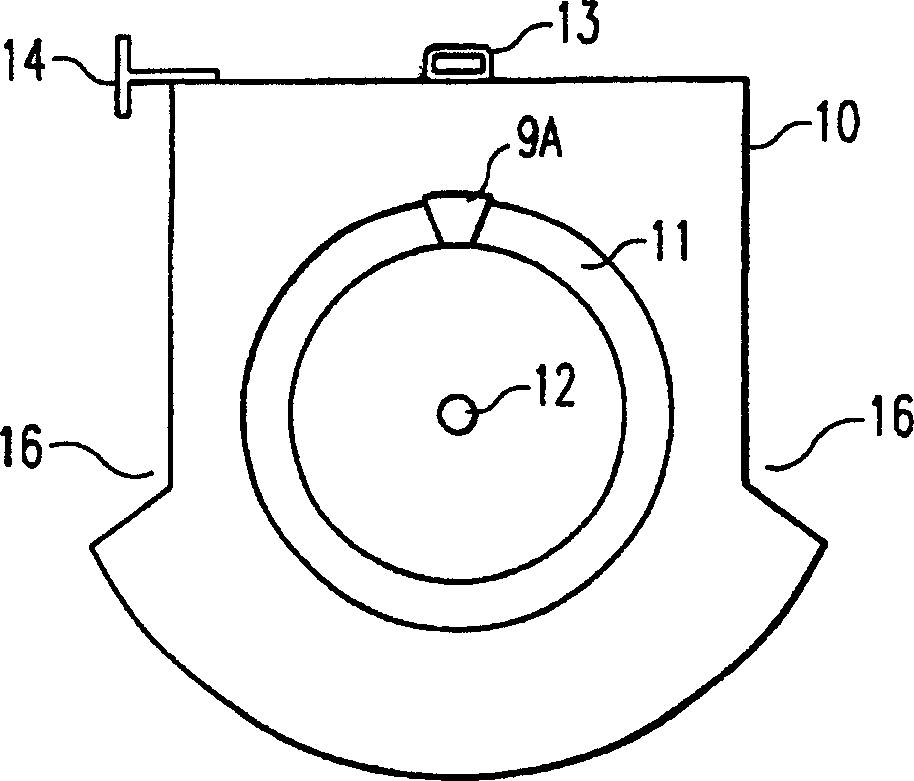

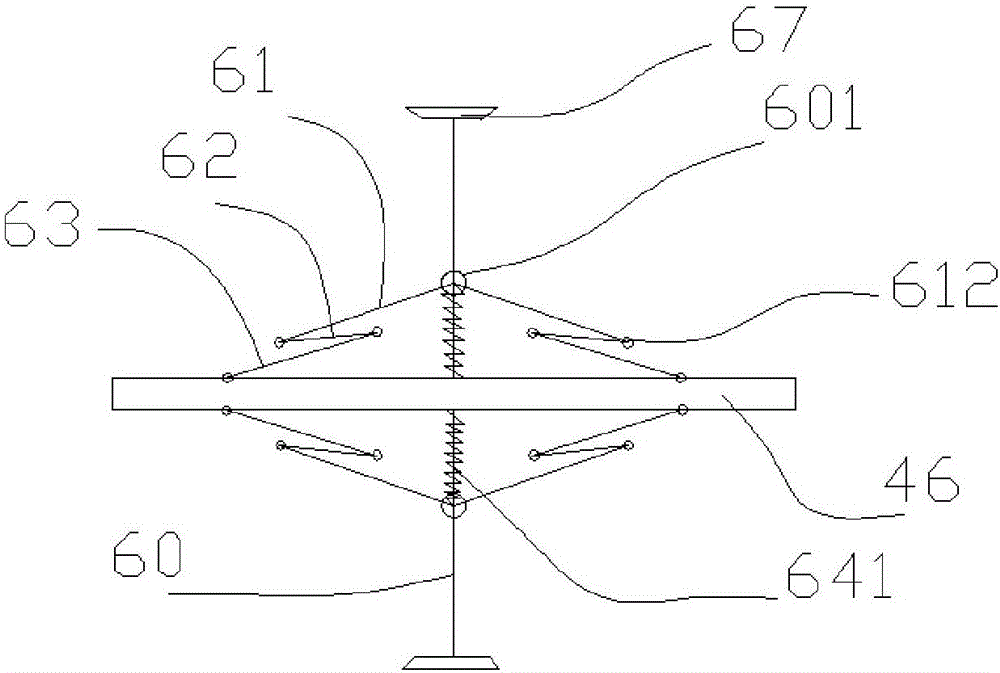

Spinning machine with compressing apparatus

InactiveCN1572925AReduced risk of getting stuckPrevent or reduce static electricityDrafting machinesCompression deviceMechanical engineering

The invention relates to a spinning machine with a drafting device (4) and a compression device (8); the compression device (8) is connected with the drafting device (4); the spinning machine comprises a conveying element (50) for conveying the drafted fibre texture (2) and a compression element (60) in the compression device (8), the compression element (60) extends along the surface of the conveying element (50). The invention is characterized in that, air is sucked into a guiding part (61), and the guiding part (61) is in the compression element (60) for compressing the fibre texture (2); at least one hole (62a, 63a) is communicated with the slots (61, 61a, 61b) for drawing in air.

Owner:MASCHINENFABRIK RIETER AG

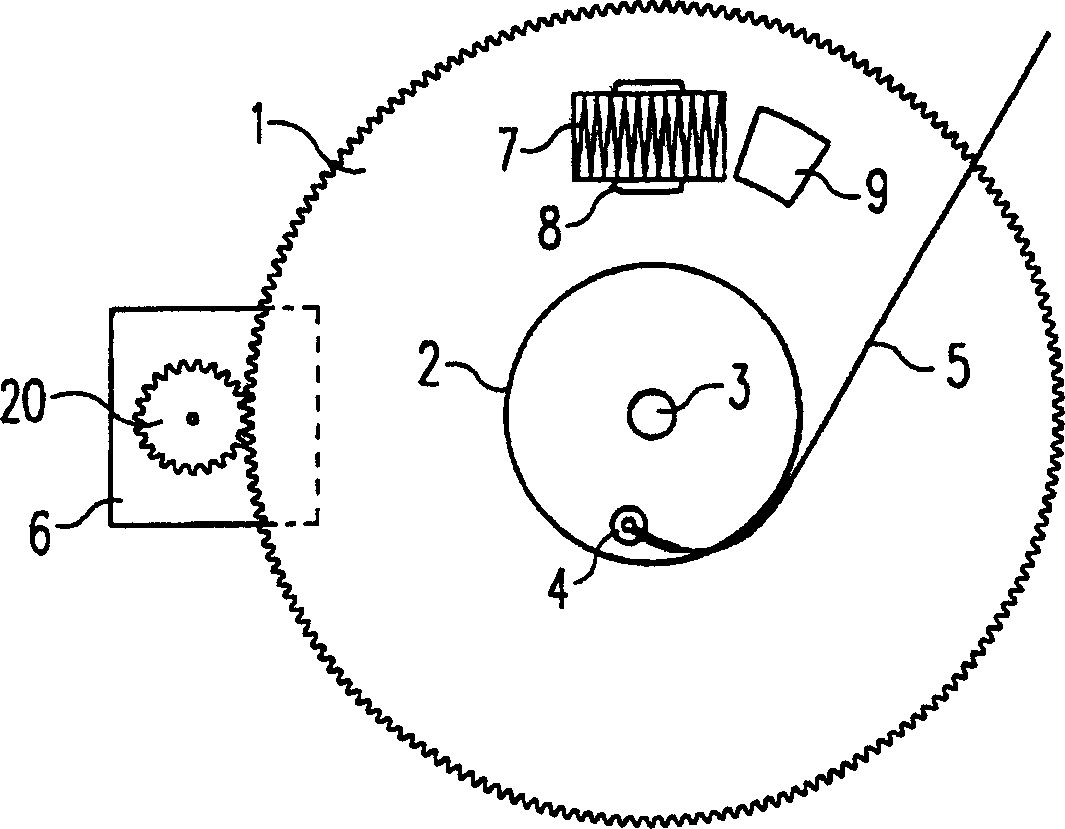

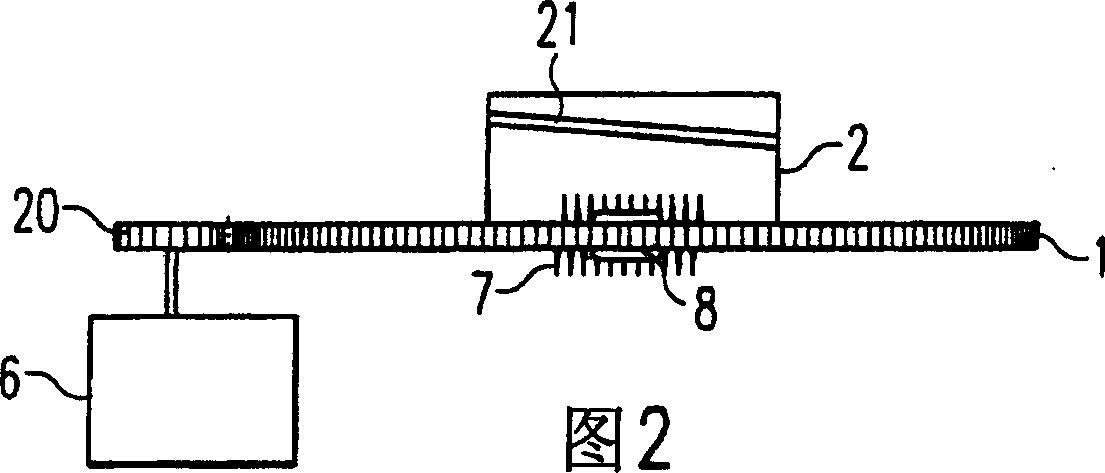

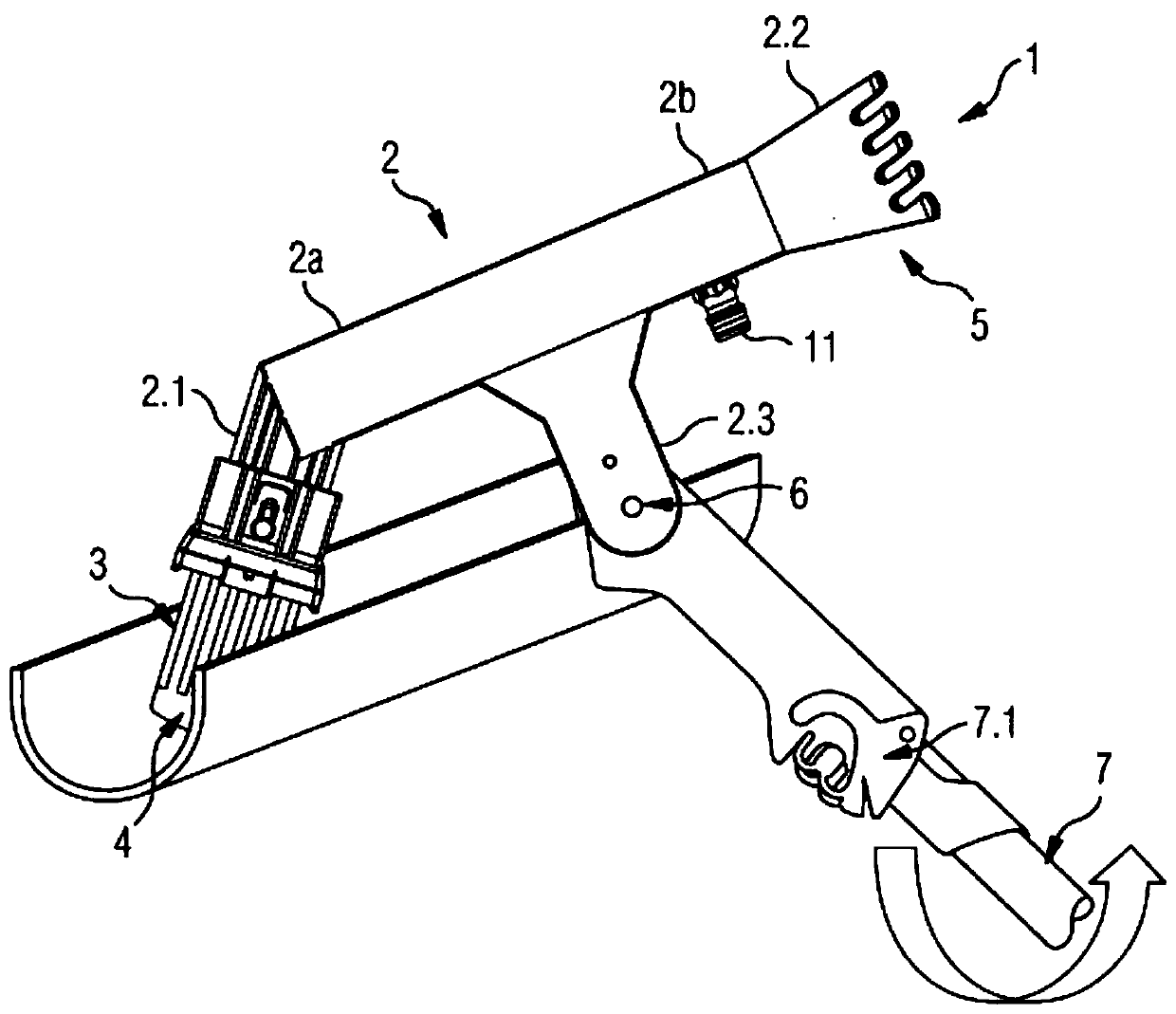

Actuator

An actuation device is provided for actuating a traction element (5), the actuation element comprising in particular a pivotally mounted force transmission element (1) for transferring an actuation force to the traction element (5). The force transmission element comprises first stop means (7), the actuation device further comprises second stop means (9), whereby a possible angle of rotation of the force transmission element (1) is limited. The first stop means (7) and / or the second stop means (9) comprise(s) a resilient element. A stop is thereby dampened and when the first stop means (7) butts against the second stop means (9) energy absorbed by the resilient element (7) can be used to assist a movement of the force transmission element (1) in an opposite direction.

Owner:SCHUKRA GERAETEBAU GMBH

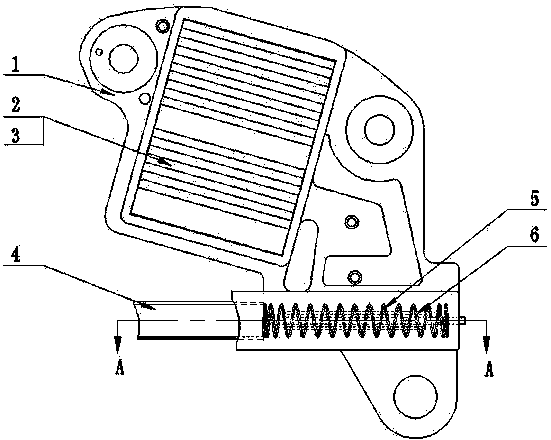

Jam releasing device and method for hydraulic fracturing packer of underground long drill hole in coal mine

ActiveCN113107426AUnlock the card smoothlyGuarantee smooth implementationWell/borehole valve arrangementsSealing/packingMining engineeringStructural engineering

The invention discloses a jam releasing device and method for a hydraulic fracturing packer of an underground long drill hole in a coal mine. The jam releasing device comprises a valve body, a plunger ball seat, a low-density ball, a lower connector and a spring, wherein one end of the lower connector is connected with the valve body, the other end of the lower connector is connected with a packer, a plurality of water outlets are formed in the positions, which correspond to the plunger ball seat, of the valve body, the plurality of water outlets are distributed around the valve body and are arranged towards the bottom of the hole, and a certain included angle is formed between the water outlets and the central axis of the valve body; and the spring is located in a cavity where the valve body and the lower connector are connected, one end of the spring is abutted with the plunger ball seat, and the other end of the spring is abutted with the lower connector. According to the jam releasing device, the technical problem that the in-hole fracturing packer cannot retreat smoothly when encountering resistance is solved, the device has the advantages of simplicity, convenience in operation and high jam releasing success rate, the risk of encountering resistance of the hydraulic fracturing packer of the long drill hole can be effectively reduced, the hydraulic construction efficiency is improved, and the fracturing engineering loss is reduced.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Chili smashing machine with foldable smashing knife

InactiveCN106076540AReduced risk of getting stuckAvoid damageSievingScreeningEngineeringMechanical engineering

The invention provides a chili smashing machine with a foldable smashing knife. The chili smashing machine with the foldable smashing knife comprises a feeding port part, a smashing chamber shell, a discharging port part, a driving device, a supporting table, the smashing knife and a screen; the smashing knife is provided with a foldable folding knife and a brush; and a gap between the brush and the screen ranges from 0 cm to 10 cm. The chili smashing machine with the foldable smashing knife can effectively reduce the risk that the smashing knife is stuck in the smashing process, avoids that the driving device is damaged, can better sweep smashed articles blocking the screen, and improves the smashing efficiency.

Owner:TIANJIN QINLIU FOOD TECH

Internal carbon brush and sleeve structure of regulator of automobile

InactiveCN103427739AAvoid partial wearAvoid jammingGenerator control detailsAgricultural engineeringEngineering

The invention discloses an internal carbon brush and sleeve structure of a regulator of an automobile. The internal carbon brush and sleeve structure comprises a plastic support of the regulator, a radiating plate of the regulator, a thick film circuit, a carbon brush, a spring and a sleeve, and is characterized in that the sleeve is arranged on a carbon brush cord in a carbon brush box of the regulator. The internal carbon brush and sleeve structure has the advantages that the carbon brush cord cannot be jammed by the spring and the walls of spring holes after the sleeve is sleeved on the carbon brush cord in the regulator, and accordingly the internal carbon brush and sleeve structure is excellent in reliability.

Owner:XUZHOU YUNTAI AUTOMOBILE ELECTRICAL APPLIANCE

Well logging robot system and well logging method

ActiveCN109356574AHighly integrated functionsReal-time measurementBorehole/well accessoriesCore removalWell loggingCoring

The invention discloses a well logging robot system and a well logging method. A core analysis module and a fluid analysis module are arranged on two sides of a drilling measurement module, and the core analysis module is connected with a cable stuck releasing module through a first instrument stuck releasing module. The fluid analysis module is connected with a second instrument stuck releasing module through a fluid sampling module, the drilling measurement module is used for performing sidewall coring, rock breaking and deep drilling, measurement and formation testing, and the core analysismodule is used for measuring a core. The fluid analysis module is used for fluid analysis, and the fluid sampling module is used for fluid storage. The first instrument stuck releasing module and thesecond instrument stuck releasing module are used for axially moving the well logging robot system, and the cable stuck releasing module is used for performing jarring stuck releasing on a cable. Thewell logging robot system has a high function integration degree and reliable work and obviously improves the well logging efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

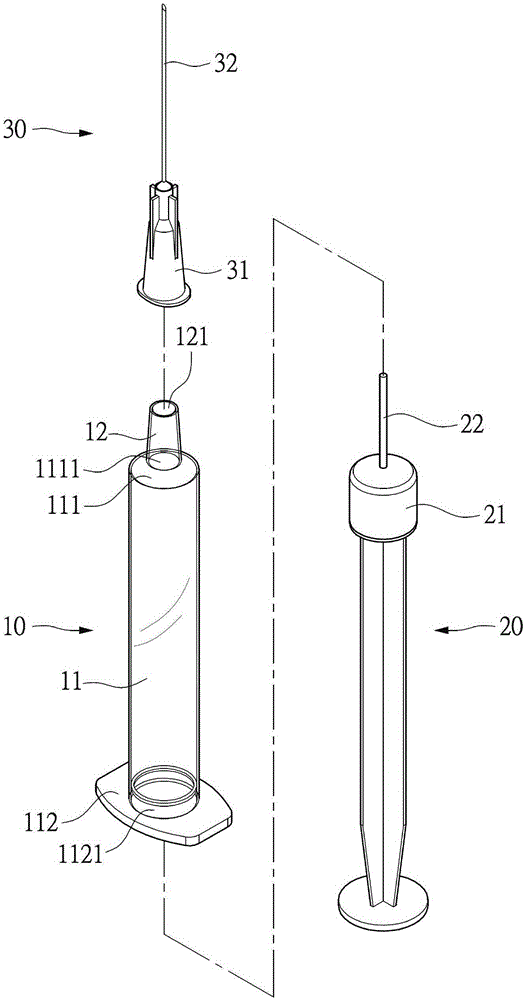

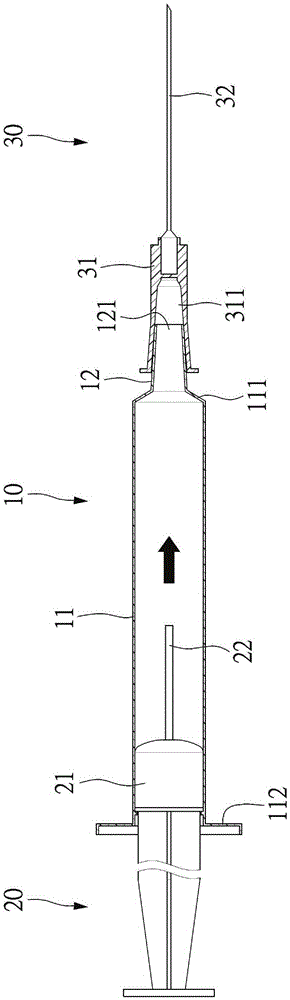

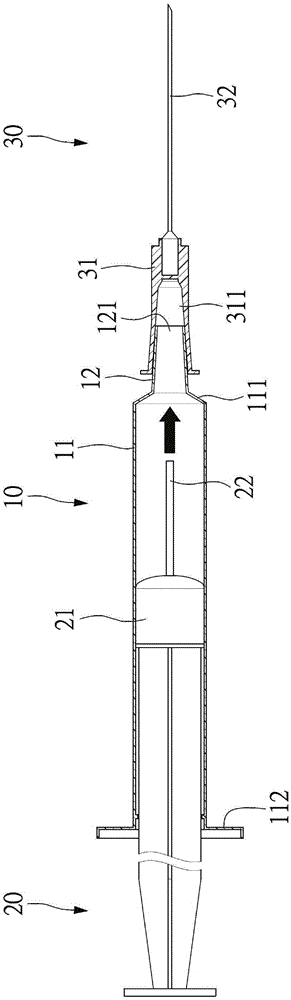

Safety syringe

InactiveCN106362244AReduce manufacturing costReduce the risk of getting stuckInfusion syringesMedical devicesSafety syringeBiomedical engineering

The invention relates to a safety syringe. The safety syringe comprises a needle cylinder, a push rod and a needle tool. The push rod can pass through the needle cylinder in a movable manner; the needle tool can sleeve in the front end of the needle cylinder in a detachable manner; one end of the push rod is provided with an elastic body and a push column protruded out of the elastic body; when the front end of the push rod moves toward the needle tool, the elastic body is pressed to be elastically deformed and is abutted against the needle cylinder, so that the push column passes through the needle cylinder and pushes the needle tool in order to make the needle to seperate from the needle cylinder.

Owner:黄文村

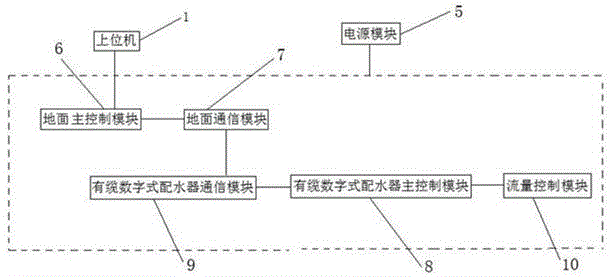

Cable digital layering injection ground control system

InactiveCN105298454AStable communicationReliable communicationFluid removalControl systemBidirectional transmission

The invention provides a cable digital layering injection ground control system. The system comprises an oil pipe and a cable digital water distributor connected to the oil pipe. The cable digital water distributor is electrically connected to a ground controller on the ground through a cable. The ground controller is electrically connected to a host computer. The cable digital layering injection ground control system can automatically adjust injection volumes for all layers, can monitor and store downhole pressure, temperature and flow parameters in a real-time manner, and can automatically perform downhole sealing examination. The ground controller is connected to the cable digital water distributor through the cable, and two-way transmission between data and instructions is carried out through the cable, so that the data can be directly read and can be controlled in a real-time manner, and a cable communication process is stable and reliable. During a testing and allocating process, a testing and allocating instrument is not required to be butt jointed with the water distributor, water volumes are automatically adjusted directly through a ground control downhole flow control system, and blocking and clamping risks during a construction process are reduced.

Owner:PETROCHINA CO LTD

Childproof container closure

InactiveCN104918862AReduce production processLow costNon-removalbe lids/coversChild proof meansMechanical engineeringChild safety

Owner:잔너게엠베하

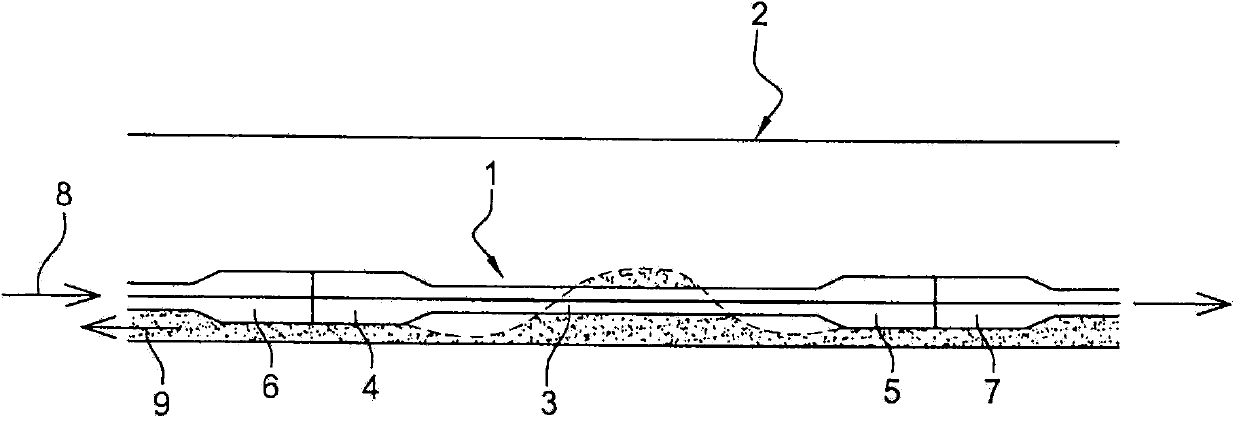

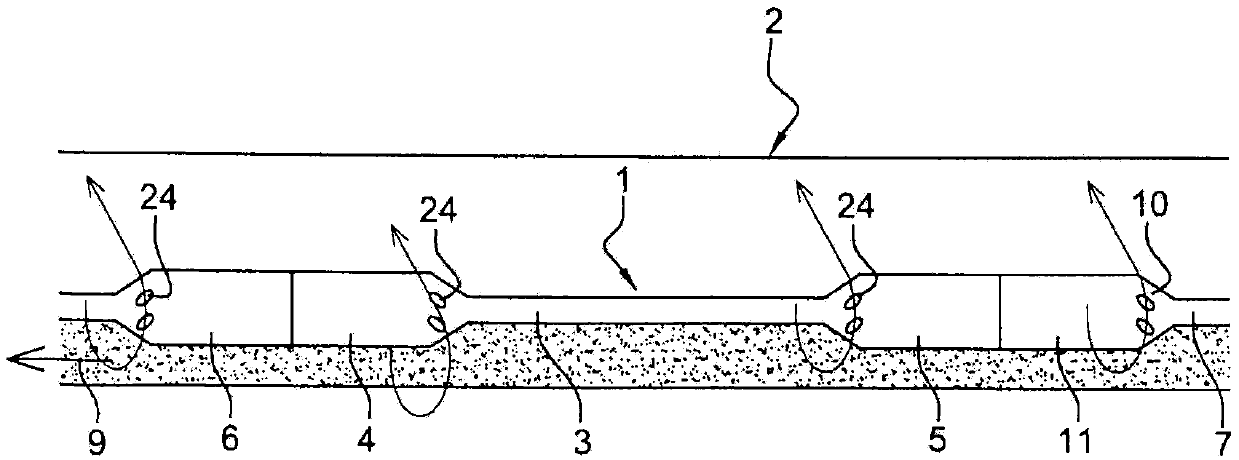

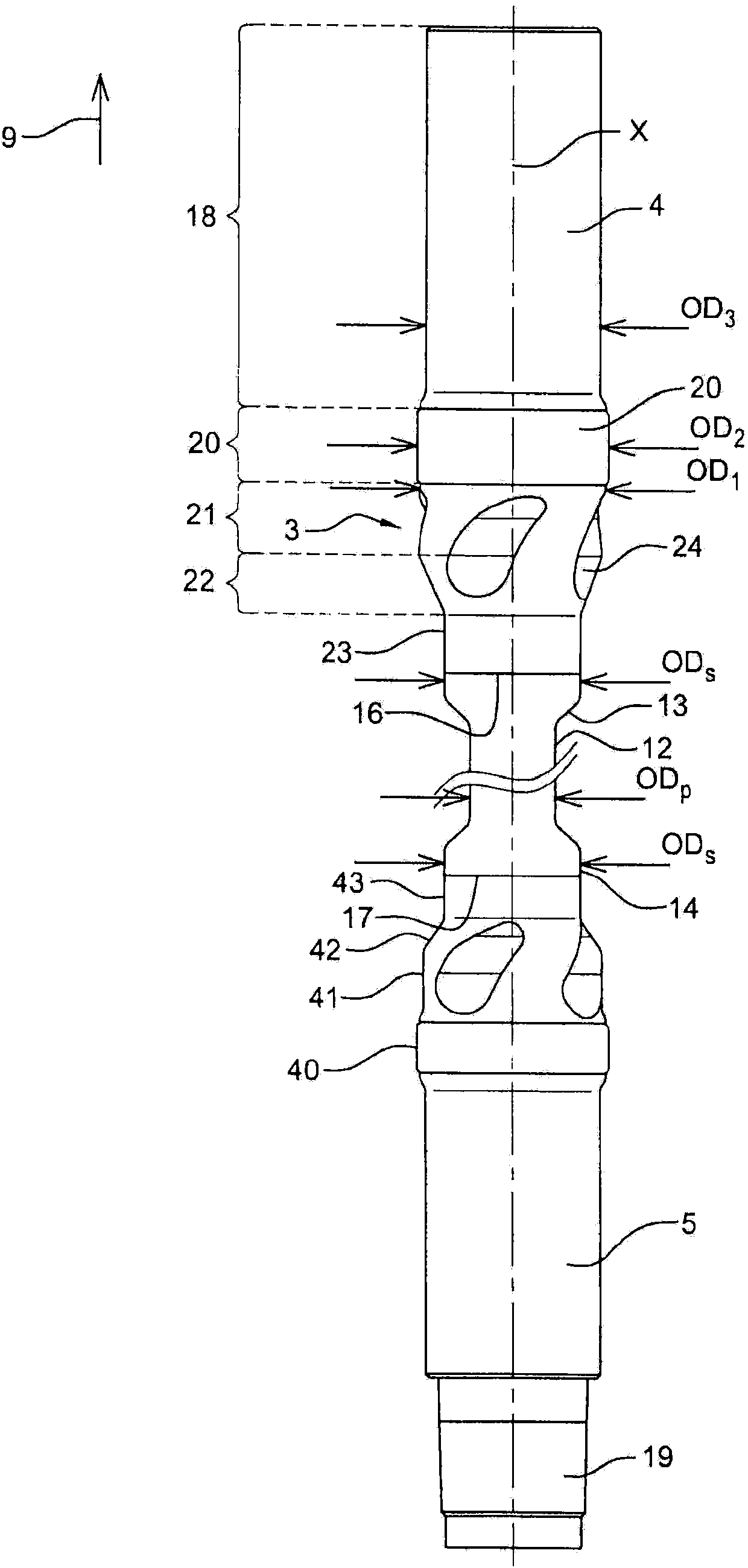

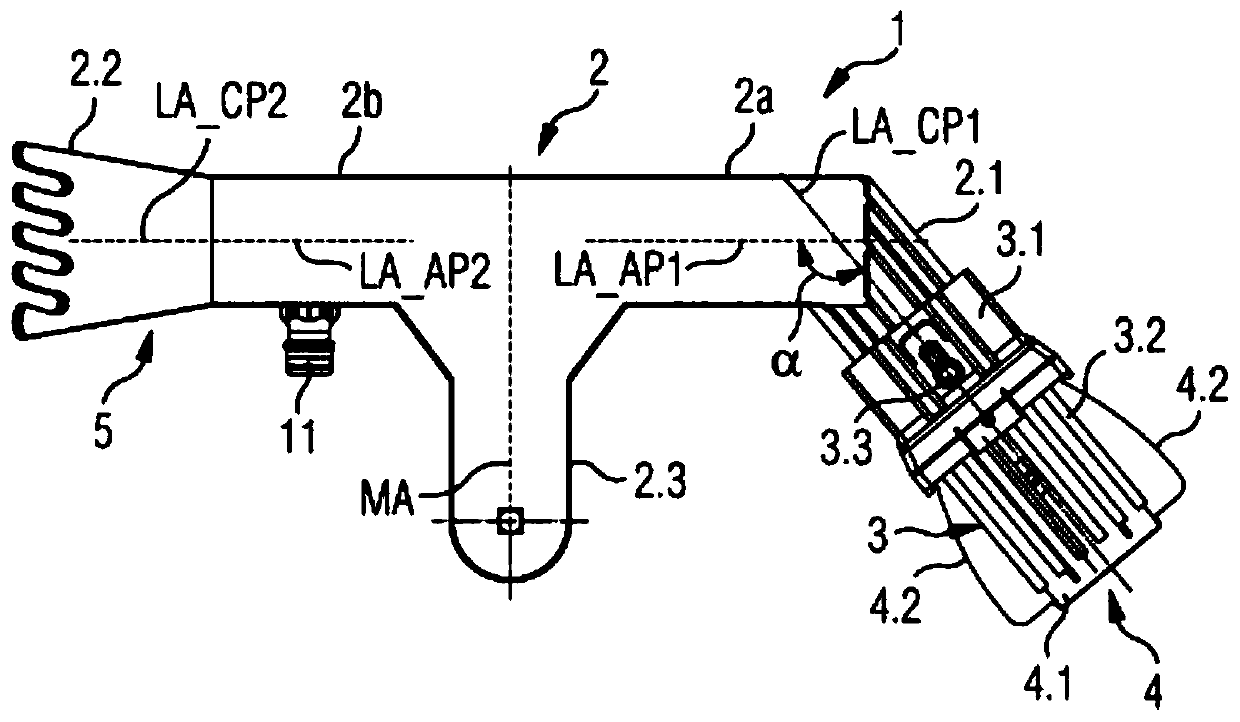

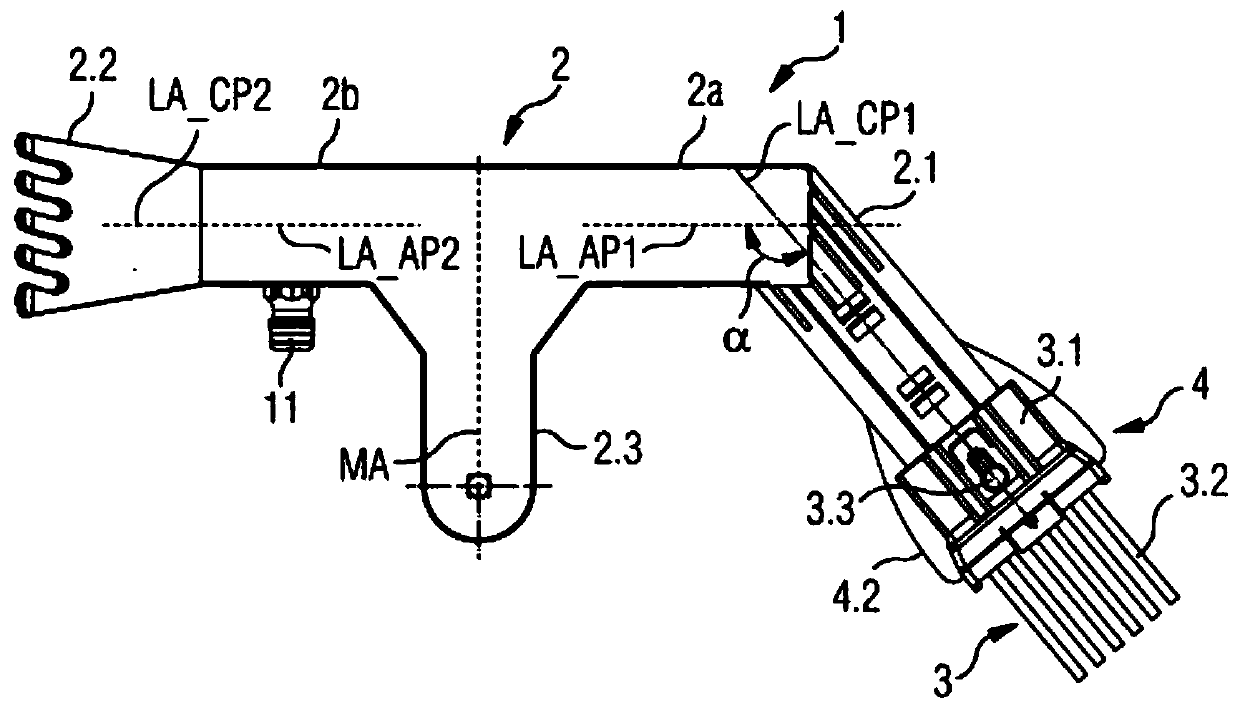

Drill string element with fluid activation area

ActiveCN103797209AReduce axial loadReduce wearDrilling rodsCleaning apparatusEngineeringBiological activation

A tubular drill string element (3) is provided. The tubular drill string element (3) comprises a substantially cylindrical body (12) and two connectors (4, 5). Each connector is arranged at an end of the body and provided with a threaded portion (18, 19) suitable for being connected to a complementary element. At least one of the two connectors is provided with a lifting surface (22) suitable for engaging with a lifting tool of the element with a view to the assembly of same in a drill string. The tubular drill string element (3) is characterized in that the lifting surface has a non-circular transverse section forming an activation area (24) for a drilling fluid.

Owner:VALLOUREC DRILLING PROD FRANCE

Bidirectional electric eccentric device

PendingCN108533252AReduced risk of getting stuckRealize up-test and down-testSurveyMaximum diameterEngineering

The invention relates to a bidirectional electric eccentric device. The bidirectional electric eccentric device is mainly composed of a circuit control unit, a push force detecting unit, a push unit and a bottom direction adjusting unit. The bidirectional electric eccentric device, with a maximum diameter of 3.625 inches (92 mm) and a length of 3.3 meters, is used for helping loggers which are needed to be eccentrically attached to well walls to conduct logging, such as a compensating neutron logging instrument and a lithology density logging instrument. The bidirectional electric eccentric device has the characteristics of achieving the upper measurement and lower measurement of the instrument under the eccentric condition.

Owner:BEIJING JIEWEISITE TECH CO LTD

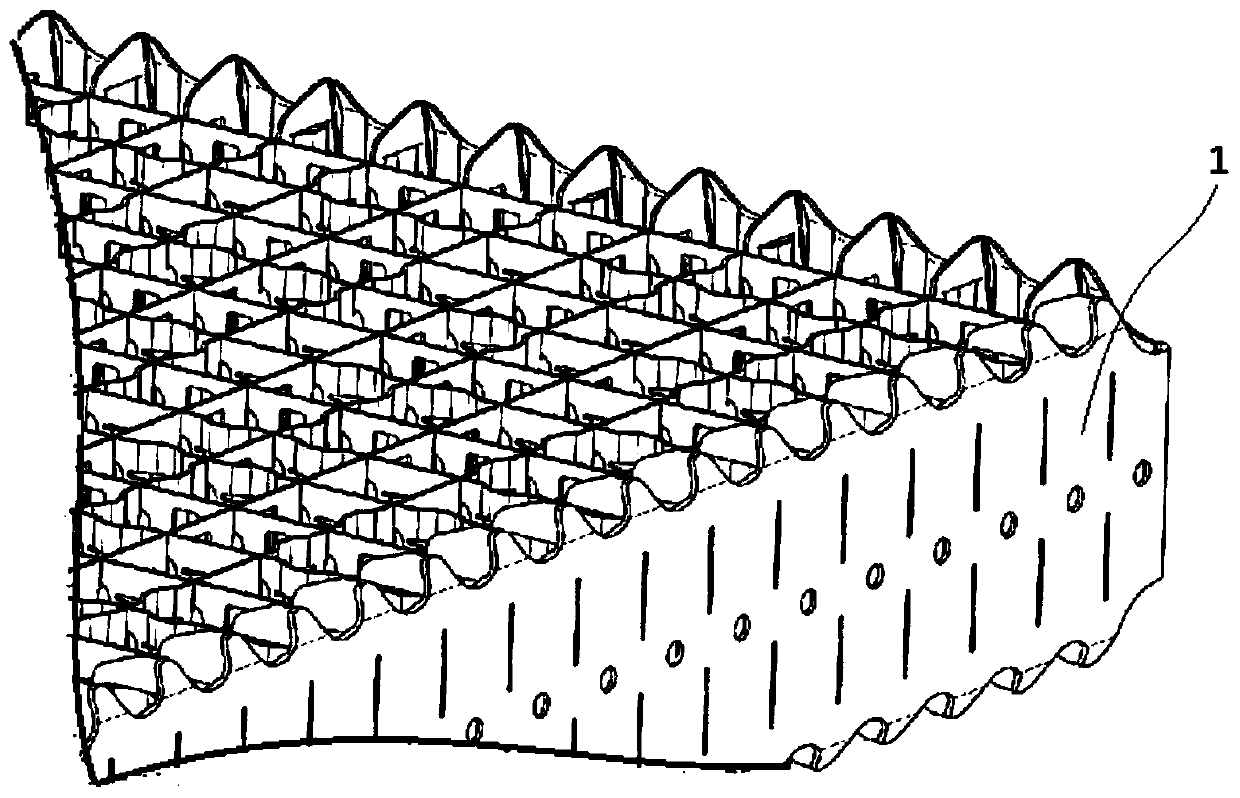

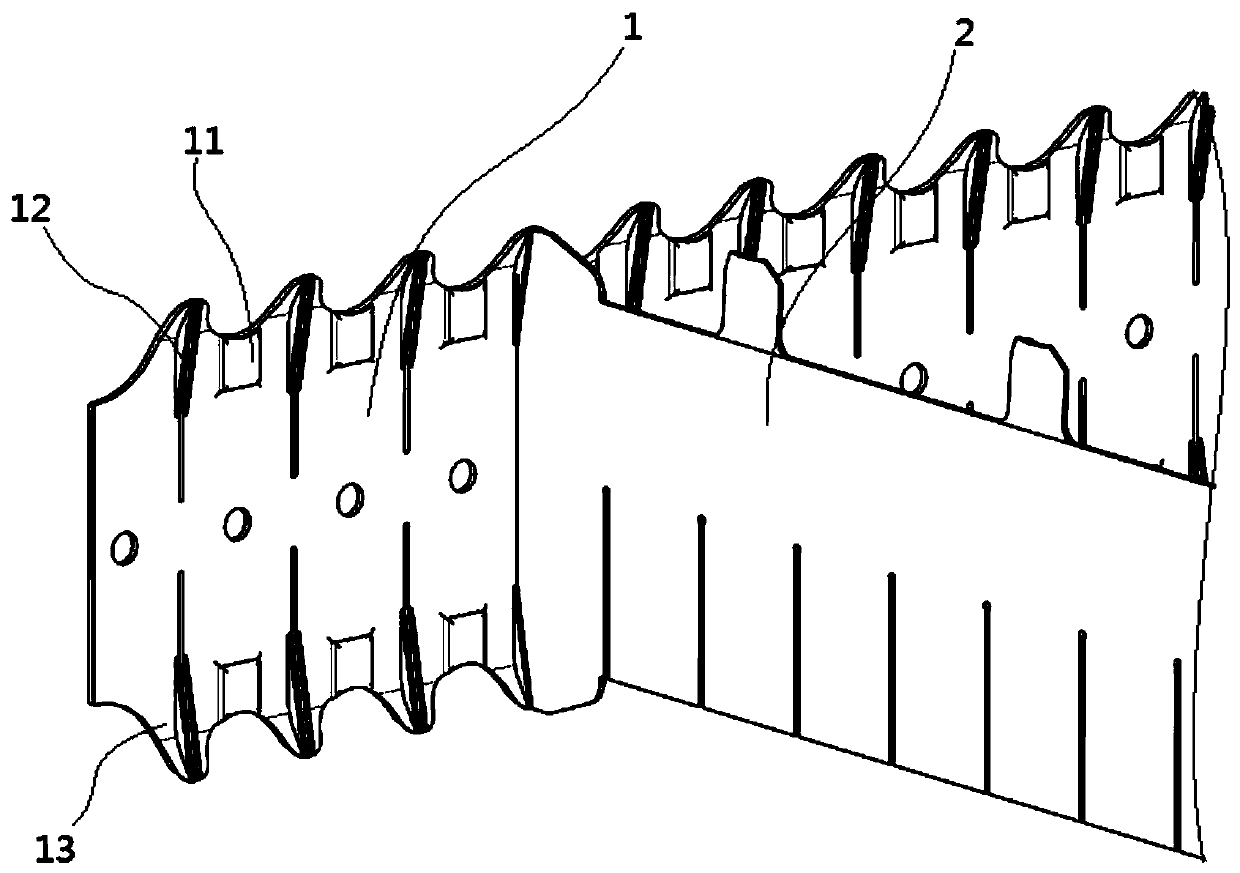

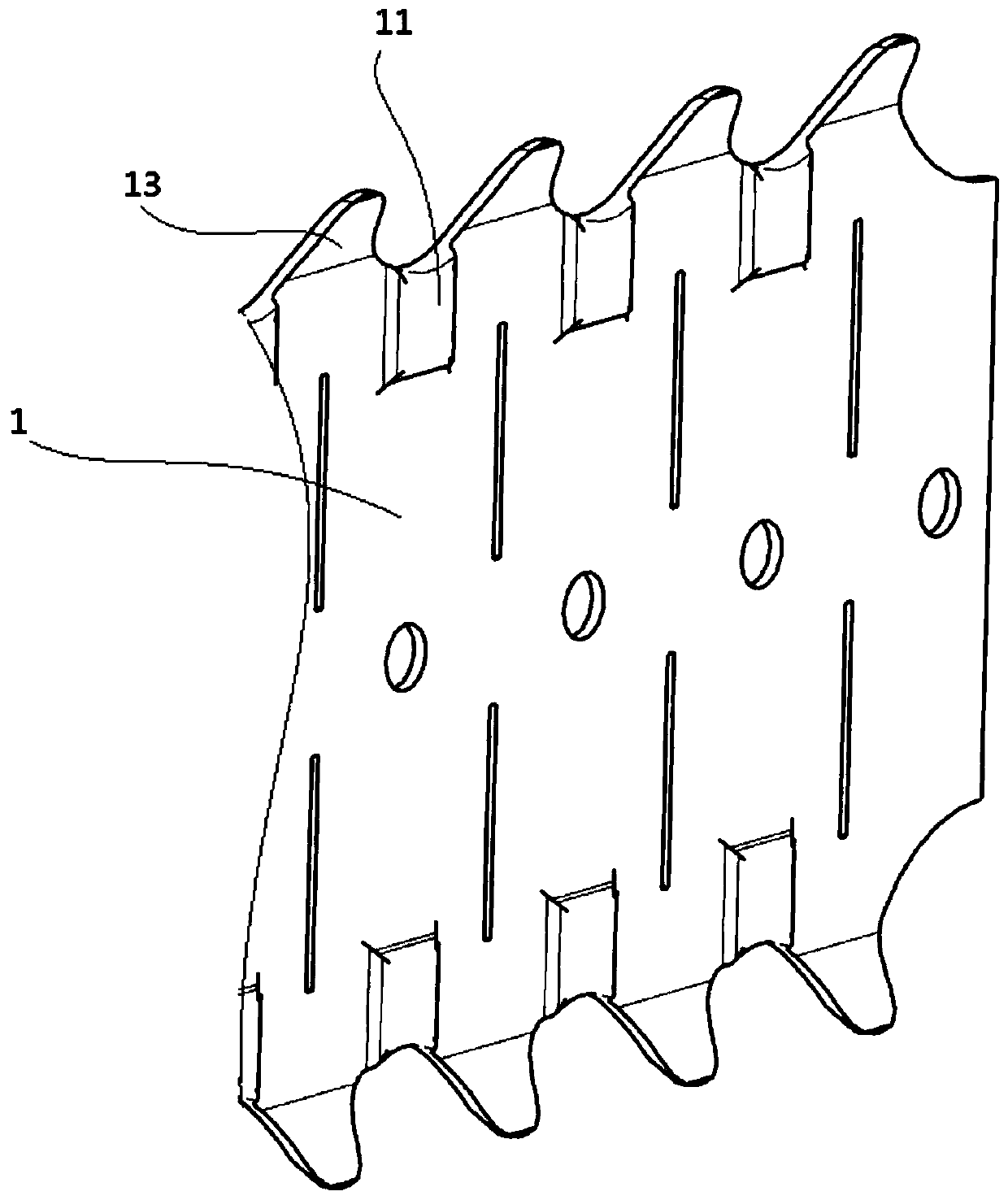

Grillwork for pressurized water reactor fuel assembly

InactiveCN110993128AHigh strengthIncrease stiffnessNuclear energy generationReactor fuel elementsPressurized water reactorStructural engineering

The invention particularly relates to a grillwork for a pressurized water reactor fuel assembly, and belongs to the field of pressurized water reactor fuel assemblies. The grillwork comprises outer strips and inner strips, and a plurality of inner strips are arranged inside a plurality of outer strips in a wrapping manner and are mutually staggered, wherein a plurality of bosses which are distributed in two rows at equal intervals are arranged on the surface of the inner side of the outer strips and the thickness of the plate on the outer strips at the joint of the bosses and the outer stripsis set to be thickened so that the thickness of the plate on the outer strips at the joint of the bosses and the outer strips is set to be thickened, the strength and the rigidity of the outer stripsat the bosses are improved in a basic mode of adding materials, cracks and deformation caused by excessive load can be effectively avoided and the reliability is higher; the process is simple and themachining efficiency is high.

Owner:JILIN AGRICULTURAL UNIV

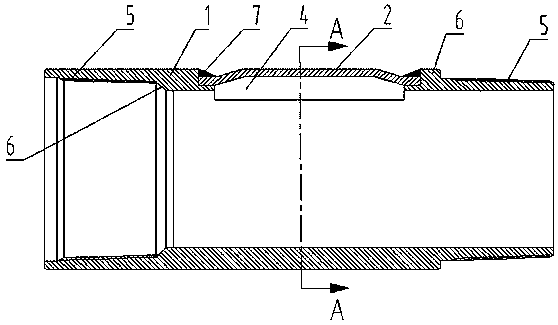

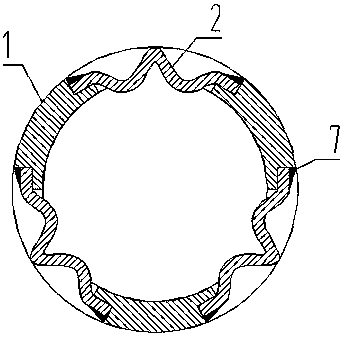

Self-adaptive casing centralizer and righting method

PendingCN110566138AEasy to operateConvenient rightingDrilling rodsSealing/packingWell cementingSelf adaptive

The invention discloses a self-adaptive casing centralizer and a righting method. The self-adaptive casing centralizer comprises a body. A plurality of self-adaptive expansion assemblies capable of being automatically expanded by pressure to automatically adapt to the diameter of a well to right and fix a casing are arranged on the body. Each self-adaptive expansion assembly comprises a bellows arranged in a stepped through-hole slot. The cross section of each bellows is in a wavy shape. The self-adaptive casing centralizer is simple in whole structure and convenient to operate and can adapt to different well diameters, the casing is effectively righted and fixed, and the well cementing quality is improved; the overall outer diameter of the body of the self-adaptive casing centralizer is smaller than the well diameter of a wellbore when the body of the self-adaptive casing centralizer is in an initial state, the centralizer can smoothly enter the well, the risk of encountering resistance is reduced, the well wall is not damaged, the bellows can uniformly expand, the supporting force is improved, the casing is effectively righted, and the centering degree of a casing column is increased; and after centering of the casing is completed, the wellbore annular clearance is uniform, the well cementing quality can be effectively improved, and the whole construction is easy and convenient.

Owner:潍坊市宇宏石油机械有限公司

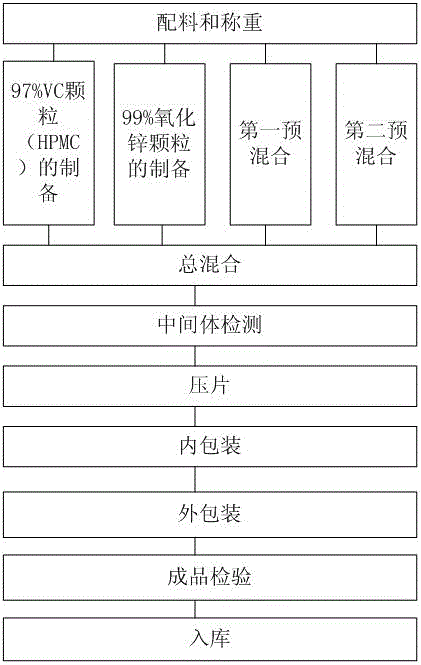

Fast-dissolvable vitamin C and zinc preparation and preparation method thereof

InactiveCN106491640AEasy to takeFit for consumptionOrganic active ingredientsMetabolism disorderVitamin CD-mannitol

The invention discloses a fast-dissolvable vitamin C and zinc preparation and a preparation method thereof. The fast-dissolvable vitamin C and zinc preparation is prepared from, by weight, 0.5%-2% of zinc oxide particles, 0.2%-0.6% of zinc gluconate, 3%-10% of vitamin C particles, 5%-10% of microcrystalline cellulose, 65%-85% of D-mannitol, 0.5%-1% of edible essence, 5%-8% of cross-linked polyvinylpyrrolidone, 0.05%-0.15% of sucralose and 0.5%-1% of magnesium stearate. The fast-dissolvable vitamin C and zinc preparation has advantages of reduction of irritation to digestive tract mucosa, convenience in administration, quickness in absorption, high bioavailability, reduction of risks in use and quickness in replenishment of essential vitamin C and zinc to human bodies.

Owner:JIANGSU ALAND NOURISHMENT

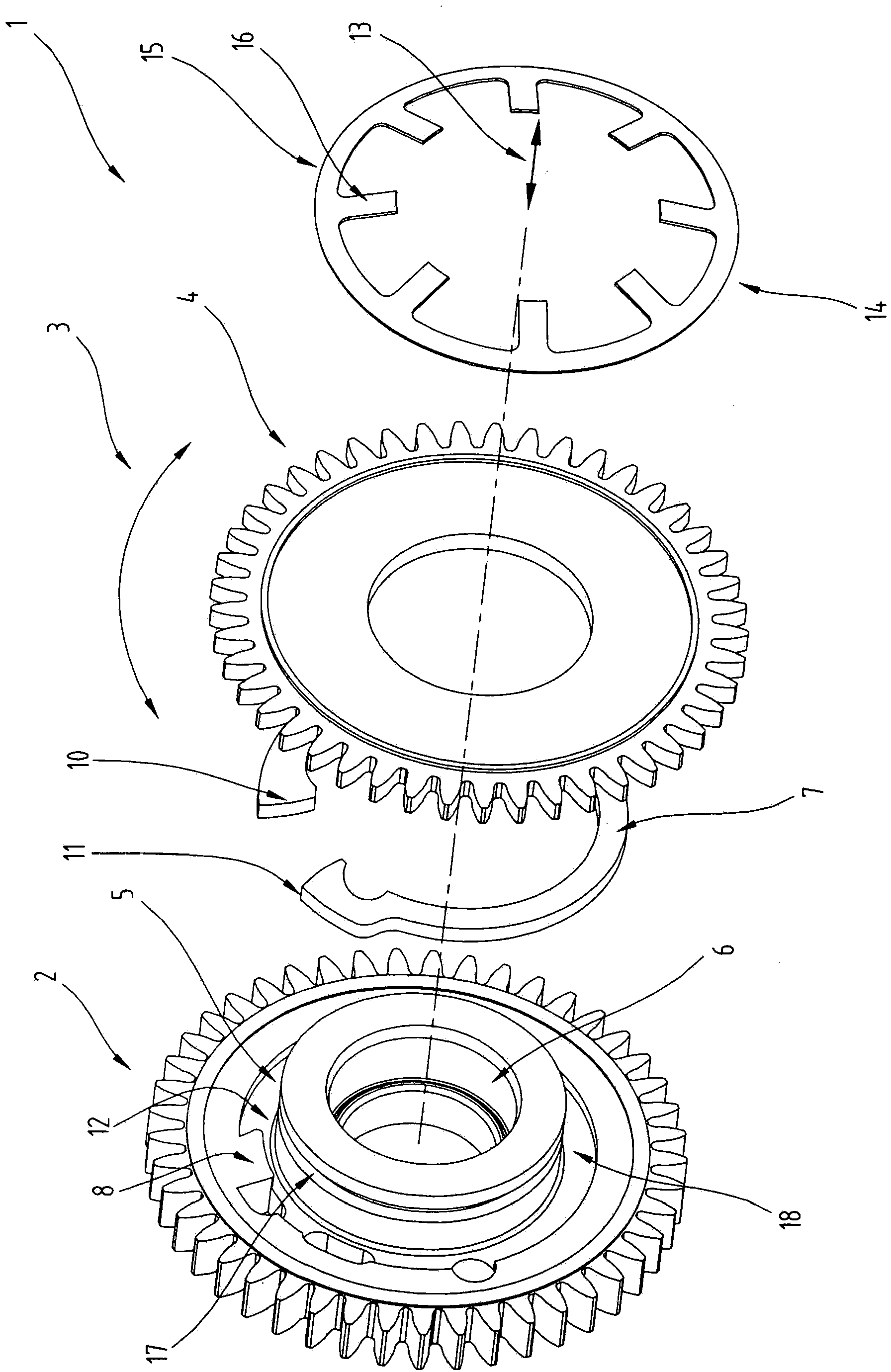

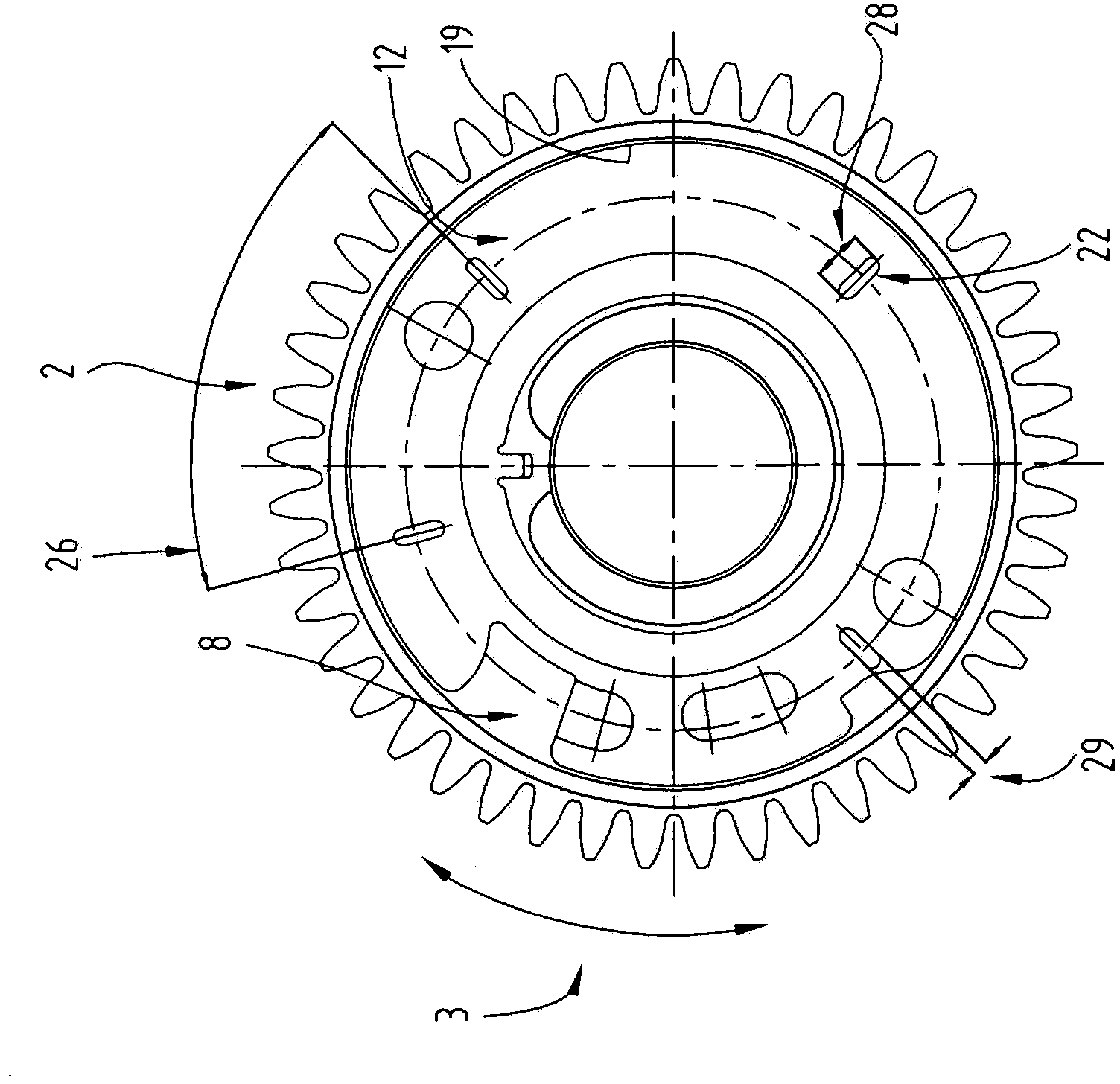

Gearwheel arrangement

Owner:MIBA SINTER AUSTRIA

Horizontal well automatic anchor release hydraulic righting device

PendingCN110259392AReduced risk of getting stuckGuaranteed to be centeredDrilling rodsFluid removalUpper jointEngineering

The invention discloses a horizontal well automatic anchor release hydraulic righting device, which comprises a front joint, a center pipe, a piston pipe, a rear joint and a righting sleeve. The front end of the righting sleeve slidably sleeves the rear end of the upper joint, and the rear end of the righting sleeve slidably sleeves the front end of the piston pipe; a plurality of through holes are formed in the surface of the righting sleeve, and a plurality balls are assembled between the inner side of the righting sleeve and the center pipe; and the diameter of the balls is larger than the aperture of the through holes, and the ball surface of each ball can stretch out from the corresponding through hole. The horizontal well automatic anchor release hydraulic righting device can keep the small diameter under the normal state, supporting righting is conducted only during setting of a string, passive righting is achieved, during pulling of the string, automatic anchor release recovery can be conducted when the internal high pressure disappears or the external pressure is high, and the jamming risk of the string can further be reduced while it is ensured that the down-hole string is centered.

Owner:PETROCHINA CO LTD

Gutter cleaner

InactiveCN110325693AReduced risk of getting stuckGet a fluid supplyRoof coveringCarpet cleanersEngineeringMechanical engineering

Owner:HUSQVARNA AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com