Actuator

The technology of an actuating device and a driving device, which is applied in hoisting devices, movable seats, transportation and packaging, etc., can solve the problems of preventing further actuation of the actuating device, expensive, high manufacturing cost of electronic control devices, etc., and achieves the elimination of stuck stuck or jammed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

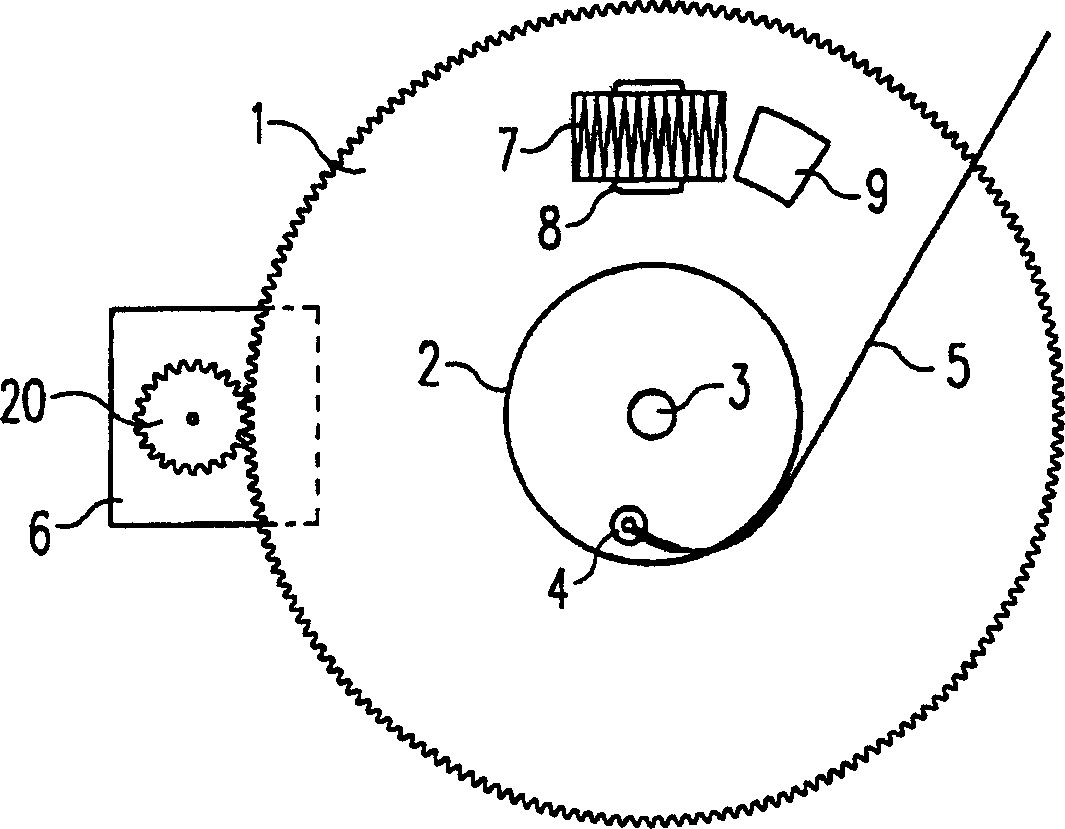

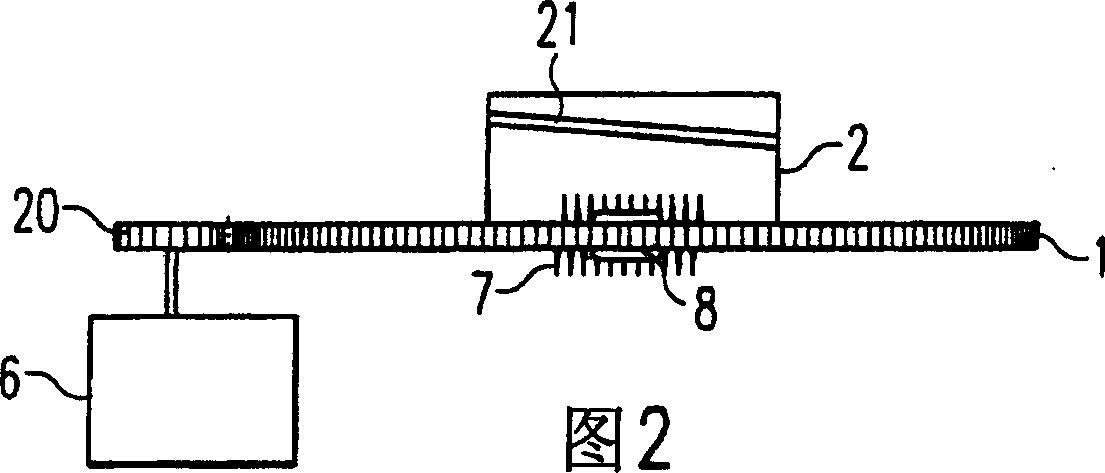

[0021] figure 1 Shown in is a top view of an actuator device according to an embodiment of the present invention. Figure 2 is the corresponding side view.

[0022] figure 1 The actuating device shown in FIG. 2 includes a driving motor 6 , such as an electric motor, whose driving force is transmitted to a gear 1 via a gear 20 . The gear 1 is used to transmit the driving force of the motor 6 to a traction element 5, such as a control cable or an operation cable. Such an operating cable may also in particular be a Bowden cable.

[0023] A drum 2 is mounted coaxially with the gear 1 for winding up traction elements 5 . The drum 2 can be integrally processed with the gear 1 or rigidly connected with the gear 1 in other different ways. Gear 1 and drum 2 comprise a groove 3 in the direction of their axis of rotation and through which a rigid shaft extends.

[0024] Such as figure 1 As shown, the drum 2 comprises a groove 4 in which a thickened end of the traction element 5 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com