Bidirectional electric eccentric device

An eccentric, electric technology, used in surveying, wellbore/well components, earth-moving drilling, etc., can solve problems such as difficulty in passing, jamming, and inability to test, and reduce the risk of jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

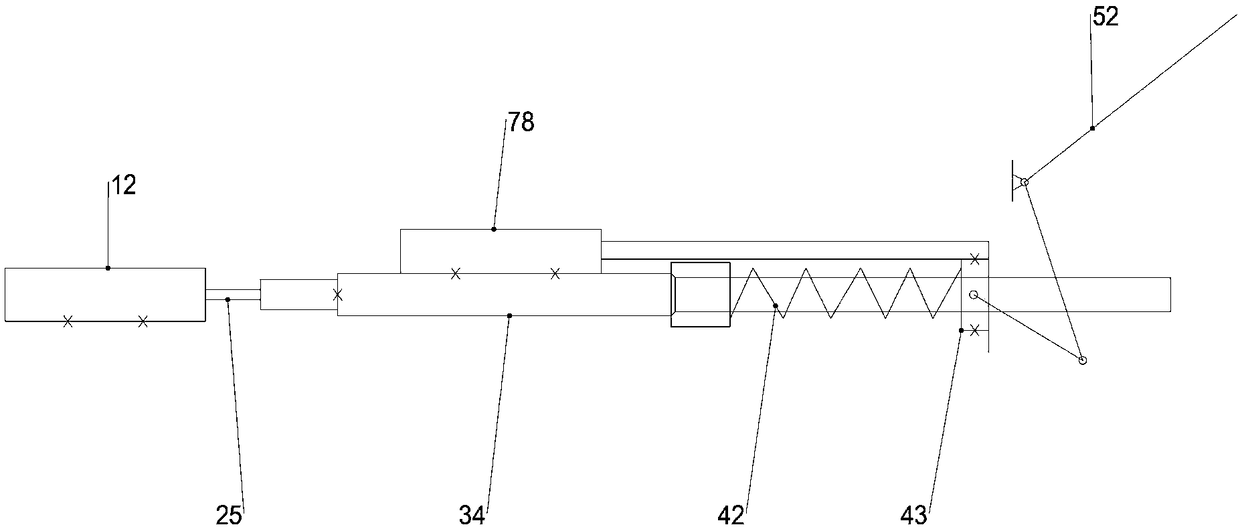

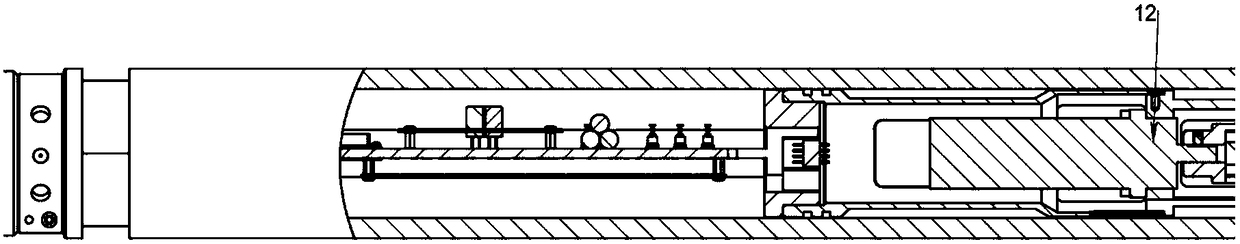

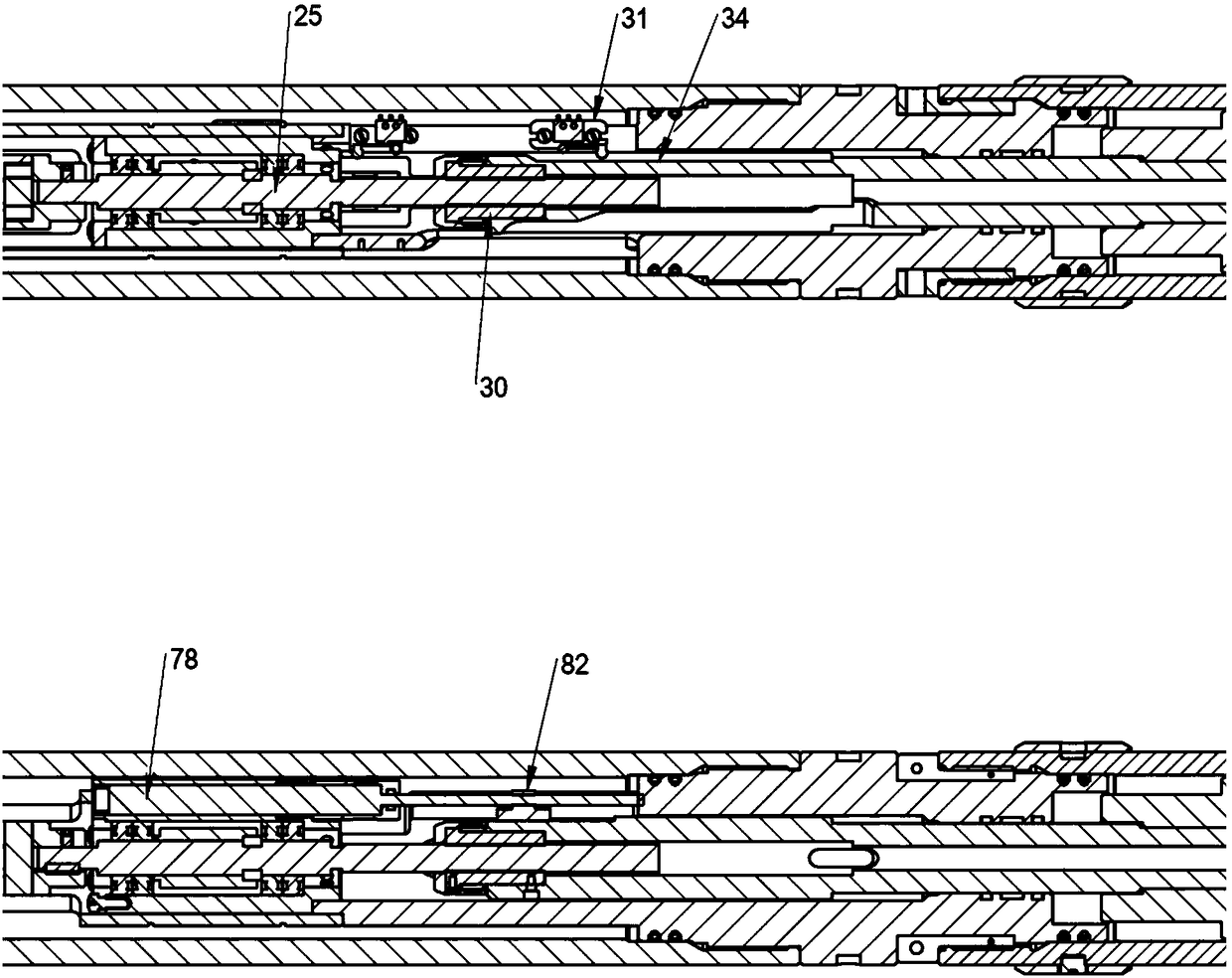

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The opening and closing legs of the instrument shown are driven by the motor (12) through the lead screw (25) and the lead screw nut (30) to drive the transmission rod (34) and the linkage rod (46) to perform linear reciprocating motion, and through the hinge (47) to drive the push rod. Arm (52) and (76) open and close leg.

[0019] The detection unit of the pushing force fixes the pull rod of the sensor (78) and the transmission rod (34) together through the connection block (82). The motor (12) drives the transmission rod (34) to move, and drives the pull bar of the sensor (78), the connecting arm fixed block (43) is fixed, and the transmission rod (34) compresses the spring (42) when moving. The travel range is limited by a limit switch (31). When the transmission rod (34) moves, the compression amount of the spring (42) will change accordingly, and the pushing force will change accordingly. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com