Patents

Literature

42 results about "Set packing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Set packing is a classical NP-complete problem in computational complexity theory and combinatorics, and was one of Karp's 21 NP-complete problems. Suppose one has a finite set S and a list of subsets of S. Then, the set packing problem asks if some k subsets in the list are pairwise disjoint (in other words, no two of them share an element). More formally, given a universe U and a family S of subsets of U, a packing is a subfamily C⊆S of sets such that all sets in C are pairwise disjoint.

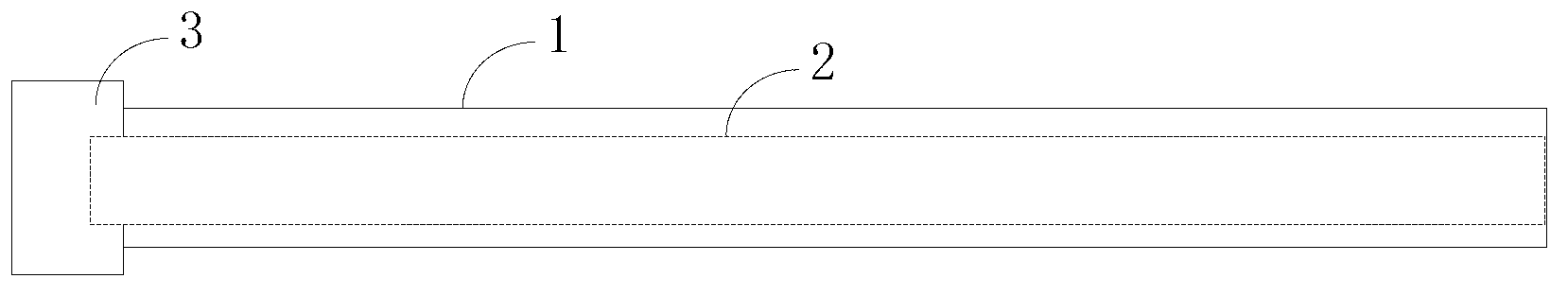

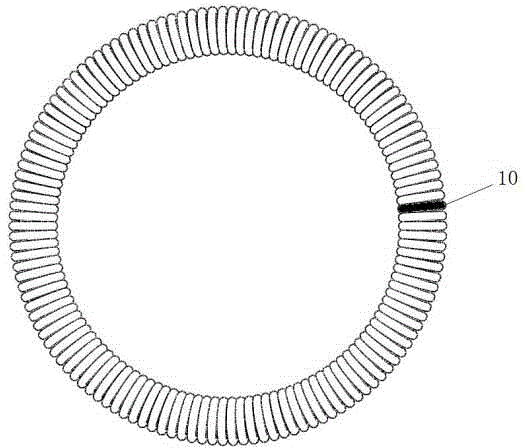

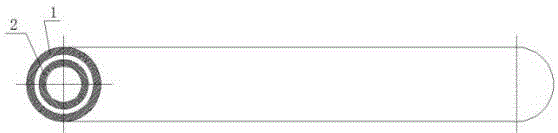

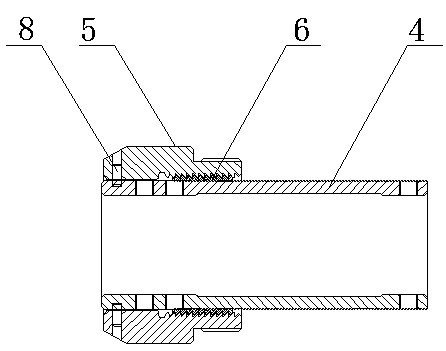

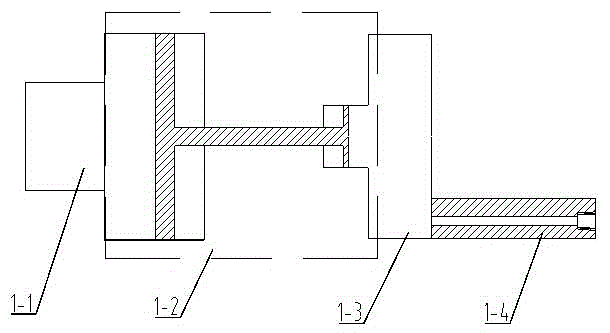

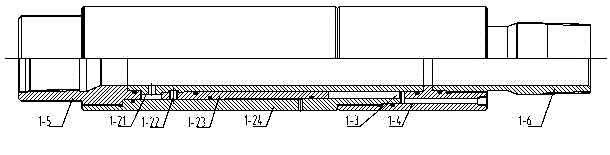

Membrane separator for methyl alcohol water hydrogen production equipment and fabrication method of membrane separator

ActiveCN103007697AImprove sealingGuaranteed preparation efficiencyHydrogen separation using solid contactDispersed particle separationAlcoholPhysical chemistry

The invention discloses a membrane separator for methyl alcohol water hydrogen production equipment and a fabrication method of the membrane separator. The method comprises the following steps that Step S1, a metal palladium membrane tube and a ceramic membrane tube are fabricated respectively; Step S2, set packing is filled in joint parts at one end of the metal palladium membrane tube and one end of the ceramic membrane tube; an expansion coefficient of the packing falls in between those of a metal palladium membrane tube material and a ceramic membrane tube material; and Step S3, the packing is sintered on site at 50-1000 DEG C, and solidified; and the joint parts of the metal palladium membrane tube and the ceramic membrane tube are sealed. With the adoption of the fabrication method of the membrane separator for the methyl alcohol water hydrogen production equipment, the membrane separator with good sealability can be fabricated, so that the preparation efficiency of hydrogen is ensured.

Owner:SHANGHAI HYDROGEN MOBILE REFRMER INSTR

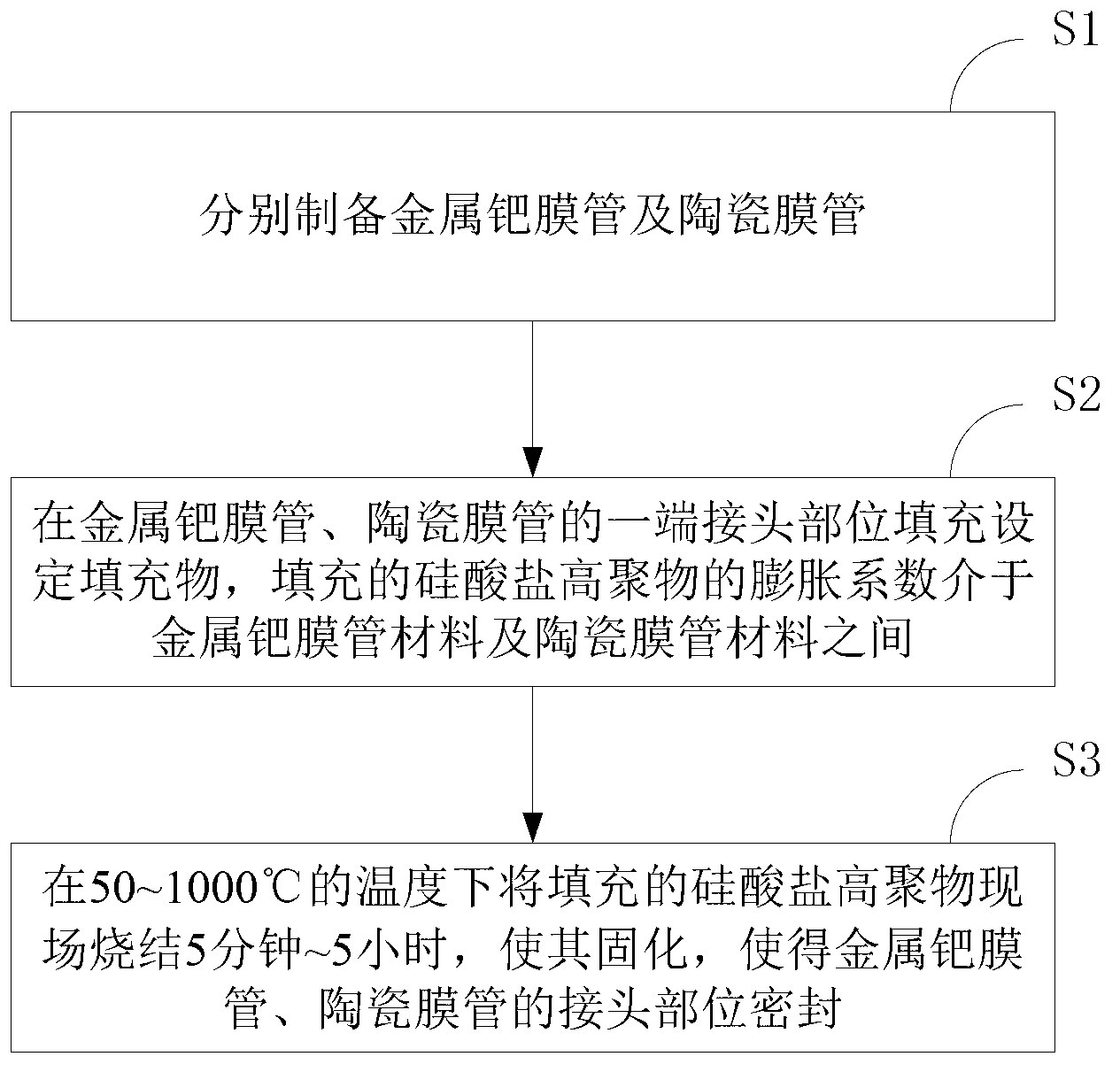

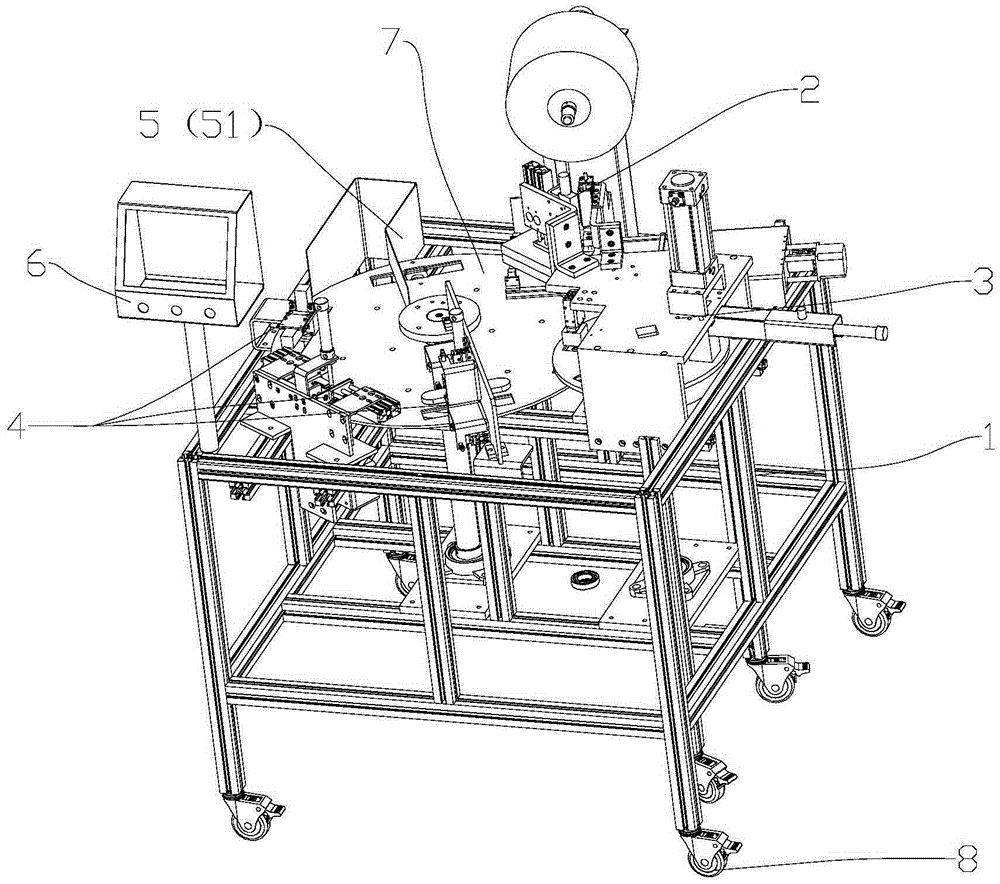

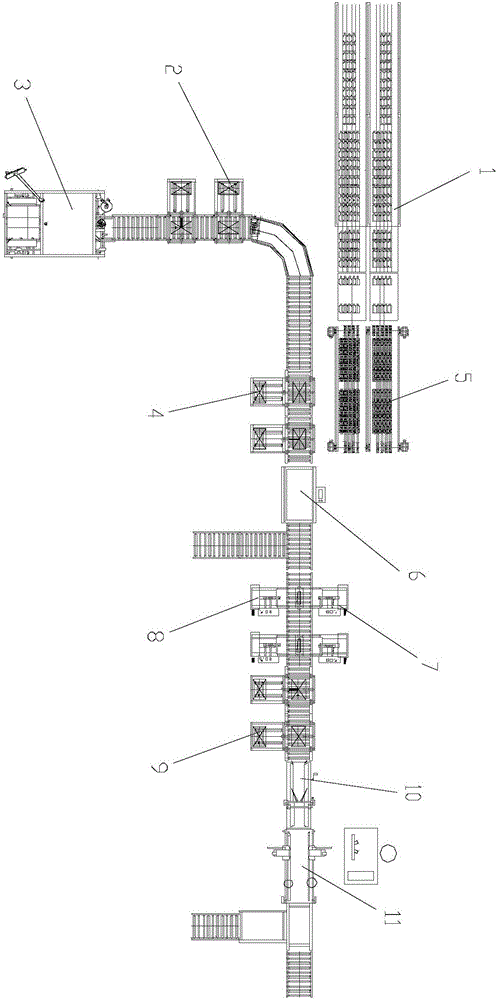

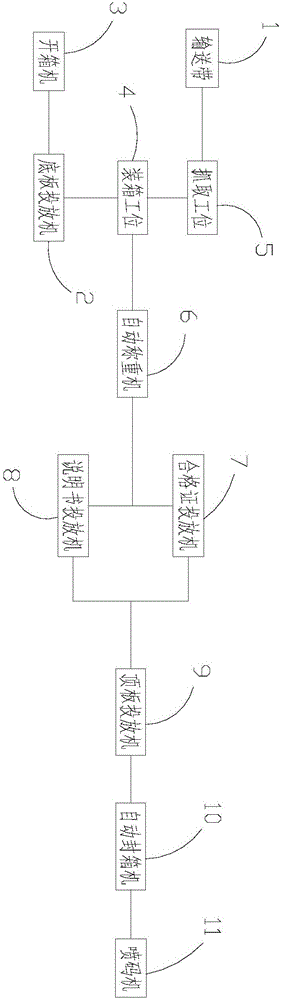

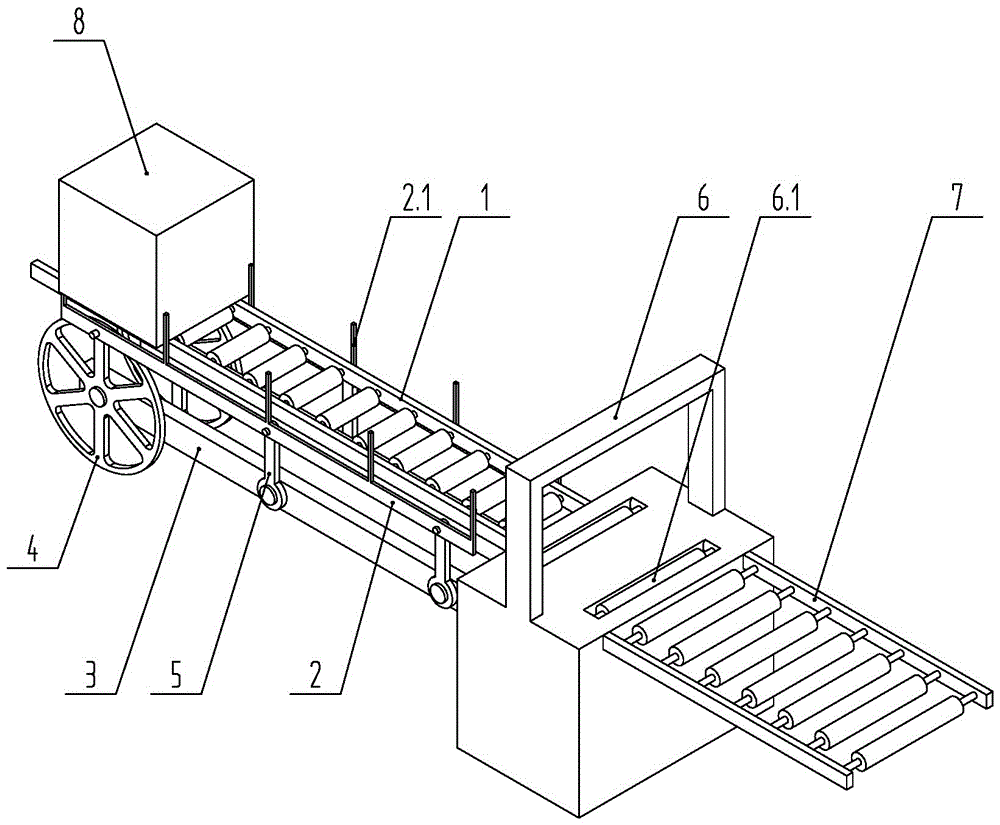

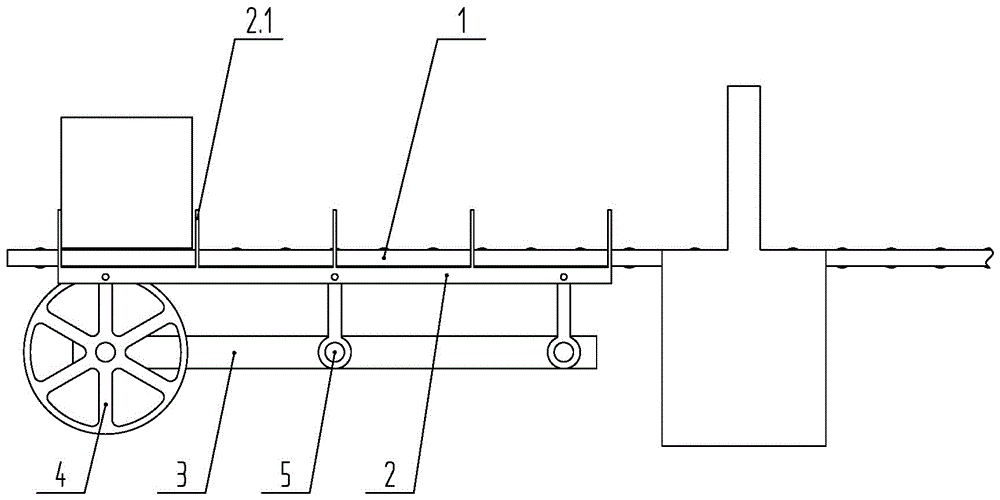

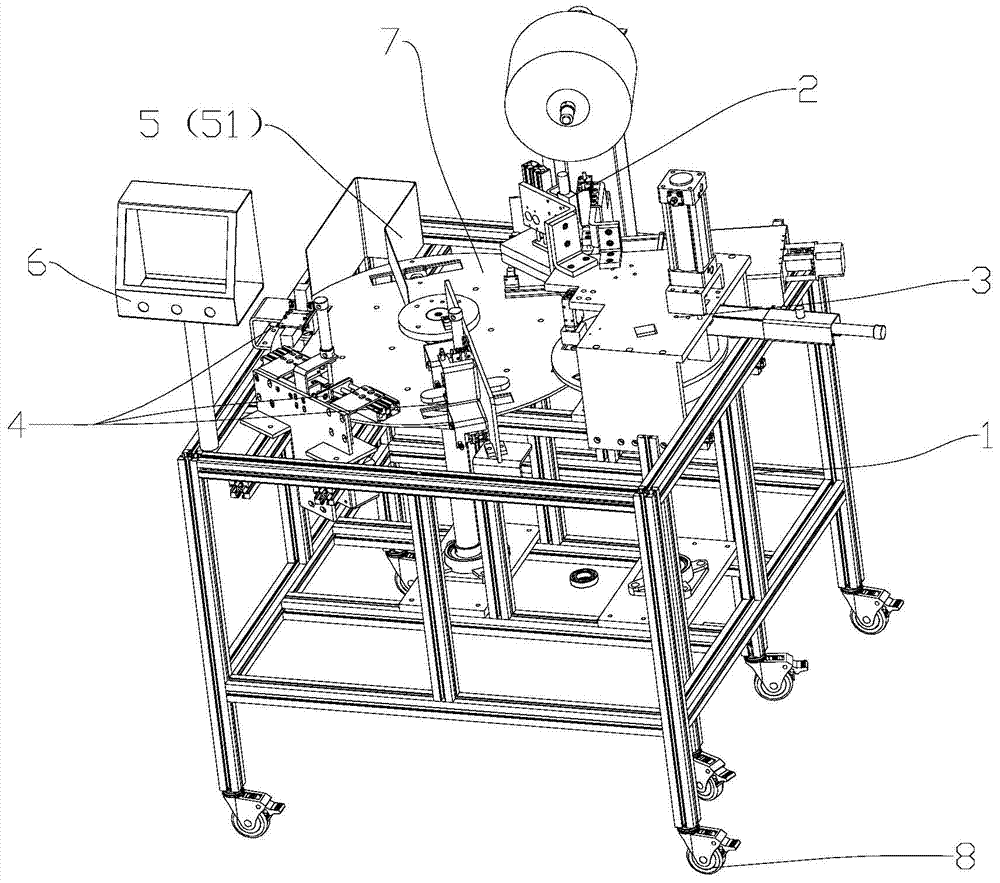

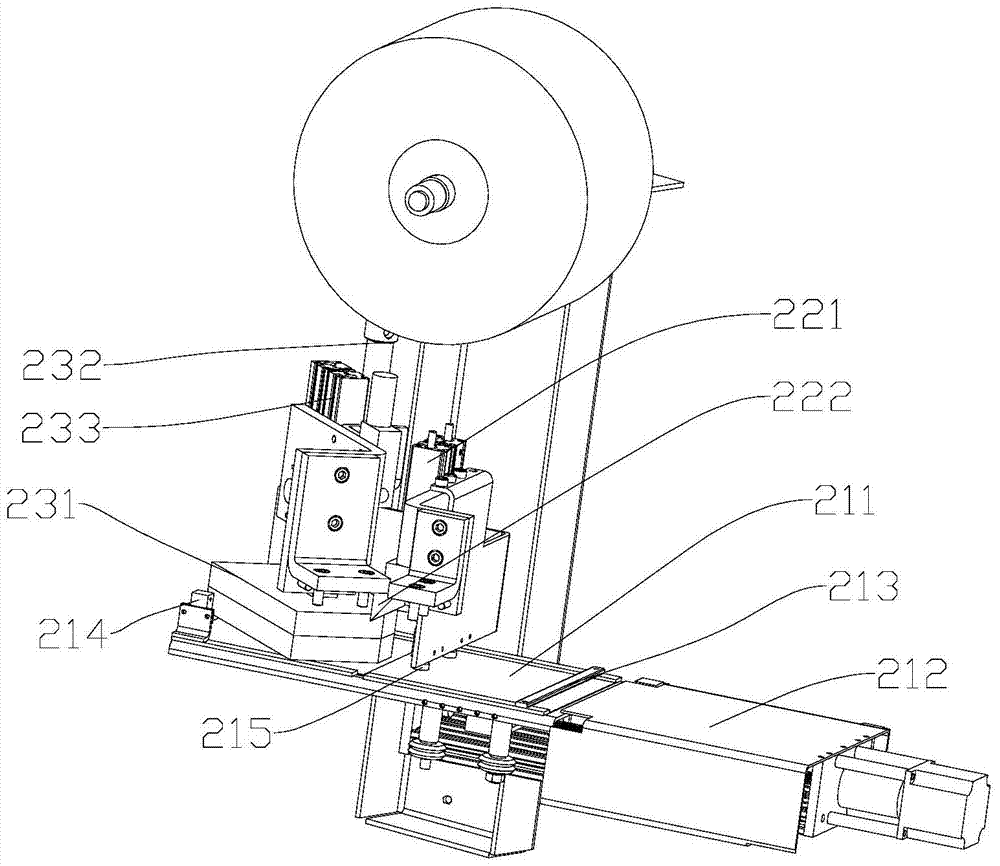

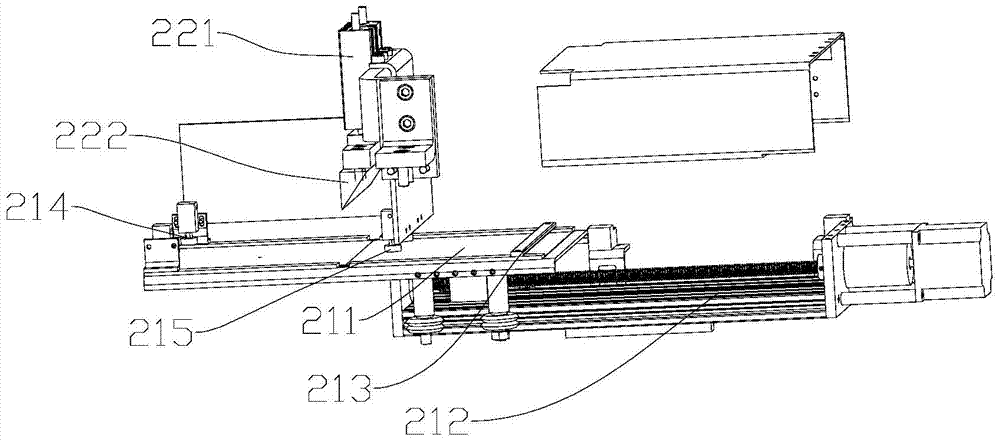

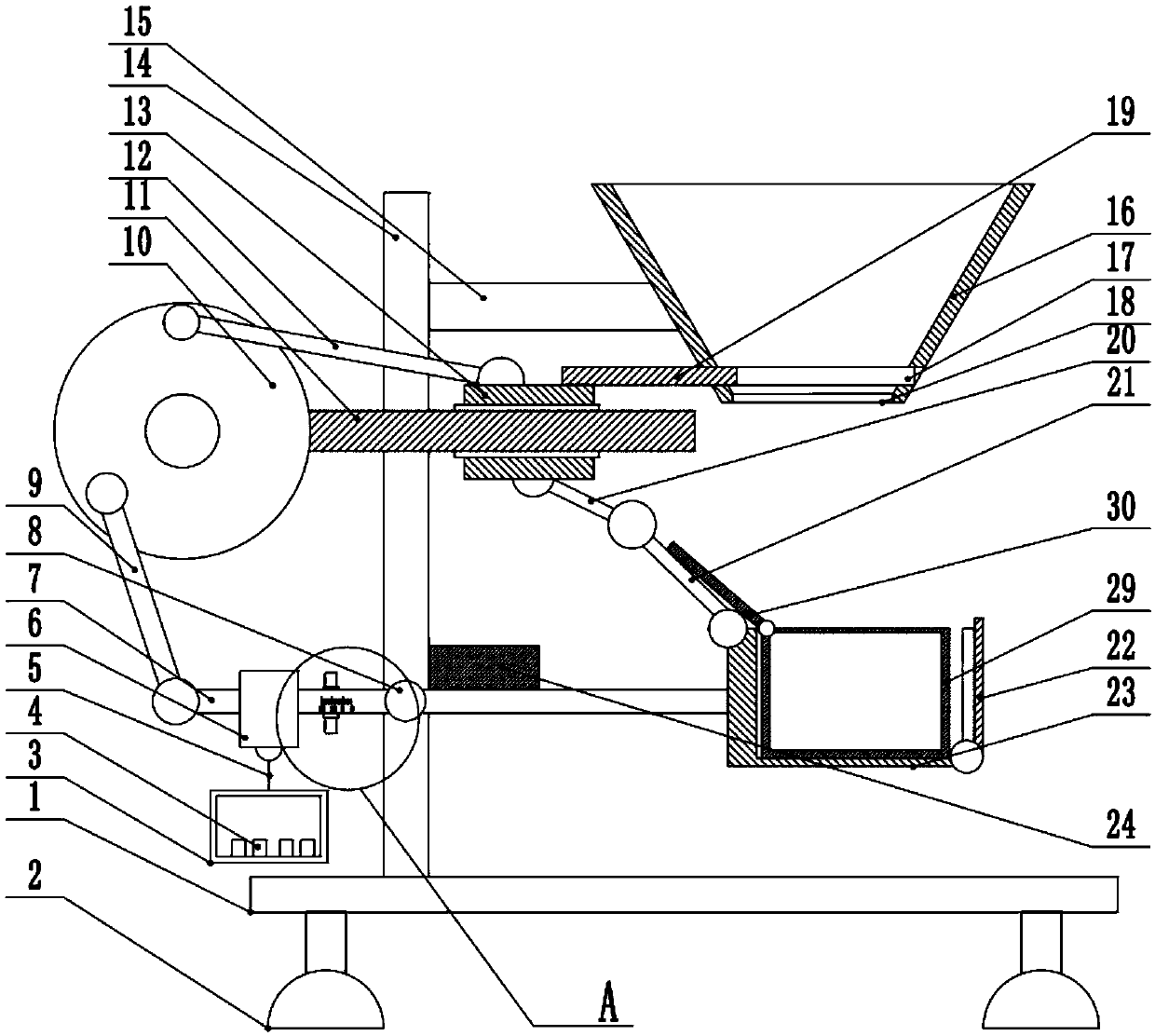

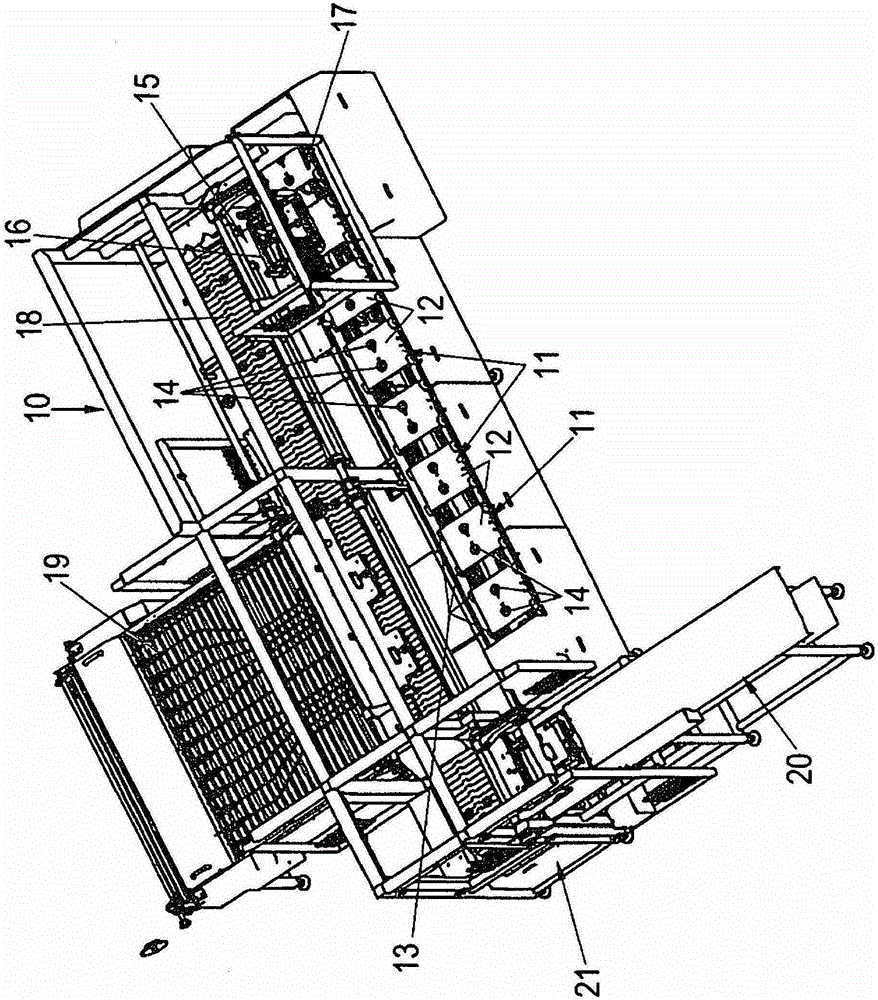

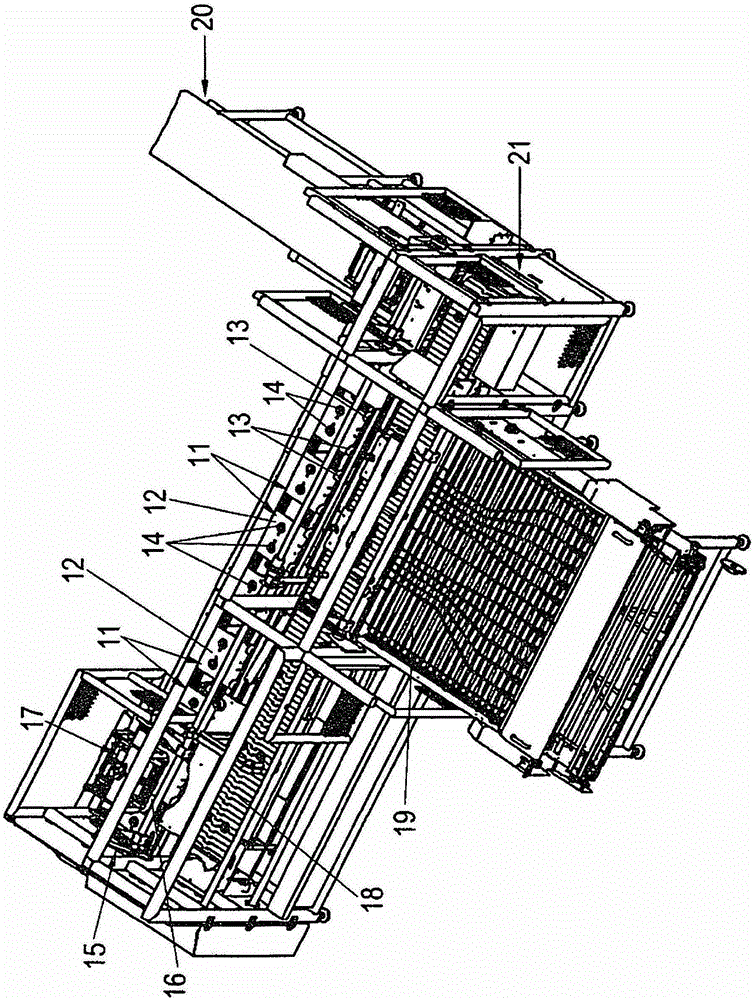

Automatic tea packing machine

ActiveCN105329693AMiniaturizationThe process is well connectedWrapper folding/bending apparatusWrappingProduction lineEngineering

The invention discloses an automatic tea packing machine. The automatic tea packing machine comprises a frame, wherein the frame is provided with a paper feeding device for automatically feeding packing papers, a molding device for putting compressed tea on the packing papers, a packing device for packing the tea according to set paper folding mode and sequence, a recovery device for recovering the packed tea and a control center; and the paper feeding device, the molding device, the packing device and the recovery device are distributed on a turntable type production line in a clockwise direction in sequence. The automatic tea packing machine can automatically realize such all procedures in tea packing as paper feeding, tea molding, tea packing and tea recovery, is excellent in joint of all procedure and compact in structure, can improve the production efficiency and reduce the labor cost, is rival to traditional manual packing in tea packing effect, and satisfies the tea packing pattern demands and the pursuit of tradition of customers.

Owner:ZHONGSHAN LONGNING AUTOMATIC EQUIP

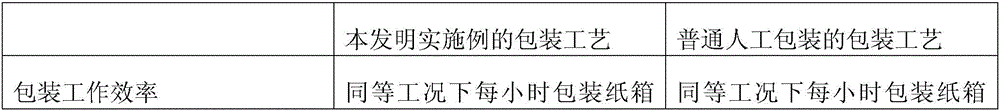

Plastic bottle packing system and packing process thereof

InactiveCN106081215AImprove work efficiencyIncrease productivitySortingPackaging bottlesProduction lineEconomic benefits

The invention relates to a plastic bottle packing system and a packing process thereof. The plastic bottle packing system comprises a conveying belt, bottom board putting machines, a case unpacking machine, case packing stations, a grabbing station, an automatic weighing machine, certificate of approval putting machines, specification putting machines, top board putting machines, an automatic case sealing machine and an ink-jet printer. Packing is carried out through processes of case unpacking, conveying and case packing, weighing and rejecting, certificate of approval and specification putting, top board putting, case sealing, electronic supervision code spraying, and removal of unqualified electronic supervision code. The plastic bottle packing system and the packing process have the advantages that automatic packing effect is realized, labor cost is lowered, wrong packing is avoided, working efficiency in packing is improved, production efficiency in packing is improved, economic benefit of enterprises is increased, 100ml plastic bottles, 200ml plastic bottles, 500ml plastic bottles and upright soft bags can be packed, the problem that one original production line can only be used for packing plastic bottles of one specification is solved, using effect is good, and popularization is facilitated.

Owner:ZHEJIANG GUOJING PHARM CO LTD

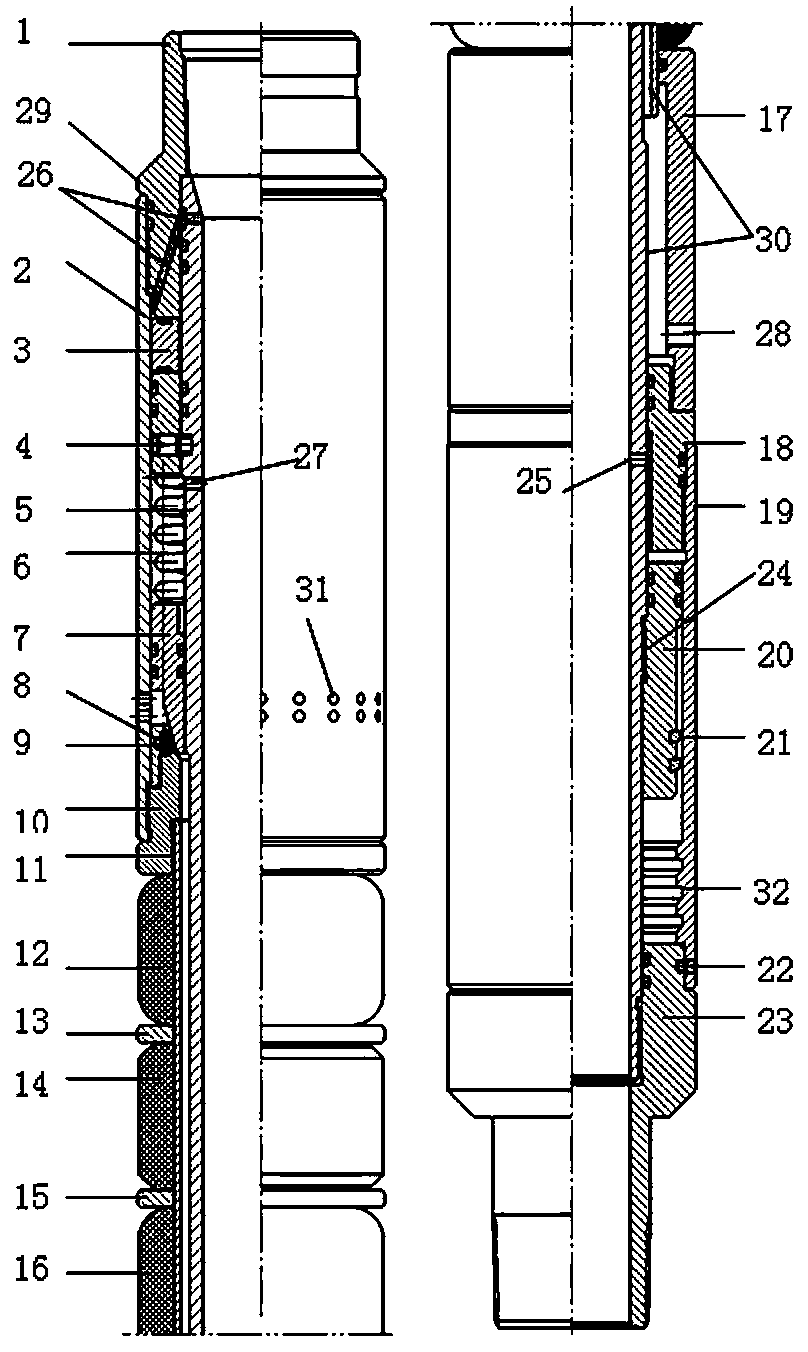

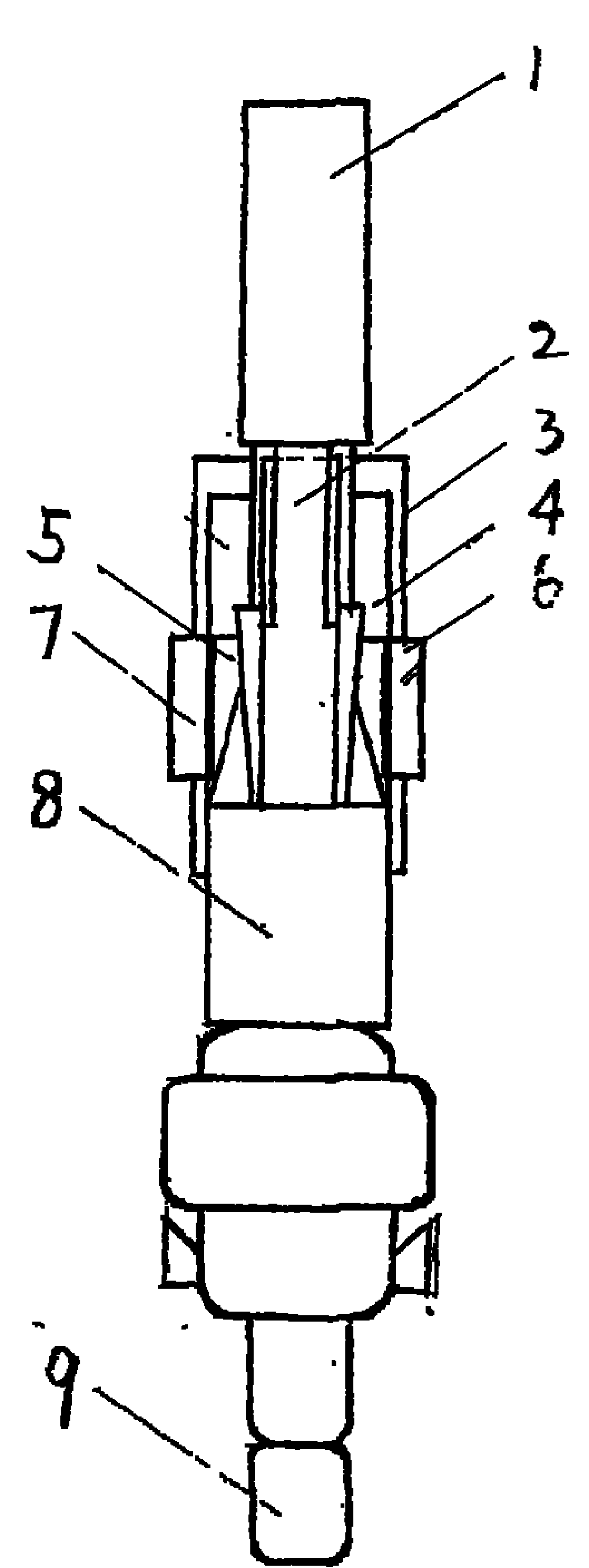

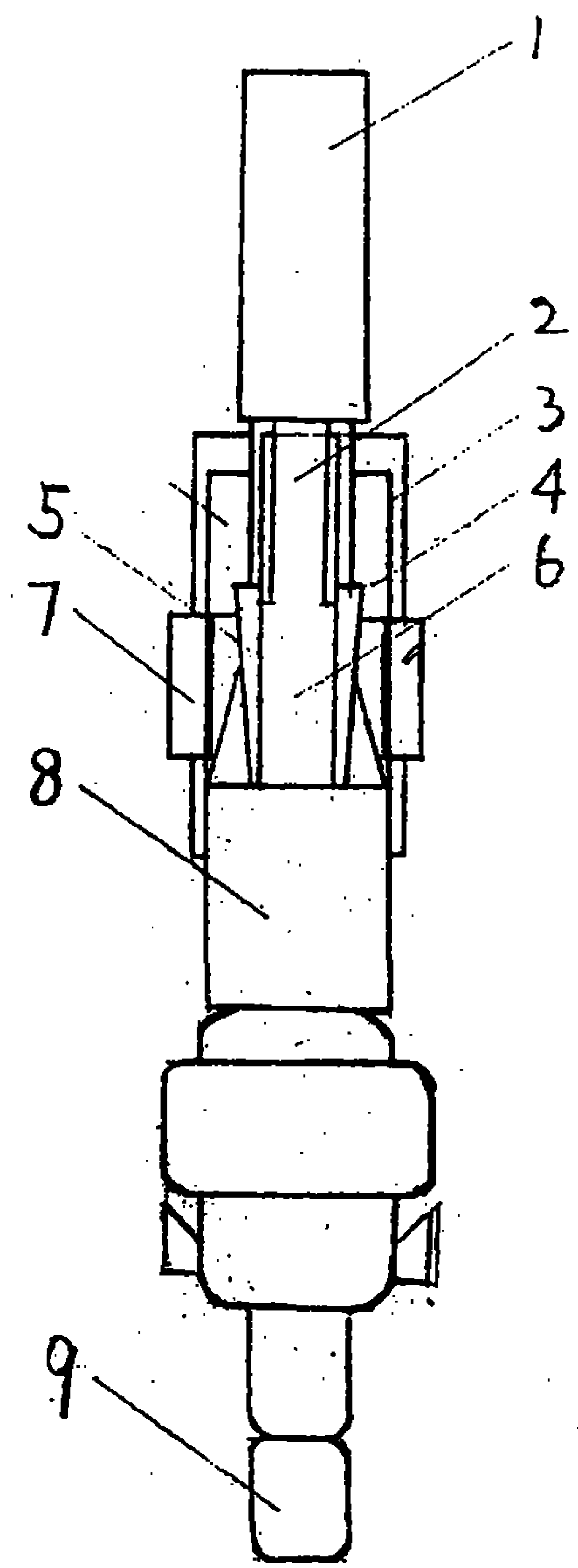

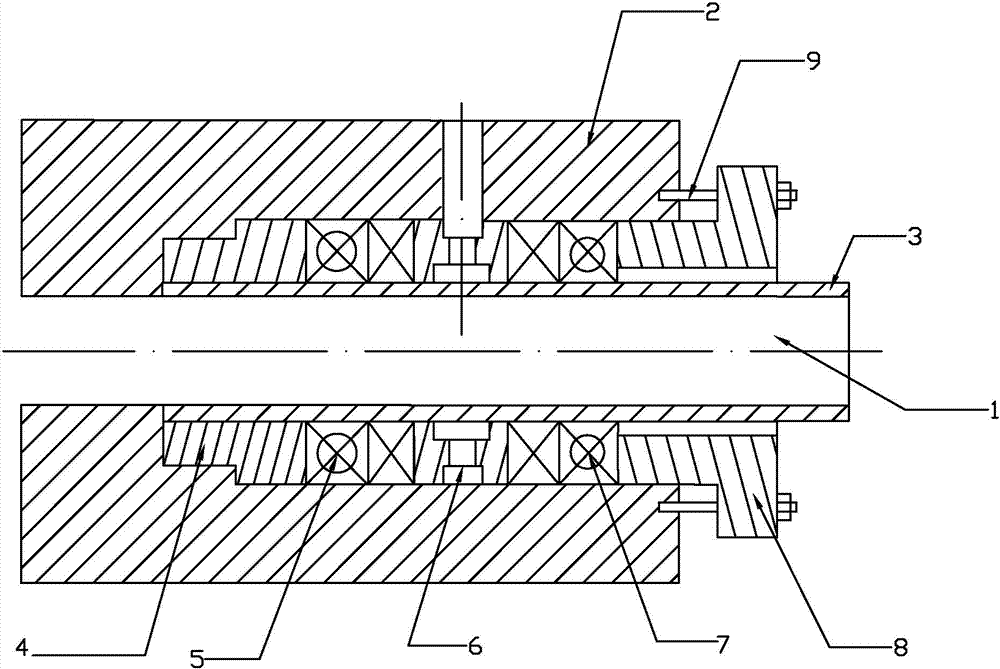

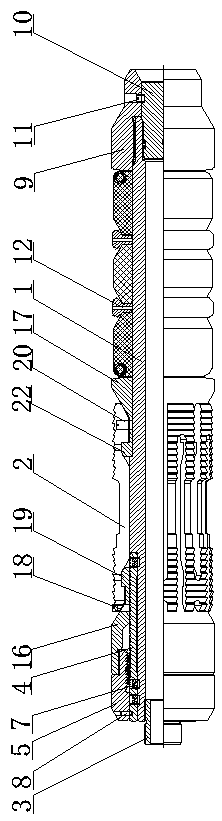

Constant-pressure classified deblocking packer

ActiveCN104265234AAvoid premature unblockingExcellent temperature and pressure resistanceSealing/packingUpper jointEngineering

A novel classified deblocking packer is characterized by comprising an upper joint, an upper connecting sleeve, a boosting piston, a deblocking pin, a center tube, a spring, a well washing piston, a pressing cap, a sealing ring, a base, an outer center tube, an upper rubber cylinder, an upper retaining ring, a middle rubber cylinder, a lower retaining ring, a lower rubber cylinder, a lower connecting sleeve, a set packing piston, a clamp spring sleeve, a clamp spring seat, a clamp spring, a set packing pin and a lower joint. The novel classified deblocking packer has the advantages that temperature-resistant and pressure-bearing performances are excellent, the novel classified deblocking packer can be successfully tripped in an oil well, deblocking can be realized step by step from top to bottom in the oil well, and the novel classified deblocking packer can solve the problem that a conventional step-by-step deblocking packer is deblocked in advance as a deblocking pin 4 is sheared in advance due to excessive load during set packing.

Owner:大庆康盛石油节能科技开发有限公司

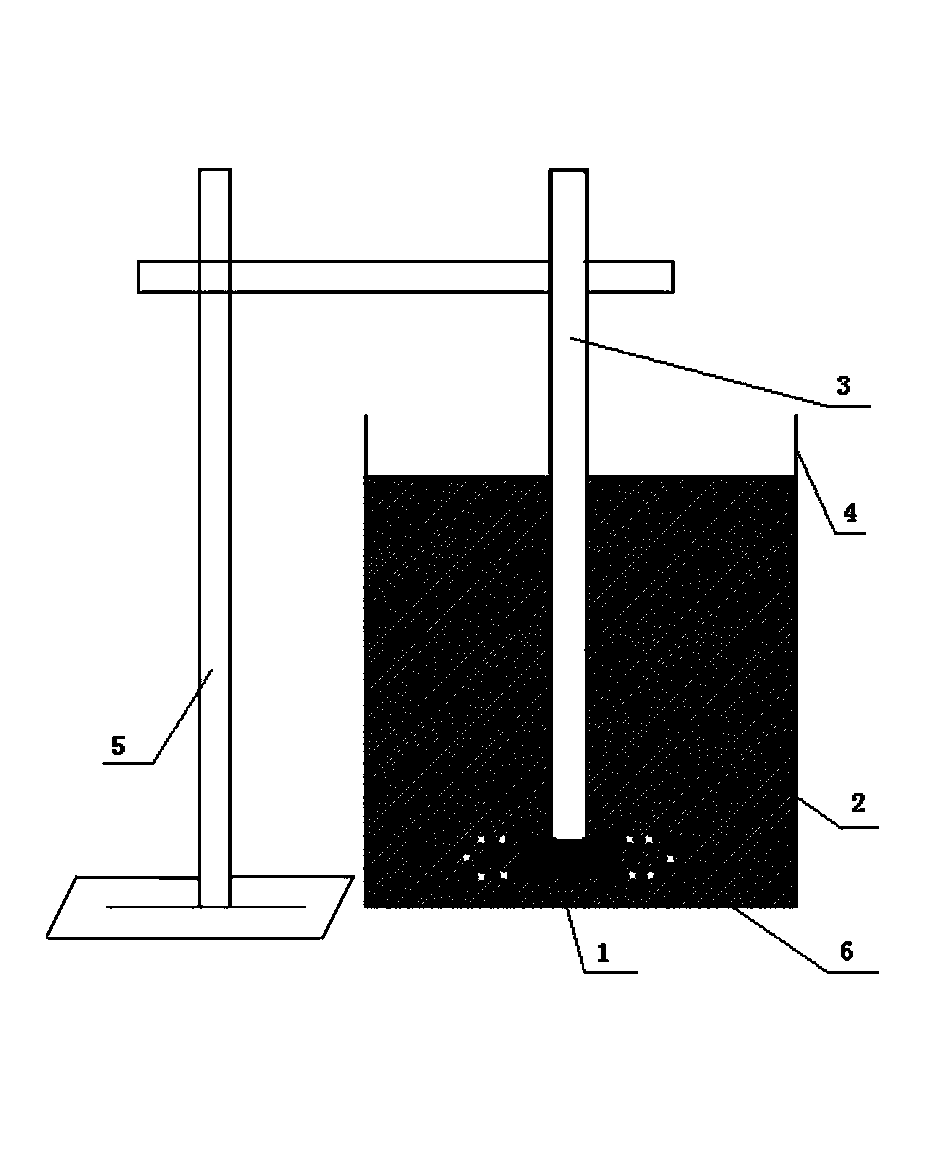

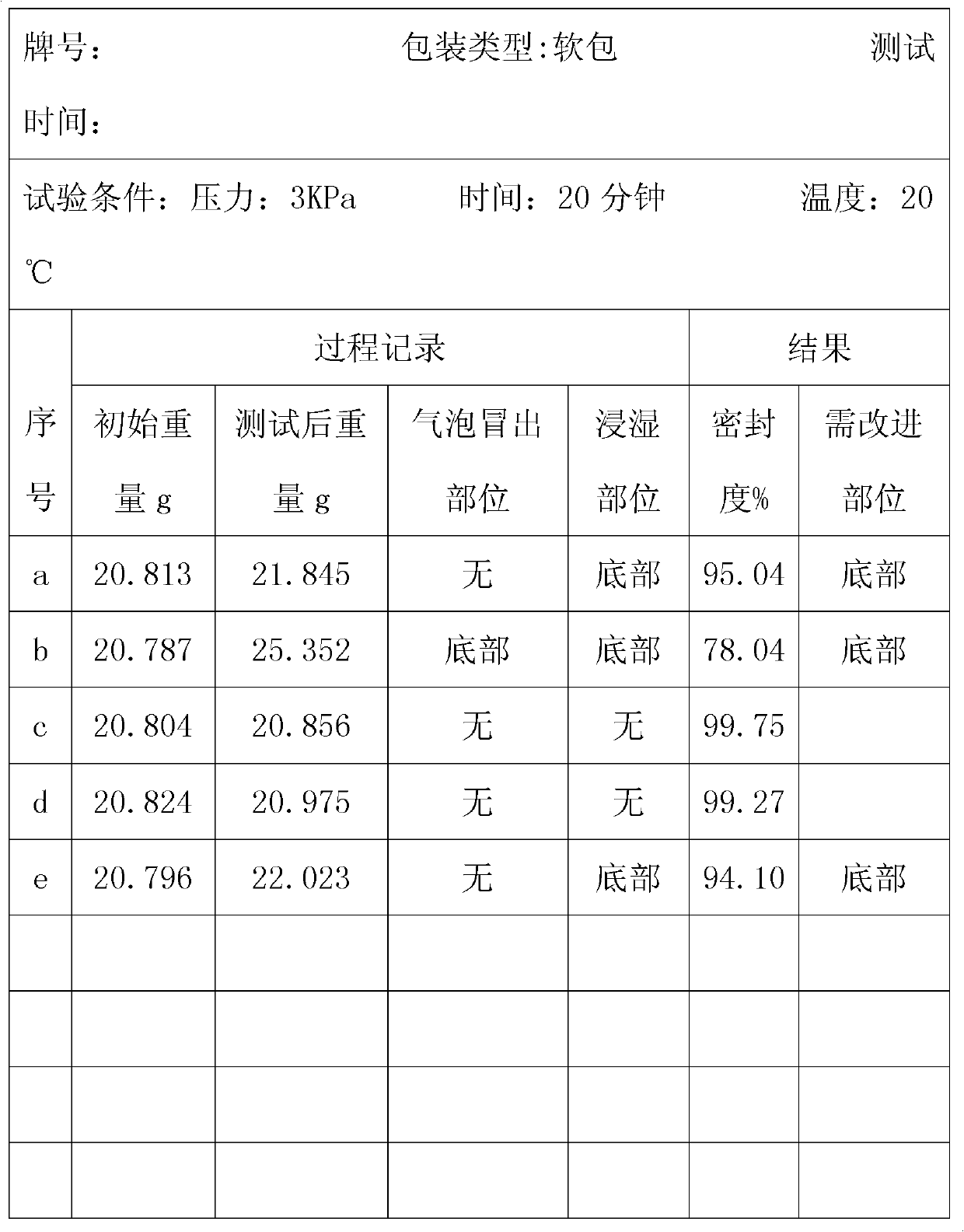

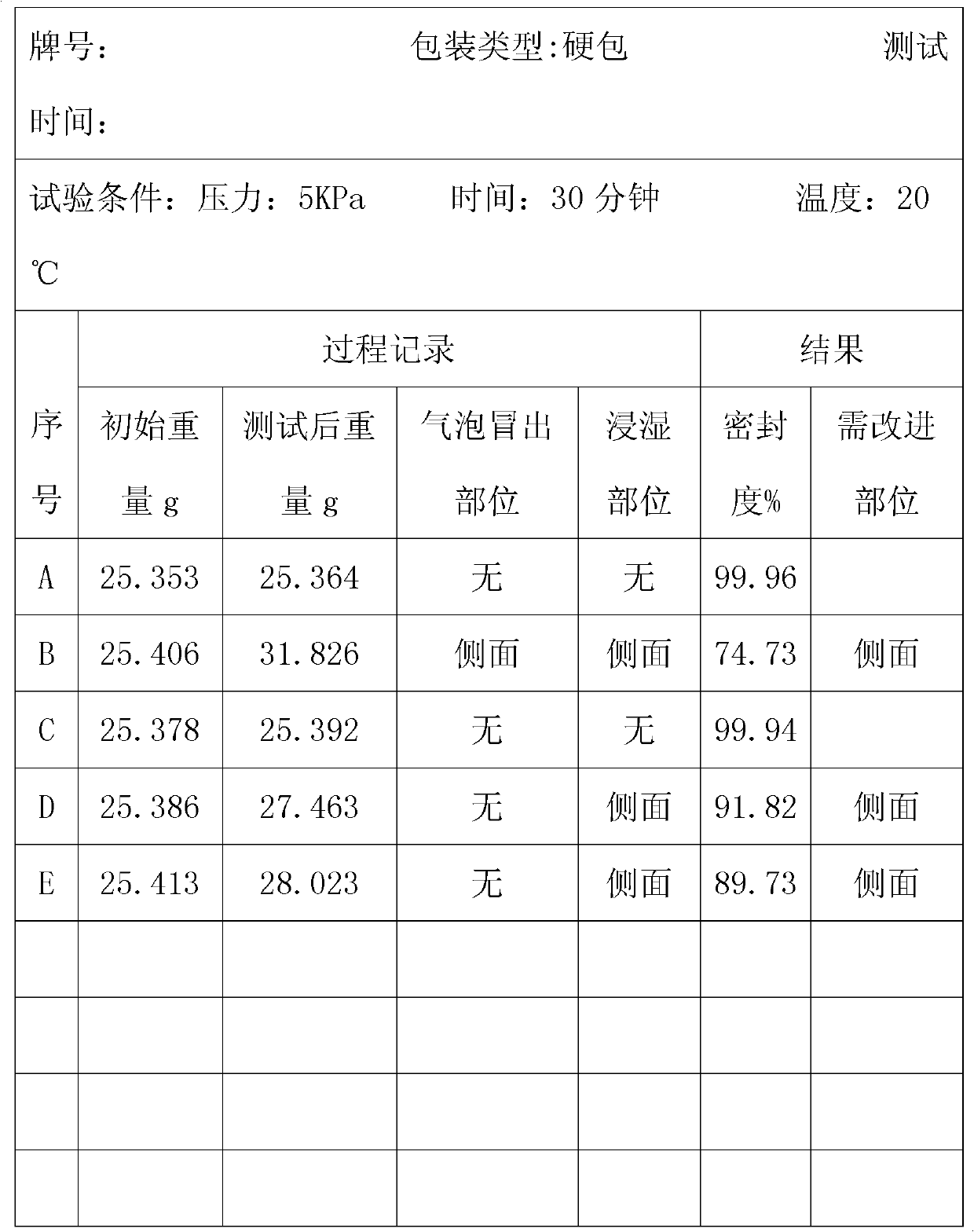

Testing method for cigarette packing sealing intensity

Owner:CHINA TOBACCO FUJIAN IND +1

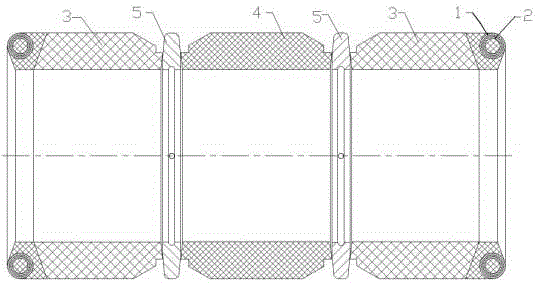

Compressed packer rubber barrel with spacer ring combined spring shoulder pad

InactiveCN104389546APrevent extrusionAvoiding Retraction Difficulty ProblemsSealing/packingEngineeringCam

The invention specifically provides a compressed packer rubber barrel with a spacer ring combined spring shoulder pad. the compressed packer rubber barrel is characterized in that a rubber barrel body comprises two side rubber barrels, and a medium rubber barrel positioned between the two side rubber barrels; two ends of the medium rubber barrels are respectively separated and in close contact with the side rubber barrels through a spacer ring; multi-layer circular spiral spring rings are respectively arranged at the shoulder parts of the two side rubber barrels and used for being radially expanded along the rubber barrel body to protect the shoulder parts of the side rubber barrels when an opposite axial extruding force is applied to the rubber barrel body. According to the compressed packer rubber barrel with the spacer ring combined spring shoulder pad, the multi-layer spiral springs can effectively protect the shoulder parts of the rubber barrel body; when in setting packing, the multi-layer spiral spring is expanded to block an a ring space to prevent the rubber barrels from being extruded; the multi-layer spiral spring is retracted under the tension force of the spring when releasing the packing and recovering; therefore, the problem of difficult retracting of the general rubber barrels can be avoided; in case that one section is failed in sealing when the rubber barrel body works, the other two sections can perform effective sealing; the compressed packer rubber barrel is high in bearing capacity and deformation resistance, and cam meet the requirements on high temperature, high pressure, and releasing and recovering.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO +1

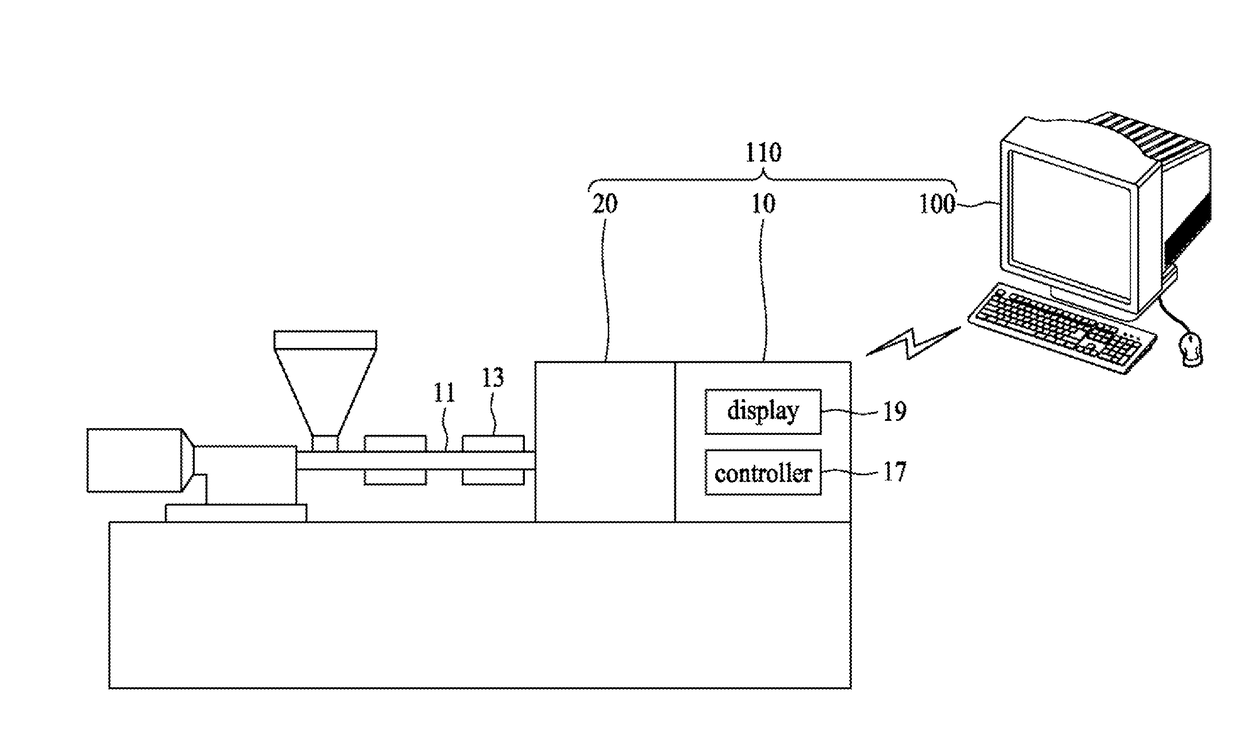

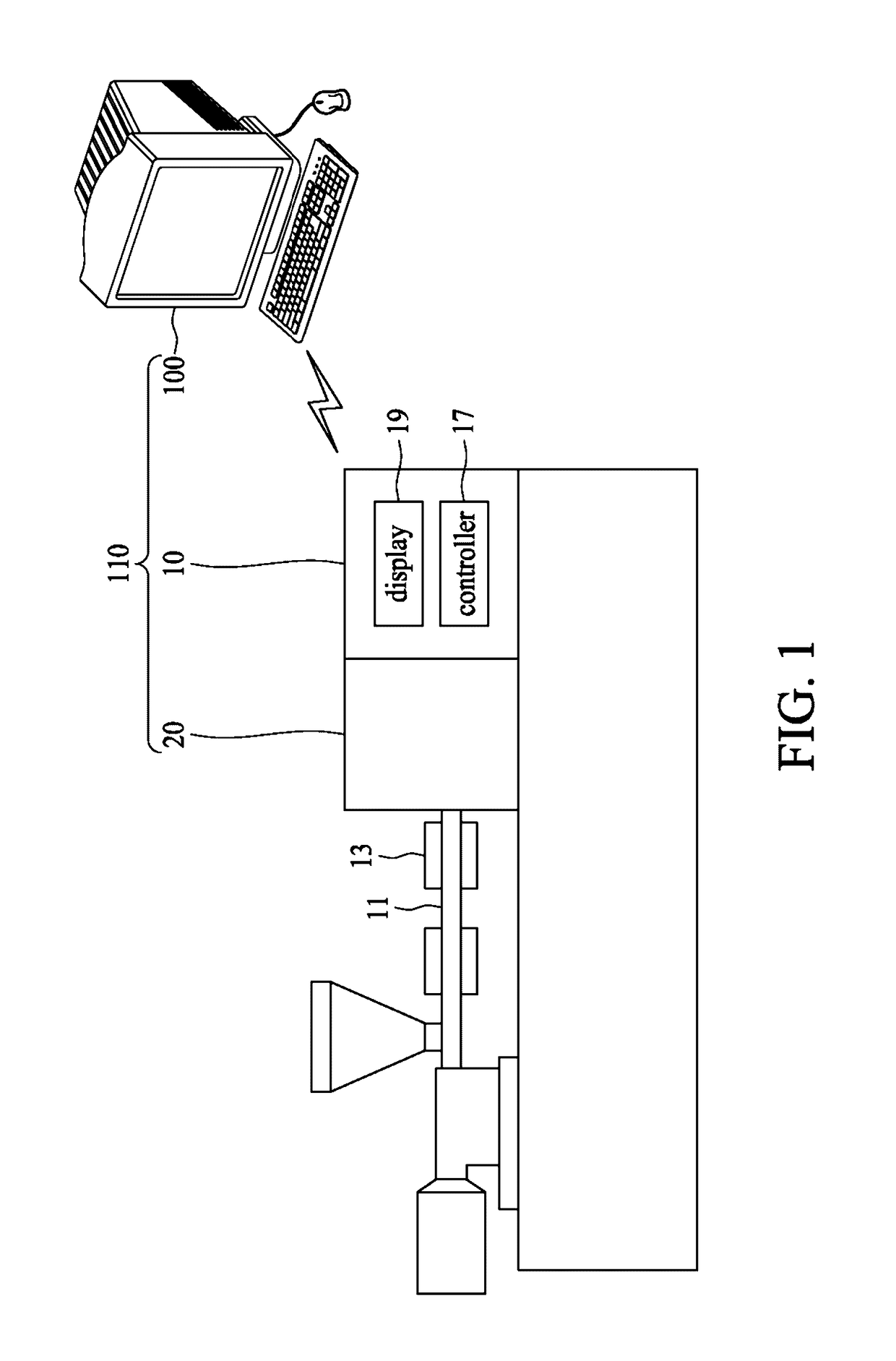

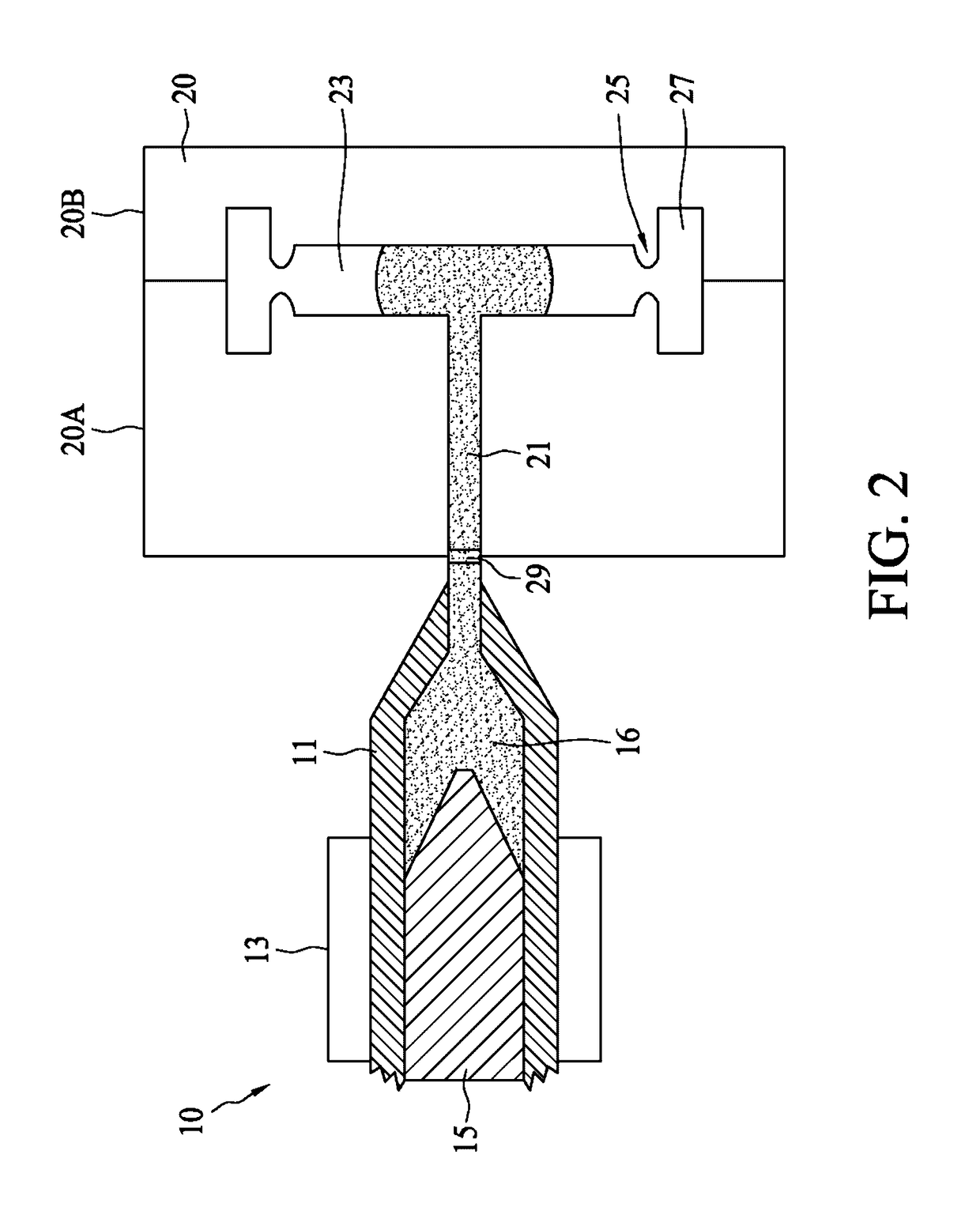

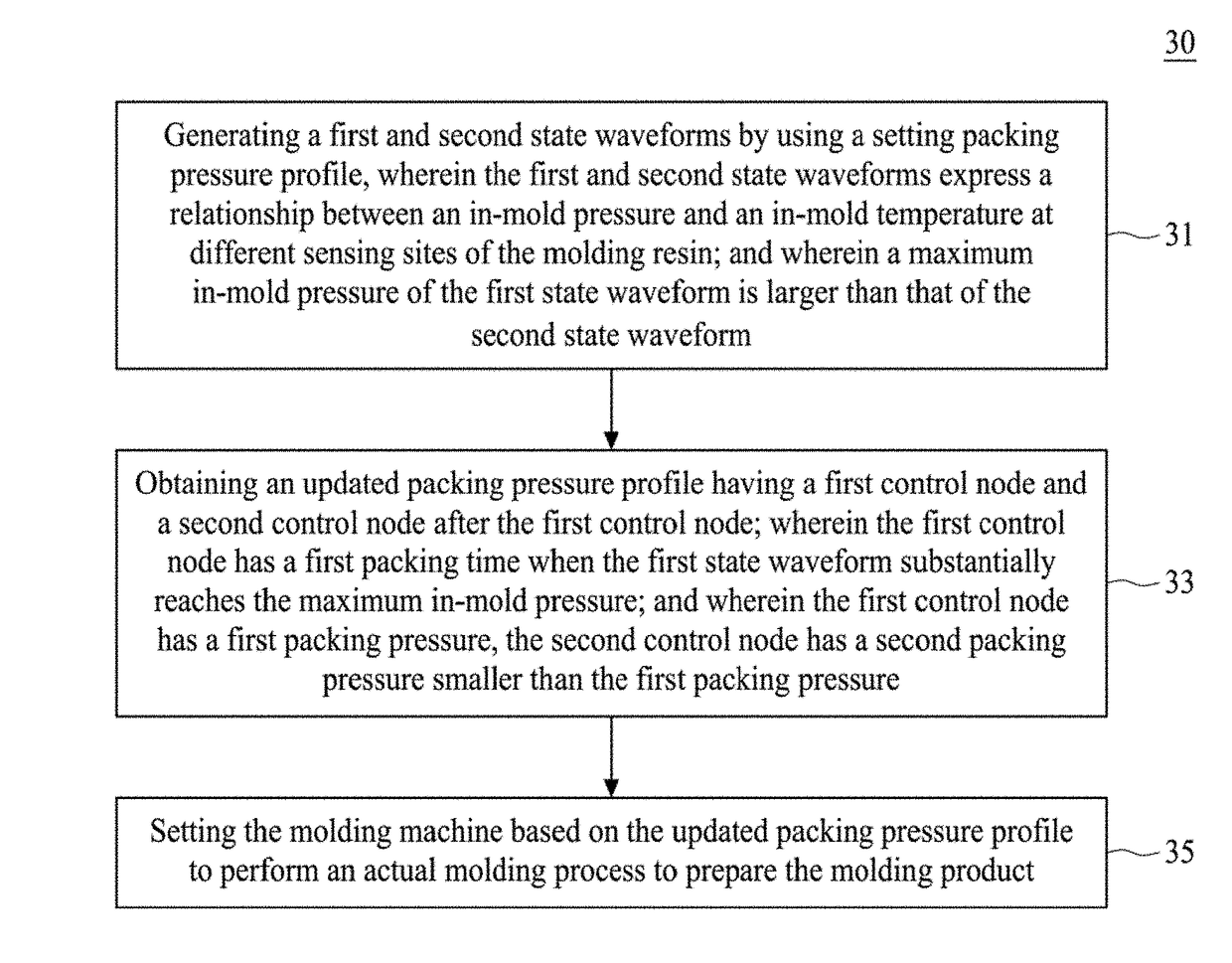

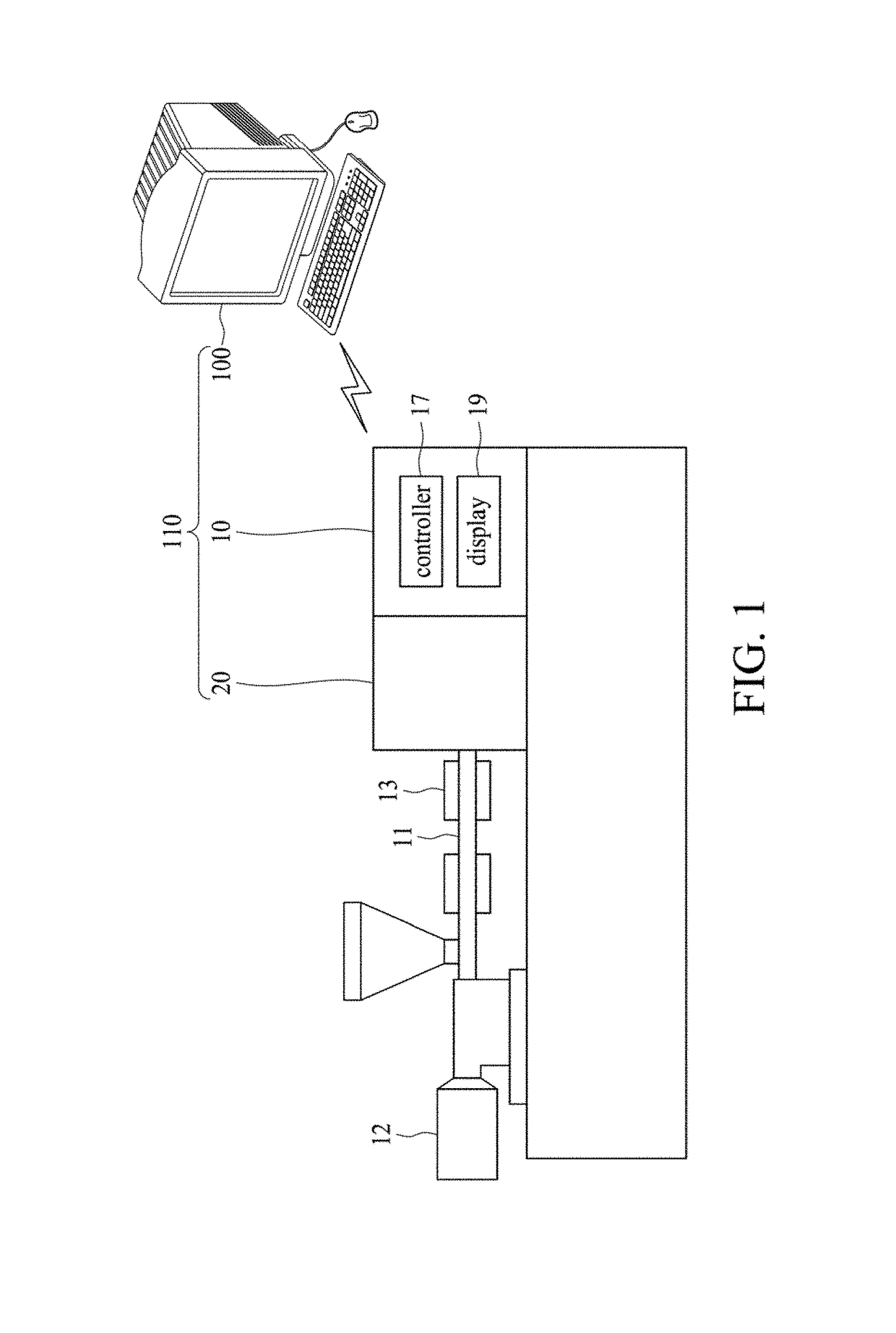

Molding system and method for operating the same

ActiveUS9684295B2Made preciselyEfficiency problemProgramme controlComputer controlMolding machineEngineering

Owner:CORETECH SYST CO LTD

Mechanical locking device for packer

InactiveCN102094587ASimple structureReduce labor intensityBorehole/well accessoriesPull forceTime delays

A mechanical locking device for locking a packer after set packing comprises two parts, namely an anchor mechanism and a time delay mechanism. The mechanical locking device comprises an upper connector, a spline mandrel, an upper cone, a sleeve, a slip dog, a spline outer barrel, a valve mandrel, an outer barrel, a lower connector and other parts. The time delay mechanism is used for guaranteeing the packer to be operated firstly when in set packing and guaranteeing the lifting force not to act on the packer in a short time when a pipe column is lifted up.

Owner:戈宝富

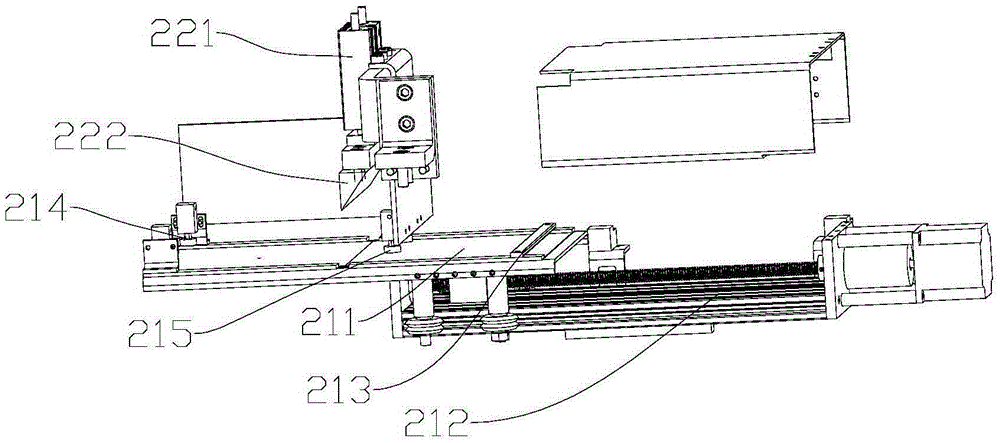

Automatic continuous double-strip packing and conveying system

InactiveCN106043784ABinding material applicationBundling machine detailsEngineeringMechanical engineering

The invention discloses an automatic continuous double-strip packing and conveying system. The automatic continuous double-strip packing and conveying system comprises a first packing and conveying mechanism, a second packing and conveying mechanism and a connecting conveying belt with a steering function. The first packing and conveying mechanism and the second packing and conveying mechanism have the same structure and each comprise a conveying mechanism capable of conveying packing boxes intermittently, a packer and an outlet conveying belt, wherein the packer is provided with a detection device used for judging whether the packing boxes are located in the packing position or not and used for packing the packing boxes conveyed from the conveying mechanism, the outlet conveying belt is capable of continuously conveying the packing boxes and used for conveying the packed packing boxes to the next step, and an inlet and an outlet of the packer are further provided with transmission rollers. The automatic continuous double-strip packing and conveying system has the beneficial effects that the conveying mechanisms capable of intermittently conveying the packing boxes are used for conveying the packing boxes into the packers to be packed according to a certain period, conveying and packing are effectively linked, and the purpose of man-free continuous packing is realized.

Owner:SUZHOU GAOTONG MACHINERY TECH CO LTD

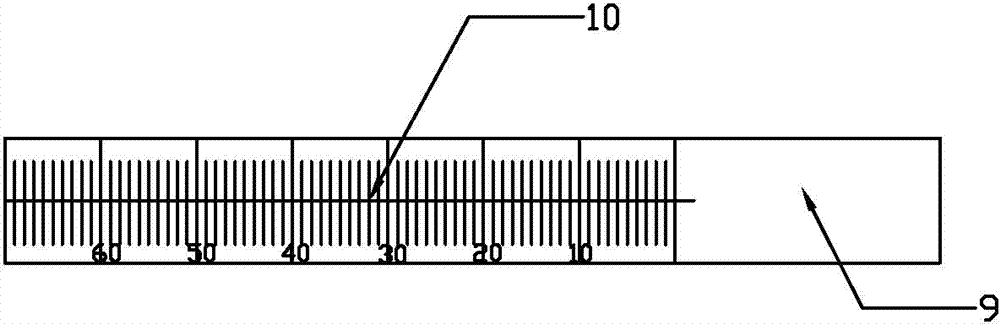

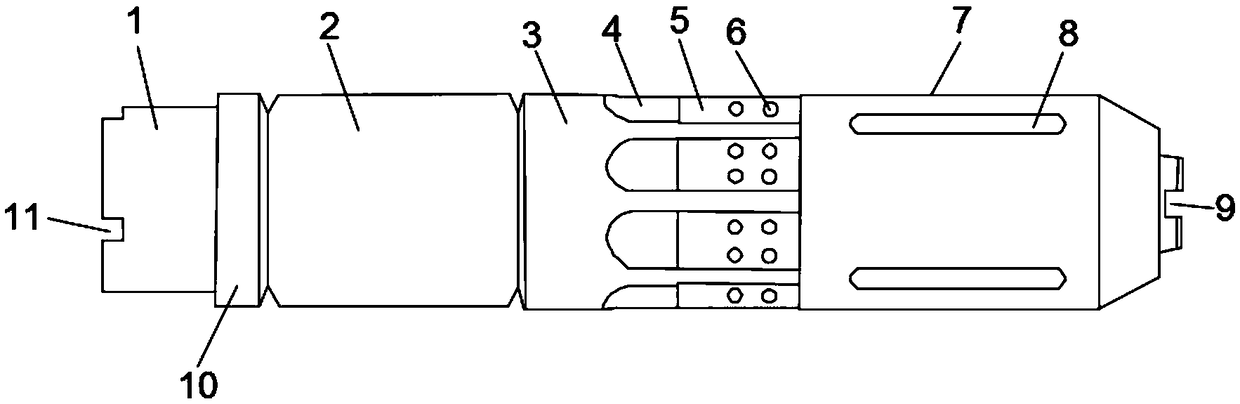

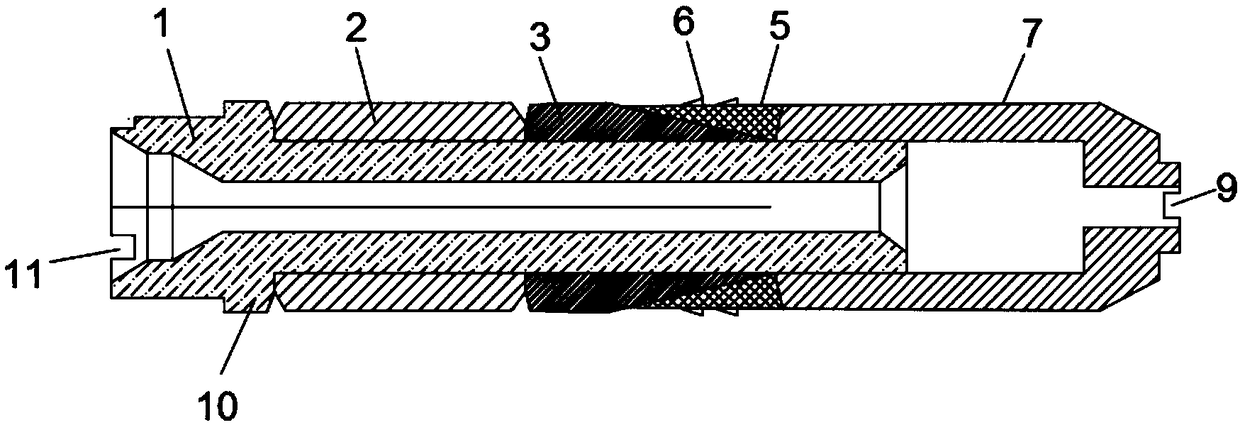

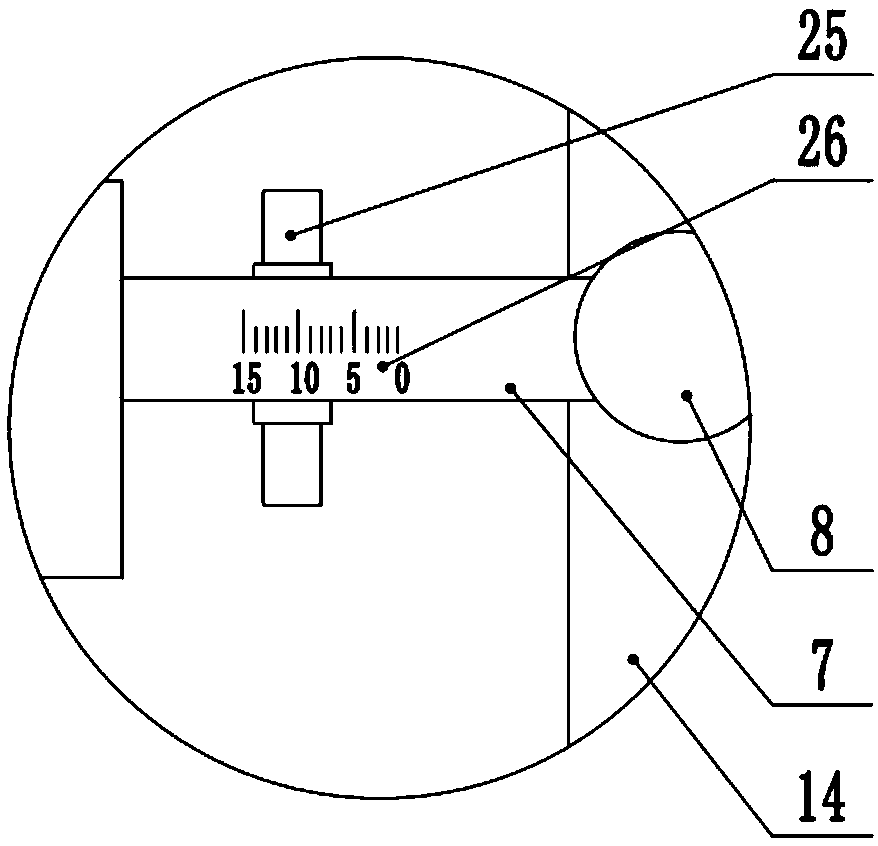

Sealing structure for asbestos packing of water pump bearing

InactiveCN103089695AUnderstand the lossEasy to installPump componentsPumpsState of artUltimate tensile strength

The invention discloses a sealing structure for asbestos packing of a water pump bearing. The sealing structure comprises a main shaft and an asbestos packing box, wherein the main shaft is provided with a shaft sleeve; and the asbestos packing box is positioned on the shaft sleeve. In the prior art, the packing material has a poor sealing effect, a packing pressing cover and the packing box are inconvenient to mount and dismount due to bolt connection, an operator judges reloading through the loosening degree of the bolts, and the labor intensity of the operator is increased. The invention solves the problems and provides an improved sealing structure for the asbestos packing of the water pump bearing; a threaded rod is welded on the packing box; the packing pressing cover is connected with the packing box only through nuts, and is convenient to mount and dismount; and the threaded rod is provided with a dividing rule, so that the operator can intuitively judge whether the packing needs to be reloaded or not, the packing reloading times are reduced, and the labor intensity is saved.

Owner:CHONGQING MING SHIELD ELECTROMAGNETIC VALVE

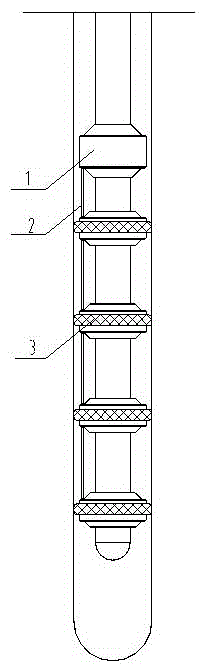

Soluble bridge plug

InactiveCN109505559AAvoid damageExtended service lifeSealing/packingPetroleum engineeringSet packing

The invention discloses a soluble bridge plug and relates to the technical field of downhole tools of oil and gas wells. The problem is solved that the slip tooth direction is simple in the setting-packing process of an existing bridge plug and accordingly the underground resistance risk is high. The soluble bridge plug comprises a mandrel, a rubber cylinder, a cone sleeve, multiple slips and a lower joint short section, wherein the mandrel is of a hollow structure and is provided with a limiting boss, the rubber cylinder and the cone sleeve sequentially and slidingly sleeve the outer surfaceof the mandrel on one side of a limiting boss, the multiple slips are located on the conical face of the cone sleeve through a radial limiting structure, one end of the lower joint short section slidingly sleeves the other end of the mandrel and abuts against the slips, each slip is provided with multiple slip teeth, the slip teeth are oblique truncated cylinders and include lower slip teeth downward inclining in the oblique cross section direction as the conical surface directions of the cone sleeve and upper slip teeth upward inclining in the oblique cross section direction as the conical surface directions of the cone sleeve. The downhole resistance risk is reduced, and the potential safety hazards of oil and gas well operation are reduced.

Owner:成都铭鉴知源油田工程科技有限公司 +1

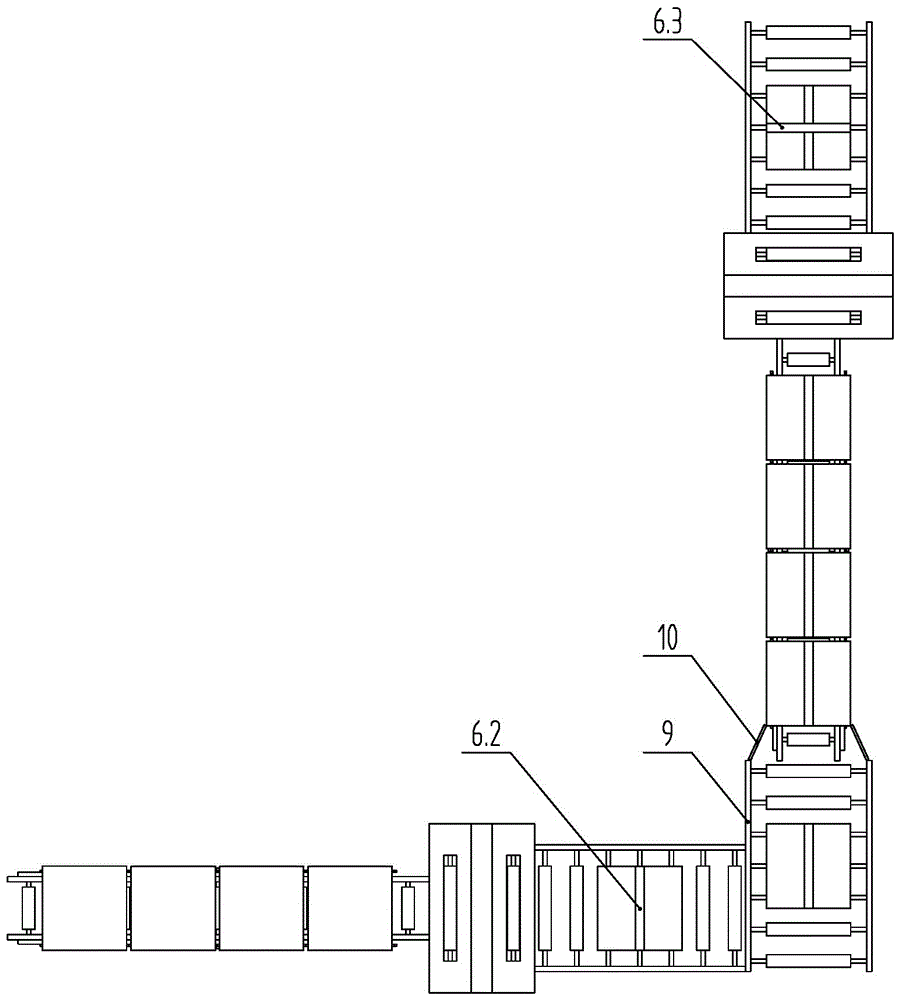

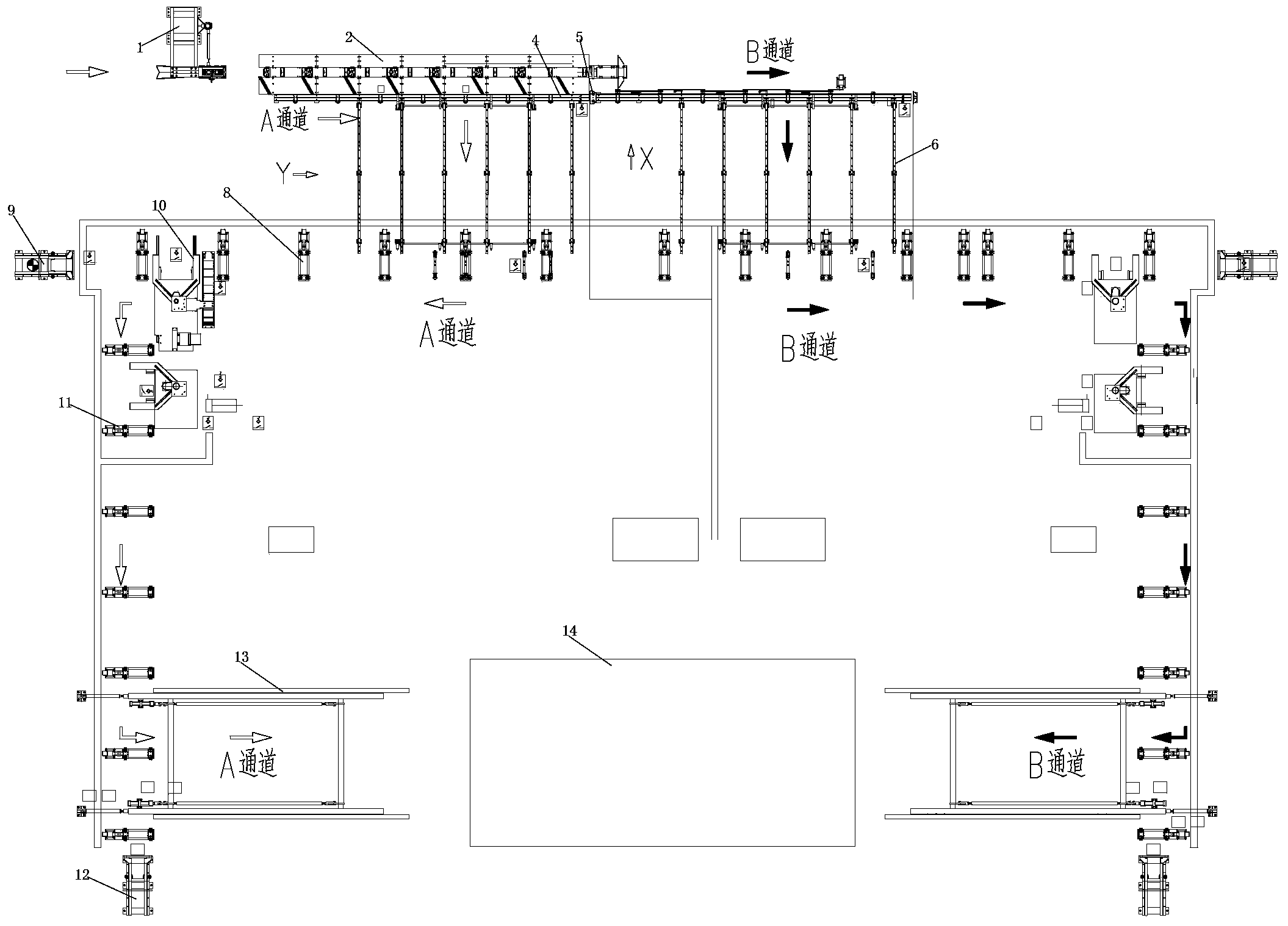

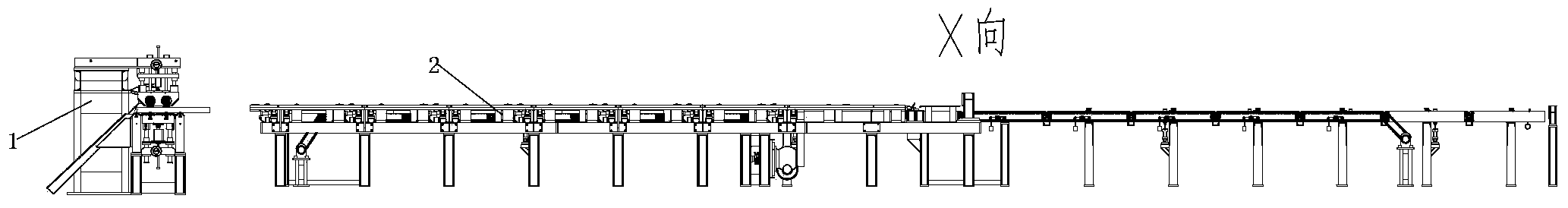

Multi-channel welded pipe high-speed packing and discharging system

ActiveCN104276305AGuaranteed connectivityGuaranteed automationPackagingEconomic benefitsUltimate tensile strength

The invention discloses a multi-channel welded pipe high-speed packing and discharging system and a method thereof. The multi-channel welded pipe high-speed packing and discharging system comprises a discharging acceleration clamping unit, an overturning roller way, a waste collecting unit, an adapting roller way, a switching unit and a temporary storage unit, wherein the discharging acceleration clamping unit is used for receiving welded pipes produced by a pipe making system and accelerating discharging output; the overturning roller way for identifying and distinguishing good welded pipes output in an accelerated manner by the discharging acceleration clamping unit; the waste collecting unit is positioned on one side of the overturning roller way and is used for collecting defective products; the adapting roller way is positioned on the other side of the overturning roller way and is used for selecting different channels to adapt the good products; the switching unit is arranged in the adapting roller way and is used for switching different channels; the temporary storage unit is used for correspondingly storing the welded pipes through different storage sub-units according to corresponding different channels. The multi-channel welded pipe high-speed packing and discharging system has a double-channel switching high-speed discharging function, the continuity and automation of pipe making are ensured, the labor intensity of workers is lowered greatly, and the production efficiency is increased. The multi-channel welded pipe high-speed packing and discharging system has great use value and economic benefit.

Owner:SUZHOU BAOLIAN HEAVY IND

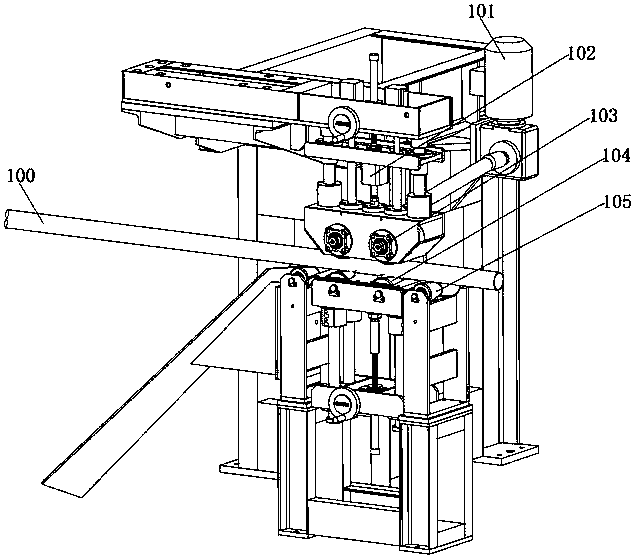

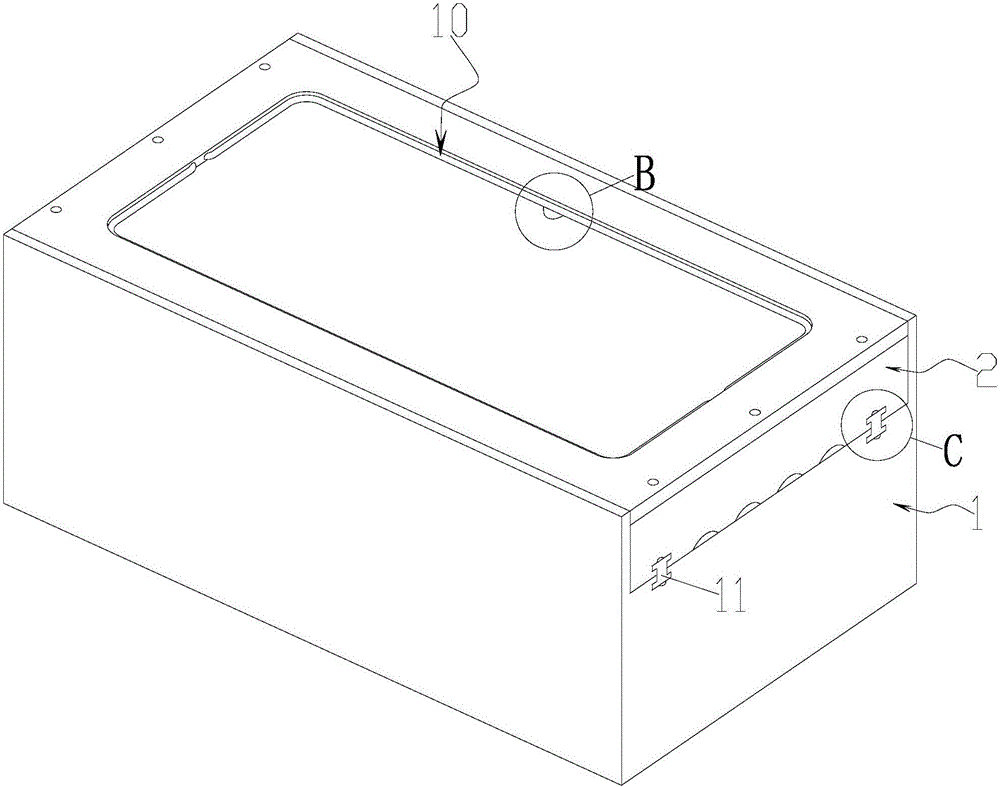

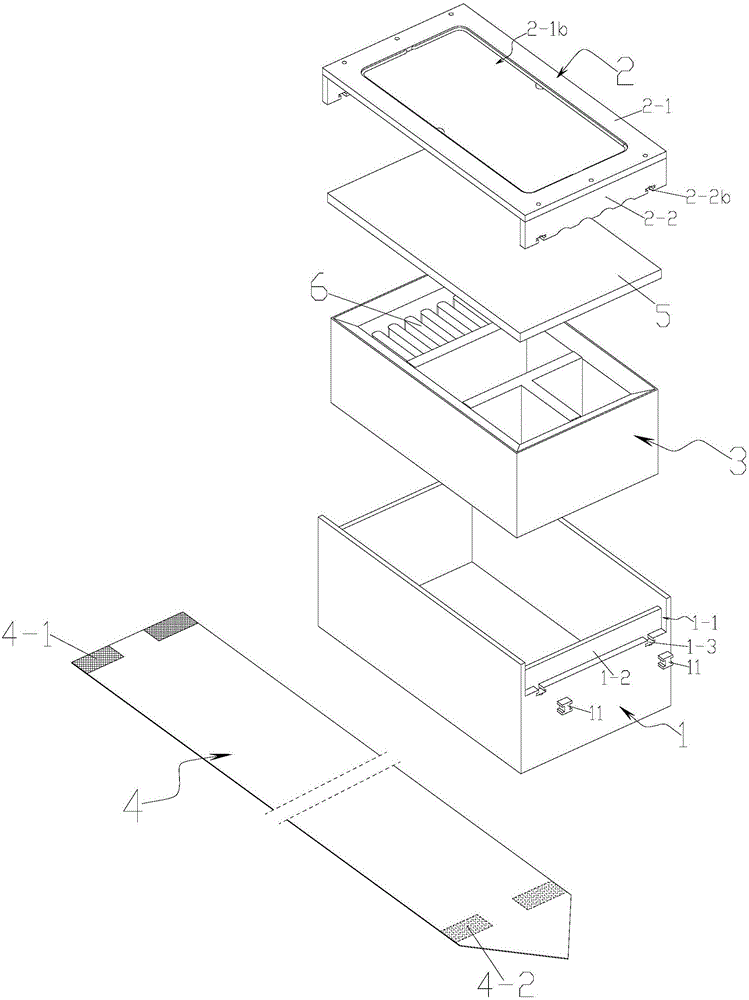

An automatic tea packaging machine

ActiveCN105329693BMiniaturizationThe process is well connectedWrapper folding/bending apparatusWrappingProduction lineClockwise

The invention discloses an automatic tea packing machine. The automatic tea packing machine comprises a frame, wherein the frame is provided with a paper feeding device for automatically feeding packing papers, a molding device for putting compressed tea on the packing papers, a packing device for packing the tea according to set paper folding mode and sequence, a recovery device for recovering the packed tea and a control center; and the paper feeding device, the molding device, the packing device and the recovery device are distributed on a turntable type production line in a clockwise direction in sequence. The automatic tea packing machine can automatically realize such all procedures in tea packing as paper feeding, tea molding, tea packing and tea recovery, is excellent in joint of all procedure and compact in structure, can improve the production efficiency and reduce the labor cost, is rival to traditional manual packing in tea packing effect, and satisfies the tea packing pattern demands and the pursuit of tradition of customers.

Owner:ZHONGSHAN LONGNING AUTOMATIC EQUIP

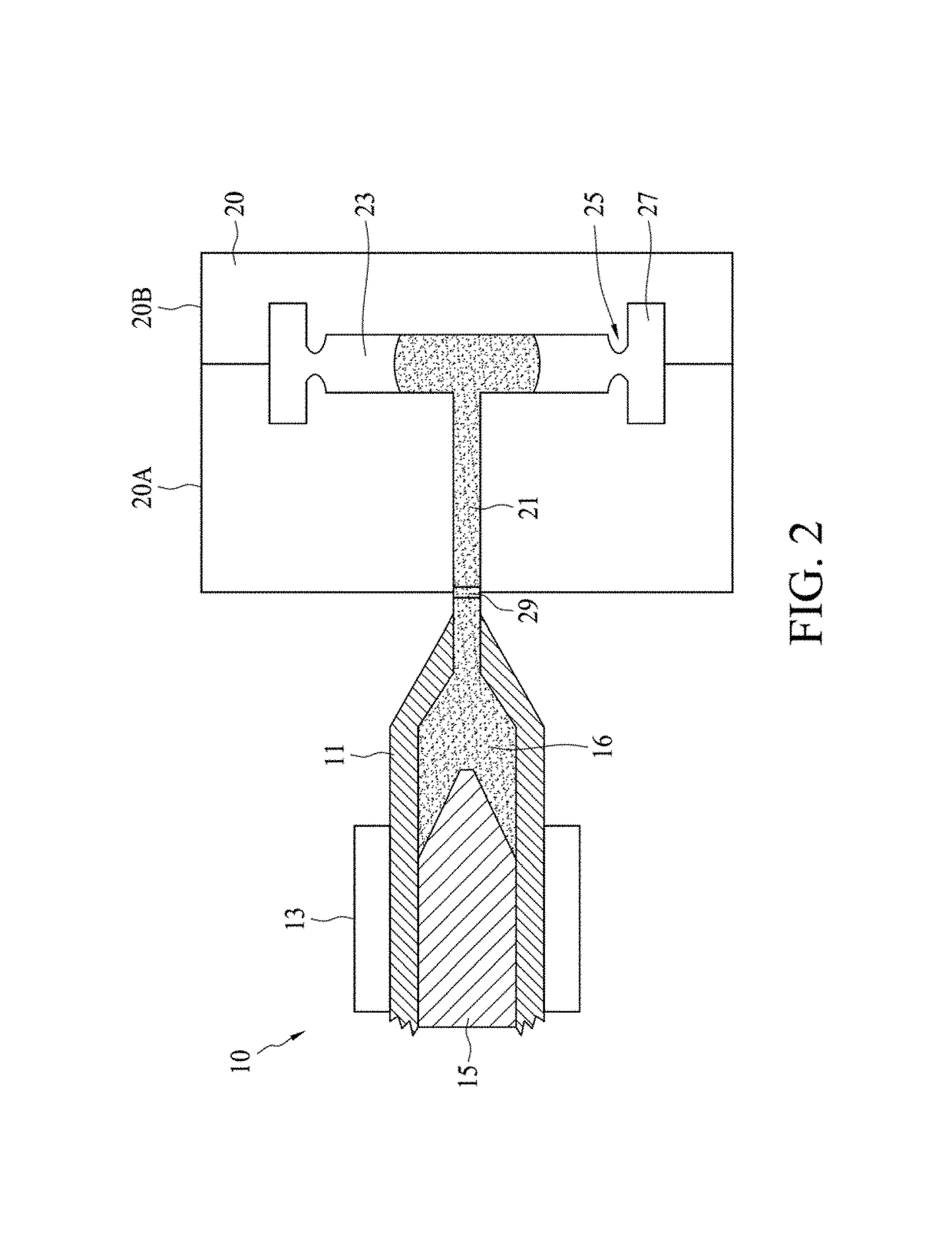

Molding system

A molding system includes a molding machine, a mold disposed on the molding machine and having a mold cavity to be filled with a molding resin from the molding machine, and a computing apparatus connected to the molding machine. The computing apparatus is configured to perform operations for setting the molding machine to prepare a molding product, wherein the operations comprise: generating a first and a second state waveforms using a setting packing pressure profile; obtaining an updated packing pressure profile based on the first and the second state waveforms; and setting the molding machine based on the updated packing pressure profile to perform an actual molding process to prepare the molding product. The first and the second state waveforms express a relationship between an in-mold pressure and an in-mold temperature at different sensing sites of the molding resin.

Owner:CORETECH SYST

Transformer collector

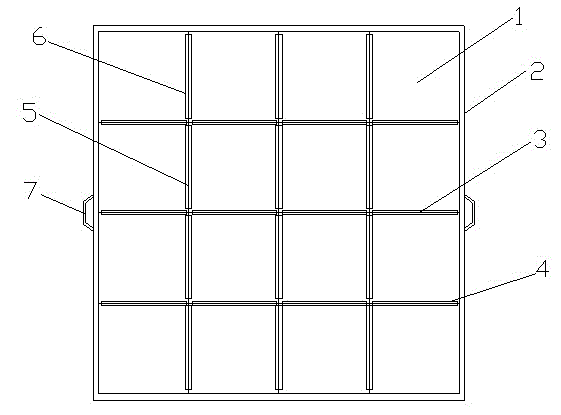

InactiveCN103950615AEasy to makeCompact structureRigid containersInternal fittingsTransformerEngineering

The invention discloses a transformer collector, comprising a chassis and side plates surrounding around the chassis; each side plate is higher than the plane of the chassis; first type of insertion slots for inserting longitude partition parts by being vertical to the plane of the chassis are arranged at the longitude directions of the chassis; second type of insertion slots for inserting latitude partition parts by being vertical to the plane of the chassis are arranged at the latitude directions of the chassis. According to the transformer collector, transformers are prevented from being randomly stacked by the arraying of the transformer one by one, the transformers are placed in packing boxes for packing and storage, fast packing is realized, the transformers with same or different sizes and dimensions can be collected in one packing part, the reliability in storage and transportation of the transformer products is improved, and the transformer collector has the advantages of compact structure, lower cost and convenience in use.

Owner:KUNSHAN DAGONG ELECTRONICS

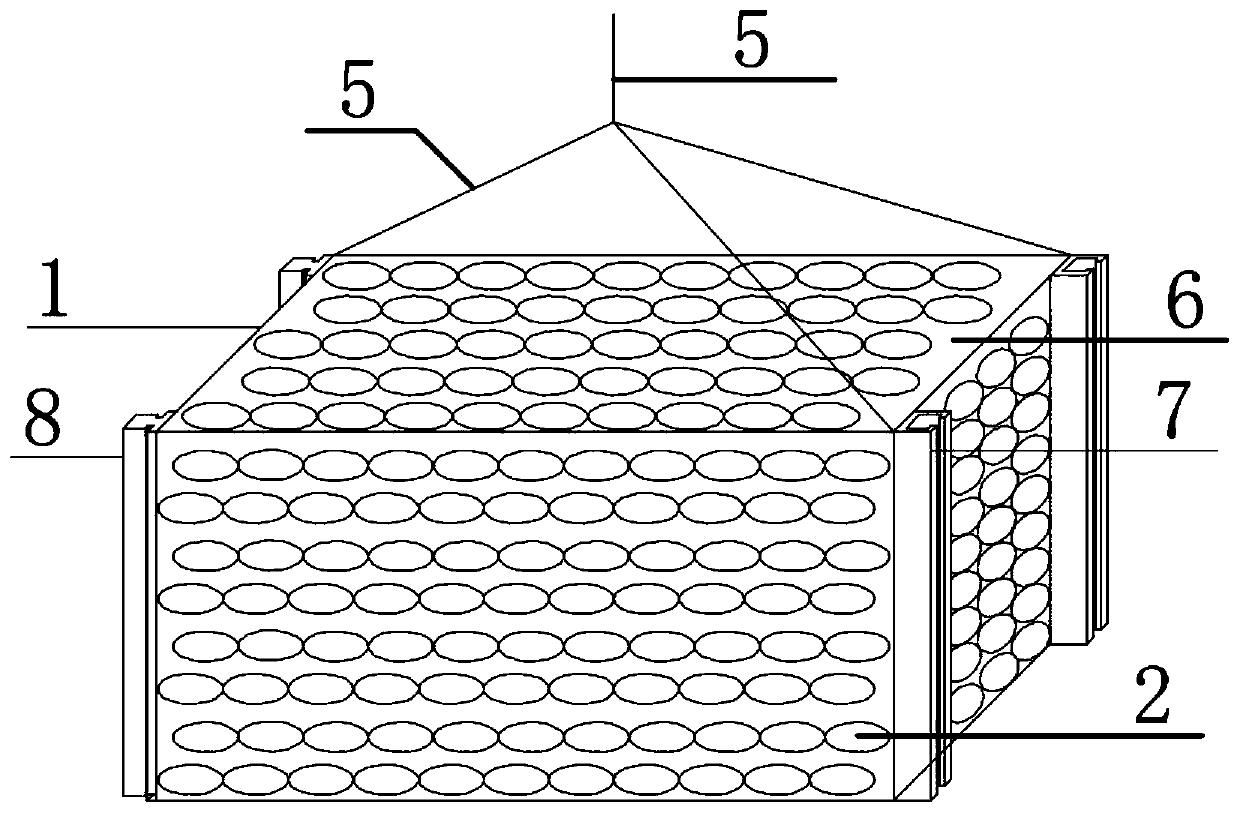

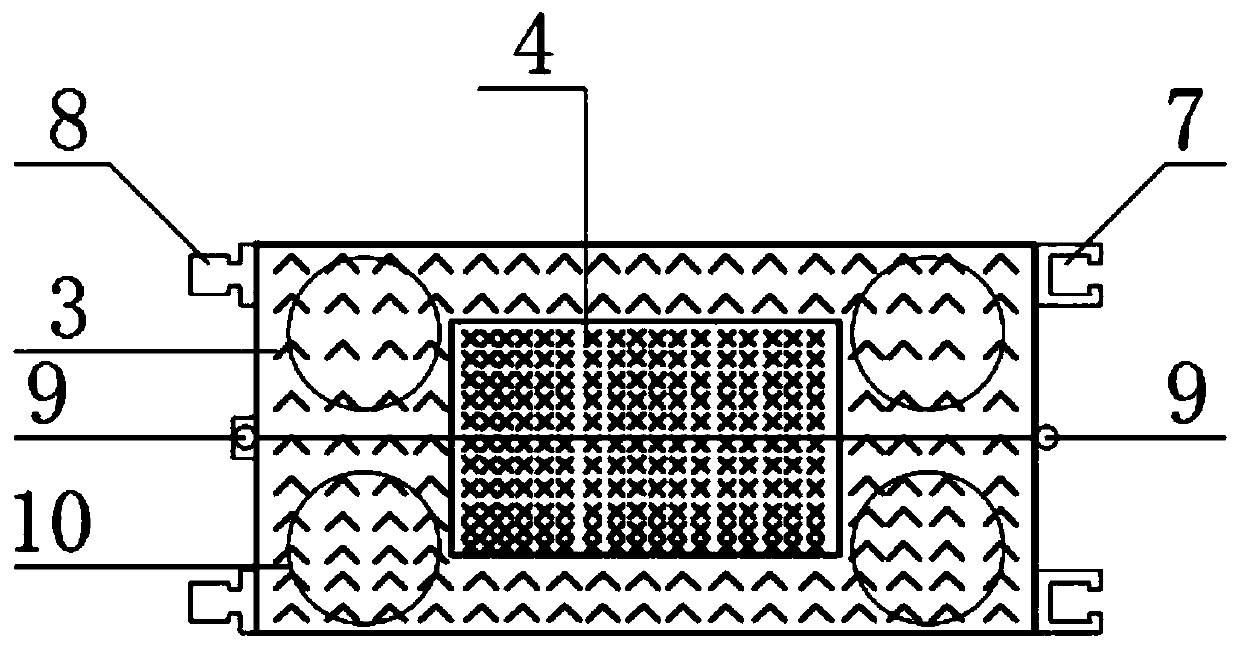

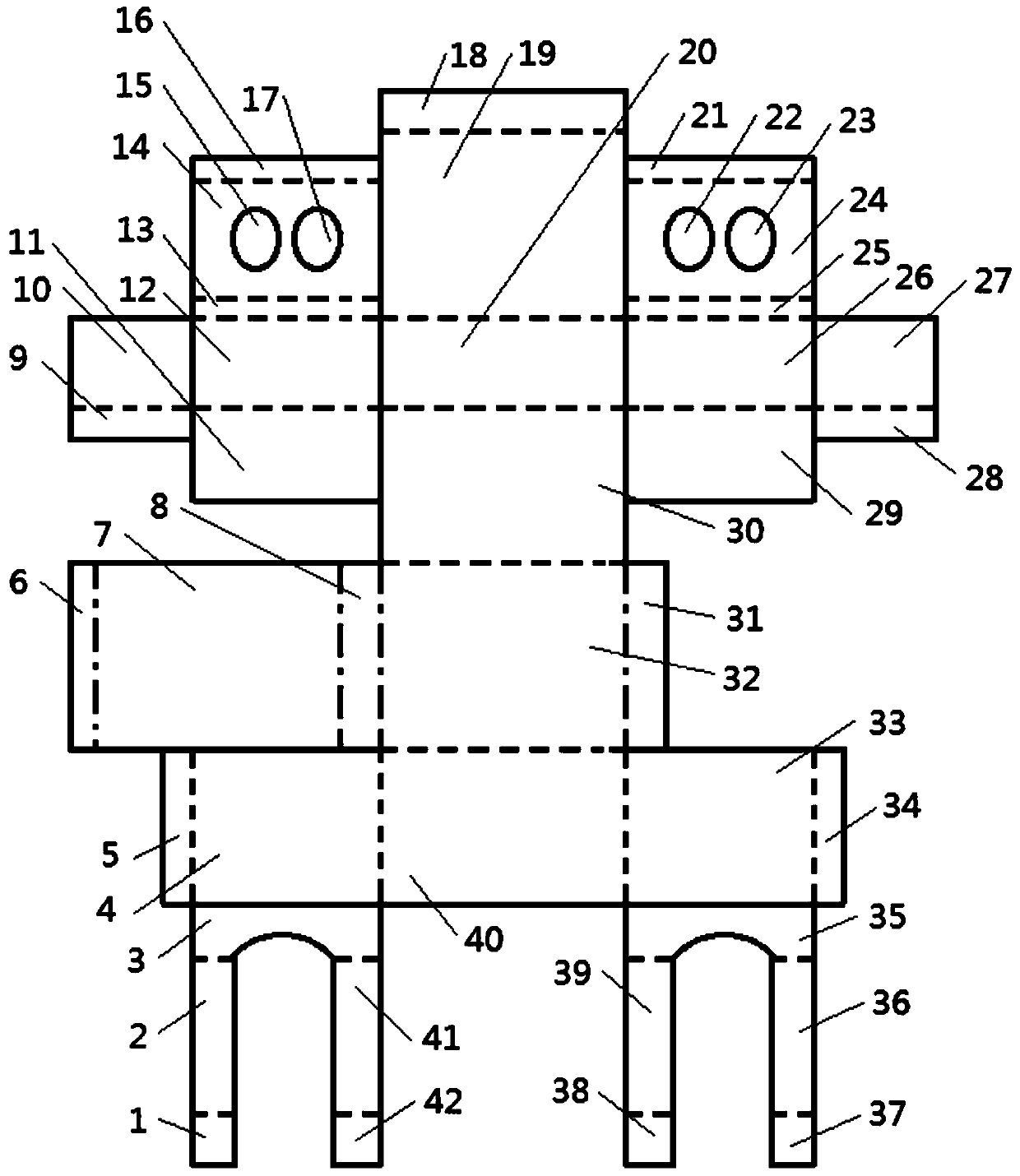

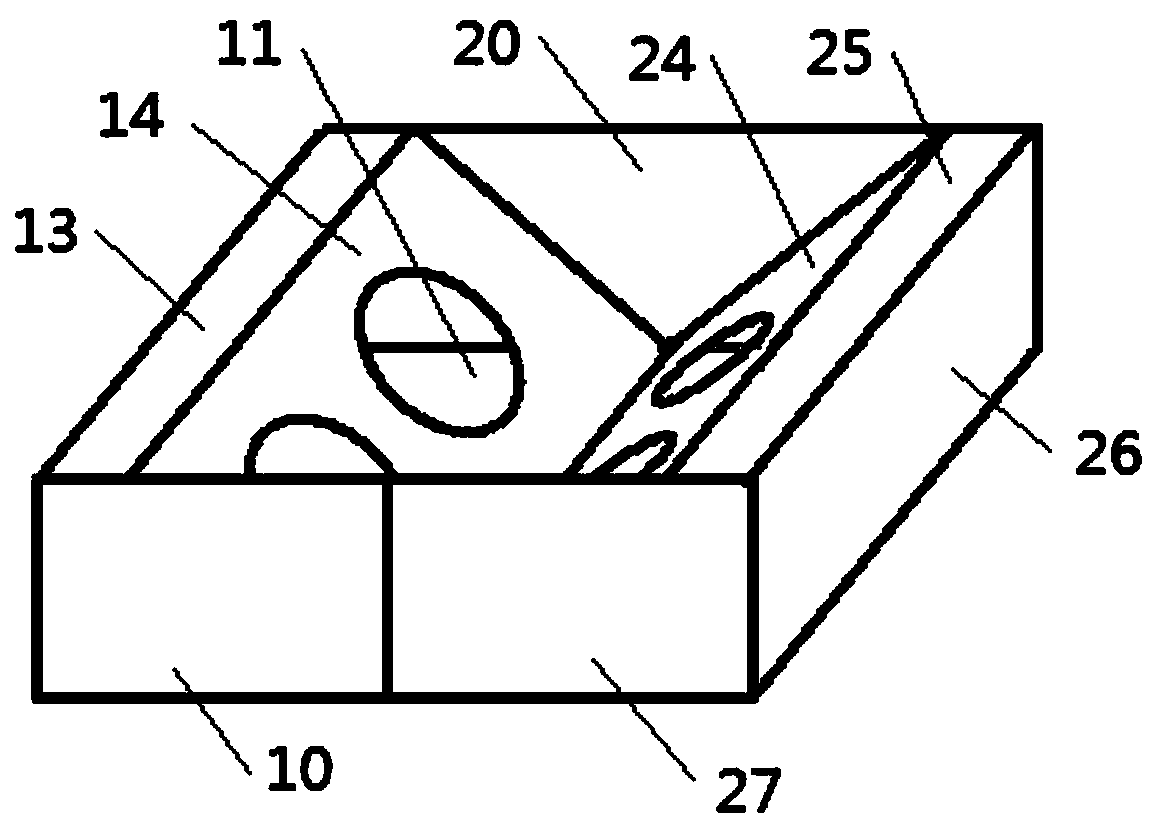

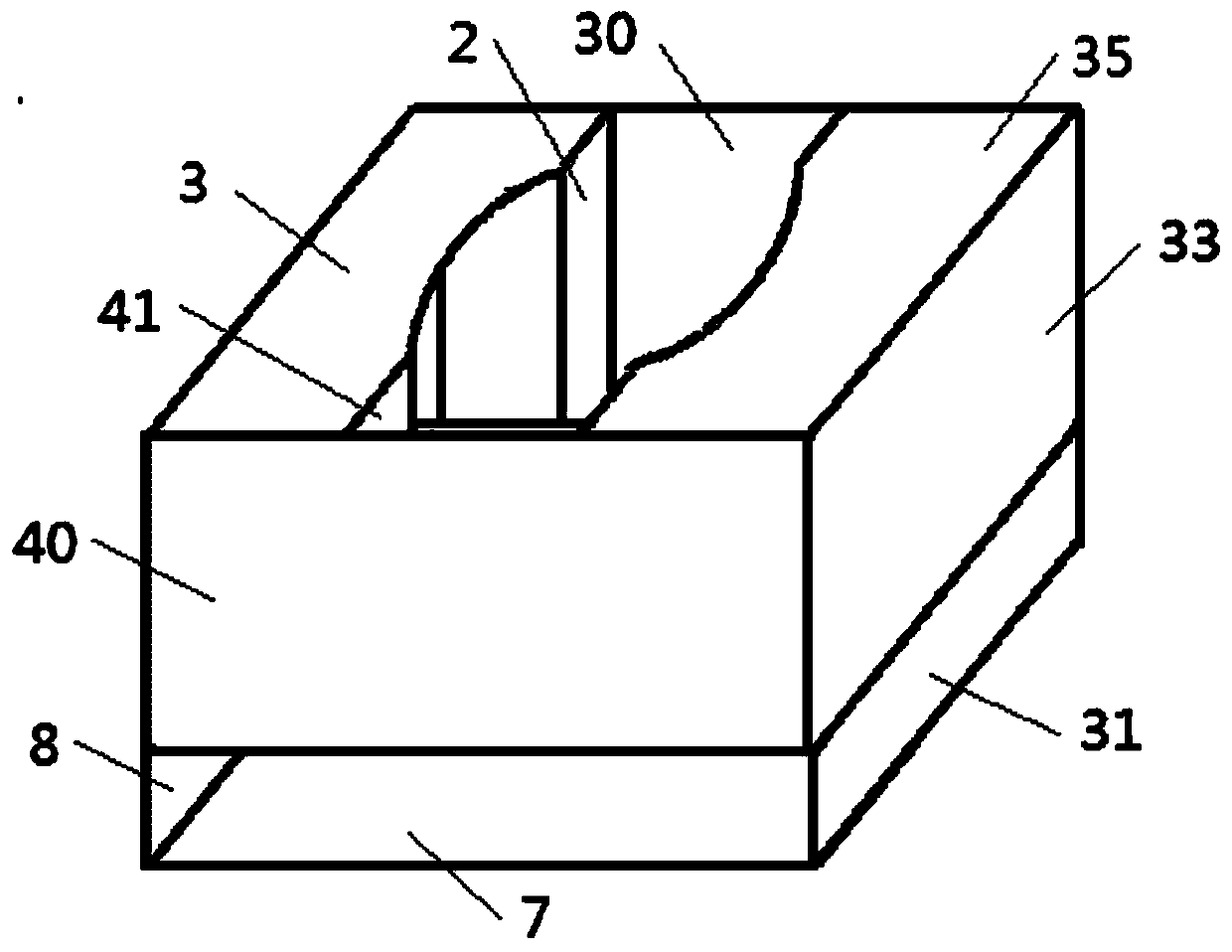

Combined packing box for water quality purification of prawn culture pond

PendingCN109744184AQuick removalLarge biomassClimate change adaptationPisciculture and aquariaFiberNitrate

The invention belongs to the technical field of aquaculture equipment, and relates to water quality purification equipment for aquaculture, in particular to a combined packing box for water quality purification of a prawn culture pond. Densely arranged elliptic pores are formed in the periphery and the lower part of a box body, and a drawer type cover is arranged on the upper side surface of the box body. A square space enclosed by partition plates with pores is arranged in the middle of the inner cavity of the box body to divide the whole box body into an inner chamber and an outer chamber. The outer chamber of the box body is filled with a packing B which is used in equal volume combination of one or more of rigid packings including polyurethane, loofah and crushed coral; and the inner chamber of the box body is filled with a packing A which is a soft packing including fiber hair balls, the diameter of the packing is 4-6 cm, and an anoxic zone can be formed after operation to facilitate the removal of nitrate. A fixing belt fixing the box body to a transverse bar is arranged on the upper side of the box body. The main structure of the combined packing box is simple, the design idea is ingenious, the manufacture cost is low, the application environment is friendly, and market prospects are broad.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

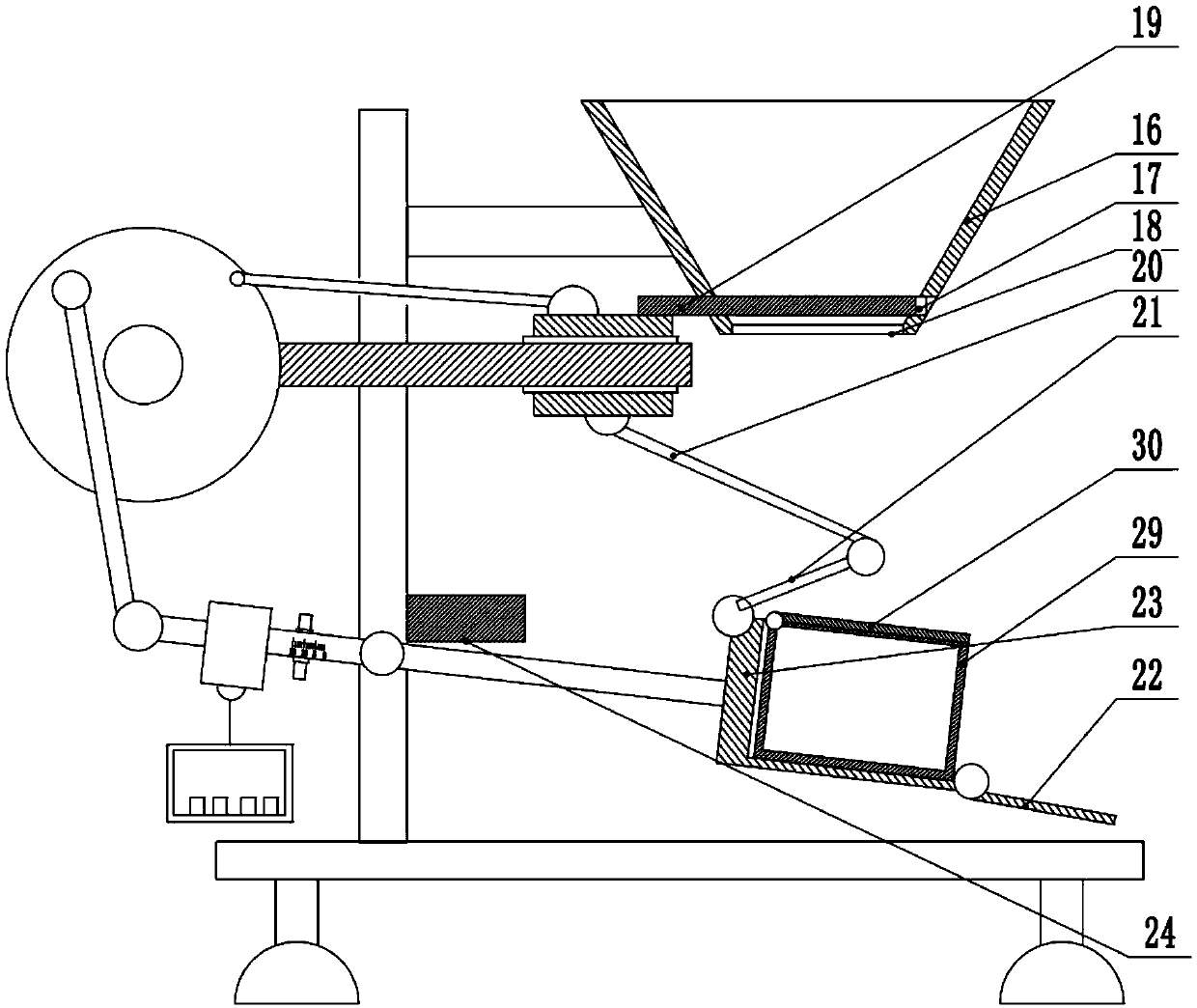

Packaging device capable of setting packing weight

The invention relates to the technical field of packaging and discloses a packaging device capable of setting packing weight. The packaging device comprises a base, wherein a stand column is fixedly connected with the left side of the base; the top of the stand column is fixedly connected with a fixed rod; the fixed rod is fixedly connected with a storage box; the bottom of the stand column is rotatably connected with a rotary shaft; the rotary shaft is fixedly connected with a rotary rod; the right side of the rotary rod is fixedly connected with a packaging case; a packaging box is arrangedin the packaging case; the rotary rod is fixedly connected with a fixed block; and the bottom of the fixed block is connected with a counter weight frame through a steel wire rope. The packaging device can be used in the packaging link of a production enterprise, is provided with the rotary rod and the counter weight frame to ensure that feeding is automatically stopped when the packaging box reaches set weight during the feeding process, is provided with a connecting mechanism composed of a first connecting rod and a second connecting rod to ensure that the box cover is actively closed afterfeeding is finished, ensures the stability through a completely mechanical linkage structure, is simple and reasonable in operation, improves the production efficiency and is suitable for popularization and application.

Owner:温雄权

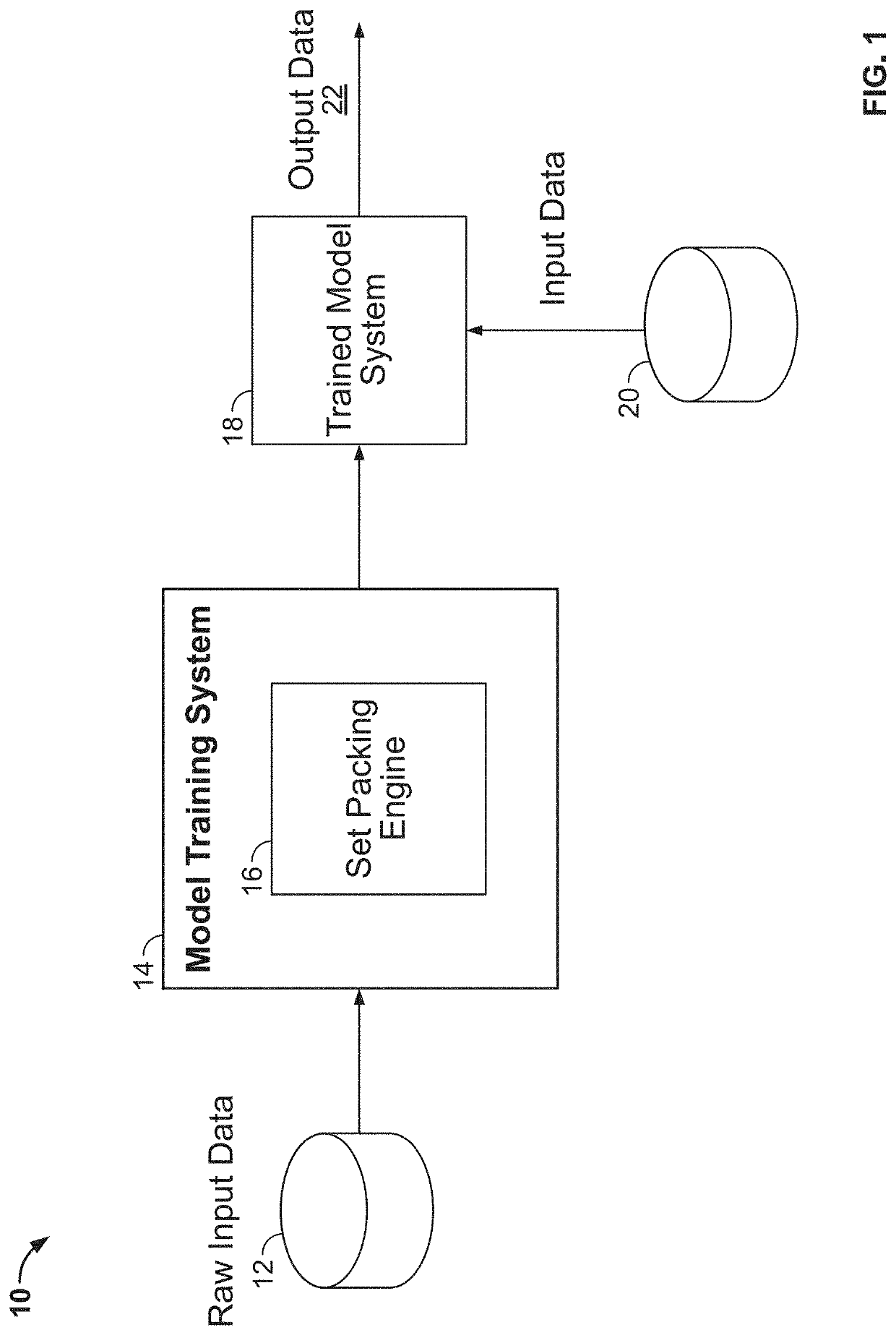

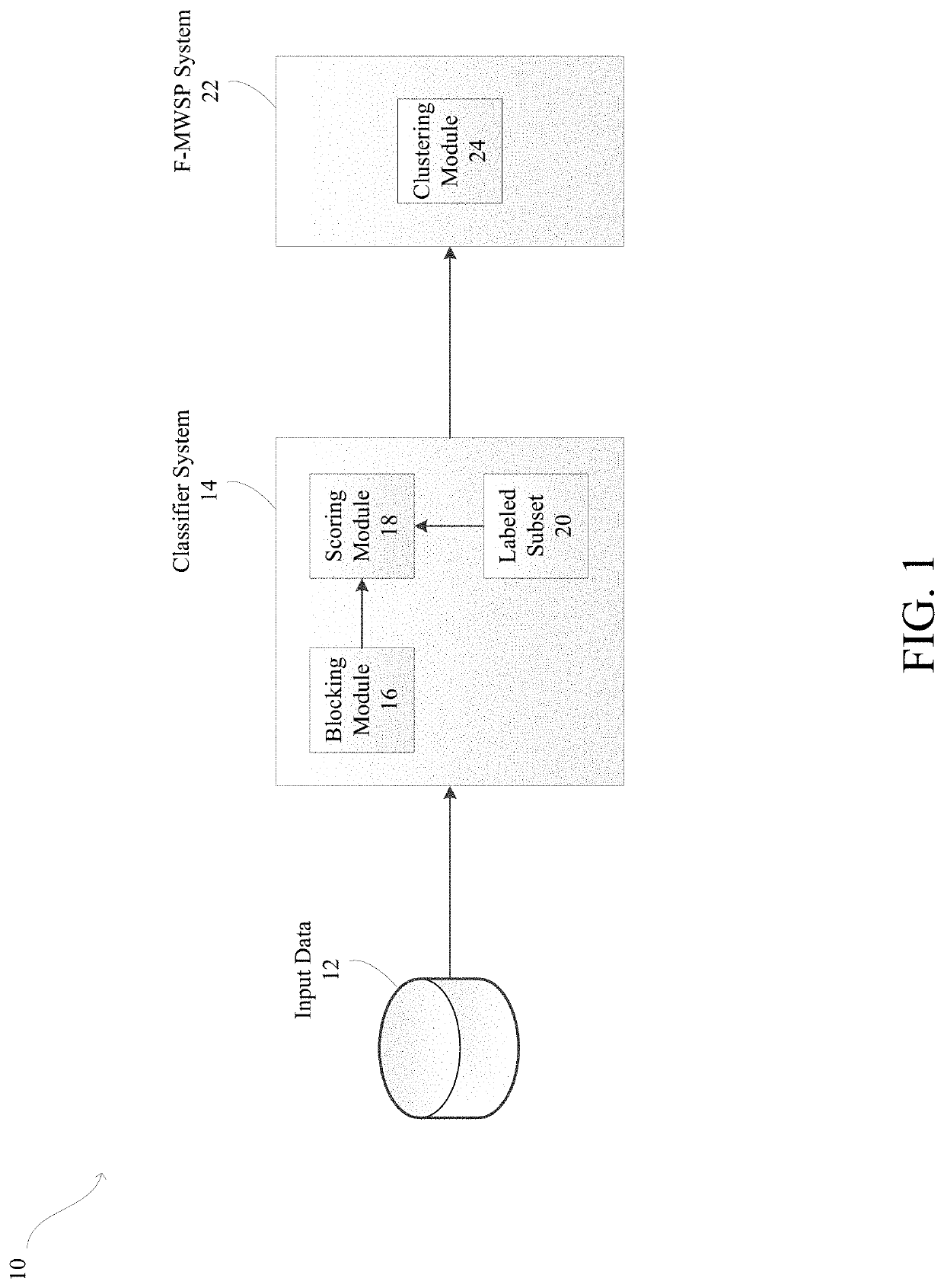

Computer Vision Systems and Methods for Machine Learning Using a Set Packing Framework

Computer vision systems and methods for machine learning using a set packing framework are provided. A minimum weight set packing (“MWSP”) framework is parameterized by a set of possible hypotheses, each of which is associated with a real valued cost that describes the sensibility of the belief that the members of the hypothesis correspond to a common cause. Using MWSP, the system then selects the lowest total cost set of hypotheses, such that no two selected hypotheses share a common observation. Observations that are not included in any selected hypothesis, define the set of false observations can be thought of as false observations / noise. The system can be utilized to support one or more trained computer models in performing computer vision on input data in order to generate output data.

Owner:INSURANCE SERVICES OFFICE INC

Permanent bridge plug available for unsetting

The invention belongs to the technical field of oil-gas well underground packers and relates to a permanent bridge plug available for unsetting. The permanent bridge plug is formed by a center pipe, apressurizing part, slips and a rubber barrel component. A port of one end of the center pipe is internally provided with a release ring by means of threaded mounting, the pressurizing part is mountedon the periphery of the center pipe on the inner side of the release ring, the end head of the other end of the center pipe is provided with a guide shoe by means of threaded mounting, the port of the center pipe is internally provided with a plug corresponding to the guide shoe, and the plug and the guide shoe are connected with each other through a release shear pin. The rubber barrel componentis mounted on the periphery of the center pipe on the inner side of the guide shoe, and the slips are mounted on the center pipe between the pressurizing part and the rubber barrel component throughan upper conical barrel and a lower conical barrel. The bridge plug has advantages of safety in well killing, freeness of milling and recovery tools and easiness in unsetting, and set packing is completed under the pressure by the rubber barrel and the slips; unsetting is realized by direct pressing and cutting of an unsetting dowel, problems of high milling risks and difficulty in recovery and unsetting of existing bridge plugs are solved, and the underground set packing requirement is met.

Owner:荆州市赛瑞能源技术有限公司

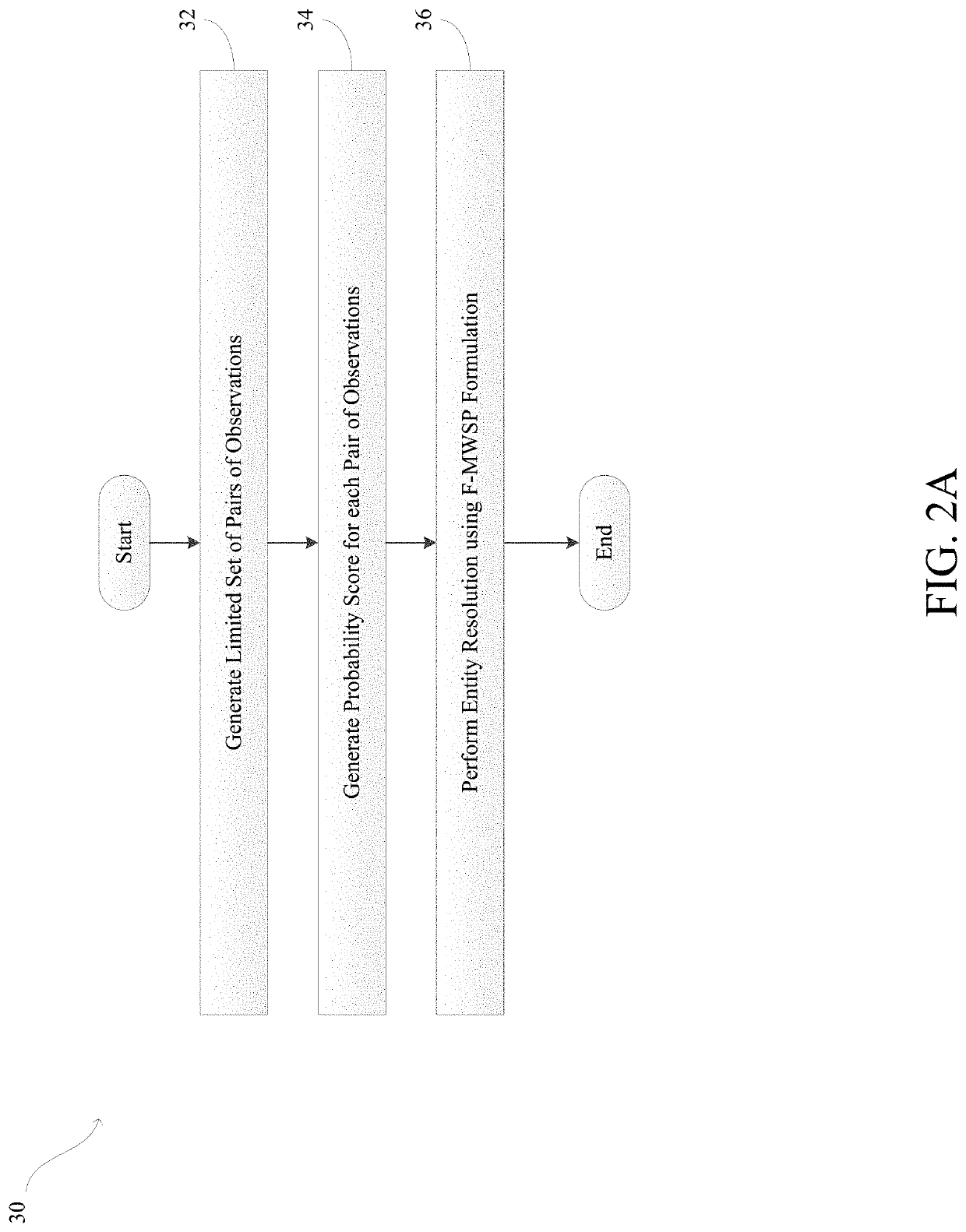

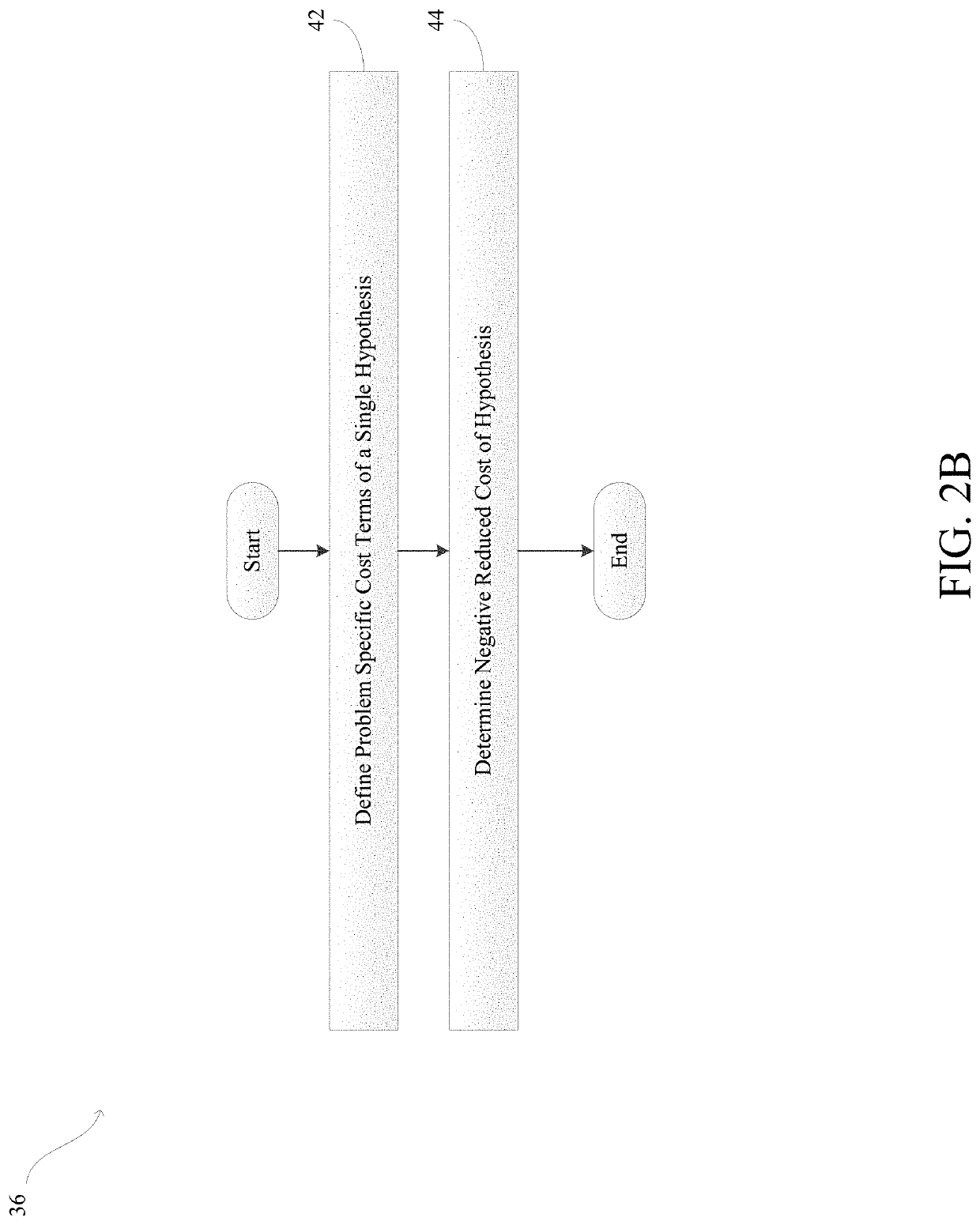

Machine Learning Systems and Methods for Performing Entity Resolution Using a Flexible Minimum Weight Set Packing Framework

Machine learning systems and methods for performing entity resolution. The system receives a dataset of observations and utilizes a machine learning algorithm to apply a blocking technique to the dataset to identify and generate a subset of pairs of observations of the dataset that could represent a same real world entity. The system generates a probability score for each pair of observations of the subset where the probability score is defined over a given pair of observations and denotes a probability that each pair is associated with a common entity in ground truth. The system utilizes a flexible minimum weight set packing framework to determine problem specific cost terms of a single hypothesis associated with the subset of pairs of observations and to perform entity resolution by partitioning the subset of pairs of observations into hypotheses based on the cost terms.

Owner:INSURANCE SERVICES OFFICE INC

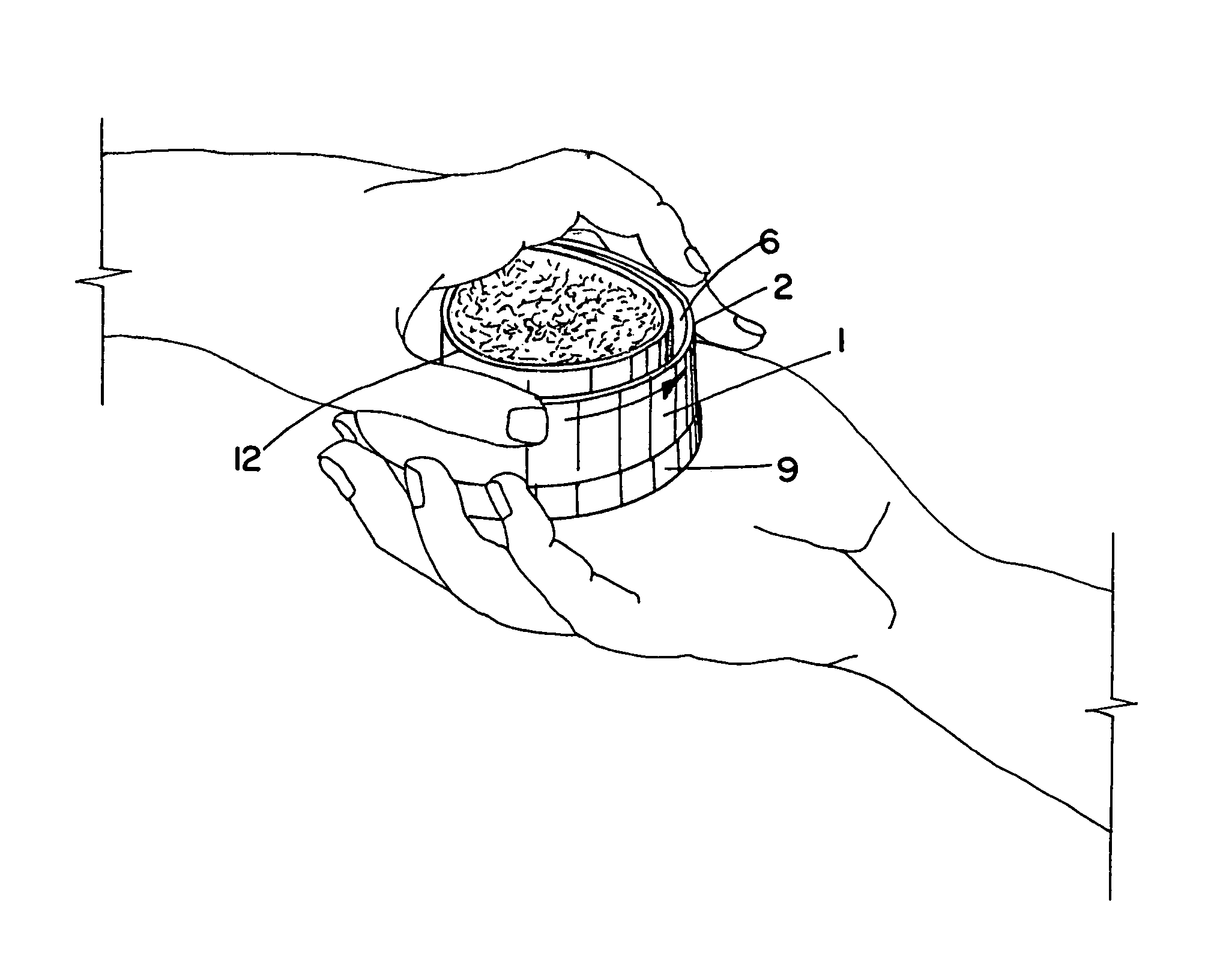

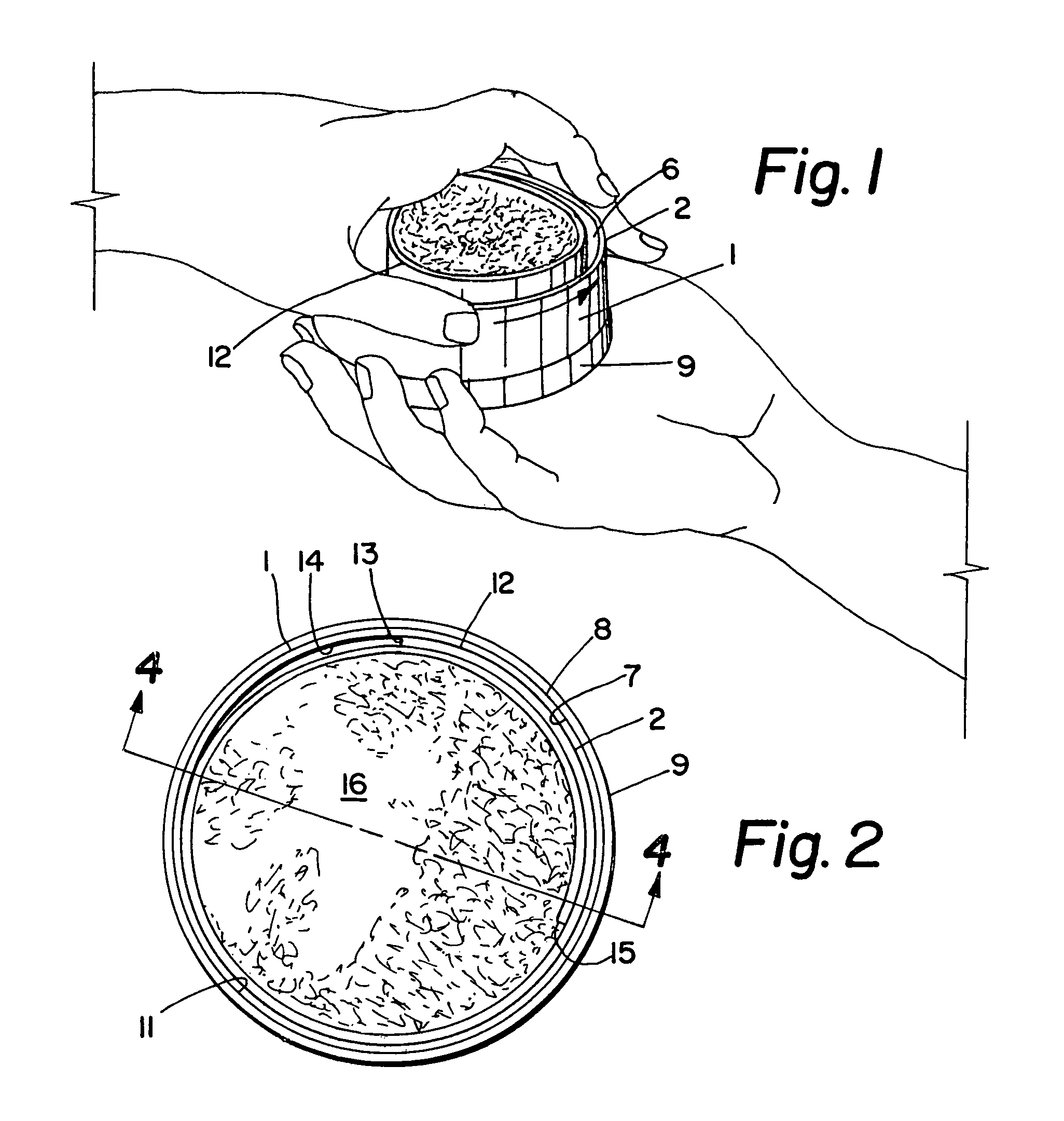

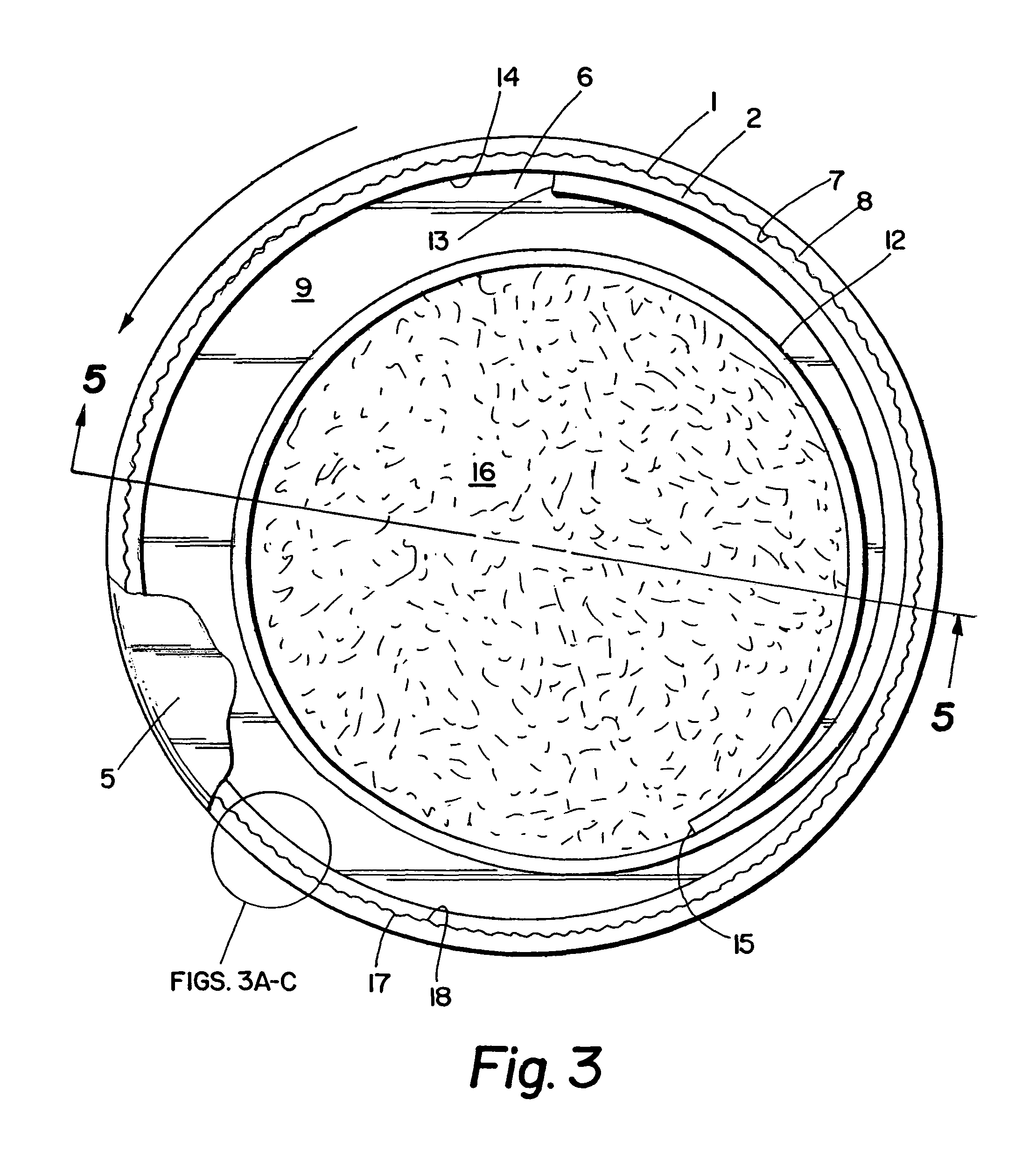

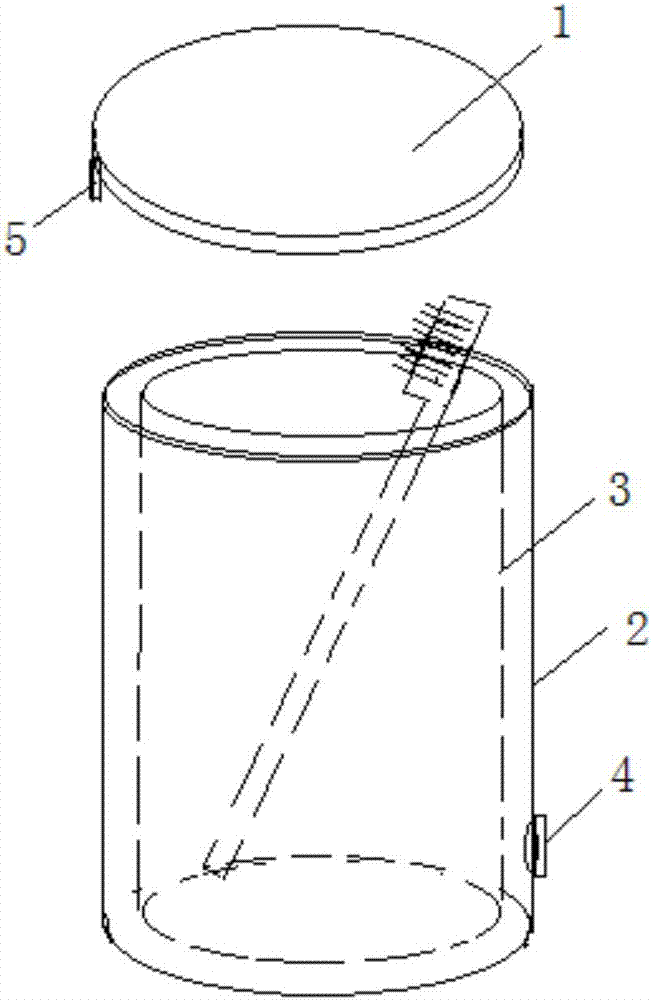

Discreet packing system

InactiveUS8079372B2Easy and discreet accessMinimize exposureTobacco preparationPackaging cigaretteEngineeringTobacco product

A discreet packing system for containing and compacting finely chopped tobacco product having a shallow cylindrical body and a lid detachably secured thereto. A flexible wall is secured at a fixed end to the interior surface of the body. The flexible inner wall generally coextends the interior surface of the body and thereby defines a cylindrical volume in which the tobacco is contained. The flexible wall may be selectively locked in place relative to the outer wall of the body. In one embodiment of the present invention, a bottom is slidably connected to a cylindrical outer wall of the body. A distal end of the flexible wall is attached to the bottom and is urged via rotation of the bottom relative to the outer wall. Other embodiments are provided wherein the flexible wall extends through the body and is urged via a grip or slider.

Owner:SMITH IV BARTLETT WADE +1

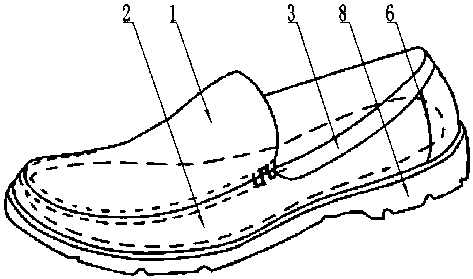

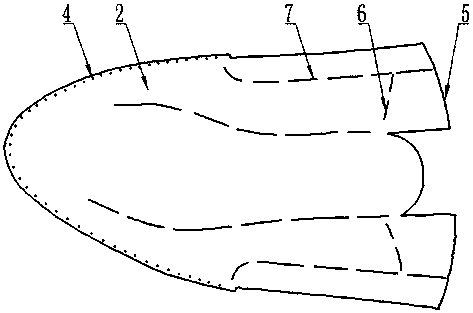

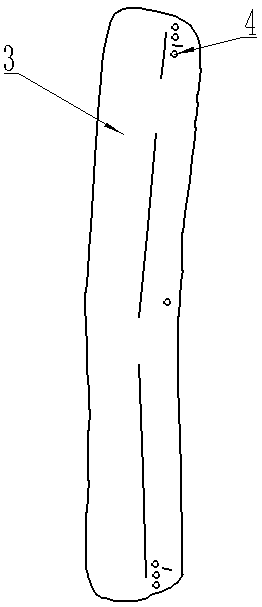

Shoe full set packaging seamless technology

The invention provides a shoe full set packaging seamless technology. The shoe full set packing seamless technology includes the following steps: a first step, pasting a lining onto a back surface ina shoe cover, gluing a surface of the shoe cover and a lining of the shoe cover together, and sewing a shoe tongue and the shoe cover; a second step, performing punching on the shoe cover and a shoe upper surrounding; a third step, sewing back seams at two sides of a shoe upper surrounding heel on a front surface of the shoe upper surrounding; a fourth step, sewing a back packaged heel and the shoe upper surrounding heel through two sewing threads; a fifth step, thinning an upper opening strip; a sixth step, sewing a part with glue, of the upper opening strip; a seventh step, punching the upper opening strip; an eighth step, sewing the shoe cover and the shoe upper surrounding together through a mark line; and a ninth step, fixing a shoe sole on the bottom of the shoe upper surrounding. The shoe full set packaging seamless technology can complete warping transferring without sewing and jointing a sewing opening, can avoid inner lining sewing, can avoid a main heel and an inner packaging head, can save processes, and can improve the production efficiency.

Owner:JIHUA 3513 IND

Packing box

InactiveCN103993850AWon't wear outExtended service lifeSealing/packingEngineeringMechanical engineering

The invention provides a packing box. The packing box comprises an upper fixed seal part, a lower connector and a retractable sleeve, the upper fixed seal part is fixed to a polished rod and comprises a seal packing box, seal packing and a pressing cap, wherein the polished rod can be sleeved with the seal packing box, the seal packing is arranged in the seal packing box, and the pressing cap can be used for pressing the seal packing into the seal packing box so that the seal packing and the polished rod can be fixedly sealed. The lower connector is used for being connected with a Christmas tree. The retractable sleeve can retract and stretch between the upper fixed seal part and the lower connector so that the distance between the upper fixed seal part and the lower connector can be changed. The first end of the retractable sleeve is connected with the seal packing box in a sealed mode, and the second end of the retractable sleeve is connected with the lower connector in a sealed mode. According to the packing box, a sliding seal part is not needed, the packing box will not be abraded, and therefore the service life of the packing box is greatly prolonged. Meanwhile, the labor amount of workers is reduced, and while the faults of an oil pumping system are reduced, a lot of oil pumping machine electric energy is saved.

Owner:TOP WELL PETROLEUM TECH COMPANY

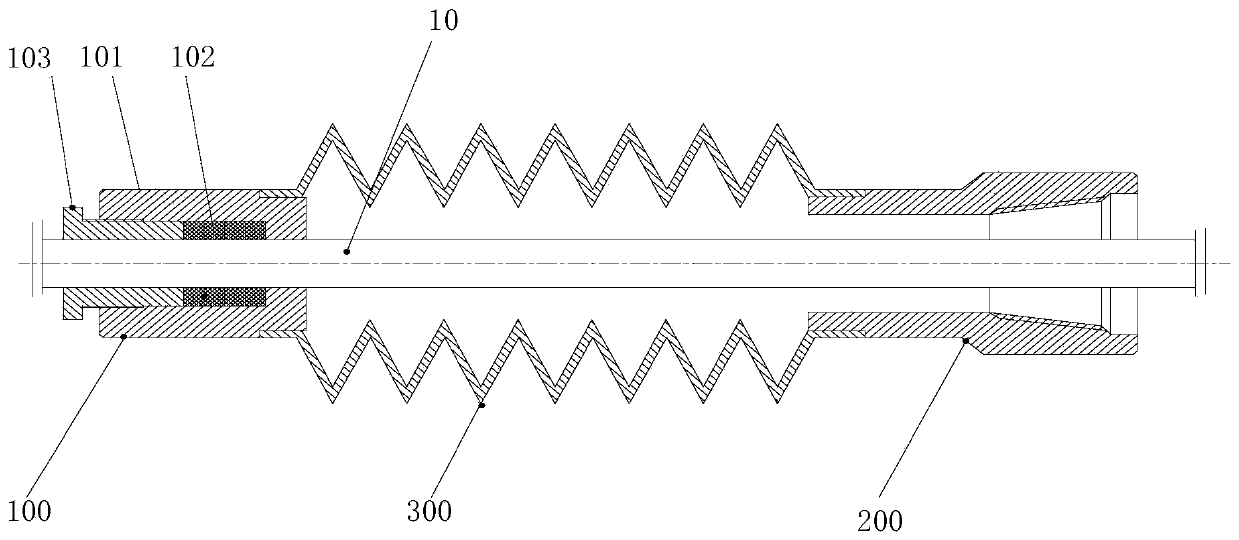

Oil-layer setting packing method and special self-pressurization controller

PendingCN106481302ASimple construction processReliable construction technologySealing/packingLine tubingPressure transmission

The invention discloses an oil-layer setting packing method and a special self-pressurization controller. The method includes the steps that a setting pipe column is put into the underground preset position, and then the self-pressurization controller is started to complete setting of packers; the setting pipe column comprises a pipe column body, the self-pressurization controller and the packers, wherein the self-pressurization controller and the packers are sequentially connected on the pipe column body from top to bottom, and the self-pressurization controller and the packers are also connected through control pipes; the self-pressurization controller is composed of a starting assembly, a pressurizing assembly and a pressure transmission joint, wherein the starting assembly, the pressurizing assembly and the pressure transmission joint are sequentially connected from top to bottom, and a high pressure area is formed between the pressurizing assembly and the pressure transmission joint; the pressurizing assembly adjusts increasing and reducing of the pressure in the high pressure area, and the pressure transmission joint is connected with a liquid control pipe through a quick joint; after the pressurizing assembly is started by the starting assembly, the pressure in the high pressure are is increased to the required set pressure through the pressurizing assembly, the pressure transmission joint is connected with the liquid control pipe through the quick joint, high pressure is transferred to the packers to allow differential pressure is generated inside and outside the packers to achieve setting.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel disposable travel tooth set packing bag

The invention relates to a novel disposable travel tooth set packing bag. The novel disposable travel tooth set packing bag comprises a bag body and a cover body detachably connected; the bag body comprises an outer bag wall and an inner bag wall; the outer bag wall and the inner bag wall mutually surround to form a cylinder with a cavity in middle; a plug hole and a hole plug are arranged at thebottom of the outer bag wall; closing of the cavity is realized through matching connection between the plug hole and the hole plug; and the bag body and the cover body are both made of flexible environmental-protection plastic. Preferably, a zipper is arranged between the bag body and the cover body; and the bag body is cylindrical. Compared with the prior art, the novel disposable travel tooth set packing bag has the beneficial effects of reasonable structural design, convenience to use and environmental protection.

Owner:威正包装制品(上海)有限公司

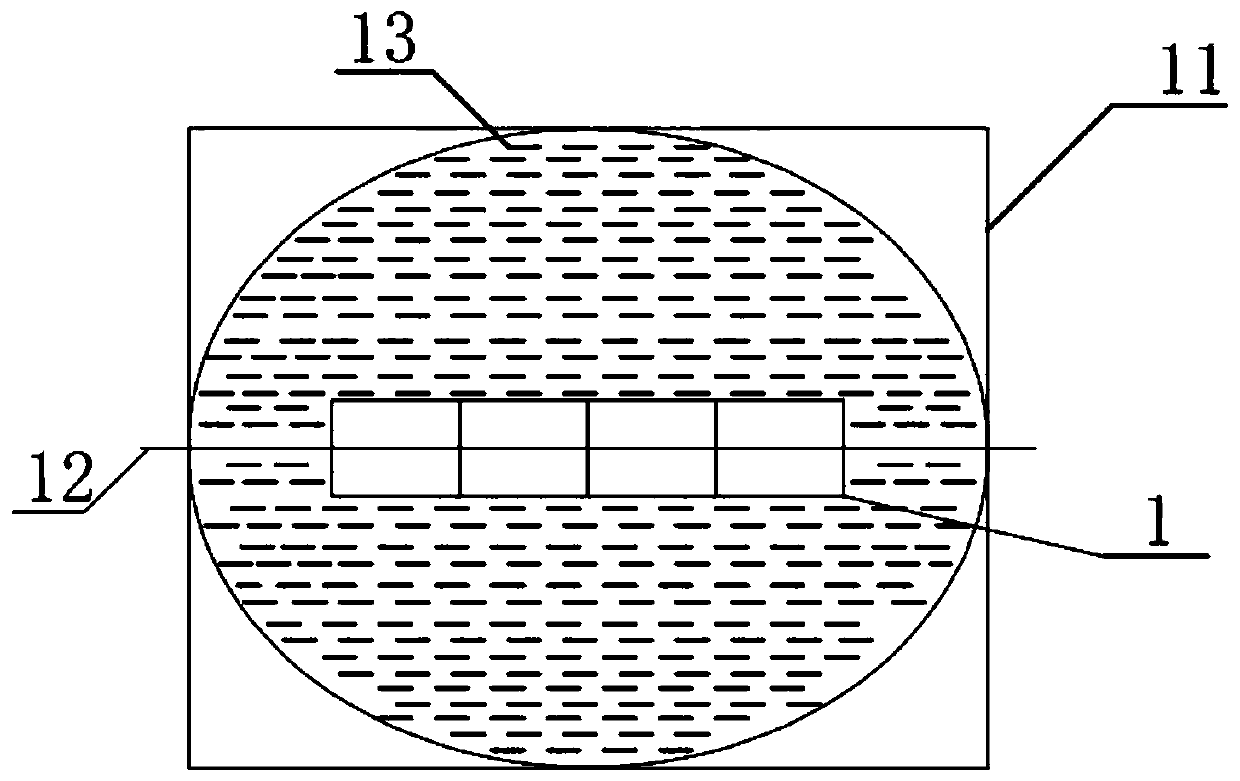

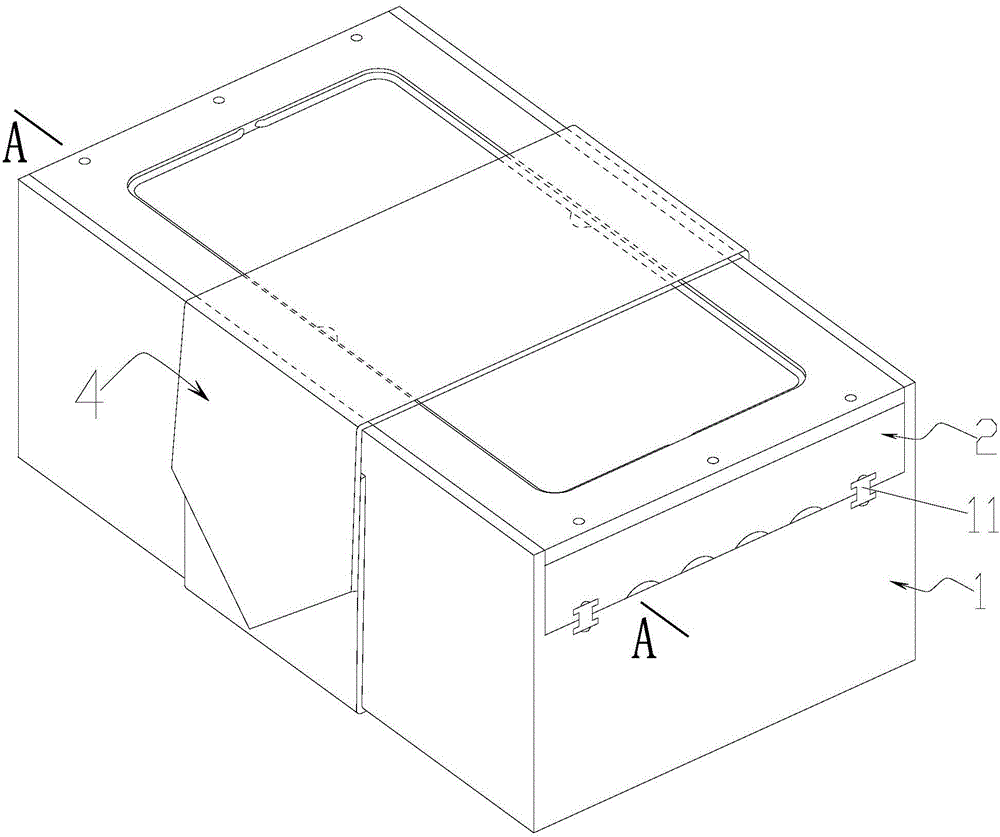

Novel travel suit tea set packing box

ActiveCN106241047AAvoid loosening and shakingHas a deodorizing effectContainer handlesEngineeringSet packing

A novel travel suit tea set packing box comprises a base with a cavity. Notches are formed in the fronts of two side walls of the base and the cavity. First vertical plates extending upwards are fixed to the inner sides of the top ends of the notches, the heights of the top ends of the first vertical plates are smaller than that of the top end of the base, the base is provided with an end cover, the end cover comprises a pressing plate and second vertical plates fixed to the left end and the right end of the pressing plate, a combination tea set placing frame is installed in the cavity of the base, and the end cover is inserted into and adheres to the outer sides of the first vertical plates through the two second vertical plates to cover an opening of the cavity of the base. The end cover is provided with a tea cloth, a male face magic tape is fixed to the top surface of one side of the tea cloth, and a female face magic tape is fixed to the bottom surface of the other side of the tea cloth. The tea cloth is wound by one round through the bottom surface of the base and is bonded through the male face magic tape and the female face magic tape to press the end cover on the base. The novel travel suit tea set packing box is ingenious and reasonable in structural design, a tea set can be installed and combined conveniently, and the novel travel suit tea set packing box is convenient to take and worth popularization and application.

Owner:LONGQUAN CITY JIAWEN WOOD IND

Inverted ventilating vacuum packaging method and use thereof

InactiveCN101503121AEasy to makeEasy to manufactureLiving organism packagingEdible seed preservationEngineeringAir change

The invention relates to a reverse direction exhaust vacuum packing method and a usage thereof. The packing method comprises: a sealed packing body at a loading hole of a sealable packaged object is provided with one or more exhaust nozzle(s) which can be check valve(s) or sealable exhaust nozzle(s); the packaged object is put into the packing body from the loading hole of the packaged object, and the loading hole of the packaged object is sealed, so that the packing body becomes a closed packing body; evacuating equipment can be connected on the exhaust nozzle(s) for air suction until the air pressure in the packing body reaches the requirement of vacuum packing. The method can be used for food packing, tea packing, textile packing, harmful object packing, raw grain packing, grain finished product packing or living body packing. The invention has the advantages that vacuum package can be made at will, the packing body can be vacuumized for a plurality of times according to the change of air pressure in the packing body, and the application scope of the vacuum package can be greatly expanded. The method for manufacturing the vacuum package is simple, convenient and flexible, and can be used for air change type near vacuum packing for living body.

Owner:刘同益

Three-layered packing box

InactiveCN110406761AImprove protectionNovel shapeDrawer-and-shell containersEngineeringSales promotion

The invention discloses a three-layered packing box. The three-layered packing box comprises an upper box, a middle box, a lower drawer, a drawer inner box which is molded through one piece of paper and a liner which is molded through one piece of paper, wherein the upper box, the middle box and the lower drawer are molded through a piece of paper; the liner is arranged as required; the upper layer of the three-layered packing box is provided with a left-and-right opening and closing type box beneficial for being opened and shown; the middle layer is high in protection performance by fixing and performing shockproof buffer on contents by the liner; and the lower layer is of a pulling-type structure, and is beneficial for taking out articles. The three-layered packing box is divided into the upper layer, the middle layer and the lower layer which are separately used for holding different articles, sorted packing is carried out, and the three-layered packing box is scientific and reasonable. The protection performance on the contents is high. The three-layered packing box is novel in style and high in sales promotion performance.

Owner:TIANJIN UNIV OF COMMERCE

Device for the transport of stacks formed from opened egg packs, as well as a separation device for egg packs and a stacker for removing empty egg packs

The invention relates to a device for transporting a stack of opened egg packs containing fresh eggs arranged one above the other, as well as a separating device for said egg packs and for empty egg packs. Packing stackers, said means for transport shall be so designed that stacks formed of egg packs, regardless of their construction, can be transported without damaging fresh eggs and, furthermore, without manual handling Next implement unstacking. According to the invention, a stack of several egg packages arranged one above the other can be transported on the platform ( 11 ) to the depalletizing station ( 15 ) in order to support the lower egg packages in the stack over their entire surface. In this case, the lower egg packs in the stack lie flat on a support plate (12) provided with centering elements (14) which engage form-fittingly into the stack from the underside in the lower part of each egg package. The device according to the invention is particularly suitable for separating and subsequently emptying egg packs containing fresh eggs that have been shipped from a cold store.

Owner:格尔德·贝格迈尔

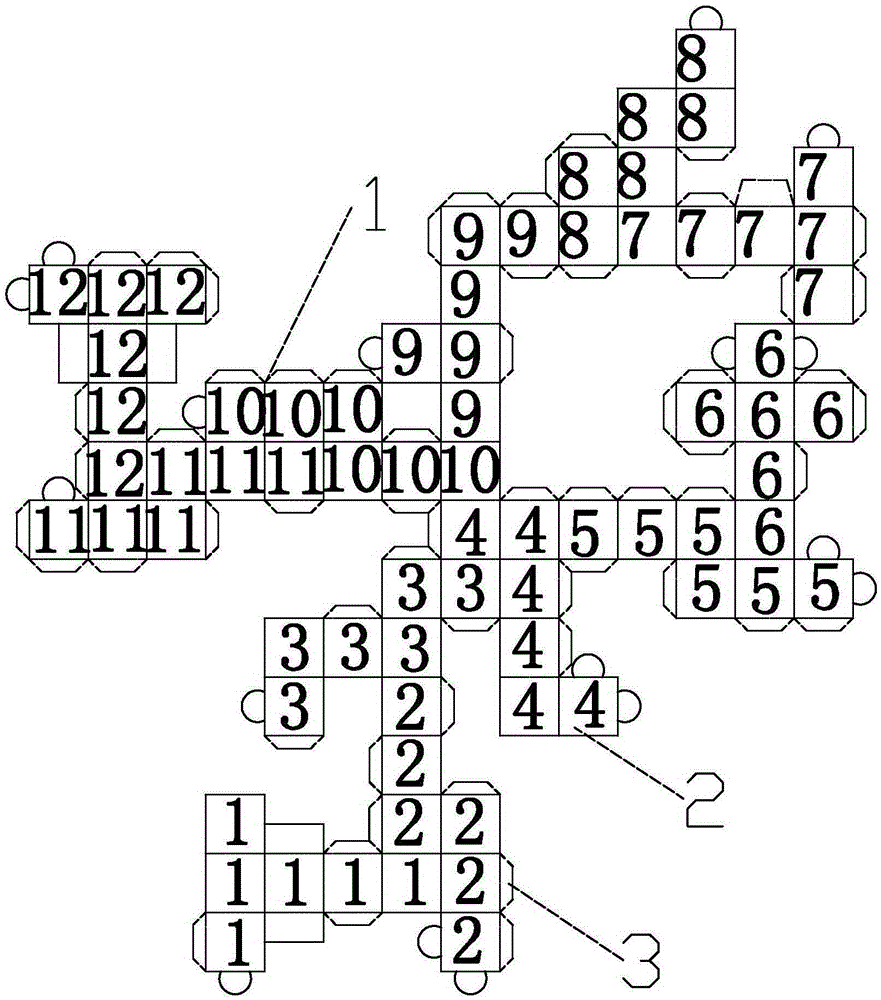

A deformable fun candy packaging box

The invention discloses a deformable fun candy box comprising a body. The body comprises 12 groups of square packing unfolding boards; each group of square packing unfolding boards includes 6 square unfolding boards; each two adjacent of the square packing unfolding boards in each group are overlapped by at least one edge; at least three of the square packing unfolding boards in each group are provided with gluing portions; at least one square packing unfolding board in the groups of square packing unfolding boards is overlapped by one edge. The deformable fun candy box allows candy package to be funnier, consumers can more interact with the package when tasting the sweet of candies and accordingly can be pleasured both physically and mentally, storage space is utilized effectively, and transporting is facilitated.

Owner:嘉兴君宏光学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com