Automatic tea packing machine

A technology for tea bags and tea, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of difficult to ensure consistent packaging quality, difficult to meet production needs, a lot of manpower and material resources, etc., to achieve compact structure, reduce labor costs, and quickly The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

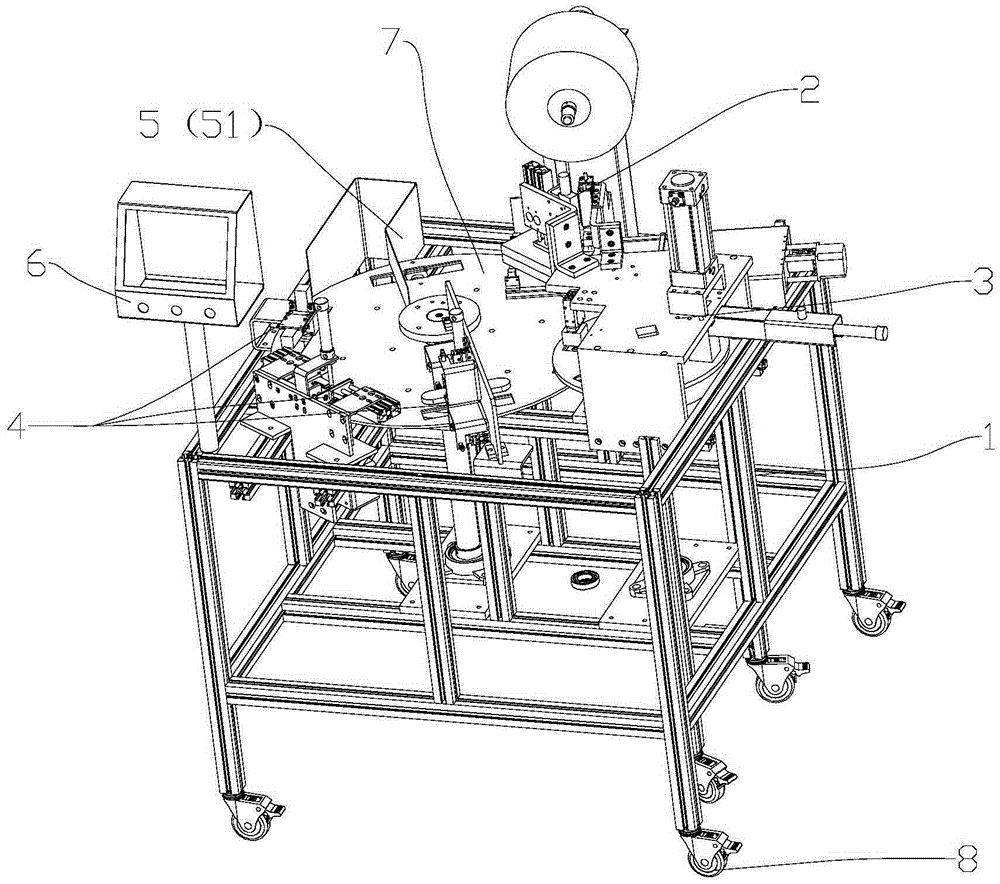

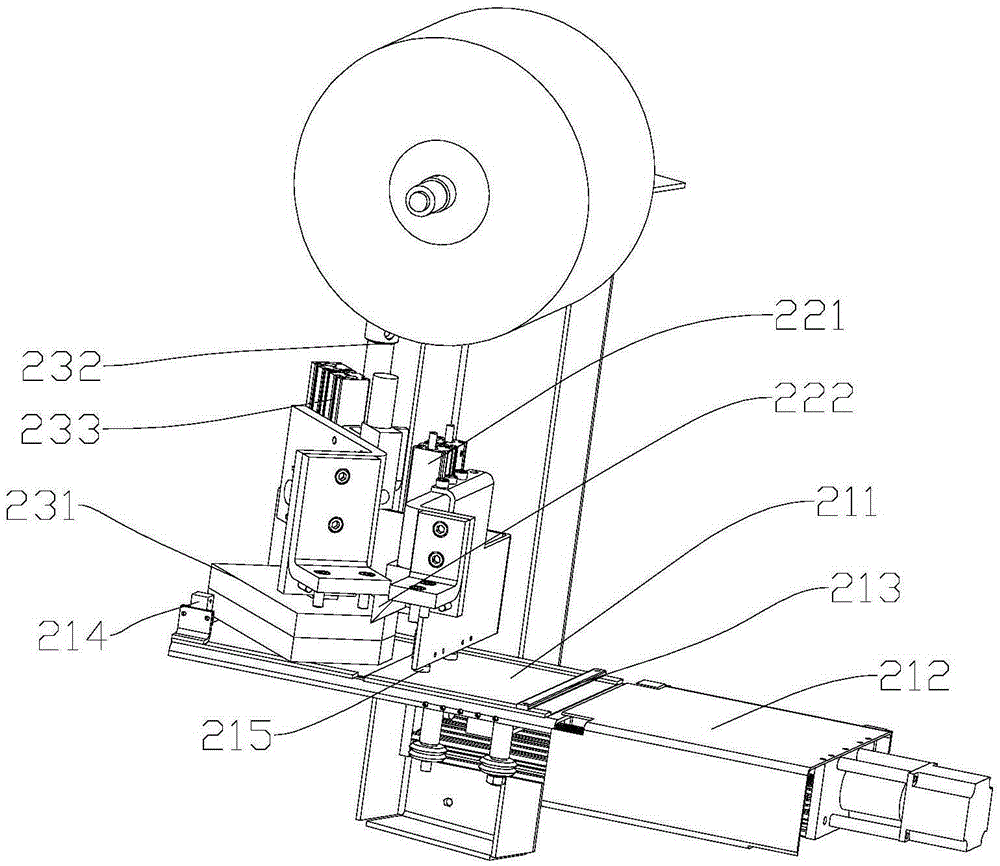

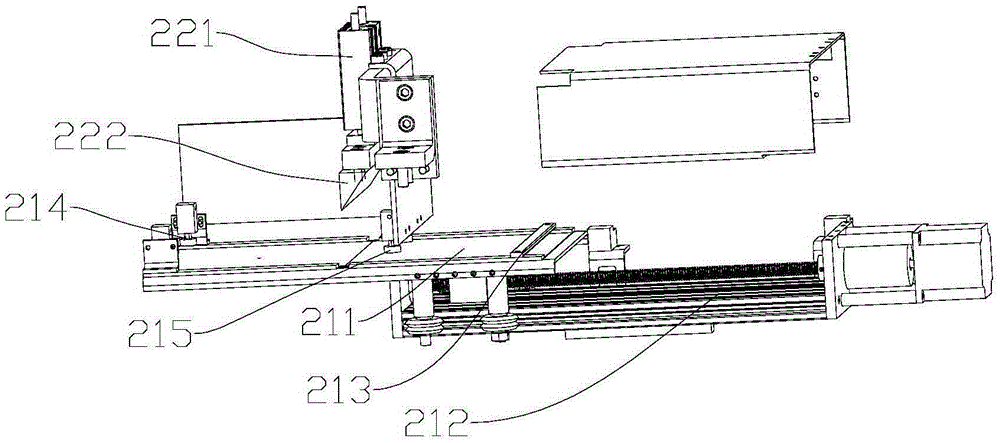

[0026] refer to figure 1 , an automatic tea packaging machine, comprising a frame 1, a paper feeding device for automatically feeding wrapping paper is arranged on the frame 1, a forming device for compressing and molding tea leaves and putting tea leaves on wrapping paper 3, according to the setting Origami method and sequence The packaging device 4 for tea packaging, the recovery device 5 for recovering the packaged tea leaves, the control center 6, the paper feeding device 2, the forming device 3, the packaging device 4, and the recycling device 5 are distributed in a clockwise direction. On a turntable assembly line 7.

[0027] By adopting the above-mentioned structural design, the present invention can automatically realize all the processes in tea packaging such as paper feeding, tea forming, tea packaging, tea recycling, etc., and the various processes are well connected and compact in structure, and are distributed on a turntable-type assembly line 7, This can improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com