Membrane separator for methyl alcohol water hydrogen production equipment and fabrication method of membrane separator

A membrane separator and hydrogen production equipment technology, applied in separation methods, hydrogen separation, chemical instruments and methods, etc., can solve the problems of easily leaking hydrogen and affecting hydrogen production, and achieve the effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

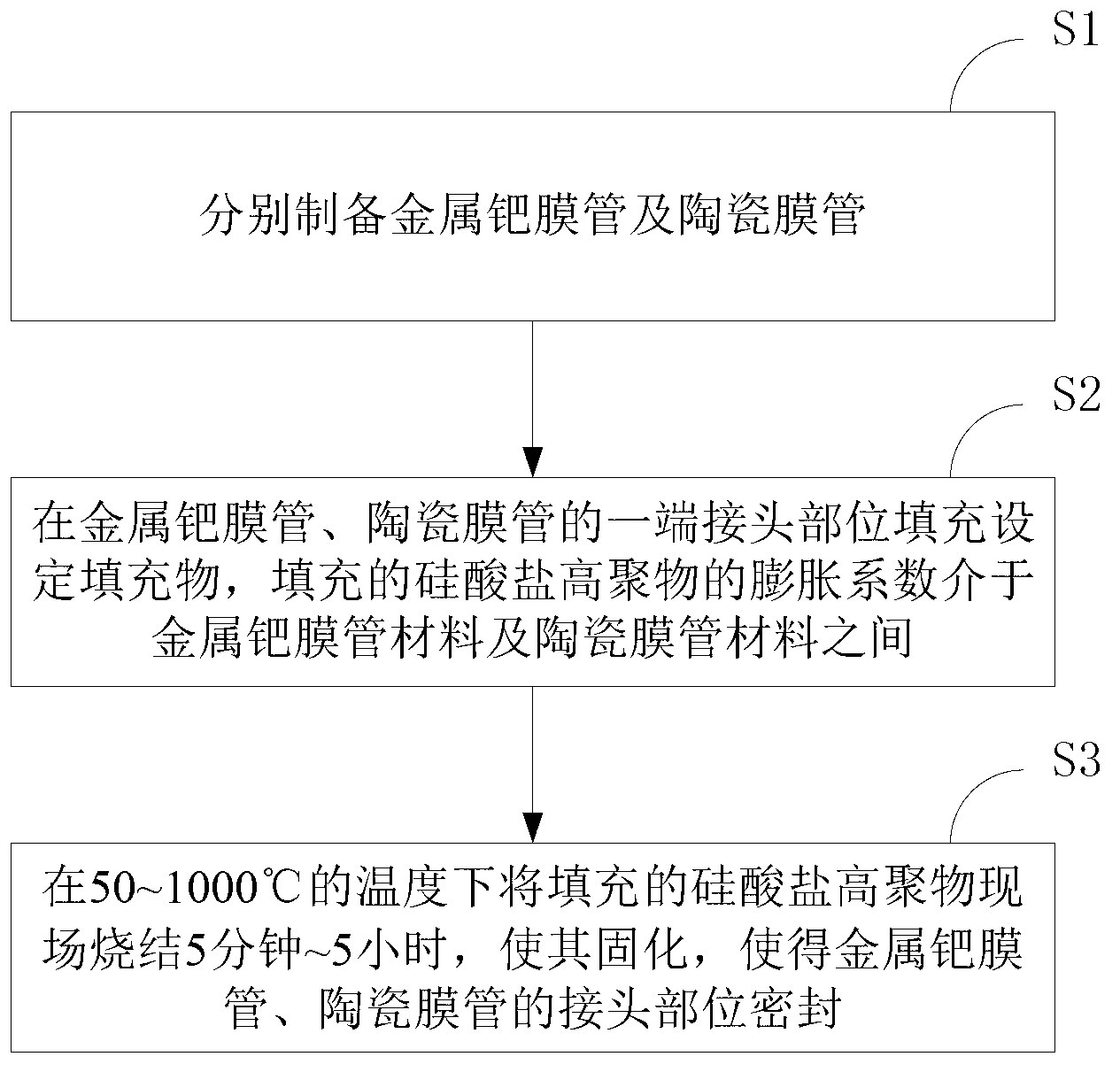

[0045] see figure 2 , the invention discloses a method for preparing a membrane separator of methanol-water hydrogen production equipment, the method comprising the following steps:

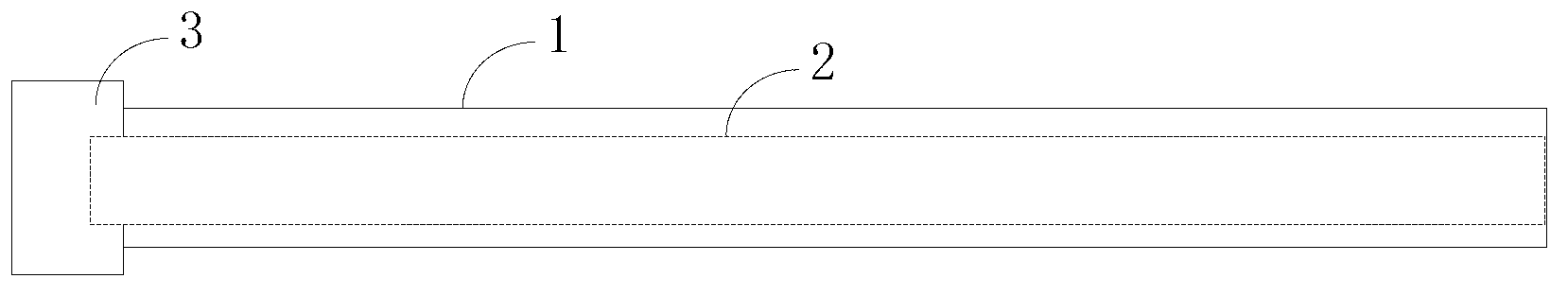

[0046] 【Step S1】If figure 1 As shown, the metal palladium membrane tube 1 and the ceramic membrane tube 2 were prepared respectively; the material of the metal palladium membrane tube was stainless steel, the material of the ceramic membrane tube was a mixture of zirconia, titania, and alumina, and zirconia, titania, and alumina The weight ratio is 2~5:3~20:5~60. For example, the weight ratio of zirconia, titanium oxide, and aluminum oxide is 2:3:5, or 4:10:59, and so on. Certainly, the material of the ceramic membrane tube may also include other materials.

[0047] [Step S2] Fill the joint part 3 of the metal palladium membrane tube 1 and the ceramic membrane tube 2 with a set filler, the filler is a mixture of a silicate polymer curing agent and a silicate crosslinking agent, silicon The w...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that in this embodiment, in step S3, the filling is heated at a temperature of 50°C for 3 to 5 hours (such as 3 hours, 4 hours or 5 hours), and the filling The materials are sintered on site at the joints of metal palladium membrane tubes and ceramic membrane tubes.

Embodiment 3

[0057] The difference between this embodiment and Embodiment 1 is that in this embodiment, in step S3, the filling is heated at a temperature of 300°C for 20 to 40 minutes (such as 20 minutes, 30 minutes or 40 minutes), and the filling The materials are sintered on site at the joints of metal palladium membrane tubes and ceramic membrane tubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com