Patents

Literature

130results about How to "Guaranteed preparation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

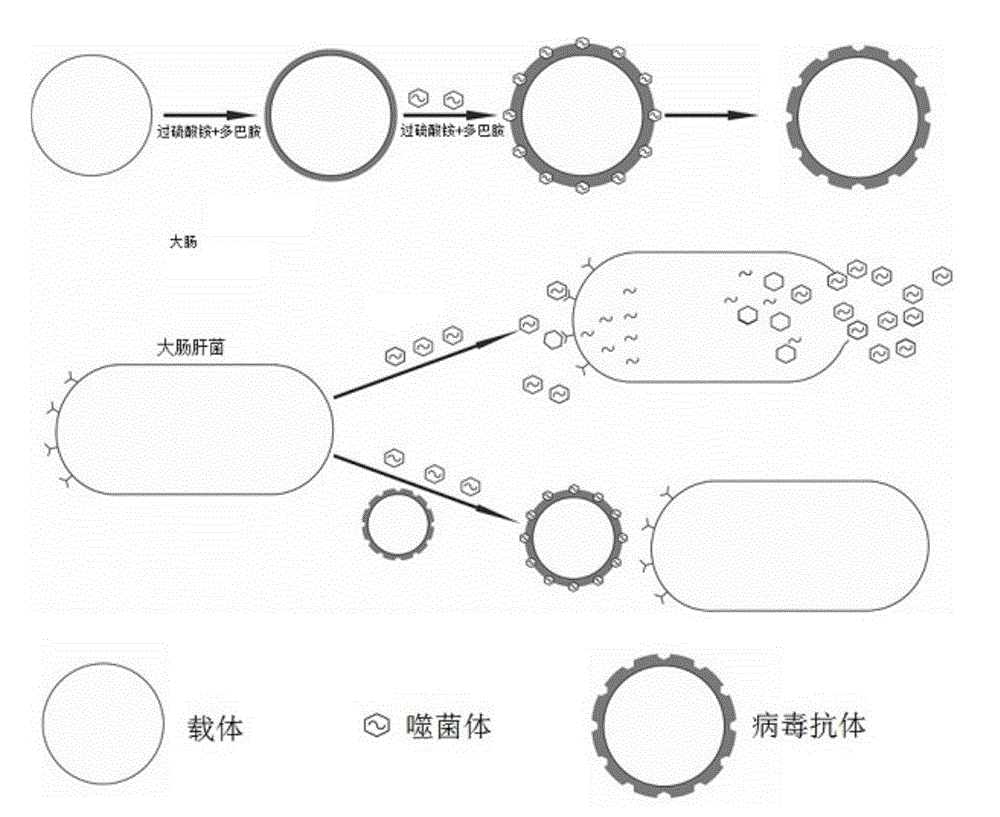

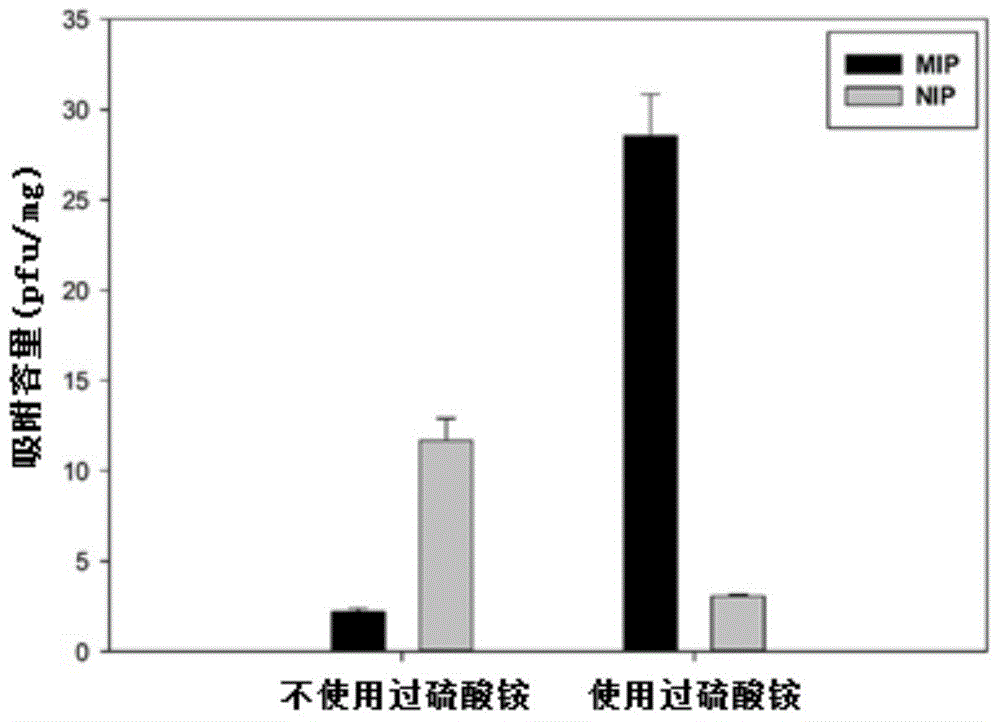

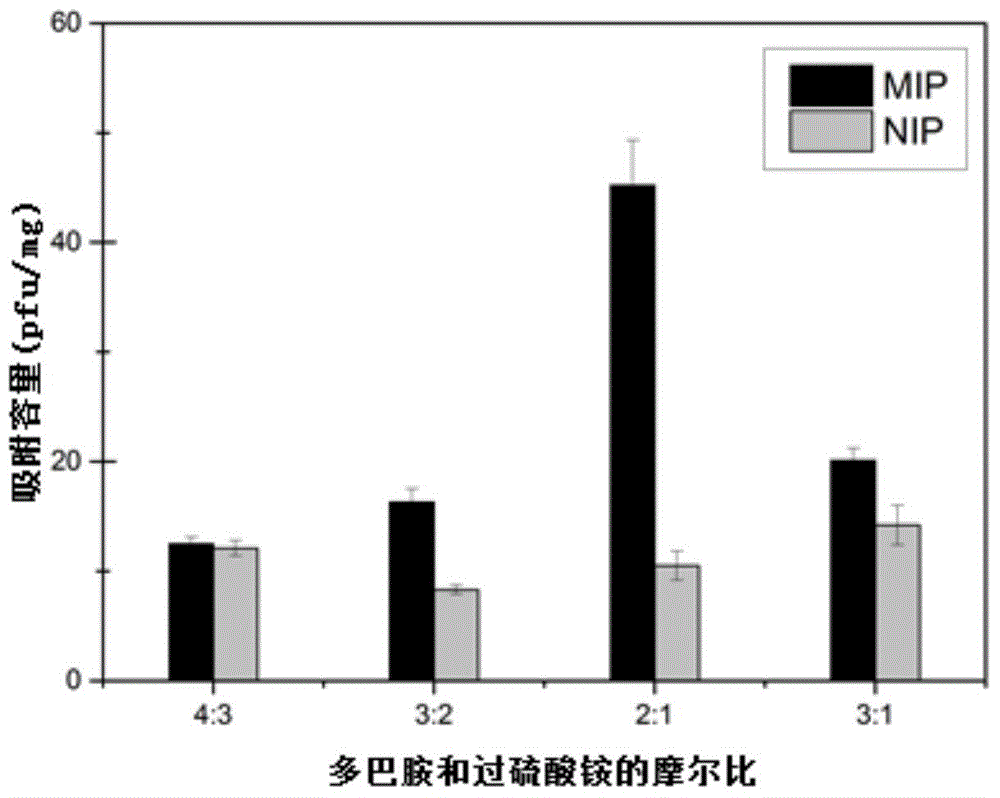

Method for preparing anti-virus molecularly imprinted polymer

InactiveCN104945623AGuaranteed preparation efficiencyGuaranteed FeaturesOther chemical processesAnti virusDopamine

The invention discloses a method for preparing an anti-virus molecularly imprinted polymer. The method comprises the steps of modifying dopamine nanofilm on a carrier material, then combining a target virus with the carrier material modified with the dopamine nanofilm, forming a virus-dopamine-carrier material compound, eluting the target virus from the compound, and obtaining the corresponding anti-virus molecularly imprinted polymer. According to the anti-virus molecularly imprinted polymer, imprinted holes left after the virus is eluted can be utilized, the target virus is combined in a specific mode, and the target virus is prevented from multiplication and infecting a host; the anti-virus molecularly imprinted polymer has the advantages of being good in using specificity, friendly in service environment and simple in regenerate, and a good using prospect in the biological immunity field is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

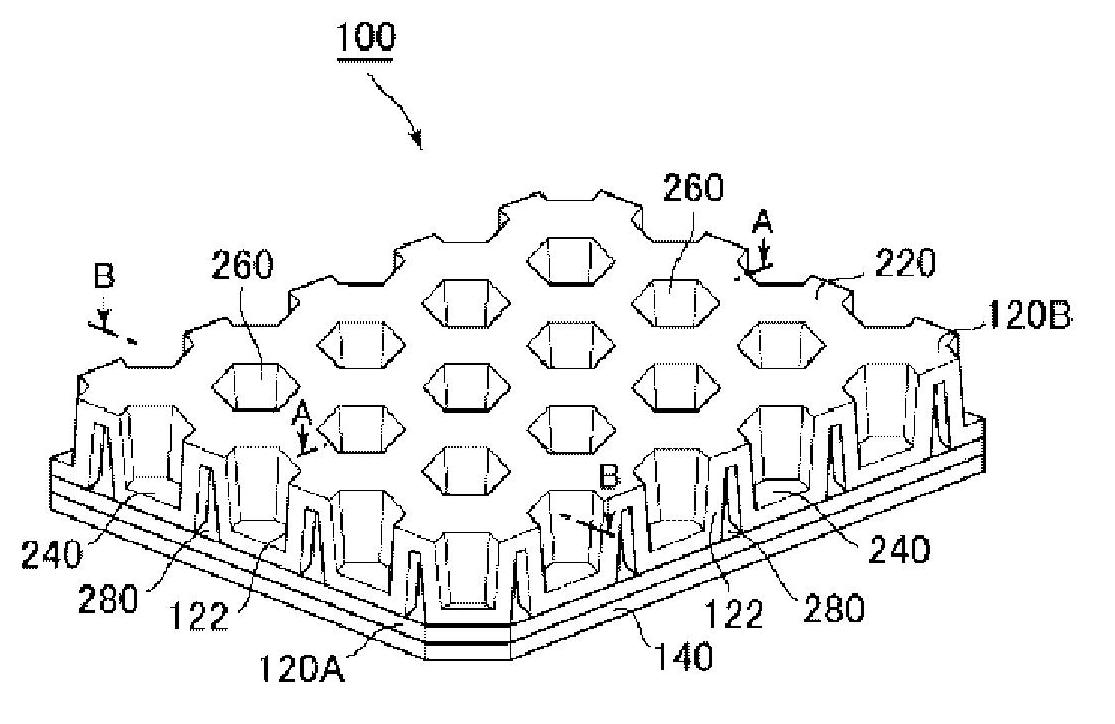

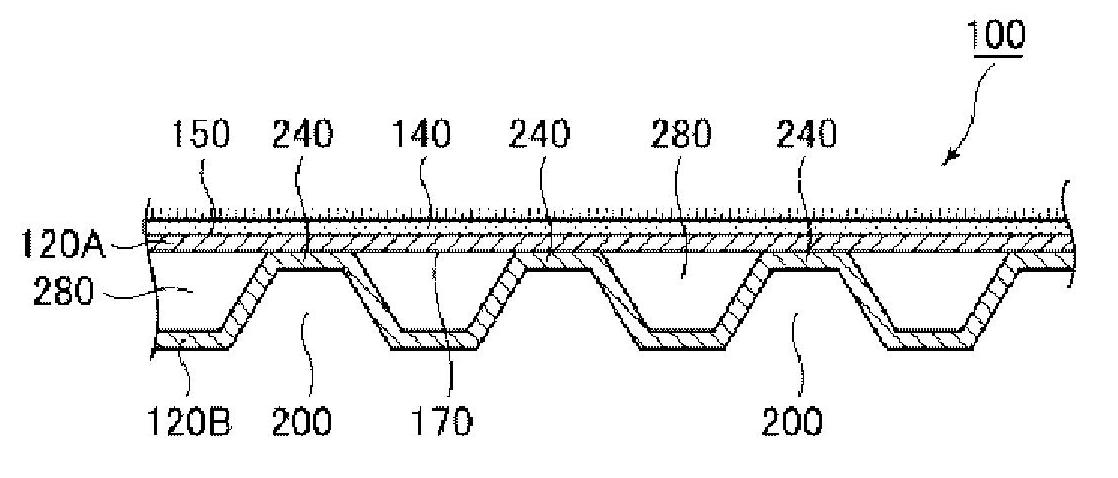

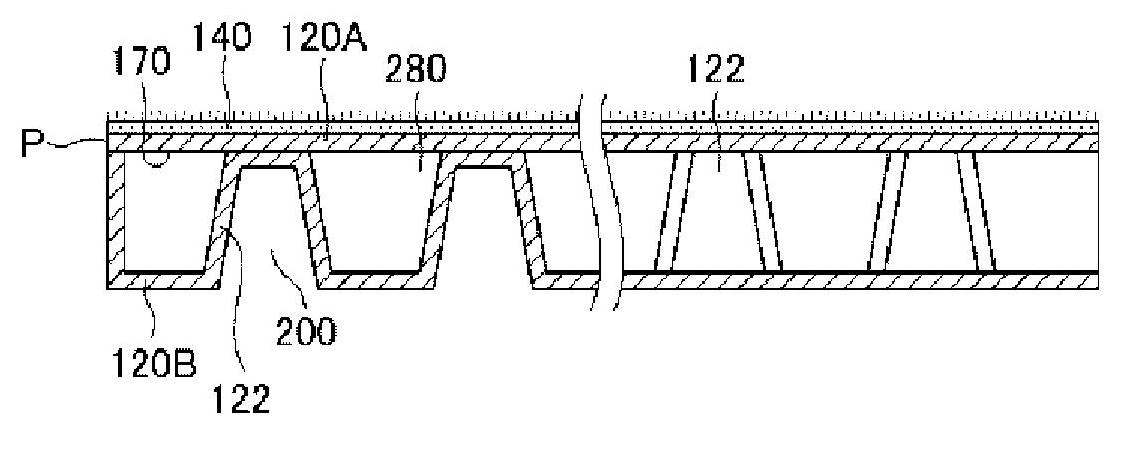

Method for manufacturing a resin laminate

ActiveCN102686379AGuaranteed qualityGuaranteed preparation efficiencySynthetic resin layered productsSuperstructure subunitsEngineeringPush ups

Provided is a method for manufacturing a resin laminate. Said method includes: a step in which a two-piece mold is provided, wherein the cavity of one piece of the mold is provided with a plurality of protrusions that protrude towards the other piece of the mold, and two thermoplastic resin sheets in a molten state are prepared with regulated thicknesses; a step in which the two molten thermoplastic resin sheets are positioned at a prescribed separation from each other between the two pieces of the two-piece mold so as to protrude outside a ring-shaped pinch-off; a step in which a sealed space is formed between one sheet and the cavity of one mold piece facing the outer surface of that sheet; a step in which suction is applied to the aforementioned sealed space from the mold piece side and the outer surface of that sheet is pushed up against the cavity of that mold, thereby diluting that sheet and forming a depression; and a step in which the mold is clamped shut, thereby bonding the outer edges of the two molten thermoplastic resin sheets to each other and also bonding the tip of the depression formed in one sheet to the inner surface of the other sheet.

Owner:KYORAKU CO LTD

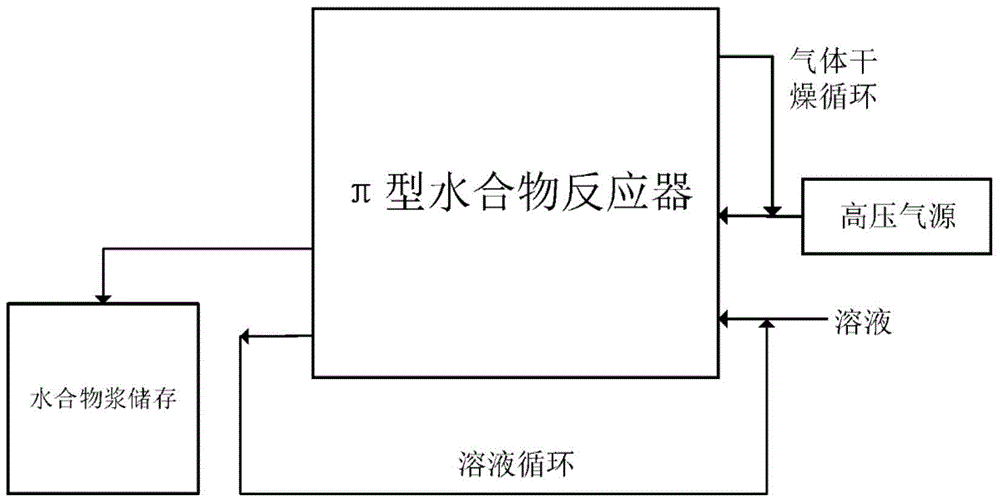

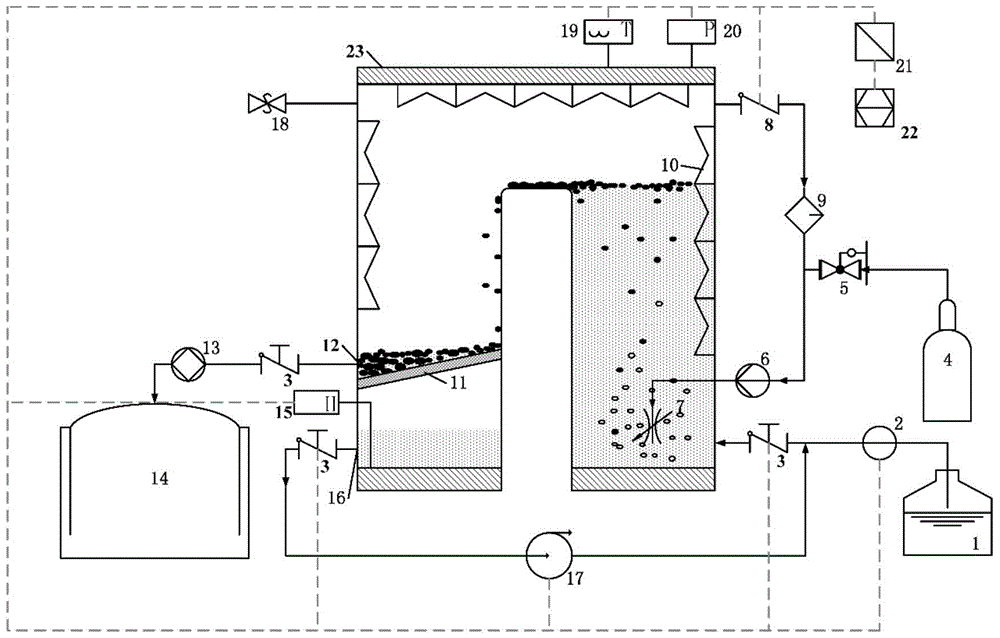

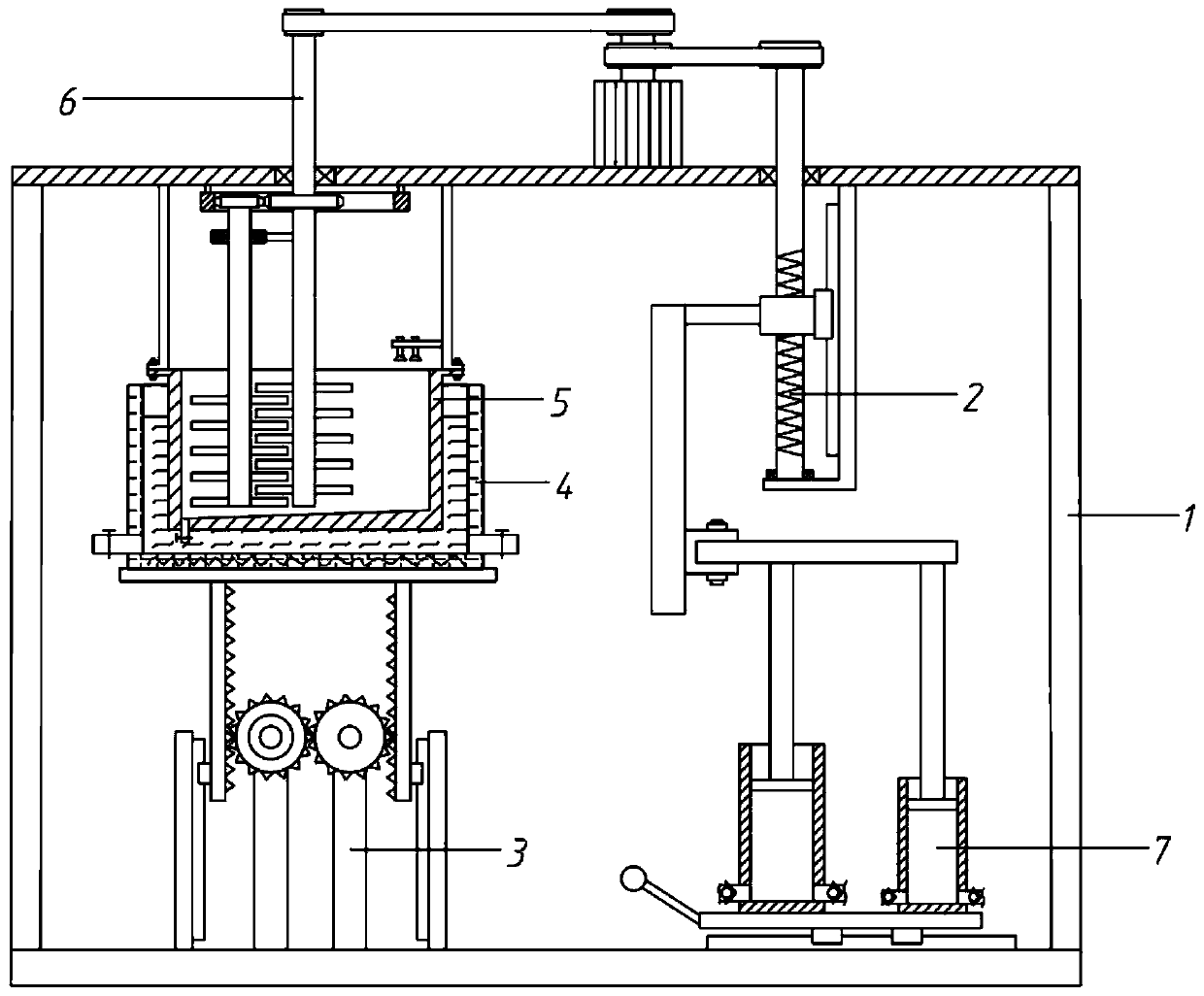

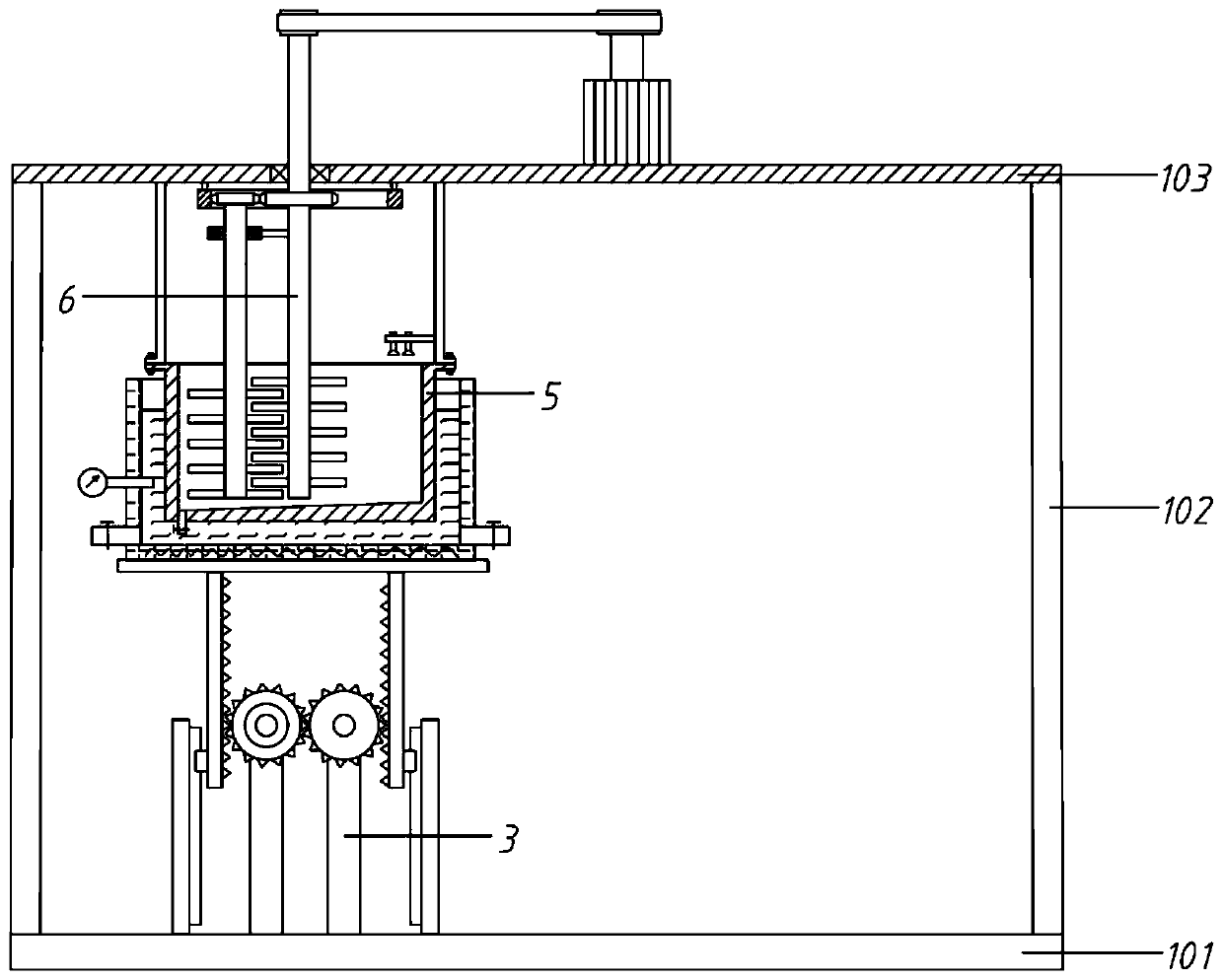

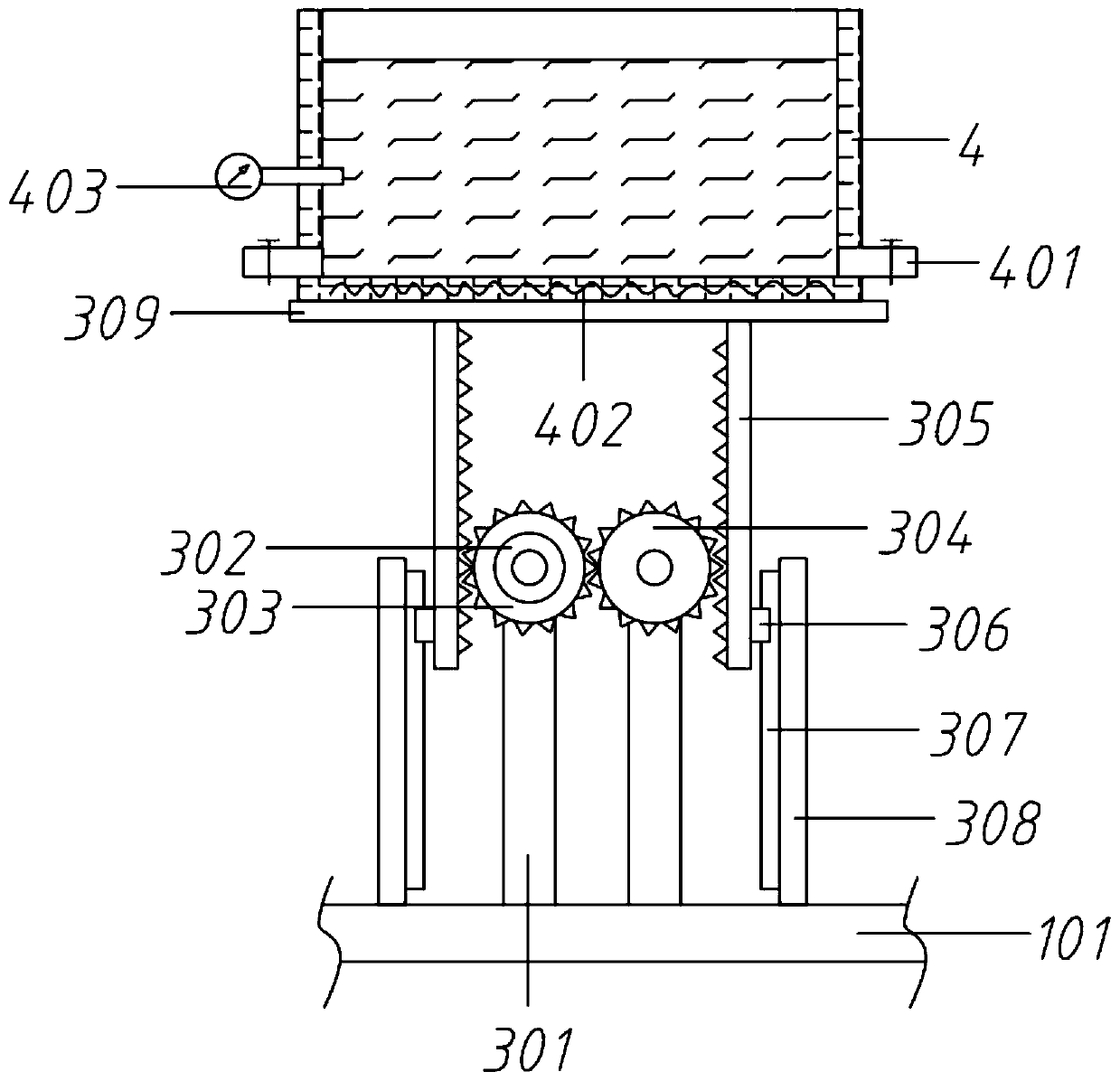

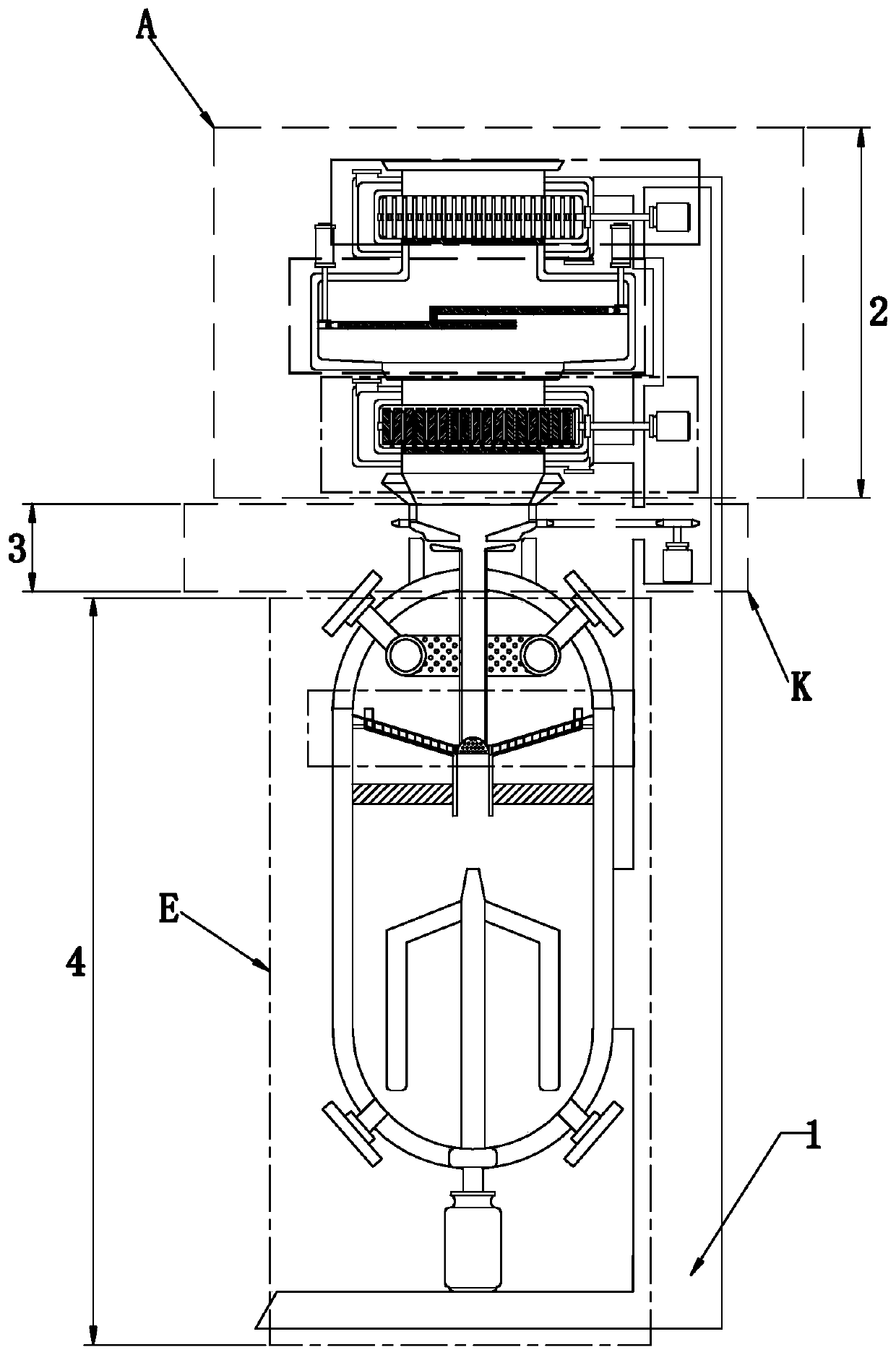

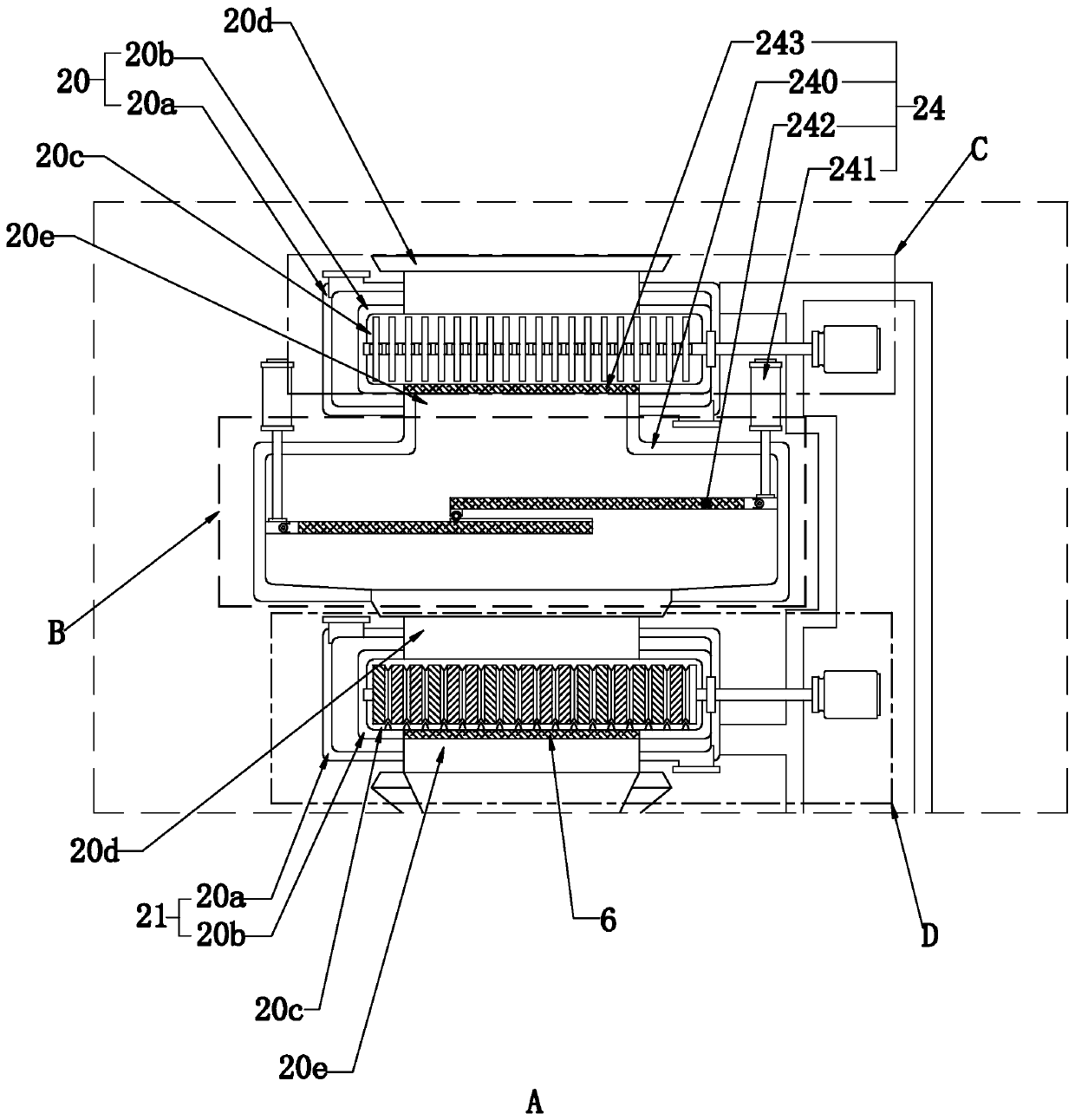

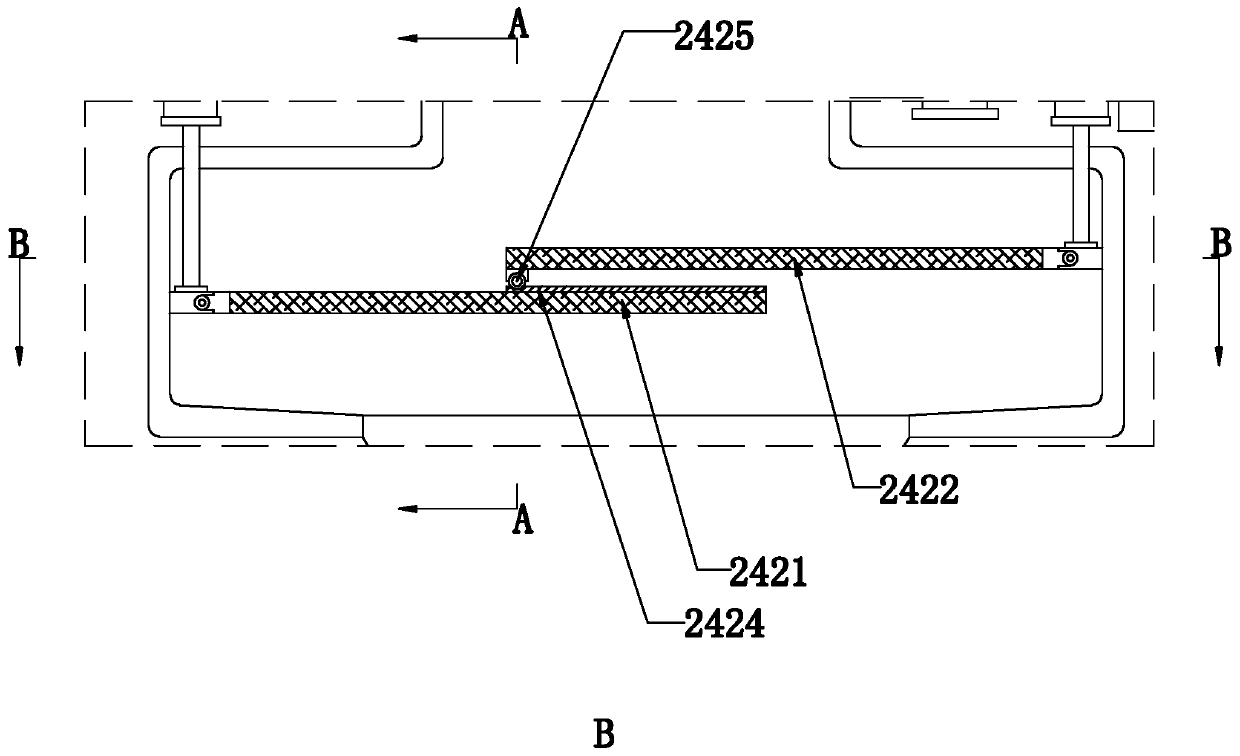

Continuous type gas hydrate slurry synthesis method and device based on gas throttling technology

ActiveCN105670725AIncrease spawn rateEasy to collectGaseous fuelsPressure vessels for chemical processTemperature controlSynthesis methods

The invention provides a continuous type gas hydrate slurry synthesis method and device based on a gas throttling technology, and belongs to the field of hydrate technology application. The device comprises a water injection-temperature control part, a gas injection-hydrate continuous production part and a hydrate slurry recycling part. The gas injection-hydrate continuous production part comprises a gas intake system and a circulation system. After gas is throttled and expanded, the gas goes into a reactor, an instantaneous low temperature is obtained, and a hydrate is promoted to be rapidly produced. With use of a characteristic that the density of the gas hydrate is lower than that of water, after hydrate particles float upward, the hydrate particles automatically flow out of the reactor, so as to realize continuous production of the hydrate. A solution obtained after the hydrate slurry is filtered can flow back into the reactor through circulation, and thus the solution is reused. The pi-type hydrate reactor is novel and simple in design, and is conducive to collection of the hydrate; the preparation method is easy to operate, and the hydrate slurry producing efficiency and output capacity are further improved. The synthesis method and device are flexible in design, and a plurality of researches on synthesis of the gas hydrate also can be carried out.

Owner:DALIAN UNIV OF TECH

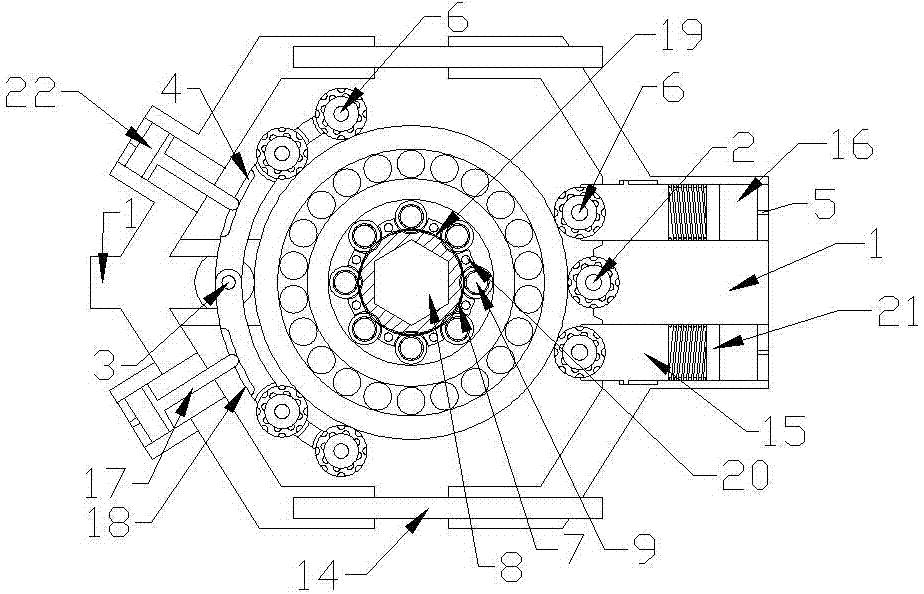

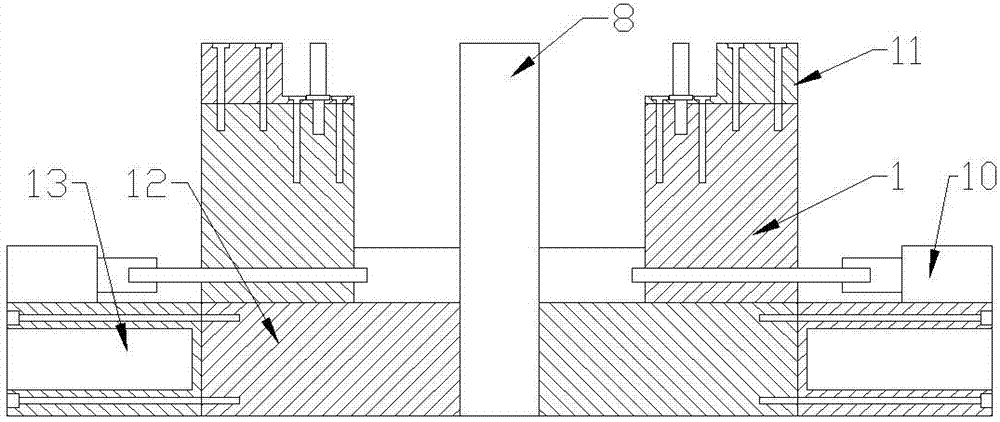

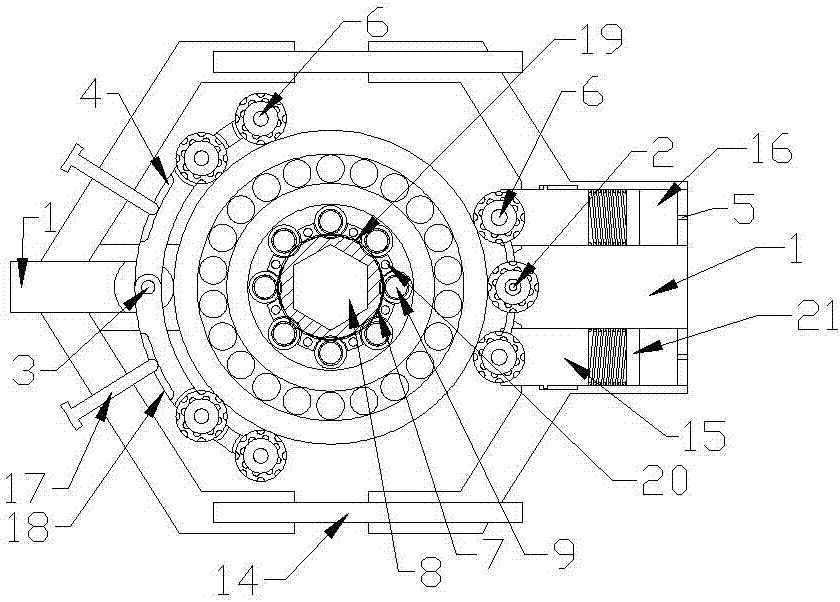

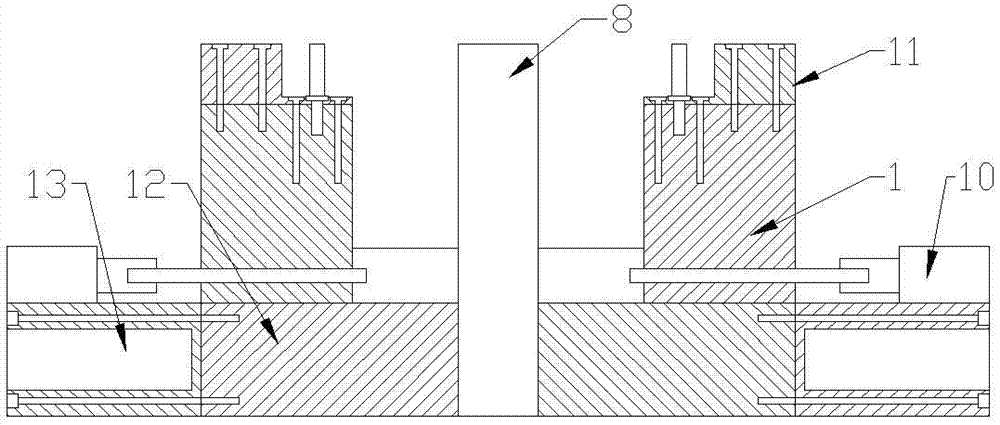

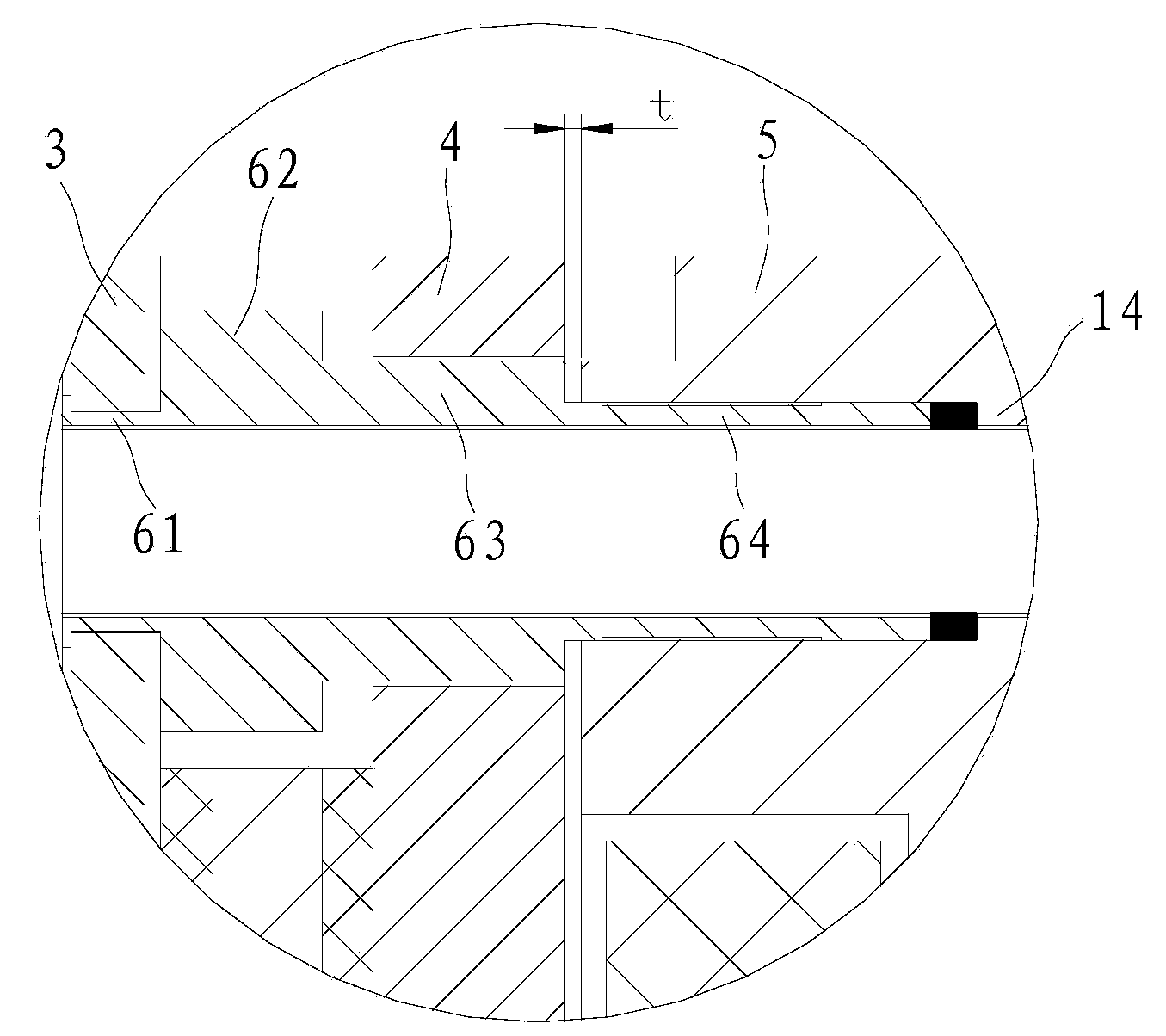

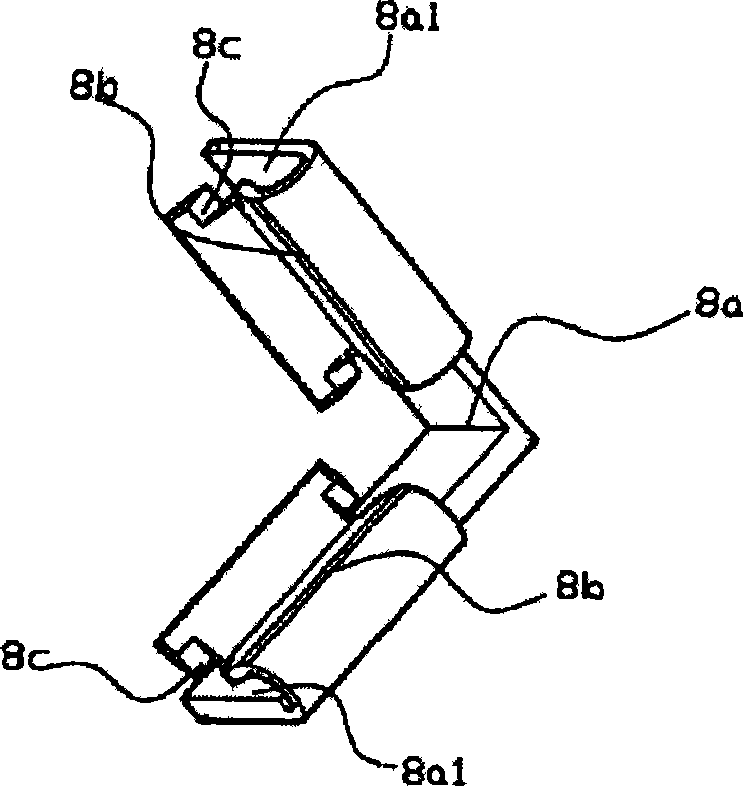

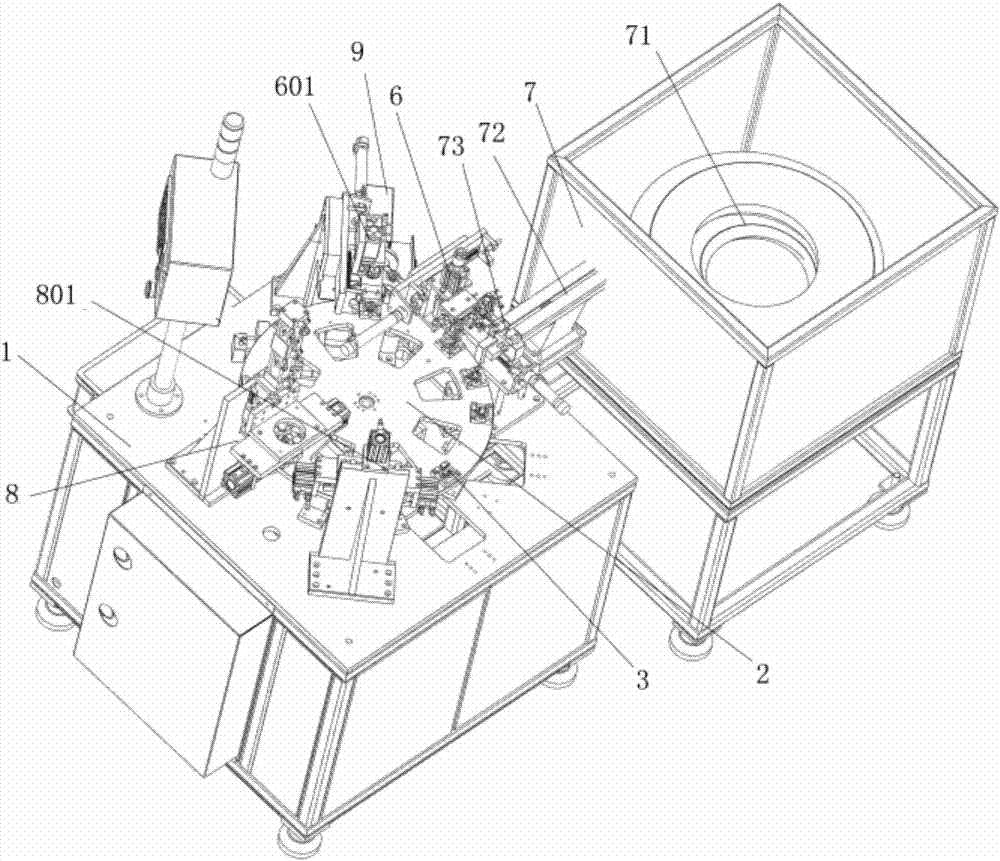

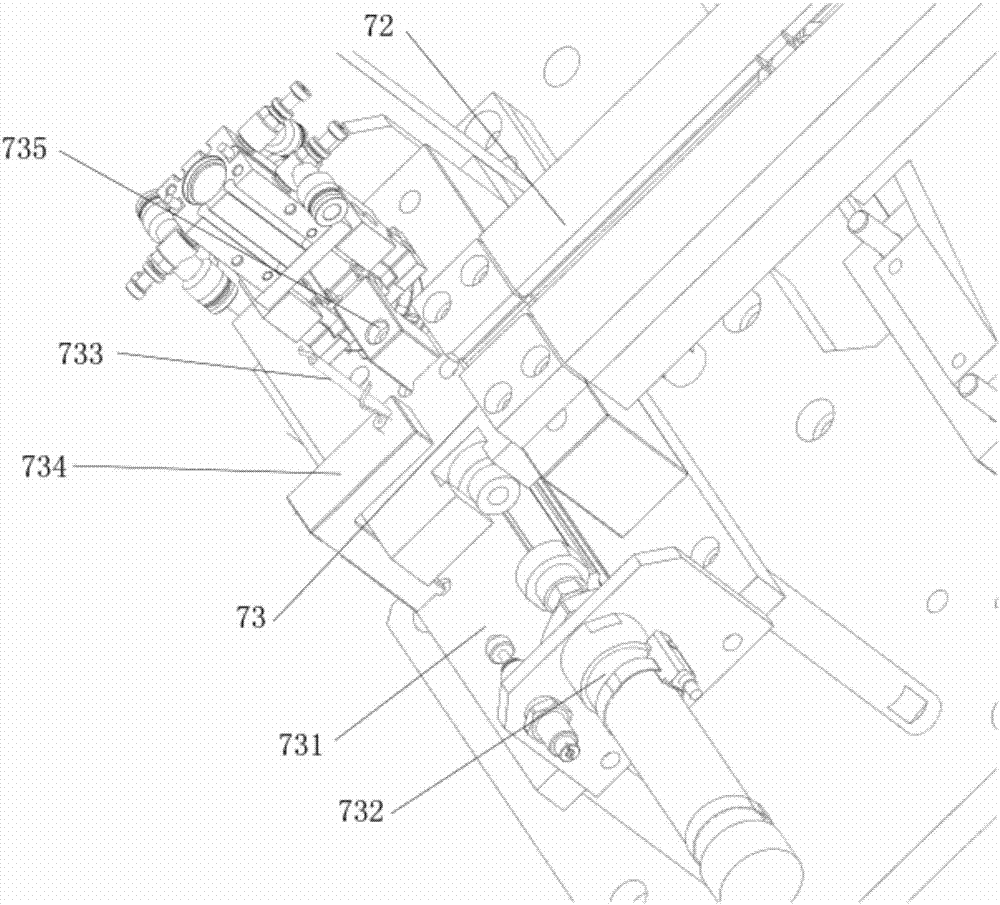

Swinging-type bearing roller installing fixture

InactiveCN107538198AAvoid forcing the bearing frameAvoid the situationMetal working apparatusEngineeringPiston

The invention relates to a swing type bearing roller installation tool, which includes a support, and a bearing inner frame fixing seat is arranged in the middle of the support. Outer frame pressing device; the bearing outer frame pressing device includes two sets of pushing mechanisms, the pushing mechanism includes a sliding block that is slidably connected with the support and a linear drive mechanism installed on the support for pushing the sliding block, one of the sliding blocks There is a bearing outer frame supporting mechanism on the upper part, and a bearing outer frame pushing mechanism is arranged on the other sliding block; the bearing outer frame supporting mechanism includes two mirror-symmetrical clamping arms arranged on one of the sliding blocks, and the other sliding block The compression mechanism driven by air pressure on the block is also provided with a supporting frame on the two sliding blocks, and the supporting frames are movably connected by a sliding sleeve structure. The pushing piston of the clamping arm is provided with a bar-shaped groove corresponding to the pushing rod of the pushing piston on the clamping arm.

Owner:JIANGYIN JIB WD PRECISION

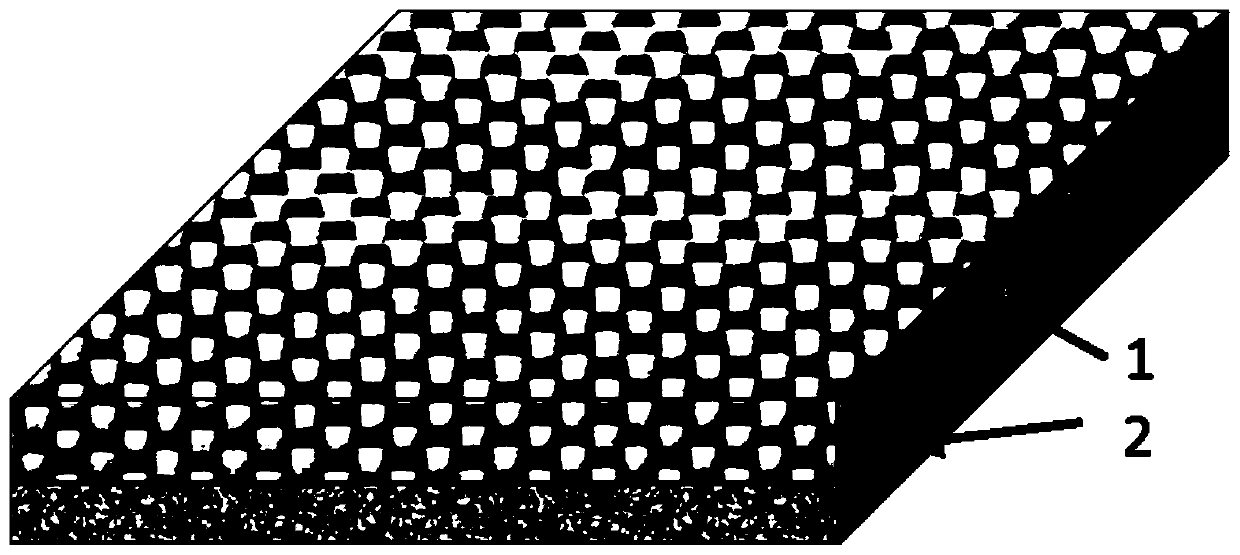

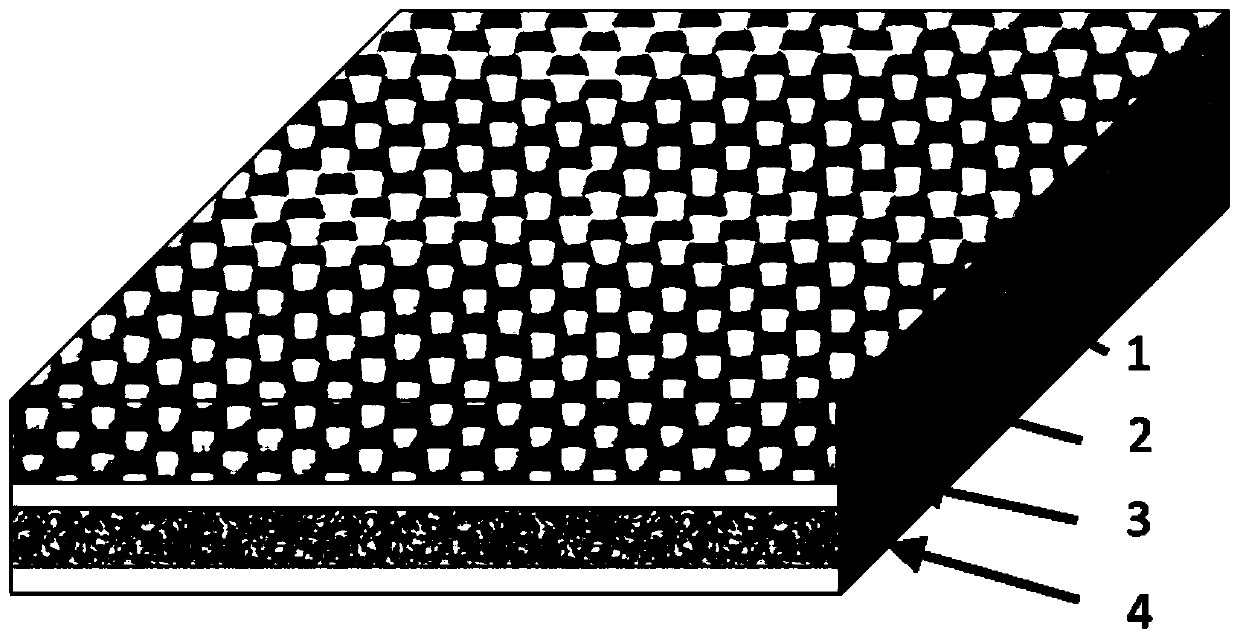

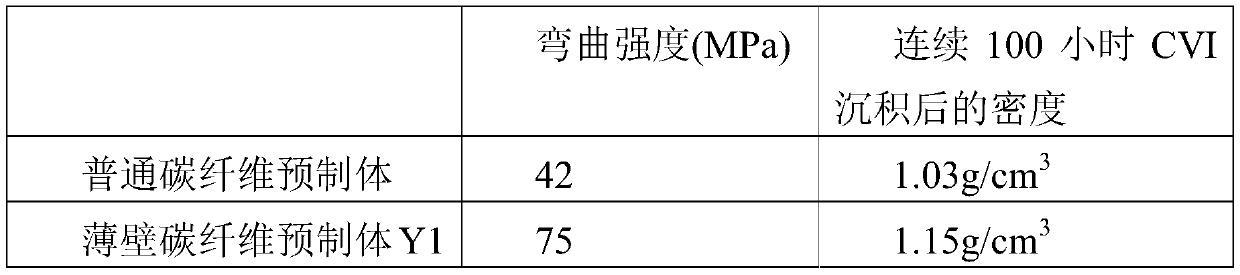

Large thin-wall carbon fiber needling prefabricated body and preparation method thereof

The invention discloses a large thin-wall carbon fiber prefabricated body. Resin exists in prefabricated body structural unit layers or among the prefabricated body structural unit layers; the unit layer structures serve as the structural unit layers formed by sequentially superposing and then needling carbon fiber net tires, resin films and carbon cloth; or the unit layer structures serve as thestructural unit layers formed by sequentially superposing and then needling carbon fiber / resin fiber net tires and carbon fiber / resin fiber mixed fabric; and the large thin-wall carbon fiber prefabricated body is prepared by superposing the unit structure layers by multiple layers via hot pressing. The prefabricated body has the certain rigidity and the relatively high size accuracy, and has a relatively small influence on the structure of C / C composite substrate carbon, and subsequent CVI technology forming is facilitated.

Owner:JIANGSU TIANNIAO HIGH TECH

Clamp for assembling bearing roller

InactiveCN107538387AGuarantee quality and efficiencyGuaranteed preparation efficiencyBearing componentsWork holdersEngineeringAtmospheric pressure

The invention relates to a jig for bearing roller assembly, comprising a support, a bearing inner frame fixing seat is arranged in the middle of the support, the bearing inner frame fixing seat includes a plurality of elastically fixed friction bars, and bearing outer The frame pressing device; the bearing outer frame pressing device includes two sets of pushing mechanisms, the pushing mechanism includes a sliding block that is slidably connected with the support and a linear drive mechanism installed on the support for pushing the sliding block, on one of the sliding blocks A bearing outer frame supporting mechanism is provided, and a bearing outer frame pushing mechanism is arranged on the other sliding block; the bearing outer frame supporting mechanism includes two mirror-symmetrical clamping arms arranged on one of the sliding blocks, and the other sliding block The compression mechanism driven by air pressure on the upper body is also provided with a supporting frame on the two sliding blocks, and the supporting frames are movably connected by a sliding sleeve structure. The supporting frame is provided with two clamps for pressing The jacking screw of the tight arm is provided with a bar-shaped groove corresponding to the jacking screw on the clamping arm.

Owner:JIANGYIN JIB WD PRECISION

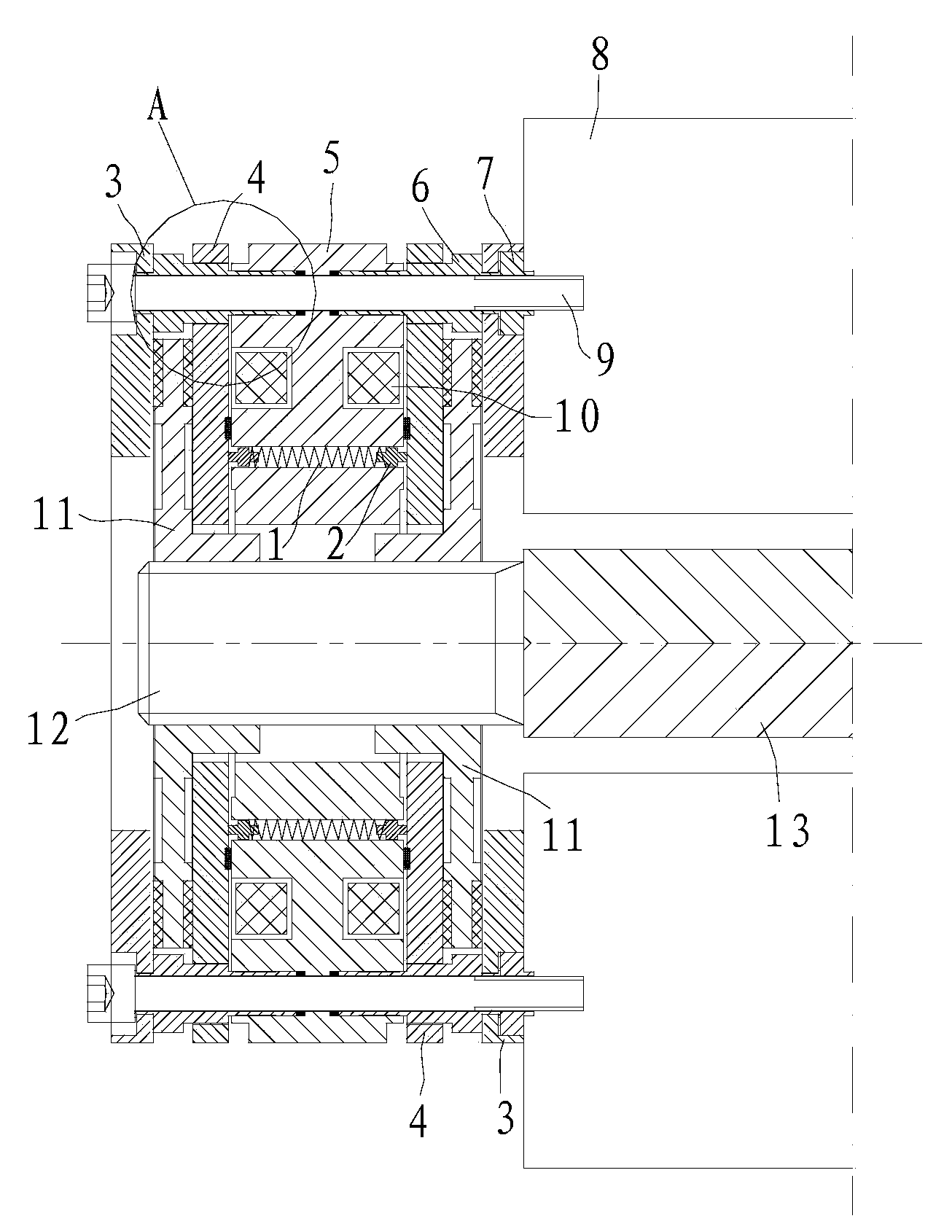

Electromagnetic disc brake and traction machine provided with same

ActiveCN104140054AReduce axial sizeLow costBuilding liftsHoisting equipmentsInterference fitElectromagnetic interference

The invention relates to an electromagnetic disc brake and a traction machine provided with the electromagnetic disc brake. The electromagnetic disc brake disclosed by the invention comprises a stationary iron core and two movable iron cores through electromagnetic interaction, two brake discs fixed with a main shaft, and two brake plates which are matched with the movable iron cores and are used for clamping the brake discs, wherein the two movable iron cores are respectively positioned on the two sides of the stationary iron core, and a brake spring is arranged between each of the two movable iron core and the stationary iron core; a coil winding acting on each movable iron core is arranged on the stationary iron core; the two brake discs and the two brake plates are arranged outside the corresponding movable iron cores in sequence. The stationary iron core, the two movable iron cores and the two brake plates are fastened in a penetrating mode through a connecting sleeve, unthreaded holes penetrating through the connecting sleeve are formed in the stationary iron core, the two movable iron cores and the two brake plates, the connecting sleeve and the stationary iron core are connected through interference fit, and the connecting sleeve and the brake plates are pressed together through riveting. The electromagnetic disc brake is smaller in size, safe and convenient to use and convenient to maintain.

Owner:浙江西子富沃德电机有限公司

Making method of cured beef

PendingCN105533467AEasy to manufactureShorten marinating timeFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentCooking & bakingAllium sativum

The invention relates to the field of food processing, in particular to a making method of cured beef. The method comprises the following steps of: the first step of pickling: grinding 2-5g of Chinese prickly ash, 10-20g of star aniseed, 5-12g of fructus tsaoko, 10-15g of garlic, 5-30g of capsicum frutescens, 10-20g of salt, 10-30g of gourmet powder and 10-20g of pepper fruit seeds into powder, making the powder into pickling seasoning, removing tendons, peel, fat and other sundries from cattle meat, cutting the cattle meat without the tendons, the peel, the fat and the other sundries into cattle meat strips of which the thickness is 2-5cm, uniformly mixing the cattle meat strips with the pickling seasoning, and pickling the uniformly mixed cattle meat strips in a pickling vat for 2-6 hours; the second step of airing: spreading the pickled cattle meat in the sun in the daytime for airing, recovering the aired cattle meat at night, enabling the processed cattle meat to be penetrated with sticks, putting the sticks with the cattle meat above charcoal fire, drying the cattle meat on the sticks under the temperature condition of 40-60 DEG C, and repeating the actions of airing and drying until the moisture content of the cattle meat is aired or dried, wherein the airing time is 20-40h, and the drying time is 15-30h; and the third step of roasting: putting the dried cattle meat on a baking pan, and roasting the cattle meat for 3-10min until the roasted cattle meat is cooked. The making method disclosed by the invention has the advantages that the cured beef is delicious, unique in fragrance, high in nutrient value and the like.

Owner:丛华伟

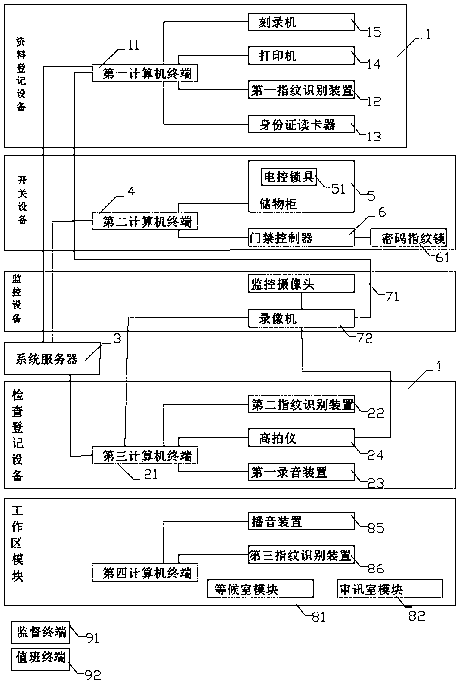

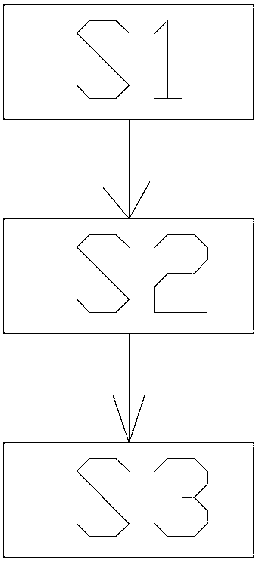

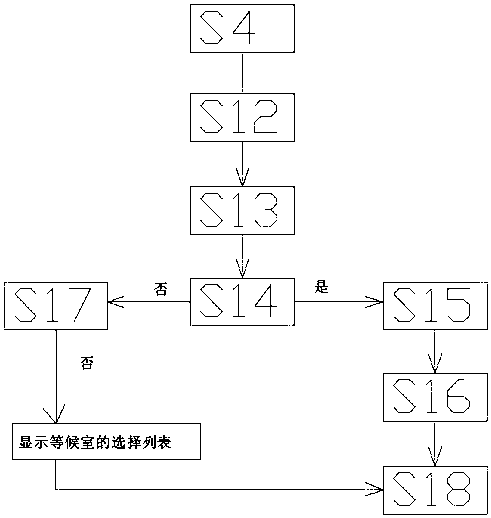

Law enforcement process management method, computer device and computer readable storage medium

InactiveCN107862461AAvoid completenessAvoid filling mistakesOffice automationResourcesSecurity checkDatabase

The invention provides a law enforcement process management method, a computer device and a computer readable storage medium. The law enforcement process management method comprises the steps that registration data are acquired and archive data are generated according to the registration data; whether the registration data and security check data are acquired is judged if a process starting instruction is acquired, and the archive data are called and the law enforcement process data are acquired if the judgment result is yes; and whether approval information is transmitted to a supervision terminal is judged according to the type of the process starting instruction, and the confirmation instruction transmitted by the supervision terminal is acquired if the judgment result is yes. The law enforcement process management method is realized when the processor of the computer device executes the program. The computer readable storage medium stores the program. The preciseness of the law enforcement process can be guaranteed.

Owner:广东省泰维思信息科技有限公司

Ink coating equipment and an ink coating method

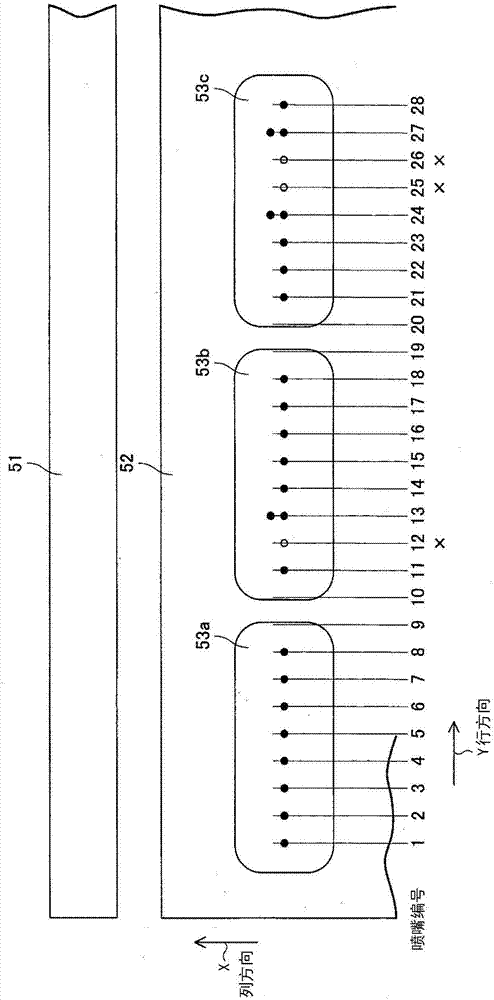

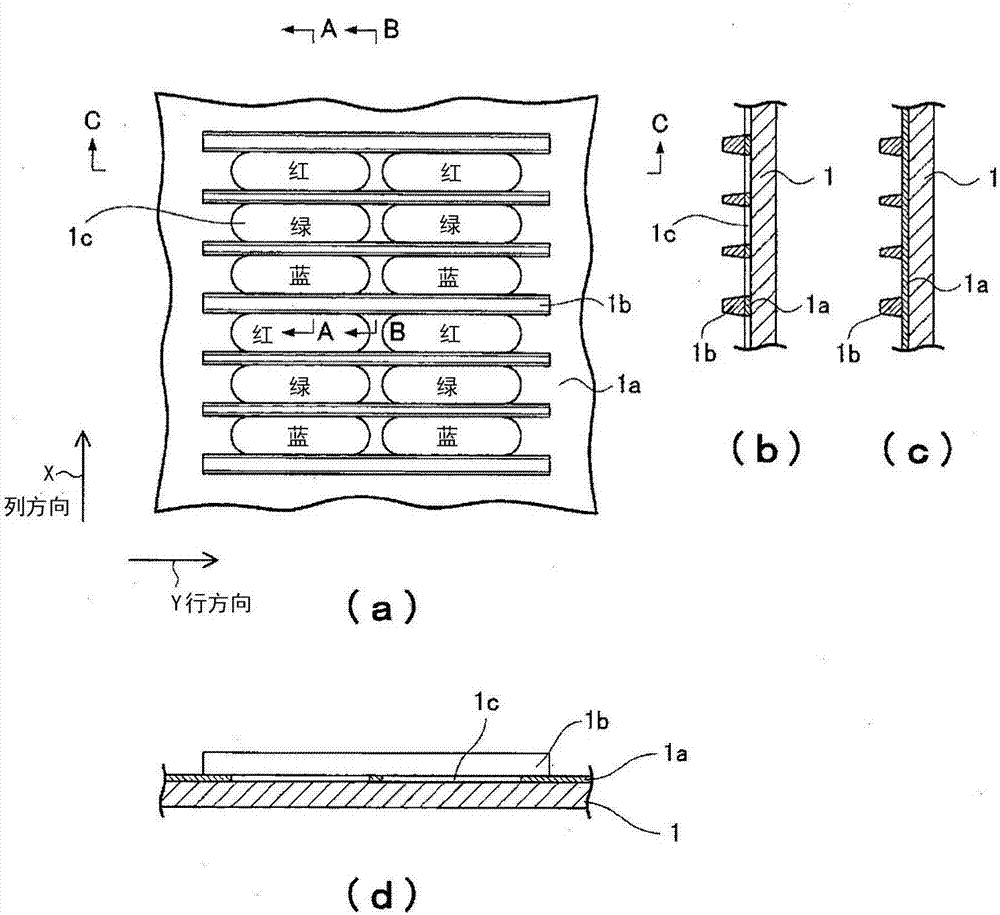

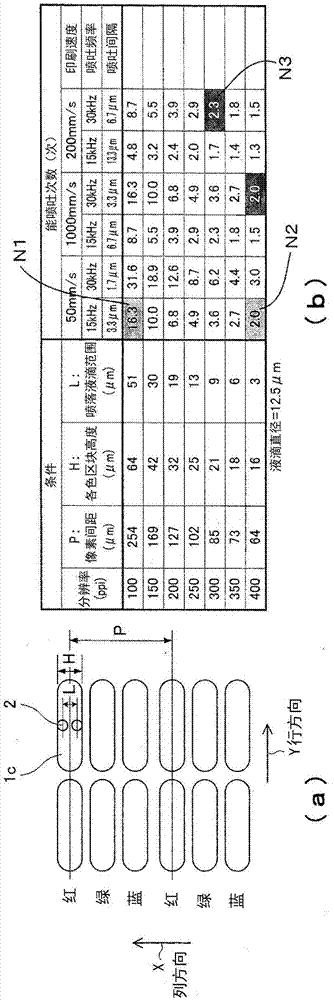

ActiveCN106915160AMaintain Manufacturing EfficiencyNo increase in makeready timeLiquid surface applicatorsSemiconductor/solid-state device manufacturingSpray nozzleMechanical engineering

The present invention provides an ink coating equipment and an ink coating method which can drop assigned number of dropping without exceeding a block in the condition that the size of the column direction X of the block is shortened. The device comprises a shower nozzle configured to spray ink liquid from nozzles; a stand keeping a coating object; a spraying timing keeping portion configured to output a reference spraying timing; a non-spraying nozzle data portion configured to store the position of non-spraying nozzle; a nozzle direction spraying quantity information portion configured to keep the nozzle direction and the spraying quantity information based on a coating image; and a control portion obtained by driving the nozzle in the condition that the nozzles of the ink liquid are not enough at the block so as to spray ink liquid for many times to other nozzles on time from the nozzles of the block.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

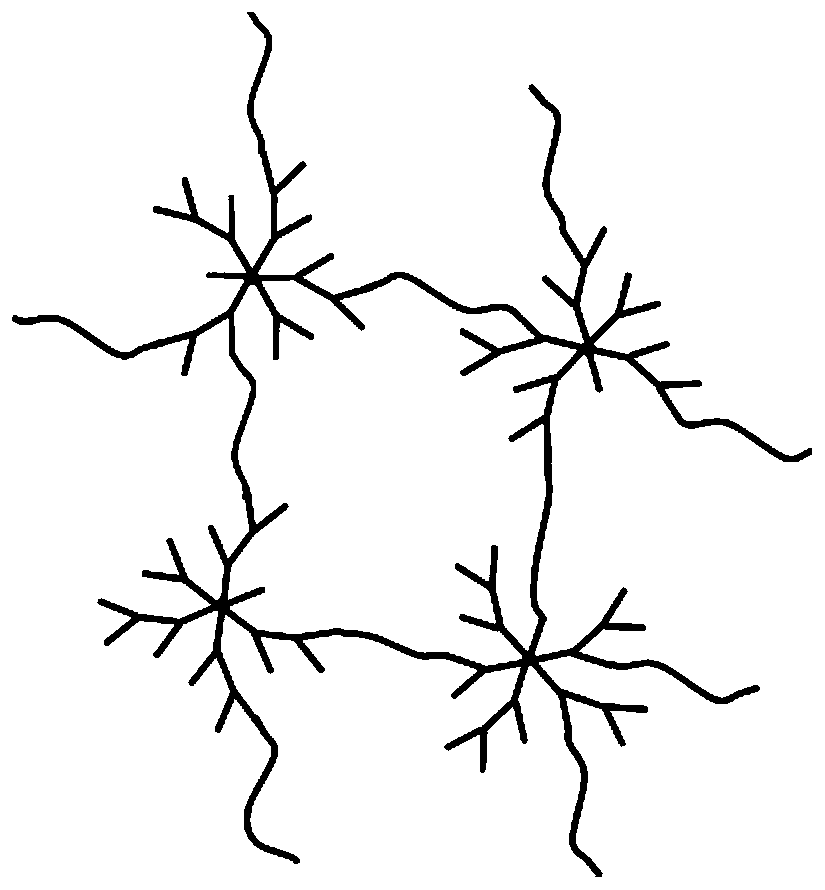

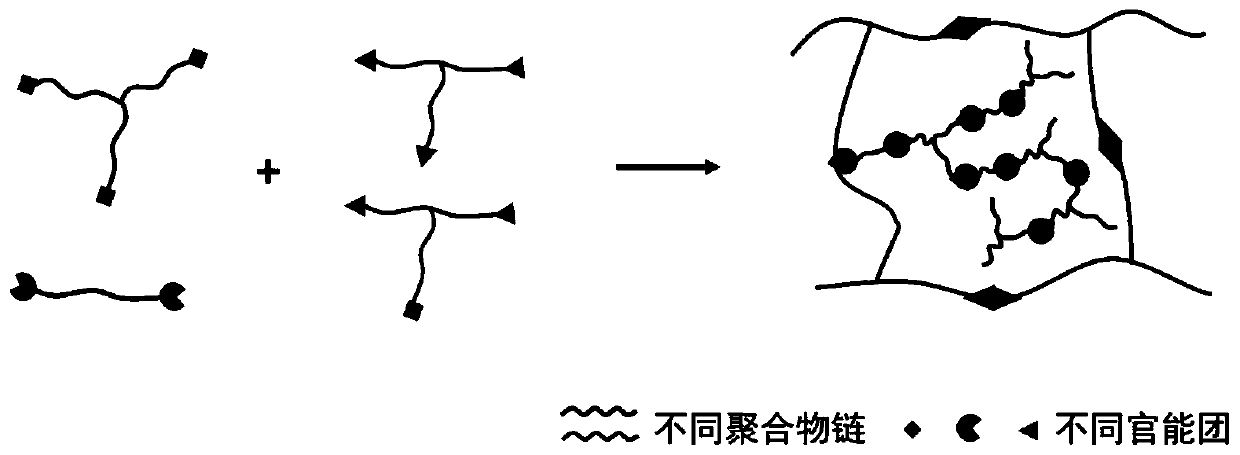

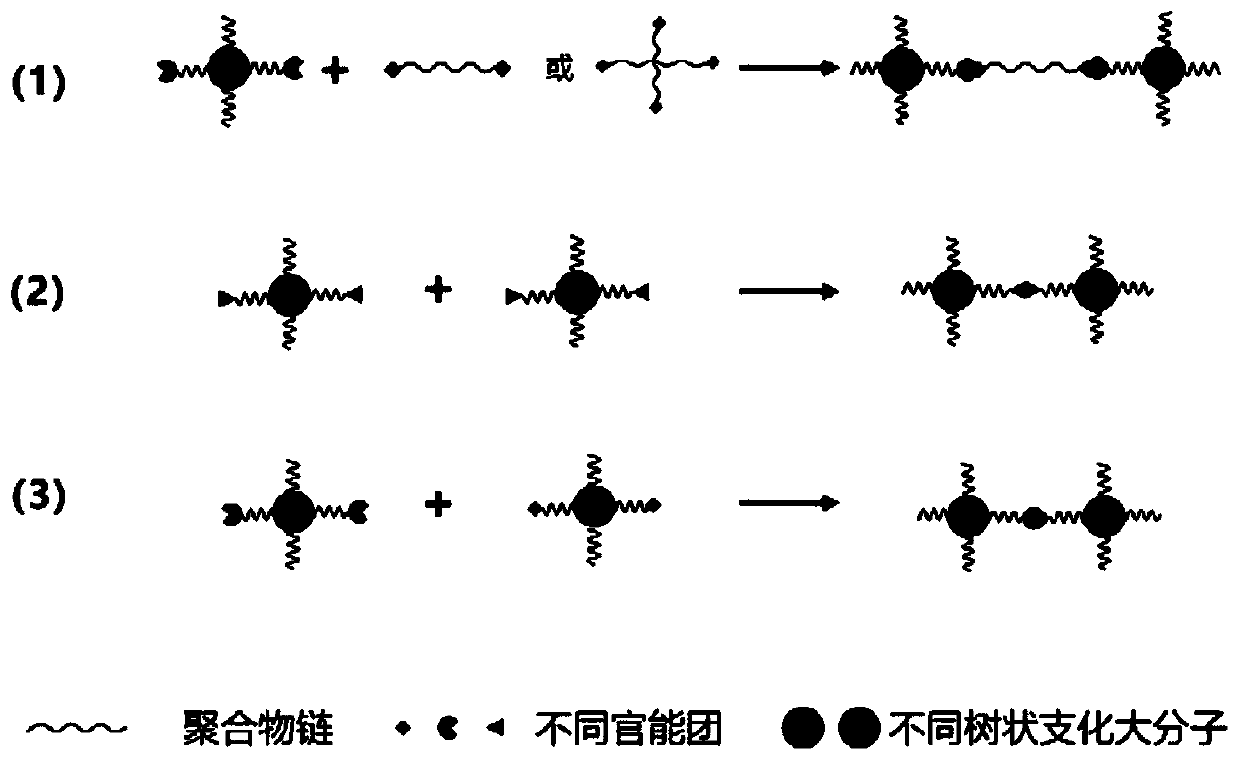

Preparation method of topological elastomer with highly branched structure and low modulus and high elasticity

The invention discloses a preparation method of a topological elastomer with a highly branched structure and low modulus and high elasticity. The topological elastomer contains dendritic branched macromolecules, and the preparation method comprises the following steps: mixing a plurality of monomers by a direct cross-linking method, reacting, and simultaneously carrying out cross-linking reactionand highly branched structure forming reaction to directly obtain the topological elastomer; or a post-crosslinking method: firstly synthesizing dendritic branched macromolecules with a highly branched structure, and then crosslinking the dendritic branched macromolecules by using a crosslinking agent to obtain the topological elastomer; or a grafting method: grafting unreacted monomers or dendritic branched macromolecules into the polymer network to form the topological elastomer; or a copolymerizing method: copolymerizing unreacted monomers or dendritic branched macromolecules and a polymernetwork to form a network or double-network / interpenetrating network elastomer. The topological elastomer prepared by the preparation method can realize low modulus on the premise of keeping high elasticity.

Owner:ZHEJIANG UNIV

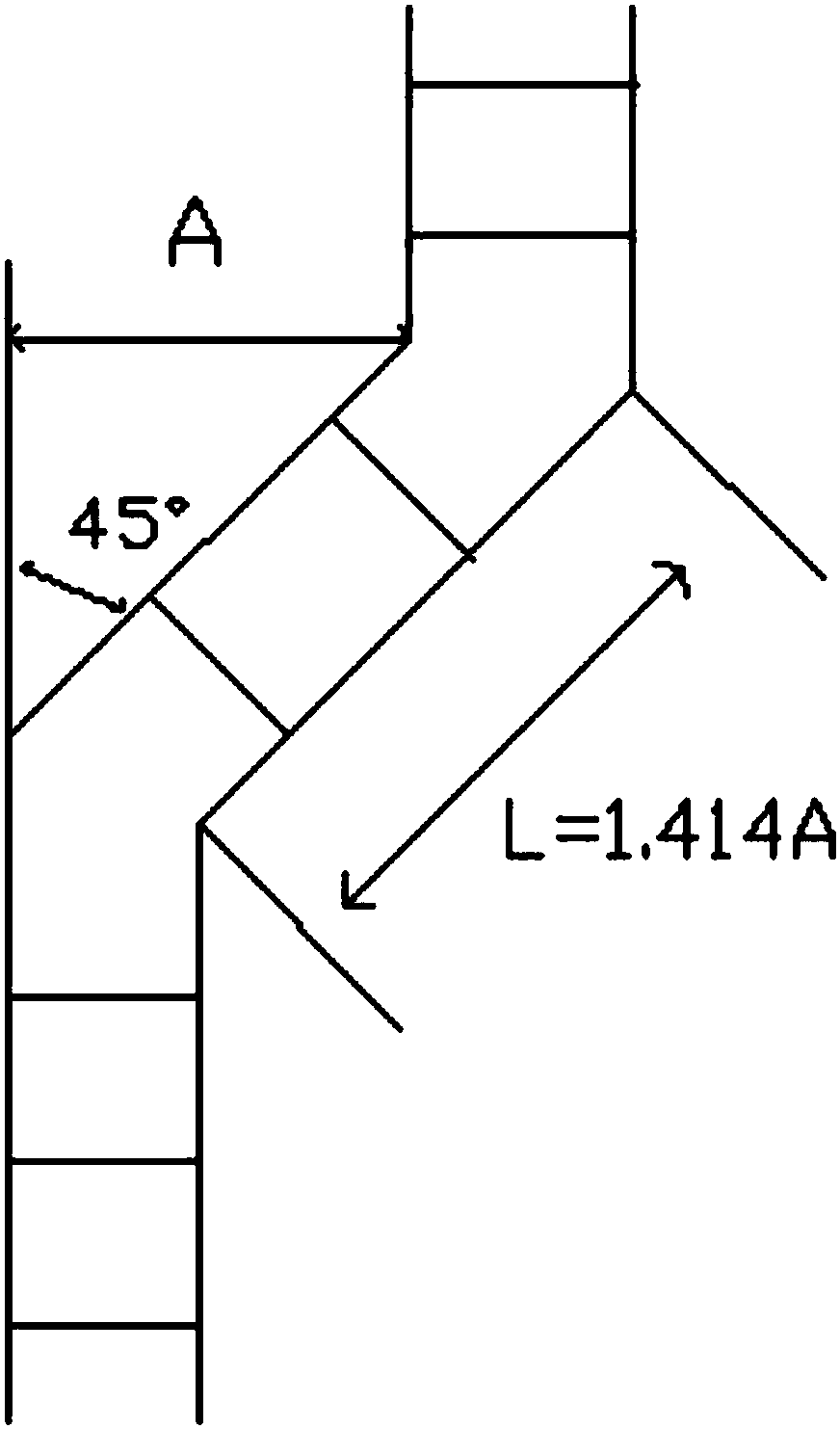

Method for manufacturing cable bridge elbow

InactiveCN108213856AGuaranteed preparation efficiencyGuarantee product qualityElectrical apparatusRebarManufacturing efficiency

The invention relate to a method for manufacturing a bridge elbow, in particular to a method for manufacturing a cable bridge elbow. The method comprises the following steps: (1) at the joint of a home-made cable bridge elbow, a bending elbow and a tee joint, conducting spot welding fixation on the inner side and burnishing a burr coating, then keeping the outer side flat, ensuring that a gap is 5-10mm, and keeping a saw kerf smooth and tidy; (2) enabling the cable bridge elbow not to be misaligned, and ensuring that the welded joint is burnished to be smooth; and (3) when adding reinforcing steel bars in a tray type cable bridge, increasing round steel with the diameter of 6-8MM, and brushing paint on the inner side and the outer side. The method has the advantage of ensuring the manufacturing efficiency and quality of the elbow.

Owner:宜宾市叙州区伍益砖厂

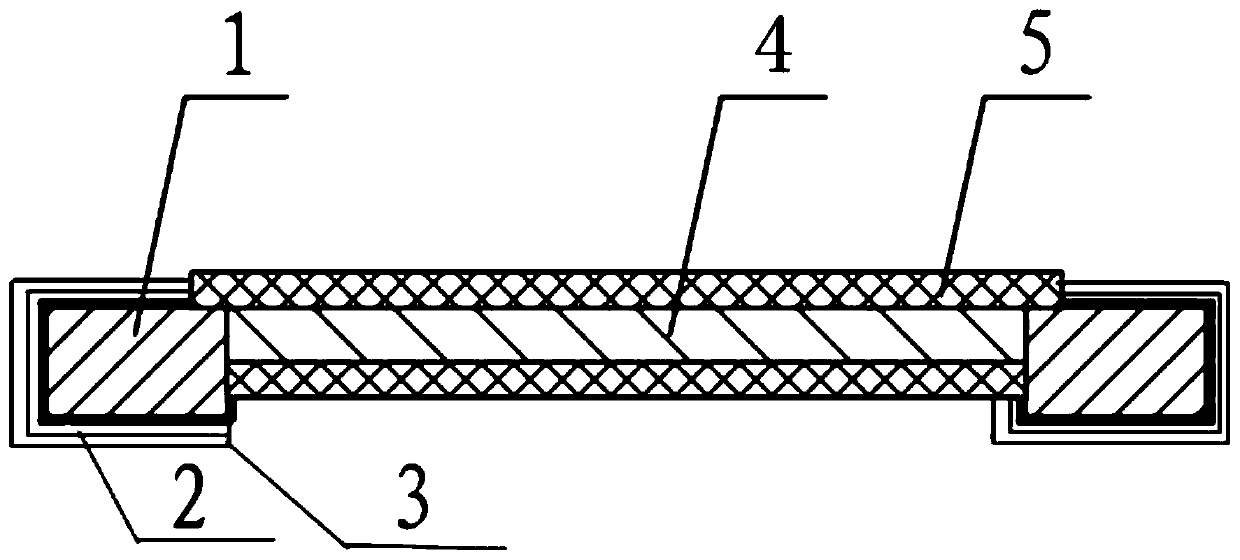

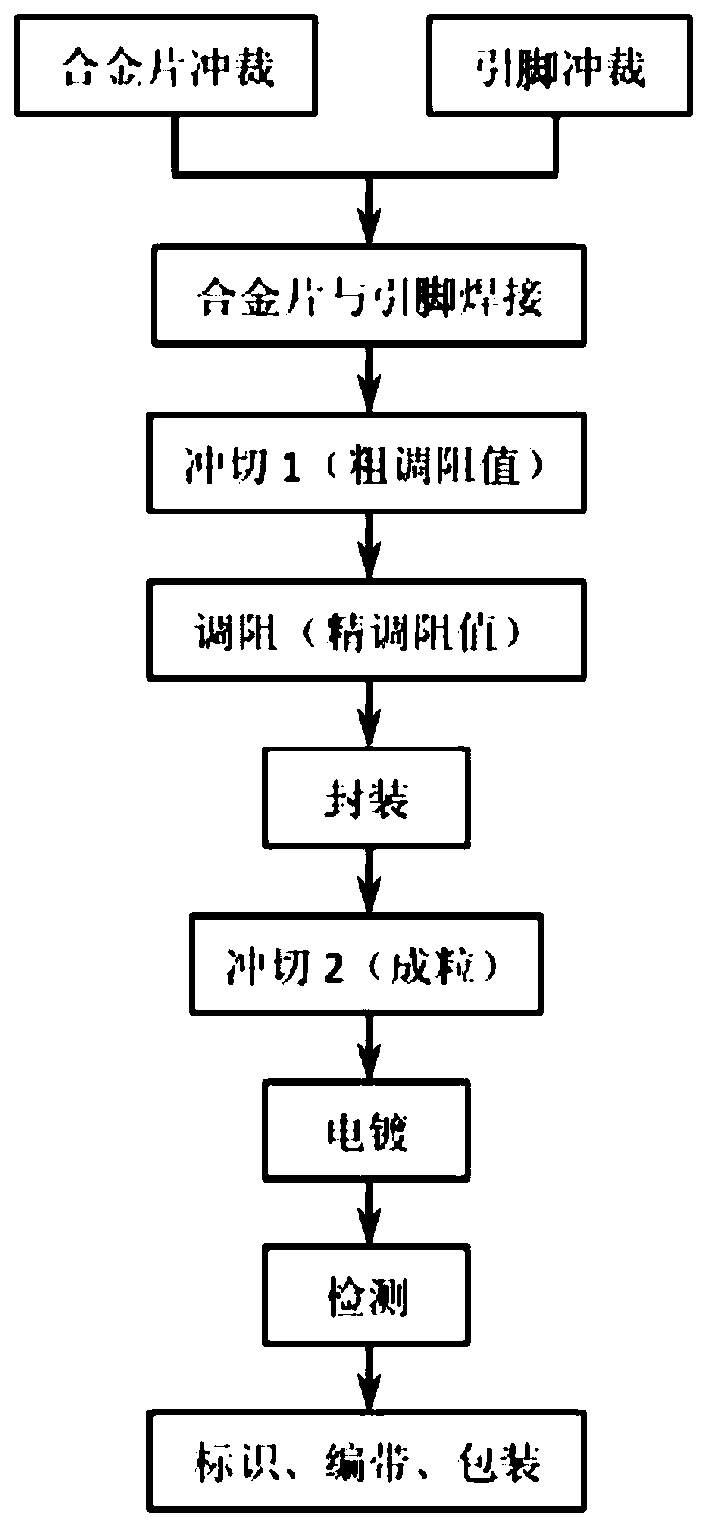

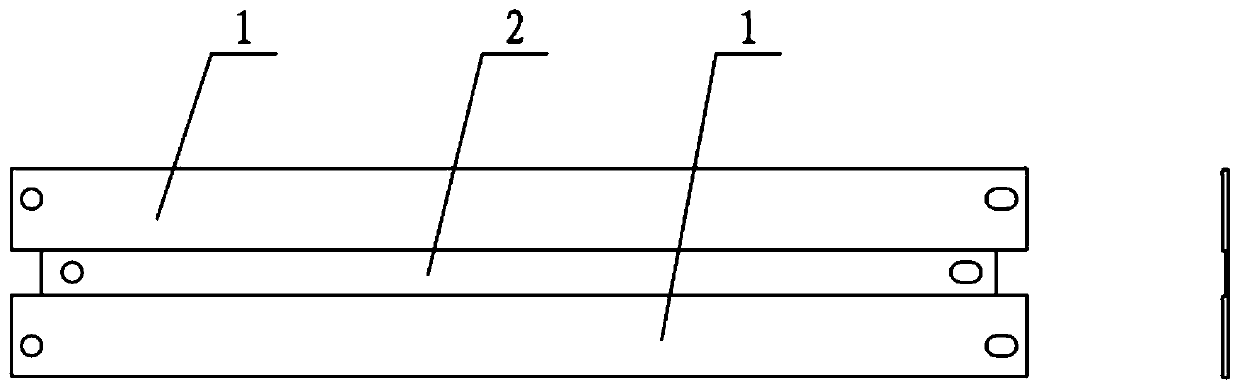

Sheet metal resistor and manufacturing method thereof

InactiveCN109841365AGuaranteed preparation efficiencyGuaranteed positioning accuracyEnvelope/housing resistor manufactureResistor trimmingPunchingBand shape

The invention discloses a sheet metal resistor and a manufacturing method thereof. The sheet metal resistor is composed of an alloy sheet, a lead wire and a shell. The alloy sheet and the lead wire are produced from a strip material. In order to ensure the manufacturing efficiency and positioning accuracy of the parts, the strip material is punched into the lead wire and the alloy sheet by continuous die punching. The alloy sheet and the lead wire after punching contain process holes for positioning, and the alloy sheet and the lead wire after punching are welded together to form a resistor body. In order to meet the accuracy requirements, the resistance adjustment of the resistor body includes two steps: rough adjustment and fine adjustment. The resistance value after rough adjustment reaches more than 95% of the target resistance value, and the resistance value after fine adjustment achieves the accuracy range of the target resistance value. The resistor body after resistance adjustment is encapsulated in a strip material form, which improves the efficiency of operation. The encapsulated stripe-shaped resistor body is punched into single resistors. A nickel layer and a tin layerare formed by electroplating on the surface of the lead wire of each single resistor, which improves the wettability of welding.

Owner:常德思高技术有限公司

Cell cryopreservation liquid capable of enabling cells to survive for long time, cell preparation and preparation method

InactiveCN105340877AImprove survival rateReduce the risk of contaminationDead animal preservationCryopreservationObserved Survival

The invention discloses cell cryopreservation liquid capable of enabling cells to survive for long time, a cell preparation and a preparation method. The cell cryopreservation liquid is mixed liquid containing human serum albumins and CryoSure-DEX40 cryopreservation liquid. The cell preparation comprises the cell cryopreservation liquid provided by the invention and cells. The preparation method comprises the following steps: uniformly mixing the CryoSure-DEX40 cryopreservation liquid and the human serum albumins to form the cell cryopreservation liquid capable of enabling the cells to survive for long time and the cell cryopreservation liquid is slowly injected into washed cell sediment; and the cell cryopreservation liquid is injected and then is uniformly mixed to finally form the cell preparation. After the cell preparation prepared by the preparation method provided by the invention is cryopreserved for long time or transported for a long distance, the survival rate of the cells is still very high; and the cell cryopreservation liquid has a clinic-grade application value; and the limitation that a previous cell preparation can be transported while being prepared is broken through and a utilization geographical range of the cell preparation is enlarged.

Owner:北京佳宸弘生物技术有限公司

Preparation method and application of ultra-micro silver-loading titanium dioxide photocatalyst

PendingCN108273499ALow silver loadingSilver loaded content is quite low, lowWater/sewage treatment by irradiationWater contaminantsDispersityFreeze-drying

The invention discloses a preparation method of an ultra-micro silver-loading titanium dioxide photocatalyst, which belongs to the field of the preparation of inorganic metal oxide nano composite materials. The preparation method is characterized by comprising the following steps: a, mixing: adding a silver nitrate alcoholic solution in an ethanol solution with dissolved titanium dioxide P25, anddispersing the mixed solution in an ultrasonic crushing instrument; b, photoreaction: pouring the dispersed solution into a quartz reactor, illuminating by using a 300W mercury lamp, introducing nitrogen to prevent nano silver generated in a reduction manner from being oxidized; and c, drying: centrifuging the solution subjected to photoreaction, removing supernatant, freeze drying precipitates ina vacuum freeze drying machine, after freeze drying for 36 hours, taking out the precipitates, and grinding, thus obtaining the ultra-micro silver-loading titanium dioxide photocatalyst. The ultra-micro silver-loading titanium dioxide photocatalyst disclosed by the invention has the advantages of very low silver content, good dispersity, large specific surface area, short entire preparation time,and capability of greatly increasing the preparation efficiency.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Shoemaking glue production equipment based on wheel transmission

InactiveCN110975679AImprove mixing effectAvoid Stirring Dead AngleRotary stirring mixersTransportation and packagingAdhesive gluePiston cylinder

The invention relates to the technical field of shoemaking glue production equipment, in particular to shoemaking glue production equipment based on wheel transmission. According to the invention, a second servo motor is adopted for driving, and a third rotating shaft is driven to rotate through wheel transmission, so a stirring rod stirs and mixes raw materials in a stirring barrel for glue making; a water bath barrel is arranged for water bath heating of the stirring barrel and for conduction of heat treatment, so preparation efficiency is guaranteed; a feeding assembly is arranged, multi-specification piston cylinders are adopted and correspond to raw material proportions, and piston rods of the piston cylinders are connected into a whole through a moving rod, so unified moving is achieved; a lead screw assembly is arranged, a second rotating shaft is driven to rotate through wheel transmission, so a reciprocating lead screw is allowed to rotate, a moving block is allowed to reciprocate up and down, and due to the fact that a C-shaped clamping plate clamps the moving rod, the lead screw assembly drives the moving rod to reciprocate up and down and power is provided for the feeding assembly; and the C-shaped clamping plate is detachably connected with the moving rod, so adjustment is convenient, and therefore, a feeding function can be added or eliminated.

Owner:安徽粒粒信数据科技有限公司

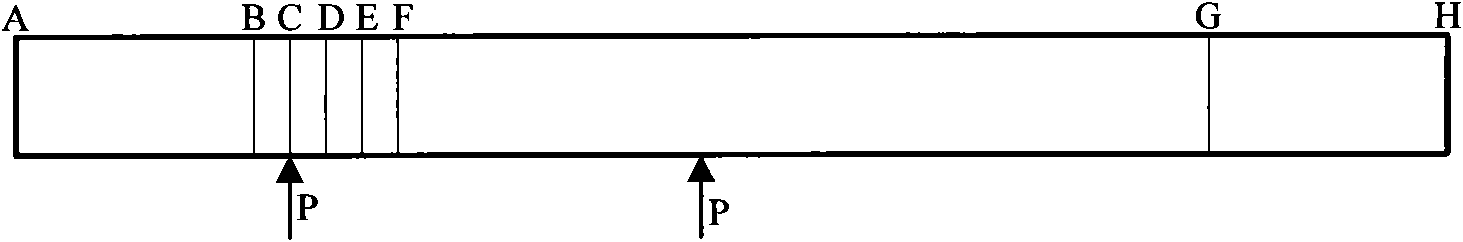

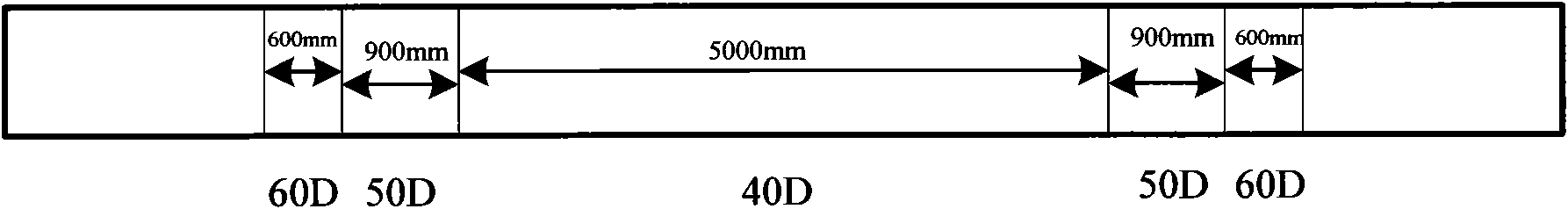

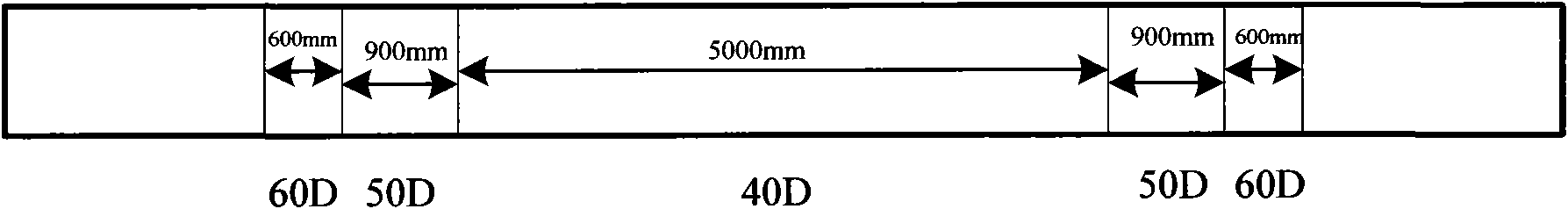

Method for manufacturing variable curvature cold bent pipe

The invention relates to a method for manufacturing a variable curvature cold bent pipe, which comprises the following steps of: (1) starting cold bending, namely performing bending by adopting a curvature radium of 45D to 60D at a cold bending start part in 2 meters apart from the pipe end; (2) after the bending length reaches 1.5 meters, performing bending by adopting a curvature radium of 40D; and (3) when the bending is performed to 3.5 meters apart from the other pipe end, and completing the bending of the whole steel pipe. Because of small curvature at the pipe end of the bent pipe, the ellipticity of the pipe end can be ensured; because the part of the pipe body apart from the pipe end is bent by adopting large curvature, the manufacturing efficiency can be improved, and the bent pipe with large angle is manufactured in an effective bending length can be ensured; and by the bending process, the appearance quality and manufacturing efficiency of the bent pipe are guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

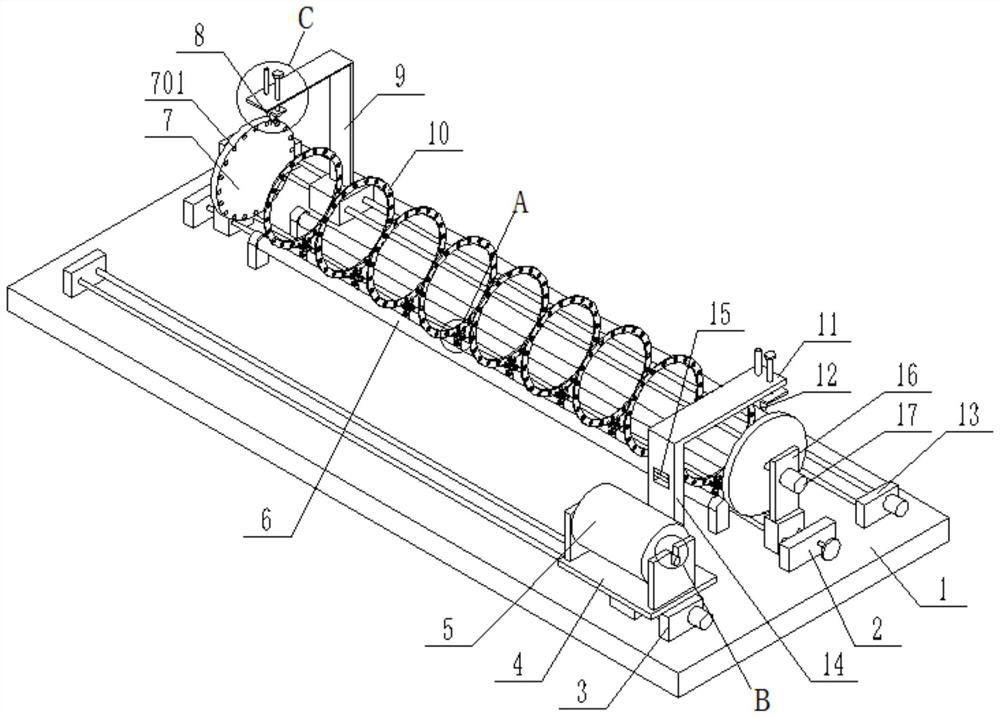

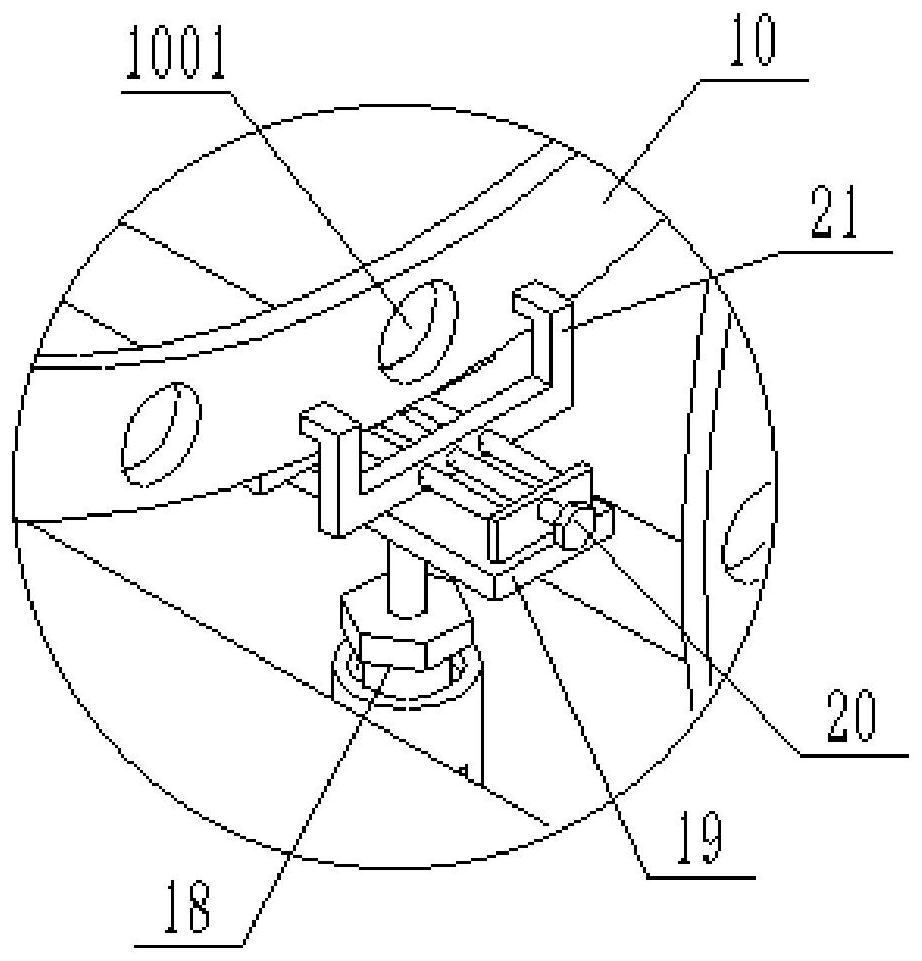

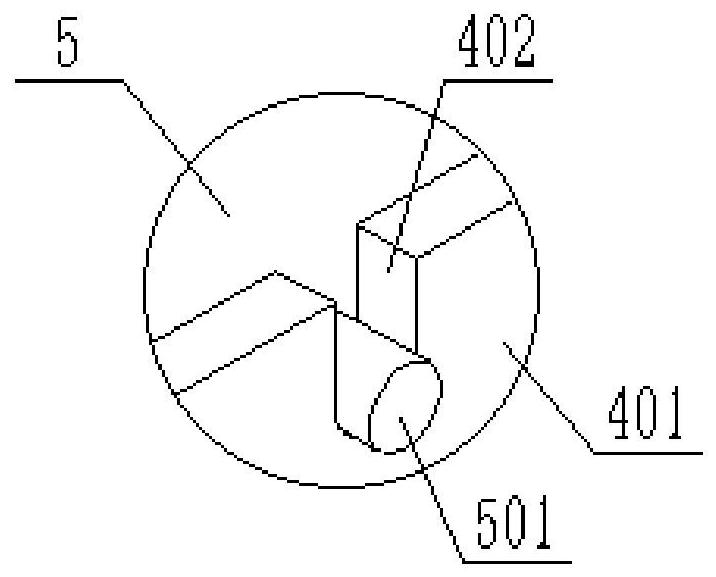

Bridge pier reinforcement cage winding device

InactiveCN113351806AAvoid lifting deformationGuarantee product qualityWire networkRebarMechanical engineering

The invention discloses a bridge pier reinforcement cage winding device which comprises a base and a framework ring. Two auxiliary supporting rollers are rotationally installed on the surface of the base, a height adjusting rod is arranged between the two auxiliary supporting rollers, a mounting plate is connected to the lifting end of the height adjusting rod, and two clamping rods are arranged on the surface of the mounting plate; a first moving assembly and a second moving assembly are arranged on the surface of the base, the moving end of the second moving assembly is connected with a bearing frame, and a second welding head is arranged on the surface of the bearing frame; and the moving end of the first moving assembly is connected with a bearing plate, the surface of the bearing plate is provided with a steel bar winding drum and a fixed vertical plate, the upper part of the bearing plate is connected with a bearing beam, and the surface of the bearing beam is provided with a first welding head. The bridge pier reinforcement cage winding device has the beneficial effects that framework weaving of the reinforcement cage and winding of external reinforcing steel bars can be achieved in sequence, the reinforcement cage framework does not need to be moved or hoisted, hoisting deformation of the reinforcement cage framework is prevented, and the manufacturing quality and the efficiency of the bridge pier reinforcement cage are guaranteed.

Owner:姚云生

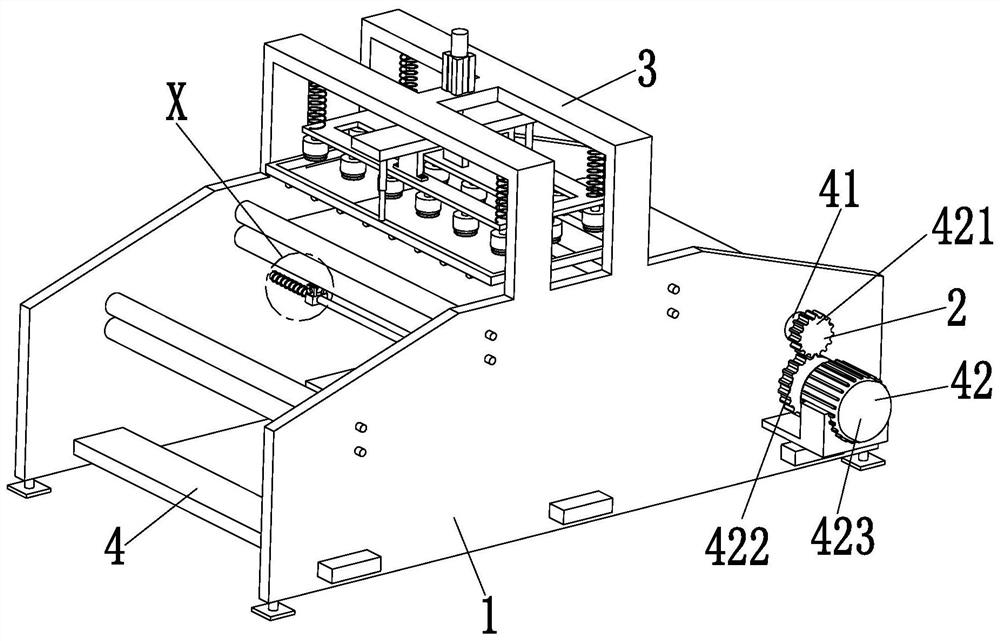

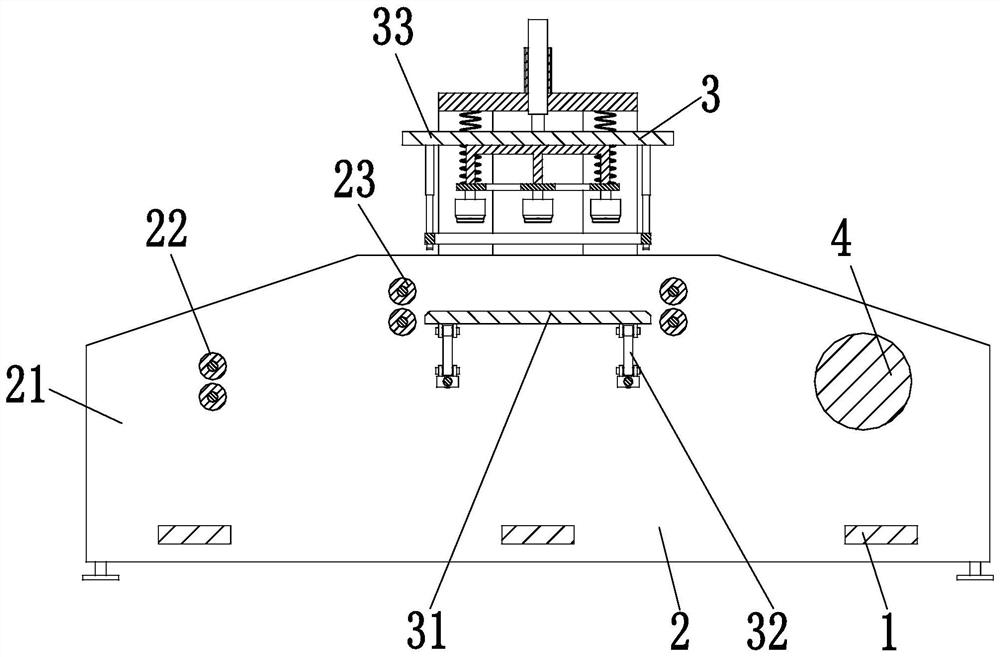

Paint preparation process and preparation device

ActiveCN110628328AGuaranteed preparation efficiencyImprove efficiencyTransportation and packagingMixersEngineeringSolvent

The invention relates to a paint preparation process, which comprises the steps of raw material preparation, solid grinding, raw material mixing and remaining material adding. The preparation device comprises a rack, and a grinding apparatus, a solid feeding assembly and a dispersing apparatus that are respectively mounted on the rack from top to bottom. The invention has the beneficial effects that: the solvent and solute are respectively filtered and crushed before mixing so as to improve the subsequent paint preparation efficiency and effect.

Owner:浙江富思丽涂料有限公司

Sheep tail grease fancy soap and production method thereof

The invention belongs to the field of preparation of fancy soaps and in particular relates to a sheep tail grease fancy soap and a production method thereof. The sheep tail grease fancy soap is prepared from the following components in percentage by weight: 20 percent to 27 percent of sheep tail grease, 20 percent to 27 percent of olive oil, 10 percent to 14 percent of coconut oil, 5 percent to 10 percent of Shea butter and 30 percent to 33 percent of sodium hydroxide with the concentration of 30 percent to 35 percent. The production method of the sheep tail grease fancy soap comprises the following steps: refining the sheep tail fat, blending compound grease, carrying out saponification reaction and molding and so on, so as to prepare the sheep tail grease fancy soap; the sheep tail grease fancy soap has the beneficial effects that the sheep tail grease fancy soap has strong cleaning powder, is moderate and moist and can be used for inhibiting skin inflammations; the sheep tail grease fancy soap has low production cost and no goaty flavor and the problems that the sheep tail grease is difficultly used in the preparation of the fancy soaps and the like are solved.

Owner:内蒙古高雅乐生物科技有限责任公司

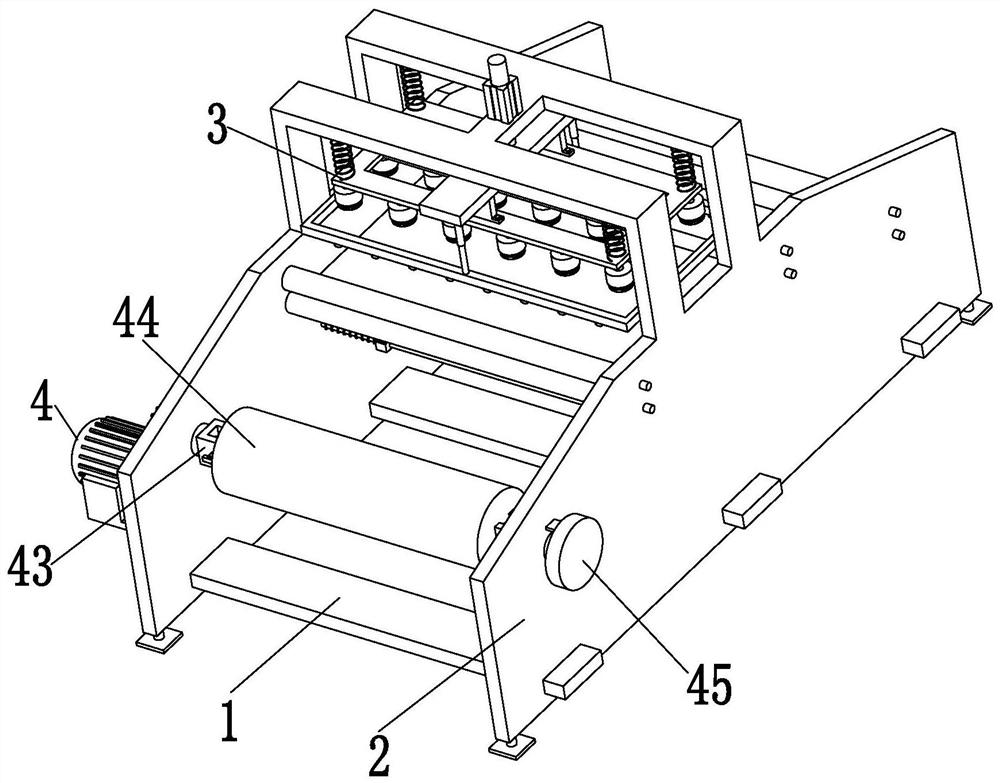

Self-adhesive label manufacturing die-cutting machine and die-cutting method

InactiveCN113021519AGuaranteed preparation efficiencyAvoid lifting or even strippingMetal working apparatusAdhesiveStructural engineering

The invention relates to a self-adhesive label manufacturing die-cutting machine and a die-cutting method. The self-adhesive label manufacturing die-cutting machine comprises connecting bottom plates, mounting plates, a die-cutting device and a driving device, wherein the mounting plates are symmetrically fixed on the front sides and the rear sides of the connecting bottom plates uniformly arranged, the die-cutting device is arranged in the middle portion between the mounting plates, and the driving device is arranged on the right side of a space between the mounting plates. The self-adhesive label manufacturing die-cutting machine and the die-cutting method can solve the problems that the die cutting effect is affected due to the fact that self-adhesive residues are prone to be accumulated at cutting edges of cutters during self-adhesive label die cutting, meanwhile, self-adhesive labels are taken up and even peeled off due to the fact that the self-adhesive labels possibly move along with the cutters, and the self-adhesive labels are wasted due to the fact that when the self-adhesive labels are subjected to die cutting treatment, winding of the self-adhesive labels needs to be stopped and then die cutting is carried out, at the moment, the self-adhesive labels are prone to reversely move, the tensioning degree of the self-adhesive labels is reduced, the die cutting positions are changed, and the die cutting positions possibly are inaccurate in serious cases.

Owner:刘芳芳

Manufacture method of eccentric shaft with three relative angles

ActiveCN107398682AGuaranteed preparation efficiencyGuaranteed manufacturing accuracyEngineeringMachining

The invention provides a manufacture method of an eccentric shaft with three relative angles. The method includes the following steps: performing cylindrical cutting of a shaft portion a, a shaft portion b, a shaft portion c, a shaft portion d and a shaft portion e of the concentric portion; machining key slots in the shaft portion a, the shaft portion b and the shaft portion c; manufacturing a clamp a which comprises a cylindrical body a concentric with an eccentric shaft portion and a mounting slot a formed in the cylindrical body a and matched with the shaft portion a; after installing the shaft portion a and the shaft portion b to the clamp a, performing cutting machining on the eccentric shaft portion after clamping the clamp a; manufacturing a clamp b which comprises a cylindrical body b concentric with the eccentric shaft portion and a mounting slot b formed in the cylindrical body b and matched with the shaft portion a, and arranging the cylindrical body b as a clamping plane; after arranging the shaft portion a and the shaft portion b to the clamp b, machining the machining face on the eccentric shaft after clamping the clamp b. Through the method, manufacture efficiency and manufacture precision of the eccentric shaft with three relative angles can be assured.

Owner:苏州达博思智能电网装备制造有限公司

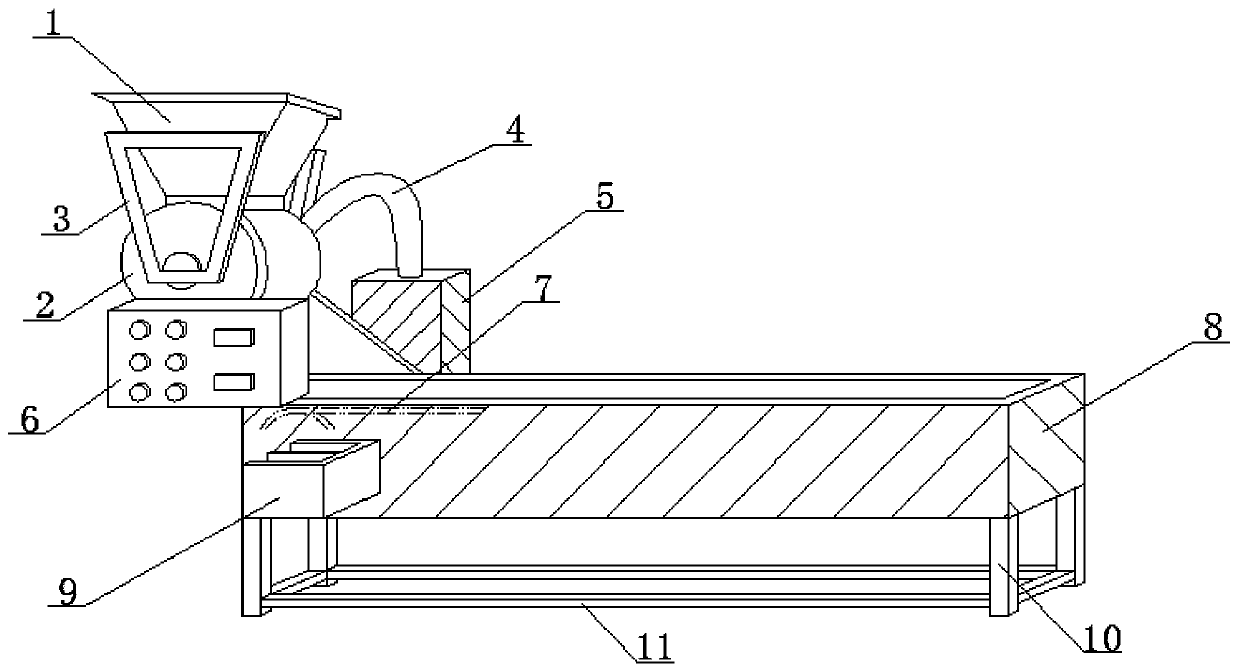

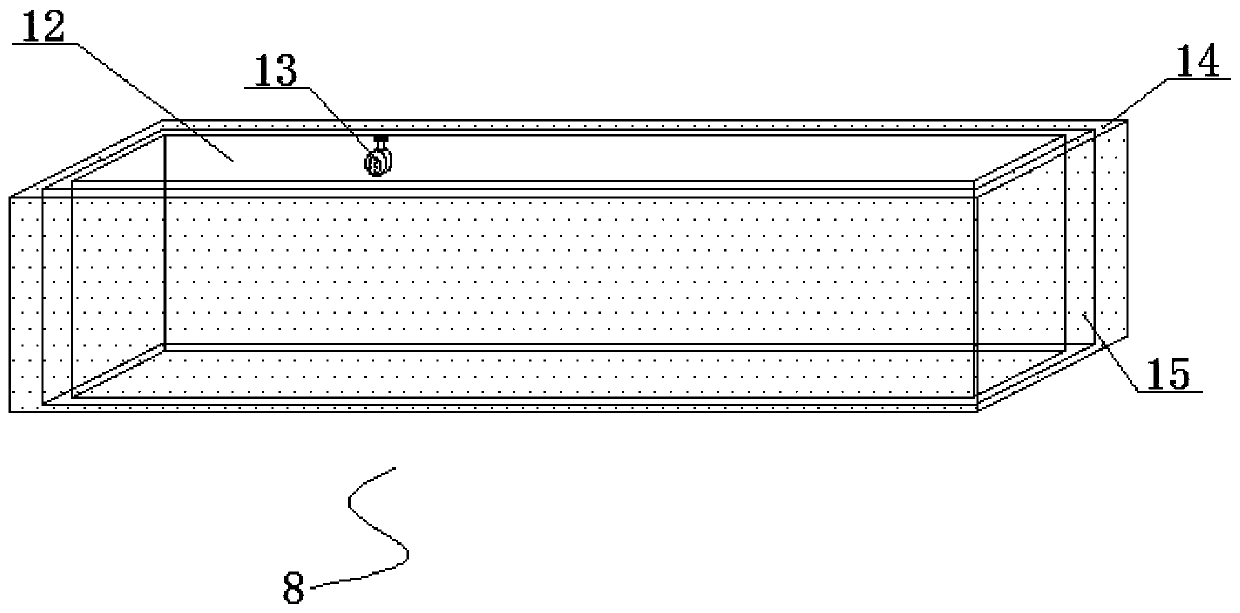

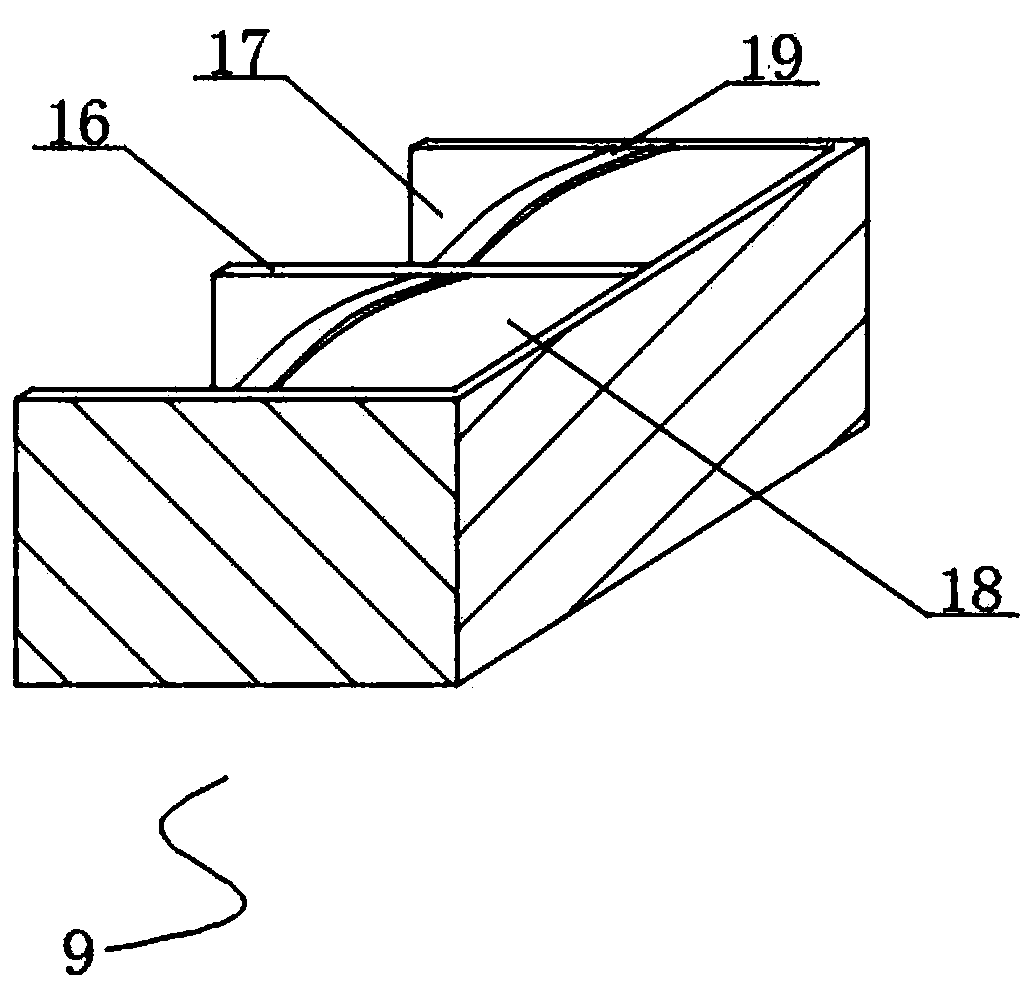

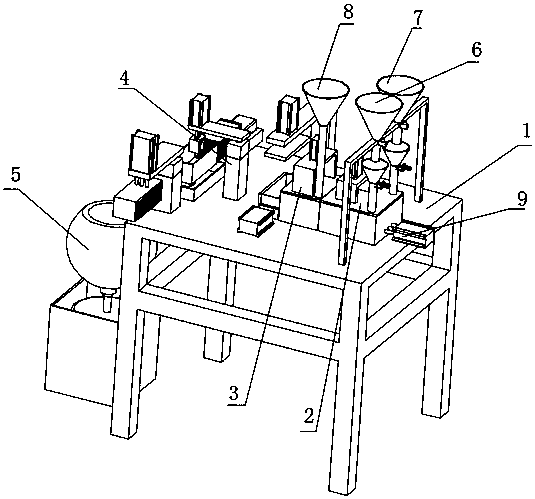

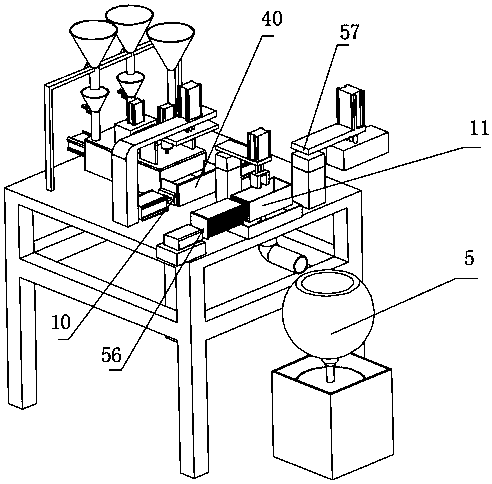

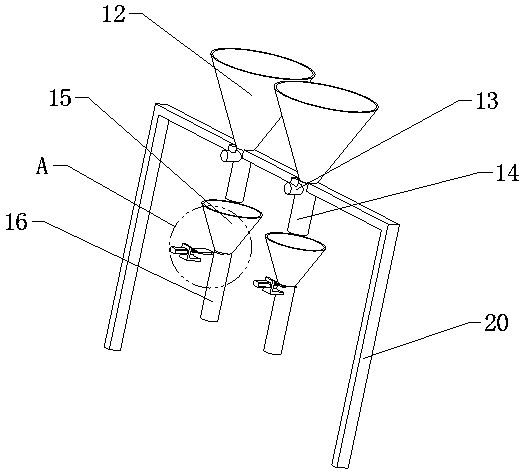

Vegetable cake processing and making device

ActiveCN109820006ASimple structureEasy to useHollow article cleaningDough embossing machinesNutrient deficiencySlurry

The invention discloses a vegetable cake processing and making device, relates to the technical field of food processing equipment. The vegetable cake processing and making device can achieve automatic making of all processes of continuous batching, forming, drying and transportation, is high in efficiency, sequentially carries out drying, prevents the problems of delicious taste caused by too fast drying and the like, reduces nutrient deficiency and ensures nutritional value. According to the vegetable cake processing and making device, a mold is adopted for making, the forming speed is high,the structure is simple, and a compaction forming assembly is used for compacting discharged slurry in a forming mold on a forming workbench so as to form a cake-shaped structure in the forming mold;formed vegetable cakes sequentially pass through a primary drying assembly and a secondary drying assembly to be dried under the rotation of the forming workbench and then are pushed to be dischargedby a pushing discharging assembly, a discharging hole for discharging the formed cakes is formed in a bearing platform, the forming mold from which the vegetable cakes are ejected is cleaned by a mold cleaning assembly and then rotates to the position below the compaction forming assembly, and the making efficiency is guaranteed.

Owner:GUIZHOU UNIV OF ENG SCI

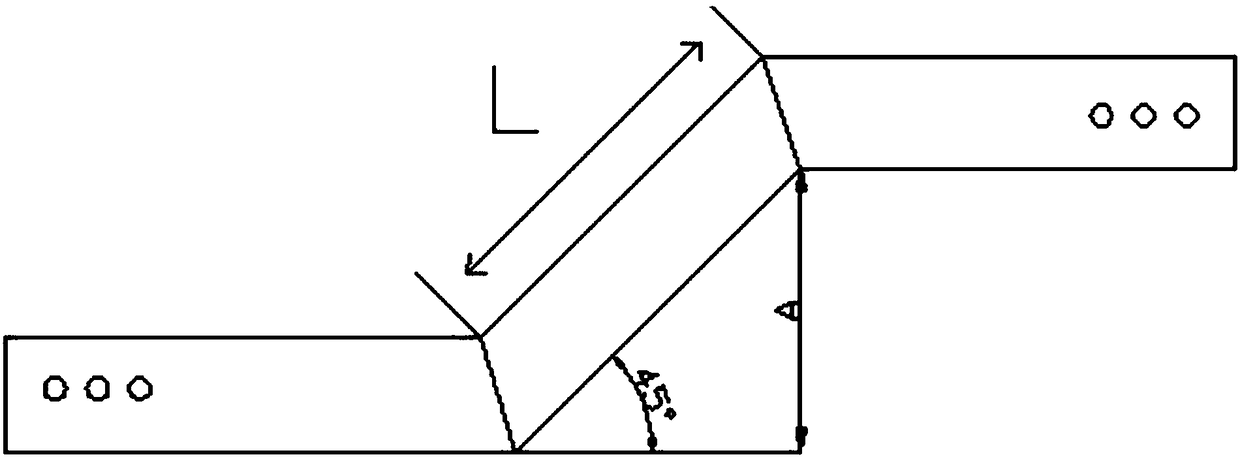

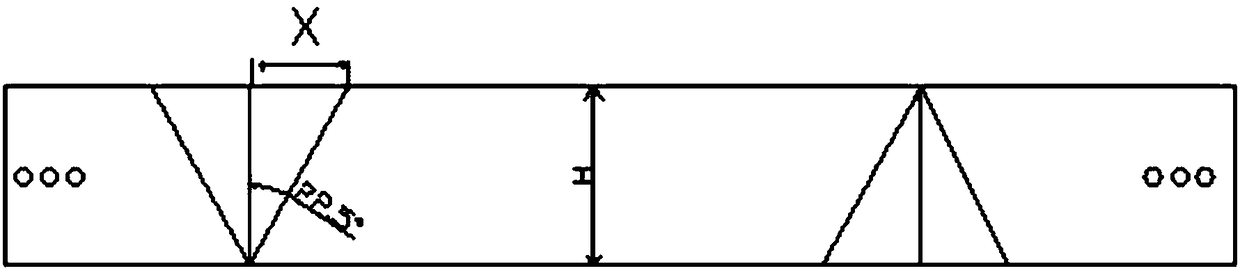

Assembly method for ensuring equipment overall coaxiality in pressure vessel for chemical industry

ActiveCN103170773AGuaranteed coaxialityGuarantee quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesChemical industryEngineering

The invention provides an assembly method for ensuring equipment overall coaxiality in a pressure vessel for chemical industry. At first, U-V-shaped grooves are processed at two ends of each tube sections to be assembled, and then reference surfaces are processed below V-shaped grooves of the U-V-shaped grooves on the inner wall of the tube sections, an axis of each tube section is simulated according to the reference surfaces of two ends of the tube section as measuring basis, and when tube sections are assembled, the axis of each tube section is located on the same straight line. According to the assembly method for ensuring equipment overall coaxiality in the pressure vessel for the chemical industry, defects of the prior art are overcome, overall coaxiality of the equipment can be ensured, assembly accuracy is improved, and product quality and manufacturing efficiency are guaranteed.

Owner:SHANGHAI BOILER WORKS

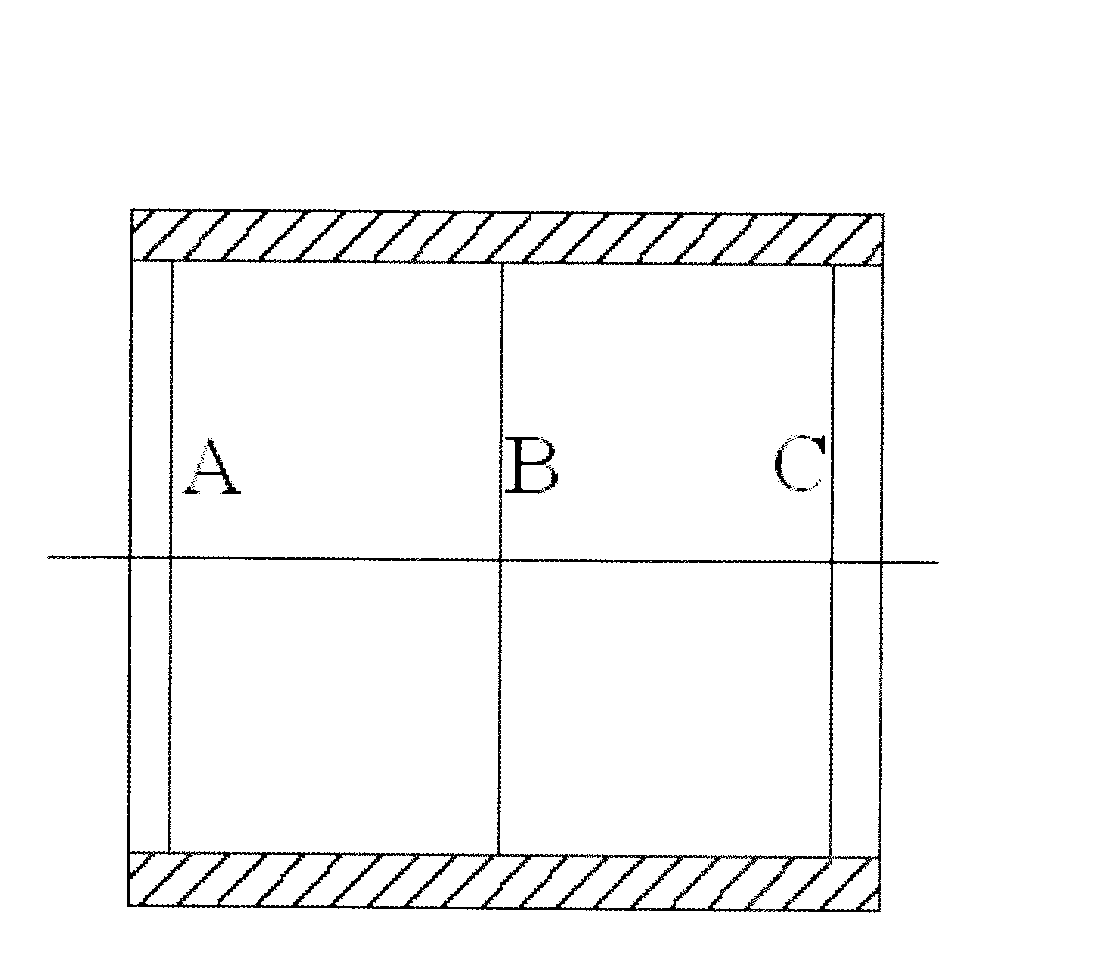

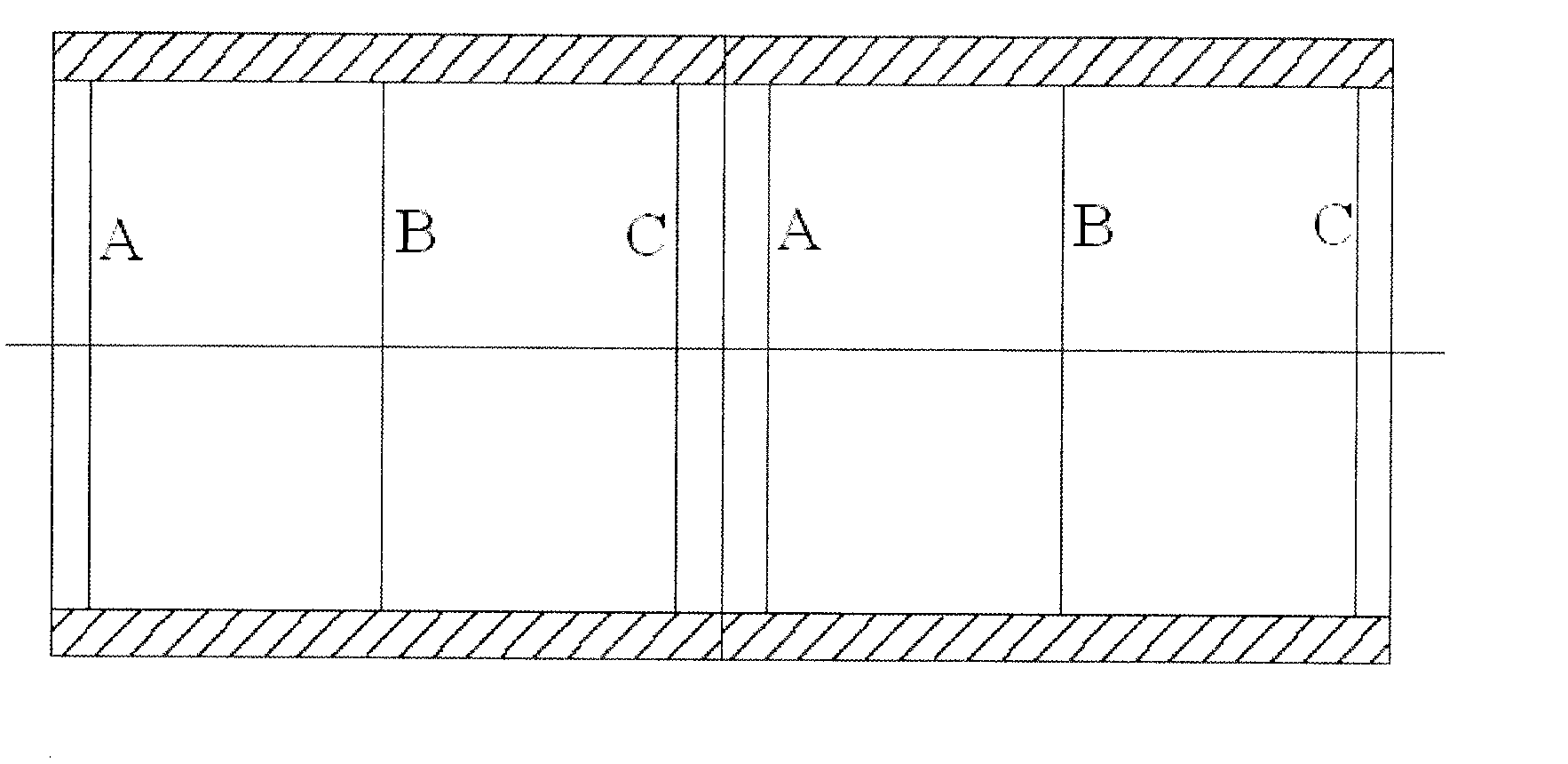

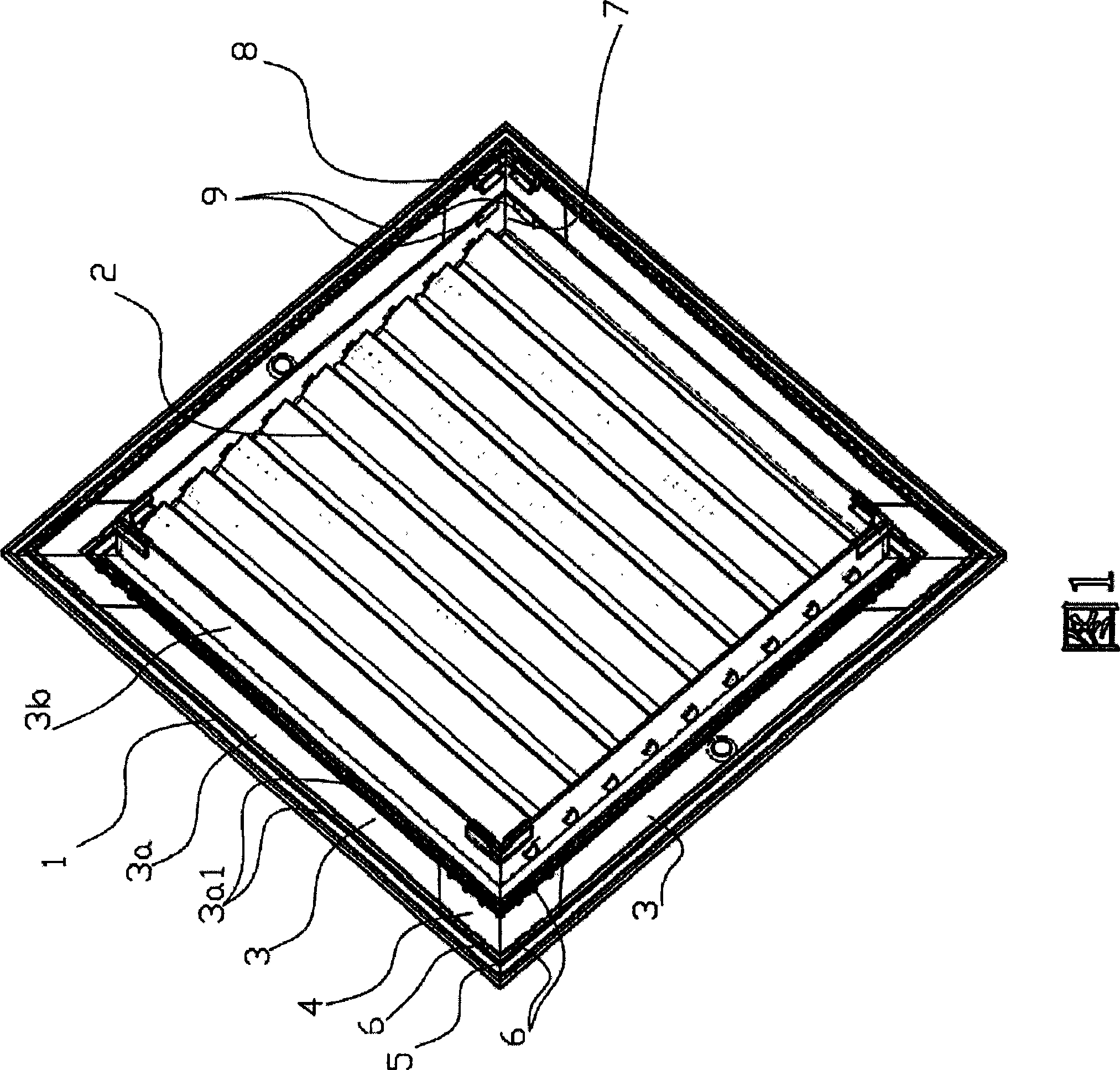

Air port

InactiveCN101387432AFirmly connectedThe connection is tight and firmDucting arrangementsAir-flow control membersQuality assuranceManufacturing efficiency

The invention discloses an air inlet, which is characterized in that the air inlet comprises a square air inlet outer frame and wind blades which are arranged in the square air inlet outer frame, wherein the square air inlet outer frame is formed by connecting four aluminum alloy sections which are butted at an angle of 45 degrees, each aluminum alloy section consists of a panel part and a air inlet wall part which is perpendicular to the panel part, the backside of the panel part of the aluminum alloy section is provided with an inlay groove, a right-angle fixing sheet is arranged in the inlay groove, and a right-angle type connecting clamp is formed on the right-angle air inlet wall formed by butting the two aluminum alloy sections at the angle of 45 degrees. Compared with the prior art, the air inlet has the advantages of firm connection, quality assurance, compact and smooth connection of connecting surfaces and high manufacturing efficiency.

Owner:梁浩鉴

Bearing roller press assembling auxiliary clamping device for supporting frame

InactiveCN107542793AAvoid forcing the bearing frameAvoid the situationBearing componentsBraced frameMechanical engineering

The invention relates to an auxiliary clamping device for bearing roller press fitting of a support frame, comprising a support, a bearing inner frame fixing seat is arranged in the middle of the support, and a bearing outer frame pressing device is arranged on both sides of the support; The outer frame pressing device includes two sets of pushing mechanisms. The pushing mechanism includes a sliding block that is slidably connected with the support and a linear drive mechanism installed on the support for pushing the sliding block. One of the sliding blocks is provided with a bearing outer frame support mechanism, a bearing outer frame pushing mechanism is arranged on the other sliding block; a guide piece is connected between the tops of the two sliding blocks, and a bearing bracket for controlling the installation height of the bearing is also arranged on the bearing fixing rod. The middle part of the sheet is provided with a bend protruding toward the upper part, and an annular inlay groove is arranged inside the bend, and an annular bearing pressure ring is inlaid concentrically in the inlay groove.

Owner:JIANGYIN JIB WD PRECISION

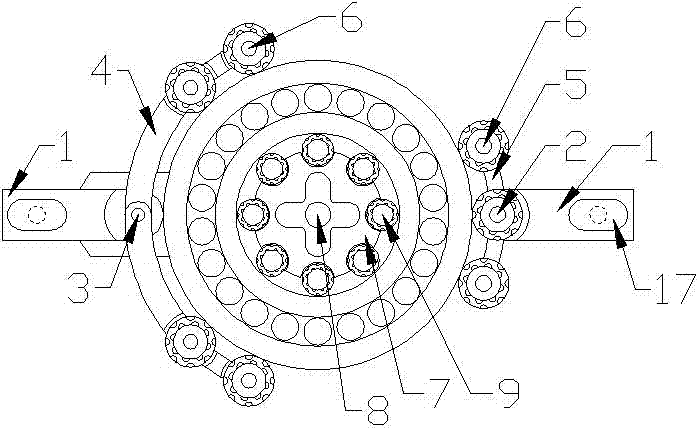

Automatic drilling and detecting machine for lampholder manufacturing

InactiveCN107225262AGuaranteed preparation efficiencyGuarantee product qualityMeasurement/indication equipmentsBoring/drilling machinesBiochemical engineeringDrilling machines

The invention discloses an automatic drilling and detecting machine for lampholder manufacturing. The automatic drilling and detecting machine comprises an index plate rotationally arranged on a machine frame, a plurality of carriers uniformly arranged on the index plate, a drilling assembly a, a drilling assembly b, a detection assembly a and a detection assembly b, wherein the drilling assembly a, the drilling assembly b, the detection assembly a and the detection assembly b are distributed with the index plate as the center, correspond to the carriers and are cooperatively used with the carriers; the index plate is further provided with a feeding assembly in a corresponding mode; the machine frame is provided with a loading assembly which is cooperatively used with the feeding assembly and the carriers arranged on the index plate; and the machine frame is further provided with a discharging assembly which is used with the index plate in a matched mode. The automatic drilling and detecting machine can automatically conduct drilling and communicating treatment on wire holes in a lampholder, and the lampholder manufacturing efficiency and finished product quality are ensured.

Owner:苏州睿立汇自动化科技有限公司

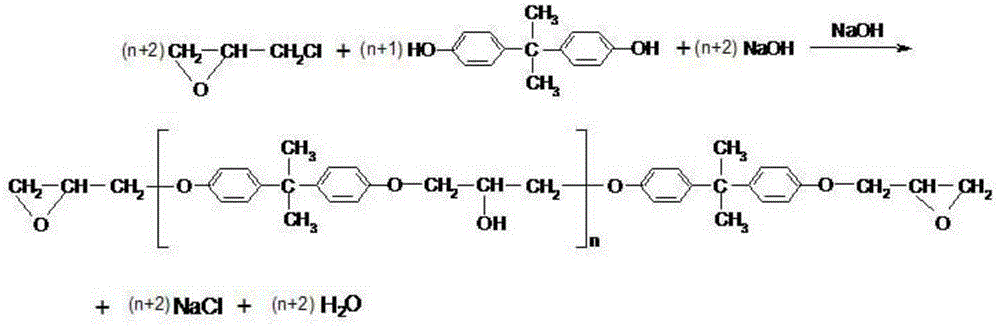

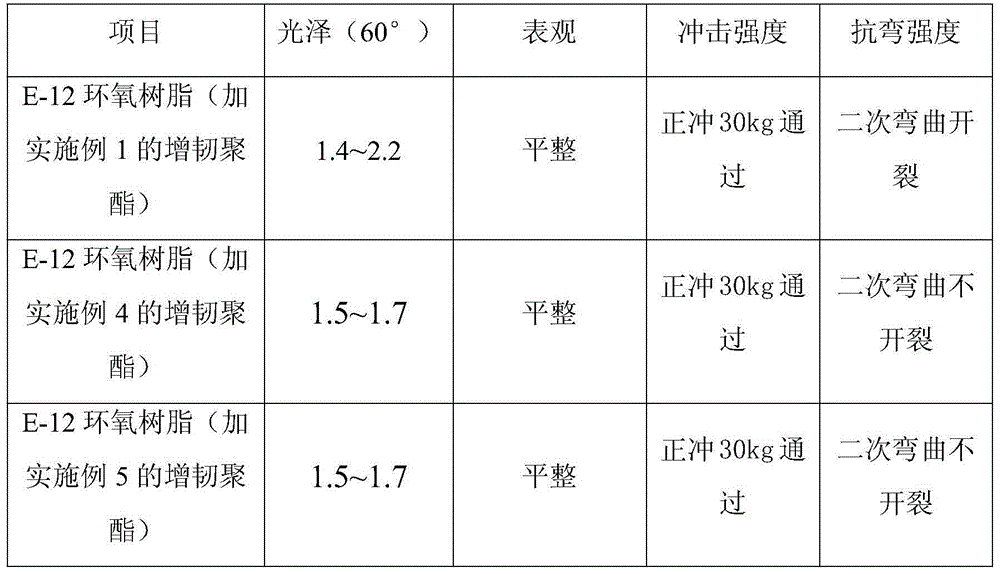

Method for preparing solid epoxy resin toughened polyester

The invention discloses a method for preparing solid epoxy resin toughened polyester. The method comprises the following steps: weighing, mixing, heating and stirring a terephthalic acid and polyol mixture and an esterification catalyst, performing esterification reaction at 175-185 DEG C, heating to 250-260 DEG C for 3.5-4.5 hours, draining the produced water, adding a defoaming agent into the mixture, controlling the vacuum degree to be less than -0.08MPa, vacuumizing for 3-5 hours, cooling, and discharging, thus obtaining a product, wherein the polyol mixture is a mixture of alkylene glycol and an organic waste liquid, and the organic waste liquid is a polyhydroxy organic compound recovered after a saturated salt water byproduct of an epoxy resin active diluent is evaporated and salted out. The solid epoxy resin toughened polyester is prepared by sufficiently using the organic waste liquid produced by preparing the solid epoxy resin active diluent as one of the raw materials, so that the production cost is reduced, the economic benefit of enterprise production is improved, direct discharge of the organic waste liquid is effectively avoided, then resource utilization of wastes is realized, and the method has certain economic benefits and social benefits.

Owner:ANHUI XINYUAN CHEM

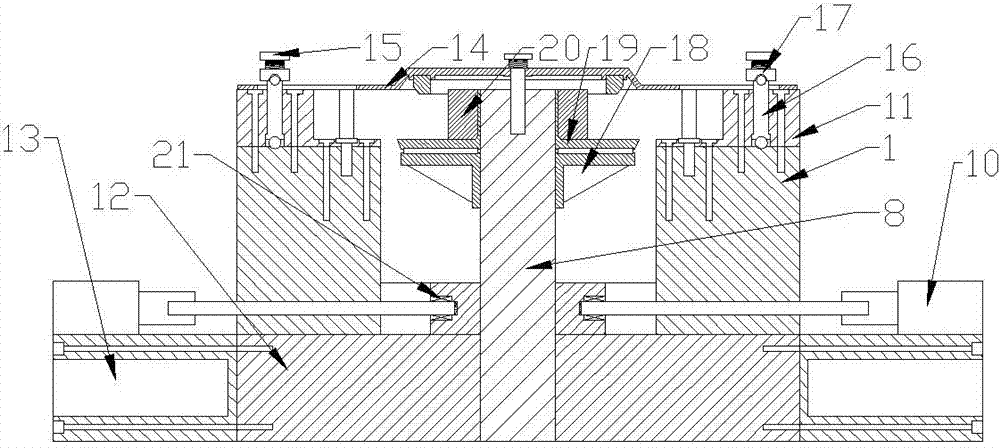

Medicine powder pill-making machine

InactiveCN108969364AGuaranteed preparation efficiencyGuaranteed accuracyPharmaceutical product form changeEngineeringMechanical engineering

The invention relates to the field of medicine equipment, particularly to a medicine powder pill-making machine. The medicine powder pill-making machine comprises a worktable, a feeding module, a mixing module, a kneading module, a shaping module, a conveying module, a cutting module and a polishing module, wherein the mixing module and the kneading module are sequentially arranged on the worktable, the feeding module is arranged above the worktable, the shaping module comprises a pushing mechanism and a pressing mechanism, the pushing mechanism is arranged on the side of the mixing module, the output end of the pushing mechanism is arranged in a direction towards the pressing mechanism, the pressing mechanism is arranged on the side of the mixing module, the cutting module comprises a cutting fixture and a cutting mechanism, the cutting fixture is arranged on the worktable and away from the mixing module, the cutting mechanism is arranged on the side of the cutting fixture, the conveying module is arranged between the shaping module and the cutting fixture, and the polishing module is arranged on the worktable and close to the cutting module. The medicine powder pill-making machine can improve the medicine powder pill-making efficiency and the like.

Owner:苗强

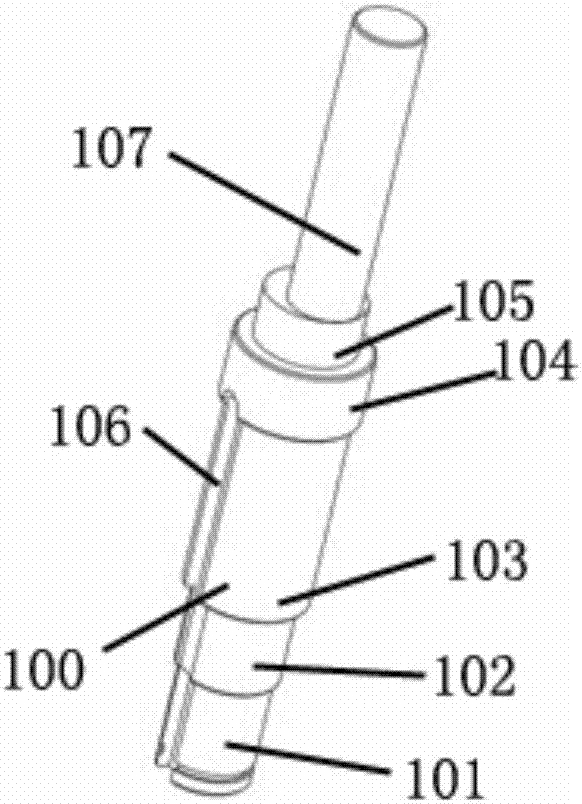

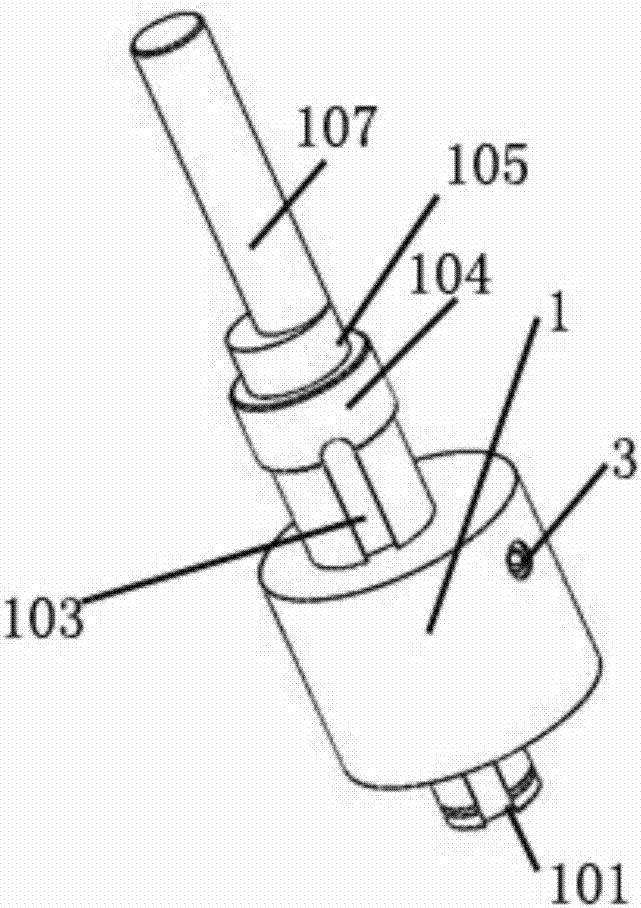

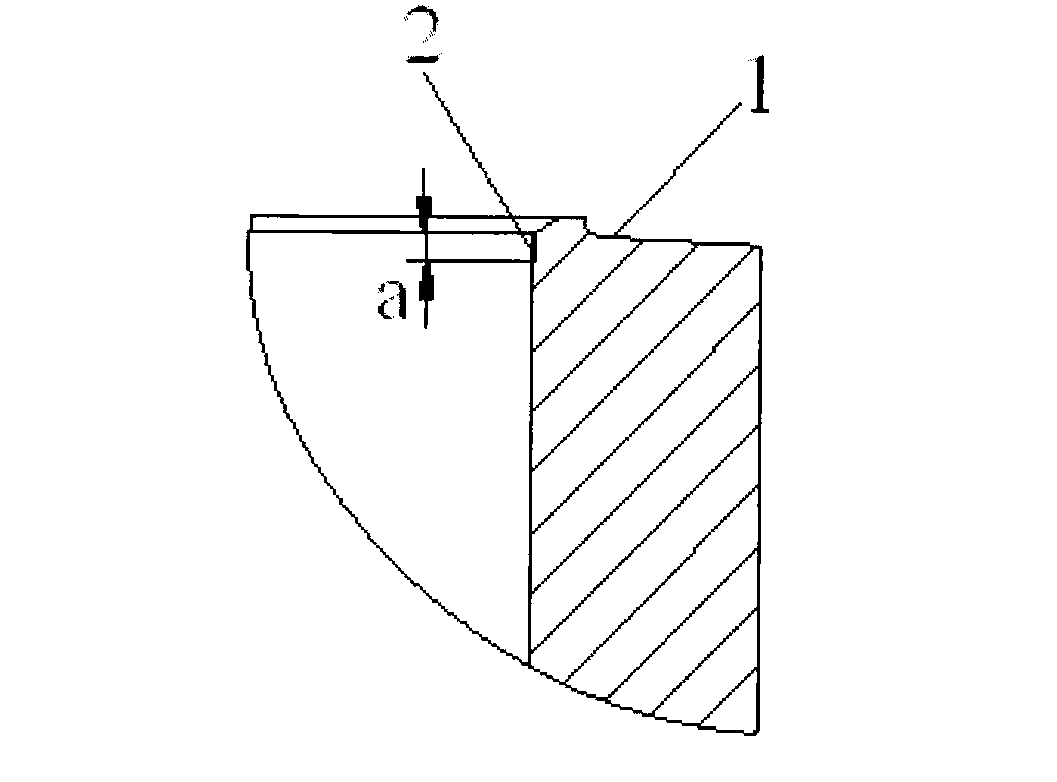

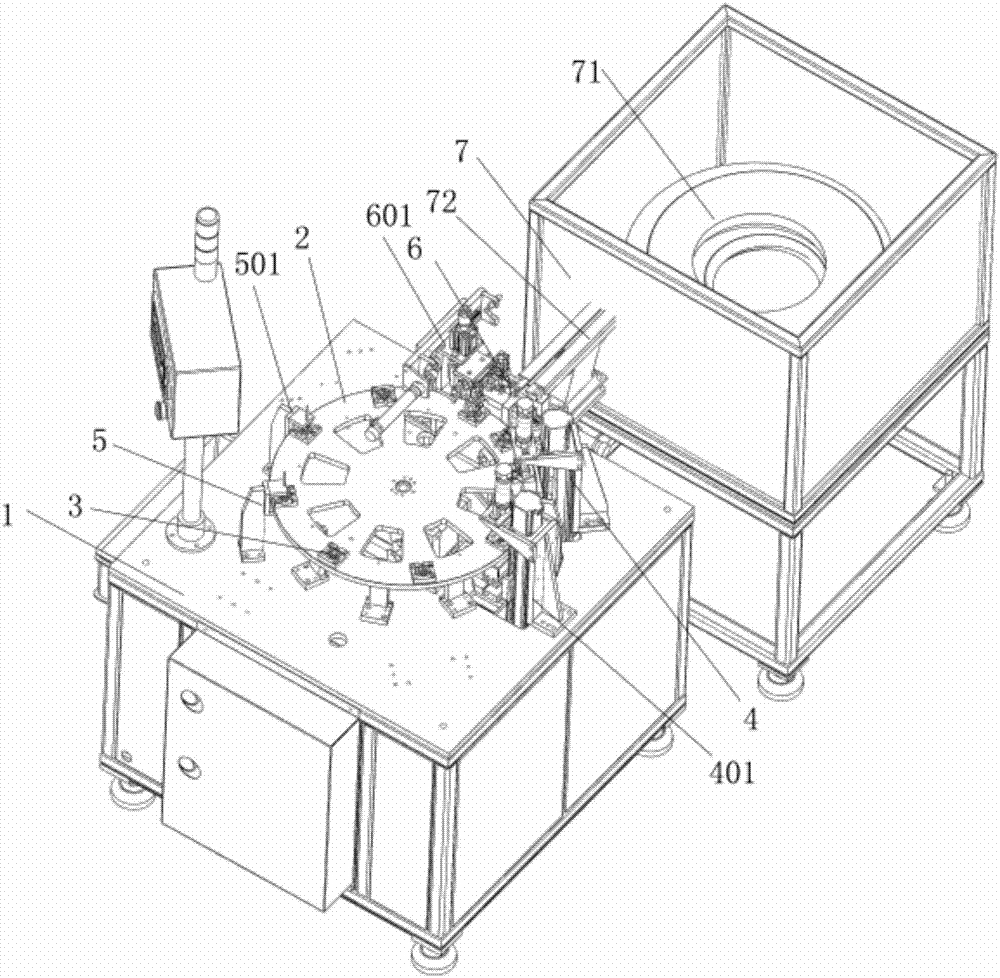

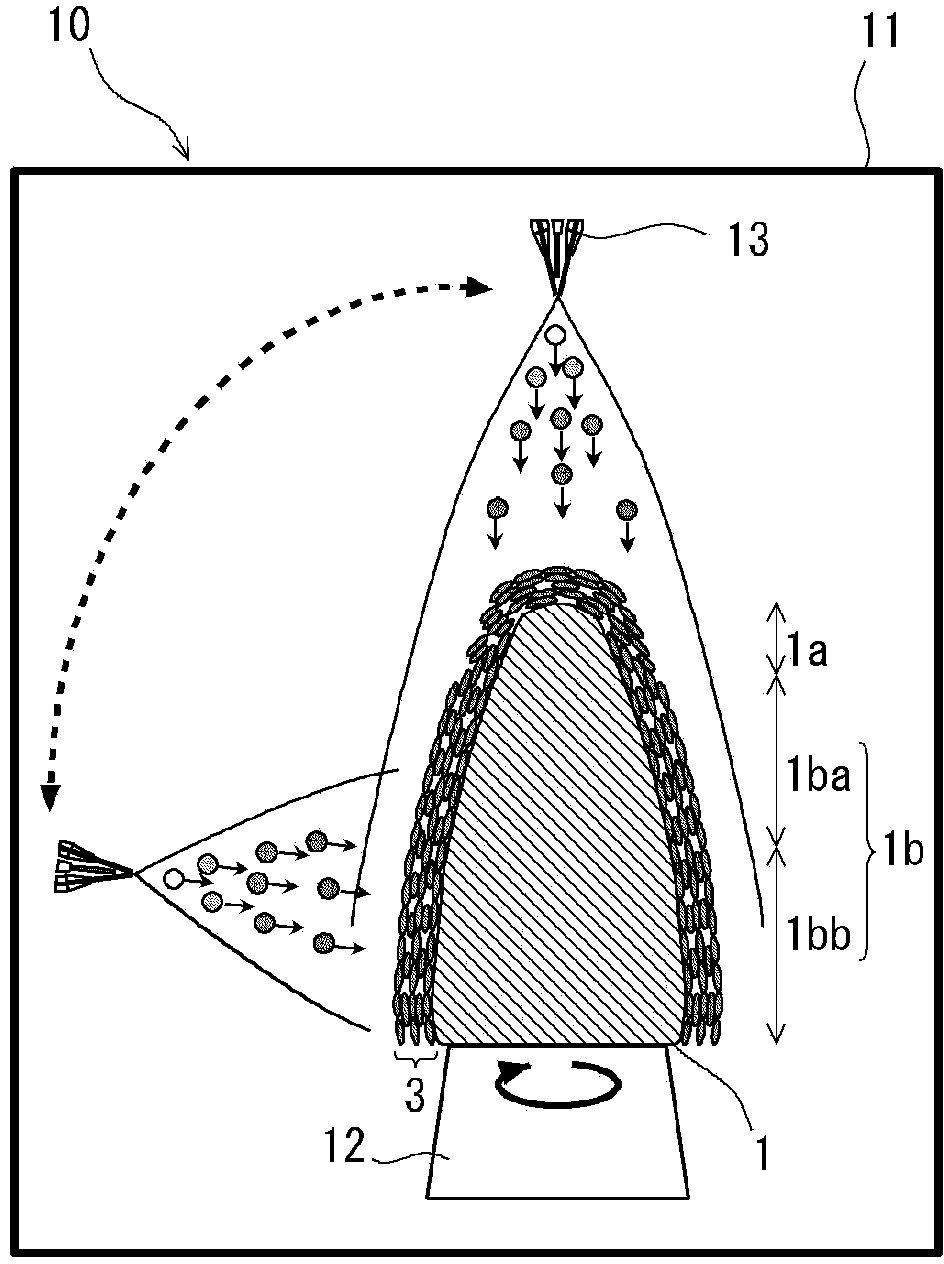

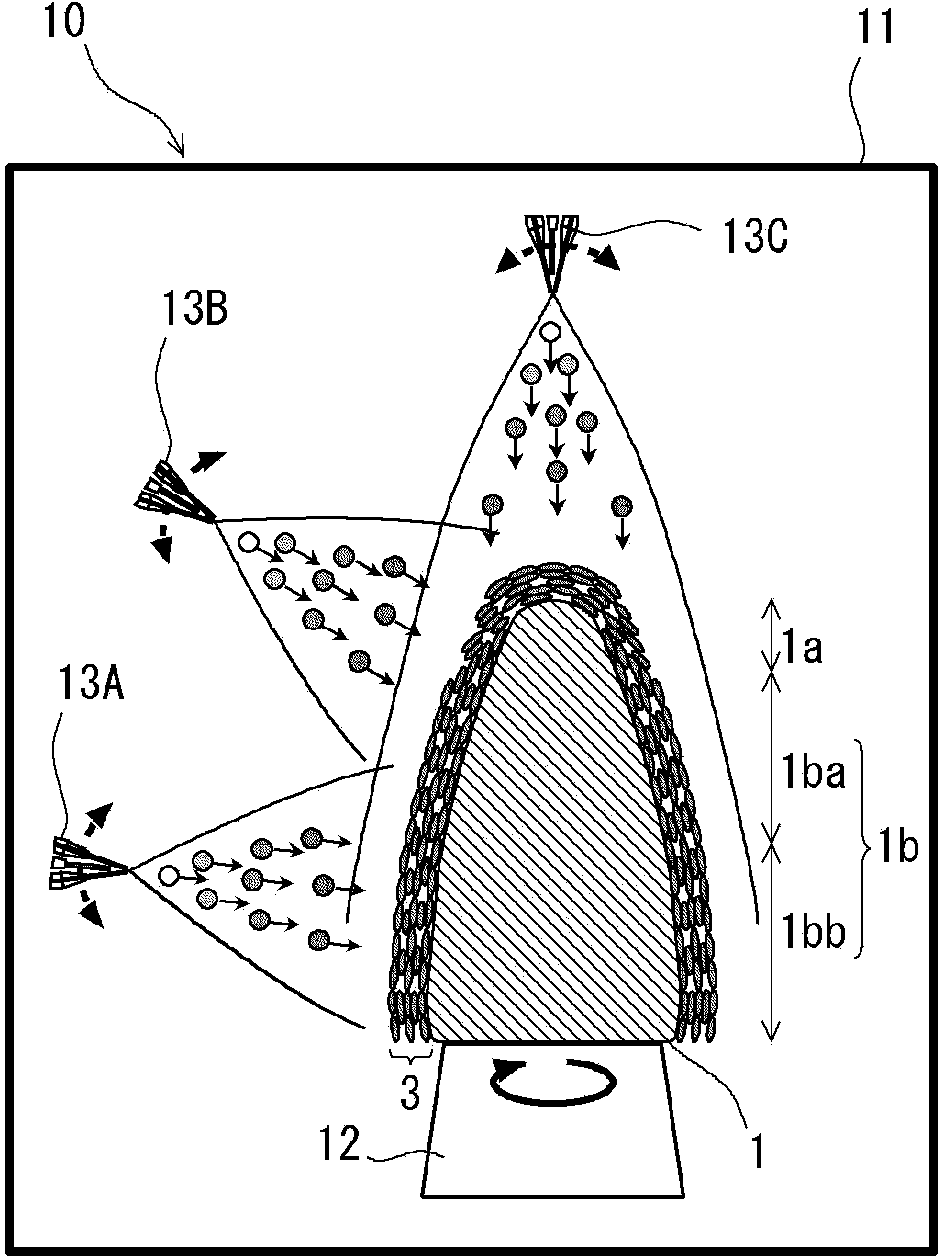

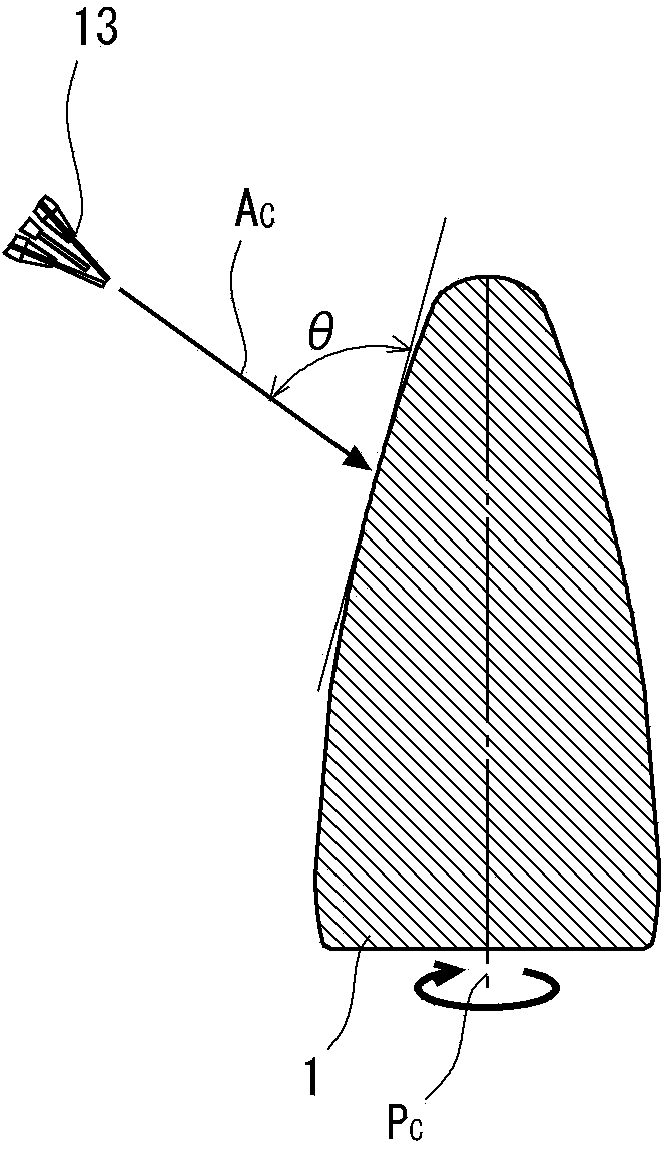

Facility for producing piercing plug

ActiveCN104245170AGuaranteed preparation efficiencyExtend your lifeMolten spray coatingMandrelsPeeningCoating

This facility for producing a plug used in a piercing mill used in the production of a seamless steel pipe is provided with: a shot blasting device that shot blasts the surface of a plug; and an arc spraying device that arc sprays an iron wire to the base material surface of the plug that has been subjected to shot blasting, forming a coating film configured from an oxide and Fe. The arc spraying device has a plurality of spraying booths that individually form a coating film for each of a plurality of regions resulting from demarcating the base material surface of the plug along the axial direction of the plug. As a result, it is possible to produce a plug that can maintain plug production efficiency at a high level, is stable during piercing, and can have increased plug life.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com