Vegetable cake processing and making device

A technology for preparing device and vegetable cake, which is applied in the directions of mixing/kneading with vertical installation tools, cleaning hollow objects, baking, etc., which can solve the problems of residues easily remaining in the machine, difficult automatic processing, and large production line space. , to achieve the effect of reducing nutrient deficiency, fast forming rate and improving mute effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

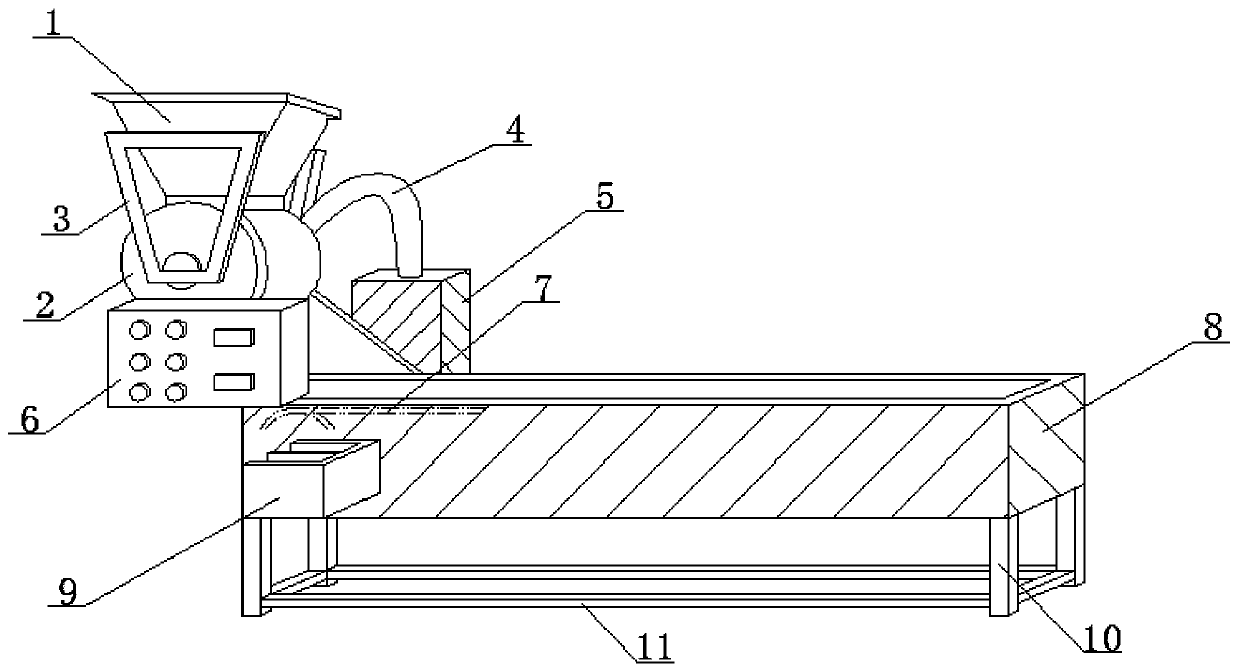

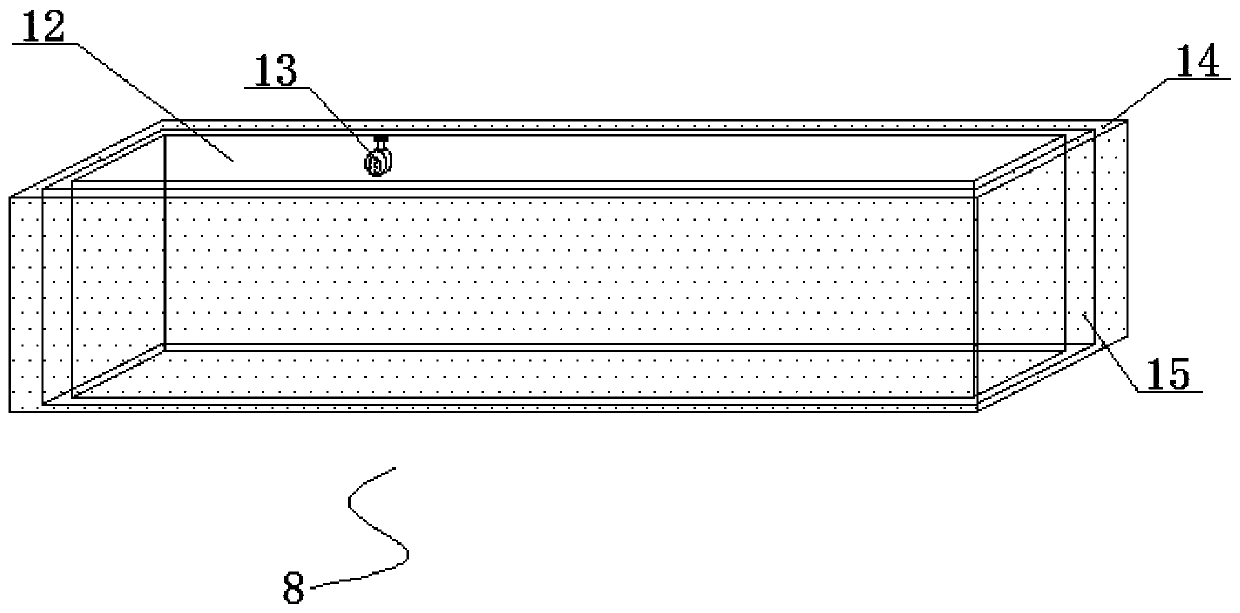

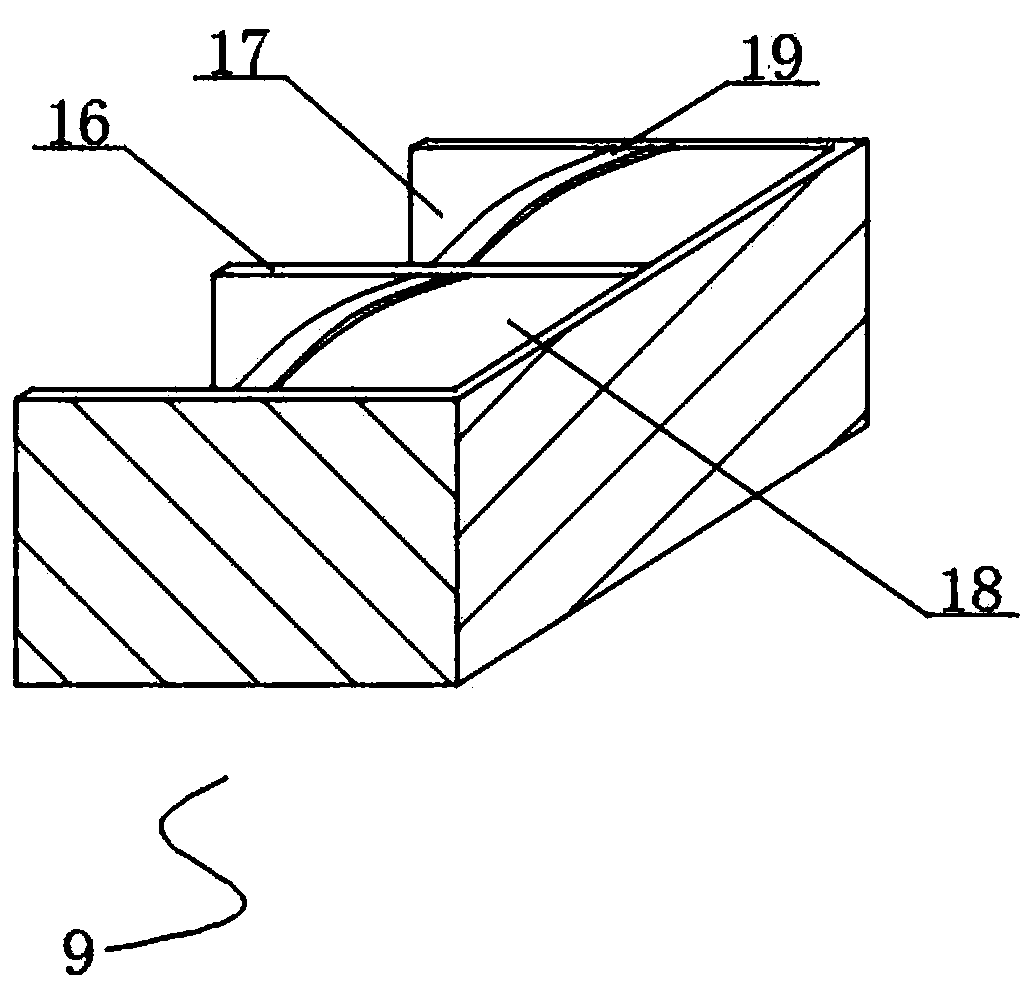

[0029] see Figure 1-7 , in an embodiment of the present invention, a vegetable cake processing and preparation device includes a hopper 1, an ingredient mixing bin 2, a forming assembly, a control box 6 and a belt conveying assembly 7, wherein the lower surface of the hopper 1 is fixedly connected with an ingredient Mixing bin 2, both sides of the batching and mixing bin 2 are fixedly connected with connectors 3, the front of the batching and mixing bin 2 is fixedly connected with a control box 6, and one side of the batching and mixing bin 2 is fixedly connected There is a water inlet pipe 4, one end of the water inlet pipe 4 is fixedly connected with a water tank 5, the bottom of the ingredient mixing bin 2 is connected to the molding assembly, and a belt for molding the formed vegetable cake is arranged below the molding assembly The conveying assembly 7, the belt conveying assembly 7 is located in the storage bin 8, so as to transfer the vegetable cakes into the storage b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com