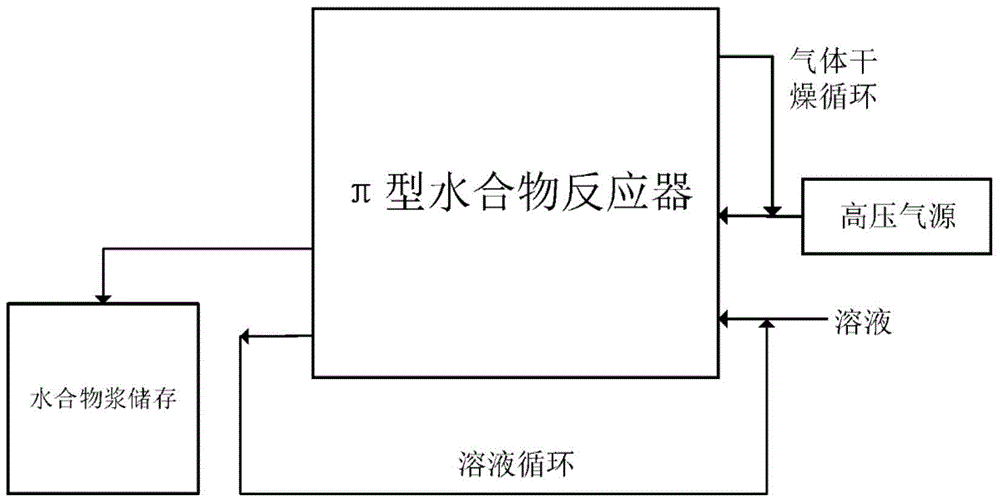

Continuous type gas hydrate slurry synthesis method and device based on gas throttling technology

A gas hydrate and gas throttling technology, which is applied in the direction of gas fuel, pressure vessels used in chemical processes, petroleum industry, etc., can solve the problems of low hydrate generation efficiency, redundant and complex preparation equipment, and large energy loss. Achieve the effect of improving energy utilization rate, ensuring preparation efficiency and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

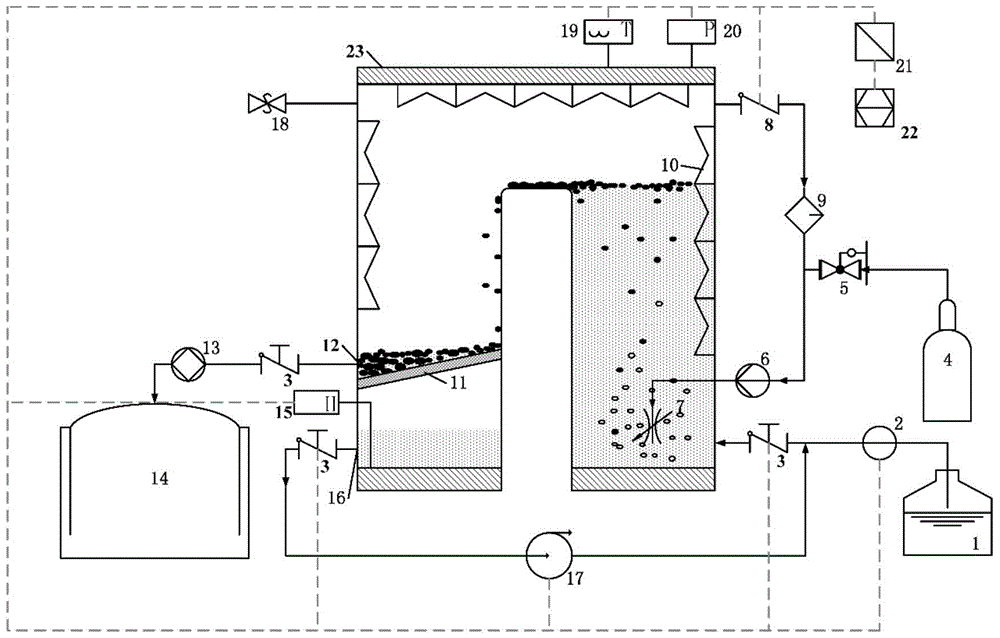

[0018] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0019] Such as figure 2 As shown, according to the device structure connection, using the device to carry out the continuous gas hydrate slurry synthesis method of gas throttling technology, the steps are as follows:

[0020] (1) Water injection-temperature control: the liquid inlet pump 2 is running, the one-way check valve 3 is automatically opened, the solution flows from the solution tank 1 into the π-type hydrate reactor, and the liquid on the left side of the π-type hydrate reactor reaches a certain height , that is, it will flow to the right side of the π-type hydrate reactor. Once the liquid level sensor 15 detects that the liquid height on the right side of the π-type hydrate reactor is greater than the set value, the liquid inlet pump 2 will stop working immediately, and the one-way check valve 3 automat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com