Ink coating equipment and an ink coating method

A coating device and coating technology, which is applied to the surface coating liquid device, coating, printing, etc., can solve the problems of mixing into other blocks, defective blocks, mixed color and light emission, etc., and achieve the goal of maintaining manufacturing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0129] Next, Embodiment 1 of the present invention will be described.

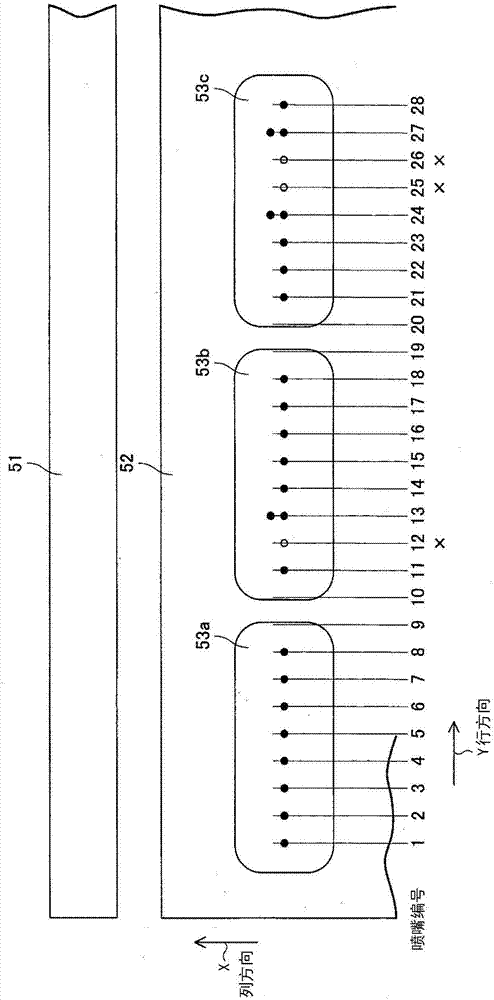

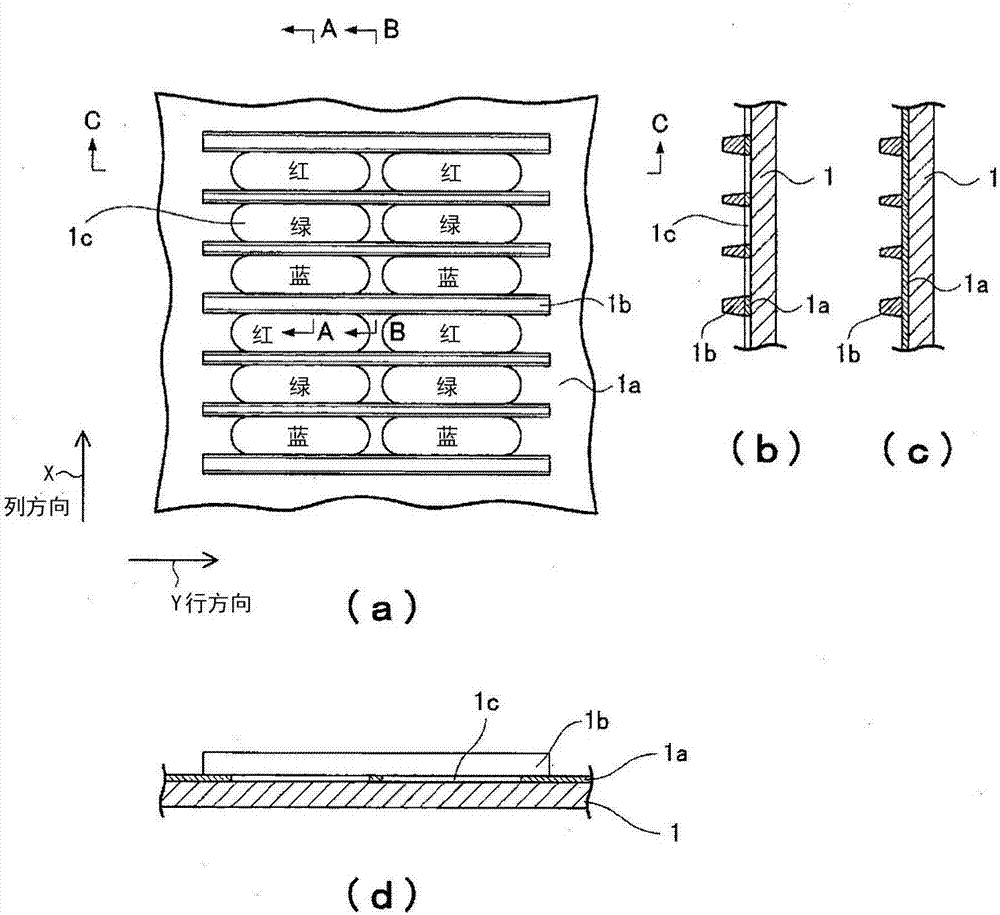

[0130] Figure 6 It is a conceptual diagram of the ink application device in Embodiment 1. Figure 7 In the case of printing with this ink application device, the application image 3 that two-dimensionally marks the ink ejection position and non-ejection nozzle information of the used nozzles are shown.

[0131] In this example, there are nine blocks 1c, and each block 1c is filled with a necessary amount of ink for three drops of ejection. The black circle is the spraying position, and the white circle is the non-spraying position.

[0132] Figure 7 The coating image 3 of is constituted by a two-dimensional coordinate system of the arrangement direction of the nozzles (row direction Y) and the scanning direction of the nozzles (column direction X). In the coating image 3, the dots at which ink should be ejected from the nozzles are connected by dotted lines to form a grid. The intersection point bec...

Embodiment approach 2

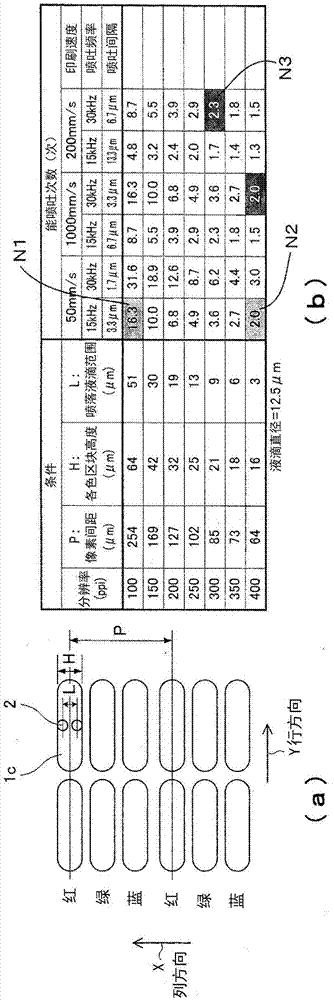

[0227] In Embodiment 2, the case of spraying to different types of panels will be described. Items not described are the same as those in Embodiment 1.

[0228] Figure 15 (a) is a plan view of a substrate 40 in which two types of display panels coexist, which is the object of the second embodiment. On the substrate 40, three small display panels 41a to 41c are arranged on the left side, and a large display panel 42 is arranged on the right side. 2k panels of 300 ppi are arranged on the small display panels 41a to 41c. A 4k panel of 200ppi is arranged on the large display panel 42 . As a result, blocks 1c of 300ppi and 200ppi are placed in the respective panel areas.

[0229] Figure 15(b) shows the positional relationship of ink ejection in the up-down direction (scanning direction, X direction) between the first block 1c of the small display panels 41a to 41c and the block 1c of the large display panel 42 .

[0230] In the block 1c of the small display panel 41a, ink i...

Embodiment approach 1、2

[0258] Embodiments 1 and 2 can be combined together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com