Manufacturing method for high-strength extremely-fine stainless steel wire

A manufacturing method, stainless steel technology, applied in the field of high-strength stainless steel ultra-fine wire manufacturing, can solve the problems of reduced mold life, insufficient strength, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

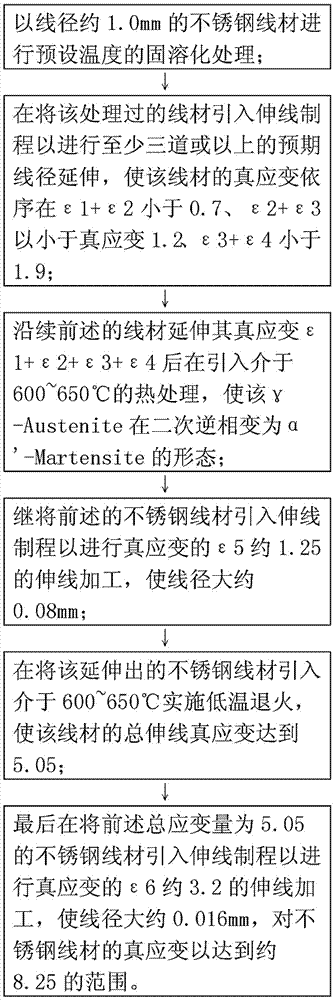

[0033] The method for manufacturing high-strength stainless steel ultra-fine wire applied in the present invention (such as figure 1 ), which is used to extend the ultra-fine stainless steel wire: use the commercially available Austenite Stainless Steel (Austenite Stainless Steel) to extend the high-strength thin wire. The Austenite Stainless Steel is based on ﹟SUS304 Wire rods are implemented, and wire rods with a wire diameter of 1.0mm are used for solution treatment at the default temperature.

[0034]When the above-mentioned wire is carried out to the wire drawing process, when the true strain is less than 0.7, the wire drawing process is temporarily terminated. At this time, the wire diameter is about 0.7mm, and the continuous wire drawing process can be carried out without intermediate annealing, during which ε1+ε2 Based on the principle of not greater than 0.8, the tensile strength can be improved under this process and the volume ratio of the α'-Martensite can reach mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com