Air port

A technology of tuyere and aluminum alloy profiles, applied in the field of tuyere, can solve the problems of heavy welding workload, heavy workload, low efficiency, etc., and achieve the effect of tight and smooth connection, high manufacturing efficiency and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

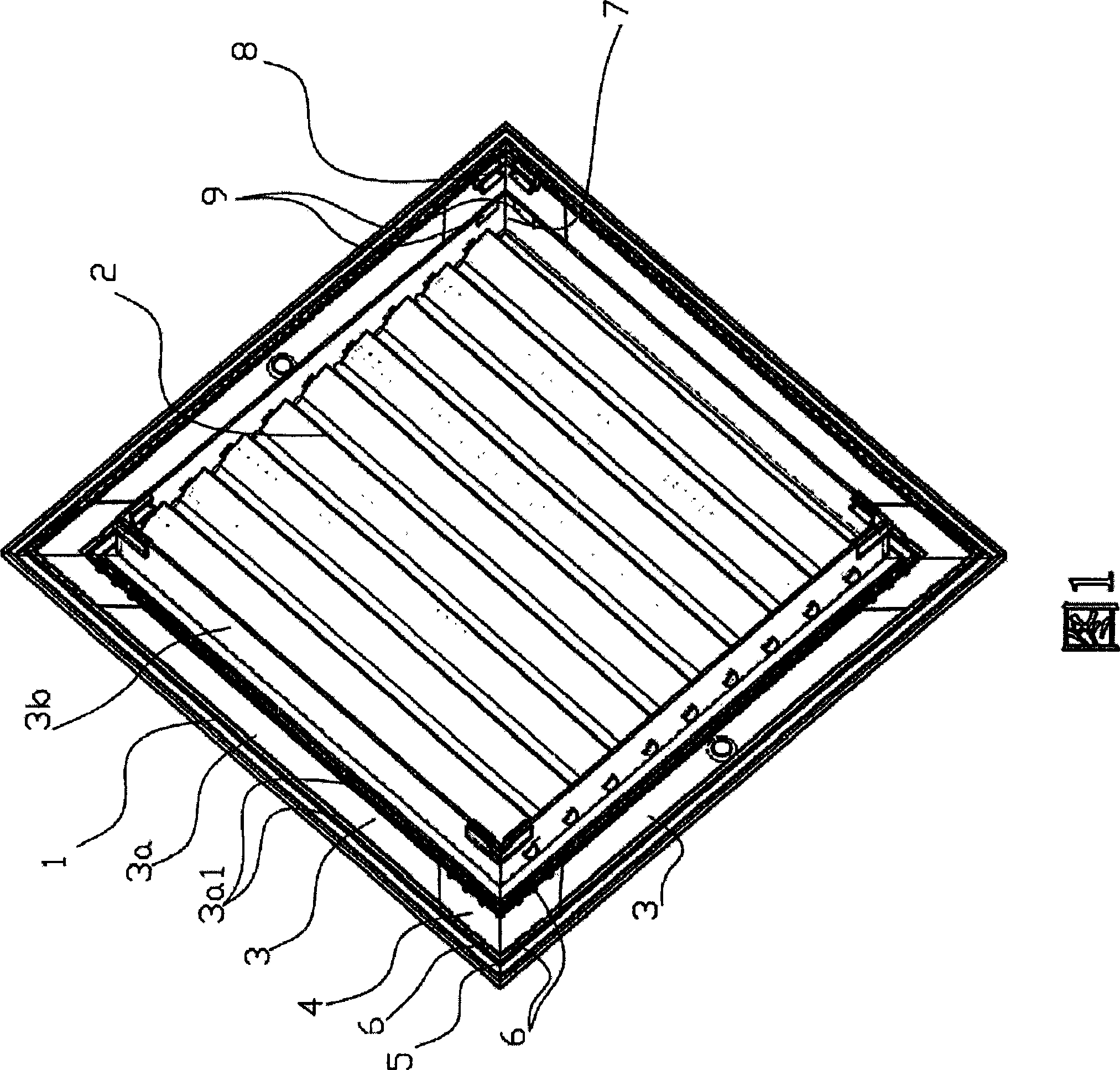

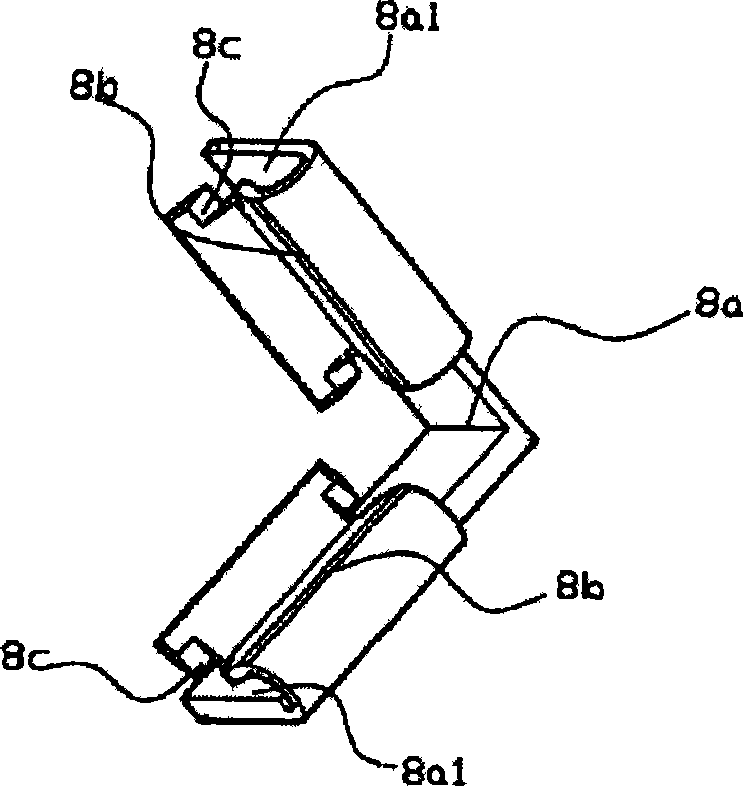

[0011] As shown in the figure, the present invention includes a square tuyere outer frame 1 and an air guide vane 2 arranged in the square tuyere outer frame 1. The square tuyere outer frame 1 is formed by connecting four aluminum alloy profiles 3 butted at an angle of 45°. The alloy profile 3 is composed of a panel part 3a and a tuyere wall part 3b perpendicular to the panel part 3a. An inlay groove 3a1 is arranged on the back of the aluminum alloy profile panel part 3a, and a right-angle fixing piece 4 is arranged in the inlay groove 3a1, and the right-angle fixing piece 4 is inlaid In the right-angle inlay groove 5 formed by butting two aluminum alloy profiles at an angle of 45°, the right-angle fixing piece 4 is fixed in the right-angle inlay groove 5 through several mechanical pressure pits 6 on both sides of the right-angle inlay groove 5, and the wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com