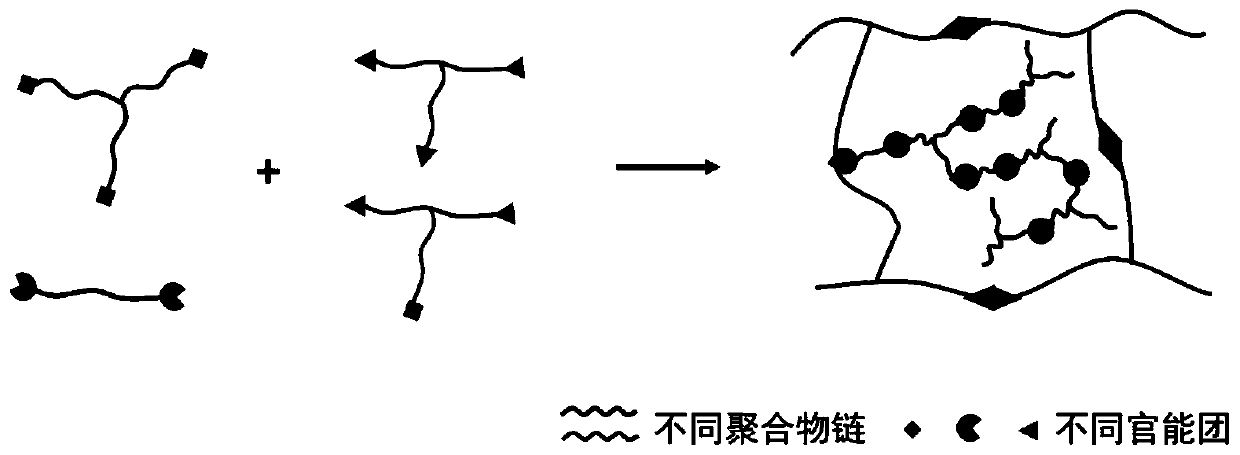

Preparation method of topological elastomer with highly branched structure and low modulus and high elasticity

A highly branched and elastomeric technology, applied in the field of preparation of topological elastomers, can solve problems such as difficult to prepare, performance-limited rigid molecular chains, low modulus, etc., and achieve low equipment requirements, diverse polymerization methods, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

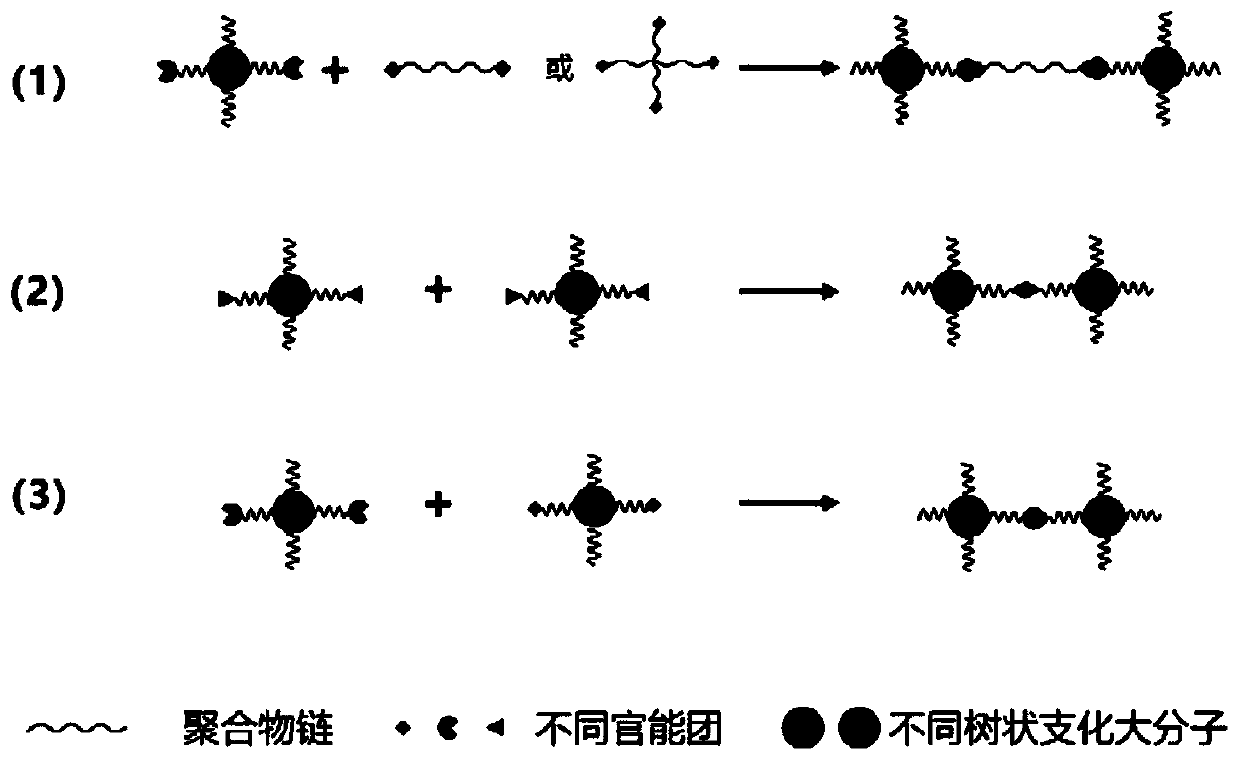

[0053] Embodiment 1 (direct cross-linking method prepares topological elastomer)

[0054] The raw material of embodiment 1 and source are as shown in table 1:

[0055] Table 1 Embodiment 1 Raw materials and source

[0056]

[0057]

[0058] Preparation of topological elastomers:

[0059] Weigh the sample according to the ratio of PCL, pentaerythritol triacrylate and HDI at 1:0.5:1 (molar ratio), and dissolve it in an appropriate amount of butyl acetate. After stirring evenly, 0.5wt% of DBTDL and 1wt% of AIBN were added in sequence, and the mixture was poured into a mold, and reacted under heating at 70°C for 3h. After evacuating the solvent in a vacuum oven, the cross-linked topological elastomer can be obtained.

[0060] The mechanical properties of materials can be tested using a universal testing machine. The modulus, elongation at break and elastic recovery properties of the material can be calculated from the tensile curve. The obtained topological elastomer ha...

Embodiment 2

[0061] Embodiment 2 (post-crosslinking method, self-polymerization of dendritic branched macromolecules to form topological elastomers)

[0062] The raw material of embodiment 2 and source are as shown in table 2:

[0063] Table 2 Embodiment 2 raw materials and source

[0064]

[0065] Preparation of dendritic branched macromolecules whose end groups are methacrylate groups:

[0066] 1. Weigh the sample according to the ratio of triallylamine and allyl acrylate of 1:6 (molar ratio), stir evenly, add 5wt% triethylamine to catalyze and react for 1h;

[0067] 2. Then, add β-mercaptoethylamine of the same molar amount as allyl acrylate, 1wt% photoinitiator, and under 365nm ultraviolet light irradiation, under heating at 40°C, β-mercaptoethylamine dissolves while reacting;

[0068] 3. After the complete reaction of β-mercaptoethylamine, add allyl acrylate twice as much as that added in step 1, and then repeat step 1;

[0069] 4. Add 2 times the amount of β-mercaptoethylamine ...

Embodiment 3

[0076] Embodiment 3 (post-crosslinking method, two kinds of dendritic branched macromolecules are copolymerized into topological elastomers)

[0077] The raw material of embodiment 3 and source are as shown in table 3:

[0078] Table 3 Embodiment 3 raw materials and sources

[0079]

[0080]

[0081] Preparation of dendritic branched macromolecules whose terminal groups are amino groups:

[0082] 1. First, weigh the sample according to the ratio of triallylamine and allyl acrylate to 1:6 (molar ratio) and stir evenly, then add 5wt% triethylamine to catalyze and react for 1 hour;

[0083] 2. Then, add β-mercaptoethylamine of the same molar amount as allyl acrylate, 1wt% photoinitiator, and under 365nm ultraviolet light irradiation, under heating at 40°C, β-mercaptoethylamine dissolves while reacting;

[0084] 3. After the complete reaction of β-mercaptoethylamine, add allyl acrylate twice as much as that added in step 1, and then repeat step 1;

[0085] 4. Add 2 times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com