Manufacture method of eccentric shaft with three relative angles

A manufacturing method and relative angle technology, applied in the field of mechanical processing, can solve the problems of affecting processing efficiency, large processing errors, unstable processing quality, etc., and achieve the effect of ensuring the preparation accuracy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

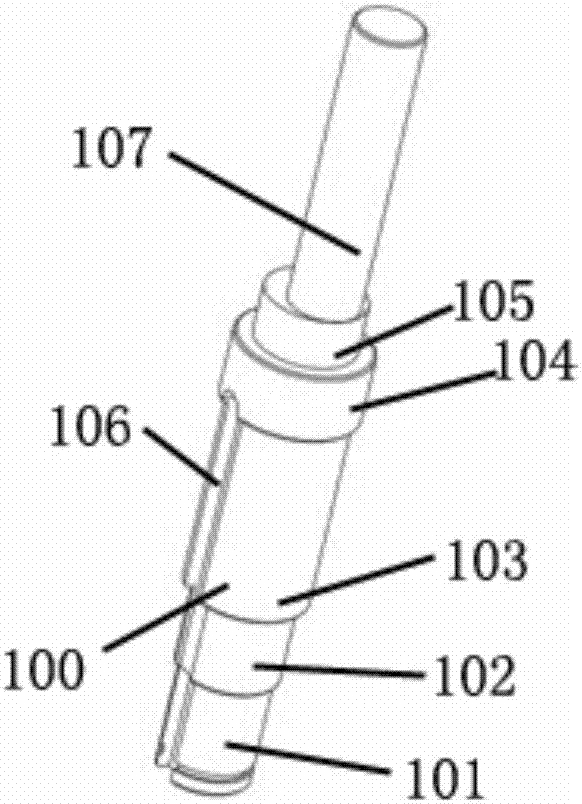

[0030] see Figure 1-5 , this implementation shows a manufacturing method with three relative angle eccentric shafts, including the following steps:

[0031] 1) Carry out the excircle cutting of the shaft part a101, the shaft part b102, the shaft part c103, the shaft part d104 and the shaft part e105 of the concentric part;

[0032] 2) Machining the shaft portion a101, the shaft portion b102, and the keyway 106 on the shaft portion c103;

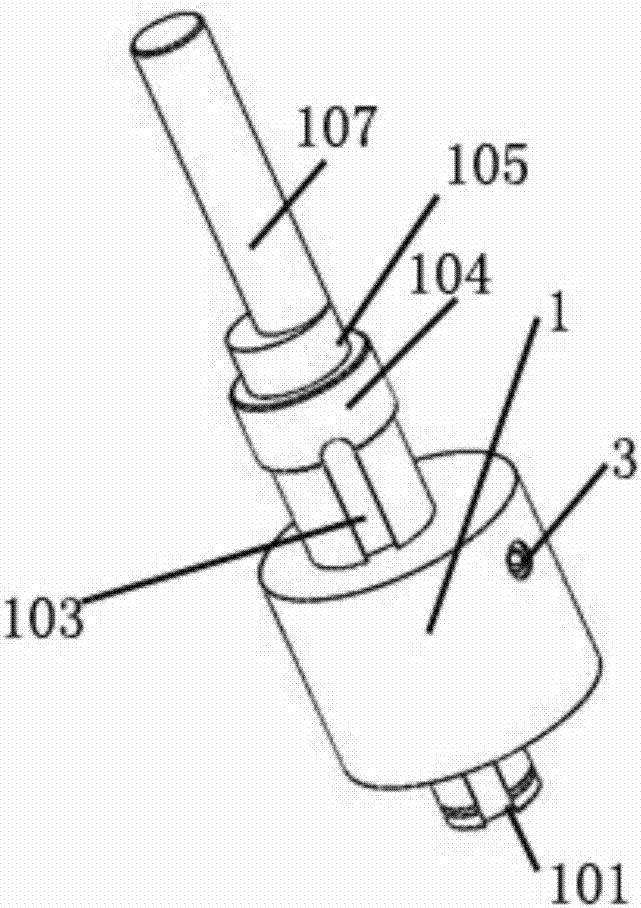

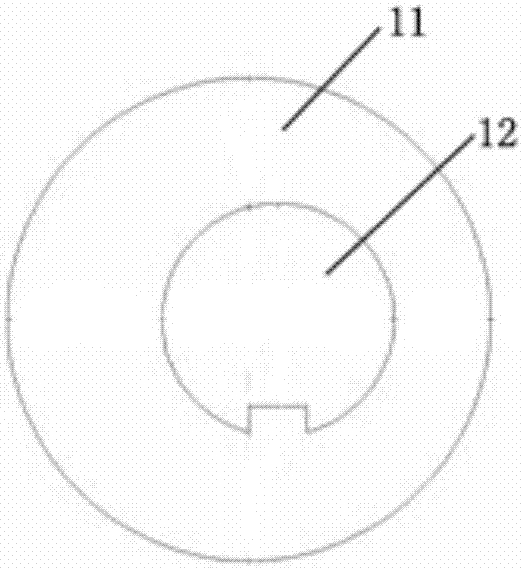

[0033] 3) Prepare a fixture a2, which includes a cylindrical body a21 concentric with the eccentric shaft part 107, a device groove a22 provided on the cylindrical body a21 and matched with the shaft part a101;

[0034] 4) After the shaft part a101 and the shaft part b102 are installed on the clamp a2, the cutting process of the eccentric shaft part 107 is performed after clamping the clamp a2;

[0035] 5) Prepare the jig b3, the jig b3 includes a cylindrical body b31 concentric with the eccentric shaft part 107, a device groove b32 opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com