Method for preparing solid epoxy resin toughened polyester

A solid epoxy resin and toughening technology, applied in the chemical industry, can solve problems such as large internal stress, waste of resources, and health threats, and achieve the effects of ensuring toughening effect and mechanical strength, saving production costs, and avoiding direct emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

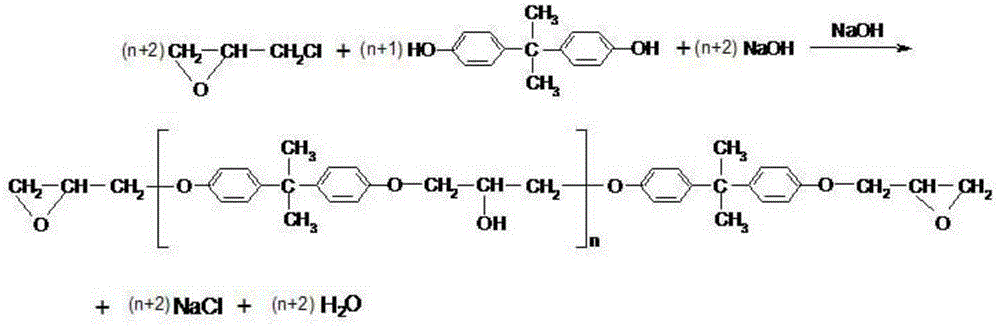

Method used

Image

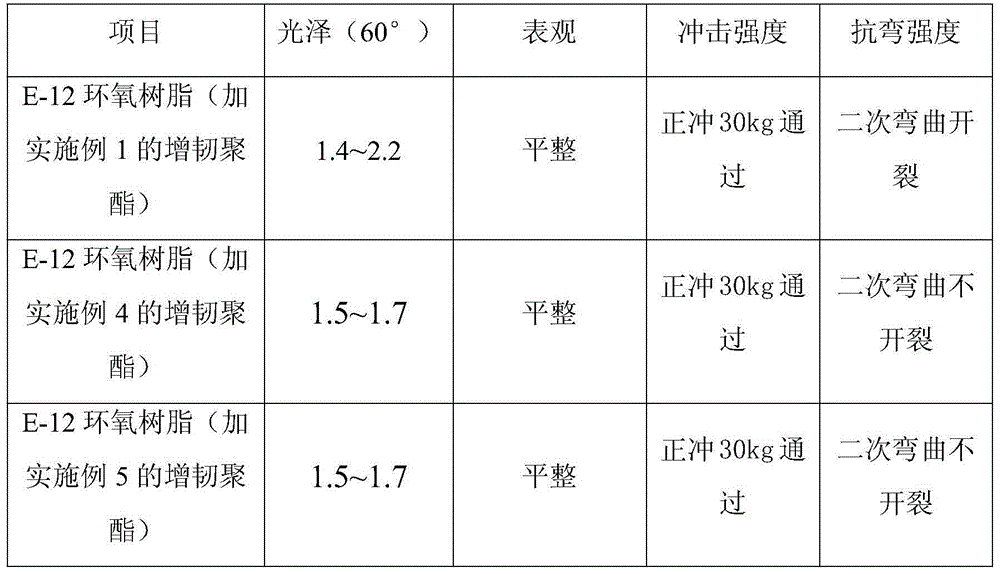

Examples

Embodiment 1

[0015] Embodiment 1: Preparation of solid epoxy resin toughened polyester (without adding organic waste liquid)

[0016] Add 98g of ethylene glycol, 116.5g of diethylene glycol, 58g of neopentyl glycol, 480g of terephthalic acid and 0.75g of butyltin oxide into a 500ml four-necked flask equipped with an electric heating mantle, a stirrer and a reflux condenser , Heat the mixture to 175-180°C within 1h for esterification reaction, and slowly heat the mixture to 255°C within 4h, drain the generated water, add 0.8g of triisobutyl phosphate, control the vacuum degree to less than -0.08MPa, Vacuumize for 4 hours, cool and discharge to obtain the product.

Embodiment 2

[0017] Embodiment 2: Preparation of solid epoxy resin toughened polyester (organic waste liquid replaces the diethylene glycol of 2.5% hydroxyl molar weight in embodiment 1)

[0018] Add 98g ethylene glycol, 110.5g diethylene glycol, 62g neopentyl glycol, 473g terephthalic acid, 9.3g organic waste liquid and 0.75g butyl tin oxide, heat the mixture to 175-180°C within 1h for esterification reaction, and slowly heat the mixture to 255°C within 4h, the water is completely discharged, add 1.0g triisobutyl phosphate, control the vacuum degree to less than - 0.08MPa, evacuated for 4 hours, cooled and discharged to obtain the product. The organic waste liquid is the polyhydroxy organic compound recovered after the saturated brine, a by-product of the reactive diluent of epoxy resin, evaporates the salt, the same below.

Embodiment 3

[0019] Embodiment 3: Preparation of solid epoxy resin toughened polyester (organic waste liquid replaces the ethylene glycol of 2.5% hydroxyl molar weight in embodiment 1)

[0020] Add 93.1g of ethylene glycol, 116.5g of diethylene glycol, 62g of neopentyl glycol, 480g of terephthalic acid, and 9.3g of organic waste liquid into a 500ml four-necked flask equipped with an electric heating mantle, a stirrer and a reflux condenser and 0.8g of butyltin oxide, the mixture was heated to 175-180°C for esterification reaction within 1h, and the mixture was slowly heated to 255°C within 4h, the generated water was discharged, and 1.0g of triisobutyl phosphate was added to control The vacuum degree is less than -0.08MPa, vacuumize for 4 hours, cool and discharge, and the product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com