Assembly method for ensuring equipment overall coaxiality in pressure vessel for chemical industry

A pressure vessel and assembly method technology, applied in the field of assembly to ensure the overall coaxiality of equipment, can solve problems such as increasing manufacturing costs, affecting delivery, and difficulty in meeting requirements, so as to improve assembly accuracy, ensure quality and manufacturing efficiency, and simultaneously The effect of axis satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

[0023] In order to ensure that the barrel section can meet the coaxiality and straightness requirements specified in the technical requirements during assembly, it is first necessary to ensure that the blanking size of the barrel section steel plate is accurate, and strictly control the ellipticity, straightness, etc. during the barrel section rolling process In addition, it should be ensured that the inner diameters of each cylinder section are the same as far as possible, so as to avoid the occurrence of large and small openings in the cylinder section.

[0024] An assembly method for ensuring the overall coaxiality of equipment in a chemical pressure vessel consists of the following seven steps:

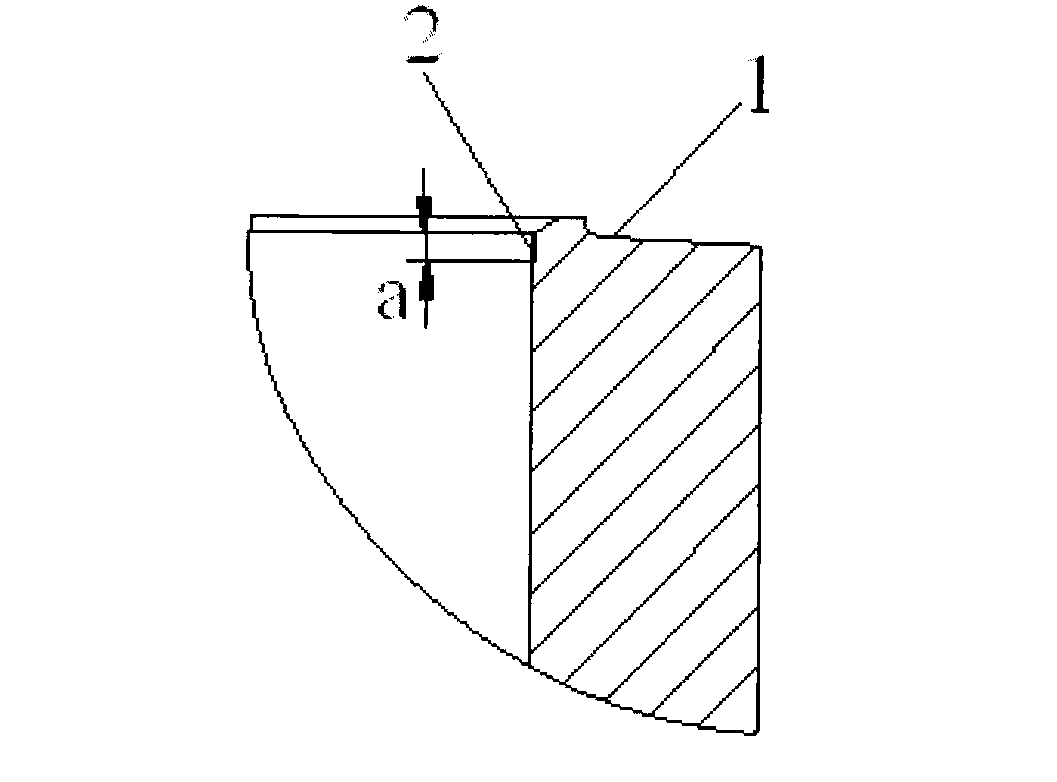

[0025] Step 1: If figure 1 As shown, process UV grooves 1 at both ends of all barrel joints to be assembled.

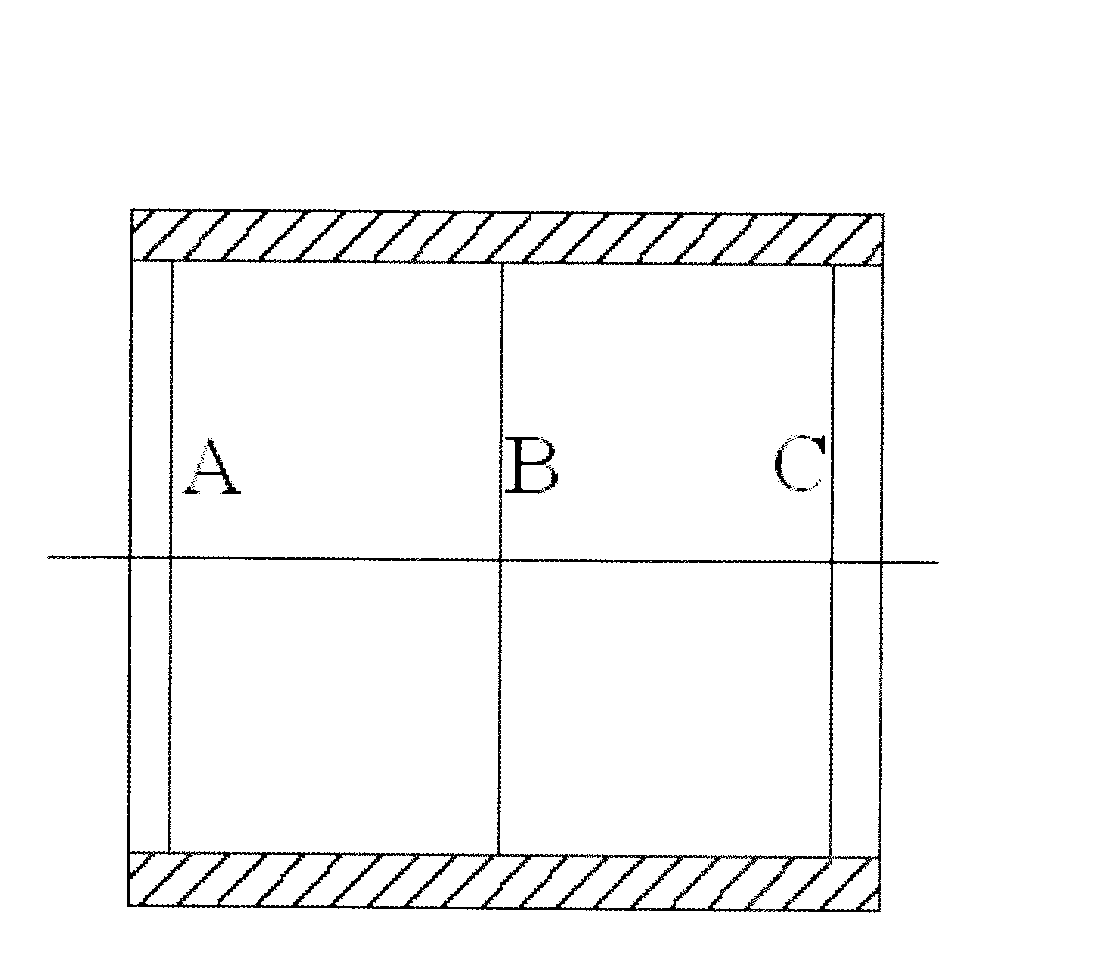

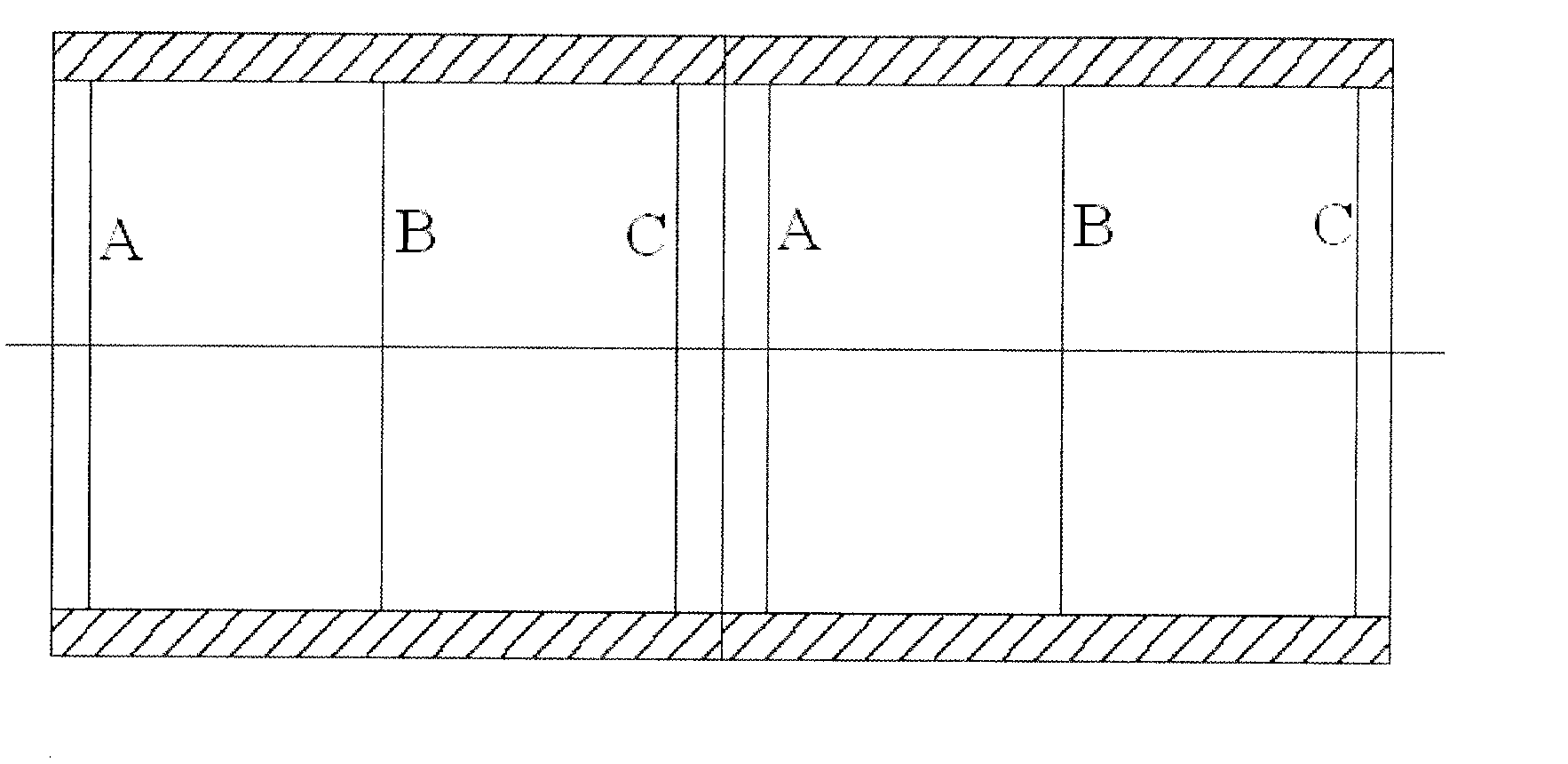

[0026] Step 2: Beca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com